Optimization of Electron-Beam Evaporation Process Parameters for ZrN Thin Films by Plasma Treatment and Taguchi Method

Abstract

1. Introduction

2. Material and Methods

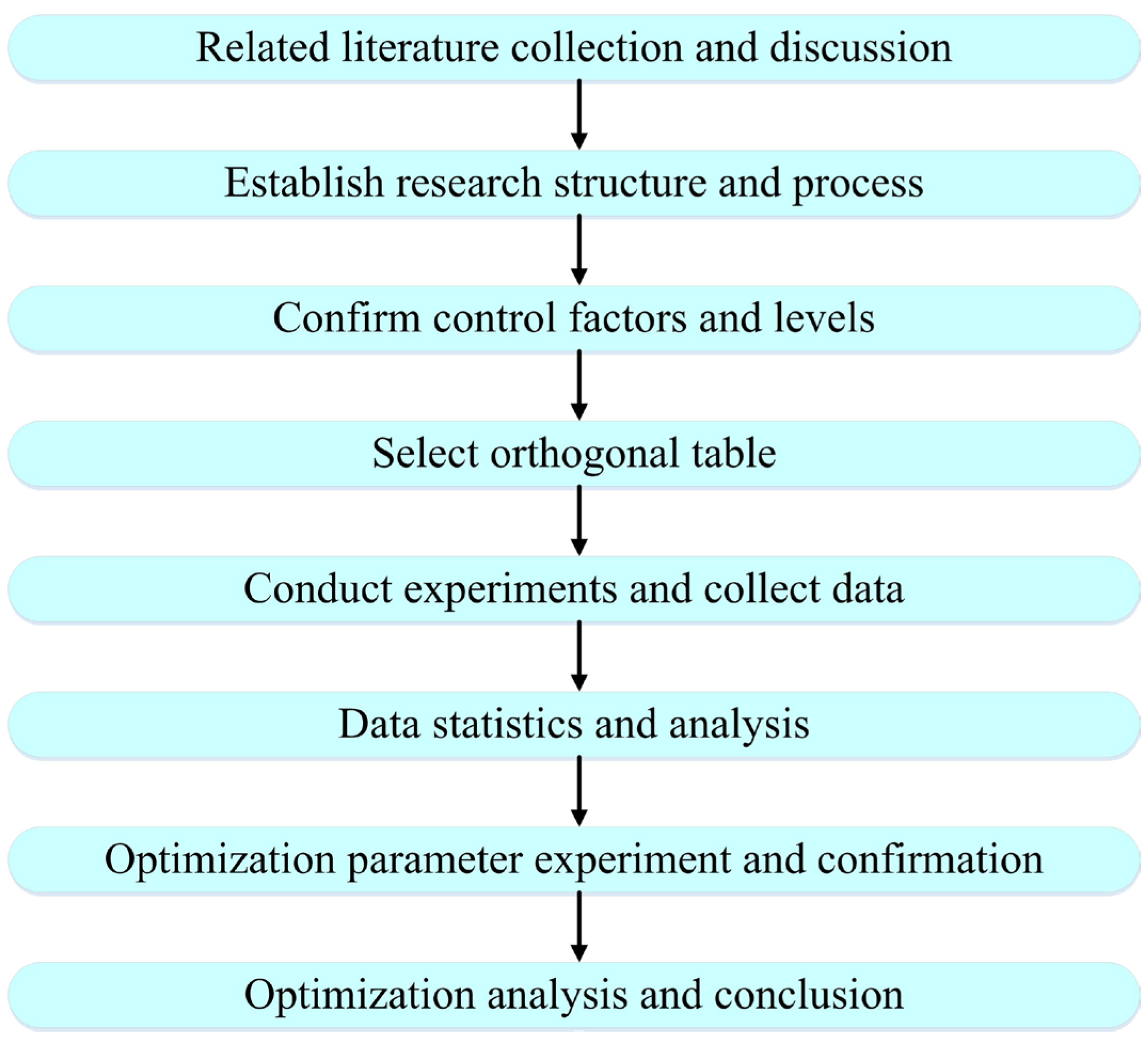

2.1. Experimental Method

2.2. Factor and Level Setting

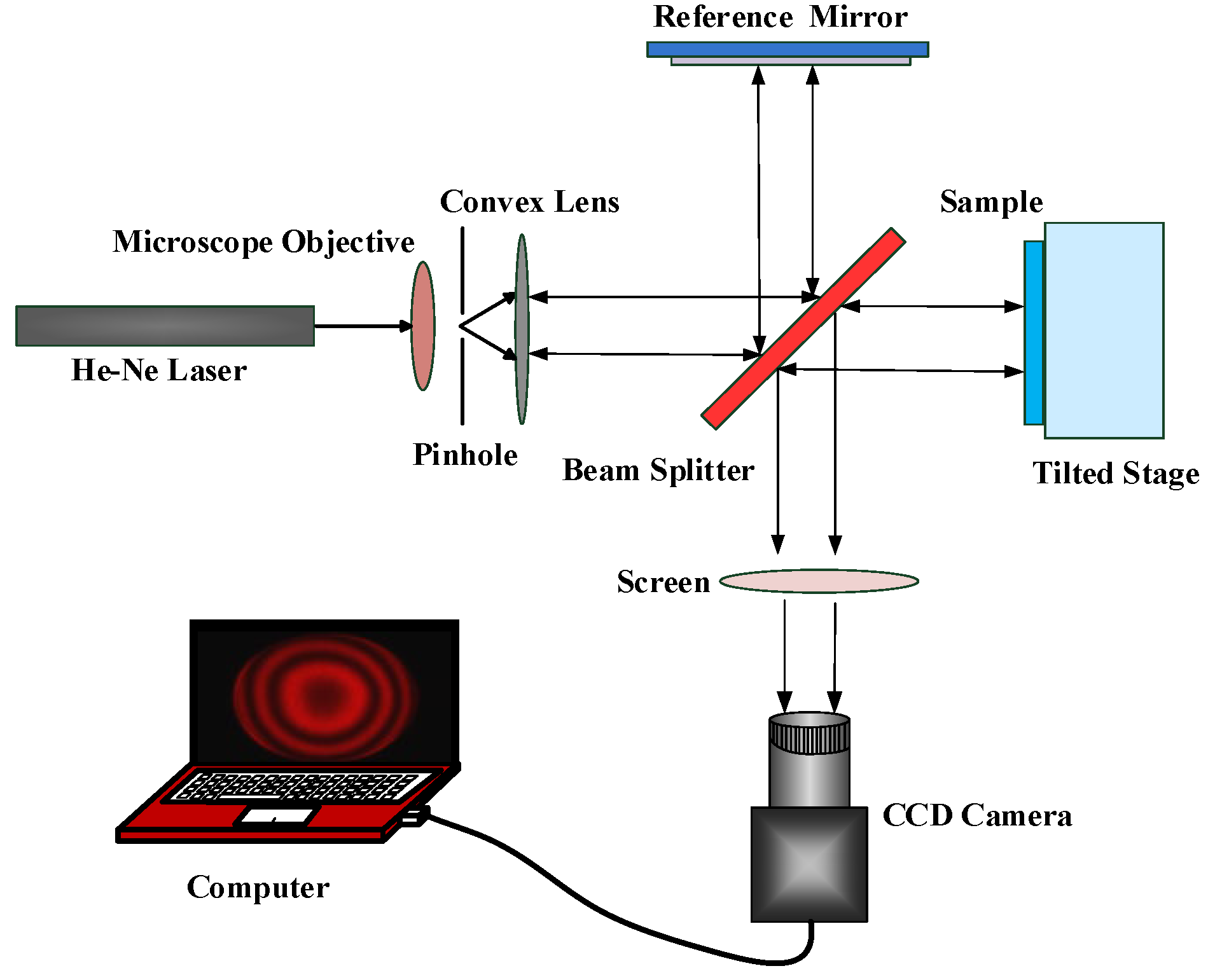

2.3. Experimental Setup

3. Results and Discussion

3.1. Taguchi Method

3.2. Response Surface Method

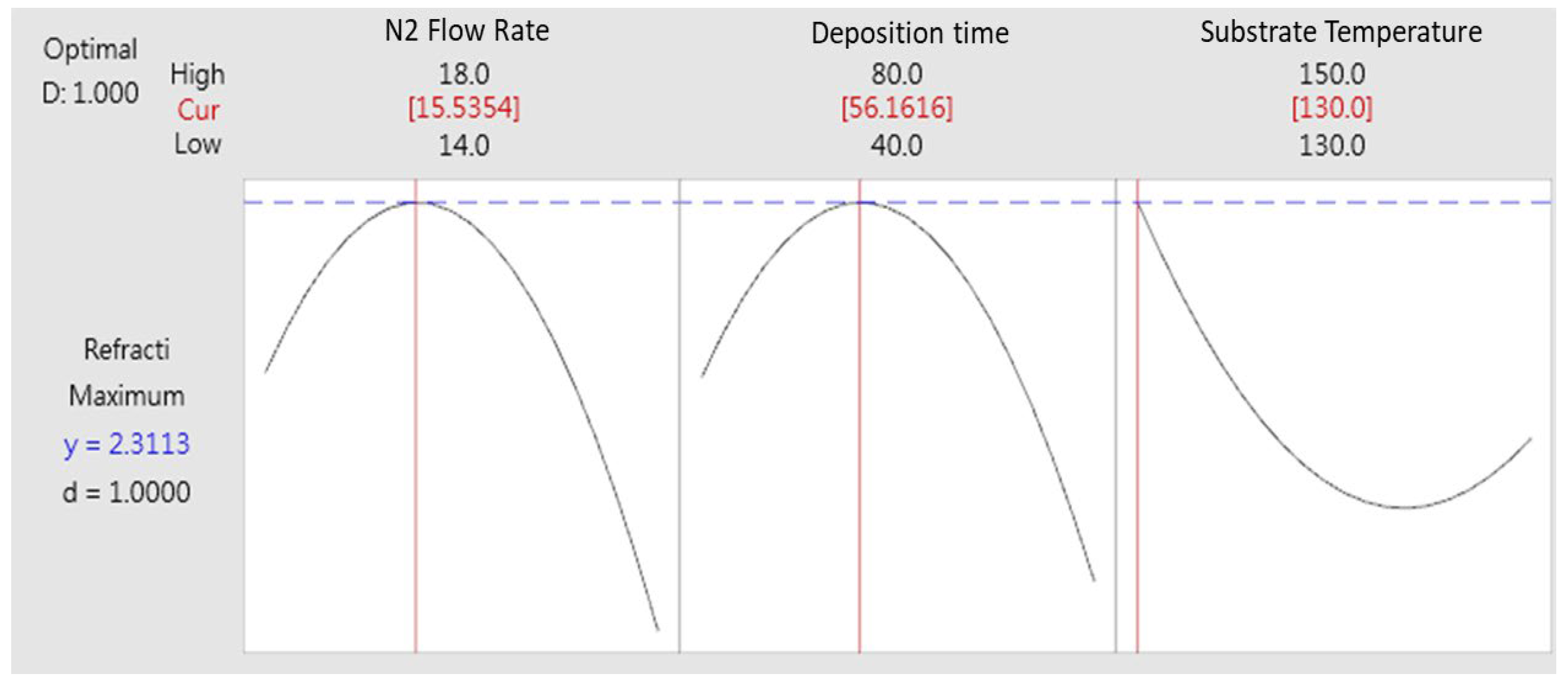

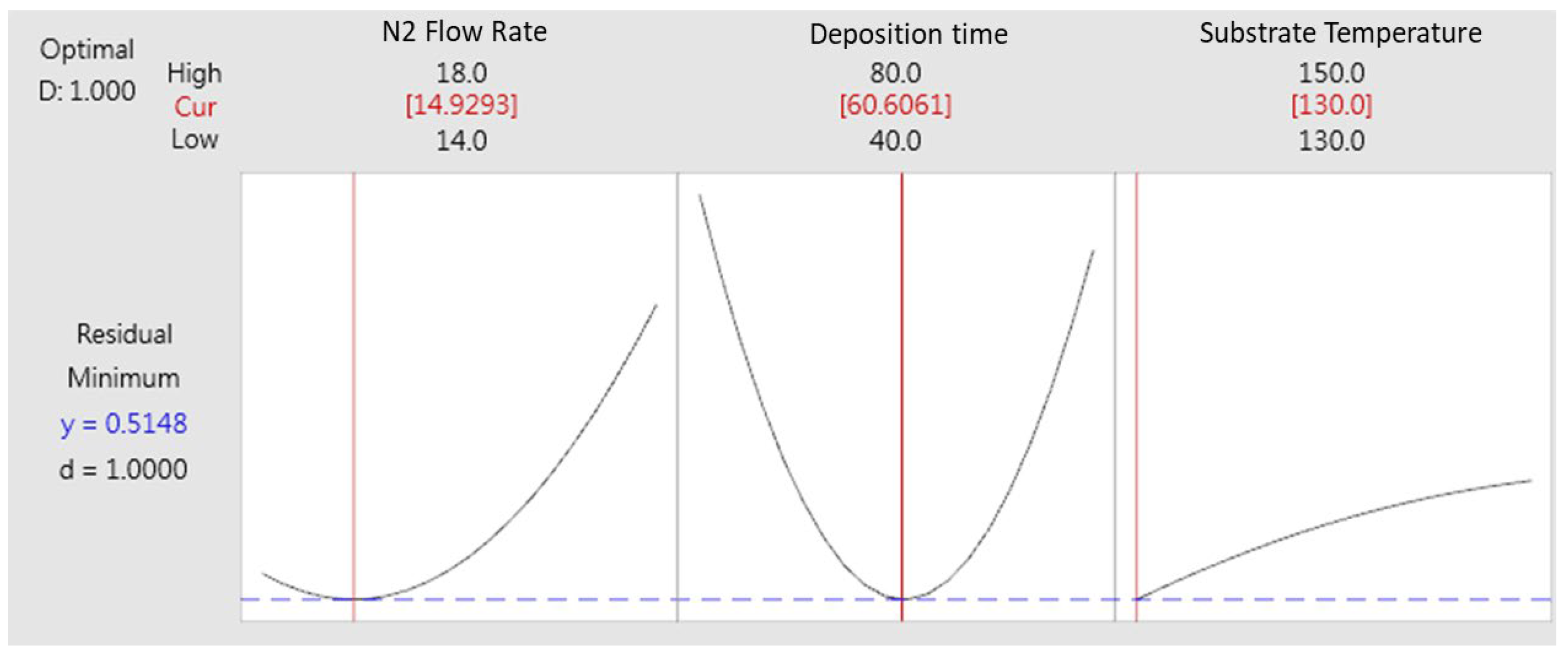

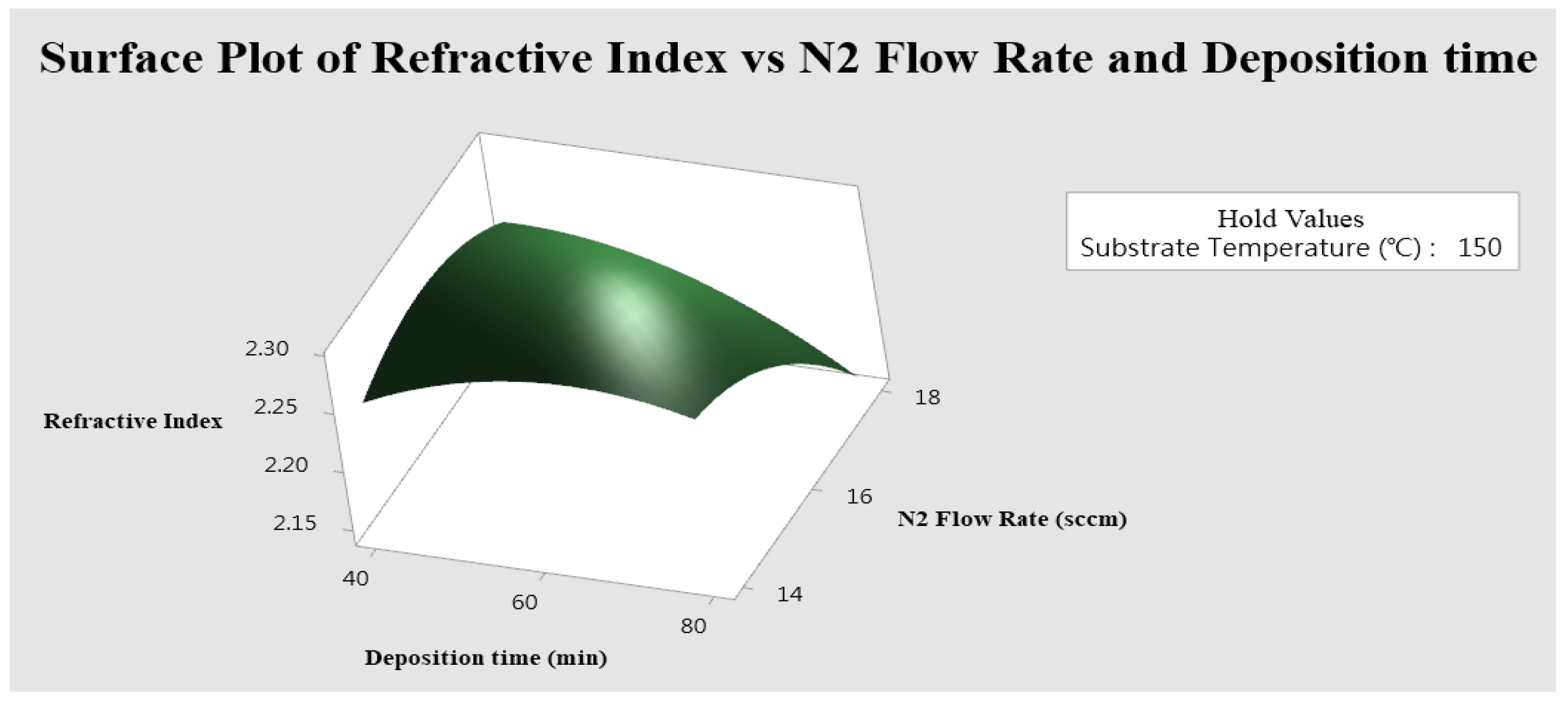

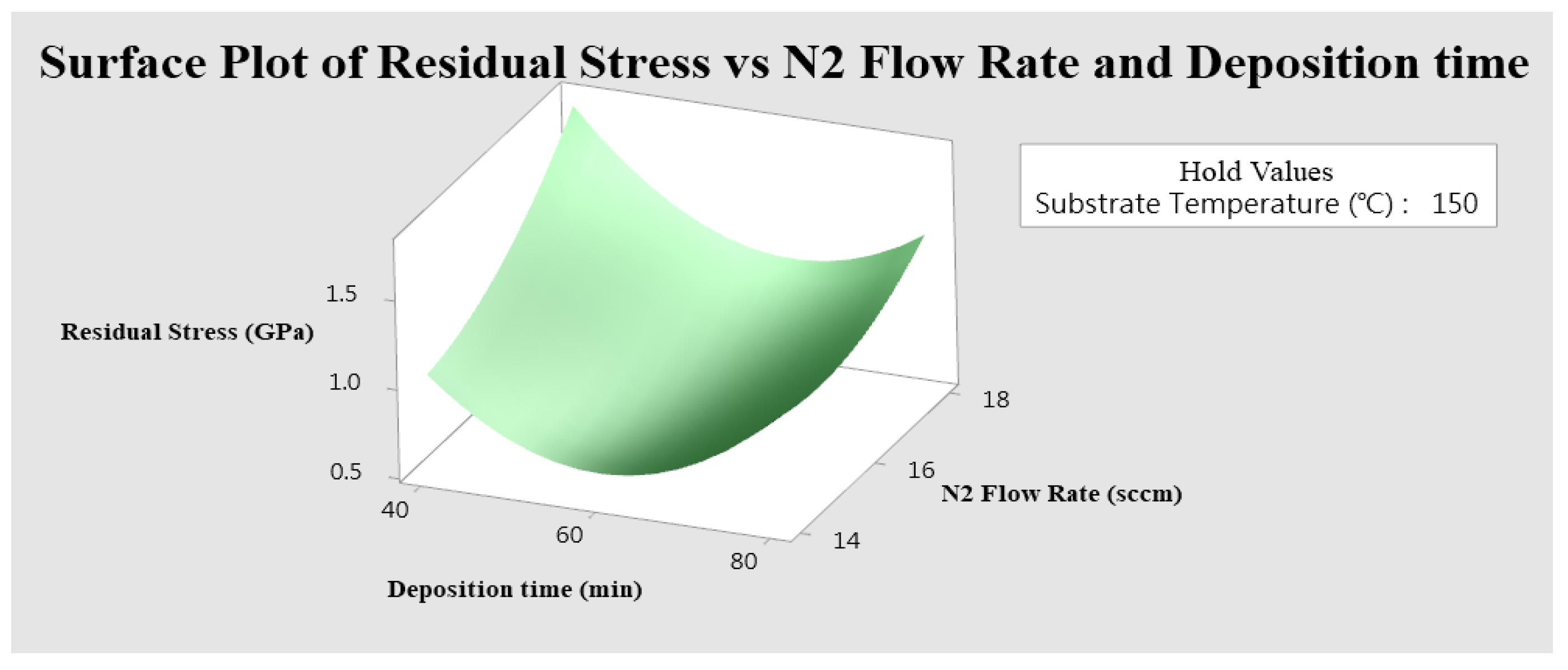

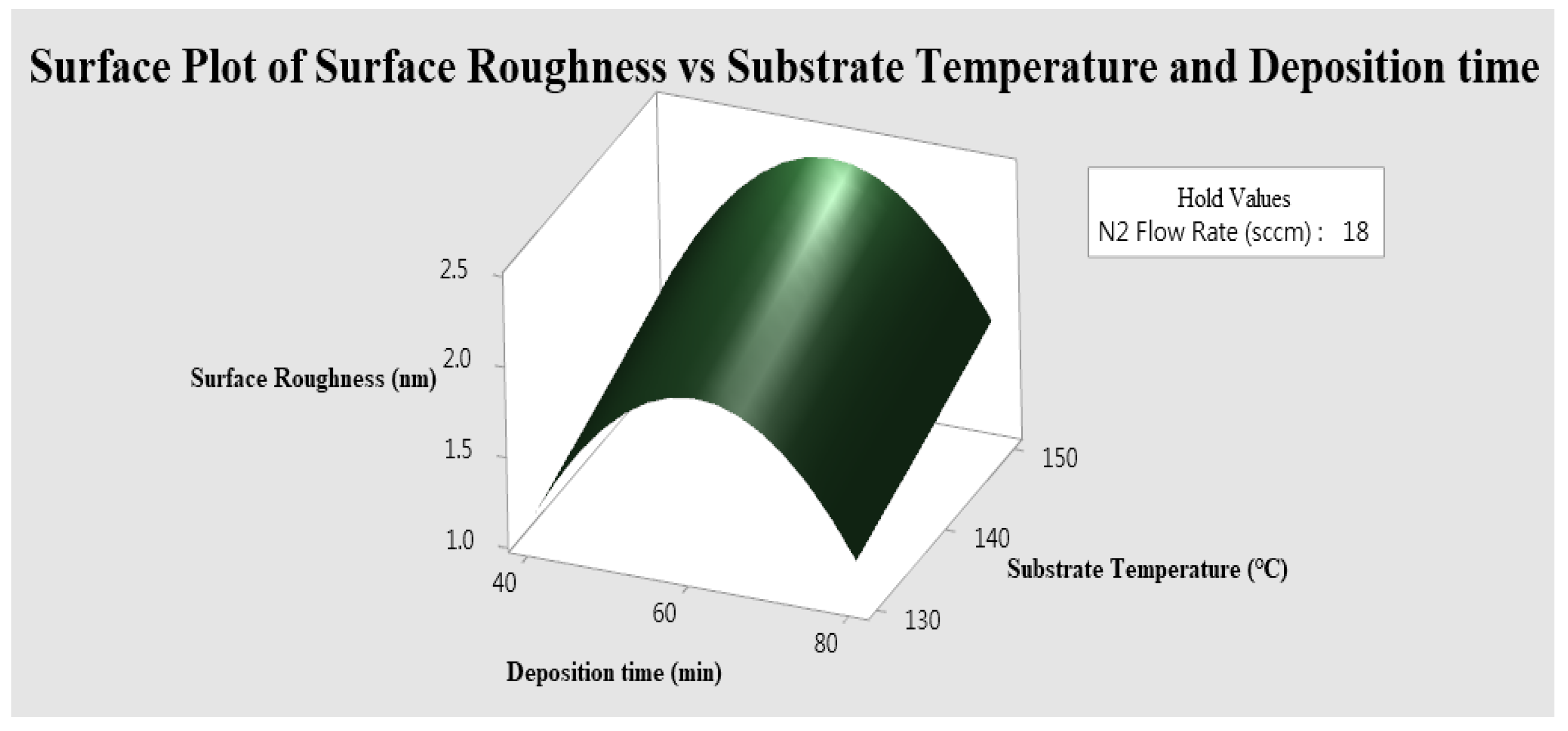

4. Conclusions

- (a)

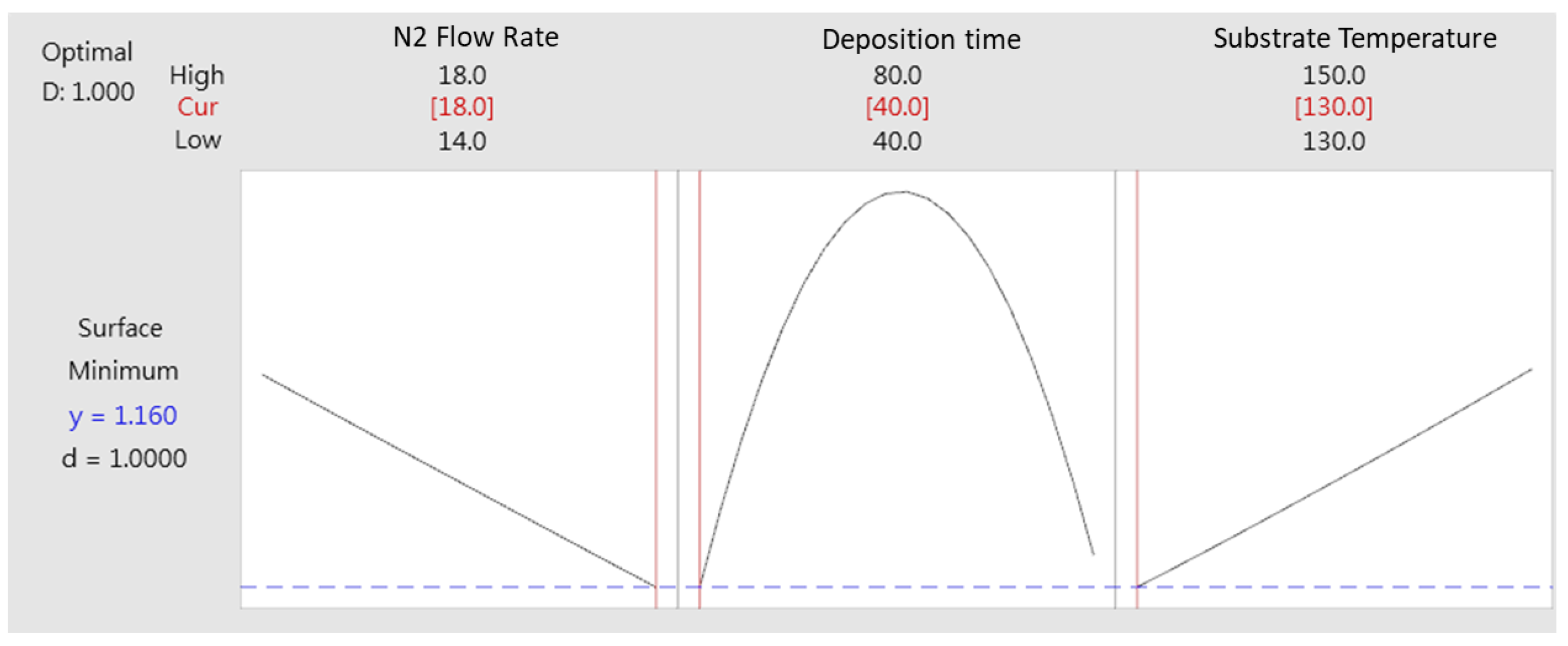

- By applying the Taguchi method, we were able to obtain optimal design parameters to achieve the best performance of ZrN thin films in terms of refractive index, residual stress, and surface roughness. Through the experimental design and statistical analysis based on the Taguchi method, we systematically investigated various factors on the ZrN thin film properties and found the optimal process conditions. This allowed us to more efficiently optimize the process parameters to achieve the desired thin film performance targets. According to the response surface methodology, polynomial equations for predicting residual stress, surface roughness, and refractive index can be obtained.

- (b)

- By applying the response surface method, we successfully performed multi-objective optimization to obtain ZrN thin films with high refractive index, low residual stress, and low surface roughness. During the optimization process, we adjusted the parameters of the optimization factors so that the N2 flow rate was 15.37 sccm, the deposition time was 80 min, and the substrate temperature was 130 °C.

- (c)

- Through systematic experiments and statistical analysis, we were able to determine the optimal combination of parameters to achieve the best properties of the ZrN thin film. This study provides essential guidance for the preparation of ZrN thin films and also demonstrates the application of the response surface method in multi-objective optimization.

- (d)

- The Taguchi method and the response surface method can be used to find the maximum or minimum value of a specific parameter characteristic for single-objective quality characteristics, while the response surface method for multi-objective quality characteristics can consider a variety of factors and find the corresponding optimized parameters.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Budke, E.; Krempel-Hesse, J.; Maidhof, H.; Schüssler, H. Decorative hard coatings with improved corrosion resistance. Surf. Coat. Technol. 1999, 112, 108–113. [Google Scholar] [CrossRef]

- Mubarak, A.; Hamzah, E.B.; Mohd Toff, M.R.H.; Hashim, A.H.B. The effect of nitrogen gas flow rate on the properties of coated high-speed steel (HSS) using cathodic arc evaporation physical vapor deposition (PVD) technique. Surf. Rev. Lett. 2005, 12, 631–643. [Google Scholar] [CrossRef]

- Mitterer, C.; Mayrhofer, P.; Waldhauser, W.; Kelesoglu, E.; Losbichler, P. The influence of the ion bombardment on the optical properties of TiNx and ZrNx coatings. Surf. Coat. Technol. 1988, 108–109, 230–235. [Google Scholar] [CrossRef]

- Liu, C.P.; Yang, H.G. The Texture and Electrical Properties of Zr and ZrNx Thin Films Deposited by DC Sputtering. Mat. Res. Soc. Symp. Proc. 2002, 721, 49. [Google Scholar] [CrossRef]

- Lide, D. CRC Handbook of Chemistry and Physics: A Ready-Reference Book of Chemical and Physical Data; CRC: Boca Raton, FL, USA, 2009. [Google Scholar]

- Mei, A.B.; Howe, B.M.; Zhang, C.; Sardela, M.; Eckstein, J.N.; Hultman, L.; Rockett, A.; Petrov, I.; Greene, J.E. Physical properties of epitaxial ZrN/MgO(001) layers grown by reactive magnetron sputtering. J. Vac. Sci. Technol. A 2013, 31, 061516. [Google Scholar] [CrossRef]

- Phadke, M. Quality Engineering Using Robust Design; Prentice Hall: Englewood Cliffs, NJ, USA, 1989. [Google Scholar]

- Musil, J.; Karvánková, P.; Kasl, J. Hard and superhard Zr-Ni-N nanocomposite films. Surf. Coat. Technol. 2001, 139, 101–109. [Google Scholar] [CrossRef]

- Kuznetsova, K.; Lapitskaya, V.; Khabarava, A.; Chizhik, S.; Warcholinski, B.; Gilewicz, A. The influence of nitrogen on the morphology of ZrN coatings deposited by magnetron sputtering. Appl. Surf. Sci. 2020, 522, 146508. [Google Scholar] [CrossRef]

- Dehnad, K. Quality Control, Robust Design, and the Taguchi Method; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Barker, T.B. Engineering Quality by Design; Marcel Dekker: New York, NY, USA, 1990. [Google Scholar]

- Hinna, M.; Hartiti, B.; Gouya, A.; Labrim, H.; Fadili, S.; Tahri, M.; Belfhailli, A.; Siadat, M.; Thévenin, P. Synthesis of ITO thin films by Spray pyrolysis based on Taguchi design. Materialstoday 2022, 66, 447–455. [Google Scholar] [CrossRef]

- Rajath, H.G.; Byregowda, H.V.; Siddesh Kumar, N.M. Optimization of ZnO Thin Films using Sol-Gel Dip Coating by Taguchi Method. Eur. Chem. Bull. 2023, 12, 670–681. [Google Scholar]

- Puźniak, M.; Gajewski, W.; Seweryn, A.; Klepka, M.T.; Witkowski, B.S.; Godlewski, M.; Mroczyński, R. Studies of Electrical Parameters and Thermal Stability of HiPIMS Hafnium Oxynitride (HfOxNy) Thin Films. Materials 2023, 16, 2539. [Google Scholar] [CrossRef]

- Wu, C.Y.; Chen, J.H.; Kuo, C.G.; Twu, M.J.; Peng, S.W.; Hsu, C.Y. Effects of deposition parameters on the structure and properties of ZrN, WN and ZrWN films. Bull. Mater. Sci. 2019, 42, 38. [Google Scholar] [CrossRef]

- Doubi, Y.; Hartiti, B.; Siadat, M.; Labrim, H.; Fadili, S.; Stitou, M.; Tahri, M.; Belfhaili, A.; Thevenin, P.; Losson, E. Optimization with Taguchi approach to prepare pure TiO2 thin films for Future Gas Sensor Application. J. Electron. Mater. 2022, 51, 3671–3683. [Google Scholar] [CrossRef]

- Maghsoodloo, S.; Ozdemir, G.; Jordan, V.; Huang, C. Strengths and limitations of Taguchi’s contributions to quality, manufacturing, and process engineering. J. Manuf. Syst. 2004, 23, 73–126. [Google Scholar] [CrossRef]

- Manifacier, J.C.; Gasiot, J.; Fillard, J.P. A simple method for the determination of the optical constants n, k and the thickness of a weakly absorbing thin film. J. Phys. E Sci. Instrum. 1976, 9, 1002–1004. [Google Scholar] [CrossRef]

- Swanepoel, R. Determination of the thickness and optical constants of amorphous silicon. J. Phys. E Sci. Instrum. 1983, 16, 1214–1218. [Google Scholar] [CrossRef]

- Nadji, S.N.; Lequime, M.; Begou, T.; Koc, C.; Grèzes-Besset, C.; Lumeau, J. In-situ interferometric monitoring of optical coatings. Opt. Express 2020, 28, 22012–22026. [Google Scholar] [CrossRef]

- Tien, C. Biaxial stresses, surface roughness and microstructures in evaporated TiO2 films with different deposition geometries. Appl. Surf. Sci. 2009, 256, 870–875. [Google Scholar] [CrossRef]

- Smith, D.L. Thin-Film Deposition: Principles and Practice; McGraw-Hill: New York, NY, USA, 1995. [Google Scholar]

- Sree Harsha, K.S. Principles of Physical Vapor Deposition of Thin Films; Elsevier: Great Britain, UK, 2006. [Google Scholar]

- Mavukkandy, M.O.; McBride, S.A.; Warsinger, D.M.; Dizge, N.; Hasan, S.W.; Arafat, H.A. Thin film deposition techniques for polymeric membranes—A review. J. Membr. Sci. 2020, 610, 118258. [Google Scholar] [CrossRef]

- Tien, C.L.; Yu, K.C.; Tsai, T.Y.; Lin, C.S.; Li, C.Y. Measurement of surface roughness of thin films by a hybrid interference microscope with different phase algorithms. Appl. Opt. 2014, 53, H213. [Google Scholar] [CrossRef]

- Tien, C.L.; Lin, T.W.; Yu, K.C.; Tsai, T.Y.; Shih, H.F. Evaluation of electrical, mechanical properties, and surface roughness of dc sputtering nickel-iron thin films. IEEE Trans. Magn. 2014, 50, 2005304. [Google Scholar] [CrossRef]

- Takeda, M.; Ina, H.; Kobayashi, S. Fourier-transform method of fringe-pattern analysis for computer-based topography and interferometry. Appl. Opt. 1982, 72, 156–160. [Google Scholar] [CrossRef]

- Takeda, M.; Mutoh, K. Fourier transform profilometry for the automatic measurement of 3-D object shapes. Appl. Opt. 1983, 22, 3977–3982. [Google Scholar] [CrossRef] [PubMed]

- Tien, C.L.; Zeng, H.D. Measuring residual stress of anisotropic thin film by fast Fourier transform. Opt. Express 2010, 18, 16594–16600. [Google Scholar] [CrossRef]

- Tien, C.L.; Lin, T.W.; Jyu, S.S.; Tseng, H.D.; Lin, C.S.; Liu, M.C. The measurement of anisotropic stress in obliquely-deposited thin films by fast Fourier transform and Gaussian filter. Phys. Procedia 2011, 19, 21–26. [Google Scholar] [CrossRef]

- Tien, C.L.; Lin, T.W. Measurement of stress anisotropy in magnetic thin films by fast Fourier transform method. IEEE Trans. Magn. 2011, 47, 3905–3908. [Google Scholar] [CrossRef]

- Tien, C.L.; Lee, C.C.; Tsai, Y.L.; Sun, W.S. Determination of the mechanical properties of thin films by digital phase shifting interferometry. Opt. Commun. 2001, 198, 325–331. [Google Scholar] [CrossRef]

- Brenner, A.; Senderoff, S. Calculation of stress in electrodeposits from the curvature of a plated strip. J. Res. Natl. Bur. Stand. 1949, 42, 105–123. [Google Scholar] [CrossRef]

- Begou, T.; Lumeau, J. Accurate analysis of mechanical stress in dielectric multilayers. Opt. Lett. 2017, 42, 3217–3220. [Google Scholar] [CrossRef]

- Begou, T.; Lemarchand, F.; Lemarquis, F.; Moreau, A.; Lumeau, J. High-performance thin-film optical filters with stress compensation. J. Opt. Soc. Am. A 2019, 36, C113–C121. [Google Scholar] [CrossRef]

| Experimental Control Factors | Levels of Factor | ||

|---|---|---|---|

| 1 | 2 | 3 | |

| N2 flow rate (sccm) | 14 | 16 | 18 |

| Deposition time (min) | 40 | 60 | 80 |

| Substrate temperature (°C) | 130 | 140 | 150 |

| Factory (Level) | |||

|---|---|---|---|

| Test Number | N2 Flow Rate (sccm) | Deposition Time (min) | Substrate Temperature (°C) |

| 1 | 14 (1) | 40 (1) | 130 (1) |

| 2 | 14 (1) | 60 (2) | 140 (2) |

| 3 | 14 (1) | 80 (3) | 150 (3) |

| 4 | 16 (2) | 40 (1) | 140 (2) |

| 5 | 16 (2) | 60 (2) | 150 (3) |

| 6 | 16 (2) | 80 (3) | 130 (1) |

| 7 | 18 (3) | 40 (1) | 150 (3) |

| 8 | 18 (3) | 60 (2) | 130 (1) |

| 9 | 18 (3) | 80 (3) | 140 (2) |

| Test Number | Experimental Measurement Results | ||

|---|---|---|---|

| Refractive Index | Surface Roughness (nm) | Residual Stress (GPa) | |

| 1 | 2.260 | 1.59 | 0.959 |

| 2 | 2.279 | 2.51 | 0.615 |

| 3 | 2.279 | 1.91 | 1.103 |

| 4 | 2.270 | 1.55 | 1.205 |

| 5 | 2.281 | 2.53 | 0.742 |

| 6 | 2.266 | 1.42 | 0.899 |

| 7 | 2.239 | 1.60 | 1.782 |

| 8 | 2.263 | 1.96 | 0.862 |

| 9 | 2.153 | 1.44 | 1.237 |

| Response Table for Signal to Noise Ratios | |||

|---|---|---|---|

| Level | N2 Flow Rate (sccm) | Deposition Time (min) | Substrate Temperature (°C) |

| 1 | * 7.130 | 7.065 | 7.093 |

| 2 | 7.029 | * 7.136 | 6.978 |

| 3 | 6.916 | 6.974 | * 7.103 |

| Delta | 0.214 | 0.162 | 0.125 |

| Rank | 1 | 2 | 3 |

| Response Table for Signal to Noise Ratios | |||

|---|---|---|---|

| Level | N2 Flow Rate (sccm) | Deposition Time (min) | Substrate Temperature (°C) |

| 1 | * 1.2262 | −2.0956 | * 0.8408 |

| 2 | 0.6109 | * 2.6673 | 0.2371 |

| 3 | −1.8715 | −0.6061 | −1.1124 |

| Delta | 3.0977 | 4.7629 | 1.9532 |

| Rank | 2 | 1 | 3 |

| Response Table for Signal to Noise Ratios | |||

|---|---|---|---|

| Level | N2 Flow Rate (sccm) | Deposition Time (min) | Substrate Temperature (°C) |

| 1 | −5.907 | −3.992 | * −4.332 |

| 2 | −4.996 | −7.317 | −5.011 |

| 3 | * −4.382 | * −3.976 | −5.943 |

| Delta | 1.524 | 3.341 | 1.611 |

| Rank | 3 | 1 | 2 |

| Optimize the Targets | Quality Characteristics | N2 Flow Rate (sccm) | Deposition Time (min) | Substrate Temperature (°C) | Results |

|---|---|---|---|---|---|

| Single-objective optimization | Refractive index | 15.54 | 56.16 | 130 | 2.283 |

| Residual stress (GPa) | 14.93 | 60.61 | 130 | 0.611 | |

| Surface roughness (nm) | 18 | 40 | 130 | 1.33 | |

| Multi-objective optimization | Refractive Index | 15.37 | 80 | 130 | 2.278 |

| Residual stress (GPa) | 0.901 | ||||

| Surface roughness (nm) | 1.481 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tien, C.-L.; Chiang, C.-Y.; Lin, S.-C. Optimization of Electron-Beam Evaporation Process Parameters for ZrN Thin Films by Plasma Treatment and Taguchi Method. Plasma 2023, 6, 478-491. https://doi.org/10.3390/plasma6030033

Tien C-L, Chiang C-Y, Lin S-C. Optimization of Electron-Beam Evaporation Process Parameters for ZrN Thin Films by Plasma Treatment and Taguchi Method. Plasma. 2023; 6(3):478-491. https://doi.org/10.3390/plasma6030033

Chicago/Turabian StyleTien, Chuen-Lin, Chun-Yu Chiang, and Shih-Chin Lin. 2023. "Optimization of Electron-Beam Evaporation Process Parameters for ZrN Thin Films by Plasma Treatment and Taguchi Method" Plasma 6, no. 3: 478-491. https://doi.org/10.3390/plasma6030033

APA StyleTien, C.-L., Chiang, C.-Y., & Lin, S.-C. (2023). Optimization of Electron-Beam Evaporation Process Parameters for ZrN Thin Films by Plasma Treatment and Taguchi Method. Plasma, 6(3), 478-491. https://doi.org/10.3390/plasma6030033