Abstract

Several studies have demonstrated that 3D-printed geopolymer concrete (3DPGPC) could be a sustainable solution to minimising waste, carbon emissions, and production costs, thereby providing quick completion of construction projects. However, for 3DPGPC to be widely adopted, it is essential to be aware of both the prospects as well as the limitations. In this regard, the scope of this perspective article includes a review of the limitations of 3DPGPC. Key limitations regarding the material, structural, technical, economic, and environmental aspects of 3DPGPC are highlighted. Additionally, this article includes the general limitations associated with geopolymer concrete. As such, geopolymer concrete suffers from several problems owing to varying alkaline activators and precursor types while exhibiting performance variability even within the same type of precursor. These limitations need to be addressed first in order to make progress in 3DPGPC. Following the limitations, this article then presents the research priorities in 3DPGPC, such as the need for a standardised code for its adoption in infrastructure projects. Hence, the information presented in this article is timely and crucial for all stakeholders in the low-carbon community. Furthermore, it serves as a call for future research to overcome the discussed limitations to realise the full potential of 3DPGPC technology.

1. Introduction

The global construction market share will reach up to USD 13.9 trillion in 2037 [1]. Countries like China, India, and South Africa will drive this milestone in the economy. In this regard, the industry is constantly looking for novel approaches to increase construction productivity, reduce waste, and decrease project costs while simultaneously optimising the use of resources [2,3]. At the same time, due to the significant carbon emissions from the construction industry, there is a global drive towards the utilisation of novel low-carbon construction materials. Such high global market growth and novel pursuit necessitate modern digital construction technologies to ensure reliability and sustainability. One such digital construction technology and method is 3D printing.

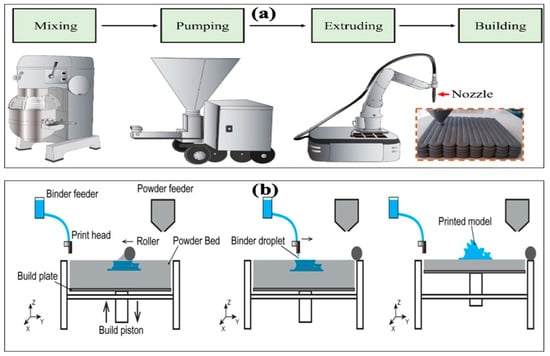

3D concrete printing, as an innovative digital construction method in the 21st century, is gaining tremendous global attention [4,5]. It incorporates digital design into construction activities, thus aiding in the effective management of several aspects of construction projects. The 3D construction printing process involves two essential steps: (i) creation of a digital model using CAD software and (ii) transformation of the model into a 3D object via a printer setup using commands [6]. Broadly, the construction sector uses two types of 3D printing concrete techniques: (i) extrusion-based printing and (ii) powder-based printing [7].

In extrusion-based printing, the fresh concrete mix is extruded out through a nozzle, depositing the mix in a layer-by-layer sequence to print the desired 3D object. Powder-based printing, such as binder jetting, differs from extrusion-based printing, in which dry concrete mix (powder) is initially laid on a bed in layers, following which a liquid binder is applied that hardens the layers. The entire process is repeated until the entire desired design is printed as a 3D object. Figure 1 shows the extrusion-based and powder-based 3D-printing setups. Each of the techniques has its own merits and demerits based on its applications, as presented in Table 1; however, of the two, extrusion-based printing is most commonly used in concrete construction due to its flexibility in printing concrete elements [8]. Utilising 3D-printing technology in the construction sector leads to a reduction in waste, physical labour costs, and time of 30–60%, 50–80%, and 50–70%, respectively [9,10]. It also provides the scope to create designs with custom-made complex geometries that are both unique and aesthetically pleasing.

Table 1.

Advantages and drawbacks of printing techniques.

Globally, there is an alarming need for the transformation of waste materials into value-added products [11]. This is not only beneficial for the economy but also very useful for the environment and human health. Primary waste materials, such as fly ash (FA), ground granulated blast furnace slag (GGBS), metakaolin (MK), red mud (RM), mine tailings (MT), silica fume (SF), and rice husk ash (RHA), are produced in enormous quantities worldwide, so immediate strategies are needed for their repurposing. In this context, the implementation of geopolymer concrete in the construction industry serves as an effective strategy.

Geopolymer concrete utilises these waste materials as precursors, and when mixed with alkaline solutions, namely sodium hydroxide (NaOH) and sodium silicate (Na2SiO3), among others, an inorganic binder is created that binds the aggregates together. Moreover, geopolymer concrete, being cementless, could help mitigate carbon emissions by 70–80% in comparison to normal as well as cement-based 3D-printed concrete [12,13]. Therefore, introducing eco-friendly materials like geopolymer concrete in modern construction is a vital step towards a low-carbon future.

Figure 1.

(a) Extrusion-based 3D printing [14]; (b) powder-based 3D printing [15].

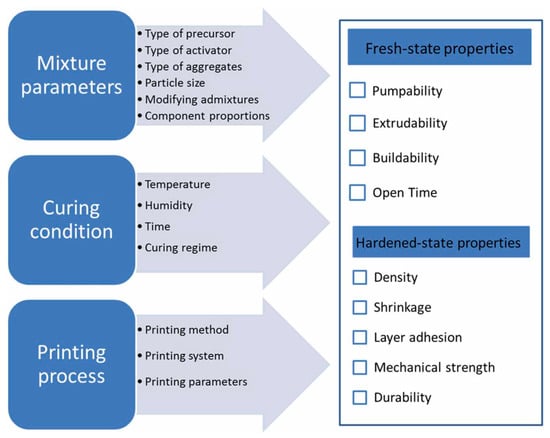

3DPGPC is a unique combination of low-carbon geopolymer and automation techniques. As shown in Figure 2, manufacturing 3DPGPC involves several factors. In the figure, the printing method refers to the technique used in 3D printing, such as extrusion-based or powder-bed, while the printing system refers to the printer/hardware setup, like a gantry-based system, which aids in controlling printing operations. Considering the sustainability aspects of construction, 3DPGPC undoubtedly provides major advantages. However, there are many challenges in developing and deploying 3DPGPC in large-scale projects worldwide. Certain aspects of 3DPGPC, such as material availability, cost, mix design, public awareness, and acceptance, are still in the early stages of development. Table 2 summarises the review articles published on 3DPGPC. The number of papers reviewed, along with the focus of the review, is listed in the table to identify the core areas that have been covered to date in the domain of 3DPGPC.

Figure 2.

Factors involved in manufacturing 3DPGPC [16].

Table 2.

Summary of the published review articles on 3DPGPC.

In light of the above discussion, this timely article aims to explore a fundamental research question: Is 3DPGPC market-ready at the current stage of research and development? Contrary to popular perceptions, this article lists several key limitations in the domain of 3DPGPC. The discussion in each section also focuses on how 3DPGPC technology, at its core, is directly related to advancing geopolymer concrete. The organisation of this article is such that it underscores the importance of 3DPGPC by considering its limitations and then presents research priorities, thereby emphasising the need to make this technology more user-friendly and widely accessible—locally and globally.

2. Key Limitations

In this section, some of the key limitations of 3DPGPC are discussed, taking into account the studies published in the last decade. Although 3DPGPC is a revolutionary technology for sustainable construction, many challenges must be addressed. The mindset towards adopting a new technology in construction industries has always been conservative. For instance, it has been nearly 45 years since the inception of geopolymer concrete. Still, it faces challenges and has not been able to penetrate the local markets. In this direction, the amalgamation of 3D printing and geopolymer concrete, however novel and promising it seems, requires actionable goals to realistically attain sustainability in construction. It is worthwhile to mention that through global collaborative efforts, this is possible. In this regard, the following sub-sections provide a brief discussion of the key limitations of geopolymer concrete as well as 3DPGPC.

2.1. Material

Geopolymer concrete utilises industrial wastes like FA, GGBS, RHA, and MK that are rich in alumina and silica as precursors. Although this method eliminates the need for cement, the availability of these wastes with consistent physical and chemical properties remains a concern. The properties of these wastes largely vary across their source of generation [25]. Consequently, the geopolymer reaction will be affected, which will then require constant changes, including several trials in the mix design principles to attain the desired properties. Further, the chemical composition of the precursors highly influences the fresh and hardened properties of geopolymer concrete [26,27,28]. Hence, the 3DPGPC method of construction will require frequent trials, leading to an increase in initial costs. Moreover, the printability and mechanical performance of 3DPGPC samples must be assessed in terms of variability in the properties of the precursors.

Another challenge is to optimise the content of the alkaline activators used in the preparation of 3DPGPC. Typical manufacturing of geopolymer concrete involves the use of a mixture of NaOH and NaSiO3, acid, and carbonate solution as activators. These activators are essential to initiating the geopolymerisation process by dissolving silica and alumina from the precursors and subsequently aid in the formation of a geopolymer network and strength development. However, the selection and proportioning of activator content in 3DPGPC is still under investigation in terms of printability and mechanical performance. At the same time, the molar ratios of the mix, for example, SiO2/Al2O3 and Na2O/SiO2, highly influence the rheology and setting time of the 3DPGPC mix [29]. For effective geopolymerisation to occur, SiO2/Al2O3 must be within 3.3–4.5, whereas Na2O/SiO2 may range from 0.25 to 0.76, depending on the strength and setting time requirements [30]. It is pertinent to mention that geopolymer mixes exhibit unique rheological properties and are particularly sensitive to factors such as the type of precursor and alkaline activator. These factors, in turn, highly influence the rheological parameters such as yield stress and viscosity. Table 3 shows the rheological properties of 3DPGPC mixes. The table shows that the rheological properties of 3DPGPC mixes vary significantly, and establishing optimal values is challenging. To avoid the collapse of the printed object, attaining the right balance of these parameters (rheology-wise) is necessary.

Table 3.

Rheological properties of 3DPGPC mixes.

Moreover, typical geopolymer mixes set rapidly. Hence, there is a high chance of difficulty during extrusion if the mixes are not properly designed in terms of the setting times. However, a retarder could be used to control the setting times [41]. By neglecting these factors, the printer could malfunction during the printing process, which could lead to unwanted machinery damage. The right choice of precursor materials, along with activator content, also accounts for the mitigation of drying shrinkages of printed samples. Generally, geopolymer mixes show higher drying shrinkages than traditional cement-based geopolymer mixes [42,43], depending on the choice of precursor. Concerning drying shrinkage, high-volume FA mixtures or a combination of FA and GGBS as precursors have been found to be favourable for 3DPGPC [44,45].

On the other hand, high-volume GGBS and MK-based geopolymer mixes can exhibit high drying shrinkage in 3DPGPC [18,46]. High drying shrinkage can negatively affect the buildability of printed structures. Hence, careful selection of the precursor becomes important in 3DPGPC extrusion, else there will be a high chance of cracking in the resulting printed structure.

2.2. Structural

3DPGPC technology initially did not consider using conventional steel reinforcement, just like the traditional construction method. Steel reinforcement typically provides the advantage of protecting concrete structures under tension or increasing ductility [47]. To date, integrating typical steel reinforcement in the printing process has been a critical challenge [48]. Yet, increasing tensile strength and ductility are important in printed concrete structures, which can lower the chances of deformation. Further, the 3DPGPC construction process does not involve formwork like traditional construction, where steel bars are placed suitably in the formwork and concrete is poured inside. Although many researchers have tried different approaches to introduce reinforcements in typical 3D-printing concrete, the developments have not been properly fully realised. One interesting study [49] clarifies this situation in 3D-printing construction fluently. The continuous extrusion process and the layer-by-layer sequence of printing impede the introduction of reinforcement and stirrups, which are essential for structural members.

To effectively address this issue, approaches such as short fibres [50], reinforced meshes [51], and hollow printed components with external reinforcement [52] have been explored. Another interesting study [53] reported using a hybrid reinforcement technique involving both short fibres and steel cables in printed samples. However, these approaches are in their early stages of development, with many limitations attached. It is not recommended to use long, hard, and excessive proportions of fibres in the printing process. These fibres may block the nozzle during printing and pose additional challenges for the successful printing of samples. At the same time, the use of fibres can disrupt the interlayer bonding in the printed samples due to uneven distribution in the concrete matrix [14,54]. In regards to 3DPGPC, for example, polypropylene fibres have been used to enhance its ductility behaviour and maintain the structural stability of printed samples [55].

Undoubtedly, 3DPGPC enables structures to have complex shapes with a subjective aesthetic element attached, which traditional construction, although systematic, fails to fully achieve. However, certain structures, such as overhangs, largely unsupported beams, and columns, present significant challenges to be overcome by 3DPGPC. This requires extensive planning before construction. As such, 3DPGPC faces geometrical constraints in this regard. Auxiliary supports are essential to provide temporary stability and accuracy, thus ensuring that the structure does not fail or sag. At the same time, there is significant post-processing required to design appropriate practical structures while minimising supports, which might escalate the overall project cost. Moreover, structures such as free-floating bridges remain a challenge. Although the extrusion-based 3DPGPC remains highly popular, it faces constraints in printing overhangs and inclined structural elements without support. In this regard, powder-based printing is recommended to be the best suitable option for printing such complicated concrete structures, as the powder beneath may serve as a support in this technique of construction [56,57]. This option also comes with its demerits (Table 1), particularly related to the issue of material compatibility suitable for commercial construction [58].

2.3. Technical

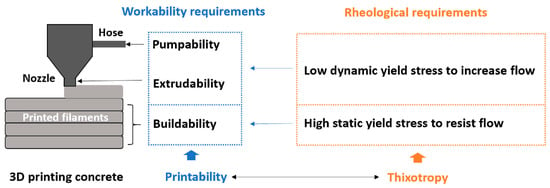

For successful printing, the major requirement is to design satisfactory mixes with good thixotropic properties—low dynamic yield stress and high static yield stress [23,24,59], as shown in Figure 3 and as can be understood from Table 3 as well. In this regard, first and foremost, a proper mix design is required, considering the rheological requirements, which in turn will influence the extrudability of the geopolymer concrete mixes. Apart from this, the entire pumping system, i.e., pumps, hose pipe, and nozzles, needs to be customised to avoid any undesirable effect on print quality. The shape and size of the nozzle, the length of the hose pipe, and the pump flow rate require careful consideration before printing geopolymer concrete structures [60]. Likewise, the open time and print time gap between layers is another important consideration in 3DPGPC. Open time refers to the time during which the mix remains extrudable and is influenced by the type of precursor, mix design, type and amount of alkaline activator, static yield stress, and setting time of the mix [14]. For example, increasing GGBS content in the mix accelerates the setting time. Consequently, the open time reduces [61]. Substituting FA with steel slag (by 40%) has been reported to increase open time [62]. Likewise, increasing activator content results in a decrease in open time due to a high rate of increment in yield strength [63]. The open time, as reported in the literature, could range from 10 to 230 min [62,64,65,66]. The print time gap refers to the interval between the printing of two successive layers, and it should be within the open time. The print time gap directly impacts the interlayer bond strength of the samples, and it depends on the printing speed and the complexity of the geometry. The quick setting time of the geopolymer concrete mix, coupled with an increase in print time gap, leads to a decrease in bond strength in 3DPGPC samples [60]. These aforementioned adjustments are more critical in the case of 3DPGPC compared with 3D printing of traditional cement-based concrete. It is, therefore, understood that an inadequately designed mix and print setup could lead to uneven extrusion, resulting in unsatisfactory printed samples.

Figure 3.

Rheological requirements in 3DPGPC [67].

Another important viewpoint is regarding the sensitivity of geopolymer concrete to temperature conditions and humidity. The setting and strength development in geopolymer concrete are highly dependent on temperature and humidity [68,69,70]. Depending on the choice of precursor and curing method, the strength gain varies. In the case of using FA as a precursor, one study reported that the compressive strength when oven-cured at 85 °C for 24 h was significantly higher than that of specimens cured at 65 °C [71]. On the other hand, when MK was used as a precursor, curing at 40–60 °C improved strength development in comparison with ambient-cured samples [72]. Hence, the curing temperature could range from 40 to 85 °C for 24–48 h for effective geopolymerisation to occur [73]. Likewise, relative humidity (RH) levels could range between 70 and 100% during the curing period, depending upon the precursor used [74,75,76]. When using FA as a precursor, an RH of 70% during curing was found to be beneficial for strength gain [74], whereas at an RH of 90%, a strength reduction was noticed.

On the other hand, when MK was used as a precursor, curing at 85% RH helped attain the best compressive strength [76]. These contrasting behaviours reveal that optimising curing conditions for geopolymer concrete has been a challenging task so far, due to which it has not been widely implemented commercially. Existing 3D printers lack the necessary technical functions/systems to monitor temperature and humidity conditions both during and after the printing process. Without these monitoring systems installed in 3D printers, the off-site 3DPGPC implementation will not be effective as per design considerations, leading to premature drying, poor interlayer bonding, and, eventually, a lack of adequate strength and durability.

2.4. Economic

The economy in construction is crucial to modern infrastructural needs. Consequently, the pursuit of cost-effective, eco-friendly construction is a top priority in today’s scenario—relating to construction materials and methods. 3DPGPC, which is a fusion of 3D-printing technology and geopolymer concrete, theoretically carries the advantage of being less costly than traditional methods of cement-based construction and 3D-printed OPC-based construction. However, practically, there is a high initial cost involved compared with 3D-printed OPC-based construction. The initial cost includes the cost of 3D-printing equipment and geopolymer materials [77]. The initial phases of geopolymer manufacturing often require raw material pretreatment. For instance, pretreatments such as mechanical and thermal activation are performed on the precursor material to modify its reactivity when combined with alkaline activators. These activation methods increase the quantity of amorphous phases in the precursors. Further, the thermal activation methods, i.e., calcination and alkali fusion, require heating of the material in the high-temperature range of 400–900 °C. GGBS does not need any pretreatment since it has enough amorphous phases within it. Even though FA does not require pretreatment, there is evidence that low-reactive FA often exhibits longer setting times and very low strength development, especially in ambient curing conditions [78,79]. Therefore, pretreatment of FA becomes necessary. Likewise, other clay minerals, mostly kaolinite, require thermal activation or alkali fusion to be converted into a disordered form, which results in MK. The iron-rich aluminosilicates (laterites) also require thermal activation to transform the kaolinite content in them [41,80,81]. All these suggest that pretreatment methods are inevitable to attain effective geopolymerisation and, therefore, become an integral part of geopolymer manufacturing. One study reported that pretreatment can be nearly 87% of the total manufacturing cost [77]. From the perspective of a large construction project, this will significantly add to the cost of printing in the case of 3DPGPC.

Then comes the issue of costly alkaline activators: NaOH, Na2SiO3, and other alkali activators. These chemicals are an expensive component of geopolymer production [82,83,84]. As such, the manufacturing cost of 3DPGPC elements, such as walls, beams, columns, and floors, includes costs related to human labour, equipment work and maintenance, and materials. Also, 3D printing consumes nearly 100 times more electricity than traditional construction methods, which leads to a significant rise in energy utilisation [8]. Moreover, depending on the cost of chemicals and source materials like MK, which vary significantly by region, the GPC cost could be nearly three times the cost of OPC-based concrete of the same grade [85]. Another study reported that the cost of production of 1 m3 of geopolymer concrete using FA and GGBS is higher than that of OPC-based concrete by 17.61% [86]. Hence, it can be assumed to some degree that the cost of 3DPGPC will increase proportionally. In addition, there is the issue of the cost of large printers. This cost can easily exceed millions of EUR/USD, and so will the maintenance cost associated with them [8,77,87,88]. Although this could be regarded as a one-time investment, the issue of the high initial cost is an important topic to consider. Moreover, this technique requires a wide range of expertise, not just from civil engineers. The material development, project management, selection of designs, and compatibility of printing equipment require expertise from materials science, robotics, and architecture, among others [89,90]—hence the overall high initial cost of 3DPGPC, particularly in comparison to 3D-printed OPC-based construction. All these economic factors have thus inhibited the growth and development of 3DPGPC technology in several countries.

2.5. Durability

One of the major requirements in concrete structures is durability, even if they have gained high or sufficient strength. It is a key factor to assess the quality of concrete. Since the 1950s, geopolymer concrete has been implemented only in isolated cases for some time now, namely in countries such as China, Australia, Belgium, and some other European countries [91]. The construction projects in these countries include precast structural members and buildings. Yet, the long-term durability data remain scattered. In other parts of the world, such as India and Africa, the construction sector has recently started implementing geopolymer concrete, for which the long-term durability data are still awaited. Adding to this, the long-term durability of extrusion-based 3DPGPC still lacks studies based on durability concerns such as acid, sulphate, and salt resistance. Though factors such as drying shrinkage and the porosity of 3DPGPC have been discussed in recent literature, it is insufficient. Printed concrete samples are more sensitive to chloride penetrations compared to traditional concrete members. This is because the pores exist in the interlayer regions of the printed samples and are susceptible to the ingression of chemical ions, thereby affecting the durability of the samples [92,93,94]. Further, one study [95] reported that the chloride penetration in printed samples is higher when printing intervals increase, thus encouraging chloride ion ingress and eventually leading to interlayer degradation. In this context, durability studies related to interlayer regions in printed samples are of high importance, as this is the weakest area in samples.

Another viewpoint is to assess the durability data of 3DPGPC concerning different precursor usage. The properties of geopolymer concrete are highly influenced by the chemical and physical characteristics of precursors. There is an abundance of literature available regarding the durability of different precursor-based geopolymer concrete, such as FA-GGBS0, GGBS-MK-, FA-MK-, and MK-GGBS-based binder systems. However, the durability parameters, such as moisture absorption, chemical attacks, efflorescence, freeze–thaw cycles, and corrosion resistance, have not been studied extensively in the 3DPGPC domain, to give a clear idea regarding the influence of precursor materials. Literature related to the deterioration of 3DPGPC samples related to the aforementioned exposure conditions is scarce, which makes 3DPGPC less accepted in conservative construction markets.

2.6. Sustainability

Reduction in carbon footprint remains the top goal in addressing the issue of greenhouse gas emissions and climate change. Sustainability means there should be minimal resource depletion in terms of future requirements [96]. Despite the advantages, sustainability concerns about 3DPGPC persist and require attention. 3DPGPC, which might be considered a sustainable alternative to traditional construction, depends heavily on the sustainability of geopolymer concrete. To date, there is no common agreement in the scientific community on whether geopolymer concrete is more environmentally friendly than traditional cement-based concrete. The reasons can be divided into two categories: (1) the environmental footprint of alkaline activators and (2) the availability and preprocessing of precursors.

The environmental impacts of geopolymer concrete are contributed to by the alkaline activators NaOH, Na2SiO3, and others. Without these chemicals, geopolymerisation cannot be initiated. The production of Na2SiO3 involves a reaction between sodium carbonate (Na2CO3) and quartz. This reaction occurs in the temperature range of 1400–1500 °C. Moreover, the entire process emits nearly 1.514 kg/kg of CO2 emissions [84]. Consequently, there is environmental stress related to the mining and processing of these minerals, leading to resource depletion. Hence, this creates a potential problem from the viewpoint of sustainability in geopolymer concrete.

Even though geopolymer concrete emits 45% less CO2 (low global warming potential) than traditional cement-based concrete, it has been reported that geopolymer concrete exhibits higher impacts in the categories of abiotic depletion, freshwater ecotoxicity, terrestrial ecotoxicity, human toxicity, eutrophication, acidification, and photochemical oxidation [97]. The high impacts are mostly ascribed to the use of chemicals (alkaline activators) like Na2SiO3 solution. These chemicals are thus responsible for transferring the pollution from global warming potential towards the other aforementioned impact categories. Thus, the advantages attained by not using cement are easily offset by the carbon emissions from using the activators. The understanding that geopolymer concrete is more sustainable than traditional cement-based concrete is thus challenged. Recently, researchers have understood this problem, and therefore, several efforts have been made to develop more affordable and eco-friendly activators derived from silica-rich wastes, namely RHA. This is a viable approach. However, currently, this lacks exhaustive studies and is still in the early stages, which necessitates proper framework and commercialisation strategies [18,98,99].

Meanwhile, there is a global shift towards renewable/green energies. Hence, FA may not be available due to the closure of coal-based thermal power plants [100]. Since FA is a commonly used precursor for geopolymerisation, the question of supply becomes relevant here. Likewise, the production of GGBS generates high carbon emissions during its processing and is already in short supply because almost all quantities are purchased by cement companies to make blended cements [101]. This means that no longer can geopolymer concrete manufacturers rely on these precursors, because their availability will be a major concern in the immediate future.

It is also important to highlight here that the end-of-life phase of the geopolymer material falls under the sustainability aspect as well, in terms of whether the material can be recycled suitably after its service period. Traditional cement-based concrete has been used as recycled aggregate when the service life period of the concrete structure ends. Remarkably, this strategy has been very effective. However, as previously discussed in this section, alkaline activators used in manufacturing geopolymer concrete have high impacts in several categories except for global warming potential [97,102]. Therefore, the utilisation of geopolymer concrete during its end-of-life phases could pose a high risk since there might be chemical leaching.

2.7. Regulatory Framework

Just like 3D printing, geopolymer concrete is an emerging and evolving technology in the construction sector. For the wide acceptance and adoption of this technology, regulatory frameworks and policies are essential. However, 3DPGPC lacks uniform and standardised code provisions at the moment, which impedes the commercialisation of this innovative technology. This is one of the major drawbacks so far. Without clear guidelines, it is challenging to incorporate 3DPGPC into present construction practices, which is why 3DPGPC, at present, can only be termed an experimental technology. Except for Australia, currently there is no extensive implementation of geopolymer concrete in real-scale applications in other parts of the world [103]. Adding to this, from a global perspective, geopolymer concrete lacks standardised guidelines. Although some standardised documents have been released by reputed organisations such as the British Standards Institution (BSI), the Bureau of Indian Standards (BIS), the American Concrete Institute (ACI) Technical Committee, and the American Society for Testing Materials (ASTM), these documents do not clarify the regulations uniformly. Further, they allow too much flexibility to practitioners in optimising concrete ingredients and the preparation process, which creates confusion.

Geopolymer concrete is not well established like traditional concrete to date, and the regulations that have been released so far have not yet been widely accepted. Most engineers see geopolymer concrete as traditional cement-based concrete. However, it should be realised that geopolymer concrete may perform satisfactorily as per desired applications, but it does not fully conform with the established standards of traditional cement-based concrete. It differs highly in terms of rheology and reaction mechanisms [104]. Relying on existing standards and knowledge that are meant for traditional cement-based concrete will only prove detrimental to the growth of geopolymer concrete [105].

Additionally, the mass production of geopolymer concrete is hindered by the absence of legal regulations, which is essential for product certifications and creating trust in public psychology. Now, 3DPGPC is facing the same issues as geopolymer concrete. There is no globally accepted framework, nor is there any legality in construction methodologies related to 3D printing in general [106]. Hence, this marks one of the biggest hurdles for 3DPGPC commercialisation, which ultimately impedes its widespread adoption.

2.8. Skilled Workforce and On-Field Applications

As discussed in Section 2.4, 3DPGPC requires materials science, robotics, and architecture expertise. This means that it is also largely dependent upon a skilled workforce, including ground staff/labour, especially during the on-site construction process and applications. In traditional construction, the knowledge regarding concrete mix design, setting, transporting, and placing is somewhat typically known to the workforce following years of repeatability and standard practice—this makes traditional construction more approachable in the view of labour availability and working efficiency. Unlike traditional cement-based concrete, geopolymer concrete and 3DPGPC do not follow this trend. Geopolymer concrete is not simply an evolution of traditional concrete technology [107]. Starting from the mixing of ingredients to the curing process, the preparation method of geopolymer concrete differs from traditional cement-based concrete. Moreover, many civil engineers are still unfamiliar with geopolymer chemistry and 3DPGPC. 3DPGPC demands special knowledge regarding the mix design and printer operation, including maintenance of the printer setup. Moreover, unlike traditional construction, where there are established quality control measures, 3DPGPC has its own evolving assessment techniques, which the workforce must be familiar with and be trained for. The workforce should assess the printed structures in terms of having exact dimensional stability and properties that match the initial design requirements. The workforce must remain focused during the sequential style of printing and is therefore required to be vigilant during the printing process for successful interlayer bonding. As such, 3DPGPC requires real-time monitoring, and there is a lack of skilled workforce/professionals [108] at the moment, which is one of the limiting factors for the widespread adoption in several developing countries.

From the preceding discussion, it is realised that 3DPGPC poses significant challenges concerning workforce. Until now, geopolymer concrete has been mostly prefabricated and then transported to the site for assembly. Quality control and manufacturing processes on-site require professional knowledge regarding several parameters. Hence, on-site 3DPGPC construction has not yet been fully developed to realise its merits. Further, on-site application will often be exposed to temperature and humidity fluctuations, unlike controlled curing conditions in the lab or precast scenarios. Handling these uncertainties has been a matter of interest. Additionally, any misalignment or improper printing arising from a lack of codes/guidelines for large-scale on-site applications/printing could lead to layer defects [109], eventually leading to an immature form of construction. Hence, all these issues limit the wide adoption of 3DPGPC technology, including the possibility of transformation from lab-scale research to large-scale on-site applications.

3. Research Priorities—The Way Forward

It is necessary to understand that every new technology takes time to be understood fully and locally adopted. This paper started with a discussion on the limitations of 3DPGPC. Given that 3DPGPC has not yet fully matured, it is equally essential to broadly outline the possible research priorities for the technology to evolve. Eventually, 3DPGPC will evolve just like geopolymer concrete is evolving at present. For instance, there is rapid development in the areas of waste-derived activators and one-part manufacturing of geopolymer concrete. Likewise, 3DPGPC could see many such revolutionary changes that would make it more appealing and transform all the previously highlighted limitations into potential strengths. In this context, this section discusses some of the major research priorities, as illustrated in Figure 4, that the civil engineering community may follow to encourage the effective deployment of 3DPGPC.

Figure 4.

Research priorities.

3.1. Improvement in Inter-Layer Bonding

Weak inter-layer bonding arises from the presence of voids in the 3DPGPC matrices [110,111]. High porosity in 3DPGPC leads to poor mechanical and durability properties [62]. Therefore, innovative approaches are needed to enhance adhesion among layers. For example, a recent study [46] found that slag inclusion reduces porosity and improves durability in metakaolin-based 3DPGPC samples. Research in this area, i.e., enhancing inter-layer bonding by reducing voids, has been limited. More studies are needed to understand the pore connectivity within the printed matrices and their behaviour against aggressive environments such as acids, salts, and frost. A thorough investigation of the transport mechanisms of water molecules will reveal relevant characteristics of the pore structure, aiding in the understanding and ultimately improving 3DPGPC matrices.

3.2. Transition Towards Seismic Resilient 3DPGPC

Seismically active areas around the world are witnessing rapid urbanisation due to an increase in population [112,113]. Earthquakes, unpredictable and natural, pose a serious threat to these areas. Consequently, it becomes imperative to pursue earthquake-resistant materials and integrate them into construction methodologies like 3DPGPC. 3DPGPC could be effectively deployed in these areas since geopolymer concrete has emerged as a promising earthquake-resistant construction material owing to its distinct set of properties. Geopolymer concrete has an inherent capacity to act as a shock absorber, as reported in several studies [114,115,116]. Hence, the behaviour of 3DPGPC should be studied in detail in terms of structural integrity under seismic loads. To date, no detailed study has been conducted in this area, particularly using 3DPGPC. Therefore, the research community may treat it as a top priority to further realise the safety of 3DPGPC structures under seismic loads/events.

3.3. Development of Design Standards and Guidelines

The absence of guidelines for 3DPGPC compromises the quality and safety of 3DPGPC structures. Further, no uniform codes are available for geopolymer concrete, as discussed in Section 2.6. This weakens the prospects of 3DPGPC in comparison to 3D-printed OPC-based concrete. Therefore, global collaborative efforts should be directed towards studying every aspect of geopolymer concrete as well as 3DPGPC to put forward a uniform guideline document based on feedback from prominent research groups/engineers across the world. Moreover, individual nations may step forward by making a separate executive body of engineers who can compile a guideline before stepping towards large-scale 3DPGPC construction. As previously iterated in this article, the test methods and materials, including techniques used for traditional concrete preparation, are not suitable for geopolymer concrete or 3DPGPC. Therefore, the development of entirely new standards consisting of theoretical and predictive models of 3DPGPC structures is necessary. This will ensure that the structures made with 3DPGPC would have adequate durability, safety, and functionality under different load conditions. Additionally, the establishment of uniform guidelines shall make 3DPGPC technology trustworthy and encourage its implementation locally.

3.4. Innovations in Materials and Increasing Sustainability

Current raw materials used in manufacturing 3DPGPC do not ensure effective buildability in the printed samples. As discussed previously in this paper, precursors need pretreatments before their use in 3DPGPC. Thus, innovations in these areas are highly necessary at the moment to reduce overall costs and enhance the characteristics of precursors. Additionally, alternative precursors must be pursued so as not to depend upon FA and GGBS, since both these wastes may not be available in the future when the world shifts towards greener production of electricity and steel. At the same time, efforts should be made to research and develop alternative activators instead of relying on only NaOH and Na2SiO3, as these are expensive and generate carbon footprints during their production. Low-carbon-waste-derived activators, such as RHA-based activators [117,118,119], have recently come into the picture in the domain of geopolymer concrete. Hence, such alternatives could be a way forward in 3DPGPC to make it truly sustainable. Other agricultural waste rich in silica can be exhaustively investigated from the viewpoint of life cycle production cost and carbon footprints and thus provide the 3DPGPC practitioners with a range of choices that could be utilised locally. Likewise, different types of fibres should be implemented to mitigate the issues arising from the absence of formwork and reinforcements in 3DPGPC structures [33,120]. The research in this area is relatively new, and more information is needed to enhance the strength of 3DPGPC structures in terms of overhangs and/or where structures need reinforcements. Only by addressing these aforementioned issues can 3DPGPC be a key sustainable solution in today’s construction scenario.

3.5. Data Availability Regarding Long-Term Durability

The journey from being just a lab-scale idea to real-scale projects require long-term durability data. Hence, to make any construction material adopted by the community, the availability of long-term durability data is essential. The data could be used in developing guidelines as well. Structures need reliability, and long-term durability is one way to assess that. To assist in the rapid deployment of 3DPGPC in remote as well as developed areas around the world, there is a high necessity at the moment for the long-term durability data of 3DPGPC structures [17,19]—particularly data regarding durability against aggressive environments, such as acids, salts, freeze–thaw cycles, and chloride penetrations.

Another important factor is to assess the durability of 3DPGPC under varying curing regimes with changes in temperature and humidity. Strength development in geopolymer concrete is highly dependent on these two factors [121,122]. Moreover, the climate conditions throughout the year change and thus will affect the performance of installed 3DPGPC structures. Thus, the influence of different climatic conditions could be simulated in lab-scale research of 3DPGPC, using appropriate methods to obtain extensive data and then utilising these data to make informed decisions. Further, these data will promptly assist on-field engineers when printing or installing desired structures that are suitable only for that site under particular climatic conditions.

3.6. Automation and Novel 3D Printers Through AI-Enabled Systems

3D printing is by itself a type of automation in comparison to traditional construction methods. However, in the age of AI, the scope for improvement gets bigger each day. Firstly, there is still a requirement to address issues related to machinery faults and inconsistency in extrusion, among others. These issues still need human intervention from time to time while reducing overall efficiency. AI-enabled systems, such as relevant quality control and monitoring systems, if integrated, could potentially improve automation, and this domain remains largely underexplored. Especially in dealing with on-site high-rise structures, deployment of AI-based sensors and other optimisation techniques could increase safety and minimise the need for human intervention in every step [123,124]. Therefore, AI-enabled high-performance and advanced robotic technologies can be a way forward to make 3DPGPC a form of mobile printing solution. As a mobile setup, this could be easily transported and deployed in the areas when required, thus increasing overall efficiency with minimal resources. Likewise, the inclusion of digital twins and immersive technologies such as virtual reality (VR) and augmented reality (AR) in the visualisation of project data and the decision-making process could be a step forward. Thus, leveraging AI to automate monitoring could be highly beneficial in the domain of 3DPGPC.

Another research priority is the need for novel printers specially designed for 3DPGPC. In this paper, the argument that is put forward in each section is that 3DPGPC involves many technical challenges in comparison with 3D printing of traditional cement-based concrete. Till now, development has been mostly focused on printing geopolymer concrete just like the way traditional concrete has been printed. However, as discussed in the paper, the material behaviour and manufacturing conditions are not the same in both types of concrete, particularly when dealing with off-site construction. Therefore, novel printers designed exclusively for geopolymer concrete could mark a pivotal change that would make 3DPGPC stand apart and allow the ease of construction without any limitations.

3.7. Integration into Academic Curriculum and Other Major Initiatives

Research and development in 3DPGPC must be simultaneously associated with activities that raise awareness among the next-generation students/workforce/stakeholders. Solely relying on lab-based results without giving priority to outreach programs such as workshops or campaigns can only slow down the progress made in 3DPGPC so far. In this context, one solution may be to integrate 3DPGPC technology into the academic curriculum in civil engineering. To shape the thinking of next-generation engineers and to make them aware of this novel technology earlier in their career will motivate them to adopt 3DPGPC as a sustainable solution in the 21st century. Moreover, publications in the form of books, not just journals, would help in educating civil engineering professionals as well. The companies involved in 3DPGPC construction, in collaboration with academic faculties, may conduct workshops at universities. Industry professionals can also provide training for upskilling the workforce required for 3DPGPC construction, especially in developing countries. These outreach programs, including workshops and educational initiatives, could help in breaking the conservative attitude towards this novel technology and aid in faster adoption of 3DPGPC in the community. Swift transition from experimental to mainstream can be enabled by focusing on the aspects discussed in this section.

4. Conclusions

The amalgamation of 3D-printing technology with geopolymer concrete is undoubtedly novel and provides the possibility to attain true sustainability in construction. But, to date, geopolymer concrete has struggled to penetrate the markets in several developing and developed nations. This can be attributed to the fact that the Portland cement industry has been known to lobby with governments and policymakers, making it difficult for geopolymer concrete to enter the market. This creates a major competitive advantage for the traditional concrete industry. At the same time, it is important to understand that it took nearly 100 years for Portland cement to be widely marketed and commercially adopted after it was patented. Therefore, the construction sector has always been a conservative industry regarding any novel technology.

Owing to the evolving trends in the current construction scenario, automated construction techniques such as 3D printing and novel low-carbon building materials such as geopolymer concrete have become an area of interest in academia as well as in the industry. 3DPGPC has huge potential to fully replace traditional construction methods. However, despite having huge potential, several limitations need to be overcome for its widespread implementation and acceptance. To date, experimental and review studies on 3DPGPC have mostly concentrated on the fresh and hardened properties of the printed samples. No study has exclusively focused entirely on limitations to understand 3DPGPC from a different perspective and thereby shift the attention of researchers to make the technology more affordable, efficient, and accessible to all.

This perspective article discussed some of the key limitations of 3DPGPC related to some crucial aspects, such as material, structural, technical, and economic aspects, among others. The limitations are categorised suitably to create awareness among current and future researchers about the issues that pose challenges to 3DPGPC. The article, in each section, also mentioned how developments in geopolymer concrete are intricately and fundamentally connected to 3DPGPC technology. Accordingly, the article presented some major research priorities as well. Several important studies conducted on 3D printing in general, geopolymer concrete, and 3DPGPC were considered to support the scope of this article.

From the current body of knowledge on limitations and priorities in 3DPGPC, it is evident that 3DPGPC offers a tangible means to advance modern construction with a low carbon footprint. However, this is possible only when attention is shifted towards making it more efficient from the viewpoint of its limitations. Considering the future, the research priorities presented in this paper should be acted upon with rigorousness and sincerity, along with a proactive policymaking attitude, thereby fostering interdisciplinary collaborations leading to faster developments. In doing so, harnessing the full potential of 3DPGPC will become a reality. The future of construction lies in addressing the challenges of 3DPGPC. This can only be attained by judicious thinking about the limitations and priorities. In this regard, the information presented in this article will serve as a reminder as well as a foundational viewpoint to the researchers, academic community, and industry professionals.

Author Contributions

Conceptualisation, J.M. and A.J.B.; writing—original draft preparation, J.M.; writing—review and editing, A.J.B. and R.C.; visualisation, J.M.; supervision, A.J.B. and R.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data sharing is not applicable to this article. No new data were created or analyzed in this study.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| 3DPGPC | 3D-printed geopolymer concrete |

| FA | Fly ash |

| GGBS | Ground granulated blast furnace slag |

| RHA | Rice husk ash |

| MK | Metakaolin |

| MT | Mine tailings |

| SF | Silica fume |

References

- Global Construction Futures. Available online: https://www.oxfordeconomics.com/resource/global-construction-futures/ (accessed on 2 February 2025).

- Regona, M.; Yigitcanlar, T.; Hon, C.; Teo, M. Artificial Intelligence and Sustainable Development Goals: Systematic Literature Review of the Construction Industry. Sustain. Cities Soc. 2024, 108, 105499. [Google Scholar] [CrossRef]

- Oyejobi, D.O.; Firoozi, A.A.; Fernández, D.B.; Avudaiappan, S. Integrating Circular Economy Principles into Concrete Technology: Enhancing Sustainability through Industrial Waste Utilization. Results Eng. 2024, 24, 102846. [Google Scholar] [CrossRef]

- Volpe, S.; Sangiorgio, V.; Fiorito, F.; Varum, H. Overview of 3D Construction Printing and Future Perspectives: A Review of Technology, Companies and Research Progression. Archit. Sci. Rev. 2024, 67, 1–22. [Google Scholar] [CrossRef]

- Alotaibi, B.S.; Shema, A.I.; Ibrahim, A.U.; Abuhussain, M.A.; Abdulmalik, H.; Dodo, Y.A.; Atakara, C. Assimilation of 3D Printing, Artificial Intelligence (AI) and Internet of Things (IoT) for the Construction of Eco-Friendly Intelligent Homes: An Explorative Review. Heliyon 2024, 10, e36846. [Google Scholar] [CrossRef]

- Khan, M.; McNally, C. Recent Developments on Low Carbon 3D Printing Concrete: Revolutionizing Construction through Innovative Technology. Clean. Mater. 2024, 12, 100251. [Google Scholar] [CrossRef]

- Xia, M.; Nematollahi, B.; Sanjayan, J.G. Chapter 11—Development of Powder-Based 3D Concrete Printing Using Geopolymers. In 3D Concrete Printing Technology; Sanjayan, J.G., Nazari, A., Nematollahi, B., Eds.; Butterworth-Heinemann: Oxford, UK, 2019; pp. 223–240. ISBN 978-0-12-815481-6. [Google Scholar]

- Singh, N.; Colangelo, F.; Farina, I. Sustainable Non-Conventional Concrete 3D Printing—A Review. Sustainability 2023, 15, 10121. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.; Dong, S.; Yu, X.; Han, B. A Review of the Current Progress and Application of 3D Printed Concrete. Compos. Part Appl. Sci. Manuf. 2019, 125, 105533. [Google Scholar] [CrossRef]

- Jaji, M.B.; van Zijl, G.P.A.G.; Babafemi, A.J. Slag-Modified Metakaolin-Based 3D Printed Geopolymer: Mechanical Characterisation, Microstructural Properties, and Nitrogen Physisorption Pore Analysis. J. Build. Eng. 2024, 81, 108166. [Google Scholar] [CrossRef]

- Chen, L.; Yang, M.; Chen, Z.; Xie, Z.; Huang, L.; Osman, A.I.; Farghali, M.; Sandanayake, M.; Liu, E.; Ahn, Y.H.; et al. Conversion of Waste into Sustainable Construction Materials: A Review of Recent Developments and Prospects. Mater. Today Sustain. 2024, 27, 100930. [Google Scholar] [CrossRef]

- Wudil, Y.S.; Al-Fakih, A.; Al-Osta, M.A.; Gondal, M.A. Intelligent Optimization for Modeling Carbon Dioxide Footprint in Fly Ash Geopolymer Concrete: A Novel Approach for Minimizing CO2 Emissions. J. Environ. Chem. Eng. 2024, 12, 111835. [Google Scholar] [CrossRef]

- Liu, S.; Liu, Z.; Harada, K.; Takasu, K.; Suyama, H.; Yamamoto, H. Investigating the Use of Bamboo Charcoal to Reduce Carbon Emissions in Geopolymer Mortar. Constr. Build. Mater. 2024, 434, 136781. [Google Scholar] [CrossRef]

- Zhong, H.; Zhang, M. 3D Printing Geopolymers: A Review. Cem. Concr. Compos. 2022, 128, 104455. [Google Scholar] [CrossRef]

- Nematollahi, B.; Xia, M.; Sanjayan, J. Post-Processing Methods to Improve Strength of Particle-Bed 3D Printed Geopolymer for Digital Construction Applications. Front. Mater. 2019, 6. [Google Scholar] [CrossRef]

- Lazorenko, G.; Kasprzhitskii, A. Geopolymer Additive Manufacturing: A Review. Addit. Manuf. 2022, 55, 102782. [Google Scholar] [CrossRef]

- Shilar, F.A.; Ganachari, S.V.; Patil, V.B.; Bhojaraja, B.E.; Yunus Khan, T.M.; Almakayeel, N. A Review of 3D Printing of Geopolymer Composites for Structural and Functional Applications. Constr. Build. Mater. 2023, 400, 132869. [Google Scholar] [CrossRef]

- Chen, K.; Liu, Q.; Chen, B.; Zhang, S.; Ferrara, L.; Li, W. Effect of Raw Materials on the Performance of 3D Printing Geopolymer: A Review. J. Build. Eng. 2024, 84, 108501. [Google Scholar] [CrossRef]

- Ricciotti, L.; Apicella, A.; Perrotta, V.; Aversa, R. Geopolymer Materials for Extrusion-Based 3D-Printing: A Review. Polymers 2023, 15, 4688. [Google Scholar] [CrossRef]

- Al-Noaimat, Y.A.; Ghaffar, S.H.; Chougan, M.; Al-Kheetan, M.J. A Review of 3D Printing Low-Carbon Concrete with One-Part Geopolymer: Engineering, Environmental and Economic Feasibility. Case Stud. Constr. Mater. 2023, 18, e01818. [Google Scholar] [CrossRef]

- Raza, M.H.; Zhong, R.Y.; Khan, M. Recent Advances and Productivity Analysis of 3D Printed Geopolymers. Addit. Manuf. 2022, 52, 102685. [Google Scholar] [CrossRef]

- Yousaf, A.; Al Rashid, A.; Koç, M. 3D Printing of Alkali-Activated Geopolymers for Sustainable and Circular Economy Advancements. Circ. Econ. 2024, 3, 100101. [Google Scholar] [CrossRef]

- Sakhare, V.; Najar, M.; Deshpande, S. Printing Performance of 3D-Printed Geopolymer through Pumpability–Extrudability–Buildability Properties—A Review. Archit. Sci. Rev. 2024, 1–25. [Google Scholar] [CrossRef]

- Qaidi, S.; Yahia, A.; Tayeh, B.A.; Unis, H.; Faraj, R.; Mohammed, A. 3D Printed Geopolymer Composites: A Review. Mater. Today Sustain. 2022, 20, 100240. [Google Scholar] [CrossRef]

- Hanani Ismail, A.; Kusbiantoro, A.; Tajunnisa, Y.; Jaya Ekaputri, J.; Laory, I. A Review of Aluminosilicate Sources from Inorganic Waste for Geopolymer Production: Sustainable Approach for Hydrocarbon Waste Disposal. Clean. Mater. 2024, 13, 100259. [Google Scholar] [CrossRef]

- Zhang, P.; Zheng, Y.; Wang, K.; Zhang, J. A Review on Properties of Fresh and Hardened Geopolymer Mortar. Compos. Part B Eng. 2018, 152, 79–95. [Google Scholar] [CrossRef]

- Swathi, B.; Vidjeapriya, R. Influence of Precursor Materials and Molar Ratios on Normal, High, and Ultra-High Performance Geopolymer Concrete—A State of Art Review. Constr. Build. Mater. 2023, 392, 132006. [Google Scholar] [CrossRef]

- Constâncio Trindade, A.C.; Ribeiro de Avillez, R.; Letichevsky, S.; de Andrade Silva, F. Influence of Precursor Materials on the Fresh State and Thermo-Chemo-Mechanical Properties of Sodium-Based Geopolymers. Ceram. Int. 2022, 48, 19806–19817. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, J.; Kashif Anwar, M.; Zhang, Y.; Gilabert, F.A. Robust Optimization of Formulation Ratios for the Mechanical, Microstructural and Printing Performance of Cost-Effective 3D Printing Geopolymer. 2024. [Google Scholar]

- Słomka-Słupik, B.; Wiśniewska, P.; Bargieł, W. Multicomponent Low Initial Molar Ratio of SiO2/Al2O3 Geopolymer Mortars: Pilot Research. Materials 2022, 15, 5943. [Google Scholar] [CrossRef]

- Zhou, Z.; Geng, J.; Jin, C.; Liu, G.; Xia, Z. Influence of Residue Soil on the Properties of Fly Ash–Slag-Based Geopolymer Materials for 3D Printing. Materials 2024, 17, 2992. [Google Scholar] [CrossRef]

- Guo, X.; Yang, J.; Xiong, G. Influence of Supplementary Cementitious Materials on Rheological Properties of 3D Printed Fly Ash Based Geopolymer. Cem. Concr. Compos. 2020, 114, 103820. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, L.; Wei, K.; Gao, H.; Liu, Z.; She, Y.; Chen, F.; Gao, H.; Yu, Q. Rheology Control and Shrinkage Mitigation of 3D Printed Geopolymer Concrete Using Nanocellulose and Magnesium Oxide. Constr. Build. Mater. 2024, 429, 136421. [Google Scholar] [CrossRef]

- Kondepudi, K.; Subramaniam, K.V.L. Formulation of Alkali-Activated Fly Ash-Slag Binders for 3D Concrete Printing. Cem. Concr. Compos. 2021, 119, 103983. [Google Scholar] [CrossRef]

- Sun, C.; Xiang, J.; Xu, M.; He, Y.; Tong, Z.; Cui, X. 3D Extrusion Free Forming of Geopolymer Composites: Materials Modification and Processing Optimization. J. Clean. Prod. 2020, 258, 120986. [Google Scholar] [CrossRef]

- Rahemipoor, S.; Hasany, M.; Mehrali, M.; Almdal, K.; Ranjbar, N.; Mehrali, M. Phase Change Materials Incorporation into 3D Printed Geopolymer Cement: A Sustainable Approach to Enhance the Comfort and Energy Efficiency of Buildings. J. Clean. Prod. 2023, 417, 138005. [Google Scholar] [CrossRef]

- Kondepudi, K.; Subramaniam, K.V.L.; Nematollahi, B.; Bong, S.H.; Sanjayan, J. Study of Particle Packing and Paste Rheology in Alkali Activated Mixtures to Meet the Rheology Demands of 3D Concrete Printing. Cem. Concr. Compos. 2022, 131, 104581. [Google Scholar] [CrossRef]

- Ma, S.; Fu, S.; Yang, T.; Li, K.; Chen, G.; Dong, Q.; He, P.; Sun, Z.; Duan, X.; Jia, D.; et al. Unveiling the Critical Role of Rheology Modifiers in Additive Manufacturing of Geopolymers and Their Mechanical Properties. Addit. Manuf. 2023, 78, 103826. [Google Scholar] [CrossRef]

- Albar, A.; Chougan, M.; Al- Kheetan, M.J.; Swash, M.R.; Ghaffar, S.H. Effective Extrusion-Based 3D Printing System Design for Cementitious-Based Materials. Results Eng. 2020, 6, 100135. [Google Scholar] [CrossRef]

- Jaji, M.B.; van Zijl, G.P.A.G.; Babafemi, A.J. Slag-Modified Metakaolin-Based Geopolymer for 3D Concrete Printing Application: Evaluating Fresh and Hardened Properties. Clean. Eng. Technol. 2023, 15, 100665. [Google Scholar] [CrossRef]

- Kamseu, E.; Alzari, V.; Nuvoli, D.; Sanna, D.; Lancellotti, I.; Mariani, A.; Leonelli, C. Dependence of the Geopolymerization Process and End-Products to the Nature of Solid Precursors: Challenge of the Sustainability. J. Clean. Prod. 2021, 278, 123587. [Google Scholar] [CrossRef]

- Xu, W.; Tang, Z.; Song, Y.; Xie, Y.; Lei, B.; Yu, H.; Long, G.; Kai, M. Drying Shrinkage of Geopolymeric Recycled Aggregate Concrete. Constr. Build. Mater. 2023, 395, 132220. [Google Scholar] [CrossRef]

- Khan, I.; Xu, T.; Castel, A.; Gilbert, R.I.; Babaee, M. Risk of Early Age Cracking in Geopolymer Concrete Due to Restrained Shrinkage. Constr. Build. Mater. 2019, 229, 116840. [Google Scholar] [CrossRef]

- Panda, B. 3D Printing of High-Volume Fly Ash Mixtures for Digital Concrete Construction. Ph.D. Thesis, Nanyang Technological University, Singapore, 2019. [Google Scholar]

- Yuan, Q.; Gao, C.; Huang, T.; Zuo, S.; Yao, H.; Zhang, K.; Huang, Y.; Liu, J. Factors Influencing the Properties of Extrusion-Based 3D-Printed Alkali-Activated Fly Ash-Slag Mortar. Materials 2022, 15, 1969. [Google Scholar] [CrossRef] [PubMed]

- Jaji, M.B.; van Zijl, G.P.A.G.; Babafemi, A.J. Durability and Pore Structure of Metakaolin-Based 3D Printed Geopolymer Concrete. Constr. Build. Mater. 2024, 422, 135847. [Google Scholar] [CrossRef]

- Rabi, M.; Shamass, R.; Cashell, K.A. Structural Performance of Stainless Steel Reinforced Concrete Members: A Review. Constr. Build. Mater. 2022, 325, 126673. [Google Scholar] [CrossRef]

- Chen, W.; Pan, J.; Zhu, B.; Ma, X.; Zhang, Y.; Chen, Y.; Li, X.; Meng, L.; Cai, J. Improving Mechanical Properties of 3D Printable ‘One-Part’ Geopolymer Concrete with Steel Fiber Reinforcement. J. Build. Eng. 2023, 75, 107077. [Google Scholar] [CrossRef]

- Li, Z.; Wang, L.; Ma, G. Mechanical Improvement of Continuous Steel Microcable Reinforced Geopolymer Composites for 3D Printing Subjected to Different Loading Conditions. Compos. Part B Eng. 2020, 187, 107796. [Google Scholar] [CrossRef]

- Kaufmann, J.; Lübben, J.; Schwitter, E. Mechanical Reinforcement of Concrete with Bi-Component Fibers. Compos. Part Appl. Sci. Manuf. 2007, 38, 1975–1984. [Google Scholar] [CrossRef]

- Hack, N.; Lauer, W.V. Mesh-Mould: Robotically Fabricated Spatial Meshes as Reinforced Concrete Formwork. Archit. Des. 2014, 84, 44–53. [Google Scholar] [CrossRef]

- Asprone, D.; Auricchio, F.; Menna, C.; Mercuri, V. 3D Printing of Reinforced Concrete Elements: Technology and Design Approach. Constr. Build. Mater. 2018, 165, 218–231. [Google Scholar] [CrossRef]

- Lim, J.H.; Panda, B.; Pham, Q.-C. Improving Flexural Characteristics of 3D Printed Geopolymer Composites with In-Process Steel Cable Reinforcement. Constr. Build. Mater. 2018, 178, 32–41. [Google Scholar] [CrossRef]

- Li, V.C.; Bos, F.P.; Yu, K.; McGee, W.; Ng, T.Y.; Figueiredo, S.C.; Nefs, K.; Mechtcherine, V.; Nerella, V.N.; Pan, J.; et al. On the Emergence of 3D Printable Engineered, Strain Hardening Cementitious Composites (ECC/SHCC). Cem. Concr. Res. 2020, 132, 106038. [Google Scholar] [CrossRef]

- Nematollahi, B.; Vijay, P.; Sanjayan, J.; Nazari, A.; Xia, M.; Naidu Nerella, V.; Mechtcherine, V. Effect of Polypropylene Fibre Addition on Properties of Geopolymers Made by 3D Printing for Digital Construction. Materials 2018, 11, 2352. [Google Scholar] [CrossRef] [PubMed]

- Perrot, A.; Jacquet, Y.; Caron, J.F.; Mesnil, R.; Ducoulombier, N.; De Bono, V.; Sanjayan, J.; Ramakrishnan, S.; Kloft, H.; Gosslar, J.; et al. Snapshot on 3D Printing with Alternative Binders and Materials: Earth, Geopolymers, Gypsum and Low Carbon Concrete. Cem. Concr. Res. 2024, 185, 107651. [Google Scholar] [CrossRef]

- Patel, C.D.; Chen, C.-H. Digital Manufacturing: The Industrialization of “Art to Part” 3D Additive Printing; Elsevier: Amsterdam, The Netherlands, 2022; ISBN 978-0-323-95063-3. [Google Scholar]

- Xia, M.; Sanjayan, J. Method of Formulating Geopolymer for 3D Printing for Construction Applications. Mater. Des. 2016, 110, 382–390. [Google Scholar] [CrossRef]

- Rehman, A.U.; Kim, J.-H. 3D Concrete Printing: A Systematic Review of Rheology, Mix Designs, Mechanical, Microstructural, and Durability Characteristics. Materials 2021, 14, 3800. [Google Scholar] [CrossRef]

- Panda, B.; Paul, S.C.; Hui, L.J.; Tay, Y.W.D.; Tan, M.J. Additive Manufacturing of Geopolymer for Sustainable Built Environment. J. Clean. Prod. 2017, 167, 281–288. [Google Scholar] [CrossRef]

- Panda, B.; Singh, G.B.; Unluer, C.; Tan, M.J. Synthesis and Characterization of One-Part Geopolymers for Extrusion Based 3D Concrete Printing. J. Clean. Prod. 2019, 220, 610–619. [Google Scholar] [CrossRef]

- Ma, G.; Yan, Y.; Zhang, M.; Sanjayan, J. Effect of Steel Slag on 3D Concrete Printing of Geopolymer with Quaternary Binders. Ceram. Int. 2022, 48, 26233–26247. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Ramakrishnan, S.; Sanjayan, J. Effect of Alkali Reactions on the Rheology of One-Part 3D Printable Geopolymer Concrete. Cem. Concr. Compos. 2021, 116, 103899. [Google Scholar] [CrossRef]

- Panda, B.; Paul, S.C.; Mohamed, N.A.N.; Tay, Y.W.D.; Tan, M.J. Measurement of Tensile Bond Strength of 3D Printed Geopolymer Mortar. Measurement 2018, 113, 108–116. [Google Scholar] [CrossRef]

- Kashani, A.; Ngo, T.D. Optimisation of Mixture Properties for 3D Printing of Geopolymer Concrete. In Proceedings of the 35th International Symposium on Automation and Robotics in Construction (ISARC 2018), Berlin, Germany, 20–25 July 2018; pp. 1–8. [Google Scholar]

- Munir, Q.; Peltonen, R.; Kärki, T. Printing Parameter Requirements for 3D Printable Geopolymer Materials Prepared from Industrial Side Streams. Materials 2021, 14, 4758. [Google Scholar] [CrossRef]

- Zhang, C.; Nerella, V.N.; Krishna, A.; Wang, S.; Zhang, Y.; Mechtcherine, V.; Banthia, N. Mix Design Concepts for 3D Printable Concrete: A Review. Cem. Concr. Compos. 2021, 122, 104155. [Google Scholar] [CrossRef]

- Dudek, M.; Sitarz, M. Analysis of Changes in the Microstructure of Geopolymer Mortar after Exposure to High Temperatures. Materials 2020, 13, 4263. [Google Scholar] [CrossRef] [PubMed]

- Noushini, A.; Castel, A. The Effect of Heat-Curing on Transport Properties of Low-Calcium Fly Ash-Based Geopolymer Concrete. Constr. Build. Mater. 2016, 112, 464–477. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, K.; Wang, S.; Wang, Z.; Yang, Z.; Shumuye, E.D.; Gong, X. Effect of Elevated Temperature on Mechanical Properties of High-Volume Fly Ash-Based Geopolymer Concrete, Mortar and Paste Cured at Room Temperature. Polymers 2021, 13, 1473. [Google Scholar] [CrossRef]

- Palomo, A.; Grutzeck, M.W.; Blanco, M.T. Alkali-Activated Fly Ashes: A Cement for the Future. Cem. Concr. Res. 1999, 29, 1323–1329. [Google Scholar] [CrossRef]

- Perera, D.S.; Uchida, O.; Vance, E.R.; Finnie, K.S. Influence of Curing Schedule on the Integrity of Geopolymers. J. Mater. Sci. 2007, 42, 3099–3106. [Google Scholar] [CrossRef]

- Singh, B.; Ishwarya, G.; Gupta, M.; Bhattacharyya, S.K. Geopolymer Concrete: A Review of Some Recent Developments. Constr. Build. Mater. 2015, 85, 78–90. [Google Scholar] [CrossRef]

- Yousefi Oderji, S.; Chen, B.; Jaffar, S.T.A. Effects of Relative Humidity on the Properties of Fly Ash-Based Geopolymers. Constr. Build. Mater. 2017, 153, 268–273. [Google Scholar] [CrossRef]

- Wang, H.; Zheng, Y.; Yu, Z. Influence of Ambient Relative Humidity on the Shrinkage Strain of Engineered Geopolymer Composites Based on Orthogonal Experimental Design. Materials 2024, 17, 4321. [Google Scholar] [CrossRef]

- García-Mejía, T.A.; Chávez-García, M.d.L. Compressive Strength of Metakaolin-Based Geopolymers: Influence of KOH Concentration, Temperature, Time and Relative Humidity. Mater. Sci. Appl. 2016, 7, 772–791. [Google Scholar] [CrossRef]

- Munir, Q.; Kärki, T. Cost Analysis of Various Factors for Geopolymer 3D Printing of Construction Products in Factories and on Construction Sites. Recycling 2021, 6, 60. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Palomo, A. Characterisation of Fly Ashes. Potential Reactivity as Alkaline Cements☆. Fuel 2003, 82, 2259–2265. [Google Scholar] [CrossRef]

- Kumar, S.; Mucsi, G.; Kristály, F.; Pekker, P. Mechanical Activation of Fly Ash and Its Influence on Micro and Nano-Structural Behaviour of Resulting Geopolymers. Adv. Powder Technol. 2017, 28, 805–813. [Google Scholar] [CrossRef]

- Tome, S.; Nana, A.; Tchakouté, H.K.; Temuujin, J.; Rüscher, C.H. Mineralogical Evolution of Raw Materials Transformed to Geopolymer Materials: A Review. Ceram. Int. 2024, 50, 35855–35868. [Google Scholar] [CrossRef]

- Kriven, W.M.; Leonelli, C.; Provis, J.L.; Boccaccini, A.R.; Attwell, C.; Ducman, V.S.; Ferone, C.; Rossignol, S.; Luukkonen, T.; van Deventer, J.S.J.; et al. Why Geopolymers and Alkali-Activated Materials Are Key Components of a Sustainable World: A Perspective Contribution. J. Am. Ceram. Soc. 2024, 107, 5159–5177. [Google Scholar] [CrossRef]

- Figueiredo, R.A.M.; Brandão, P.R.G.; Soutsos, M.; Henriques, A.B.; Fourie, A.; Mazzinghy, D.B. Producing Sodium Silicate Powder from Iron Ore Tailings for Use as an Activator in One-Part Geopolymer Binders. Mater. Lett. 2021, 288, 129333. [Google Scholar] [CrossRef]

- Assi, L.N.; Carter, K.; Deaver, E.; Ziehl, P. Review of Availability of Source Materials for Geopolymer/Sustainable Concrete. J. Clean. Prod. 2020, 263, 121477. [Google Scholar] [CrossRef]

- Nanda, B.; Mishra, J.; Patro, S.K. Synthesis of Rice Husk Ash Based Alkaline Activators for Geopolymer Binder Systems: A Review. J. Build. Eng. 2024, 91, 109694. [Google Scholar] [CrossRef]

- Abbas, R.; Khereby, M.A.; Ghorab, H.Y.; Elkhoshkhany, N. Preparation of Geopolymer Concrete Using Egyptian Kaolin Clay and the Study of Its Environmental Effects and Economic Cost. Clean Technol. Environ. Policy 2020, 22, 669–687. [Google Scholar] [CrossRef]

- Rao, G.M.; Kumar, Y.A.; Vengala, J.; Venu, M. Performance of Fly Ash and Ggbs Based Geopolymer Concrete Using Single Alkaline Activator Solution and Its Cost Analysis. IOP Conf. Ser. Mater. Sci. Eng. 2020, 998, 012051. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Nerella, V.N.; Will, F.; Näther, M.; Otto, J.; Krause, M. Large-Scale Digital Concrete Construction—CONPrint3D Concept for on-Site, Monolithic 3D-Printing. Autom. Constr. 2019, 107, 102933. [Google Scholar] [CrossRef]

- El-Sayegh, S.; Romdhane, L.; Manjikian, S. A Critical Review of 3D Printing in Construction: Benefits, Challenges, and Risks. Arch. Civ. Mech. Eng. 2020, 20, 34. [Google Scholar] [CrossRef]

- Khan, M.S.; Sanchez, F.; Zhou, H. 3-D Printing of Concrete: Beyond Horizons. Cem. Concr. Res. 2020, 133, 106070. [Google Scholar] [CrossRef]

- Buchli, J.; Giftthaler, M.; Kumar, N.; Lussi, M.; Sandy, T.; Dörfler, K.; Hack, N. Digital in Situ Fabrication—Challenges and Opportunities for Robotic in Situ Fabrication in Architecture, Construction, and Beyond. Cem. Concr. Res. 2018, 112, 66–75. [Google Scholar] [CrossRef]

- Mancke, R.; Stephan, D.; Firdous, R. Case Study—Sustainable Concrete Development: Assessing Social, Environmental, and Performance Factors of Geopolymers and CEM-I Concretes. Case Stud. Constr. Mater. 2024, 21, e03448. [Google Scholar] [CrossRef]

- Kruger, J.; van Zijl, G. A Compendious Review on Lack-of-Fusion in Digital Concrete Fabrication. Addit. Manuf. 2021, 37, 101654. [Google Scholar] [CrossRef]

- Kruger, J.; du Plessis, A.; van Zijl, G. An Investigation into the Porosity of Extrusion-Based 3D Printed Concrete. Addit. Manuf. 2021, 37, 101740. [Google Scholar] [CrossRef]

- Malan, J.D.; van Rooyen, A.S.; van Zijl, G.P.A.G. Chloride Induced Corrosion and Carbonation in 3D Printed Concrete. Infrastructures 2022, 7, 1. [Google Scholar] [CrossRef]

- Van Der Putten, J.; De Volder, M.; Van den Heede, P.; Deprez, M.; Cnudde, V.; De Schutter, G.; Van Tittelboom, K. Transport Properties of 3D Printed Cementitious Materials with Prolonged Time Gap between Successive Layers. Cem. Concr. Res. 2022, 155, 106777. [Google Scholar] [CrossRef]

- Basiago, A.D. Methods of Defining ‘Sustainability’. Sustain. Dev. 1995, 3, 109–119. [Google Scholar] [CrossRef]

- Habert, G.; d’Espinose de Lacaillerie, J.B.; Roussel, N. An Environmental Evaluation of Geopolymer Based Concrete Production: Reviewing Current Research Trends. J. Clean. Prod. 2011, 19, 1229–1238. [Google Scholar] [CrossRef]

- Adesanya, E.; Perumal, P.; Luukkonen, T.; Yliniemi, J.; Ohenoja, K.; Kinnunen, P.; Illikainen, M. Opportunities to Improve Sustainability of Alkali-Activated Materials: A Review of Side-Stream Based Activators. J. Clean. Prod. 2021, 286, 125558. [Google Scholar] [CrossRef]

- Raza, M.H.; Zhong, R.Y. A Sustainable Roadmap for Additive Manufacturing Using Geopolymers in Construction Industry. Resour. Conserv. Recycl. 2022, 186, 106592. [Google Scholar] [CrossRef]

- Borno, I.B.; Nair, N.; Ashraf, W. Alkali Thermal Fusion: A Prospective Route to Enhance the Reactivity of Low-Grade Clay and Utilize as Supplementary Cementitious Material (SCM). Cem. Concr. Compos. 2024, 147, 105417. [Google Scholar] [CrossRef]

- Alberici, S.; de Beer, J.; van der Hoorn, I.; Staats, M. Fly Ash and Blast Furnace Slag for Cement Manufacturing; Department for Business, Energy, and Industrial Strategy (BEIS): London, UK, 2017; pp. 1–34. [Google Scholar]

- Colangelo, F.; Navarro, T.G.; Farina, I.; Petrillo, A. Comparative LCA of Concrete with Recycled Aggregates: A Circular Economy Mindset in Europe. Int. J. Life Cycle Assess. 2020, 25, 1790–1804. [Google Scholar] [CrossRef]

- Green Geopolymer Concretes for Australian Construction Industry|ANSTO. Available online: https://www.ansto.gov.au/our-facilities/australian-synchrotron/case-studies/advanced-manufacturing/green-geopolymer-concretes (accessed on 26 March 2025).

- Zhang, P.; Gao, Z.; Wang, J.; Guo, J.; Hu, S.; Ling, Y. Properties of Fresh and Hardened Fly Ash/Slag Based Geopolymer Concrete: A Review. J. Clean. Prod. 2020, 270, 122389. [Google Scholar] [CrossRef]

- Martínez, A.; Miller, S.A. A Review of Drivers for Implementing Geopolymers in Construction: Codes and Constructability. Resour. Conserv. Recycl. 2023, 199, 107238. [Google Scholar] [CrossRef]

- Alami, A.H.; Olabi, A.G.; Ayoub, M.; Aljaghoub, H.; Alasad, S.; Abdelkareem, M.A. 3D Concrete Printing: Recent Progress, Applications, Challenges, and Role in Achieving Sustainable Development Goals. Buildings 2023, 13, 924. [Google Scholar] [CrossRef]

- van Deventer, J.S.J.; Provis, J.L.; Duxson, P.; Brice, D.G. Chemical Research and Climate Change as Drivers in the Commercial Adoption of Alkali Activated Materials. Waste Biomass Valorization 2010, 1, 145–155. [Google Scholar] [CrossRef]

- Shivendra, B.T.; Shahaji; Sharath Chandra, S.; Singh, A.K.; Kumar, R.; Kumar, N.; Tantri, A.; Naganna, S.R. A Path towards SDGs: Investigation of the Challenges in Adopting 3D Concrete Printing in India. Infrastructures 2024, 9, 166. [Google Scholar] [CrossRef]

- Babafemi, A.J.; Kolawole, J.T.; Miah, M.J.; Paul, S.C.; Panda, B. A Concise Review on Interlayer Bond Strength in 3D Concrete Printing. Sustainability 2021, 13, 7137. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Y.; Xie, Y.; Zhang, Z.; Banthia, N. Unraveling Pore Structure Alternations in 3D-Printed Geopolymer Concrete and Corresponding Impacts on Macro-Properties. Addit. Manuf. 2022, 59, 103137. [Google Scholar] [CrossRef]

- Özkılıç, H.; İlcan, H.; Aminipour, E.; Tuğluca, M.S.; Aldemir, A.; Şahmaran, M. Bond Properties and Anisotropy Performance of 3D-Printed Construction and Demolition Waste-Based Geopolymers: Effect of Operational- and Material-Oriented Parameters. J. Build. Eng. 2023, 78, 107688. [Google Scholar] [CrossRef]

- Pan, Y.; Jiang, L.; Wang, J.; Ma, J.; Bao, S.; Lin, Y.; Shi, K. Mapping and Evaluating Spatiotemporal Patterns of Urban Expansion in Global Earthquake-Affected Areas: A Nighttime Light Remote Sensing Perspective. Int. J. Digit. Earth 2024, 17, 2419938. [Google Scholar] [CrossRef]

- Huang, Q.; Meng, S.; He, C.; Dou, Y.; Zhang, Q. Rapid Urban Land Expansion in Earthquake-Prone Areas of China. Int. J. Disaster Risk Sci. 2019, 10, 43–56. [Google Scholar] [CrossRef]

- Tran, T.T.; Pham, T.M.; Huang, Z.; Chen, W.; Ngo, T.T.; Hao, H.; Elchalakani, M. Effect of Fibre Reinforcements on Shear Capacity of Geopolymer Concrete Beams Subjected to Impact Load. Int. J. Impact Eng. 2022, 159, 104056. [Google Scholar] [CrossRef]

- Hao, H.; Bi, K.; Chen, W.; Pham, T.M.; Li, J. Towards next Generation Design of Sustainable, Durable, Multi-Hazard Resistant, Resilient, and Smart Civil Engineering Structures. Eng. Struct. 2023, 277, 115477. [Google Scholar] [CrossRef]

- Mostofizadeh, S.; Tee, K.F. Review of Next-Generation Earthquake-Resistant Geopolymer Concrete. Discov. Mater. 2024, 4, 62. [Google Scholar] [CrossRef]

- Passuello, A.; Rodríguez, E.D.; Hirt, E.; Longhi, M.; Bernal, S.A.; Provis, J.L.; Kirchheim, A.P. Evaluation of the Potential Improvement in the Environmental Footprint of Geopolymers Using Waste-Derived Activators. J. Clean. Prod. 2017, 166, 680–689. [Google Scholar] [CrossRef]

- Sona, S.; Sangeetha, S.P. Eco-Friendly Alternative Activators Derived from Industrial Wastes for the Sustainable Production of Two-Part Geopolymer Concrete at Low Cost. Constr. Build. Mater. 2025, 467, 140374. [Google Scholar] [CrossRef]

- Kallamalayil Nassar, A.; Kathirvel, P. Effective Utilization of Agricultural Waste in Synthesizing Activator for Sustainable Geopolymer Technology. Constr. Build. Mater. 2023, 362, 129681. [Google Scholar] [CrossRef]

- Nematollahi, B.; Xia, M.; Sanjayan, J.; Vijay, P. Effect of Type of Fiber on Inter-Layer Bond and Flexural Strengths of Extrusion-Based 3D Printed Geopolymer. Mater. Sci. Forum 2018, 939, 155–162. [Google Scholar] [CrossRef]

- Zhu, H.; Zhang, Z.; Deng, F.; Cao, Y. The Effects of Phase Changes on the Bonding Property of Geopolymer to Hydrated Cement. Constr. Build. Mater. 2013, 48, 124–130. [Google Scholar] [CrossRef]

- Nasvi, M.M.C.; Gamage, R.P.; Jay, S. Geopolymer as Well Cement and the Variation of Its Mechanical Behavior with Curing Temperature. Greenh. Gases Sci. Technol. 2012, 2, 46–58. [Google Scholar] [CrossRef]

- Ng, W.L.; Goh, G.L.; Goh, G.D.; Ten, J.S.J.; Yeong, W.Y. Progress and Opportunities for Machine Learning in Materials and Processes of Additive Manufacturing. Adv. Mater. 2024, 36, 2310006. [Google Scholar] [CrossRef]