Dependence of Optical Emission Spectra on Argon Gas Pressure during Modulated Pulsed Power Magnetron Sputtering (MPPMS)

Abstract

1. Introduction

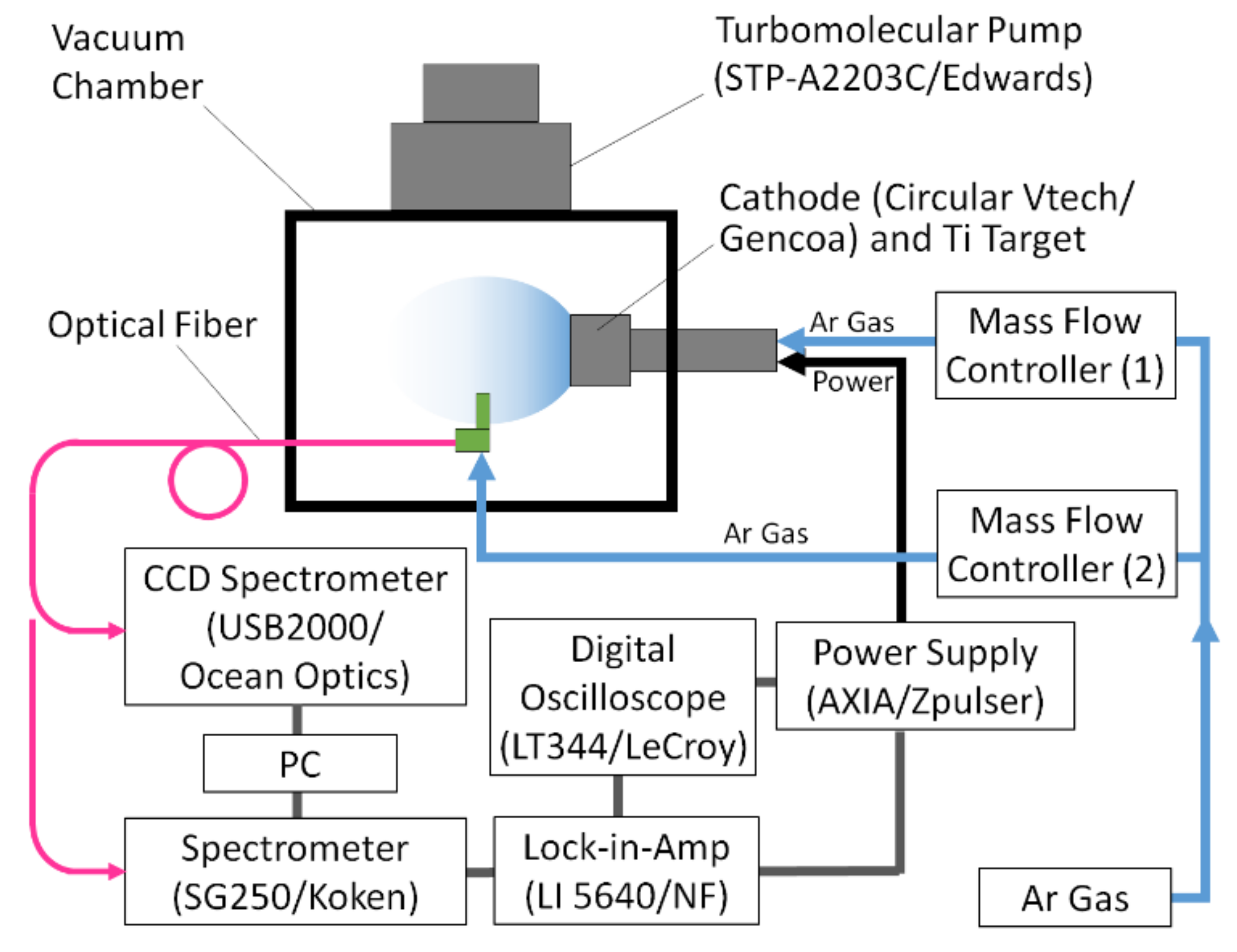

2. Materials and Methods

3. Results and Discussion

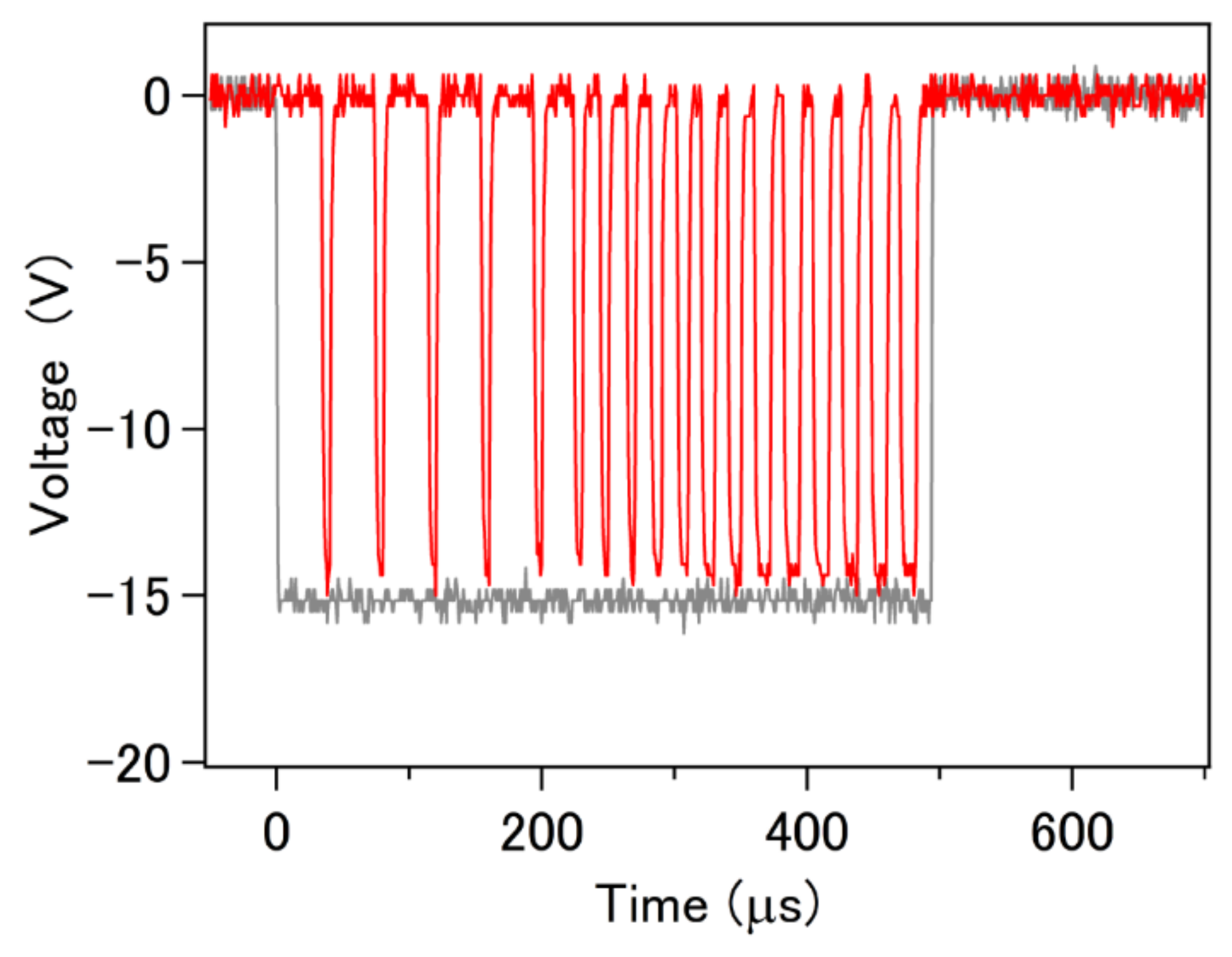

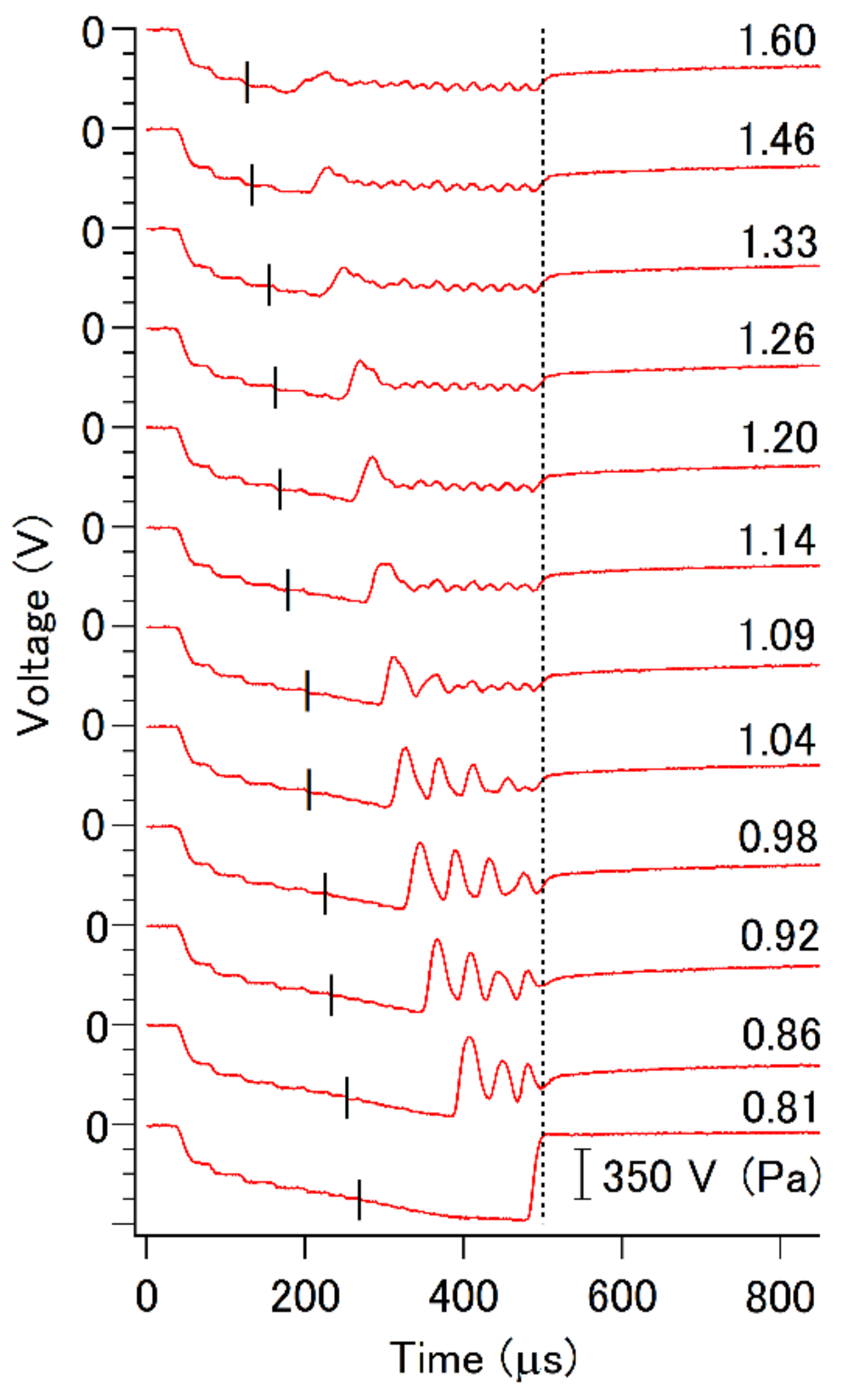

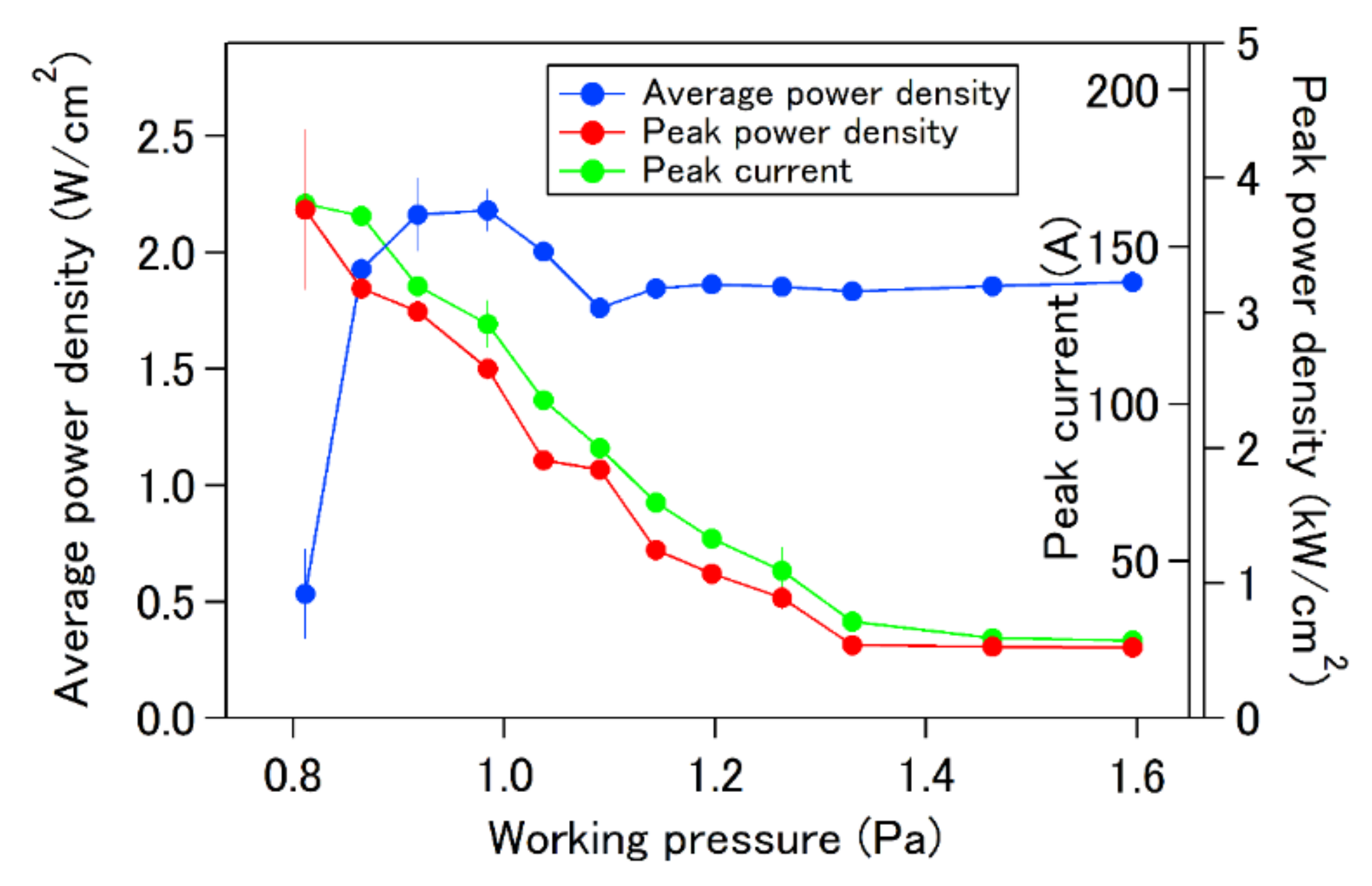

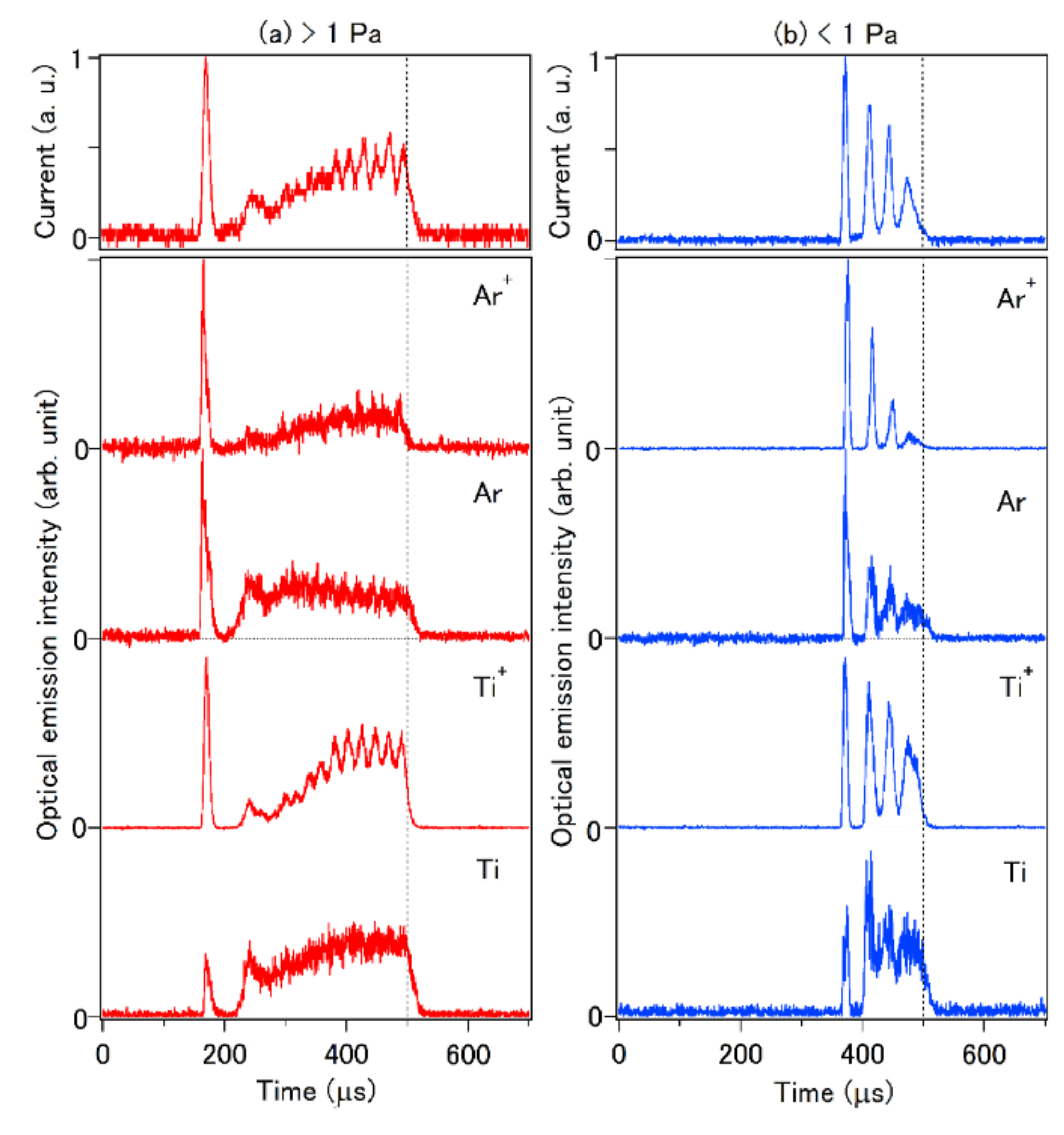

3.1. Discharge Pulse Waveforms

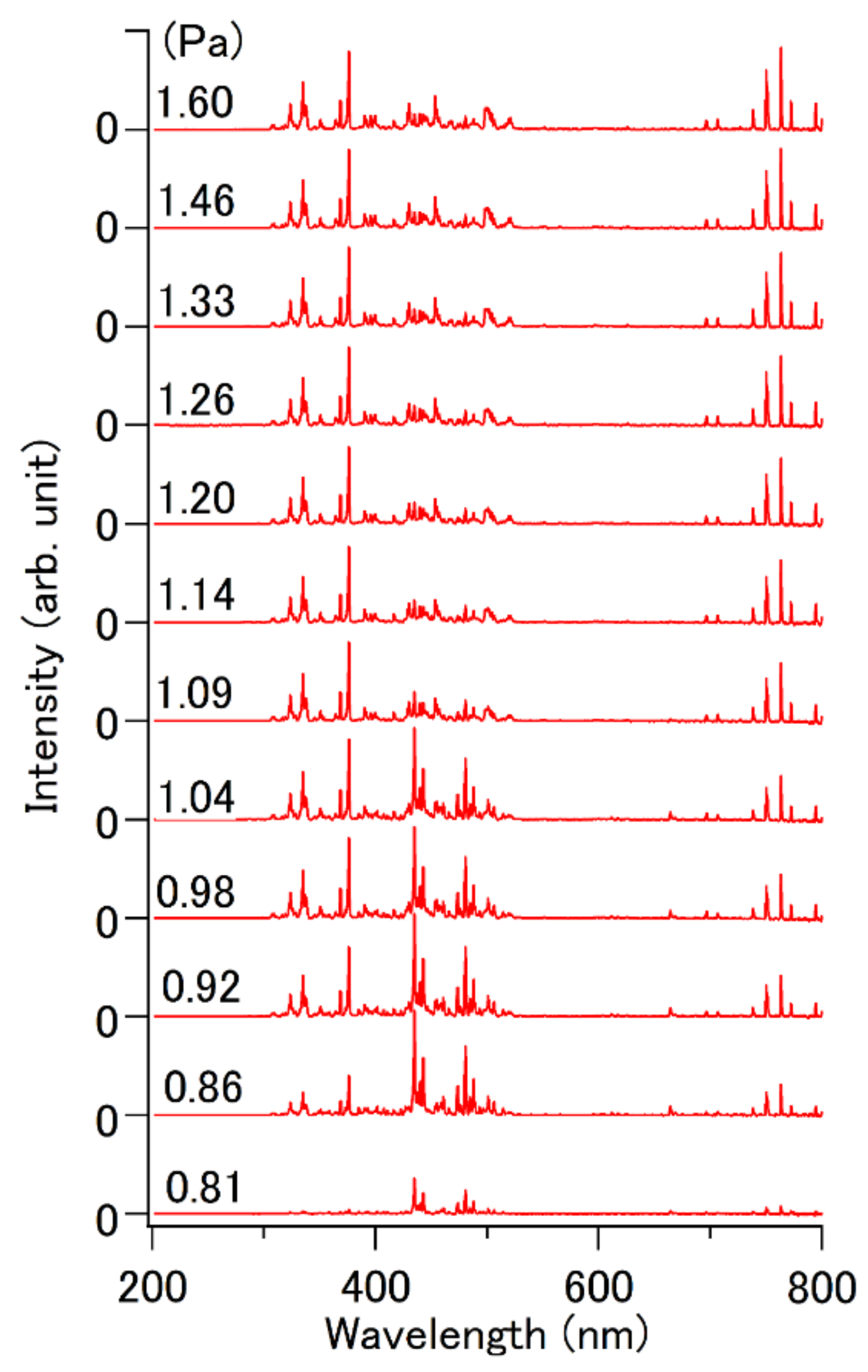

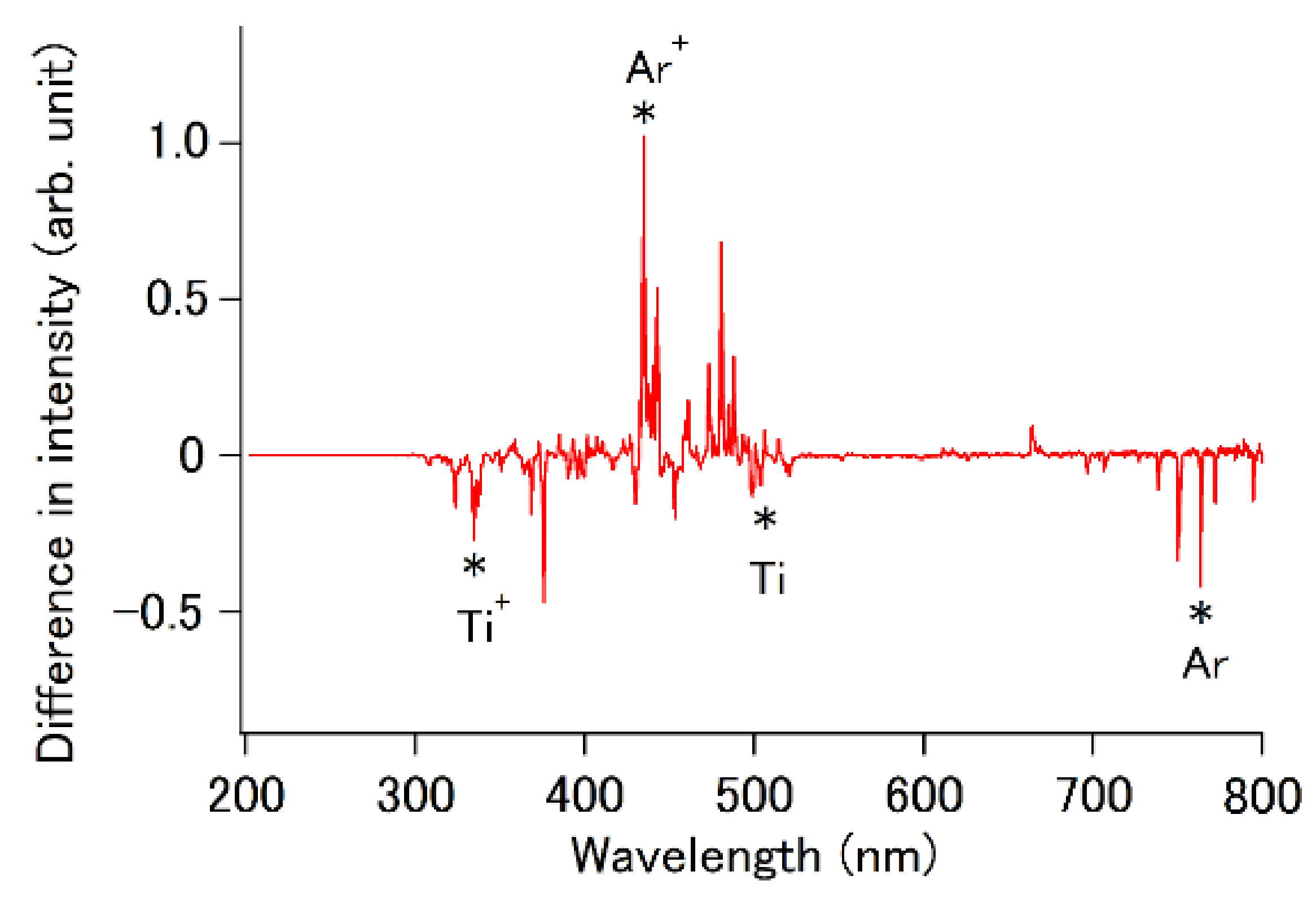

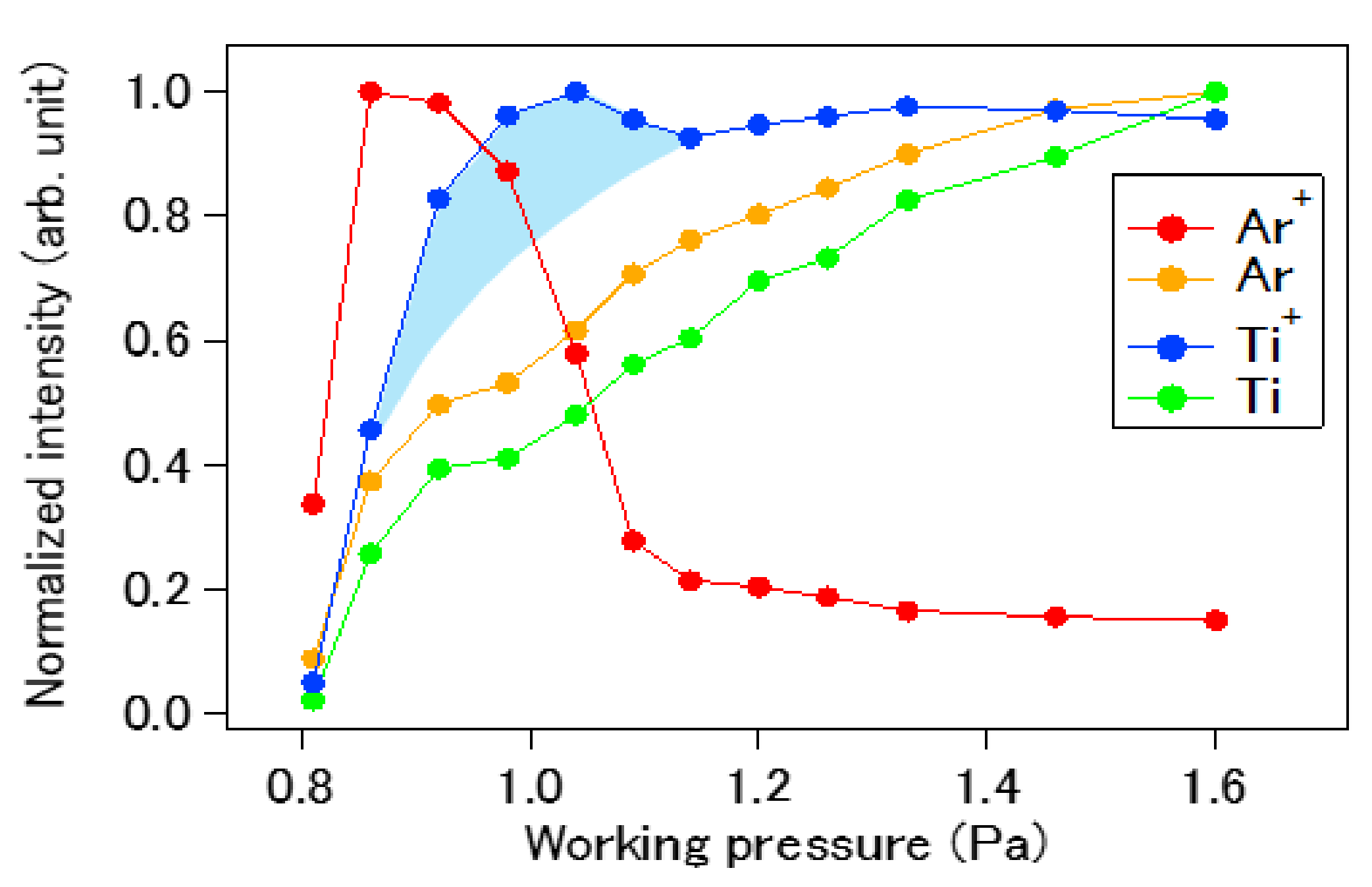

3.2. OES

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gudmundsson, J.T.; Brenning, N.; Lundin, D.; Helmersson, U. High power impulse magnetron sputtering discharge. J. Vac. Sci. Technol. A 2012, 30, 030801. [Google Scholar] [CrossRef]

- Helmersson, U.; Lattemann, M.; Bohlmark, J.; Ehiasarian, A.P.; Gudmundsson, J.T. Ionized physical vapor deposition (IPVD): A review of technology and applications. Thin Solid Films 2006, 513, 1–24. [Google Scholar] [CrossRef]

- Anders, A. Tutorial: Reactive high power impulse magnetron sputtering (R-HiPIMS). J. Appl. Phys. 2017, 121, 171101. [Google Scholar] [CrossRef]

- Sarakinos, K.; Alami, J.; Konstantinidis, S. High power pulsed magnetron sputtering: A review on scientific and engineering state of the art. Surf. Coat. Technol. 2010, 204, 1661–1684. [Google Scholar] [CrossRef]

- Britun, N.; Minea, T.; Konstantinidis, S.; Snyders, R. Plasma diagnostics for understanding the plasma–surface interaction in HiPIMS discharges: A review. J. Phys. D Appl. Phys. 2014, 47, 224001. [Google Scholar] [CrossRef]

- Anders, A. A structure zone diagram including plasma-based deposition and ion etching. Thin Solid Films 2010, 518, 4087–4090. [Google Scholar] [CrossRef]

- Lattemann, M.; Ehiasarian, A.P.; Bohlmark, J.; Persson, P.Å.O.; Helmersson, U. Investigation of high power impulse magnetron sputtering pretreated interfaces for adhesion enhancement of hard coatings on steel. Surf. Coat. Technol. 2006, 200, 6495–6499. [Google Scholar] [CrossRef]

- Shimizu, T.; Teranishi, Y.; Morikawa, K.; Komiya, H.; Watanabe, T.; Nagasawa, N.; Yang, M. Impact of pulse duration in high power impulse magnetron sputtering on the low-temperature growth of wurtzite phase (Ti,Al)N films with high hardness. Thin Solid Films 2015, 581, 39–47. [Google Scholar] [CrossRef]

- Lin, J.; Moore, J.J.; Sproul, W.D.; Mishra, B.; Wu, Z. Modulated pulse power sputtered chromium coatings. Thin Solid Films 2009, 518, 1566–1570. [Google Scholar] [CrossRef]

- Lin, J.; Moore, J.J.; Sproul, W.; Mishra, B.; Wu, Z.; Wang, J. The structure and properties of chromium nitride coatings deposited using dc, pulsed dc and modulated pulse power magnetron sputtering. Surf. Coat. Technol. 2010, 204, 2230–2239. [Google Scholar] [CrossRef]

- Hála, M.; Čapek, J.; Zabeida, O.; Klemberg-Sapieha, J.E.; Martinu, L. Pulse management in high power pulsed magnetron sputtering of niobium. Surf. Coat. Technol. 2012, 206, 4186–4193. [Google Scholar] [CrossRef]

- Liebig, B.; Braithwaite, N.S.J.; Kelly, P.J.; Chistyakov, R.; Abraham, B.; Bradley, J.W. Time-resolved plasma characterisation of modulated pulsed power magnetron sputtering of chromium. Surf. Coat. Technol. 2011, 205, S312–S316. [Google Scholar] [CrossRef]

- Papa, F.; Gerdes, H.; Bradorf, R.; Ehiasarian, A.P.; Kolev, I.; Braeuer, G.; Tietema, R.; Krug, T. Deposition rate characteristics for steady state high power impulse magnetron sputtering (HIPIMS) discharges generated with a modulated pulsed power (MPP) generator. Thin Solid Films 2011, 520, 1559–1563. [Google Scholar] [CrossRef]

- Lin, J.; Wang, B.; Sproul, W.D.; Ou, Y.; Dahan, I. Anatase and rutile TiO2 films deposited by arc-free deep oscillation magnetron sputtering. J. Phys. D: Appl. Phys. 2013, 46, 084008. [Google Scholar] [CrossRef]

- Lin, J.; Sproul, W.D. Structure and properties of Cr2O3 coatings deposited using DCMS, PDCMS, and DOMS. Surf. Coat. Technol. 2015, 276, 70–76. [Google Scholar] [CrossRef]

- Ou, Y.X.; Lin, J.; Tong, S.; Che, H.L.; Sproul, W.D.; Lei, M.K. Wear and corrosion resistance of CrN/TiN superlattice coatings deposited by a combined deep oscillation magnetron sputtering and pulsed dc magnetron sputtering. Appl. Surf. Sci. 2015, 351, 332–343. [Google Scholar] [CrossRef]

- Ferreira, F.; Oliveira, J.C.; Cavaleiro, A. CrN thin films deposited by HiPIMS in DOMS mode. Surf. Coat. Technol. 2016, 291, 365–375. [Google Scholar] [CrossRef]

- Oliveira, J.C.; Fernandes, F.; Serra, R.; Cavaleiro, A. On the role of the energetic species in TiN thin film growth by reactive deep oscillation magnetron sputtering in Ar/N2. Thin Solid Films 2018, 645, 253–264. [Google Scholar] [CrossRef]

- Tiron, V.; Velicu, I.L.; Dobromir, M.; Demeter, A.; Samoila, F.; Ursu, C.; Sirghi, L. Reactive multi-pulse HiPIMS deposition of oxygen-deficient TiOx thin films. Thin Solid Films 2016, 603, 255–261. [Google Scholar] [CrossRef]

- Fekete, M.; Hnilica, J.; Vitelaru, C.; Minea, T.; Vašina, P. Ti atom and Ti ion number density evolution in standard and multi-pulse HiPIMS. J. Phys. D Appl. Phys. 2017, 50, 365202. [Google Scholar] [CrossRef]

- Tiron, V.; Velicu, I.-L.; Mihǎilǎ, I.; Popa, G. Deposition rate enhancement in HiPIMS through the control of magnetic field and pulse configuration. Surf. Coat. Technol. 2018, 337, 484–491. [Google Scholar] [CrossRef]

- Oskirko, V.O.; Zakharov, A.N.; Pavlov, A.P.; Grenadyorov, A.S.; Semenov, V.A. Unipolar and bipolar mode of deep oscillation magnetron sputtering. J. Phys.:Conf. Ser. 2019, 1393, 012051. [Google Scholar] [CrossRef]

- Oskirko, V.O.; Zakharov, A.N.; Pavlov, A.P.; Solovyev, A.A.; Grenadyorov, A.S.; Semenov, V.A. Dual mode of deep oscillation magnetron sputtering. Surf. Coat. Technol. 2020, 387, 125559. [Google Scholar] [CrossRef]

- Bean, J.C.; Becker, G.E.; Petroff, P.M.; Seidel, T.E. Dependence of residual damage on temperature during Ar+ sputter cleaning of silicon. J. Appl. Phys. 1977, 48, 907–913. [Google Scholar] [CrossRef]

- Ehiasarian, P.; Wen, J.G.; Petrov, I. Interface microstructure engineering by high power impulse magnetron sputtering for the enhancement of adhesion. J. Appl. Phys. 2007, 101, 054301. [Google Scholar] [CrossRef]

- Rossnagel, S.M.; Hopwood, J.J. Phase transformation of thin sputter-deposited tungsten films at room temperature. Vac. Sci. Technol. B 1994, 12, 449–453. [Google Scholar] [CrossRef]

- Antonin, O.; Tiron, V.; Costin, C.; Popa, G.; Minea, T.M. On the HiPIMS benefits of multi-pulse operating mode. J. Phys. D Appl. Phys. 2015, 48, 015202. [Google Scholar] [CrossRef]

- Sanekata, M.; Nishida, H.; Watabe, T.; Nakagomi, Y.; Hirai, Y.; Nishimiya, N.; Tona, M.; Yamamoto, H.; Hirata, N.; Tsukamoto, K.; et al. Delayed Discharge bridging two sputtering modes from modulated pulsed power magnetron sputtering (MPPMS) to deep oscillation magnetron sputtering (DOMS). Plasma 2021, 4, 16. [Google Scholar] [CrossRef]

- Hála, M.; Čapek, J.; Zabeida, O.; Klemberg-Sapieha, J.E.; Martinu, L. Hysteresis-free deposition of niobium oxide films by HiPIMS using different pulse management strategies. J. Phys. D Appl. Phys. 2012, 45, 055204. [Google Scholar] [CrossRef]

- Britun, N.; Konstantinidis, S.; Belosludtsev, A.; Silva, T.; Snyders, R. Quantification of the hysteresis and related phenomena in reactive HiPIMS discharges. J. Appl. Phys. 2017, 121, 171905. [Google Scholar] [CrossRef]

- Tsukamoto, K.; Tamura, T.; Matsusaki, H.; Tona, M.; Yamamoto, H.; Nakagomi, Y.; Nishida, H.; Hirai, Y.; Nishimiya, N.; Sanekata, M.; et al. Time-of-flight mass spectrometric diagnostics for ionized and neutral species in high-power pulsed magnetron sputtering of titanium. Jpn. J. Appl. Phys. 2020, 59, SHHB05. [Google Scholar] [CrossRef]

- Raizer, Y.P. Gas Discharge Physics; Allen, J.E., Ed.; Springer: New York, NY, USA, 1991; pp. 52–137. [Google Scholar]

- Yushkov, G.Y.; Anders, A. Origin of the delayed current onset in high-power impulse magnetron sputtering. IEEE Trans. Plasma Sci. 2010, 38, 3028–3034. [Google Scholar] [CrossRef]

- Lin, J.; Moore, J.J.; Sproul, W.D.; Mishra, B.; Rees, J.A.; Wu, Z.; Chistyakov, R.; Abraham, B. Ion energy and mass distributions of the plasma during modulated pulse power magnetron sputtering. Surf. Coat. Technol. 2009, 203, 3676–3685. [Google Scholar] [CrossRef]

- Kramida, K.; Ralchenko, Y.; Reader, J.; NIST ASD Team. NIST Atomic Spectra Database (Ver. 5.6.1); National Institute of Standards and Technology: Gaithersburg, MD, USA, 2018. Available online: https://physics.nist.gov/asd (accessed on 11 April 2019).

- Musil, J.; Leština, J.; Vlček, J.; Tölg, T. Pulsed dc magnetron discharge for high-rate sputtering of thin films. J. Vac. Sci. Technol. A 2001, 19, 420–424. [Google Scholar] [CrossRef]

- Gudmundsson, J.T.; Alami, J.; Helmersson, U. Spatial and temporal behavior of the plasma parameters in a pulsed magnetron discharge. Surf. Coat. Technol. 2002, 161, 249–256. [Google Scholar] [CrossRef]

- Vašina, P.; Meško, M.; Imbert, J.C.; Ganciu, M.; Boisse-Laporte, C.; de Poucques, L.; Touzeau, M.; Pagnon, D.; Bretagne, J. Experimental study of a pre-ionized high power pulsed magnetron discharge. Plasma Sources Sci. Technol. 2007, 16, 501–510. [Google Scholar] [CrossRef]

| Atomic -Line | Wavelength (nm) | Nature of Lower Level (Energy from Ground Level in cm−1) | Spectral Transition (Upper Level → Lower Level) |

|---|---|---|---|

| 434-Ar+ | 434.80 | Metastable (134,241.7) | 4D°7/2 (3s23p44p) → 4P5/2 (3s23p44s) |

| 763-Ar | 763.51 | Metastable (93,143.7) | 2[3/2]2 (3s23p54p) → 2[3/2] °2 (3s23p54s) |

| 334-Ti+ | 334.94 | Ground (393.4) | z4G°11/2 (3d24p) → a4F9/2 (3d24s) |

| 503-Ti | 503.99 | Ground (170.1) | z3D°2 (3d24s4p) → a3F3 (3d24s2) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sanekata, M.; Nishida, H.; Nakagomi, Y.; Hirai, Y.; Nishimiya, N.; Tona, M.; Hirata, N.; Yamamoto, H.; Tsukamoto, K.; Ohshimo, K.; et al. Dependence of Optical Emission Spectra on Argon Gas Pressure during Modulated Pulsed Power Magnetron Sputtering (MPPMS). Plasma 2021, 4, 269-280. https://doi.org/10.3390/plasma4020018

Sanekata M, Nishida H, Nakagomi Y, Hirai Y, Nishimiya N, Tona M, Hirata N, Yamamoto H, Tsukamoto K, Ohshimo K, et al. Dependence of Optical Emission Spectra on Argon Gas Pressure during Modulated Pulsed Power Magnetron Sputtering (MPPMS). Plasma. 2021; 4(2):269-280. https://doi.org/10.3390/plasma4020018

Chicago/Turabian StyleSanekata, Masaomi, Hiroshi Nishida, Yuki Nakagomi, Yoshihiro Hirai, Nobuo Nishimiya, Masahide Tona, Naoyuki Hirata, Hiroaki Yamamoto, Keizo Tsukamoto, Keijiro Ohshimo, and et al. 2021. "Dependence of Optical Emission Spectra on Argon Gas Pressure during Modulated Pulsed Power Magnetron Sputtering (MPPMS)" Plasma 4, no. 2: 269-280. https://doi.org/10.3390/plasma4020018

APA StyleSanekata, M., Nishida, H., Nakagomi, Y., Hirai, Y., Nishimiya, N., Tona, M., Hirata, N., Yamamoto, H., Tsukamoto, K., Ohshimo, K., Misaizu, F., & Fuke, K. (2021). Dependence of Optical Emission Spectra on Argon Gas Pressure during Modulated Pulsed Power Magnetron Sputtering (MPPMS). Plasma, 4(2), 269-280. https://doi.org/10.3390/plasma4020018