Design and Analysis of Thermistors in Low Temperature Cofired Ceramics

Abstract

1. Introduction

Temperature Coefficient of Resistance

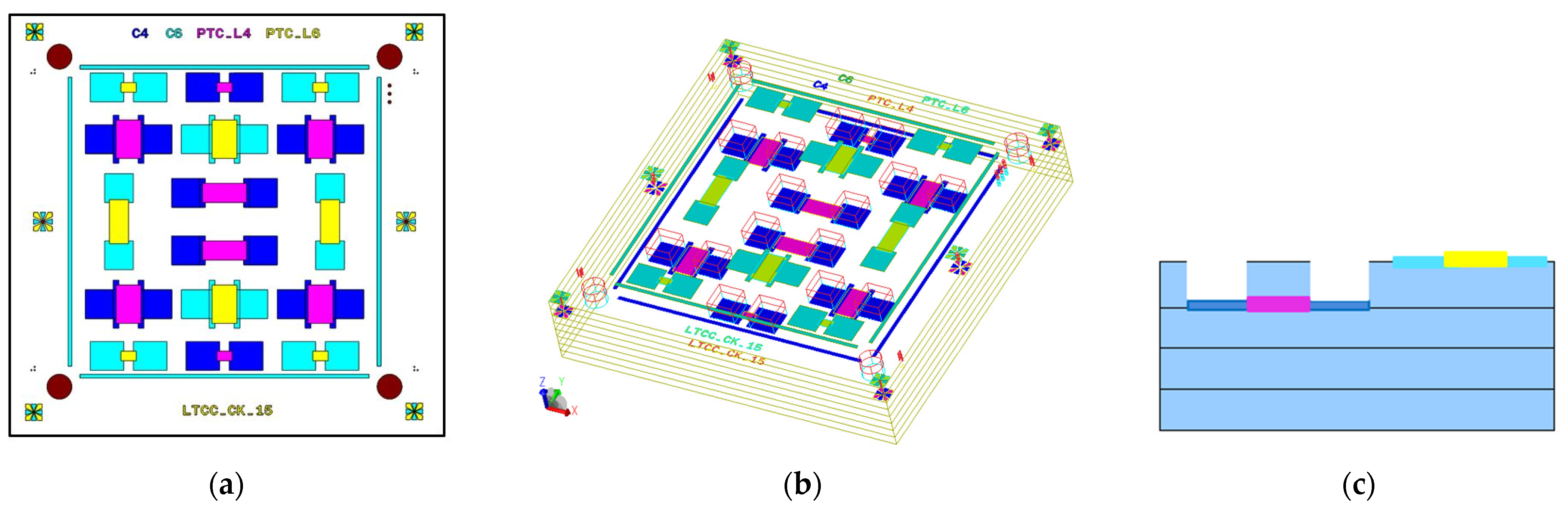

2. Materials and Methods

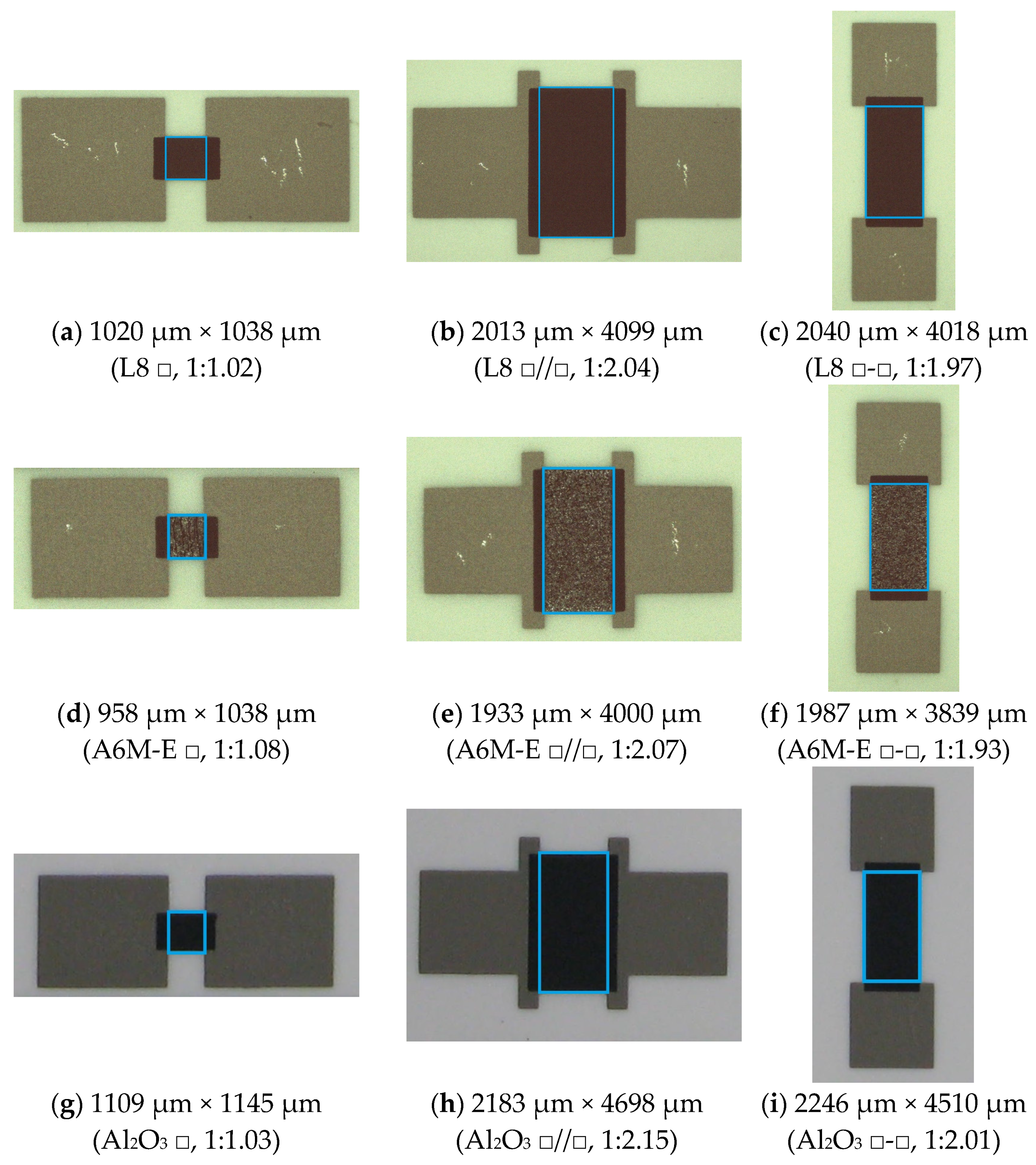

- 1 mm × 1 mm square (denoted □)

- 2 mm × 4 mm (i.e., two 2 mm × 2 mm squares in parallel, denoted □//□)

- 4 mm × 2 mm (i.e., two 2 mm × 2 mm squares in series, denoted □-□)

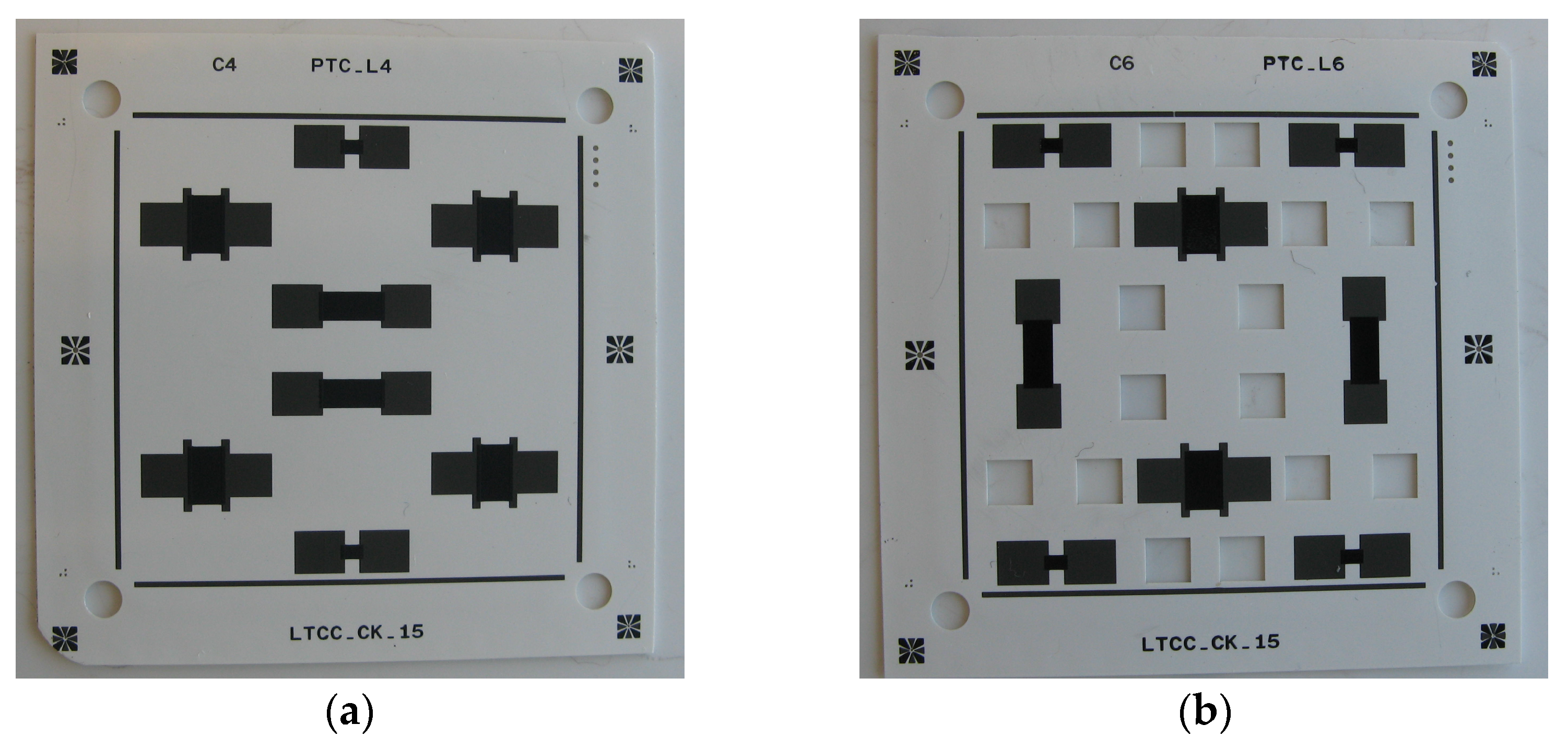

- Slitting and blanking;

- Cavity and alignment hole creation (1064 nm fiber laser, LEM2 from Laser Cheval, Marnay, France);

- Screen printing of terminals followed by leveling and drying (EKRA M2H screen printer, from EKRA Automatisierungssysteme GmbH, Bönnigheim‚ Germany);

- Screen printing of thermistors followed by leveling drying (EKRA M2H screen printer, from EKRA Automatisierungssysteme GmbH, Bönnigheim‚ Germany);

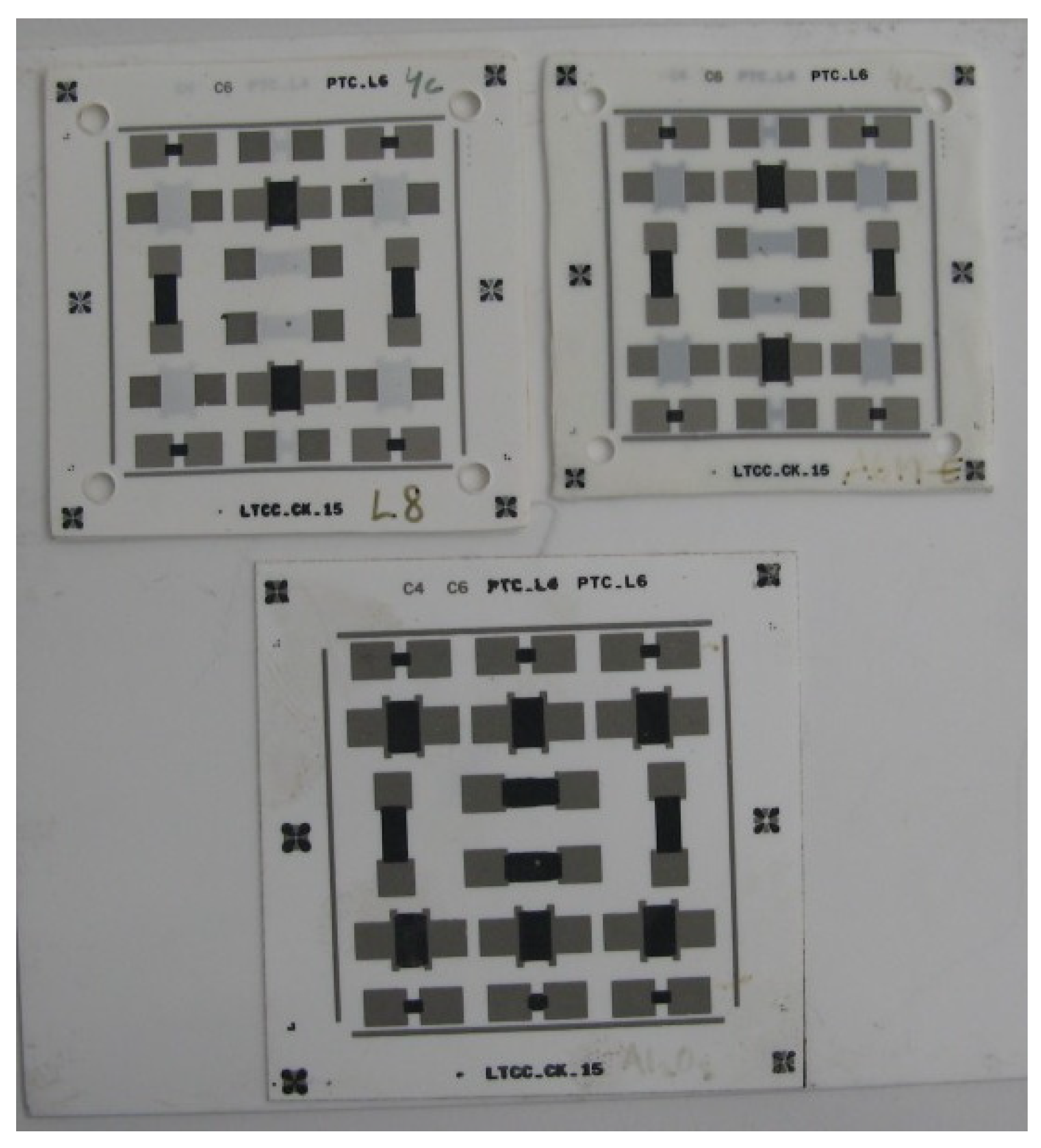

- Stacking (using sacrificial tape ESL49000, from ESL Electroscience, King of Prussia, Pennsylvania, USA, in the cavities);

- Lamination using a uniaxial press (Colorking, Fuzhou, China);

- Firing (Nabertherm programmable furnace from Nabertherm GmbH, Lilienthal, Germany).

3. Results

3.1. Dimensional Analysis

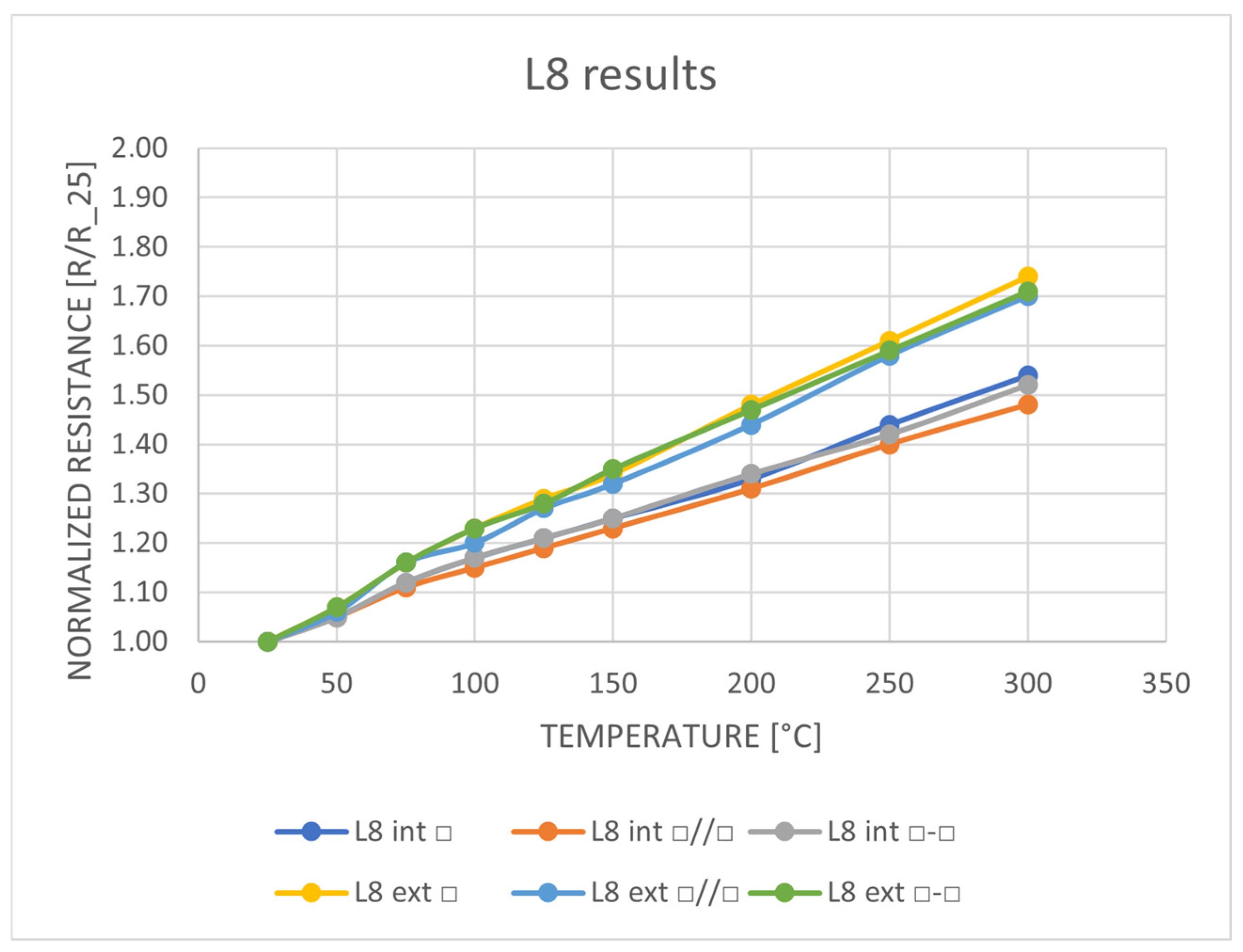

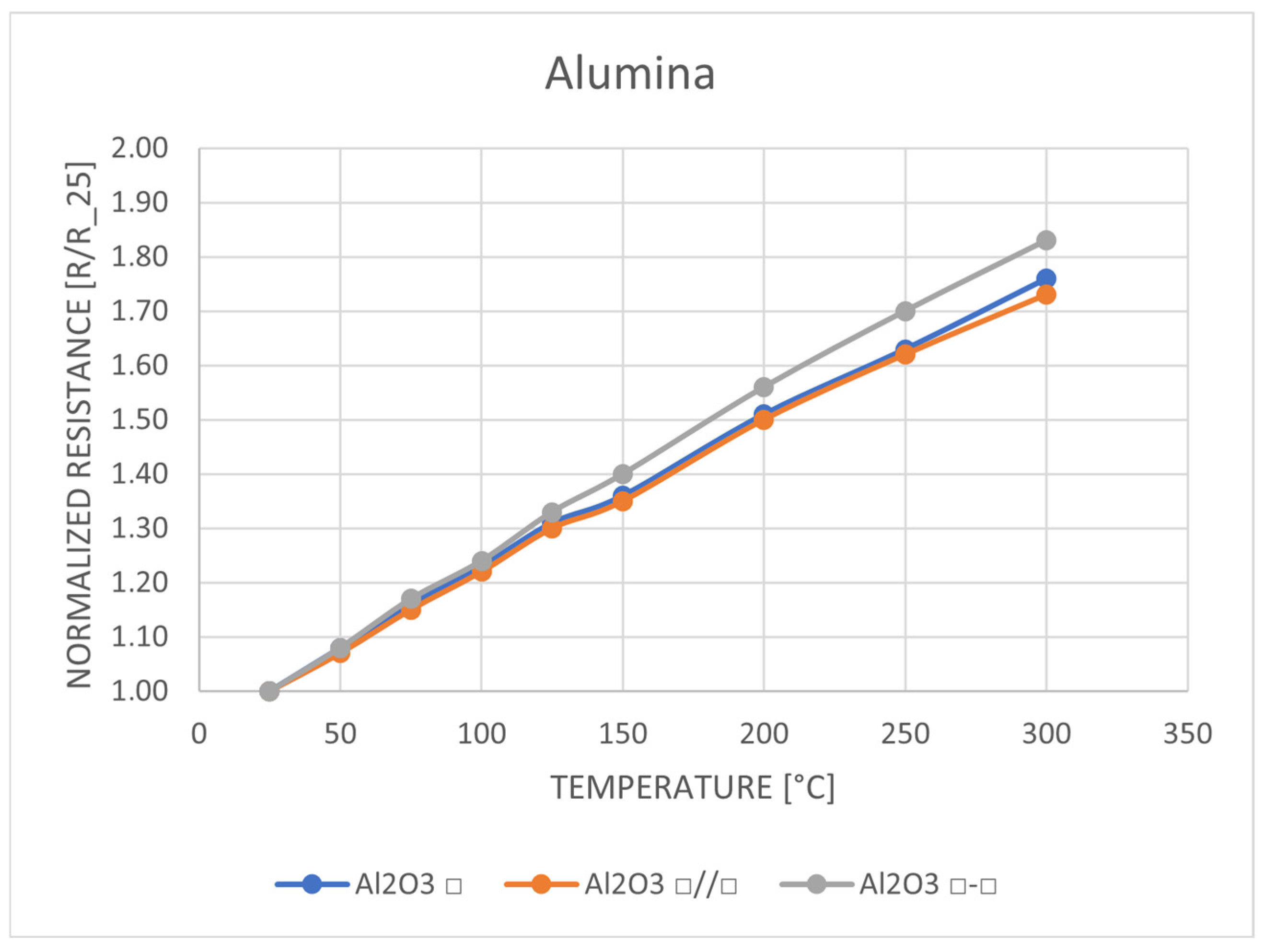

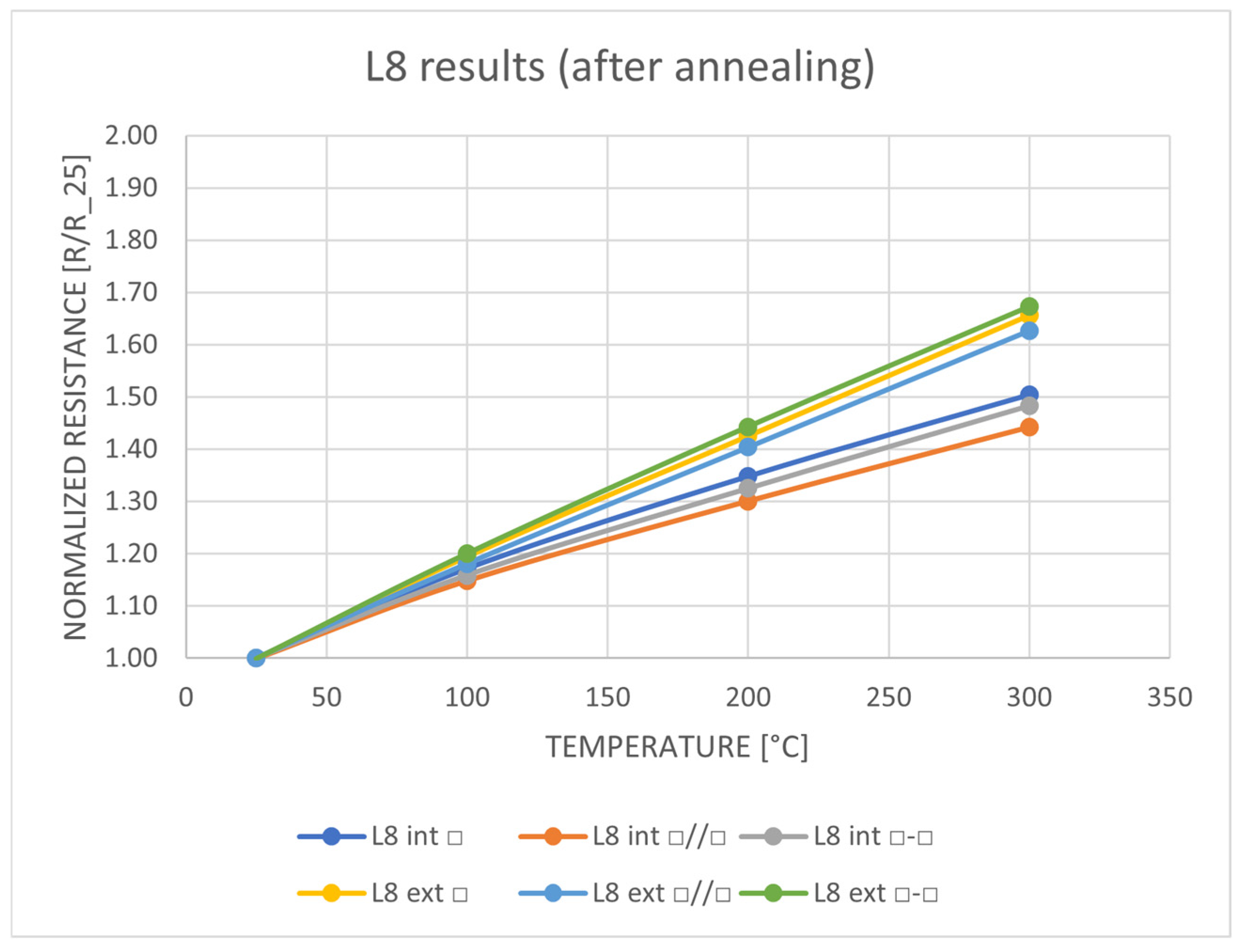

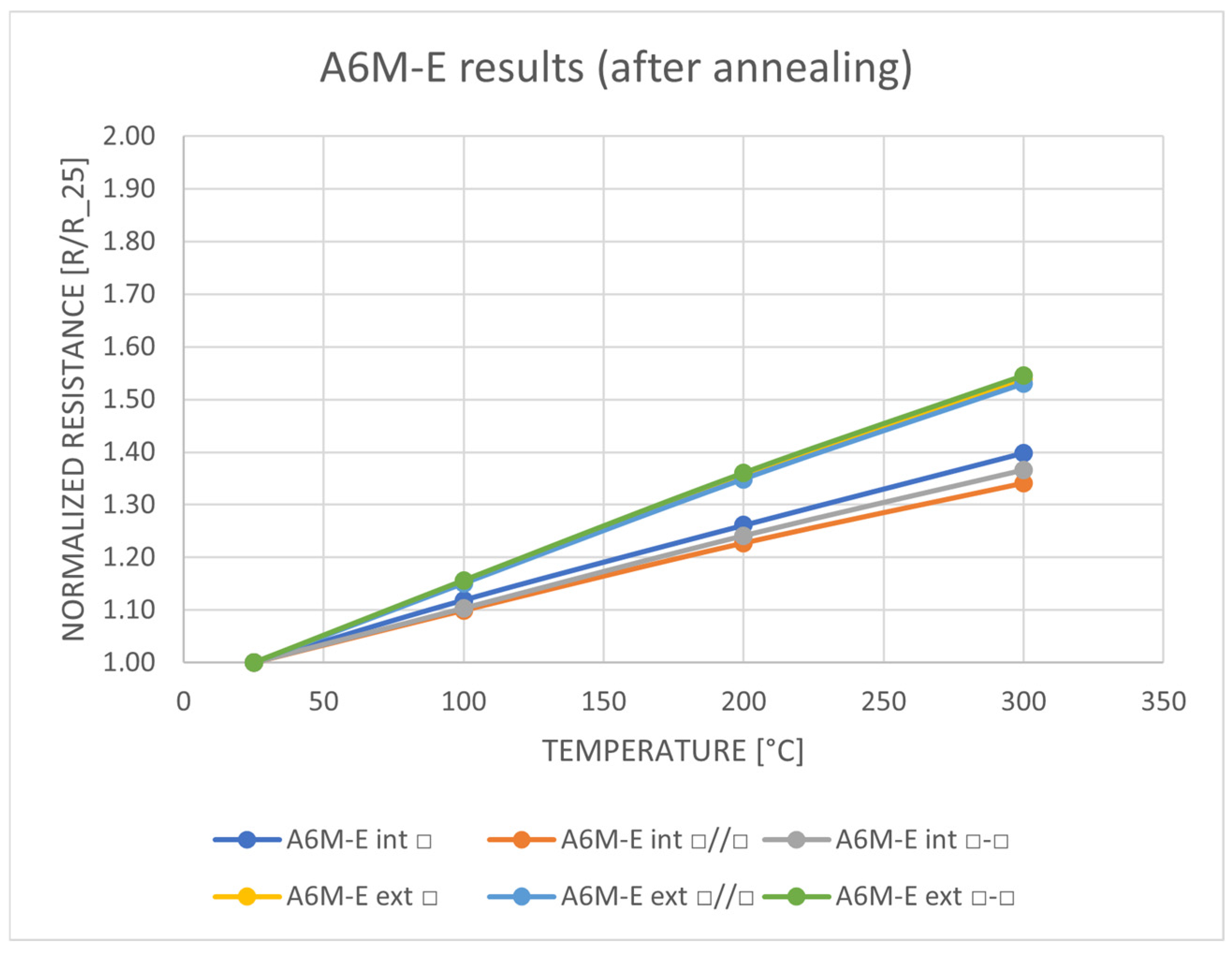

3.2. Resistance vs. Temperature

3.2.1. Results Before Annealing

3.2.2. Results After Annealing

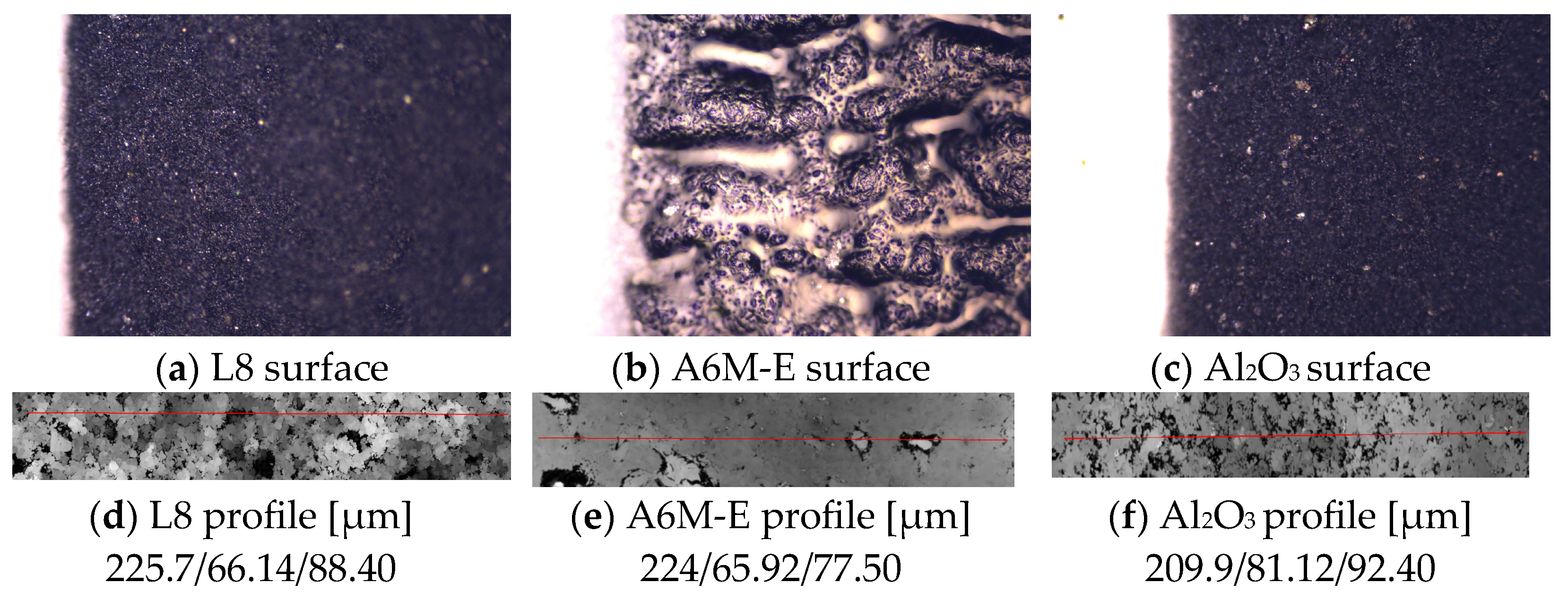

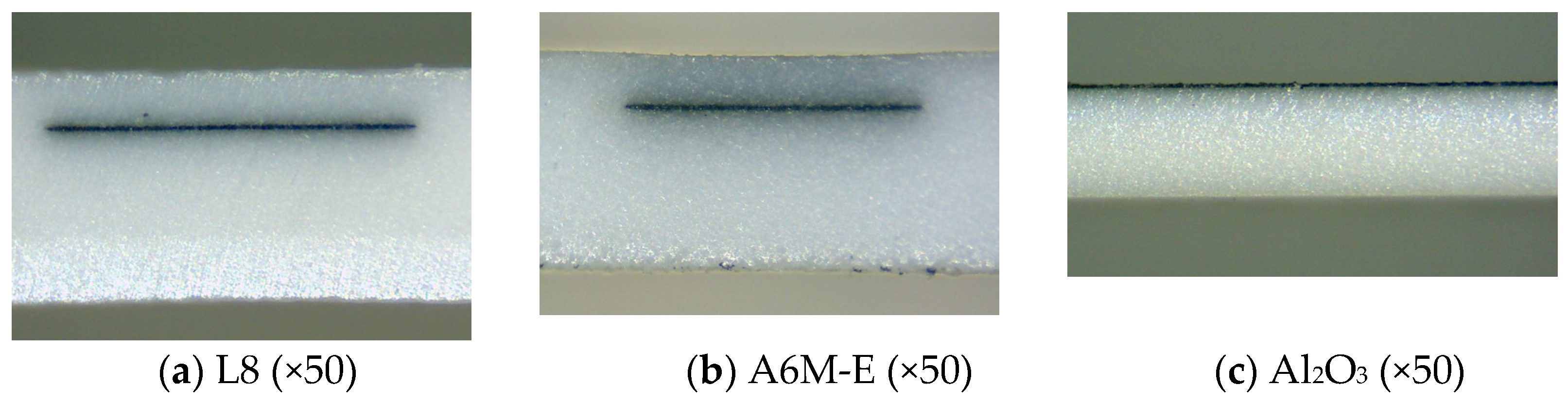

3.3. Delamination Check and Printed Thickness Measurement

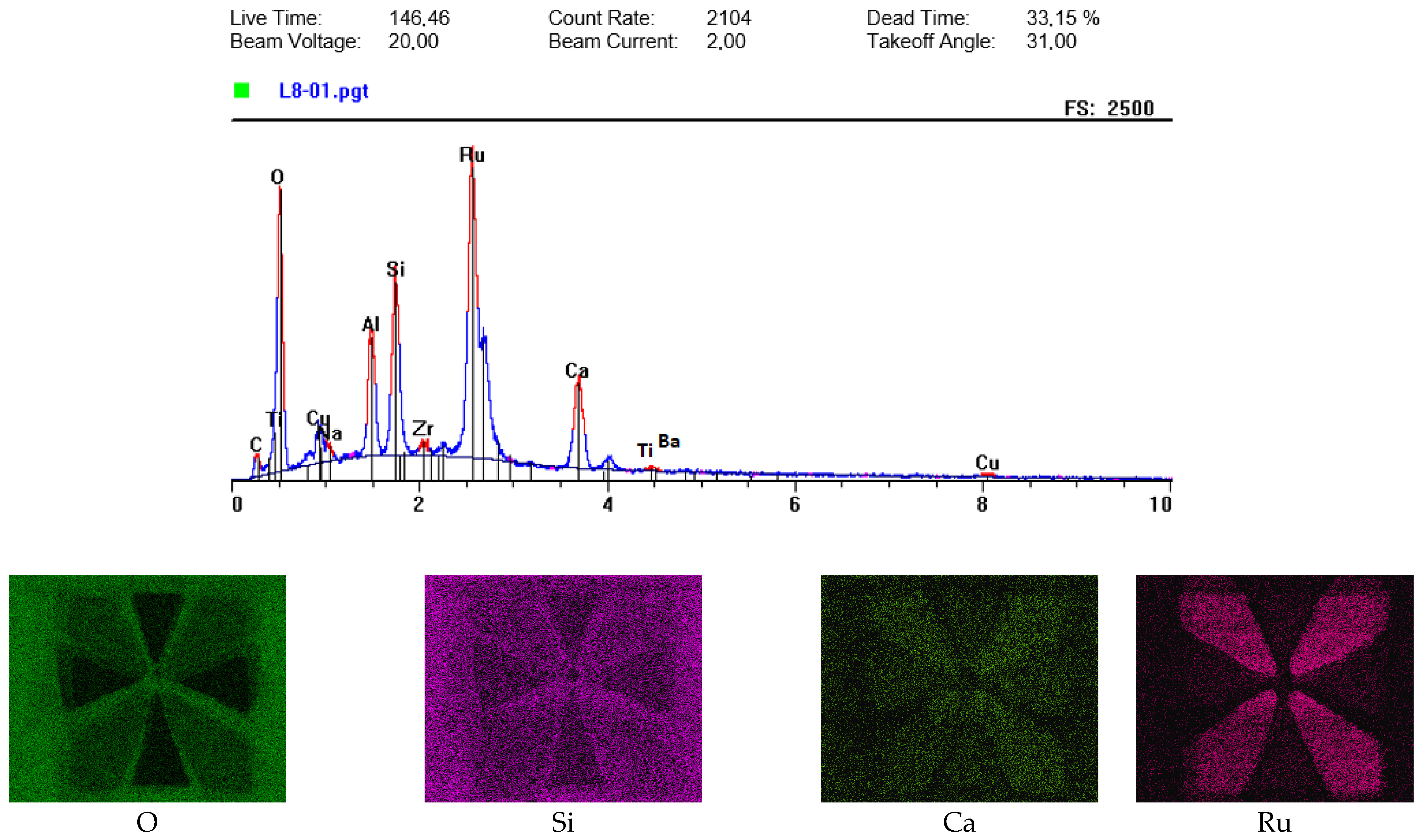

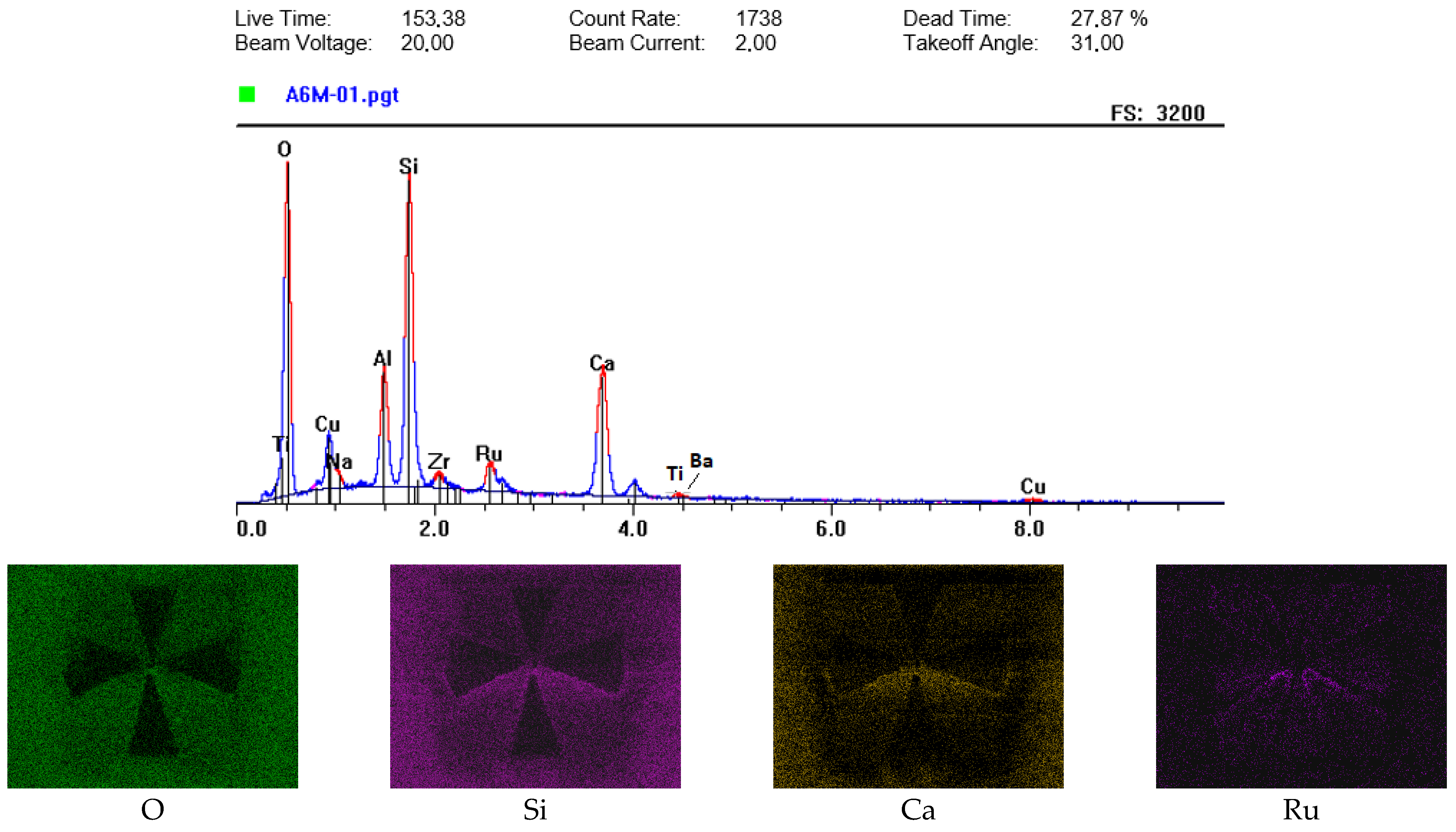

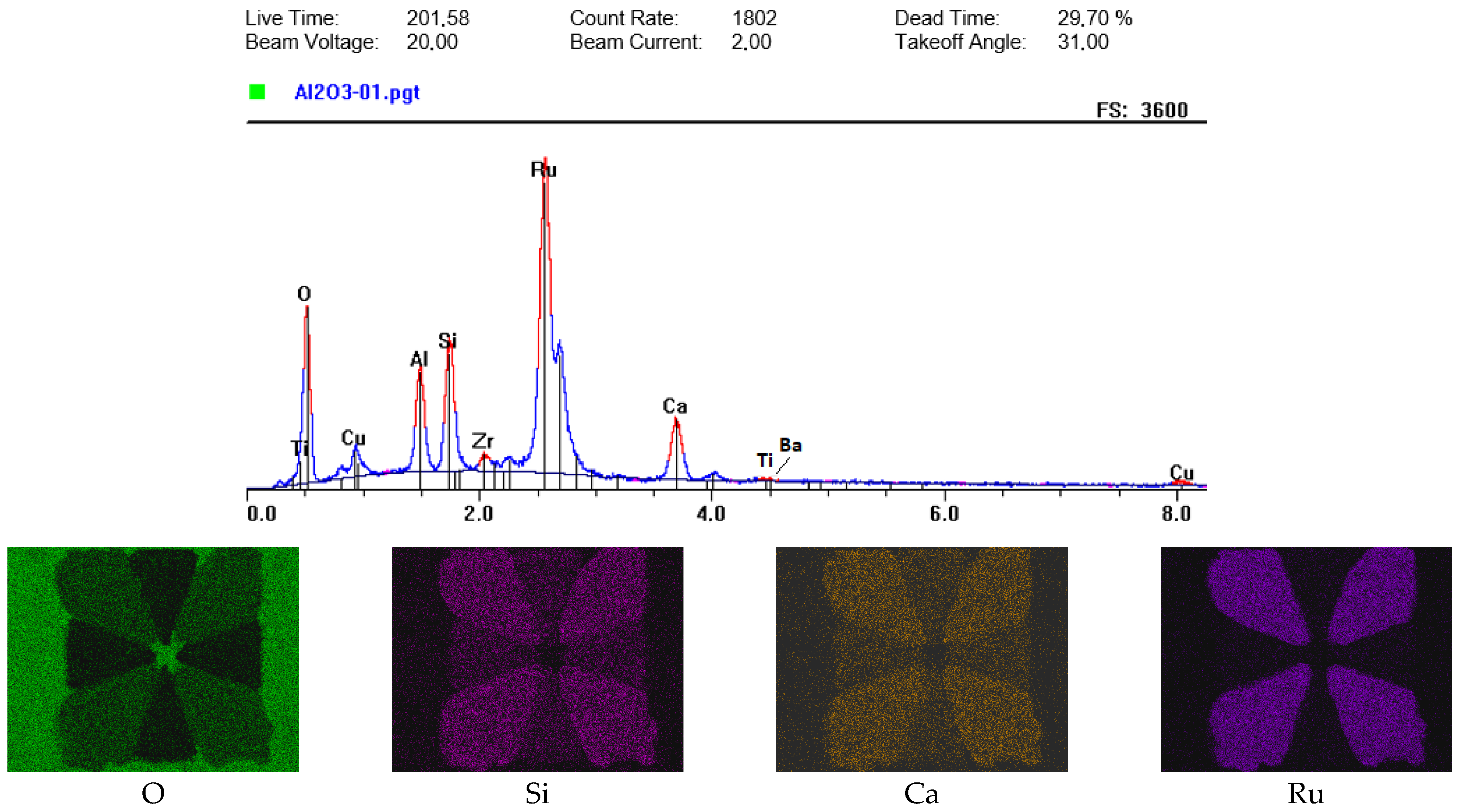

3.4. EDX Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Birol, H.; Maeder, T.; Jacq, C.; Ryser, P. Effects of Firing Conditions on Thick-Film PTC Thermistor Characteristics in LTCC Technology. In Proceedings of the Ceramic Interconnect Technology Conference, Denver, CO, USA, 27–28 April 2004. [Google Scholar]

- Hrovat, M.; Belavič, D.; Kita, J.; Holc, J.; Cilenšek, J.; Drnovšek, S. Thick-Film NTC Thermistors and LTCC Materials: The Dependence of the Electrical and Microstructural Characteristics on the Firing Temperature. J. Eur. Ceram. Soc. 2009, 29, 3265–3271. [Google Scholar] [CrossRef]

- Hrovat, M.; Belavič, D.; Kita, J.; Holc, J.; Cilenšek, J.; Golonka, L.; Dziedzic, A. Thick-Film PTC Thermistors and LTCC Structures: The Dependence of the Electrical and Microstructural Characteristics on the Firing Temperature. J. Eur. Ceram. Soc. 2007, 27, 2237–2243. [Google Scholar] [CrossRef]

- Martínez-Cisneros, C.S.; Ibáñez-García, N.; Valdés, F.; Alonso, J. LTCC Microflow Analyzers with Monolithic Integration of Thermal Control. Sens. Actuators A: Phys. 2007, 138, 63–70. [Google Scholar] [CrossRef]

- Reimann, T.; Barth, S.; Capraro, B.; Bartsch, H.; Töpfer, J. Cofiring of LTCC Multilayer Assemblies with Integrated NTC Thermistor Temperature Sensor Layers. Ceram. Int. 2021, 47, 27849–27853. [Google Scholar] [CrossRef]

- Available online: https://vibrantz.com/wp-content/uploads/2023/02/Vibrantz_PC_Electronic-Materials-5G_Brochure_012023.pdf (accessed on 14 October 2024).

- ESL CERMET RESISTOR SYSTEM PTC 2611-I Special. Available online: http://www.czpartner.com/upfile/7-12610QQ_103250212_29GBJuHI9779835.pdf (accessed on 5 July 2025).

- Ma, J.; Zhu, X.; Zhang, F.; Xu, Q.; Jiang, W.; Zhou, X. Positive Temperature Coefficient of Resistivity Effects of Semiconducting (Bi½ Na½) TiO3-CaTiO3-BaTiO3 Ceramics Sintered in Air Atmosphere. J. Shanghai Univ. (Engl. Ed.) 2010, 14, 452–455. [Google Scholar] [CrossRef]

| Material | Int. □ | Ext. □ | Int. □//□ | Ext. □//□ | Int. □-□ | Ext. □-□ |

|---|---|---|---|---|---|---|

| L8 | 38.4 ± 20.9 | 21.6 ± 10.0 | 26.3 ± 11.4 | 12.4 ± 3.1 | 86.9 ± 10.3 | 48.4 ± 0.6 |

| A6M-E | 115.4 ± 8.9 | 46.7 ± 4.2 | 104.8 ± 10.6 | 25.6 ± 0.2 | 346.4 ± 1.5 | 102.7 ± 6.8 |

| Al2O3 | NA | 101.2 ± 66.7 | NA | 73.6 ± 71.1 | NA | 115.0 ± 13.2 |

| Material | Int. □ | Ext. □ | Int. □//□ | Ext. □//□ | Int. □-□ | Ext. □-□ |

|---|---|---|---|---|---|---|

| L8 | 2027 | 2739 | 1843 | 2566 | 1878 | 2597 |

| A6M-E | 1579 | 2062 | 1355 | 2166 | 1432 | 2132 |

| Al2O3 | NA | 2808 | NA | 2800 | NA | 3009 |

| Material | Int. □ | Ext. □ | Int. □//□ | Ext. □//□ | Int. □-□ | Ext. □-□ |

|---|---|---|---|---|---|---|

| L8 | 39.1 ± 54.4 | 22.4 ± 46.0 | 27.0 ± 42.5 | 13.0 ± 23.8 | 87.8 ± 12.0 | 49.2 ± 1.2 |

| % change in mean value | +1.8 | +3.7 | +2.7 | +4.8 | +1.0 | +1.7 |

| A6M-E | 116.4 ± 7.6 | 46.9 ± 10.0 | 105.7 ± 10.0 | 26.2 ± 0.8 | 348 ± 1.41 | 103.7 ± 6.7 |

| % change in mean value | +0.9 | +0.4 | +0.9 | +2.3 | +0.5 | +1.0 |

| Al2O3 | NA | 98.3 ± 61.1 | NA | 73.6 ± 91.0 | NA | 117.2 ± 11.4 |

| % change in mean value | NA | −3 | NA | 0 | NA | +1.9 |

| Material | Int. □ | Ext. □ | Int. □//□ | Ext. □//□ | Int. □-□ | Ext. □-□ |

|---|---|---|---|---|---|---|

| L8 | 1930 | 2455 | 1692 | 2291 | 1763 | 2453 |

| A6M-E | 1450 | 1962 | 1240 | 1926 | 1332 | 1983 |

| Al2O3 | NA | 2414 | NA | 2404 | NA | 2606 |

| Element | Line | keV | Wt% | At% | At Prop | Net (cps) |

|---|---|---|---|---|---|---|

| O | KA1 | 0.523 | 40.48 | 73.50 | 0.0 | 101.7 |

| C | KA1 | 0.277 | 0.46 | 1.11 | 0.0 | 1.6 |

| Al | KA1 | 1.487 | 4.05 | 4.36 | 0.0 | 86.0 |

| Ru | LA1 | 2.558 | 43.49 | 12.50 | 0.0 | 309.5 |

| Si | KA1 | 1.740 | 4.19 | 4.34 | 0.0 | 104.4 |

| Cu | KA1 | 8.046 | 0.71 | 0.33 | 0.0 | 5.7 |

| Ca | KA1 | 3.691 | 3.32 | 2.41 | 0.0 | 60.0 |

| Zr | LA1 | 2.042 | 2.26 | 0.72 | 0.0 | 17.3 |

| Na | KA1 | 1.041 | 0.46 | 0.59 | 0.0 | 5.3 |

| Ba | LA1 | 4.465 | 0.51 | 0.11 | 0.0 | 2.2 |

| Ti | KA1 | 4.510 | 0.05 | 0.03 | 0.0 | 0.8 |

| Total | 100.00 | 100.00 | 0.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kärnfelt, C.; Sinou, M. Design and Analysis of Thermistors in Low Temperature Cofired Ceramics. Ceramics 2025, 8, 103. https://doi.org/10.3390/ceramics8030103

Kärnfelt C, Sinou M. Design and Analysis of Thermistors in Low Temperature Cofired Ceramics. Ceramics. 2025; 8(3):103. https://doi.org/10.3390/ceramics8030103

Chicago/Turabian StyleKärnfelt, Camilla, and Maïna Sinou. 2025. "Design and Analysis of Thermistors in Low Temperature Cofired Ceramics" Ceramics 8, no. 3: 103. https://doi.org/10.3390/ceramics8030103

APA StyleKärnfelt, C., & Sinou, M. (2025). Design and Analysis of Thermistors in Low Temperature Cofired Ceramics. Ceramics, 8(3), 103. https://doi.org/10.3390/ceramics8030103