Abstract

Agricultural and other residues are promising renewable energy sources. However, they can cause problems in combustion processes. One of these problems is also low ash melting temperatures. Except, the ash melting behavior can be impacted by many factors, such as ash preparation or used atmosphere. This article deals with comparing different atmosphere conditions during measurements of ash melting temperatures of three agricultural pellets: alfalfa, straw, and hay. The first one was oxidizing with compressed air and nitrogen. The second atmosphere was reduced with the air purge, and the last was only reduced, consisting of 60% carbon monoxide and 40% carbon dioxide. Differences between individual atmospheres were none, up to 9.8%. The most significant differences have appeared between oxidizing and reducing atmospheres. In general, the oxidizing atmosphere presents a less expensive way. More attention should be paid to the use of oxidizing atmosphere for applications in heat sources mainly due to its similarity to the combustion process. However, it would be suitable to realize more comprehensive research regarding ash preparation in different ways and with using of different types of fuel.

1. Introduction

Fossil fuel extraction and global environmental issues present significant problems for energy consumption. The development of energy-efficient technology and the shift to non-fossil energy sources, such as renewable energy sources, are expected and appear to be very promising [1,2]. Except, huge amounts of waste are produced by consumer society, and their disposal can negatively impact human health and ecosystems [3,4]. Agricultural residues can be used as fuels due to their energy potential and also the emission reduction compared to fossil fuels. In general, the quality of these fuels is lower than wood biomass. The main problems are their low bulk density, high ash content, low ash melting temperatures, and low calorific values [5,6]. High ash content and low ash melting temperatures cause deposit formation, slagging, and sintering, which lead to problems during combustion [7].

Radačovská et al. [8] stated that occurred sintering causes the blocking of airflow to the fuel layer. Wood bark has a negative impact on the ash melting temperatures. Jandačka et al. [9] mentioned that a higher amount of agglomerates and deposits occurred during the combustion of phytomass pellets. Deposits caused the reduction of both the free burner cross-section and the reaction space of the burning bed. The temperatures at the edge of the burner exceeded 1000 °C, up to nearly 1200 °C. Therefore, their long-term combustion and operation would not be possible without regular cleaning at least 1–2 times per week. The melting temperatures also depend on the chemical composition of the ash. Various types of straw, cereals, grasses, and seeds, which are low in Ca and high in Si and K, have an initial ash melting point significantly lower than wood fuels [10,11]. Zhai et al. [12] identified the irregular aggregation of KCl, K2SO4, and other fusible matters as the main factor affecting the ash fusion of wheat straw and corn straw pellets. The ash completely melted at 1300 °C, and the Si, MgO, and CaO contents increased and formed low-melting-point eutectics. Link et al. [13] mentioned that ash melting behavior is important due to avoiding the agglomeration of the fluidized bed. Therefore, knowledge about ash melting temperatures is an important parameter of fuel quality. When the melting temperatures are known, the combustion process can be optimized, for example, by air supply or by adding additives to increase the melting temperatures. Various previous works showed that this behavior of the blends could differ from that of single-parent fuels. Link et al. focused on blends of reed, pine wood pellets, and fir wood chips. The ash sample was heated up to the final temperature stepwise. The melting started at 700 °C. All these tests were realized under the air atmosphere.

The determination of ash melting behavior for solid biofuels is described in ISO 21404: 2020 [14]. Samples are prepared from fuel by ashing at 550 °C (alternatively, 710 °C and 815 °C may be used). An oxidizing and also reducing atmosphere may be used during ash melting measurements. An oxidizing atmosphere is obtained with air or carbon dioxide. The reducing atmosphere is obtained by introducing a mixture of 55% to 65% carbon monoxide with 35% to 45% carbon dioxide or 45% to 55% hydrogen with 45% to 55% carbon dioxide. Phases in the ash melting processes are recorded and evaluated as shrinkage starting temperature (SST), deformation temperature (DT), hemisphere temperature (HT), and flow temperature (FT). However, the method of determination of ash melting temperature can impact the resulting temperature values such as ash preparation or used atmosphere [15]. ISO 21404: 2020 allows to use of alternative temperatures for the preparation of ash and also allows to use of two atmospheres: oxidizing and reducing. This article is mainly focused on the comparison of resulting values of ash melting temperatures, which were obtained during three types of atmospheres: oxidizing, reducing, and reducing with the air purge.

Individual authors use both atmospheres described in ISO 21404: 2020 [14] in their research. Reinmöller et al. [16] used air for oxidizing conditions and also the atmosphere composed of 65% carbon monoxide and 35% carbon dioxide for reducing conditions. The ash fusion temperatures were determined according to the German standard DIN 51730. They tested a set of samples originating from 23 hard coals, 17 brown coals, and 26 biomasses. The resulting lowest ash fusion temperatures were addressed to the presence of low-temperature melting mixtures of several mineral phases. Horák et al. [17] tested biomass: corn cobs, sunflower husks, olive pomace, hay pellets, and rice husks and coal: lignite and bituminous; and alternative fuel: paper sludge. They used both atmospheres, described as oxidative and reductive. Similar values of ash melting temperatures were obtained for some samples, but for some, they were different. The lowest temperatures were found for the ashes produced from hay pellets and corn cobs, for which the DTs were below 1000 °C. However, for ashes made from paper sludge, sunflower husks, and rice husks, the DT exceeded 1500 °C.

Chaloupková et al. [18] prepared ash from rice straw at 550 °C in a muffle furnace. Ash melting temperatures were determined according to the ČSN P CEN/TS 15370-1:2007, and ash was prepared according to EN ISO 18122:2015. The authors added calcium additives and concluded that increasing the additive ratio did not bring linear growth of the melting temperatures, but an optimal positive impact was reached with 1% CaCO3. Mudryk et al. [19] evaluated the urban tree leaf biomass potential. The ash content was performed according to ISO 18122: 2015. The ashing process was realized in the muffle furnace at 550 °C. The melting lozenges were made according to ISO 540:2001. The ash behavior was observed in a tube furnace with a special camera. Wang et al. [20] investigated spruce bark as additive fuel regarding its ability to lower the melting and also the flowing temperature of spruce wood ash. Ash was obtained from the 550 °C heating treatment of samples. Then each sample was shaped into a 3 × 3 mm cubical specimen and put into an ash fusion analyzer according to ISO standard 540:1995. The specimen was heated up to 1500 °C with a heating rate of 2 °C/min in an oxidizing atmosphere. The sintering and letting of the ash specimen caused the changes to the outer shape. High ash melting temperature and low sintering was observed during spruce melting due to the formation of calcium-rich silicates. The melting temperature considerably decreased upon mixing with 10% of the bar.

Oladejo et al. [21] investigated the ash fusion behavior of coal/biomass blends. Ash samples were prepared in a muffle furnace according to British Standards (Solid Biofuels. Determination of ash content, Solid mineral fuels. Determination of ash), biomass at 550 °C, coal and coal/biomass blends at 815 °C. Temperatures were obtained under reducing conditions. Their results showed that slagging could be mitigated due to blending the coal with biomass rich in alkali and alkaline earth metals. Chen et al. [22] observed the influence of biomass addition on Jincheng coal ash fusion temperatures. Ash was prepared at 575 °C according to the ASTM E1755-01 and investigated under reducing atmospheres for the determination of ash melting temperatures according to Chinese Standard GB/T 219-2008.

Based on this knowledge, it can be summarized that it is allowed to choice of the temperature of ash preparation and also the atmosphere, which can impact on resulting values of ash melting temperatures. This article observes and compares the resulting values obtained during different atmospheres: oxidizing, reducing, and reducing with the air purge. The standard ISO 21404: 2020 allows to use of both atmospheres: oxidizing and reducing. However, the oxidizing atmosphere is more similar to the combustion process and presents a less expensive way. The using of carbon dioxide with carbon monoxide presents different atmosphere conditions but often using way in ash melting tests. Three types of agricultural pellets have been used for these purposes: alfalfa, straw, and hay pellets. The elemental analysis of these fuels has also been realized for the comparison of carbon, hydrogen, and nitrogen content.

2. Materials and Methods

The tested pellet samples are stated in Figure 1, and they consisted of the following agricultural residues: alfalfa, straw, and hay. All tested samples were purchased and, therefore, not produced in research laboratories. Used pellets are pure without additives. The alfalfa pellets and hay pellets had a diameter of 6 mm and an average length between 10 and 50 mm. The straw pellets had a diameter of 8 mm and an average length between 10 and 30 mm. All pellets samples were crushed to fractions with a maximum size of 1 mm before ashing.

Figure 1.

Pellet samples: (a) alfalfa, (b) straw, (c) hay.

Pellet samples were ashed in a muffle furnace according to ISO 21404: 2020 [14]. The furnace temperature was raised to 250 °C for 45 min and maintained this temperature level for 120 min, then continued the raise furnace temperature evenly to 550 °C and maintained this temperature at this level for at least 240 min. Finally, it stopped heating and was let to cool down the furnace with a sample to below 200 °C. The ash was further ground in a mortar for fine particles (approx. smaller than 100 µm) and analyzed in LECO CHN628, where was found the content of carbon, hydrogen, and nitrogen. Ash samples were weighed and combusted in the absence of atmospheric gases. The sulfur content was determined in the separate module LECO 628S.

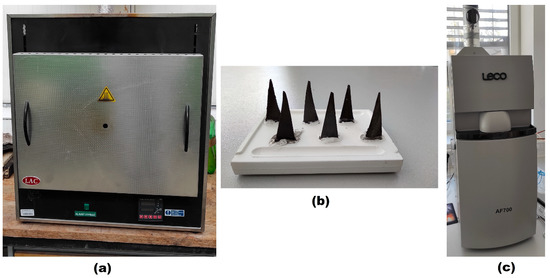

The ash paste was prepared by blending the created ash with a few drops of Dextrin. Further, this paste was formed into pyramids using a LECO mold. Pyramid samples were glued on ceramic slabs and placed in the ash fusion analyzer LECO AF 700. The furnace was heated up to 1500 °C, and images were recorded by a digital camera. Based on these images, individual ash melting temperatures were evaluated. Ash preparation with the appropriate equipment is stated in Figure 2.

Figure 2.

Ash preparation: (a) muffle furnace, (b) pyramid samples, (c) ash fusion analyzer.

Ash melting temperatures are evaluated as shrinkage starting temperature (SST), deformation temperature (DT), hemisphere temperature (HT), and flow temperature (FT) in ISO 21404: 2020 [10]. However, this standard considers a cylinder of height 3 mm to 4 mm and with a diameter equal to the height. The mold used in this research is a pyramid shape. Therefore, ash melting temperatures were evaluated as follows: (I) Deformation temperature (DT) when the first signs of rounding off the tip of the test sample; (II) Sphere temperature (ST) when the height was the same as the width; (III) Hemisphere temperature (HT) when the height was equal to half the diameter of the base; (IV) Flow temperature (FT) when the height was one-third of the height of the test sample. The ash fusion analyzer allows us to automatically determine the individual ash melting temperatures using Image Recognition Functions (IRF) within the software. IRF also has the option of analysis to be automatically terminated after all deformation points have been reached for all samples.

Three types of atmosphere were used. The first was oxidizing with compressed air and nitrogen. The temperature was raised up to 750 °C, where the air purge was going on, then the supply of air and nitrogen was provided. The second atmosphere was reduced with the air purge, which means the purge was realized up to 750 °C and further reduced supply. The reducing conditions were obtained by introducing a mixture of 60% carbon monoxide with 40% carbon dioxide. The last atmosphere was only reducing, which presented the supply of a mixture of 60% carbon monoxide and 40% carbon dioxide all the time until 1500 °C.

The ash melting tests were realized at least three times for each sample. The resulting values are stated that average values with standard deviations calculated in the Microsoft Excel program. Percentage differences between individual used atmospheres were also evaluated in this program. The results of the elemental analysis have been provided in a similar way at least three times for each sample.

3. Results

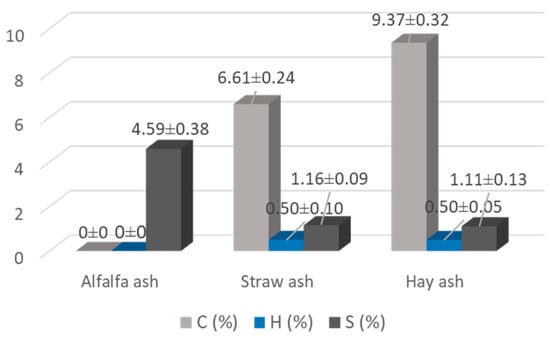

The results of the elemental analysis are stated in Figure 3. The elemental analysis showed no nitrogen content in all samples. Carbon and hydrogen content in the alfalfa ash had not been detected. Carbon content was 6.61 ± 0.24% in straw ash and 9.37 ± 0.32% in hay ash. The observed difference in carbon content between straw ash and hay ash was approximately 2.8%. Hydrogen content was 0.50 ± 0.10% in straw ash and 0.50 ± 0.05% in the hay ash. The observed difference in hydrogen content between straw ash and hay ash was approximately none. However, the alfalfa ash had a higher content of sulfur, 4.59 ± 0.38%, which was approximately 3.5% higher than the sulfur content in straw ash or hay ash. Straw ash and hay ash had only a slight difference in sulfur content. The sulfur content was 1.16 ± 0.09% in straw ash and 1.11 ± 0.13% in hay ash.

Figure 3.

Elemental analysis of individual ash samples.

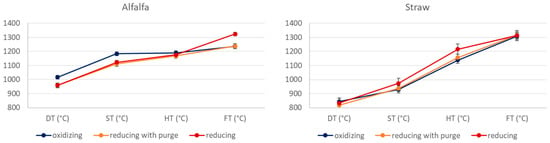

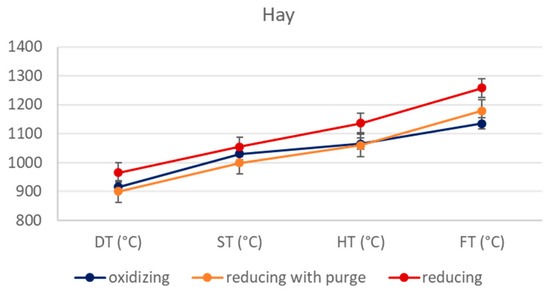

The resulting values of ash melting temperatures are shown in the following figures and tables. Figure 4 presents the summary differences between resulting values obtained during three different atmospheres: oxidizing, reducing with the air purge, and reducing. The most significant differences have been observed between oxidizing and reducing atmospheres, with average values of 4.5%. The least significant differences have been observed between oxidizing and reducing with the air purge atmospheres, with average values of 2.4%. The average difference between reducing and reducing with the air purge atmospheres was 3.6%.

Figure 4.

Differences in ash melting temperatures between individual used atmospheres.

The individual percentage differences between used atmospheres are stated in Table 1. There were observed differences between individual atmospheres from none up to 9.8%.

Table 1.

Percentage differences between individual used atmospheres.

The most significant difference has been observed for the FT temperature of the hay sample between the oxidizing and reducing atmospheres, with a value of 9.8%. The other significant differences appeared between the oxidizing and reducing atmospheres with values of 6.5% for the FT temperature of the alfalfa sample, 6.4% for the HT temperature of the straw sample, 6.4% for the HT temperature of the hay sample, then between oxidizing and reducing with the air purge atmospheres with the value of 6.0% for the ST temperature of alfalfa sample and also between reducing and reducing with the air purge atmospheres with the values of 6.8% for the DT temperatures of hay sample, 6.8% for the HT temperature of hay sample, 6.5% for the FT temperature of alfalfa sample and 6.3% for the FT temperature of hay sample.

No difference has been seen for the DT temperature of the alfalfa sample between reducing and reducing with the air purge atmospheres. Except for it, the least significant difference has been observed for the FT temperature of the alfalfa sample between oxidizing and reducing with the air purge atmospheres with the value of 0.1%. Similarly, little significant difference has been found for the FT temperature of the straw sample between reducing and reducing with the air purge atmospheres with the value of 0.2%.

The average values with standard deviations of reached ash melting temperatures for all used atmospheres (oxidizing, reducing with air purge, and reducing) are stated in Table 2. To ensure high-quality-graded wood pellets for commercial and residential applications, these pellets should have DT temperatures higher than 1200 °C to meet A1 quality and higher than 1100 °C to meet A2 and B quality according to ISO 17225-2: 2021 [23]. SST, DT, HT, and FT for non-woody pellets should be stated in ISO 17225-6: 2021 [24] in the future. Class A1 is the first-class quality used in boilers and stoves in households. Class A2 is used in larger boilers and produces more ash during its combustion. Class B indicates wood pellets for industrial use.

Table 2.

Resulting values of ash melting temperatures with their standard deviations.

The tested pellet samples had DT temperatures lower than 1100 °C, and only ash alfalfa had ST temperatures higher than 1100 °C. However, ash alfalfa during the reducing atmosphere and ash straw during all used atmospheres had FT temperatures higher than 1300 °C. Ash hay had FT temperature even less than 1200 °C during oxidizing and reducing with air purge atmospheres. However, lower ash melting temperatures are generally reached for agricultural residues compared to wood biomass.

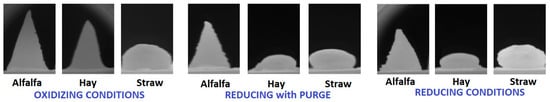

Figure 5 shows the individual shapes of tested samples during their melting at 1000 °C. Based on these records, alfalfa ash and hay ash were less deformed by heat during oxidizing conditions than during reducing conditions. Alfalfa ash had the greatest heat resistance, and straw ash had the lowest heat resistance, on the other hand.

Figure 5.

Differences in melting at 1000 °C between individual tested samples.

4. Discussion

The carbon and hydrogen content in straw ash and hay ash samples could be caused by many factors such as insufficient residence time of the fuel sample at a temperature of 550 °C or too large a fuel sample, or insufficient supply of oxygen to all parts of the fuel sample during ash sample preparation or handling error. All these factors were tried to avoid, and ashing was finished only after the weight of the sample did not change for at least 30 min. The measured carbon content also could be caused by heating of ash to a temperature of 950 °C where carbonates and bicarbonates in the ash, especially calcium carbonate, could be thermally decomposed into calcium oxide and carbon monoxide and, in reaction with oxygen into carbon dioxide that the elemental analyzer detects as carbon in the sample. The most significant difference in the elemental analysis was for carbon content between straw ash and hay ash. Hay had approximately 2.8% more carbon after the combustion in the muffle furnace at 550 °C than straw. Alfalfa had no carbon after the combustion in the same way. The small amounts of hydrogen in ash samples of straw and hay ash could be caused by insufficient drying of samples before elemental analysis or by absorbing atmospheric moisture into the samples, and this water appeared as a small amount of hydrogen in the ash samples. Higher content of sulfur has been measured for the ash sample of alfalfa, which could also be affected by the higher content of sulfur in the alfalfa fuel.

Observed result differences between individual atmospheres in ash melting testes were none, up to 9.8%. However, the most significant differences have appeared between oxidizing and reducing atmospheres. Nevertheless, all tested samples had DT temperatures lower than 1100 °C. The highest measured DT has been observed in the alfalfa sample during the oxidizing atmosphere. The lowest measured DT has been found in the straw sample during the reducing atmosphere with the air purge. Horák et al. [17] stated the value of 840 °C for the DT temperature of hay pellets for reducing atmosphere and 880 °C for oxidizing atmosphere. Their DT results for wheat straw [15] in the other article were the following: 1090 °C for oxidizing atmosphere, 1080 °C for ½ reducing atmosphere, and less than 984 °C for reducing atmosphere according to ČSN ISO 540.

The highest measured FT has been observed in the alfalfa sample during the reducing atmosphere. However, the straw sample had also higher FT temperatures and more than 1300 °C for all atmospheres. Hay samples had higher measured FT value for reducing atmosphere, but less than 1300 °C. Horák’s results for FT temperatures are the following: 1300 °C during the reducing atmosphere and 1260 °C during oxidizing atmosphere for hay pellets [17], 1370 °C during the oxidizing atmosphere, and 1360 °C for ½ reducing and pure reducing atmosphere for wheat straw [15].

However, the resulting differences in this work and in Horák’s works [15,17] can be caused primarily by different types of input raw materials contained in hay or straw pellets and secondary by a different way of sample preparation for the measurements of ash melting temperature.

These results and also other results obtained in various works, such as Horák’s works [15,17] and so on, confirmed the importance of ash preparation for ash melting tests and the methodology itself used in these tests. The methodology also consists of the choice of the atmosphere and purge used in these tests.

Lower ash melting temperatures are generally reached for agricultural residues compared to wood biomass. Therefore, these fuels are not suitable for direct combustion. Despite it, agricultural residues present promising renewable energy sources. In general, biomass is carbon-neutral. Energy from biomass with carbon capture and storage can significantly contribute to the decarburization of various energy sectors such as transport and industry. Various applications can be used during their combustion, such as the separators of carbon dioxide, which can be further stored in reservoirs. CO2 can be captured directly from the combustion process by various methods such as absorption or gas separation, but these methods are not yet widespread because they are expensive. However, the combustion process can be optimized, for example, by air supply, by adding additives to increase the melting temperatures, or by blending with wood residues. Pafcuga et al. [25] stated that the rotary burner could be the best choice for wheat straw combustion. Its construction allows for obtaining the highest possible energy from combustion. The using of a rotary combustion chamber can also improve thermal efficiency and reduce emissions. The secondary air inlet through the secondary air pores is important due to complete burn. Royo et al. [26] investigated the influence of inlet airflow and temperature on sintering degree and deposition ratio. They observed a relation inversely proportional between air excess ratio and deposition ratio. However, deposition was more substantial for the four tested agropellets.

Knowing the correct ash melting temperature of the fuel can help the operator of the heat source in dosing the fuel, mixing the fuel with another fuel with a higher ash melting temperature, or he can add additives to the fuel, or changing the combustion process, e.g., by changing the amount or redistribution of combustion air. Thanks to these measures, it is possible to efficiently burn even low-quality fuels based on phytomass with minimal production of emissions. Therefore, it is necessary to specify the used atmosphere conditions due to possible different resulting values. The used atmosphere conditions should be stated together with the resulting values of melting temperatures.

5. Conclusions

Ash melting behavior can be impacted by many factors, such as ash preparation or the used atmosphere in ash melting measurements, which was the aim of this article. The first used atmosphere was oxidized with compressed air and nitrogen. The second atmosphere was reduced with the air purge, and the last was only reduced, consisting of 60% carbon monoxide and 40% carbon dioxide. No difference has been seen for the DT temperature of the alfalfa sample between reducing and reducing with the air purge atmospheres. Except, the least significant difference has been observed for the FT temperature of the alfalfa sample between oxidizing and reducing with the air purge atmospheres with the value of 0.1%. Similarly, little significant difference has been found for the FT temperature of the straw sample between reducing and reducing with the air purge atmospheres with the value of 0.2%.

However, there were differences in the resulting values in most cases. The most significant difference has been observed for the FT temperature of the hay sample between the oxidizing and reducing atmospheres, with a value of 9.8%. The other significant differences appeared between the oxidizing and reducing atmospheres with values of 6.5% for the FT temperature of the alfalfa sample, 6.4% for the HT temperature of the straw sample, 6.4% for the HT temperature of the hay sample, then between oxidizing and reducing with the air purge atmospheres with the value of 6.0% for the ST temperature of alfalfa sample and also between reducing and reducing with the air purge atmospheres with the values of 6.8% for the DT temperatures of hay sample, 6.8% for the HT temperature of hay sample, 6.5% for the FT temperature of alfalfa sample and 6.3% for the FT temperature of hay sample.

The standard ISO 21404: 2020 allows to use of both atmospheres: oxidizing and reducing. Therefore, resulting values in various works can differ due to different ash preparation or used atmosphere. The oxidizing atmosphere is more similar to the combustion process and presents a less expensive way. The using of carbon dioxide with carbon monoxide presents different atmosphere conditions but often using way in ash melting tests. Therefore, the choice of the atmosphere in ash melting tests can impact the resulting values of melting temperatures, and used atmosphere conditions should be stated together with the resulting values of melting temperatures. More attention should also be paid to the use of oxidizing atmosphere for combustion applications in heat sources. It would be suitable to realize more comprehensive research regarding ash preparation in different ways and with using of different types of fuel. Future work should be focused on the method of ash melting temperature and different ash preparation (different specimen shapes, different ash sizes).

The reduction of emissions (carbon dioxide and greenhouse gas) can also be achieved by using renewable energy sources instead of fossil fuels. Due to the measurements of ash melting temperatures and other quantities in the combustion process, it is also possible to efficiently burn even low-quality fuels based on phytomass with minimal production of emissions.

Author Contributions

N.Č.K. conceptualization, investigation, writing—original draft preparation, data curation; M.H. writing—review and editing, funding acquisition, methodology; J.T. data curation; A.Č. formal analysis, conceptualization. All authors have read and agreed to the published version of the manuscript.

Funding

This publication has been produced with the support of the Grant System of the University of Zilina no. 1/2022 (17287), VEGA no. 1/0150/22: Energy utilization of produced waste in connection with the COVID-19 pandemic through pellets as an alternative fuel, KEGA 032ŽU-4/2022 Implementation of knowledge about modern ways of reducing environmental burden in the energy use of solid fuels and waste into the pedagogical process and APVV-21-0452 Impact of using small electrostatic precipitators to reduce particulate pollutants in domestic fuel combustion.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are available in a publicly accessible repository.

Conflicts of Interest

The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results. The authors declare no conflict of interest.

References

- Vitázek, I.; Šotnar, M.; Hrehová, S.; Darnadyová, K.; Mareček, J. Isothermal Kinetic Analysis of the Thermal Decomposition of Wood Chips from an Apple Tree. Processes 2021, 9, 195. [Google Scholar] [CrossRef]

- Rimar, M.; Kizek, J.; Kulikov, A.; Fedak, M. Study of selected burner parameters on the gas-air mixture combustion. MM Sci. J. 2022, 2022, 6251–6256. [Google Scholar] [CrossRef]

- Kubonova, L.; Janakova, I.; Malikova, P.; Drabinova, S.; Dej, M.; Smelik, R.; Skalny, P.; Heviankova, S. Evaluation of waste blends with sewage sludge as a potential material input for pyrolysis. Appl. Sci. 2021, 11, 1610. [Google Scholar] [CrossRef]

- Križan, P.; Šooš, Ľ.; Kolláth, Ľ. Research of municipal waste material recovery by briquetting technology. Waste Forum 2022, 2, 116–132. [Google Scholar]

- Picchio, R.; Latterini, F.; Venanzi, R.; Stefanoni, W.; Suardi, A.; Tocci, D.; Pari, L. Pellet production from woody and non-woody feedstocks: A review on biomass quality evaluation. Energies 2020, 13, 2937. [Google Scholar] [CrossRef]

- Nosek, R.; Backa, A.; Ďurčanský, P.; Holubčík, M.; Jandačka, J. Effect of paper sludge and dendromass on properties of phytomass pellets. Appl. Sci. 2021, 11, 65. [Google Scholar] [CrossRef]

- Matúš, M.; Križan, P.; Šooš, Ľ.; Beniak, J. The effect of papermaking sludge as an additive to biomass pellets on the final quality of the fuel. Fuel 2018, 219, 196–204. [Google Scholar] [CrossRef]

- Radačovská, L.; Holubčík, M.; Nosek, R.; Jandačka, J. Influence of bark content on ash melting temperature. Procedia Eng. 2017, 192, 759–764. [Google Scholar] [CrossRef]

- Jandačka, J.; Mičieta, J.; Holubčík, M.; Nosek, R. Experimental determination of bed temperatures during wood pellet combustion. Energy Fuels 2017, 31, 2919–2926. [Google Scholar] [CrossRef]

- Toscano, G.; Corinaldesi, F. Ash fusibility characteristics of some biomass feedstocks and examination of the effects of inorganic additives. J. Agric. Eng. 2010, 41, 13–19. [Google Scholar] [CrossRef]

- Vassilev, S.; Baxter, D.; Andersen, L.; Vassileva, C. An overview of the chemical composition of biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Zhai, M.; Li, X.; Yang, D.; Ma, Z.; Dong, P. Ash fusion characteristics of biomass pellets during combustion. J. Clean. Prod. 2022, 336, 130361. [Google Scholar] [CrossRef]

- Link, S.; Yrjas, P.; Lindberg, D.; Trikkel, A.; Mikli, V. Ash melting behaviour of reed and woody fuels blends. Fuel 2022, 314, 123051. [Google Scholar] [CrossRef]

- ISO 21404; Solid Biofuels-Determination of Ash Melting Behavior. International Organization for Standardization: Geneva, Switzerland, 2020.

- Horák, J.; Jankovská, Z.; Branc, M.; Straka, F.; Buryan, P.; Kubesa, P.; Hopan, F.; Krpec, K. Problematika stanovení charakteristických teplot tavitelnosti popela biomasy [Problems of determination of characteristic temperatures of biomass ash fusibility]. Chem. Listy 2013, 107, 502–509. [Google Scholar]

- Reinmöller, M.; Klinger, M.; Schreiner, M.; Gutte, H. Relationship between ash fusion temperatures of ashes from hard coal, brown coal, and biomass and mineral phases under different atmospheres: A combined FactSage™ computational and network theoretical approach. Fuel 2015, 15, 118–123. [Google Scholar] [CrossRef]

- Horák, J.; Kuboňová, L.; Dej, M.; Laciok, V.; Tomšejová, Š.; Hopan, F.; Krpec, K.; Koloničný, J. Effects of the type of biomass and ashing temperature on the properties of solid fuel ashes. Pol. J. Chem. Technol. 2019, 21, 43–51. [Google Scholar] [CrossRef]

- Chaloupková, V.; Ivanova, T.; Hutla, P.; Špunarová, M. Ash Melting Behavior of Rice Straw and Calcium Additives. Agriculture 2021, 11, 1282. [Google Scholar] [CrossRef]

- Mudryk, K.; Jewiarz, M.; Wrobel, M.; Niemiec, M.; Dyjakon, A. Evaluation of Urban Tree Leaf Biomass-Potential, Physico-Mechanical and Chemical Parameters of Raw Material and Solid Biofuel. Energies 2021, 14, 818. [Google Scholar] [CrossRef]

- Wang, L.; Skreiberg, Ø.; Khalil, R.; Li, H. Effect of fuel mixing on melting behavior of spruce wood ash. Energy Procedia 2019, 158, 1342–1347. [Google Scholar] [CrossRef]

- Oladejo, J.M.; Adegbite, S.; Pang, C.; Liu, H.; Lester, E.; Wu, T. In-situ monitoring of the transformation of ash upon heating and the prediction of ash fusion behaviour of coal/biomass blends. Energy 2020, 199, 117330. [Google Scholar] [CrossRef]

- Chen, X.; Tang, J.; Tian, X.; Wang, L. Influence of biomass addition on Jincheng coal ash fusion temperatures. Fuel 2015, 160, 614–620. [Google Scholar] [CrossRef]

- ISO 17225; 2 Solid Biofuels—Fuel Specifications and Classes—Part 2: Graded Wood Pellets. International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO 17225; 6 Solid Biofuels—Fuel Specifications and Classes—Part 6: Graded Non-Woody Pellets. International Organization for Standardization: Geneva, Switzerland, 2021.

- Pafcuga, M.; Holubcik, M.; Durcansky, D.; Kapjor, A.; Malcho, M. Small heat source used for combustion of wheat-straw pellets. Appl. Sci. 2021, 11, 5239. [Google Scholar] [CrossRef]

- Royo, J.; Canalís, P.; Quintana, D.; Díaz-Ramírez, M.; Sin, A.; Rezeau, A. Experimental study on the ash behaviour in combustion of pelletized residual agricultural biomass. Fuel 2019, 239, 991–1000. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).