On The Flame Behavior during Cable Insulation Material Ignited by Fault Arc: A Flame Extracting and Noise Reduction Algorithm

Abstract

1. Introduction

2. Experimental Setup and Methods

2.1. High-Speed Photos Acquisition

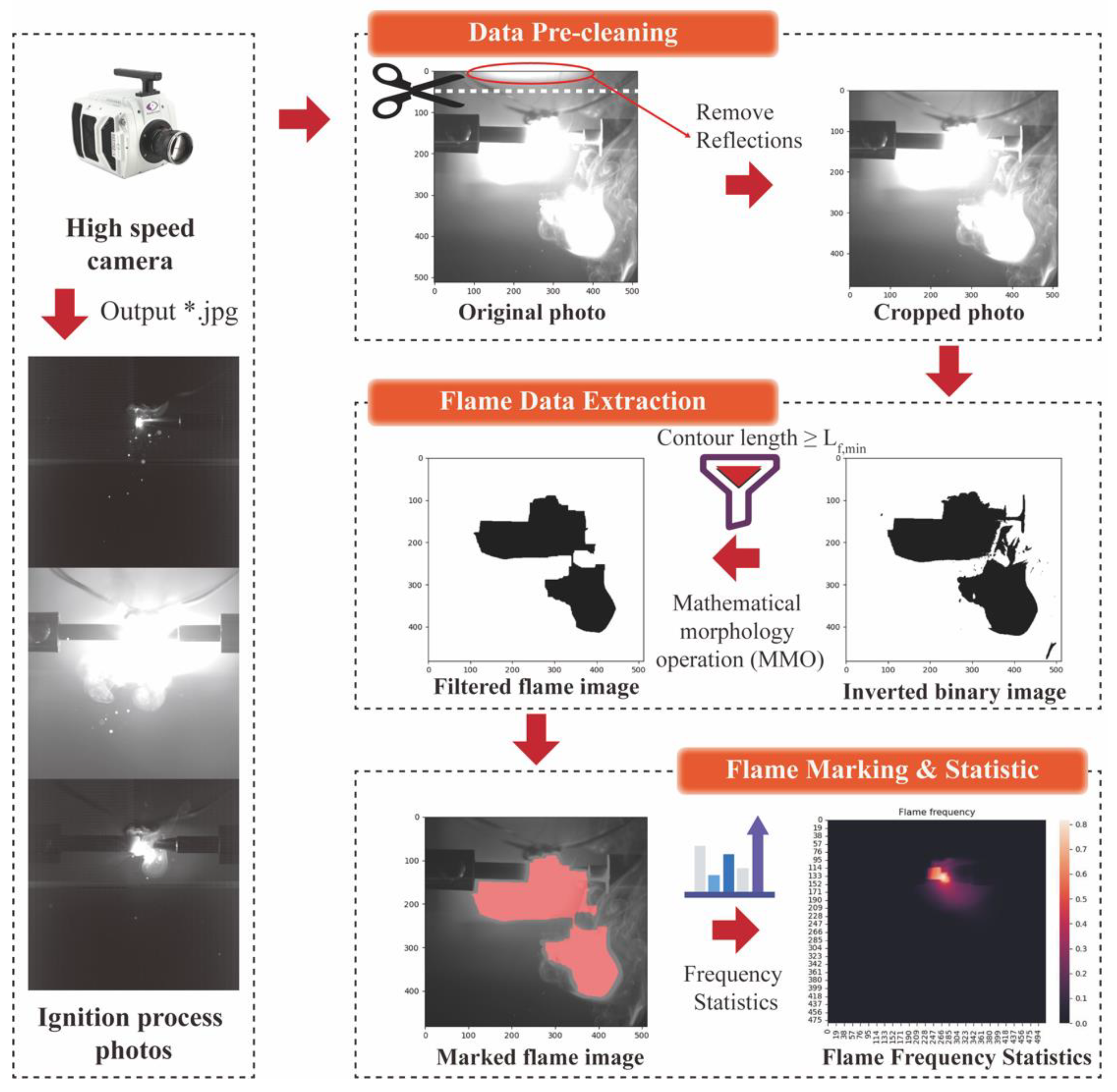

2.2. Image-Based Data Cleaning Algorithm Process

| Step 1: Pre-cleaning step |

| Crop the upper part (512 × 30) of the high-speed camera photo (512 × 512) to exclude reflections from the top wall of the stainless-steel experimental chamber. |

| Step 2: Flame data extraction |

| 2-1 The pixel points in the cropped photo are plotted as the inverted binary image; |

| 2-2 The image edge of the binary image is recognized according to the difference between the gray value of the flame and the particle and the gray value of the background; |

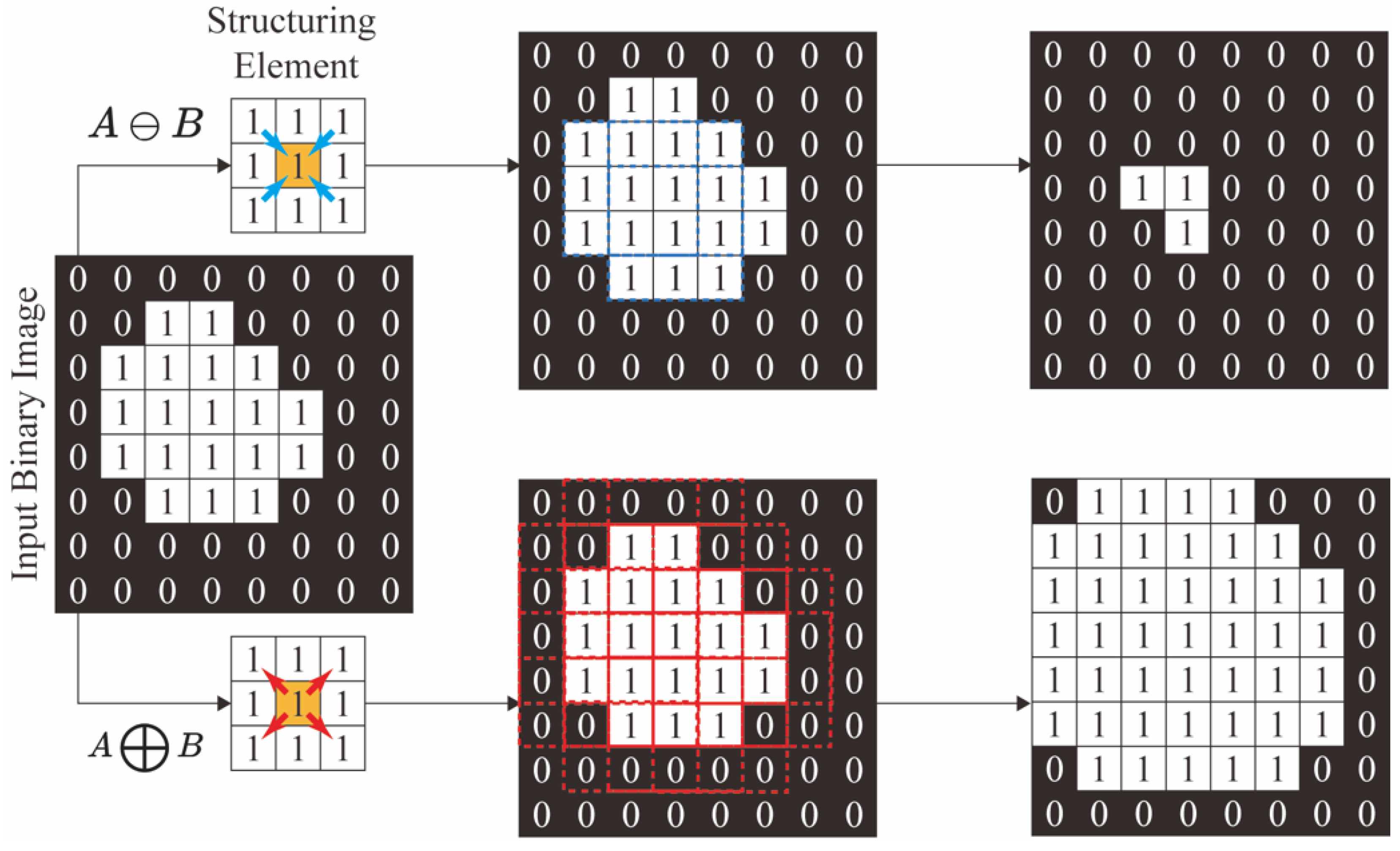

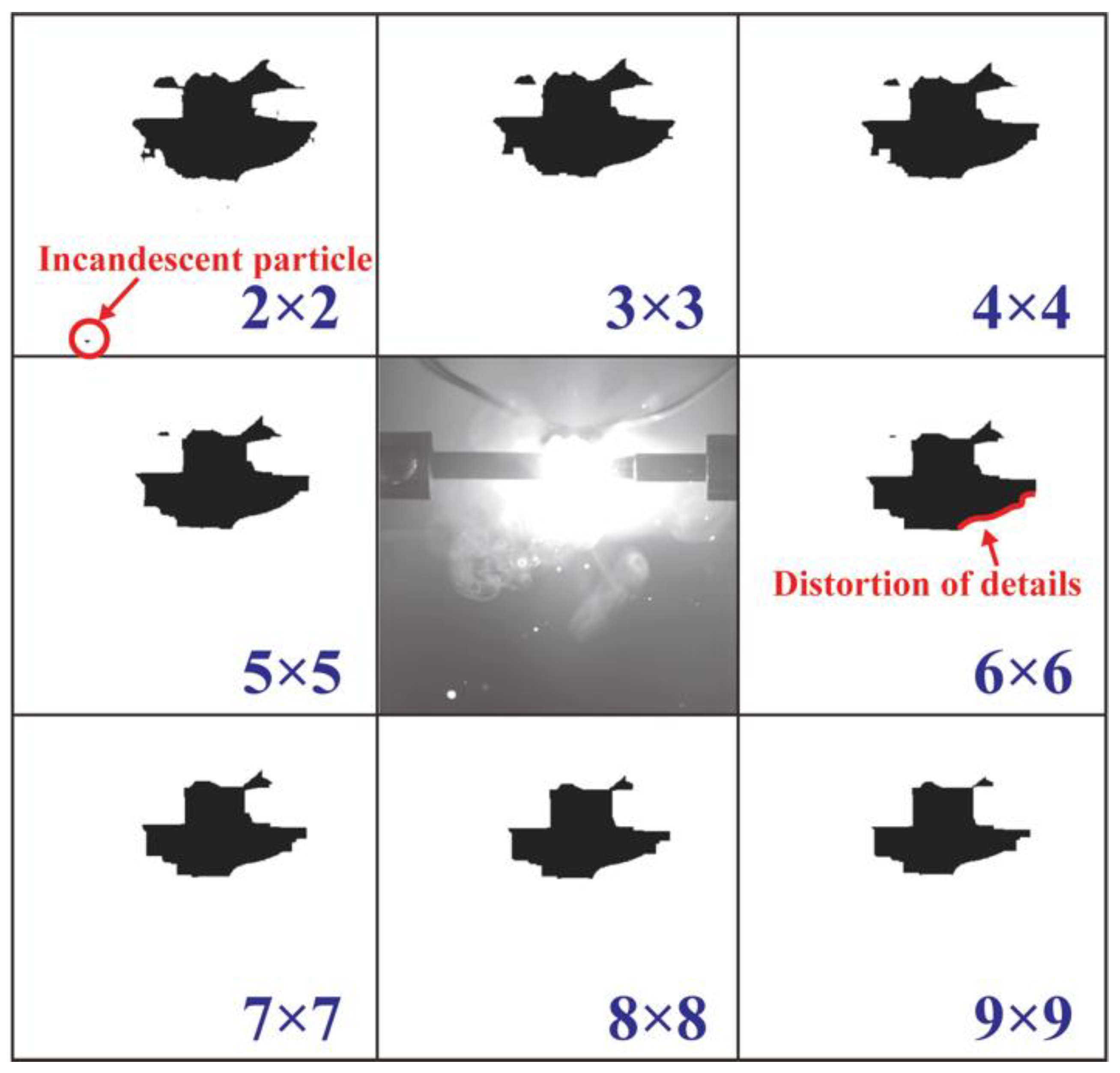

| 2-3 The principal part of the inverted binary image is extracted by the mathematical morphology operation with the structuring elements in different sizes. |

| Step 3: Flame marking & statistic |

| 3-1 Mark the flame area in the original photo; |

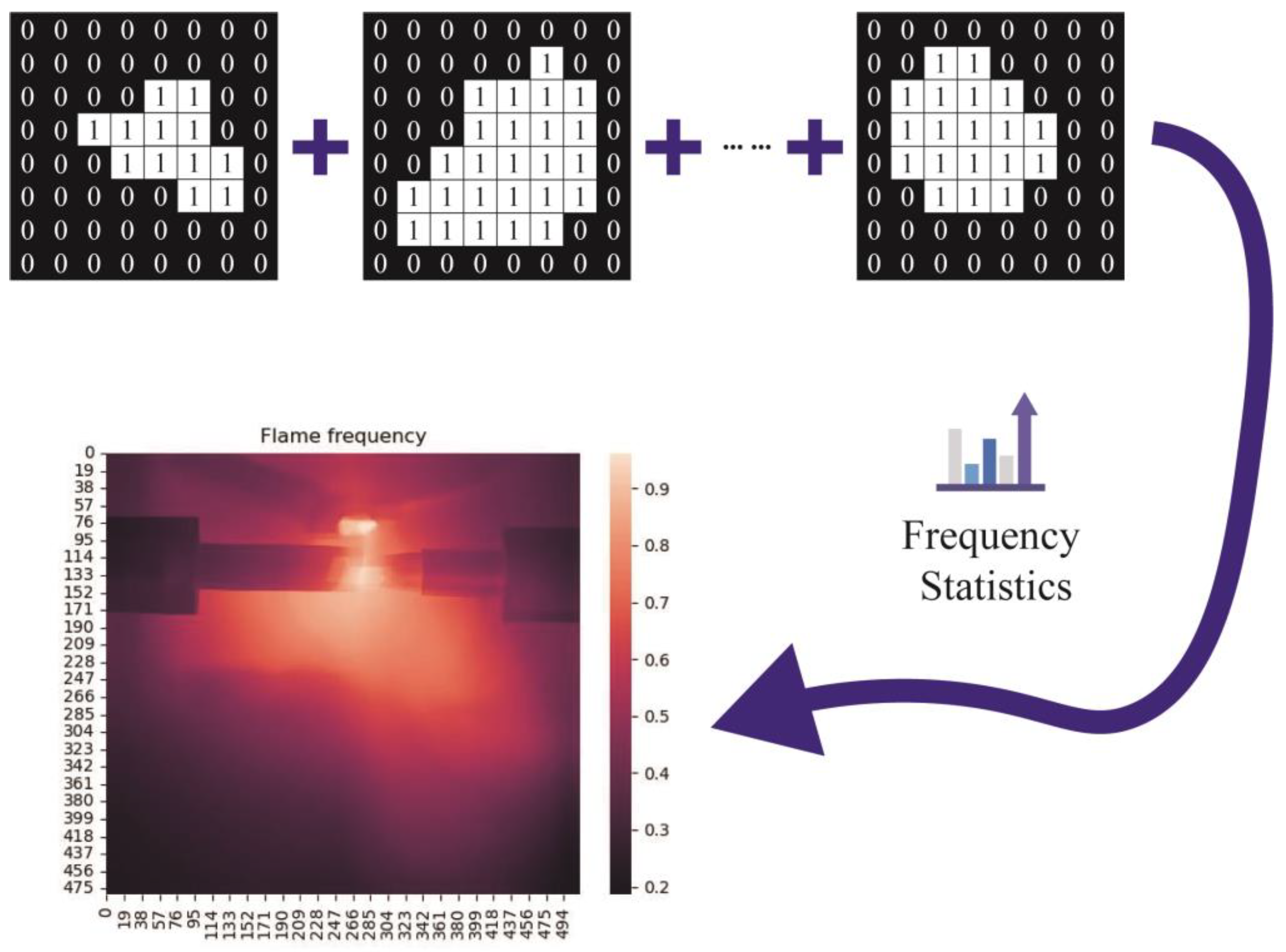

| 3-2 Overlay the images at all times, where the pixel value of the flame area is set to 1, and the pixel value of the non-flame area is set to 0, and count the frequency of the flame at each position in the camera field of view; |

| 3-3 Calculate the actual area of the flame according to the distance ratio between the photo and the actual object. |

2.3. Image-Based Flame Data Extraction

2.4. Flame Marking & Statistic

3. Results and Discussions

3.1. Performance of the Proposed Method

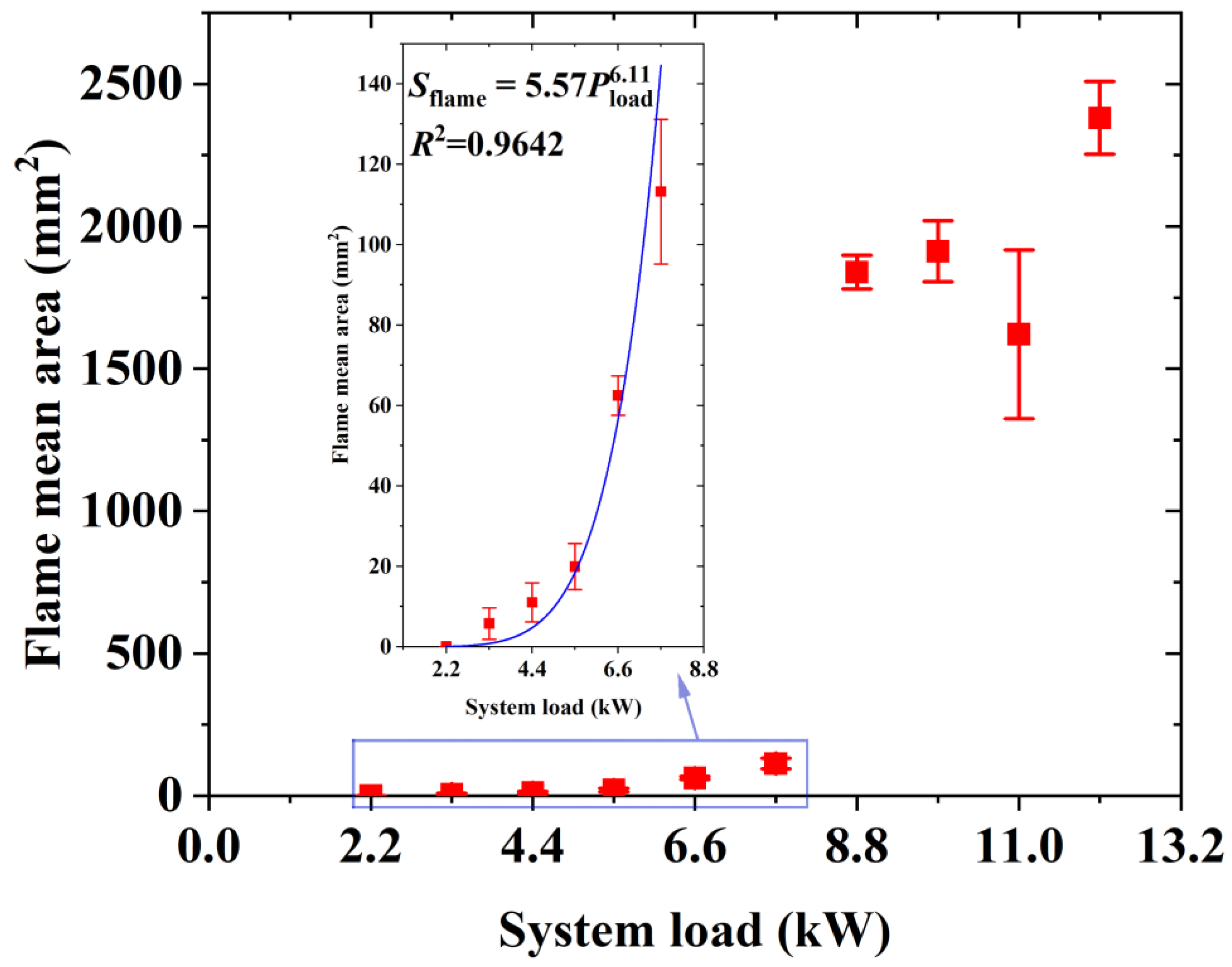

3.2. The Time Evolution Law of the Size of the Flame under Different System Loads

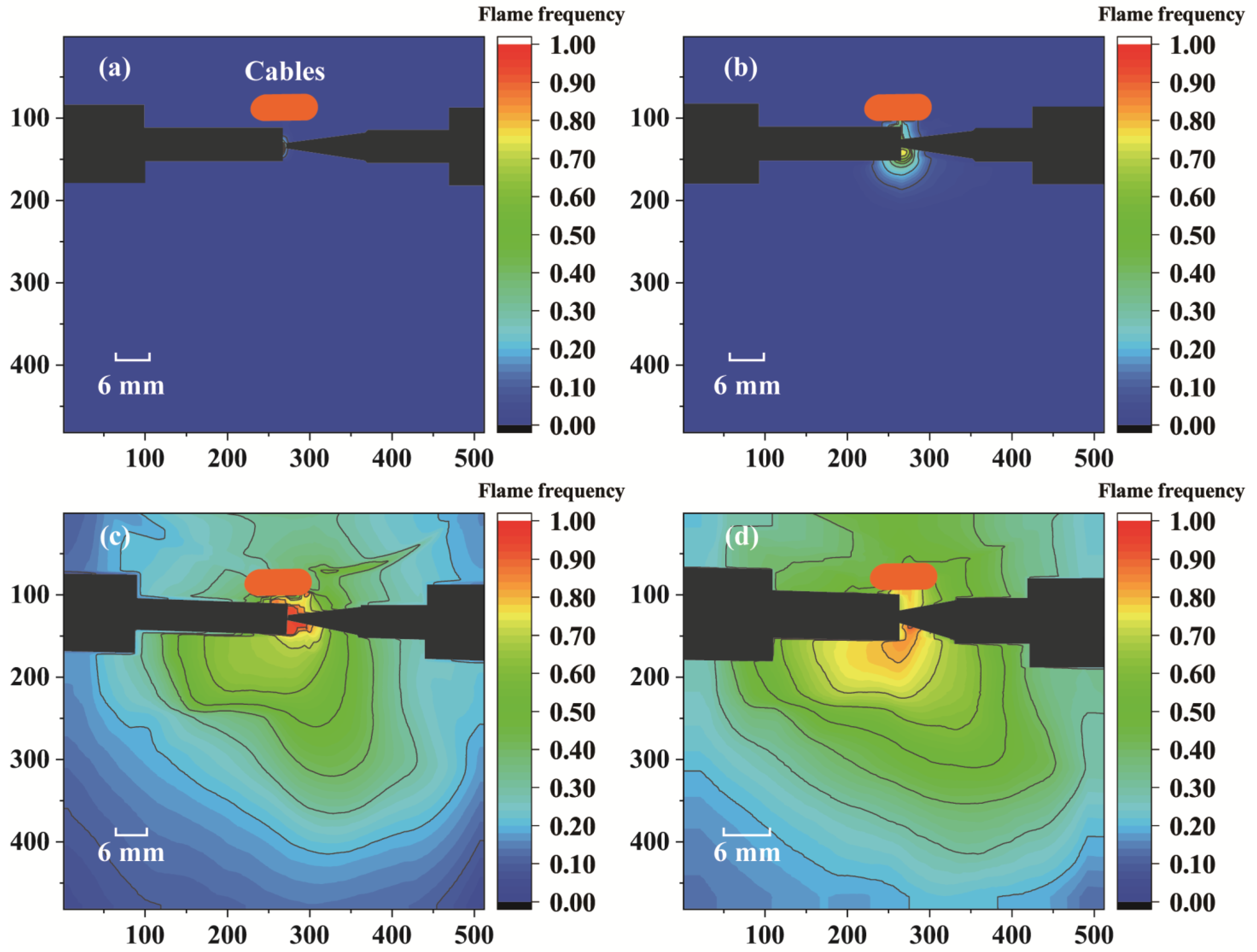

3.3. The Impact of the System Load on Flame Frequency Spatial Distribution

4. Conclusions

- The size of the structuring element plays an essential role in filtering flame region in photos. A too-small structuring element may result in the wrong recognition of large incandescent particles in the flame, while too large a structuring element will give the outer contour of the flame in the photo a jagged distortion;

- The flame mean area increased as the system load grew. An extremely significant increase in flame area was found between 7.7 kW and 8.8 kW of the system load. The flame mean area and the system load showed an exponential relationship in the 2.2 to 7.7 kW system load. When the system load was above 8.8 kW, the flame radius was able to reach six times the cable sample’s radius, exhibiting a significant ignition hazard to surrounding combustibles;

- The flame behavior during cable insulation material ignited by a fault arc showed a dependence on system load. The flame size became more prominent and appeared more frequently in specific locations when the system load increased.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Campbell, R.B. Home Electrical Fires; National Fire Protection Association: Park Quincy, MA, USA, 2019. [Google Scholar]

- Babrauskas, V. Research on electrical fires: The state of the art. Fire Safety Science 2008, 9, 3–18. [Google Scholar] [CrossRef]

- Moon, W.-S.; Kim, J.-C.; Jo, A.; Bang, S.-B.; Koh, W.-S. Ignition Characteristics of Residential Series Arc Faults in 220-V HIV Wires. IEEE Trans. Ind. Appl. 2015, 51, 2054–2059. [Google Scholar] [CrossRef]

- Gregory, G.D.; Scott, G. The arc-fault circuit interrupter, an emerging product. In Proceedings of the 1998 IEEE Industrial and Commercial Power Systems Technical Conference, Edmonton, AB, Canada, 3–8 May 1998. [Google Scholar]

- Xiong, L.; Xiong, L.; Zeng, Z.; Yang, J.; Zhong, Y.; Guo, K. Mathematical Model and Characteristics of Low Current DC Fault Arc. Diangong Jishu Xuebao/Trans. China Electrotech. Soc. 2019, 34, 2820–2829. [Google Scholar]

- Babrauskas, V. Minimum Values of Voltage, Current, or Power for the Ignition of Fire. Fire 2022, 5, 201. [Google Scholar] [CrossRef]

- Babrauskas, V. Electrical Fires. In SFPE Handbook of Fire Protection Engineering; Hurley, M., Gottuk, D., Hall, J.R., Jr., Harada, K., Kuligowski, E., Puchovsky, M., Torero, J., Watts, J.M., Jr., Wieczorek, C., Eds.; Springer: New York, NY, USA, 2016; pp. 662–704. [Google Scholar]

- Babrauskas, V. Ignition of Wood: A Review of the State of the Art. J. Fire Prot. Eng. 2002, 12, 163–189. [Google Scholar] [CrossRef]

- Sanderson, J. Carbon tracking: Poor insulation combined with contaminants is potential fire cause. Fire Find. 2000, 8, 1–3. [Google Scholar]

- Blackburn, T.; Pau, L. Characteristics of a simulated high impedance fault. In Proceedings of the Electric Energy Conference 1985: Modern Trends in the Generation, Transmission, Distribution and Utilisation of Electrical Energy, Springfield, IL, USA, 28–30 April 1985. [Google Scholar]

- Kinbara, T.; Sue, S. On the Outbreak of Fire due to Leakage of Electricity from Neon-Transformer through Planking. Bull. Jpn. Assoc. Fire Sci. Eng. 1953, 2, 39–41. [Google Scholar]

- Kinbara, T.; Takizawa, K. Ignition of a Salt-soaked Wooden Board by an Electric Current through it: Part 1. Bull. Jpn. Assoc. Fire Sci. Eng. 1961, 11, 26–31. [Google Scholar]

- Yin, B.; Sun, W.; Zhang, X.; Liew, K. Deciphering structural biological materials: Viewing from the mechanics perspective and their prospects. Compos. Part B-Eng. 2022, 245, 19. [Google Scholar] [CrossRef]

- Wang, Y.; Kang, N.; Lin, J.; Lu, S.; Liew, K.M. Cross-heating-rate prediction of thermogravimetry of PVC and XLPE cable insulation material: A novel artificial neural network framework. J. Therm. Anal. Calorim. 2022, 12, 14467–14478. [Google Scholar] [CrossRef]

- Fernandez–Pello, A.C.; Hasegawa, H.K.; Staggs, K.; Lipska-Quinn, A.E.; Alvares, N.J. A study of the fire performance of electrical cables. In Fire Safety Science—Proceedings of the Third International Symposium; Routledge: Abingdon, UK, 2006. [Google Scholar]

- Hoffmann, J.; Hoffmann, D.; Kroll, E.; Wallace, J.; Kroll, M. Electrical Power Cord Damage from Radiant Heat and Fire Exposure. Fire Technol. 2001, 37, 129–141. [Google Scholar] [CrossRef]

- Novak, C.J.; Stoliarov, S.I.; Keller, M.R.; Quintiere, J.G. An analysis of heat flux induced arc formation in a residential electrical cable. Fire Saf. J. 2013, 55, 61–68. [Google Scholar] [CrossRef]

- Iwashita, T.; Keller, M.R.; Hagimoto, Y.; Sugawa, O. Leakage currents precede short circuits in PVC-insulated cable when exposed to external radiant heat. Fire Mater. 2017, 41, 339–348. [Google Scholar] [CrossRef]

- Iwashita, T.; Hagimoto, Y.; Sugawa, O. Characterization of arc beads on energized conductors exposed to radiant heat. Fire Mater. 2017, 41, 1072–1078. [Google Scholar] [CrossRef]

- Iwashita, T.; Hagimoto, Y.; Sugawa, O. Survey of fire testing of electrical cables. Fire Mater. 1992, 16, 107–118. [Google Scholar]

- Fisher, R.P.; Stoliarov, S.; Keller, M. A criterion for thermally-induced failure of electrical cable. Fire Saf. J. 2015, 72, 33–39. [Google Scholar] [CrossRef]

- Shea, J.J. Comparing 240 Vrms to 120 Vrms Series Arcing Faults in Residential Wire; IEEE: Piscataway, NJ, USA, 2008. [Google Scholar]

- Shea, J.J. Identifying causes for certain types of electrically initiated fires in residential circuits. Fire Mater. 2011, 35, 19–42. [Google Scholar] [CrossRef]

- Takenaka, K.; Ishikawa, Y.; Mizuno, Y.; Lin, W. Arc Discharge–Induced Ignition of Combustibles Placed on a Damaged AC Power Supply Cord. Energies 2020, 13, 681. [Google Scholar] [CrossRef]

- Li, Y.; Sun, Y.; Gao, Y.; Sun, J.; Lyu, H.-F.; Yu, T.; Yang, S.; Wang, Y. Analysis of overload induced arc formation and beads characteristics in a residential electrical cable. Fire Saf. J. 2022, 131, 8. [Google Scholar] [CrossRef]

- U.L. Inc. UL Standard for Arc-Fault Circuit-Interrupters, 3rd ed.; Underwriters Laboratories Inc.: New York, NY, USA, 2017. [Google Scholar]

- Long, H.; Sang, L.; Wu, Z.; Gu, W. Image-Based Abnormal Data Detection and Cleaning Algorithm via Wind Power Curve. IEEE Trans. Sustain. Energy 2020, 11, 938–946. [Google Scholar] [CrossRef]

- Wang, J.; Wang, J.; Shao, J.; Li, J. Image Recognition of Icing Thickness on Power Transmission Lines Based on a Least Squares Hough Transform. Energies 2017, 10, 415. [Google Scholar] [CrossRef]

- Liu, Y.; Urban, J.L.; Xu, C.; Fernandez-Pello, C. Temperature and Motion Tracking of Metal Spark Sprays. Fire Technol. 2019, 55, 2143–2169. [Google Scholar] [CrossRef]

- Yan, W.G.; Wang, C.; Guo, J. One Extended OTSU flame Image recognition Method Using RGBL and Stripe segmentation. In Proceedings of the 2nd International Conference on Frontiers of Manufacturing and Design Science (ICFMD 2011), Taichung, Taiwan, 11–13 December 2011; Trans Tech Publications Ltd.: Taipei, Taiwan, 2011. [Google Scholar]

- Haralick, R.M.; Sternberg, S.; Zhuang, X. IMAGE-ANALYSIS USING MATHEMATICAL MORPHOLOGY. IEEE Trans. Pattern Anal. Mach. Intell. 1987, 9, 532–550. [Google Scholar] [CrossRef]

- Zhang, A.Q.; Ji, T.Y.; Li, M.S.; Wu, Q.H.; Zhang, L.L. An Identification Method Based on Mathematical Morphology for Sympathetic Inrush. IEEE Trans. Power Deliv. 2018, 33, 12–21. [Google Scholar] [CrossRef]

- Deng, C.X.; Wang, G.B.; Yang, X.R. Image Edge Detection Algorithm Based on Improved Canny Operator. In Proceedings of the International Conference on Wavelet Analysis and Pattern Recognition (ICWAPR), Tianjin, China, 14–17 July 2013; IEEE: Piscataway, NJ, USA, 2013. [Google Scholar]

| No. | System Load | Structuring Element X | Structuring Element Y | Filter Gray Value |

|---|---|---|---|---|

| 1 | 2.2 | 7 | 9 | 230 |

| 2 | 2.2 | 3 | 5 | 230 |

| 3 | 3.3 | 3 | 5 | 230 |

| 4 | 3.3 | 3 | 5 | 230 |

| 5 | 3.3 | 3 | 5 | 230 |

| 6 | 4.4 | 5 | 5 | 230 |

| 7 | 4.4 | 3 | 3 | 230 |

| 8 | 4.4 | 3 | 3 | 230 |

| 9 | 5.5 | 3 | 3 | 230 |

| 10 | 5.5 | 3 | 3 | 230 |

| 11 | 5.5 | 5 | 3 | 230 |

| 12 | 6.6 | 5 | 3 | 230 |

| 13 | 6.6 | 5 | 3 | 230 |

| 14 | 6.6 | 5 | 3 | 230 |

| 15 | 7.7 | 3 | 3 | 230 |

| 16 | 7.7 | 3 | 3 | 230 |

| 17 | 7.7 | 3 | 3 | 230 |

| 18 | 8.8 | 3 | 3 | 230 |

| 19 | 8.8 | 5 | 7 | 230 |

| 20 | 8.8 | 3 | 3 | 230 |

| 21 | 9.9 | 3 | 3 | 230 |

| 22 | 9.9 | 5 | 3 | 230 |

| 23 | 9.9 | 3 | 3 | 230 |

| 24 | 11 | 3 | 3 | 250 |

| 25 | 11 | 3 | 3 | 250 |

| 26 | 11 | 3 | 3 | 250 |

| 27 | 12.1 | 7 | 5 | 250 |

| 28 | 12.1 | 7 | 5 | 252 |

| 29 | 12.1 | 7 | 9 | 253 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Li, C.; Liu, H.; Lin, J.; Lu, S.; Liew, K.M. On The Flame Behavior during Cable Insulation Material Ignited by Fault Arc: A Flame Extracting and Noise Reduction Algorithm. Fire 2023, 6, 45. https://doi.org/10.3390/fire6020045

Wang Y, Li C, Liu H, Lin J, Lu S, Liew KM. On The Flame Behavior during Cable Insulation Material Ignited by Fault Arc: A Flame Extracting and Noise Reduction Algorithm. Fire. 2023; 6(2):45. https://doi.org/10.3390/fire6020045

Chicago/Turabian StyleWang, Yalong, Chaoying Li, Haidong Liu, Jin Lin, Shouxiang Lu, and Kim Meow Liew. 2023. "On The Flame Behavior during Cable Insulation Material Ignited by Fault Arc: A Flame Extracting and Noise Reduction Algorithm" Fire 6, no. 2: 45. https://doi.org/10.3390/fire6020045

APA StyleWang, Y., Li, C., Liu, H., Lin, J., Lu, S., & Liew, K. M. (2023). On The Flame Behavior during Cable Insulation Material Ignited by Fault Arc: A Flame Extracting and Noise Reduction Algorithm. Fire, 6(2), 45. https://doi.org/10.3390/fire6020045