Vacuum Arc Plasma Coating for Polymer Surface Protection— A Plasma Enhanced In-Orbit Additive Manufacturing Concept

Abstract

1. Introduction

2. Materials and Methods

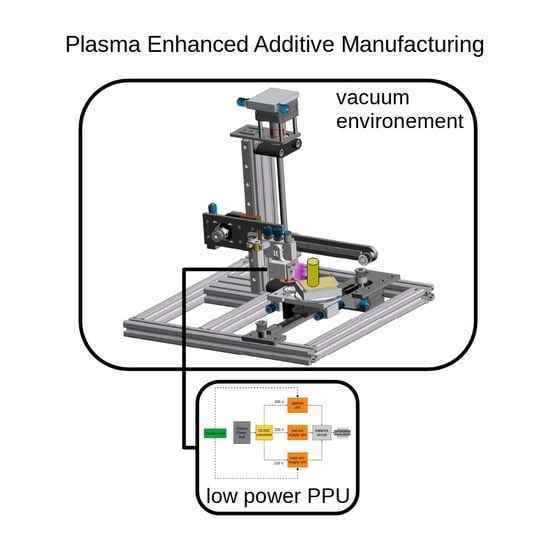

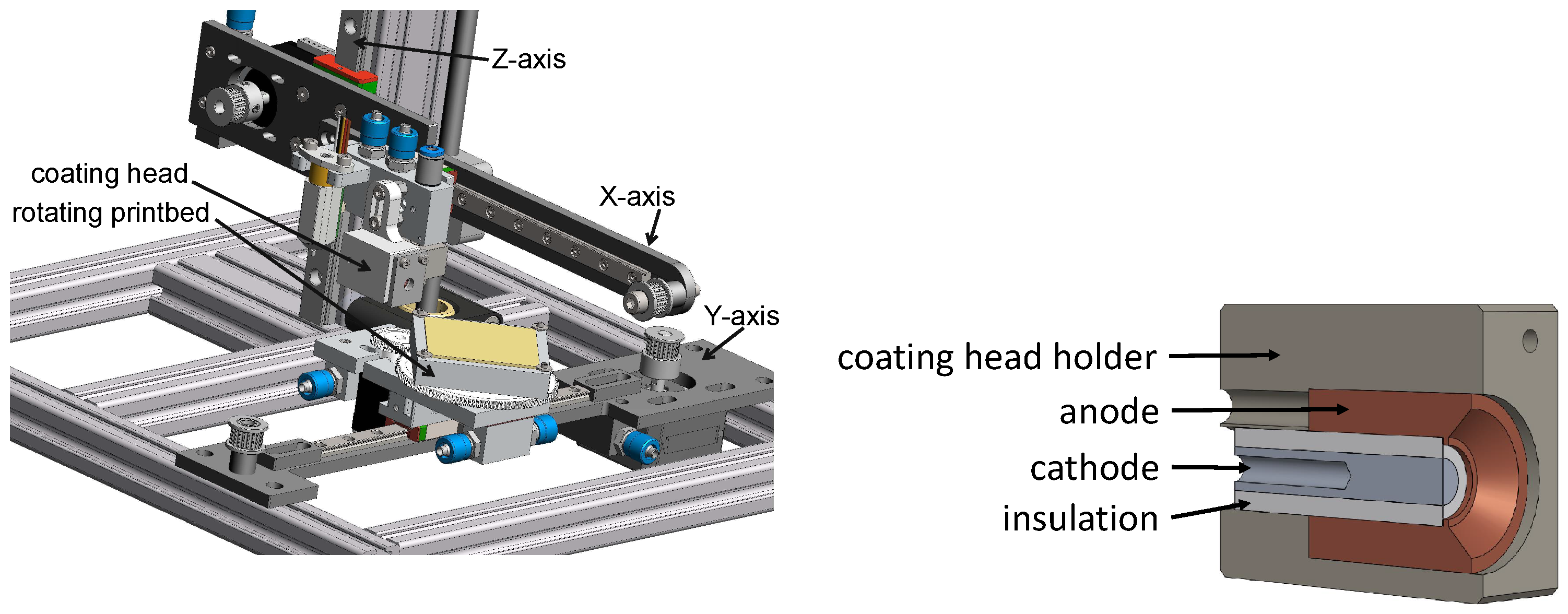

2.1. FFF System

2.2. Vacuum Arc Plasma Coating Unit

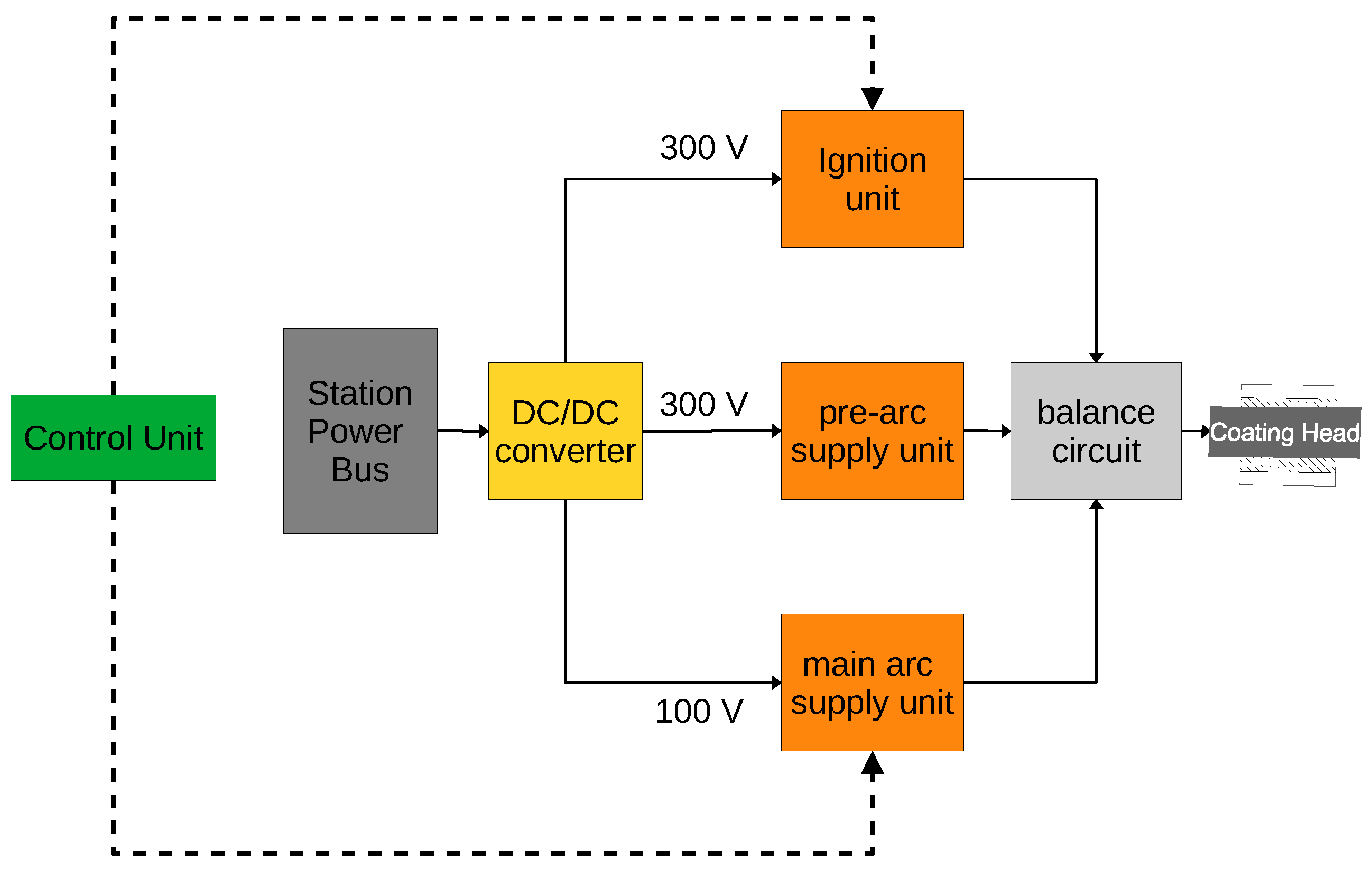

2.3. Power Supply Design

2.4. Vacuum Setup

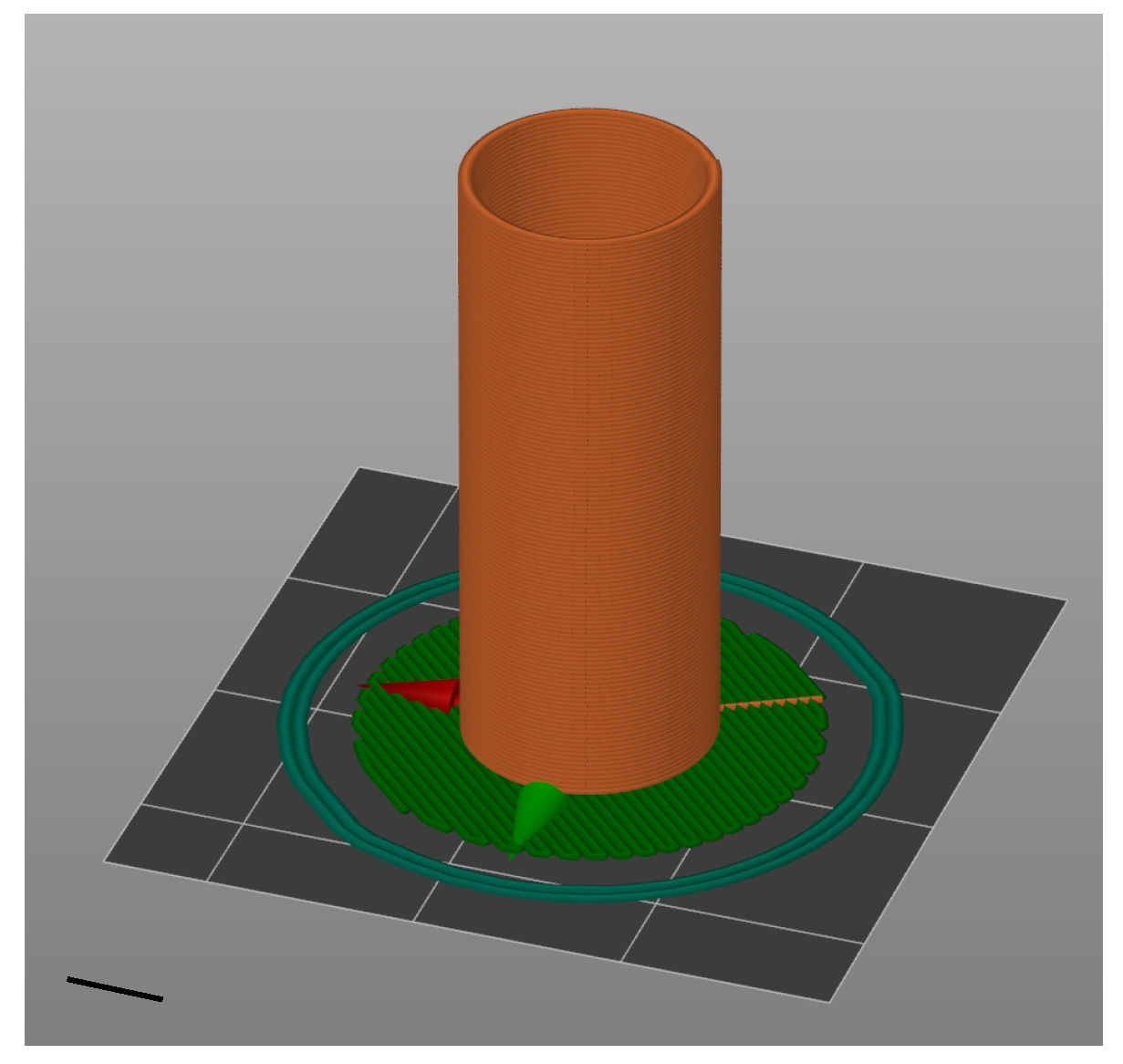

2.5. Use Case

2.6. Coating Analysis

3. Results and Discussions

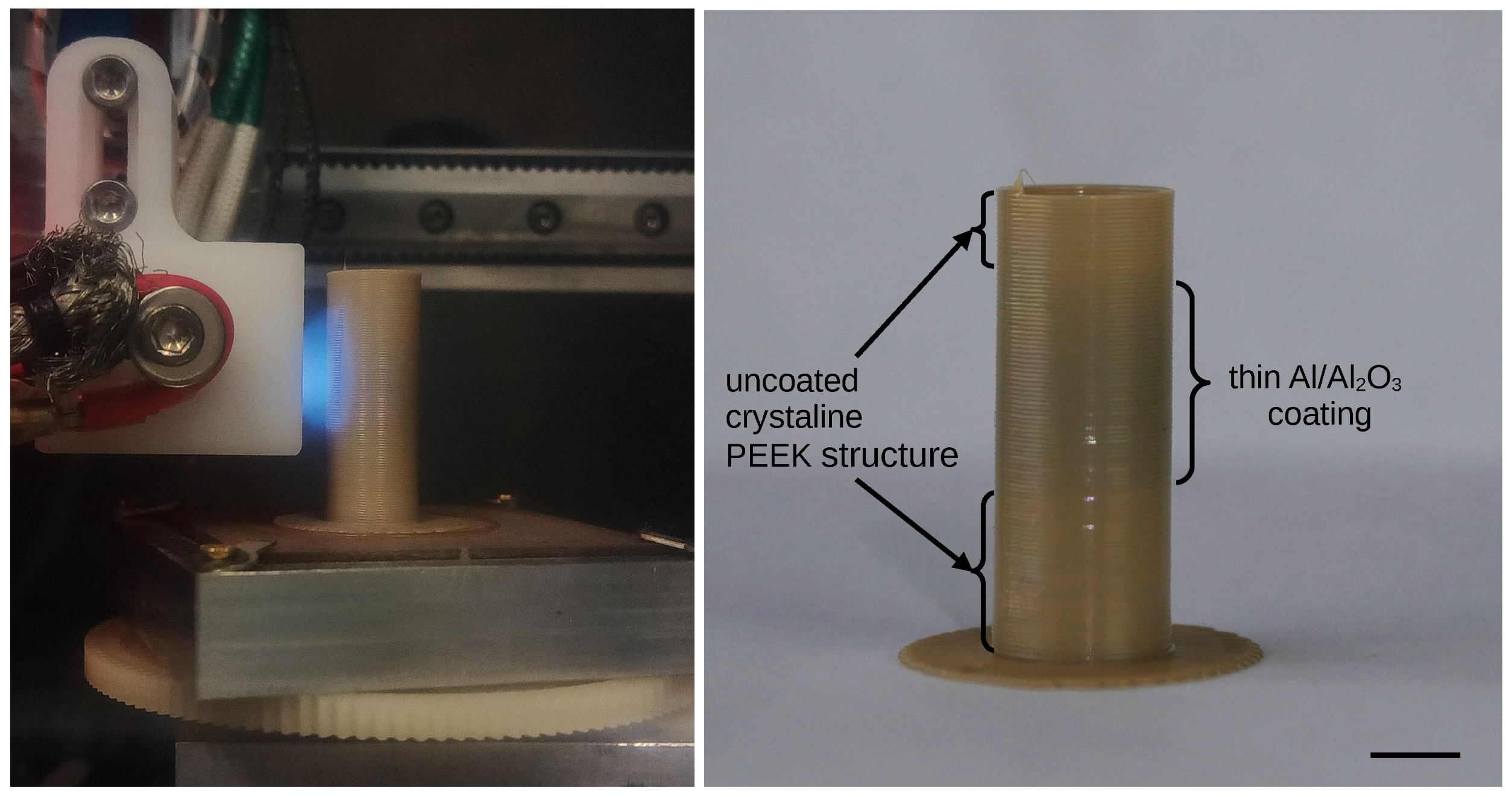

3.1. Additive Manufacturing and Coating of Polymer Structures

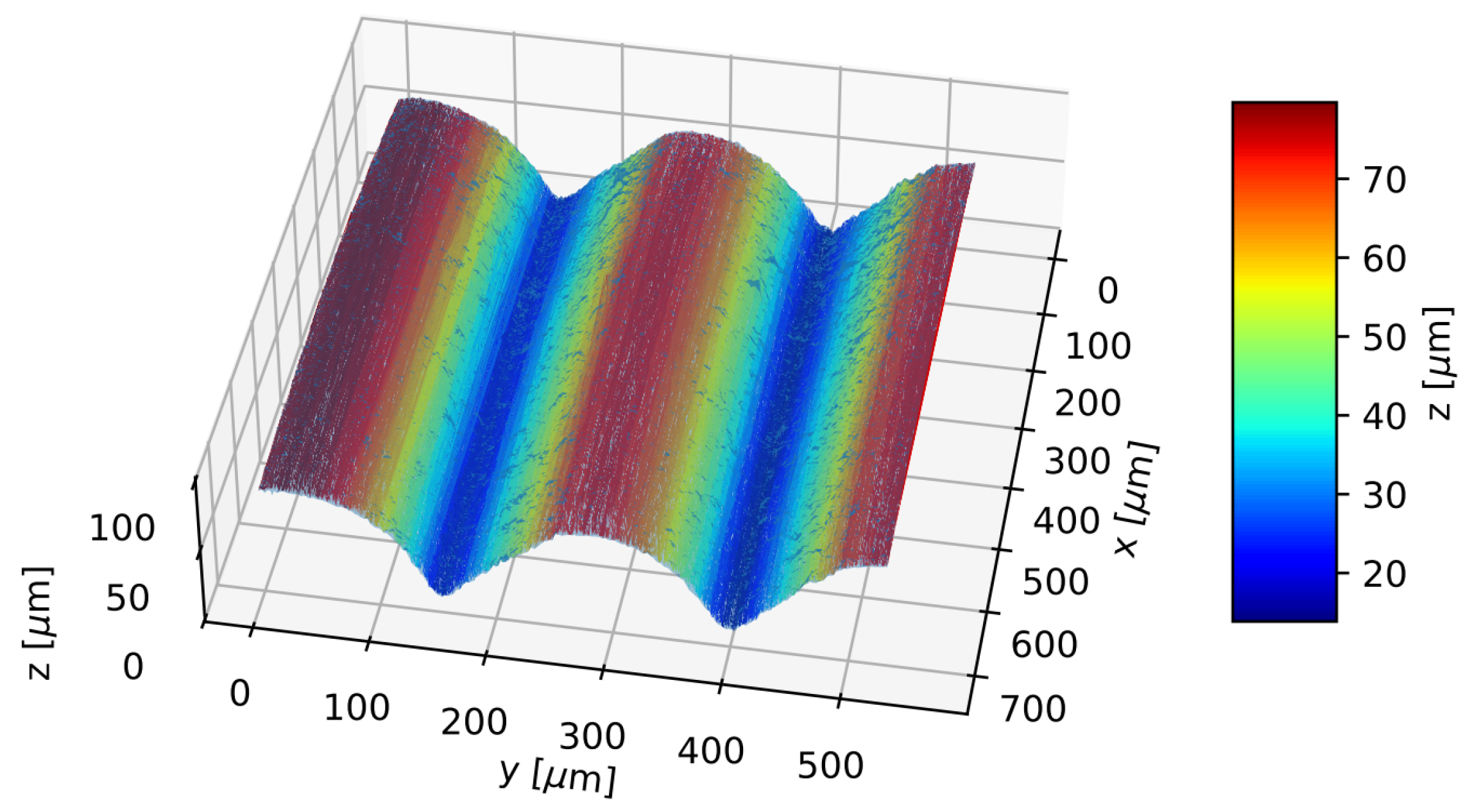

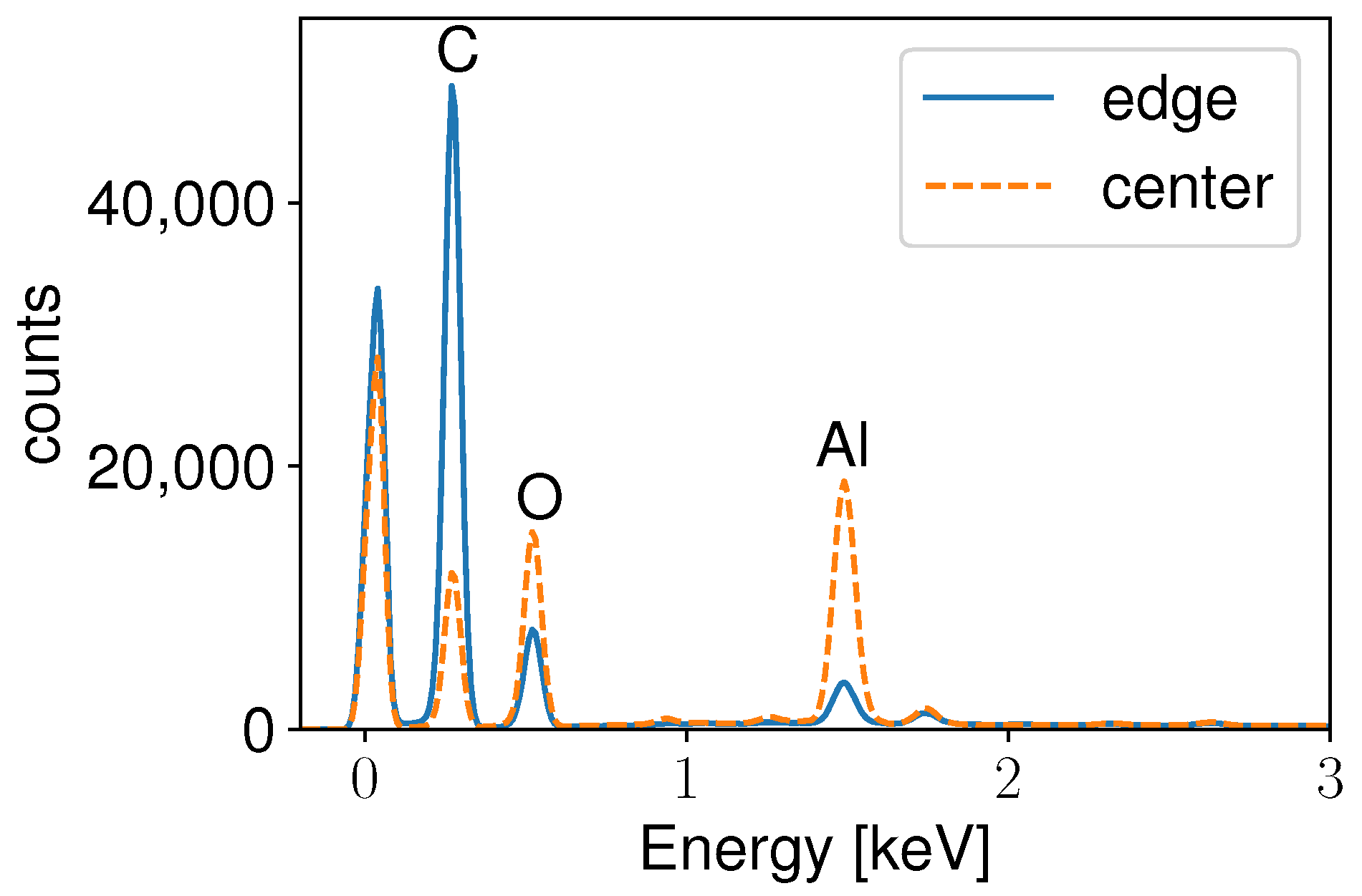

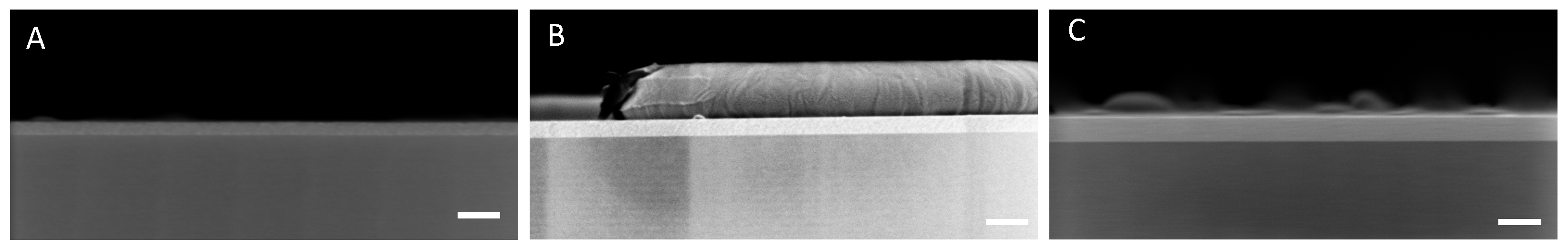

3.2. Coating Characterization

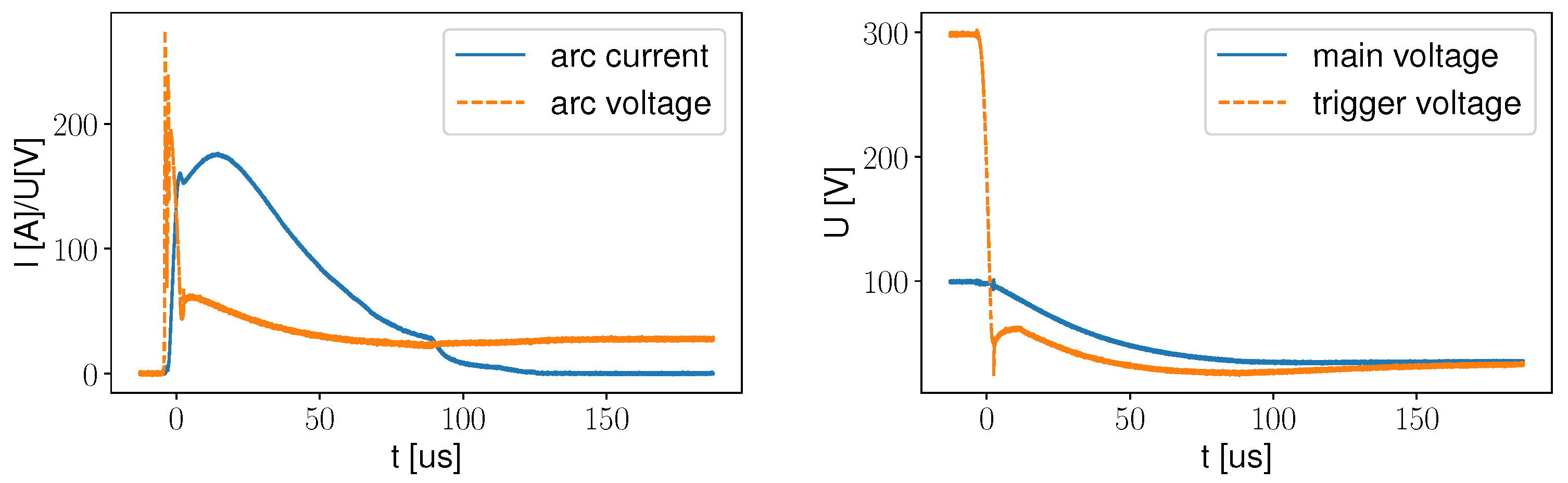

3.3. PPU Performance

4. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| FFF | Fused Filament Fabrication |

| PPU | Power Processing Unit |

| AO | Atomic Oxygen |

| SWAP-C | Space, Weight, Power and Cost |

| LEO | Low Earth Orbit |

| PEEK | Polyetheretherketon |

| UV | Ultraviolet |

| IR | Infrared |

| SEM | Scanning Electron Microscopy |

| EDX | Energy Dispersive X-ray spectroscopy |

| LSM | Laser Scanning Microscope |

References

- ESA. SOLARIS: Preparing for Space-Based Solar Power; ESA: Nordwijk, Netherlands, 2022; Available online: https://www.esa.int/ESA_Multimedia/Videos/2022/08/SOLARIS_Preparing_for_Space-Based_Solar_Power (accessed on 12 September 2022).

- Samwel, S.W. Low Earth Orbital Atomic Oxygen Erosion Effect on Spacecraft Materials. Space Res. J. 2014, 7, 1–13. [Google Scholar] [CrossRef]

- Smith, C.T.G.; Delkowski, M.; Anguita, J.V.; Cox, D.C.; Haas, C.; Silva, S.R.P. Complete Atomic Oxygen and UV Protection for Polymer and Composite Materials in a Low Earth Orbit. ACS Appl. Mater. Interfaces 2021, 13, 6670–6677. [Google Scholar] [CrossRef] [PubMed]

- Banks, B.A.; Snyder, A.; Miller, S.K.; de Groh, K.K.; Demko, R. Atomic-Oxygen Undercutting of Protected Polymers in Low Earth Orbit. J. Spacecr. Rocket. 2004, 41, 335–339. [Google Scholar] [CrossRef]

- Fulton, M.; Anders, A. Concept for lightweight spaced-based deposition technology. In Proceedings of the 49th Annual Meeting of Society of Vacuum Coaters; Washington DC, USA, 22–27 April 2006. Available online: https://www.osti.gov/biblio/889329 (accessed on 12 September 2022).

- Keski-Kuha, R.A.M.; Larruquert, J.I.; Gum, J.S.; Fleetwood, C.M. Optical Coatings and Materials for Ultraviolet Space Applications. Ultrav.-Opt. Space Astron. Beyond HST ASP Conf. Ser. 1999, 164, 406. [Google Scholar]

- Kruzelecky, R.V.; Haddad, E.; Jamroz, W.; Soltani, M.; Chaker, M.; Nikanpour, D.; Jiang, X.X. Passive Dynamically-Variable Thin-Film Smart Radiator Device. SAE Trans. 2003, 112, 182–192. Available online: http://www.jstor.org/stable/44699191 (accessed on 2 November 2022).

- Boyd, I.D.; Buenconsejo, R.S.; Piskorz, D.; Lal, B.; Crane, K.W. ; De La Rosa, Blanco, E. On-Orbit Manufacturing and Assembly of Spacecraft; Institute for Defense Analyses: Washington, DC, USA, 2017. [Google Scholar]

- Anders, A. Cathodic Arcs; Springer: New York, NY, USA, 2008. [Google Scholar] [CrossRef]

- Mirza, I.; O’Connell, G.; Wang, J.J.; Lunney, J.G. Comparison of nanosecond and femtosecond pulsed laser deposition of silver nanoparticle films. Nanotechnology 2014, 25, 265301. [Google Scholar] [CrossRef] [PubMed]

- Kolbeck, J.; Keidar, M. A Pulsed Vacuum Arc Ion Thruster for SmallSat Applications. In Proceedings of the 36th International Electric Propulsion Conference, Vienna, Austria, 15–20 September 2019; Available online: http://electricrocket.org/2019/657.pdf (accessed on 12 September 2022).

- Minami, T.; Ida, S.; Miyata, T.; Minamino, Y. Transparent conducting ZnO thin films deposited by vacuum arc plasma evaporation. Thin Solid Films 2003, 445, 268–273. [Google Scholar] [CrossRef]

- Kühn, M.; Schein, J. Development of a High-Reliability Vacuum Arc Thruster System. J. Propuls. Power 2022, 38, 752–758. [Google Scholar] [CrossRef]

- Kühn, M.; Toursel, C.; Schein, J. Thrust Measurements on the High Efficient and Reliable Vacuum Arc Thruster (HERVAT). Appl. Sci. 2021, 11, 2274. [Google Scholar] [CrossRef]

- Jitschin, W.; Lachenmann, R.; Jünemann, A.; Friedrichsen, U.; Lippelt, E.; Kossek, B.; Altenheimer, F. Wutz Handbuch Vakuumtechnik: Theorie und Praxis; Springer: Berlin/Heidelberg, Germany, 2013; p. 668. [Google Scholar]

- Pietzka, M. Development and Characterization of a Propulsion System for CubeSats Based on Vacuum Arc Thrusters. Ph.D. Thesis, Universität der Bundeswehr München, Neubiberg, Germany, 2016. [Google Scholar]

- Anders, A.; Oks, E.M.; Yushkov, G.Y.; Savkin, K.P.; Brown, I.G.; Nikolaev, A.G. Measurements of the total ion flux from vacuum arc cathode spots. IEEE Trans. Plasma Sci. 2005, 33, 1532–1536. [Google Scholar] [CrossRef]

- Polk, J.E.; Sekerak, M.J.; Ziemer, J.K.; Schein, J.; Qi, N.; Anders, A. A Theoretical Analysis of Vacuum Arc Thruster and Vacuum Arc Ion Thruster Performance. IEEE Trans. Plasma Sci. 2008, 36, 2167–2179. [Google Scholar] [CrossRef]

- Vetter, J.; Müller, J.; Erkens, G. Domino Platform: PVD Coaters for Arc Evaporation and High Current Pulsed Magnetron Sputtering. IOP Conf. Ser. Mater. Sci. Eng. 2012, 39, 012004. [Google Scholar] [CrossRef]

| Properties | Value (Range) |

|---|---|

| Power consumption/budget | 0.5 –30 |

| Pulse lengths | 50 –5000 |

| Repetition rate | 0 –10 |

| Output current | 20 –300 |

| Output voltage | 150 –5000 |

| Input current | 0.1 –3 |

| Input voltage | 24 |

| Minimal size (length × width × height) | 60 mm × 60 mm × 25 mm |

| Minimal mass | 100 |

| Parameter | Value | |

|---|---|---|

| printed substrate | wafer | |

| Operating pressure [] | 4 × 10−4 | 4 × 10−4 |

| Material | PEEK | Si |

| Nozzle temperature [] | 365 | - |

| Chamber temperature [] | room temperature | room temperature |

| Nozzle speed [] | 5 | - |

| Layer height [] | 0.2 | - |

| Extrusion width [] | 0.65 | - |

| Manufacturing time [] | 17 | - |

| coating | ||

| Coating material | Al | Ti |

| Cathode diameter [] | 3 | 3 |

| PPU main capacitor [] | 144 | 144 |

| Main charging voltage [] | 100 | 100 |

| Operation frequency [] | 2 | 2 |

| Rotation step [] | 0.25 | - |

| Total number of pulses | 14,400 | 1000–2000 |

| Cathode-specimen distance [] | 8 | 30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kühn-Kauffeldt, M.; Kühn, M.; Mallon, M.; Saur, W.; Fuchs, F. Vacuum Arc Plasma Coating for Polymer Surface Protection— A Plasma Enhanced In-Orbit Additive Manufacturing Concept. Plasma 2022, 5, 470-481. https://doi.org/10.3390/plasma5040035

Kühn-Kauffeldt M, Kühn M, Mallon M, Saur W, Fuchs F. Vacuum Arc Plasma Coating for Polymer Surface Protection— A Plasma Enhanced In-Orbit Additive Manufacturing Concept. Plasma. 2022; 5(4):470-481. https://doi.org/10.3390/plasma5040035

Chicago/Turabian StyleKühn-Kauffeldt, Marina, Marvin Kühn, Michael Mallon, Wolfgang Saur, and Fabian Fuchs. 2022. "Vacuum Arc Plasma Coating for Polymer Surface Protection— A Plasma Enhanced In-Orbit Additive Manufacturing Concept" Plasma 5, no. 4: 470-481. https://doi.org/10.3390/plasma5040035

APA StyleKühn-Kauffeldt, M., Kühn, M., Mallon, M., Saur, W., & Fuchs, F. (2022). Vacuum Arc Plasma Coating for Polymer Surface Protection— A Plasma Enhanced In-Orbit Additive Manufacturing Concept. Plasma, 5(4), 470-481. https://doi.org/10.3390/plasma5040035