Laser-Based Powder Bed Fusion of Copper Powder on Aluminum Nitride Ceramics for Power Electronic Applications

Abstract

1. Introduction

| Property | AlN | Al2O3 | Si3N4 |

|---|---|---|---|

| Thermal conductivity | 170 W/m K | 24 W/m K | 90 W/m K |

| Coefficient of thermal expansion (CTE) | 4.7 ppm/K | 6.8 ppm/K | 2.5 ppm/K |

| Flexural strength at 20 °C | >320 MPa | 300–470 MPa | 850 MPa |

| Dielectric strength | >15 kV/mm | 17–30 kV/mm | 19 kV/mm |

2. Fundamentals and State of the Art

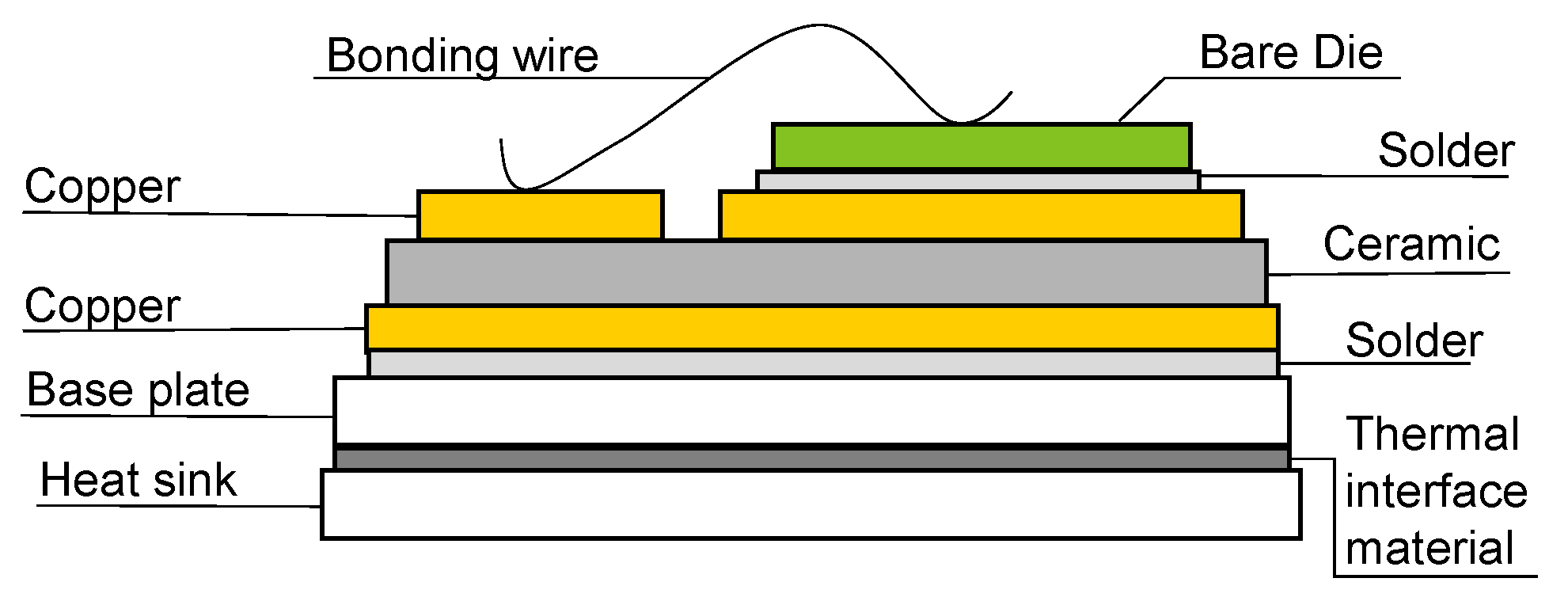

2.1. Power Electronics

2.2. Properties of Aluminum Nitride Ceramics

2.3. Laser-Based Powder Bed Fusion

3. Materials, Methods, and Equipment

3.1. AlN Ceramics and Cu Powder

3.2. PBF-LB/M Machine

3.3. Qualification

4. Results and Discussion

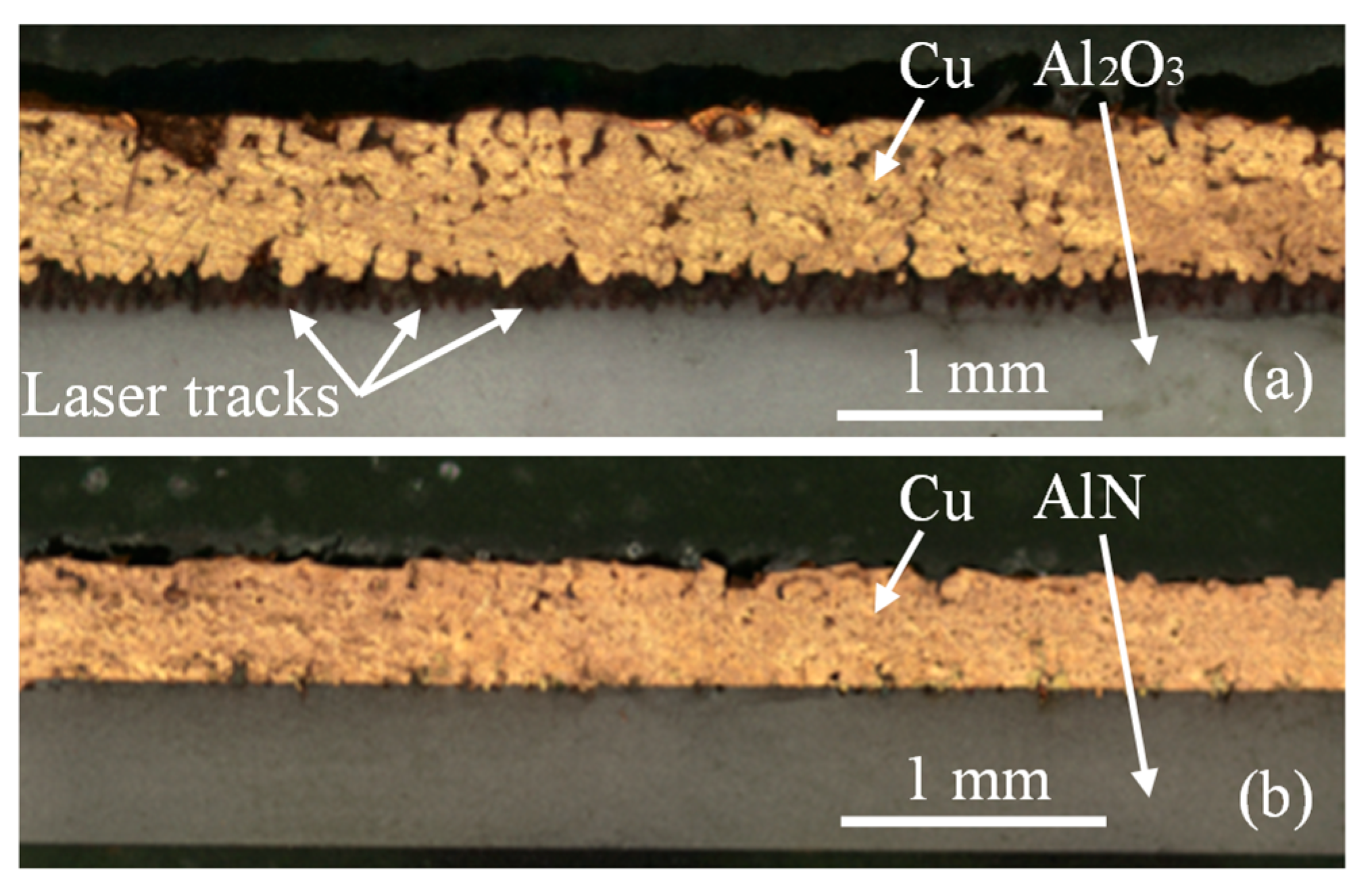

4.1. Parameter Study of PBF-LB/M with Cu on AlN

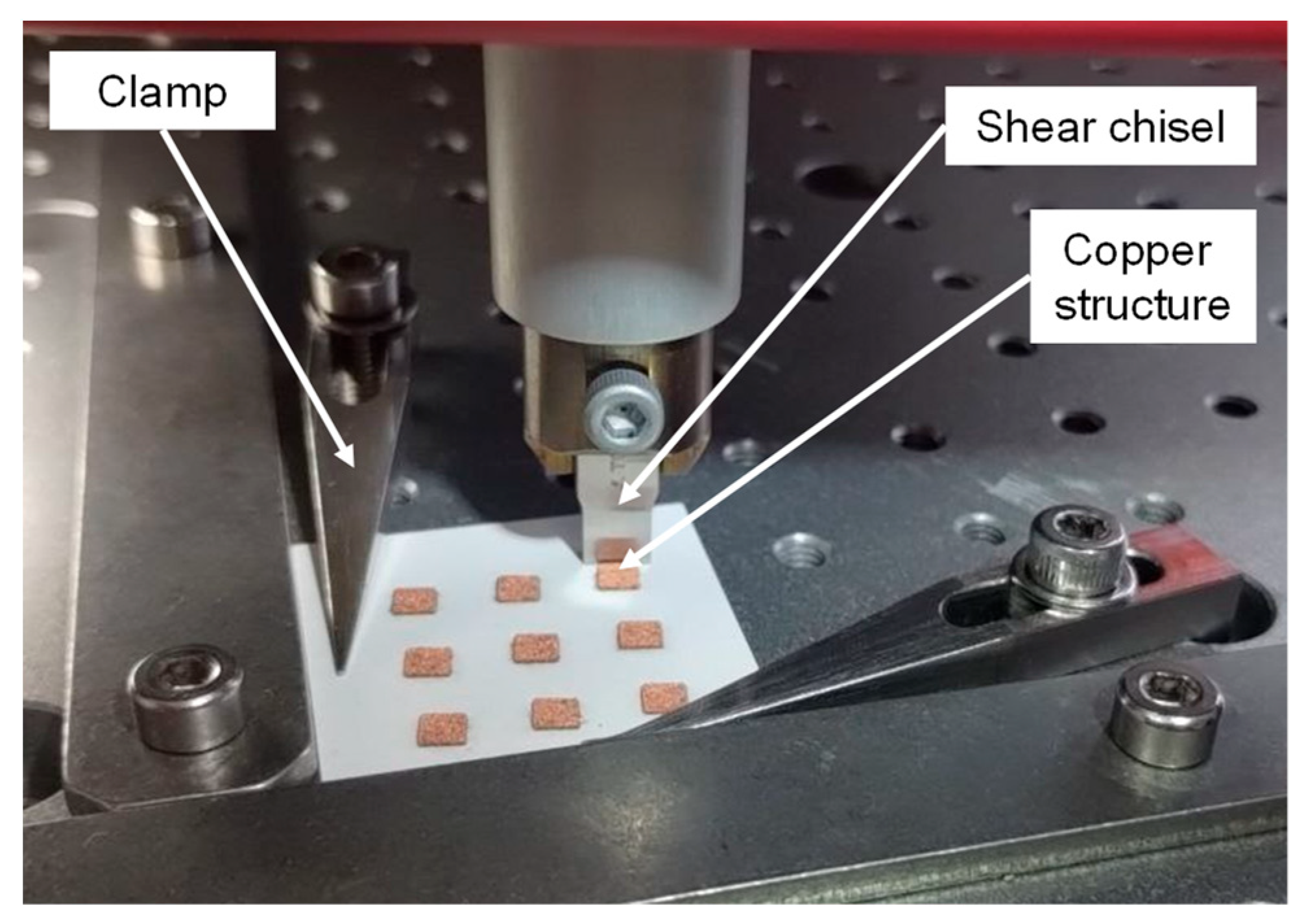

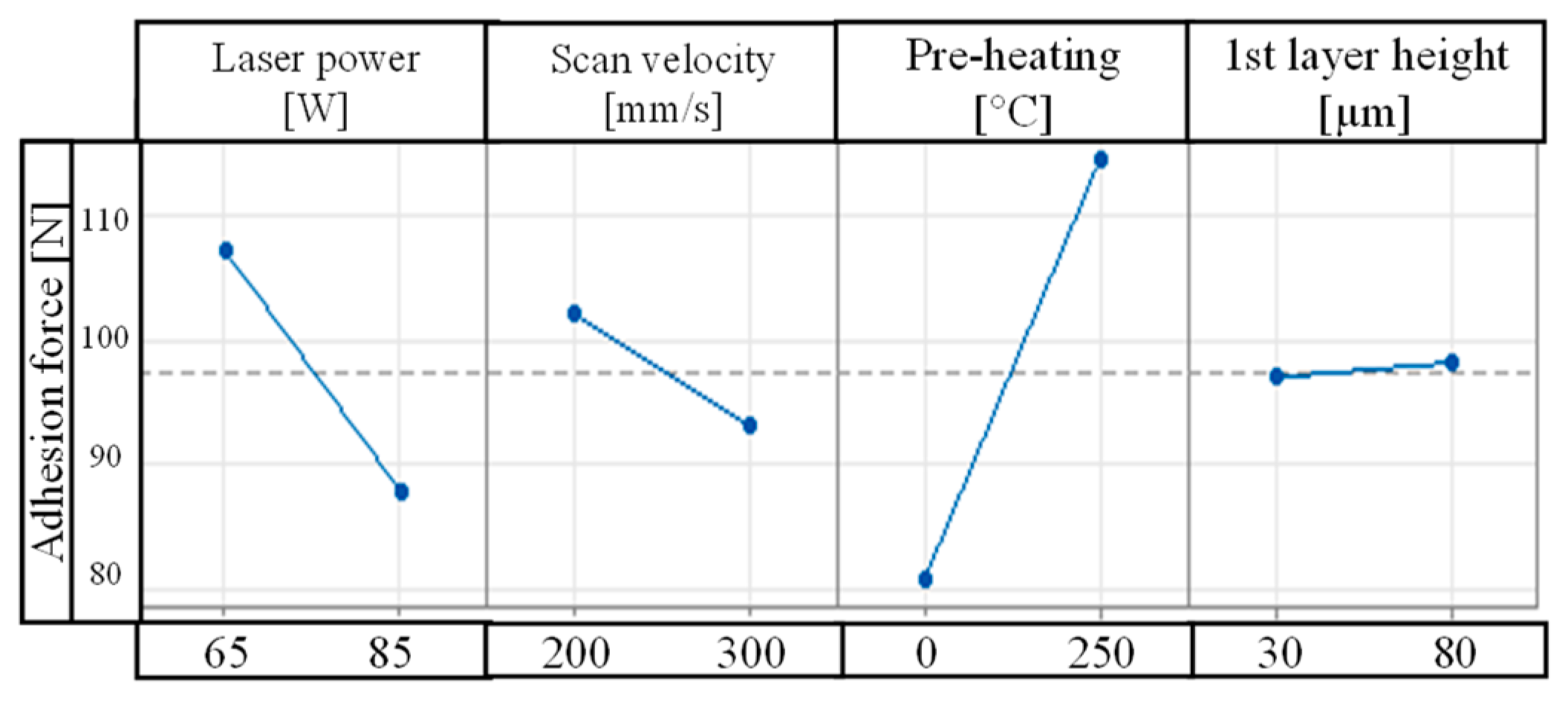

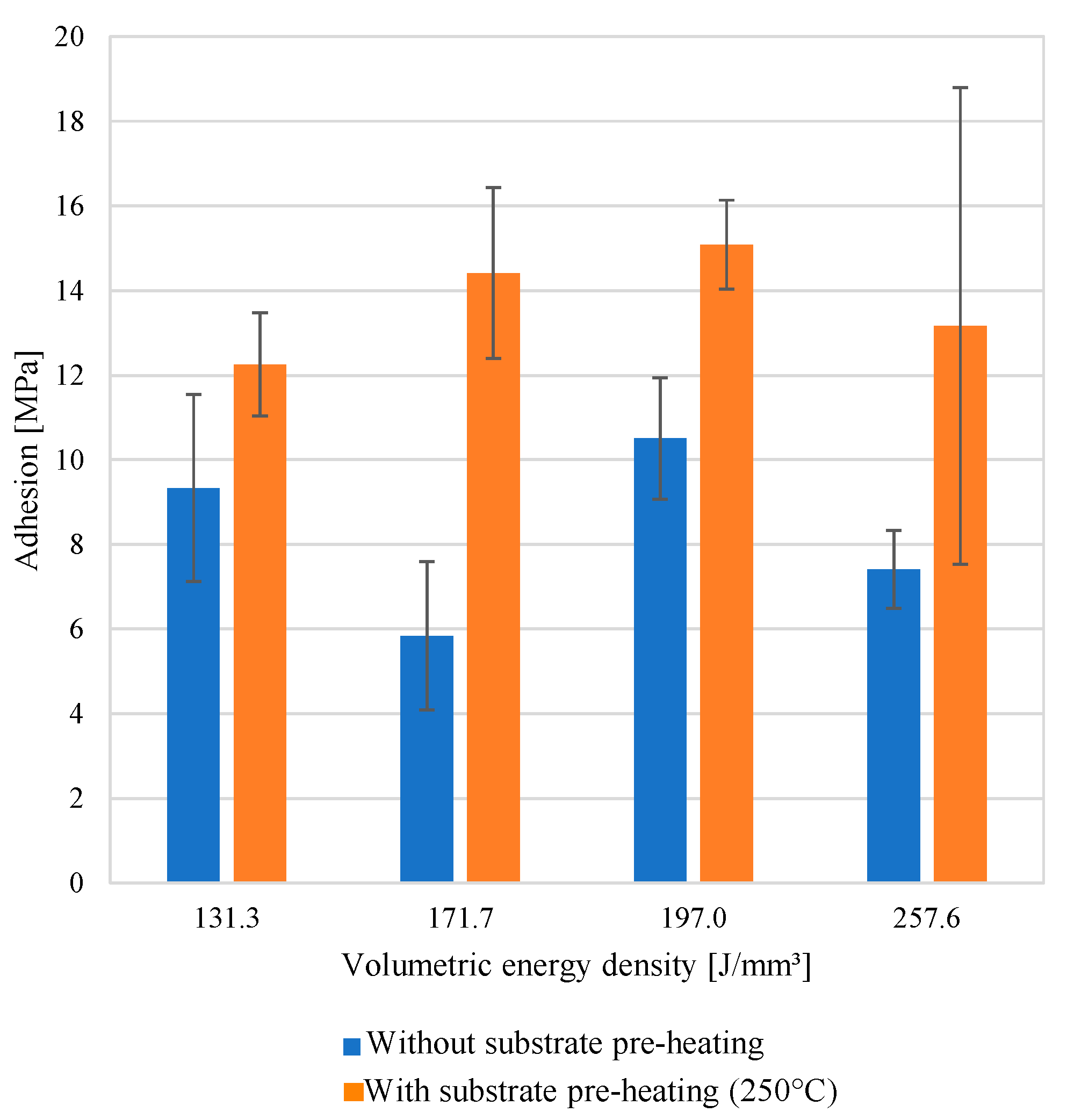

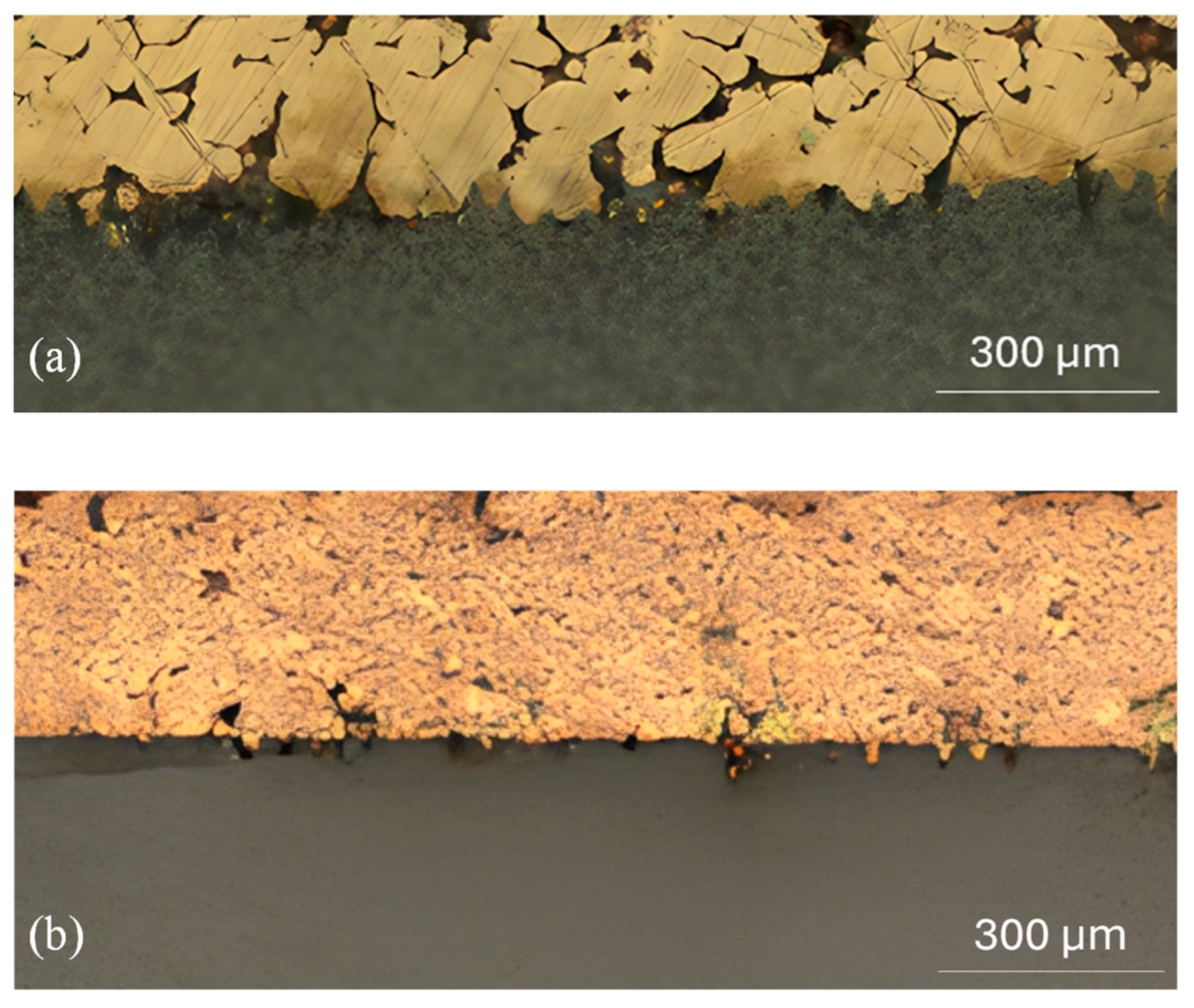

4.2. Adhesion

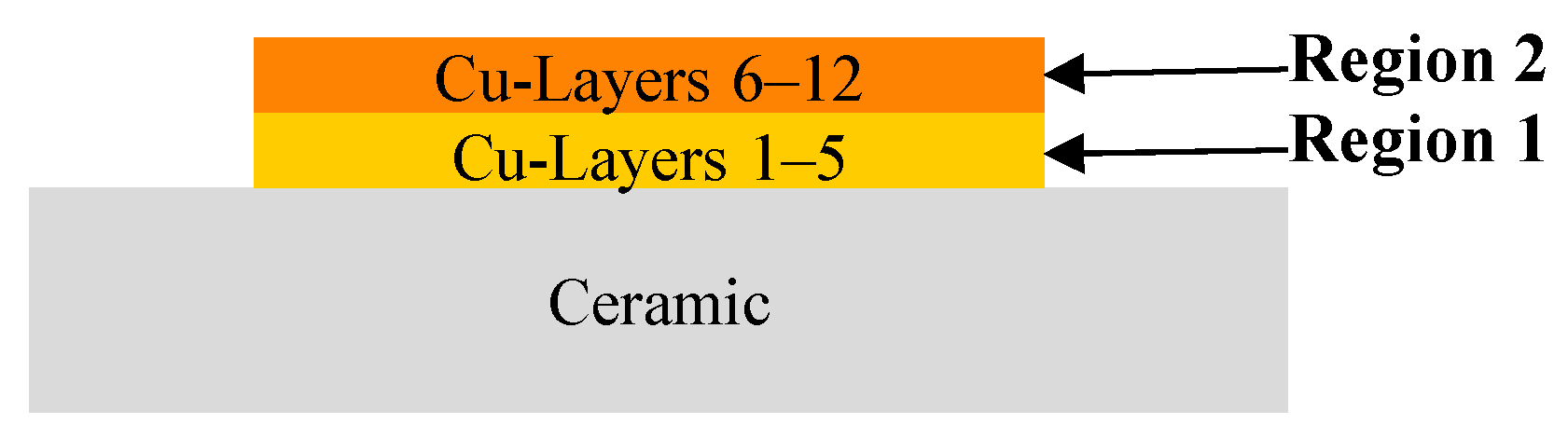

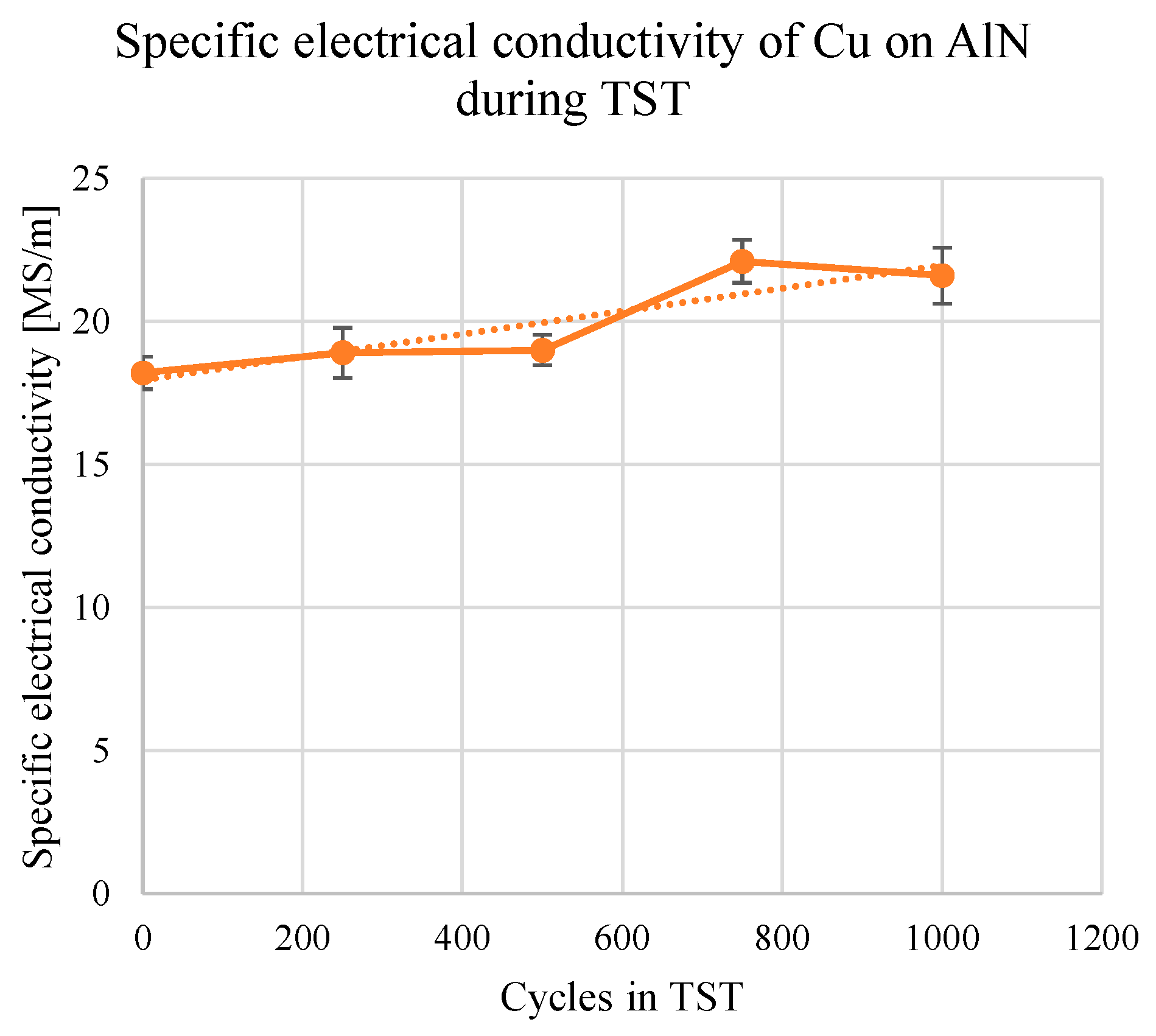

4.3. Specific Electrical Conductivity

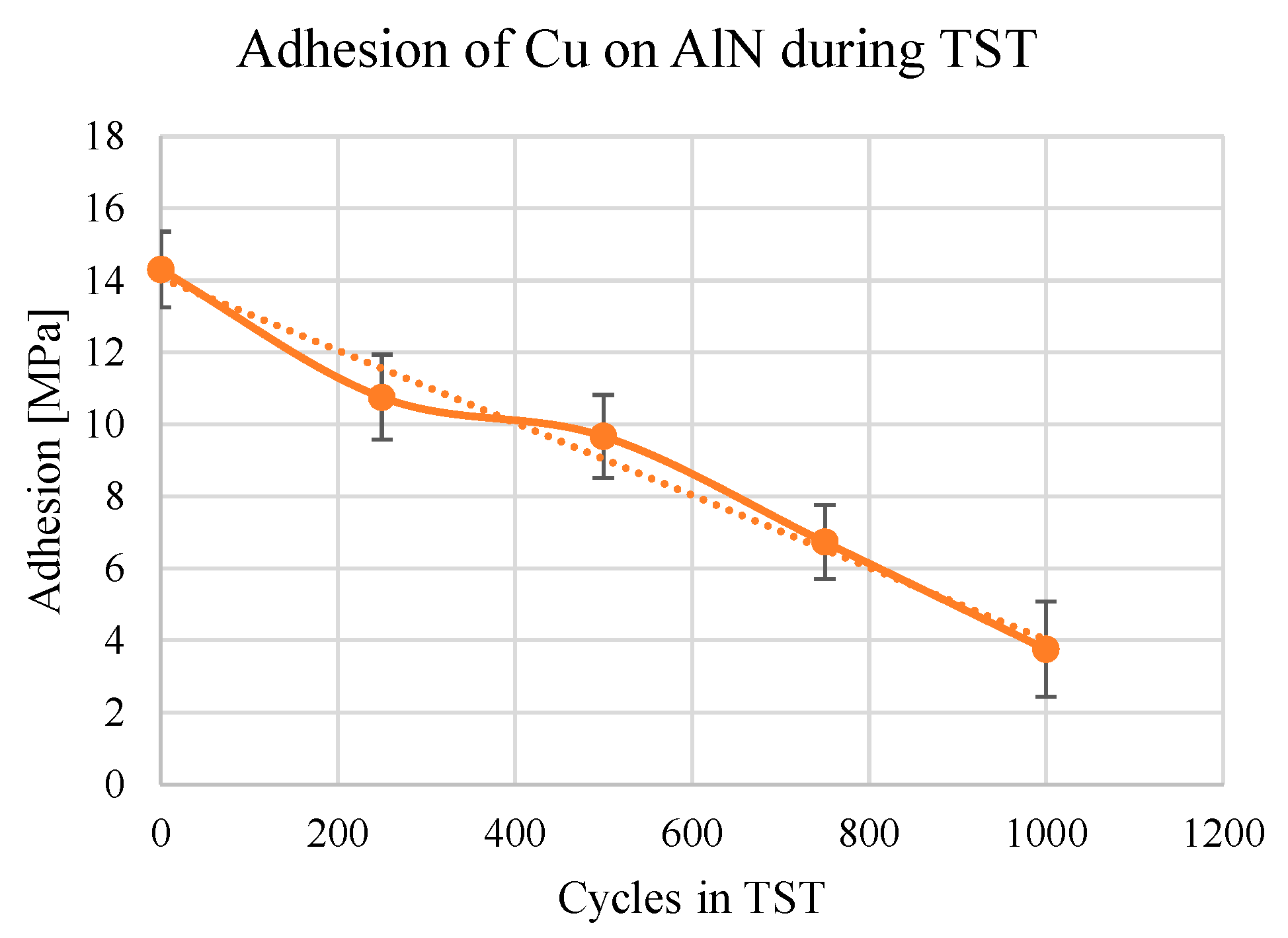

4.4. Reliability

5. Summary and Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lopera, L.; Rodriguez, R.; Yakout, M.; Elbestawi, M.; Emadi, A. Current And Potential Applications Of Additive Manufacturing For Power Electronics. IEEE Open J. Power Electron. 2021, 2, 33–42. [Google Scholar] [CrossRef]

- Yang, Y.; Dorn-Gomba, L.; Rodriguez, R.; Mak, C.; Emadi, A. Automotive Power Module Packaging: Current Status and Future Trends. IEEE Access 2020, 8, 160126–160144. [Google Scholar] [CrossRef]

- Khazaka, R.; Mendizabal, L.; Henry, D.; Hanna, R. Survey of High-Temperature Reliability of Power Electronics Packaging Components. IEEE Trans. Power Electron. 2015, 30, 2456–2464. [Google Scholar] [CrossRef]

- CeramTec. Advanced Ceramics for Electronic Applications. Material Properties of Rubalit, Alunit, Zirkolit and Sinalit. 2024. Available online: https://www.ceramtec-industrial.com/fileadmin/user_upload/Corporate/11_Downloads/06_Electronic_Heatsinks/Datasheet_Electronic_Applications.pdf (accessed on 30 May 2025).

- Kumar, A.; Moradour, M.; Losito, M.; Franke, W.-T.; Ramasamy, S.; Baccoli, R.; Gatto, G. Wide Band Gap Devices and Their Application in Power Electronics. Energies 2022, 15, 9172. [Google Scholar] [CrossRef]

- Rafin, S.; Ahmed, R.; Mohammed, O. Wide Band Gap Semiconductor Devices for Power Electronic Converters. In Proceedings of the 2023 Fourth International Symposium on 3D Power Electronics Integration and Manufacturing (3D-PEIM), Miami, FL, USA, 1–3 February 2023; pp. 1–8. [Google Scholar] [CrossRef]

- Hecht, C.; Ockel, M.; Stoll, T.; Franke, J. Fabrication of metal-ceramic substrates by laser powder bed fusion using a high-power green laser and high temperature preheating. In Proceedings of the Laser 3D Manufacturing XI27, San Francisco, CA, USA, 27 January–1 February 2024; ISBN 9781510670129. [Google Scholar]

- Syed-Khaja, A.; Schwarz, D.; Franke, J. Advanced substrate and packaging concepts for compact system integration with additive manufacturing technologies for high temperature applications. In Proceedings of the 2015 IEEE CPMT Symposium Japan (ICSJ), Kyoto, Japan, 9–11 November 2015; pp. 156–159, ISBN 978-1-4799-8814-3. [Google Scholar]

- Stoll, T. Laser Powder Bed Fusion von Kupfer auf Aluminiumoxid-Keramiken; FAU University Press: Erlangen, Germany, 2023; ISBN 978-3-96147-632-9. [Google Scholar]

- Rogers Corp.; CURAMIK (R). curamik (R) Ceramic Substrates. Technical Datasheet. 2019. Available online: https://rogerscorp.com/-/media/project/rogerscorp/documents/advanced-electronics-solutions/english/product-information/curamik-ceramic-substrates-product-information-and-data-sheet.pdf (accessed on 26 May 2025).

- Specovius, J. Grundkurs Leistungselektronik. Bauelemente, Schaltungen, Systeme. 7; Springer: Wiesbaden, Germany, 2015; ISBN 978-3658033088. [Google Scholar]

- Eustathopoulos, N.; Hodaj, F.; Kozlova, O. The wetting process in brazing. In Advances in Brazing; Elsevier: Amsterdam, The Netherlands, 2013; pp. 3–30. ISBN 9780857094230. [Google Scholar]

- Hromadka, K.; Stulik, J.; Reboun, J.; Hamacek, A. DBC Technology for Low Cost Power Electronic Substrate Manufacturing. Procedia Eng. 2014, 69, 1180–1183. [Google Scholar] [CrossRef]

- Chua, S.; Siow, K.S. Microstructural studies and bonding strength of pressureless sintered nano-silver joints on silver, direct bond copper (DBC) and copper substrates aged at 300 °C. J. Alloys Compd. 2016, 687, 486–498. [Google Scholar] [CrossRef]

- Schmenger, M.; Meisser, M.; Hamilton, D.; Leyrer, B.; Bernd, M.; Mawby, P. Highly integrated power modules based on copper thick-film-on-DCB for high frequency operation of SiC semiconductors—Design and manufacture. In Proceedings of the 2015, 17th European Conference on Power Electronics and Applications (EPE’15 ECCE-Europe), Geneva, Switzerland, 8–10 September 2015; pp. 1–8. [Google Scholar] [CrossRef]

- Durand, C.; Klingler, M.; Coutellier, D.; Naceur, H. Power Cycling Reliability of Power Module: A Survey. IEEE Trans. Device Mater. Reliab. 2016, 16, 80–97. [Google Scholar] [CrossRef]

- DIN EN ISO/ASTM 52900; Additive Fertigung. DIN Deutsches Institut fuer Normung e.V. Beuth Verlag GmbH: Berlin, Germany, 2022.

- Colopi, M.; Caprio, L.; Demir, A.G.; Previtali, B. Selective laser melting of pure Cu with a 1 kW single mode fiber laser. Procedia CIRP 2018, 74, 59–63. [Google Scholar] [CrossRef]

- Ikeshoji, T.-T.; Nakamura, K.; Yonehara, M.; Imai, K.; Kyogoku, H. Selective Laser Melting of Pure Copper. JOM 2018, 70, 396–400. [Google Scholar] [CrossRef]

- Jadhav, S.D.; Dadbakhsh, S.; Goossens, L.; Kruth, J.-P.; Humbeeck, J.V.; Vanmeensel, K. Influence of selective laser melting process parameters on texture evolution in pure copper. J. Mater. Process. Technol. 2019, 270, 47–58. [Google Scholar] [CrossRef]

- Kaden, L.; Matthäus, G.; Ramm, R.; Ullsperger, T.; Seyfarth, B.; Nolte, S. Additive manufacturing of pure copper using ultrashort laser pulses. In Proceedings of the Laser 3D Manufacturing VI, San Francisco, CA, USA, 2–7 February 2019; ISBN 9781510624603. [Google Scholar]

- Shibata, T.; Tsukamoto, M.; Sato, Y.; Masuno, S. Effect of input energy on densification for pure copper fabricated by SLM with blue diode laser. In Proceedings of the Laser 3D Manufacturing VI, San Francisco, CA, USA, 2–7 February 2019; ISBN 9781510624603. [Google Scholar]

- Stoll, T.; Kirstein, M.; Franke, J. A novel approach of copper-ceramic-joints manufactured by selective laser melting. In Proceedings of the Material Technologies and Applications to Optics, Structures, Components, and Sub-Systems IV, San Francisco, CA, USA, 11–15 August 2019; ISBN 9781510628953. [Google Scholar]

- Hecht, C.; Schueller, D.; Utsch, D.; Stoll, T.; Franke, J. Investigations on processing copper-titanium powder blends via PBF-LB/M. In Proceedings of the Lasers in Manufacturing Conference, Munich, Germany, 26–29 June 2023. [Google Scholar]

- Hecht, C.; Schadow, E.; Sprenger, M.; Häußler, F.; Stoll, T.; Franke, J. Additive Metallization of Alumina with Copper-Titanium Powder Blends for Power Electronic Applications. In Proceedings of the 2023 24th European Microelectronics and Packaging Conference & Exhibition (EMPC), Cambridge, UK, 11–14 September 2023; pp. 1–6, ISBN 978-0-9568086-9-1. [Google Scholar]

- Hecht, C.; Sprenger, M.; Franke, J. Laser powder bed fusion of titanium alloyed copper powder for power electronic substrates. In Proceedings of the 2024 47th International Spring Seminar on Electronics Technology (ISSE), Prague, Czech Republic, 15–19 May 2024; pp. 1–6, ISBN 979-8-3503-8547-2. [Google Scholar]

- Wallis, C.; Buchmayr, B.; Bermejo, R.; Supancic, P. Fabrication of 3D metal-ceramic (Al-AlN) architectures using laser-powder bed fusion process. Addit. Manuf. 2021, 38, 101799. [Google Scholar] [CrossRef]

- Werdecker, W.; Aldinger, F. Aluminum Nitride-An Alternative Ceramic Substrate for High Power Applications in Microcircuits. IEEE Trans. Compon. Hybrids Manuf. Technol. 1984, 7, 399–404. [Google Scholar] [CrossRef]

- Harris, J.H. Sintered aluminum nitride ceramics for high-power electronic applications. JOM 1998, 50, 56–60. [Google Scholar] [CrossRef]

- Hickman, A.L.; Chaudhuri, R.; Bader, S.J.; Nomoto, K.; Li, L.; Hwang, J.C.M.; Xing, H.G.; Jena, D. Next generation electronics on the ultrawide-bandgap aluminum nitride platform. Semicond. Sci. Technol. 2021, 36, 044001. [Google Scholar] [CrossRef]

- DIN EN 15340; Thermisches Spritzen—Bestimmung des Scherbeanspruchungs widerstandes bei thermisch gespritzten Schichten. DIN Deutsches Institut fuer Normung e.V. Beuth Verlag GmbH: Berlin, Germany, 2007.

- IEC 60068-2-14; Umweltpruefungen. DIN Deutsches Institut fuer Normung e.V. Beuth Verlag GmbH: Berlin, Germany, 2000.

- Utsch, D.; Häußler, F.; Sprenger, M.; Zirn, J.; Franke, J. Reliability of Piezojet-Printed Conductive Lines on Alumina Substrates Produced by Fused Filament Fabrication. In Proceedings of the 2023 15th International Congress Mechatronic Integration Discourse (MID), Amberg, Germany, 21–22 June 2023; pp. 1–6, ISBN 979-8-3503-7473-5. [Google Scholar]

- Dupont, L.; Lefebvre, S.K.; Bontemps, S. Evaluation of Substrate Technologies under High Temperature Cycling. In Proceedings of the International Conference on Integrated Power Systems, Naples, Italy, 7–9 June 2006. [Google Scholar]

- Mitic, G.; Beinert, R.; Klofac, P.; Schultz, H.J.; Lefranc, G. Reliability of AlN substrates and their solder joints in IGBT power modules. Microelectron. Reliab. 1999, 39, 1159–1164. [Google Scholar] [CrossRef]

- Lee, J.W.; Radu, I.; Alexe, M. Oxidation behavior of AlN substrate at low temperature. J. Mater. Sci. Mater. Electron. 2002, 13, 131–137. [Google Scholar] [CrossRef]

- Wei, X.; Xu, H.; Zhan, J.; Zhang, H.; Cao, Y.; Cui, S.; Tang, W. Comparative studies on microstructures, strengths and reliabilities of two types of AlN direct bonding copper substrates. Ceram. Int. 2018, 44, 18935–18941. [Google Scholar] [CrossRef]

- Yeh, C.-T.; Tuan, W.-H. Oxidation mechanism of aluminum nitride revisited. J. Adv. Ceram. 2017, 6, 27–32. [Google Scholar] [CrossRef]

| Factor | Laser Power [W] | Scan Velocity [mm/s] | Pre-Heating Temperature [°C] | First Layer Height [µm] |

|---|---|---|---|---|

| Level 1 | 65 | 200 | 0 | 30 |

| Level 2 | 85 | 300 | 250 | 80 |

| Factors | Laser Power [W] | Scan Velocity [mm/s] | VED [J/mm3] |

|---|---|---|---|

| Variant 1 | 65 | 300 | 131.3 |

| Variant 2 | 85 | 300 | 171.7 |

| Variant 3 | 65 | 200 | 197.0 |

| Variant 4 | 85 | 200 | 257.6 |

| Parameters | Laser Power [W] | Scan Velocity [mm/s] | [MS/m] |

|---|---|---|---|

| Layers 1–5 | 65 | 300 | - |

| Layers 6–12 (var. 1) | 100 | 300 | 18.7 |

| Layers 6–12 (var. 2) | 100 | 200 | 16.7 |

| Layers 6–12 (var. 3) | 120 | 300 | 18.2 |

| Var. 3 and tempering with 650 °C/8 h | 22.1 | ||

| Var. 3 and tempering with 850 °C/10 h | 31.3 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Utsch, D.; Turowski, T.; Hecht, C.; Thielen, N.; Ockel, M.; Franke, J.; Risch, F. Laser-Based Powder Bed Fusion of Copper Powder on Aluminum Nitride Ceramics for Power Electronic Applications. Ceramics 2025, 8, 105. https://doi.org/10.3390/ceramics8030105

Utsch D, Turowski T, Hecht C, Thielen N, Ockel M, Franke J, Risch F. Laser-Based Powder Bed Fusion of Copper Powder on Aluminum Nitride Ceramics for Power Electronic Applications. Ceramics. 2025; 8(3):105. https://doi.org/10.3390/ceramics8030105

Chicago/Turabian StyleUtsch, Daniel, Timo Turowski, Christoph Hecht, Nils Thielen, Manuela Ockel, Jörg Franke, and Florian Risch. 2025. "Laser-Based Powder Bed Fusion of Copper Powder on Aluminum Nitride Ceramics for Power Electronic Applications" Ceramics 8, no. 3: 105. https://doi.org/10.3390/ceramics8030105

APA StyleUtsch, D., Turowski, T., Hecht, C., Thielen, N., Ockel, M., Franke, J., & Risch, F. (2025). Laser-Based Powder Bed Fusion of Copper Powder on Aluminum Nitride Ceramics for Power Electronic Applications. Ceramics, 8(3), 105. https://doi.org/10.3390/ceramics8030105