The Effects of the Large-Scale Factor on the Integrity Parameters of Monolithic Fire-Resistant Glass

Abstract

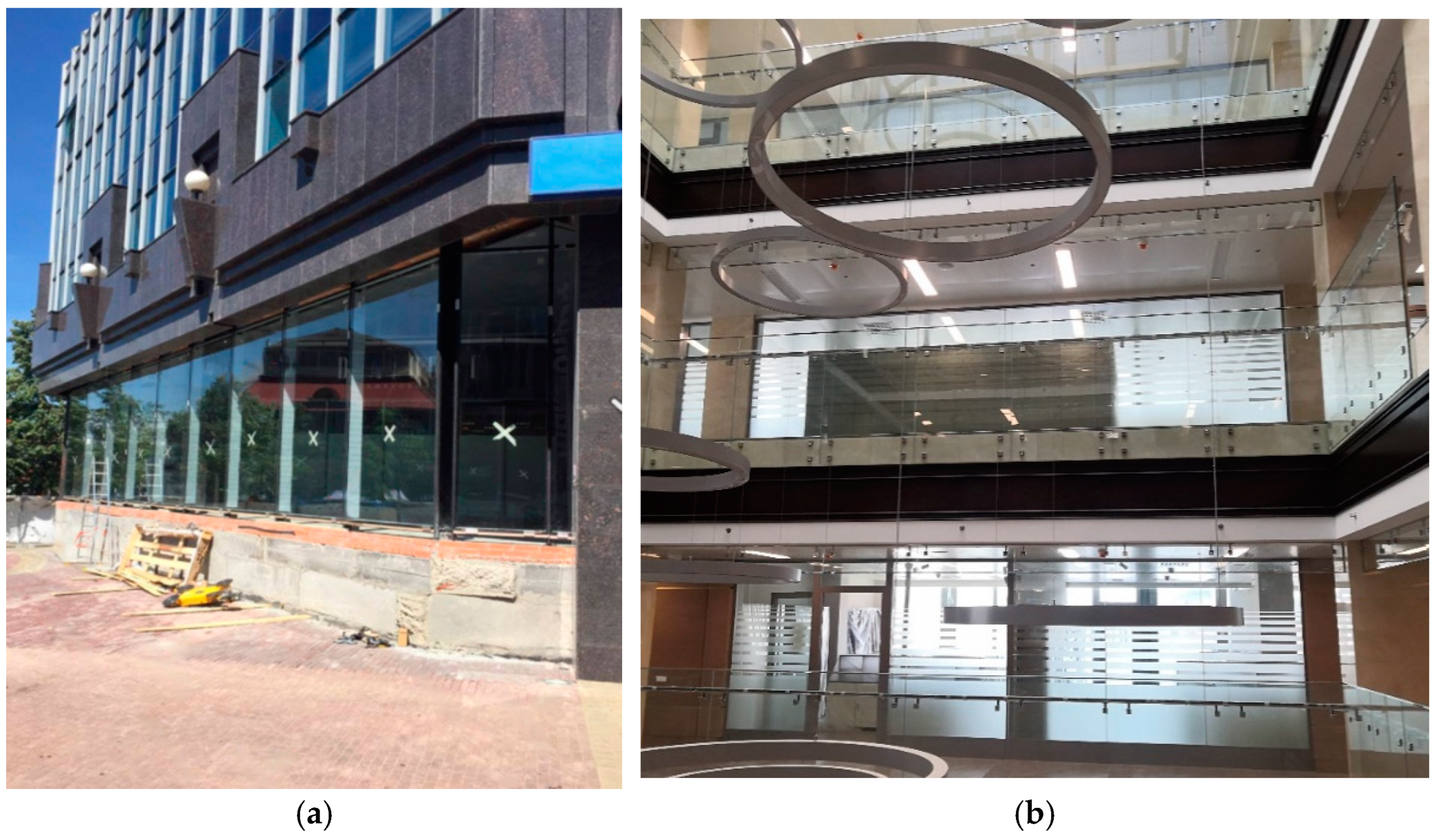

1. Introduction

- -

- -

- loss of integrity (E) as a result of the glass falling out of the test frame, the appearance of a stable flame on the unheated side of the glass for 10 s or more, the formation of a through hole in the glass and ignition or smoldering;

- -

- loss of thermal insulation capacity (I) due to an increase of more than 140 °C in the average temperature at any point on the surface of the unheated side of the glass or a temperature more than 180 °C above the temperature of the structure before the test;

- -

- restriction of the thermal radiation flux density (W) upon reaching a thermal radiation flux density of 3.5 kW/m2 at a distance of 0.5 m from the unheated side.

2. Materials and Methods

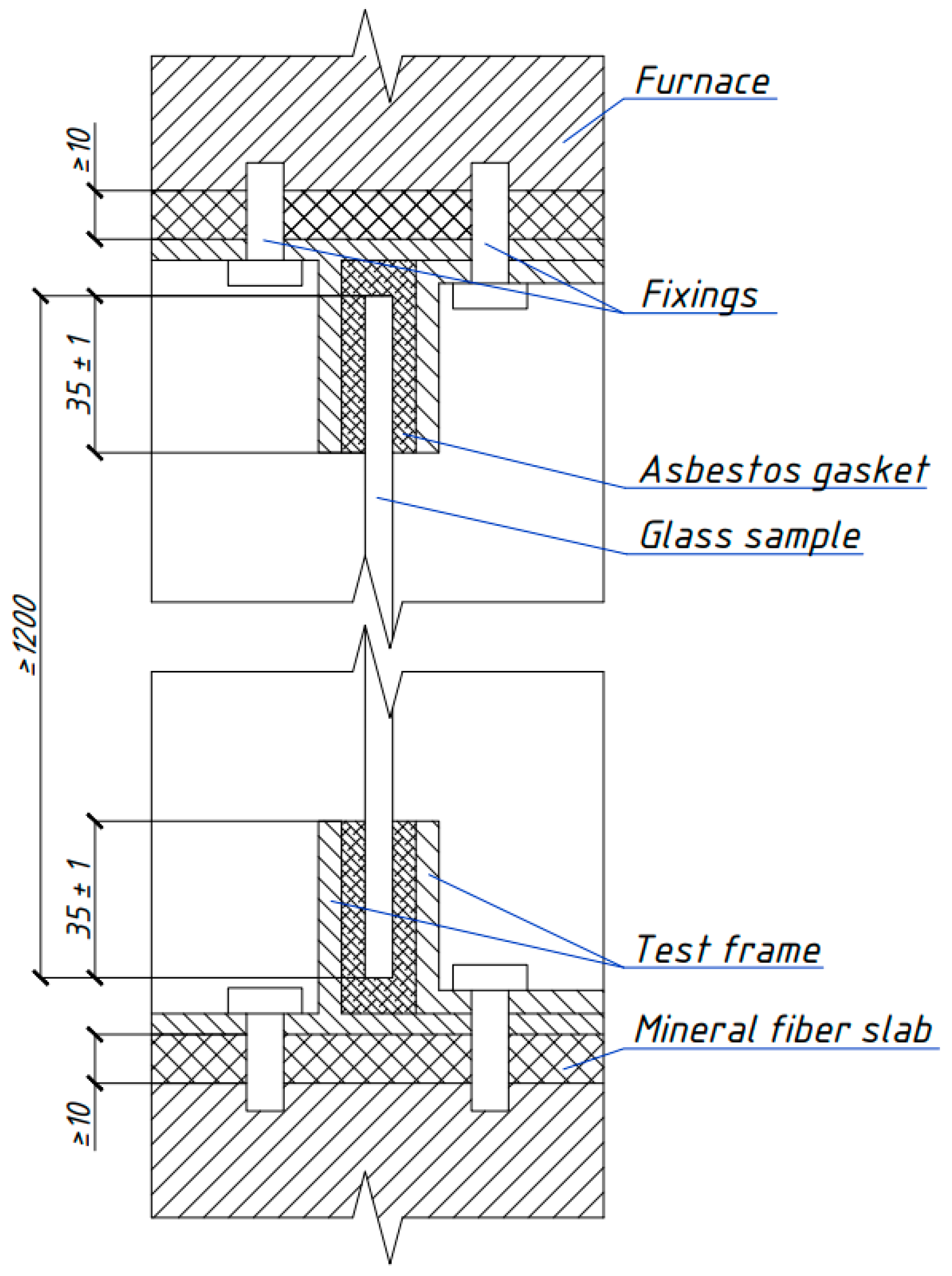

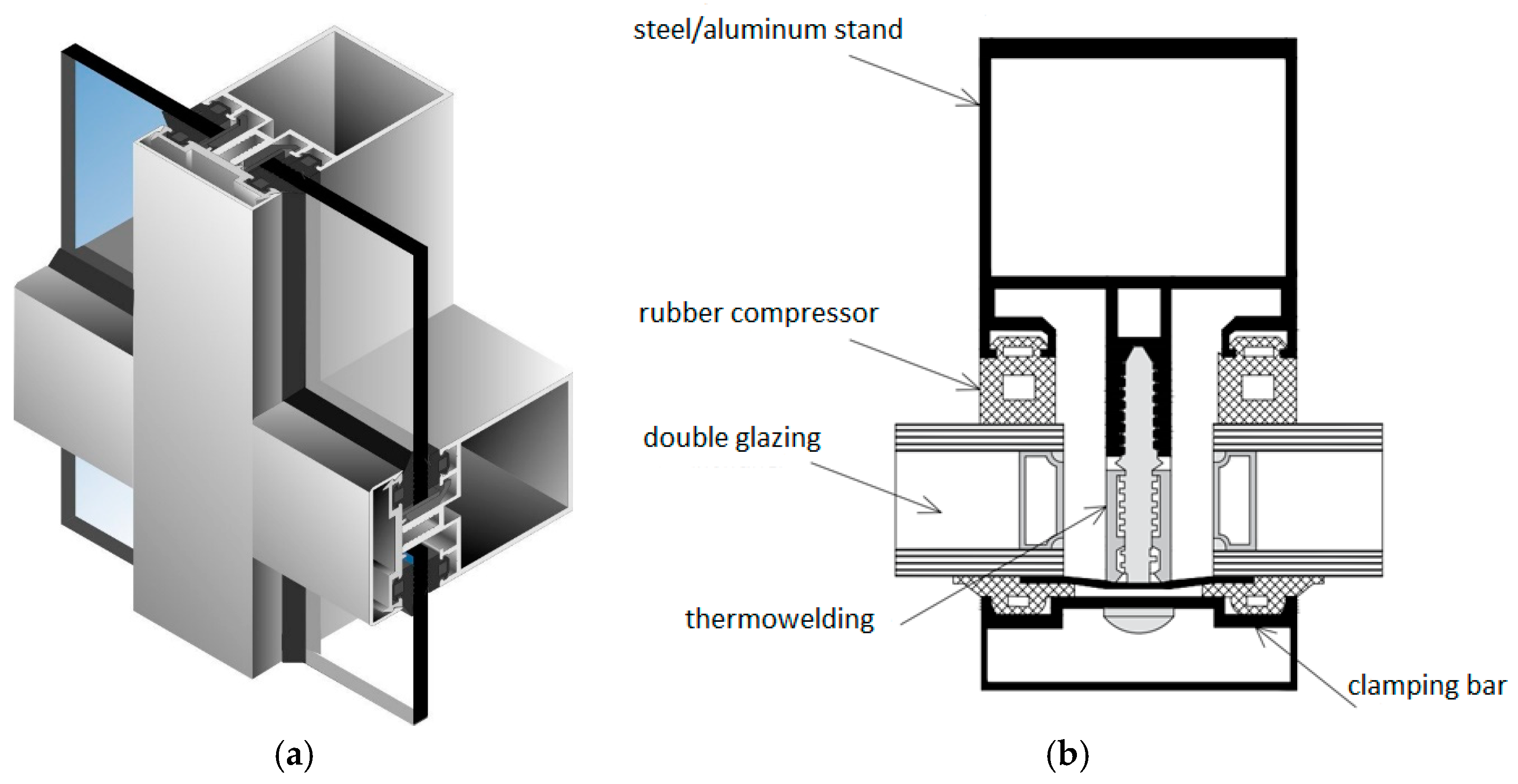

2.1. Experiments on Glass Structures

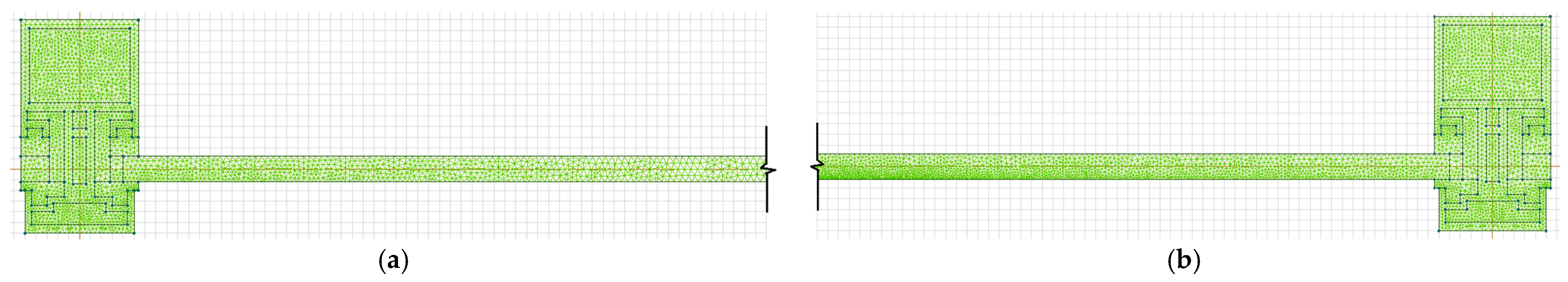

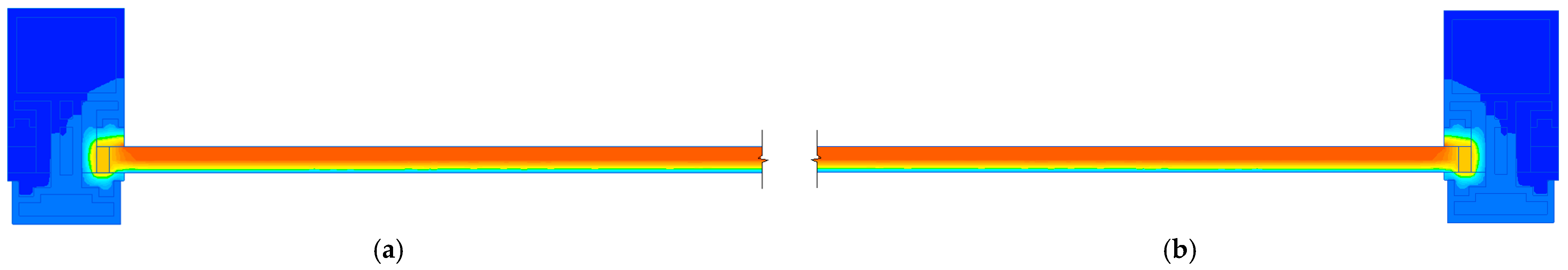

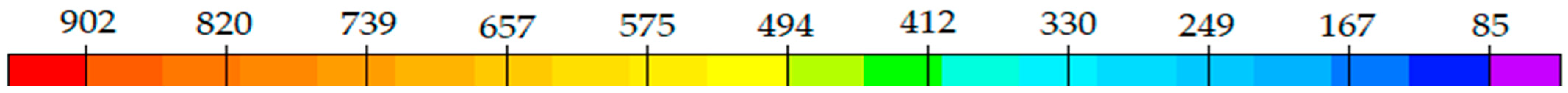

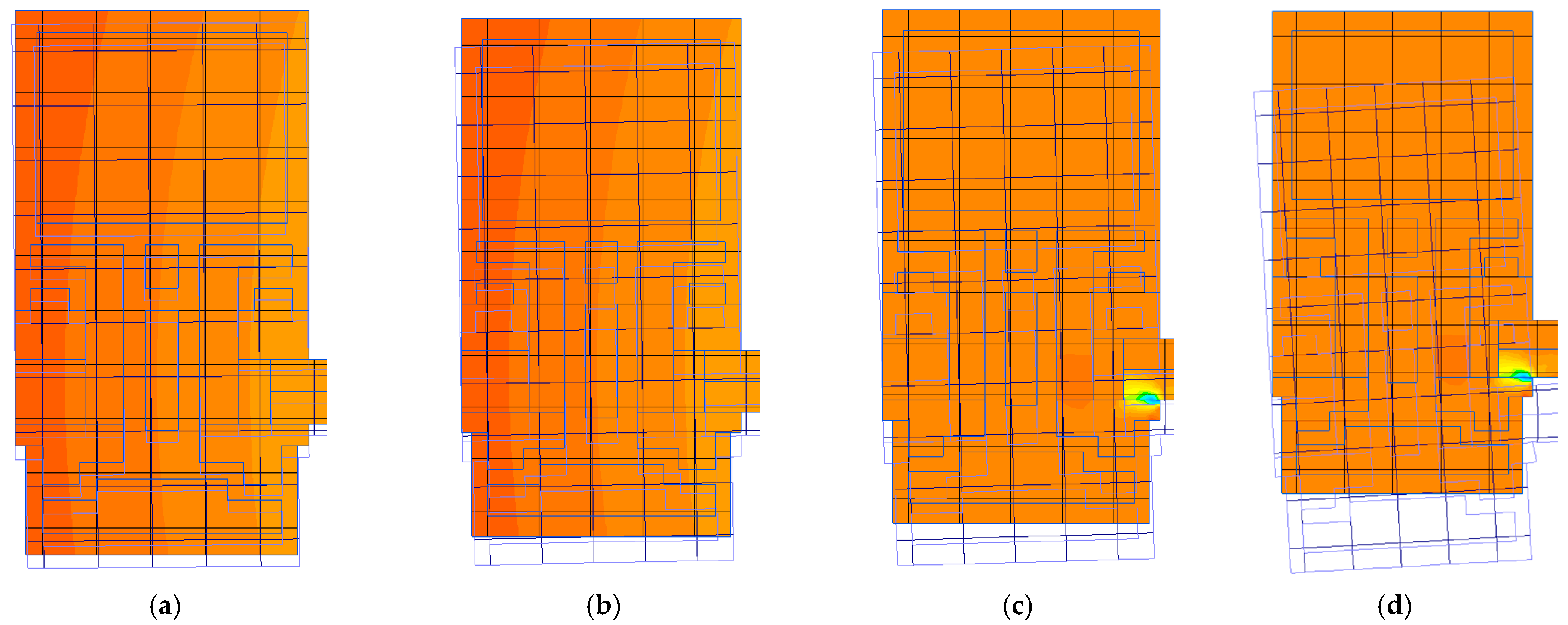

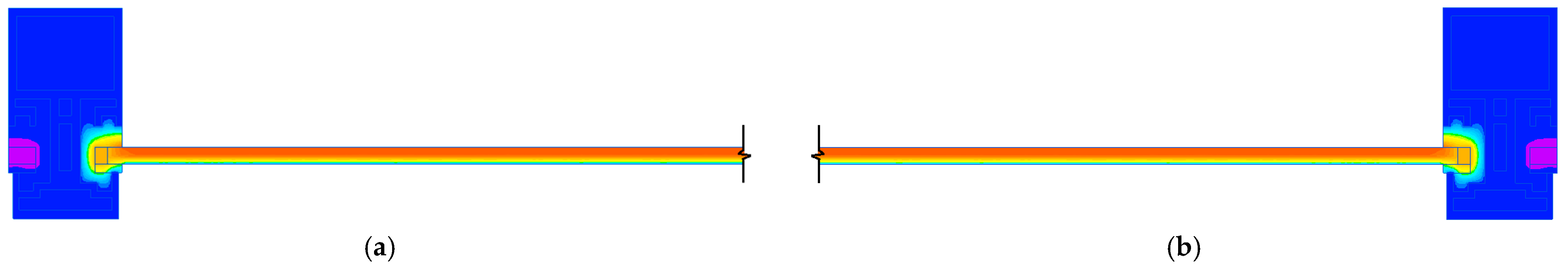

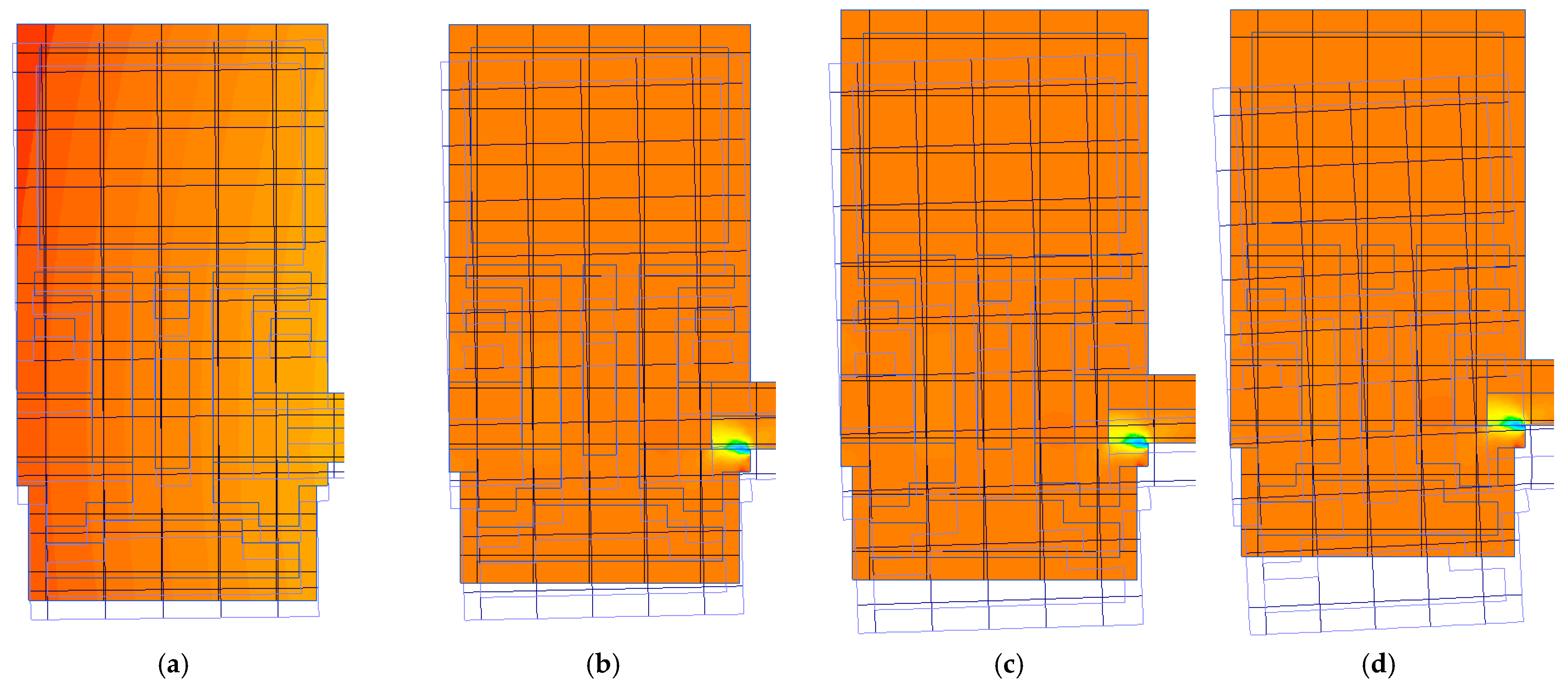

2.2. Simulation in SP QuickField

3. Results

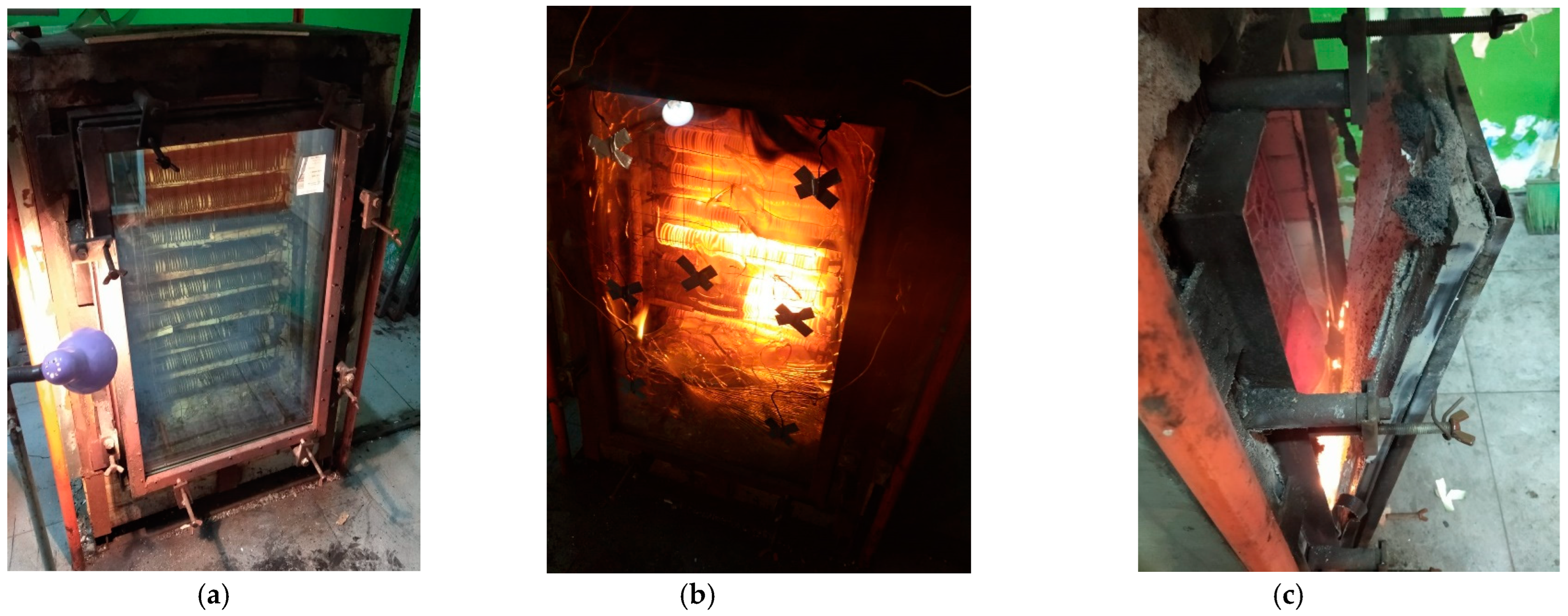

3.1. Results of Experiments on Glass Structures

3.1.1. Experimental Results of Small-Sized Samples

3.1.2. Experimental Results of Large-Sized Samples

3.2. Results of Simulations in the SP QuickField

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Macfarlane, T. Engineering Invention in Glass Architecture. In Proceedings of the Challenging Glass 3: Conference on Architectural and Structural Applications of Glass CGC 2012, Delft, The Netherlands, 28–29 June 2012; pp. 11–16. [Google Scholar] [CrossRef]

- Nemova, D.V.; Vasileva, I.L.; Vatin, N.I. Introduction of Double-Skin Facades in the Russian Federation. Constr. Unique Build. Struct. 2019, 84, 51–62. [Google Scholar] [CrossRef]

- Taylor, C.A.; Herreman, K. An Open Office Plan Case Study: Demountable Glass Partitions and Speech Privacy. In Proceedings of the INTER-NOISE 2018-47th International Congress and Exposition on Noise Control Engineering: Impact of Noise Control Engineering, Chicago, IL, USA, 26–29 August 2018. [Google Scholar]

- Ledbetter, S.R.; Walker, A.R.; Keiller, A.P. Structural Use of Glass. J. Archit. Eng. 2006, 12, 137–149. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.; Wang, Q.; Yang, Y.; Sun, J. The Effect of Glass Panel Dimension on the Fire Response of Glass Façades. Constr. Build. Mater. 2018, 181, 588–597. [Google Scholar] [CrossRef]

- Han, J.; Kim, H.; Lee, B.; Jin, S.; Kwon, Y. Fire Risk Analysis of Glass Installed in an Opening. J. Korean Soc. Hazard Mitig. 2020, 20, 195–202. [Google Scholar] [CrossRef]

- Bedon, C. Structural Glass Systems under Fire: Overview of Design Issues, Experimental Research, and Developments. Adv. Civ. Eng. 2017, 2017, 2120570. [Google Scholar] [CrossRef]

- Shields, T.J.; Silcock, G.W.H.; Flood, M. Performance of a Single Glazing Assembly Exposed to a Fire in the Centre of an Enclosure. Fire Mater. 2002, 26, 51–75. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Q.; Shao, G.; Chen, H.; Su, Y.; Sun, J.; He, L.; Liew, K.M. Fracture Behavior of a Four-Point Fixed Glass Curtain Wall under Fire Conditions. Fire Saf. J. 2014, 67, 24–34. [Google Scholar] [CrossRef]

- Chow, W.K.; Gao, Y. Thermal Stresses on Window Glasses upon Heating. Constr. Build. Mater. 2008, 22, 2157–2164. [Google Scholar] [CrossRef]

- Sabsabi, A.; Youssef, M.A.; El-Fitiany, S.F.; Vedrtnam, A. Simplified Structural Analysis of Framed Ordinary Non-Tempered Glass Panels during Fire Exposure. Fire Saf. J. 2021, 122, 103357. [Google Scholar] [CrossRef]

- Zhou, X.Q.; Wang, M.Y.; Li, L.X. Dynamic Damage Assessment of Float Glass under Blast Loading. Adv. Struct. Eng. 2019, 22, 2517–2529. [Google Scholar] [CrossRef]

- Park, S.; Carriquiry, A.; Horkley, L.K.; Peate, D.W. A Database of Elemental Compositions of Architectural Float Glass Samples Measured by LA-ICP-MS. Data Brief 2020, 30, 105449. [Google Scholar] [CrossRef]

- Jørgensen, J.D.; Nielsen, J.H.; Giuliani, L. Thermal Resistance of Framed Windows: Experimental Study on the Influence of Frame Shading Width. Saf. Sci. 2022, 149, 105683. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, J.; He, L.; Wang, Q.; Rush, D. Experimental Study on Fallout Behaviour of Tempered Glass Façades with Different Frame Insulation Conditions in an Enclosure Fire. Proc. Combust. Inst. 2019, 37, 3889–3898. [Google Scholar] [CrossRef]

- Debuyser, M.; Sjöström, J.; Lange, D.; Honfi, D.; Sonck, D.; Belis, J. Behaviour of Monolithic and Laminated Glass Exposed to Radiant Heating. Constr. Build. Mater. 2017, 130, 212–229. [Google Scholar] [CrossRef]

- ISO 12543-1:2011; Glass in Building-Laminated Glass and Laminated Safety Glass-Evaluation of Conformity/Product Standard. European Committee for Standardization: Brussels, Belgium, 2005; pp. 1–52.

- Binte Mohd Faudzi, F.; Schulz, J.; Dodd, G. Qualitative Assessment of Fire Hazard Posed by Laminated Glass Balcony Balustrades on Fire Spread. Fire Technol. 2021, 57, 1951–1967. [Google Scholar] [CrossRef]

- Suzuki, K.; Hisada, T.; Sato, A.; Ohmiya, Y. Experimental Study for Laminated Glass Composed of Tempered Fire Resistance Glass Exposed to Standard Heating. J. Environ. Eng. 2018, 83, 415–424. [Google Scholar] [CrossRef]

- Louter, C.; Bedon, C.; Kozłowski, M.; Nussbaumer, A. Structural Response of Fire-Exposed Laminated Glass Beams under Sustained Loads; Exploratory Experiments and FE-Simulations. Fire Saf. J. 2021, 123, 103353. [Google Scholar] [CrossRef]

- EN 1363–1: 2012; Fire Resistance Tests−Part 1: General Requirements (NEQ). European Committee for Standardization: Brussels, Belgium, 2012; p. 64.

- Bedon, C.; Honfi, D.; Kozłowski, M. Numerical Modelling of Structural Glass Elements under Thermal Exposure. In Proceedings of the 3rd International Electronic Conference on Materials, Basel, Switzerland, 14–28 May 2018. [Google Scholar] [CrossRef]

- Yang, Z.; Zhao, X.; Wu, X.; Li, H.L. Application and Integrity Evaluation of Monolithic Fire-Resistant Glass. Procedia Eng. 2011, 11, 603–607. [Google Scholar] [CrossRef]

- Russian State Standard GOST 33000-2014; Glass and Glass Products. Fire Resistance Test Method. Russian Committee for Standardization: Moscow, Russia, 2014; p. 16. Available online: https://docs.cntd.ru/document/1200120594 (accessed on 12 March 2022).

- Bedon, C.; Louter, C. Thermo-Mechanical Numerical Modelling of Structural Glass under Fire-Preliminary Considerations and Comparisons. In Proceedings of the Challenging Glass 6: Conference on Architectural and Structural Applications of Glass, CGC 2018-Proceedings, Delft, The Netherlands, 17–18 May 2018. [Google Scholar]

- Wang, X.; Tan, Q.; Wang, Z.; Kong, X.; Cong, H. Preliminary Study on Fire Protection of Window Glass by Water Mist Curtain. Int. J. Therm. Sci. 2018, 125, 44–51. [Google Scholar] [CrossRef]

- ISO 834-75; Elements of Building Constructions. Fire-Resistance Test Methods. General Requirements. International Organization for Standardization: New York, NY, USA, 1975; p. 16. Available online: https://docs.cntd.ru/document/9055248 (accessed on 2 November 2021).

- Federal Law of 22.07.2008 N 123-FZ. “Technical Regulations on Fire Safety Requirements”. Available online: https://base.garant.ru/12161584/ (accessed on 8 December 2021).

- Tera Analysis Ltd. QuickField Finite Element Analysis System. Version 6.6 User’s Guide. 2021. Available online: https://quickfield.com/downloads/quickfield_manual.pdf (accessed on 10 December 2022).

- Gravit, M.; Klimin, N.; Karimova, A.; Fedotova, E.; Dmitriev, I. Fire Resistance Evaluation of Tempered Glass in Software ELCUT. Smart Innov. Syst. Technol. 2021, 220, 523–537. [Google Scholar] [CrossRef]

- Gravit, M.; Shabunina, D. Numerical and Experimental Analysis of Fire Resistance for Steel Structures of Ships and Offshore Platforms. Fire 2022, 5, 9. [Google Scholar] [CrossRef]

- Gravit, M.; Lavrinenko, M.; Lazarev, Y.; Rozov, A.; Pavlenko, A. Modeling of Cold-Formed Thin-Walled Steel Profile with the MBOR Fire Protection. Adv. Intell. Syst. Comput. 2021, 1259, 577–592. [Google Scholar] [CrossRef]

- Markus, E.S.; Snegirev, A.Y.; Kuznetsov, E.A. Numerical Simulation of a Fire Using Fire Dynamics; St. Petersburg Polytech-Press: St. Petersburg, Russia, 2021; p. 175.26. [Google Scholar]

- EN 1991-1-2; Eurocode 1: Actions on Structures-Part 1–2: General Actions-Actions on Structures Exposed to Fire. European Committee for Standardization: Brussels, Belgium, 2002; p. 61. Available online: https://www.phd.eng.br/wp-content/uploads/2015/12/en.1991.1.2.2002.pdf (accessed on 25 October 2021).

- Gravit, M.; Klimin, N.; Dmitriev, I.; Karimova, A.; Fedotova, E. Fire Technical Properties of Intumescent and Ablative Fire-Resistant Glass. IOP Conf. Ser. Mater. Sci. Eng. 2019, 666, 012095. [Google Scholar] [CrossRef]

- Pourmoghaddam, N.; Schneider, J. Finite-Element Analysis of the Residual Stresses in Tempered Glass Plates with Holes or Cut-Outs. Glas. Struct. Eng. 2018, 3, 17–37. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, L.; Yue, R. Simulation of Temperature Field within Flat Tempered Glass Cooling Process. In Proceedings of the International Conference: Applied Mechanics, Mechanical and Materials Engineering (AMMME), Sanya, China, 25–26 June 2017. [Google Scholar]

| Sample | Dimensions, mm | Thickness, mm | Frame |

|---|---|---|---|

| Sample No. 1.1 | 1000 × 700 | 8 | - |

| Sample No. 1.2 | 1000 × 700 | 8 | - |

| Sample No. 2.1 | 4250 × 2000 | 8 | steel |

| Sample No. 2.2 | 4250 × 2000 | 8 | steel |

| Sample No. 2.3 | 4250 × 2000 | 8 | steel |

| Sample No. 2.4 | 4250 × 2000 | 8 | aluminum |

| Sample No. 3.1 | 2000 × 3000 | 8 | steel |

| Material | Density, kg/m3 | λ, W/(m∙K) at T, °C | C p, J/(kg∙K), at T, °C | ||||

|---|---|---|---|---|---|---|---|

| 20 | 100 | 300 | 20 | 100 | 300 | ||

| Steel | 7800 | 49 | 49 | 47 | 460 | 475 | 510 |

| Aluminum | 2700 | 225 | 232 | 237 | 900 | 940 | 1030 |

| Glass | 2400 | 0.200 | 0.750 | 1450 | 490 | 560 | 710 |

| Name Quantities | Meaning Quantities | Source Information |

|---|---|---|

| Heat transfer coefficient by convection at standard temperature conditions, W/(m2∙K) | 25 | [28] |

| Coefficient takeovers surfaces | 0.5 | [27] |

| Initial ambient temperature, °C | 20 | - |

| Time step for calculating the temperature gradient of the structure, s | 60 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gravit, M.; Shabunina, D.; Stratiy, P.; Kotlyarskaya, I.L.; Sychov, M. The Effects of the Large-Scale Factor on the Integrity Parameters of Monolithic Fire-Resistant Glass. Fire 2023, 6, 114. https://doi.org/10.3390/fire6030114

Gravit M, Shabunina D, Stratiy P, Kotlyarskaya IL, Sychov M. The Effects of the Large-Scale Factor on the Integrity Parameters of Monolithic Fire-Resistant Glass. Fire. 2023; 6(3):114. https://doi.org/10.3390/fire6030114

Chicago/Turabian StyleGravit, Marina, Daria Shabunina, Pavel Stratiy, Irina Leonidovna Kotlyarskaya, and Maxim Sychov. 2023. "The Effects of the Large-Scale Factor on the Integrity Parameters of Monolithic Fire-Resistant Glass" Fire 6, no. 3: 114. https://doi.org/10.3390/fire6030114

APA StyleGravit, M., Shabunina, D., Stratiy, P., Kotlyarskaya, I. L., & Sychov, M. (2023). The Effects of the Large-Scale Factor on the Integrity Parameters of Monolithic Fire-Resistant Glass. Fire, 6(3), 114. https://doi.org/10.3390/fire6030114