Effects of Plasma on Physical Properties of Water: Nanocrystalline-to-Amorphous Phase Transition and Improving Produce Washing

Abstract

1. Introduction

2. Improved Cleaning of the Produce by PAW

3. Methods and Materials

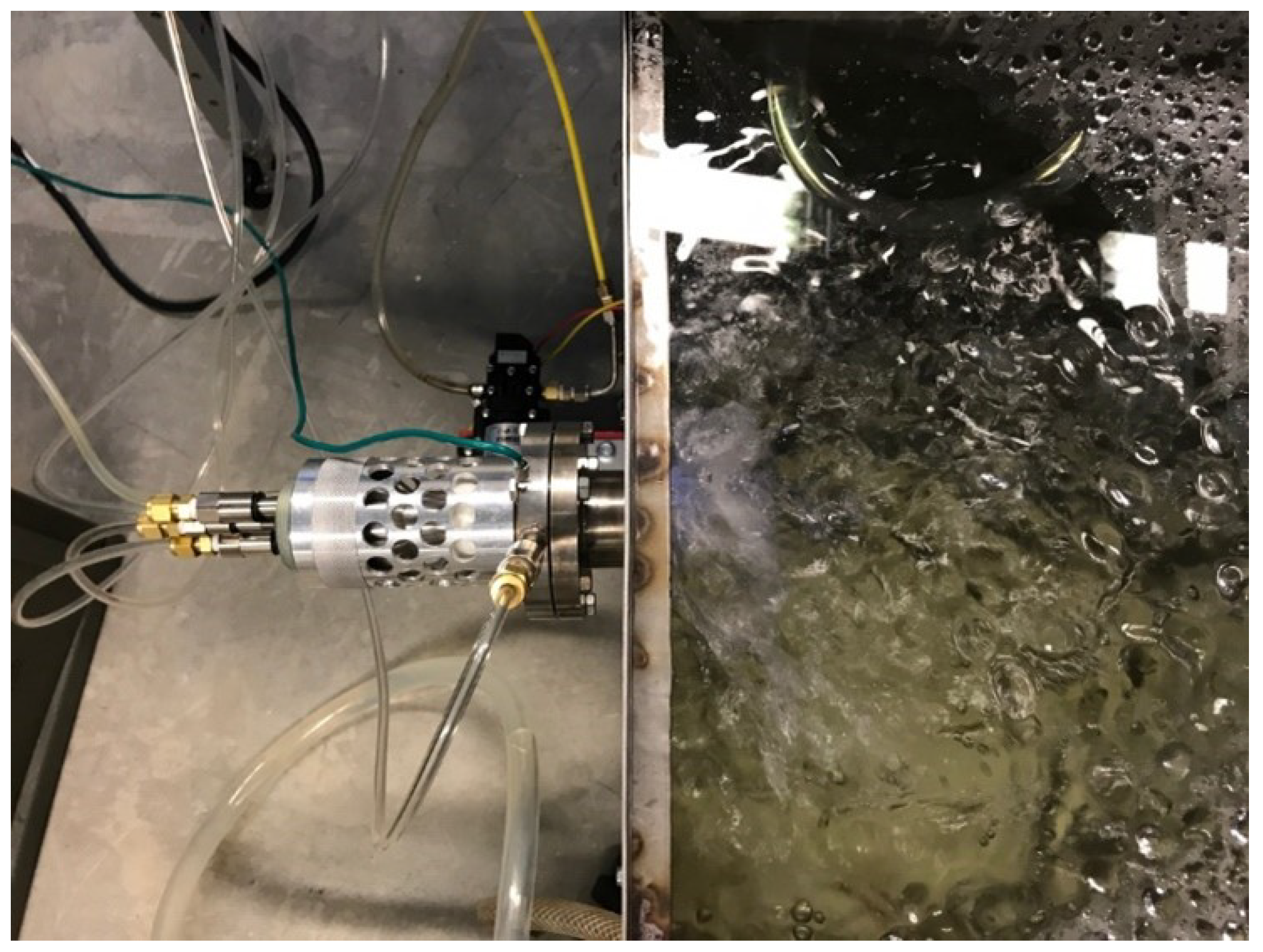

3.1. Plasma Production

3.2. Bacteria Preparation

3.3. Produce Preparation

3.4. Washing Procedure

3.5. Quantification of Remained DNA

4. Results

4.1. Changes in Physical Properties of PAW May Explain Improved Washability

4.2. Free Energy, Phase Transition, and the Debye–Huckel Term

5. Discussion and Conclusions

6. Declaration of Originality

Author Contributions

Funding

Conflicts of Interest

References

- Julien-Javaux, F.; Gérard, C.; Campagnoli, M.; Zuber, S. Strategies for the safety management of fresh produce from farm to fork. Curr. Opin. Food Sci. 2019, 27, 145–152. [Google Scholar] [CrossRef]

- Banach, J.L.; Sampers, I.; VanHaute, S.; der Fels-Klerx, V. Effect of disinfectants on preventing the cross-contamination of pathogens in fresh produce washing water. Int. J. Environ. Res. Public Health 2015, 12, 8658–8677. [Google Scholar] [CrossRef] [PubMed]

- Artés, F.; Gómez, P.; Aguayo, E.; Escalona, V.; Artés-Hernández, F. Sustainable sanitation techniques for keeping quality and safety of fresh-cut plant commodities. Postharvest Biol. Technol. 2009, 51, 287–296. [Google Scholar] [CrossRef]

- Gil, M.I.; Selma, M.V.; López-Gálvez, F.; Allende, A. Fresh-cut product sanitation and wash water disinfection: Problems and solutions. Int. J. Food Microbiol. 2009, 134, 37–45. [Google Scholar] [CrossRef]

- Tomás-Callejas, A.; López-Velasco, G.; Artés, F.; Artés-Hernández, F. Acidified sodium chlorite optimisation assessment to improve quality of fresh-cut tatsoi baby leaves. J. Sci. Food Agric. 2012, 92, 877–885. [Google Scholar] [CrossRef] [PubMed]

- López-Gálvez, F.; Tudela, J.A.; Allende, A.; Gil, M.I. Microbial and chemical characterization of commercial washing lines of fresh produce highlights the need for process water control. Innov. Food Sci. Emerg. Technol. 2019, 51, 211–219. [Google Scholar] [CrossRef]

- Koutchma, T. UV light for processing foods. Ozone Sci. Eng. 2008, 30, 93–98. [Google Scholar] [CrossRef]

- VanHaute, S.; Tryl, I.; Veys, A.; Sampers, I. Wash water disinfection of a full-scale leafy vegetables washing process with hydrogen peroxide and the use of a commercial metal ion mixture to improve disinfection efficiency. Food Control 2015, 50, 173–183. [Google Scholar] [CrossRef]

- Huang, K.; Nitin, N. Enhanced removal of Escherichia coli O157: H7 and Listeria innocua from fresh lettuce leaves using surfactants during simulated washing. Food Control 2017, 79, 207–217. [Google Scholar] [CrossRef]

- Thirumdas, R.; Kothakota, A.; Annapure, U.; Siliveru, K.; Blundell, R.; Gatt, R.; Valdramidis, V.P. Plasma activated water (PAW): Chemistry, physico-chemical properties, applications in food and agriculture. Trends Food Sci. Technol. 2018, 77, 21–31. [Google Scholar] [CrossRef]

- Xiang, Q.; Fan, L.; Li, Y.; Dong, S.; Li, K.; Bai, Y. A review on recent advances in plasma-activated water for food safety: Current applications and future trends. Crit. Rev. Food Sci. Nutr. 2022, 62, 2250–2268. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.M.; Ojha, S.; Burgess, C.M.; Sun, D.W.; Tiwari, B.K. Inactivation efficacy and mechanisms of plasma activated water on bacteria in planktonic state. J. Appl. Microbiol. 2020, 129, 1248–1260. [Google Scholar] [CrossRef] [PubMed]

- Kojtari, A.; Ercan, U.K.; Smith, J.; Friedman, G.; Sensenig, R.B.; Tyagi, S.; Joshi, S.G.; Ji, H.F.; Brooks, A.D. Chemistry for antimicrobial properties of water treated with non-equilibrium plasma. J. Nanomed. Biother. Discov. 2013, 4, 120. [Google Scholar]

- Guo, L.; Xu, R.; Gou, L.; Liu, Z.; Zhao, Y.; Liu, D.; Zhang, L.; Chen, H.; Kong, M.G. Mechanism of virus inactivation by cold atmospheric-pressure plasma and plasma-activated water. Appl. Environ. Microbiol. 2018, 84, e00726-18. [Google Scholar] [CrossRef] [PubMed]

- Su, X.; Tian, Y.; Zhou, H.; Li, Y.; Zhang, Z.; Jiang, B.; Yang, B.; Zhang, J.; Fang, J. Inactivation efficacy of nonthermal plasma-activated solutions against Newcastle disease virus. Appl. Environ. Microbiol. 2018, 84, e02836-17. [Google Scholar] [CrossRef] [PubMed]

- Ma, R.; Yu, S.; Tian, Y.; Wang, K.; Sun, C.; Li, X.; Zhang, J.; Chen, K.; Fang, J. Effect of non-thermal plasma-activated water on fruit decay and quality in postharvest Chinese bayberries. Food Bioprocess Technol. 2016, 9, 1825–1834. [Google Scholar] [CrossRef]

- Schnabel, U.; Sydow, D.; Schluter, O.; Andrasch, M.; Ehlbeck, J. Decontamination of fresh-cut iceberg lettuce and fresh mung bean sprouts by non-thermal atmospheric pressure plasma processed water (PPW). Mod. Agric. Sci. Technol. 2015, 1, 23–39. [Google Scholar]

- Patange, A.; Lu, P.; Boehm, D.; Cullen, P.J.; Bourke, P. Efficacy of cold plasma functionalised water for improving microbiological safety of fresh produce and wash water recycling. Food Microbiol. 2019, 84, 103226. [Google Scholar] [CrossRef]

- Vargaftik, N.B.; Volkov, B.N.; Voljak, L.D. International tables of the surface-tension of water. J. Geophys. Res. (Space Phys.) 1983, 12, 817–820. [Google Scholar] [CrossRef]

- Rusuniak, L. Electric properties of water new experimental data. Acta Geophys. Pol. 2004, 52, 63–76. [Google Scholar]

- Semak, V.V.; Gerakis, A.; Shneider, M.N. Measurement of temperature dependent absorption coefficient of water at 1064 nm wavelength. AIP Adv. 2019, 9, 085016. [Google Scholar] [CrossRef]

- Maestro, L.M.; Marques, M.I.; Camarillo, E.; Jaque, D.; GarcíaSole, J.; Gonzalo, J.A.; Jaque, F.; Valle, J.C.; Mallamace, F.; Stanley, H.E. On the existence of two states in liquid water: Impact on biological and nanoscopic systems. Int. J. Nanotechnol. 2016, 13, 667–677. [Google Scholar] [CrossRef]

- Yakhno, T.; Yakhno, V. A Study of the Structural Organization of Water and Aqueous Solutions by Means of Optical Microscopy. Crystals 2019, 9, 52. [Google Scholar] [CrossRef]

- Pettersson, L.G.M.; Nilsson, A.; Henchman, R.H. Water-The Most Anomalous Liquid. Chem. Rev. 2016, 116, 7459–7462. [Google Scholar] [CrossRef] [PubMed]

- Brites, C.D.S.; Zhuang, B.; Debasu, M.L.; Ding, D.; Qin, X.; Maturi, F.E.; Lim, W.W.; Soh, D.W.; Rocha, J.; Yi, Z.; et al. Decoding a Percolation Phase Transition of Water at 330 K with a Nanoparticle Ruler. J. Phys. Chem. Lett. 2020, 11, 6704–6711. [Google Scholar] [CrossRef]

- Wernet, P.; Nordlund, D.; Bergmann, U.; Cavalleri, M.; Odelius, M.; Ogasawara, H.; Naslund, L.A.; Hirsch, T.K.; Ojamae, L.; Glatzel, P.; et al. The Structure of the First Coordination Shell in Liquid Water. Science 2004, 304, 995–999. [Google Scholar] [CrossRef]

- Tokushima, T.; Harada, Y.; Takahashi, O.; Senba, Y.; Ohashi, H.; Pettersson, L.G.M.; Nilsson, A.; Shin, S. Emission Spectroscopy of Liquid Water: The Observation of Two Structural Motifs. Chem. Phys. Lett. 2008, 460, 387–400. [Google Scholar] [CrossRef]

- Nilsson, A.; Pettersson, L.G.M. The structural origin of anomalous properties of liquid water. Nat. Commun. 2015, 6, 8998. [Google Scholar] [CrossRef]

- Fridman, A. Plasma Chemistry; Cambridge University Press: Cambridge, UK, 2008. [Google Scholar]

- Graves, D.B. The emerging role of reactive oxygen and nitrogen species in redox biology and some implications for plasma applications to medicine and biology. J. Phys. D Appl. Phys. 2012, 45, 263001. [Google Scholar] [CrossRef]

- Fridman, A.; Kennedy, L.A. Plasma Physics and Engineering; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Fridman, A.; Friedman, G. Plasma Medicine; Wiley: Hoboken, NJ, USA, 2013. [Google Scholar]

- Kim, H.S.; Cho, Y.I.; Hwang, I.H.; Lee, D.H.; Cho, D.J.; Rabinovich, A.; Fridman, A. Use of plasma gliding arc discharges on the inactivation of E. coli in water. Sep. Purif. Technol. 2013, 120, 423–428. [Google Scholar] [CrossRef]

- Fridman, A. Physics and applications of the gliding arc discharge. In Proceedings of the 31st IEEE International Conference on Plasma Science, Baltimore, MD, USA, 22–26 May 2004. [Google Scholar]

- Tanaka, H. Two-order-parameter description of liquids. I. A general model of glass transition covering its strong to fragile limit. J. Chem. Phys. 1999, 111, 3163–3174. [Google Scholar] [CrossRef]

- Tanaka, H. Two-order-parameter description of liquids. II. Criteria for vitrification and predictions of our model. J. Chem. Phys. 1999, 111, 3175–3182. [Google Scholar] [CrossRef]

- Tanaka, H. Simple physical model of liquid water. J. Chem. Phys. 2000, 112, 799–809. [Google Scholar] [CrossRef]

| Wash Out Efficiency [log] | E. coli Remained [%] | |

|---|---|---|

| PAW | 0.67 ± 0.21 | 24% ± 11% |

| PAW w/organic load | 0.70 ± 0.33 | 26% ± 19% |

| Tap | 0.55 ± 0.32 | 36% ± 25% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, J.; Rabinovich, A.; Vainchtein, D.; Fridman, A.; Sales, C.; Shneider, M.N. Effects of Plasma on Physical Properties of Water: Nanocrystalline-to-Amorphous Phase Transition and Improving Produce Washing. Plasma 2022, 5, 462-469. https://doi.org/10.3390/plasma5040034

He J, Rabinovich A, Vainchtein D, Fridman A, Sales C, Shneider MN. Effects of Plasma on Physical Properties of Water: Nanocrystalline-to-Amorphous Phase Transition and Improving Produce Washing. Plasma. 2022; 5(4):462-469. https://doi.org/10.3390/plasma5040034

Chicago/Turabian StyleHe, Jinjie, Alexander Rabinovich, Dmitri Vainchtein, Alexander Fridman, Christopher Sales, and Mikhail N. Shneider. 2022. "Effects of Plasma on Physical Properties of Water: Nanocrystalline-to-Amorphous Phase Transition and Improving Produce Washing" Plasma 5, no. 4: 462-469. https://doi.org/10.3390/plasma5040034

APA StyleHe, J., Rabinovich, A., Vainchtein, D., Fridman, A., Sales, C., & Shneider, M. N. (2022). Effects of Plasma on Physical Properties of Water: Nanocrystalline-to-Amorphous Phase Transition and Improving Produce Washing. Plasma, 5(4), 462-469. https://doi.org/10.3390/plasma5040034