Reducing the Transition Hysteresis of Inductive Plasmas by a Microwave Ignition Aid

Abstract

:1. Introduction

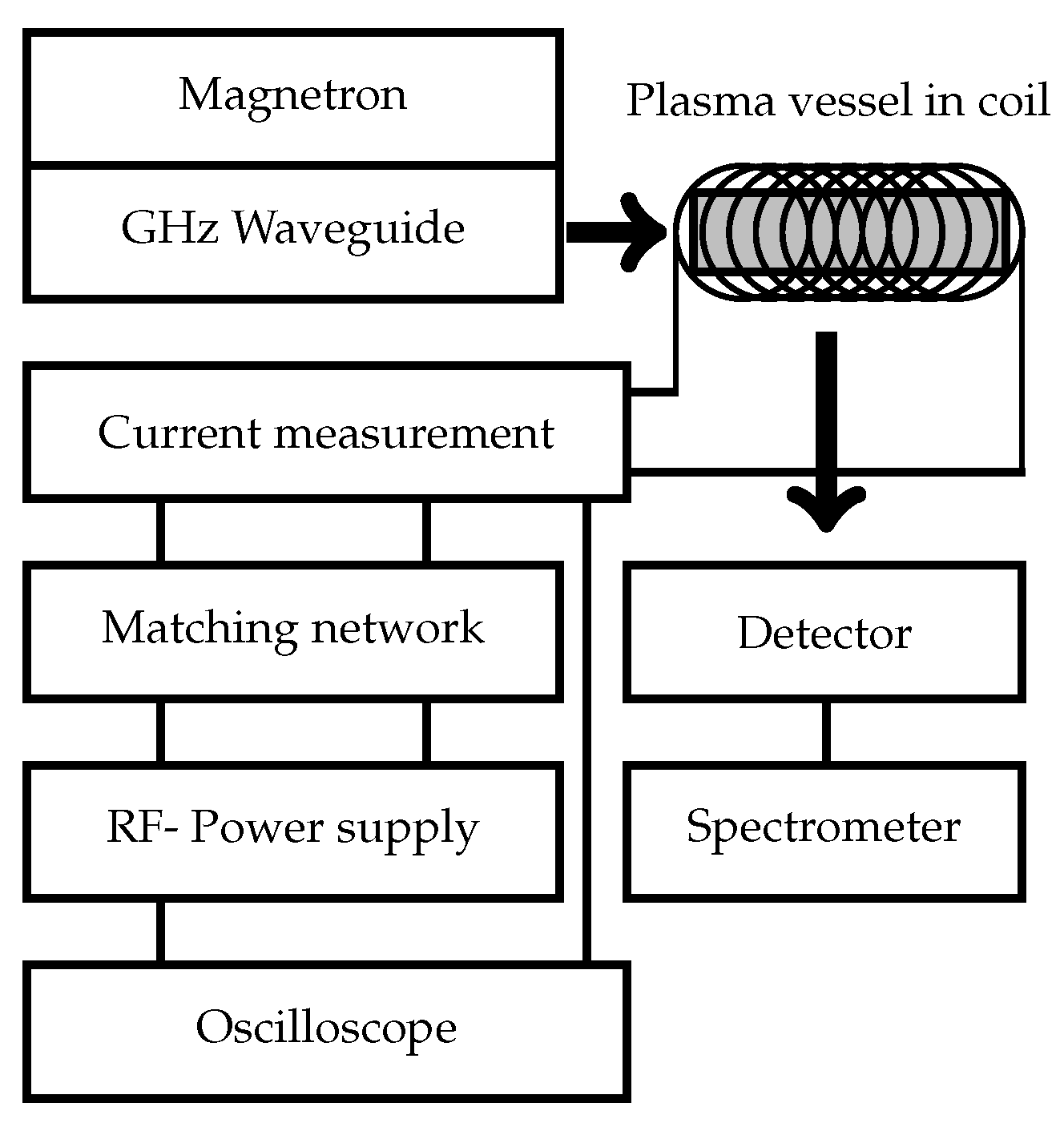

2. Experimental Setup

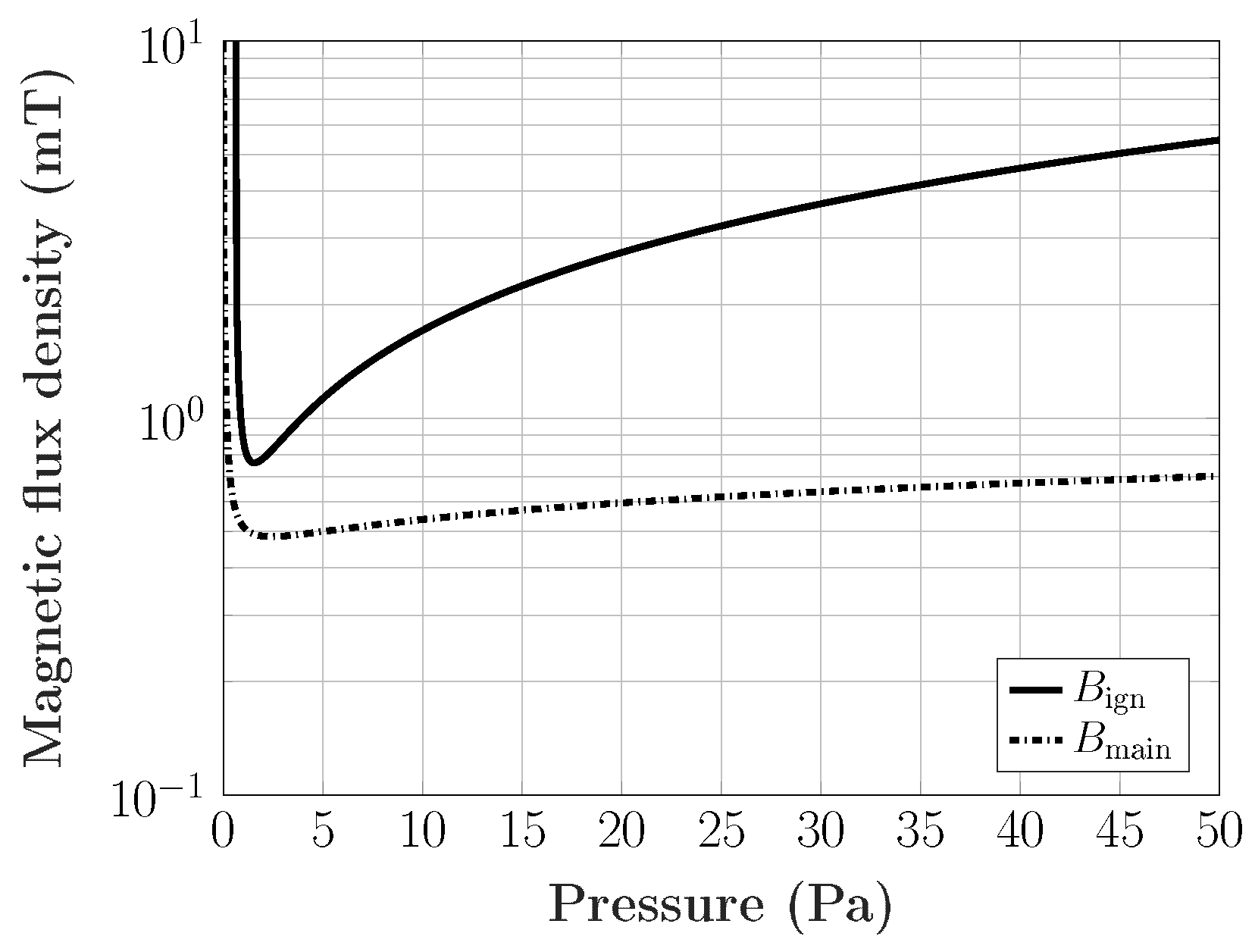

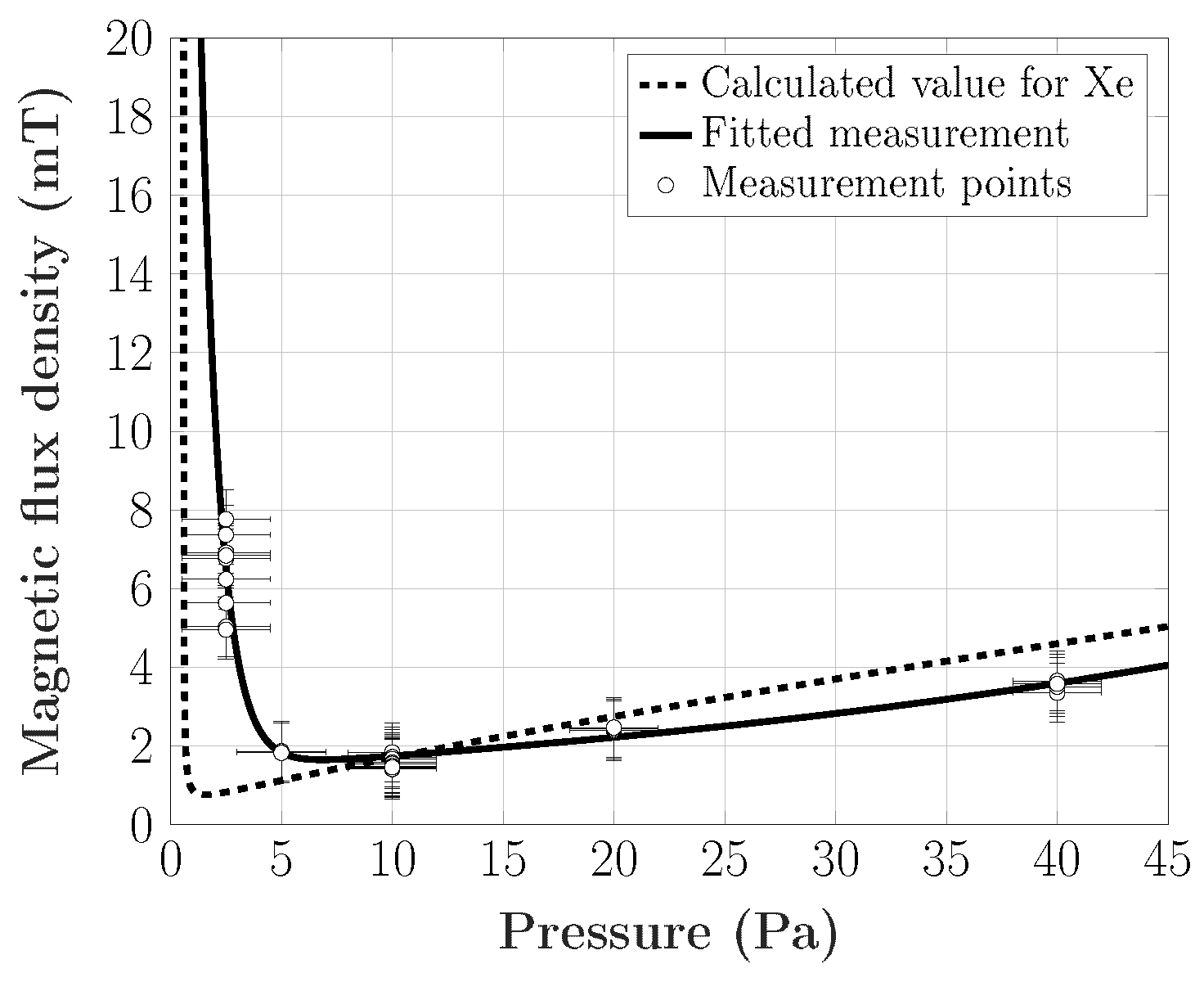

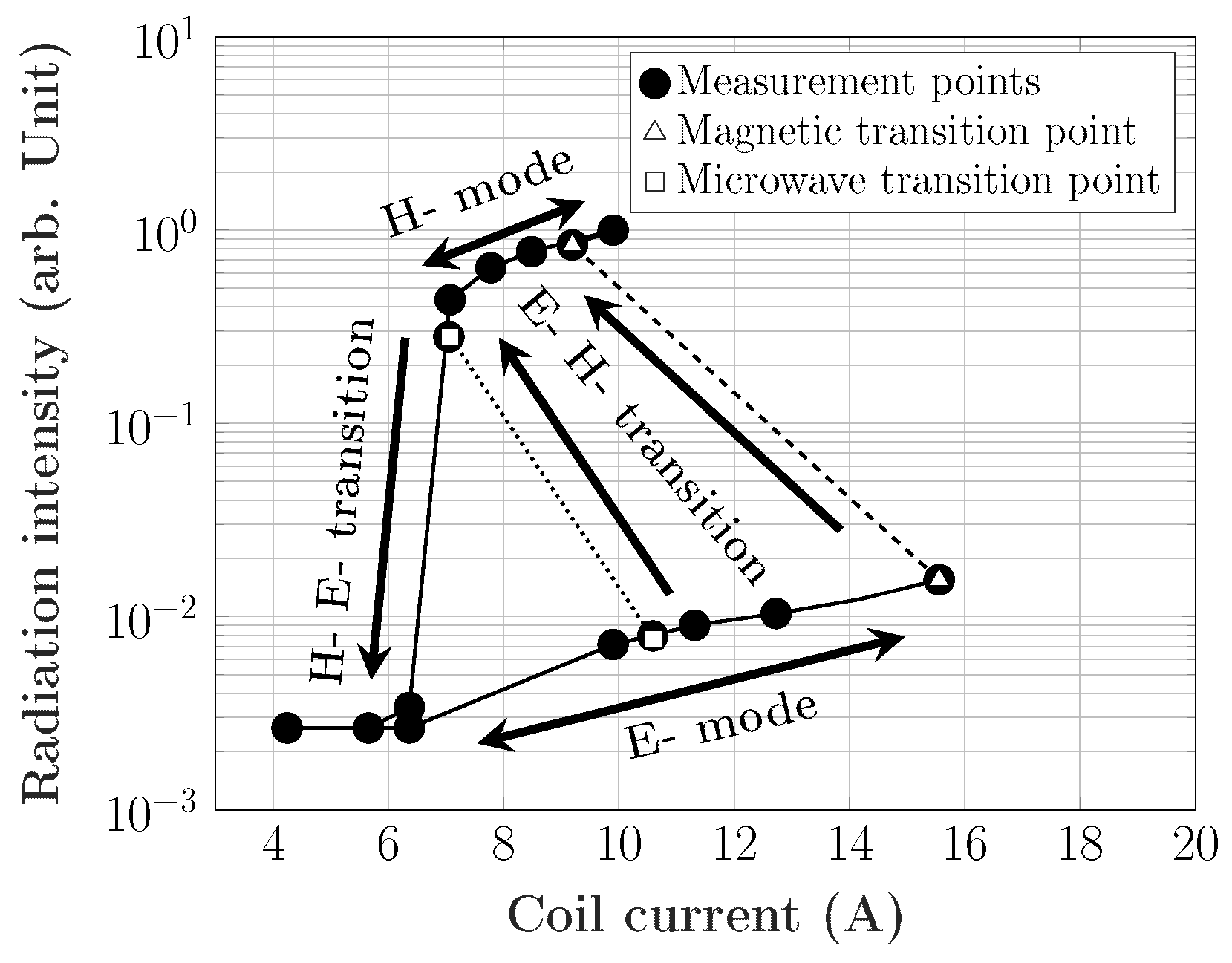

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Denk, F.; Haehre, K.; Simon, C.; Eizaguirre, S.; Heidinger, M.; Kling, R.; Heering, W. 25 kW high power resonant inverter operating at 2.5 MHz based on SiC SMD phase-leg modules. In Proceedings of the PCIM Europe 2018; International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuernberg, Germany, 5–7 June 2018. [Google Scholar]

- Burm, K. Breakdown magnetic field in an inductively coupled plasma. Phys. Lett. A 2008, 372, 6280–6283. [Google Scholar] [CrossRef]

- BURM, K.T.A.L. Breakdown minimum in magnetic field-driven metal plasmas. J. Plasma Phys. 2011, 77, 675–678. [Google Scholar] [CrossRef]

- BURM, K.T.A.L. Paschen curves for metal plasmas. J. Plasma Phys. 2012, 78, 199–202. [Google Scholar] [CrossRef]

- Kortshagen, U.; Gibson, N.D.; Lawler, J.E. On the E–H mode transition in RF inductive discharges. J. Phys. D Appl. Phys. 1996, 29, 1224–1236. [Google Scholar] [CrossRef]

- BURM, K.T.A.L. The electronic identity of inductive and capacitive plasmas. J. Plasma Phys. 2008, 74, 155–161. [Google Scholar] [CrossRef]

- Lieberman, M.A.; Lichtenberg, A.J. Principles of Plasma Discharges and Materials Processing, 2nd ed.; Wiley-Interscience: Hoboken, NJ, USA, 2005. [Google Scholar] [CrossRef]

- COMSOL. Multiphysics V. 5.4; COMSOL AB: Stockholm, Sweden. Available online: www.comsol.com (accessed on 25 June 2019).

- COMSOL. Plasma Module User’s Guide; COMSOL AB: Stockholm, Sweden, 2019; Available online: https://www.doc.comsol.com/5.4/doc/com.comsol.help.plasma/PlasmaModuleUsersGuide.pdf (accessed on 25 June 2019).

- SIGLO Database. Available online: www.lxcat.net (accessed on 25 April 2019).

- TRINITI Database. Available online: www.lxcat.net (accessed on 25 April 2019).

- Lee, M.H.; Chung, C.W. On the E to H and H to E transition mechanisms in inductively coupled plasma. Phys. Plasmas 2006, 13, 063510. [Google Scholar] [CrossRef]

- Turner, M.M.; Lieberman, M.A. Hysteresis and the E-to-H transition in radiofrequency inductive discharges. Plasma Sources Sci. Technol. 1999, 8, 313–324. [Google Scholar] [CrossRef]

| No. | Process | Reaction | (eV) |

|---|---|---|---|

| 1 | Elastic | ||

| 2 | Excitation | 8.31 | |

| 3 | Superelastic collision | −8.31 | |

| 4 | Ionization | 12.1 | |

| 5 | Step-wise ionization | 3.8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gehring, T.; Jin, Q.; Denk, F.; Eizaguirre, S.; Karcher, D.; Kling, R. Reducing the Transition Hysteresis of Inductive Plasmas by a Microwave Ignition Aid. Plasma 2019, 2, 341-347. https://doi.org/10.3390/plasma2030026

Gehring T, Jin Q, Denk F, Eizaguirre S, Karcher D, Kling R. Reducing the Transition Hysteresis of Inductive Plasmas by a Microwave Ignition Aid. Plasma. 2019; 2(3):341-347. https://doi.org/10.3390/plasma2030026

Chicago/Turabian StyleGehring, Tim, Qihao Jin, Fabian Denk, Santiago Eizaguirre, David Karcher, and Rainer Kling. 2019. "Reducing the Transition Hysteresis of Inductive Plasmas by a Microwave Ignition Aid" Plasma 2, no. 3: 341-347. https://doi.org/10.3390/plasma2030026

APA StyleGehring, T., Jin, Q., Denk, F., Eizaguirre, S., Karcher, D., & Kling, R. (2019). Reducing the Transition Hysteresis of Inductive Plasmas by a Microwave Ignition Aid. Plasma, 2(3), 341-347. https://doi.org/10.3390/plasma2030026