Improving the Transparency of a MgAl2O4 Spinel Damaged by Sandblasting through a SiO2-ZrO2 Coating

Abstract

1. Introduction

2. Experimental Procedure

2.1. Materials and Methods

2.1.1. Powders and SPS Sintering

2.1.2. Optical Transmission

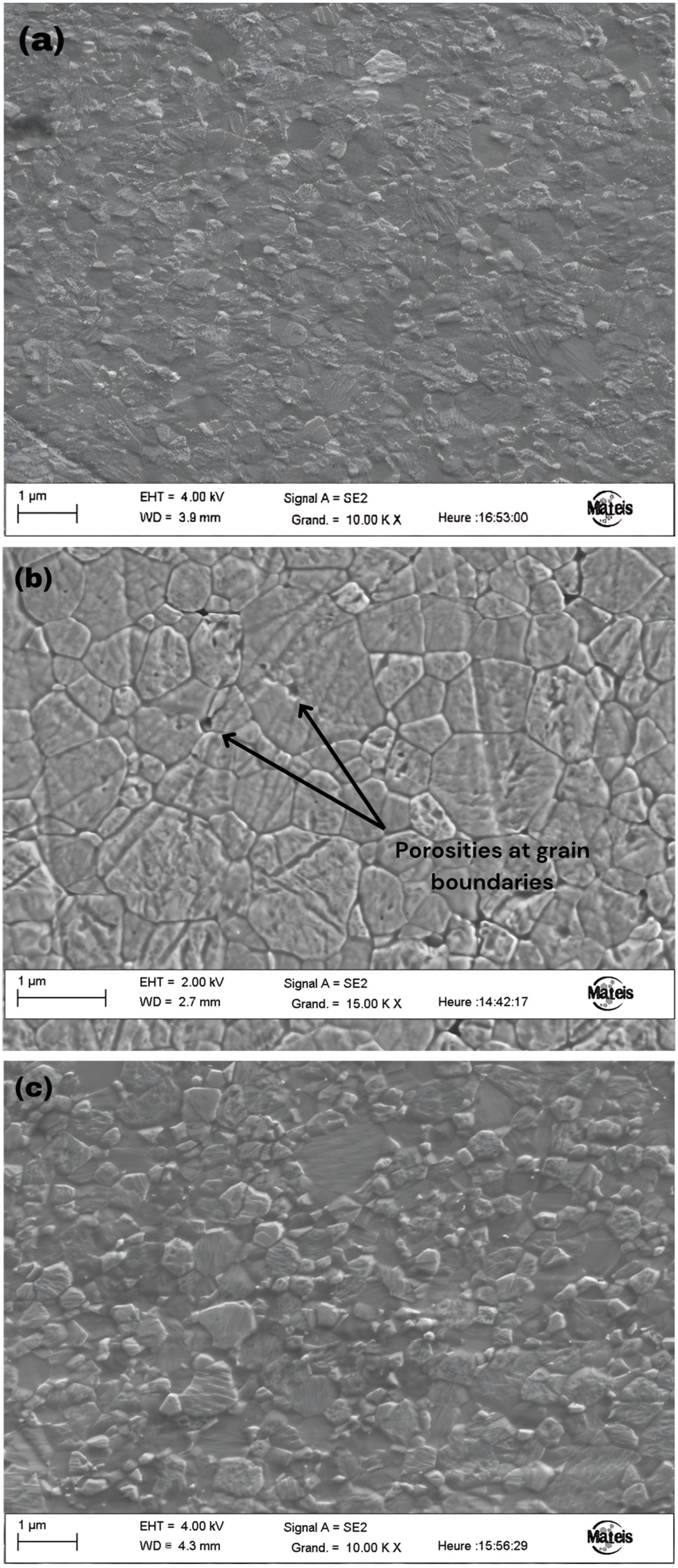

2.1.3. Microscopic Observations

2.1.4. Sandblasting

2.1.5. Coating of Sintered Samples

3. Results and Discussion

- -

- A sandblasted and coated sample is again exposed to sandblasting; thus, the optical endurance of the repaired ceramic can be determined.

- -

- A pristine sample is directly coated and characterized without sandblasting: what is the potential of such treatment and how it will perform when sandblasting.

4. Conclusions

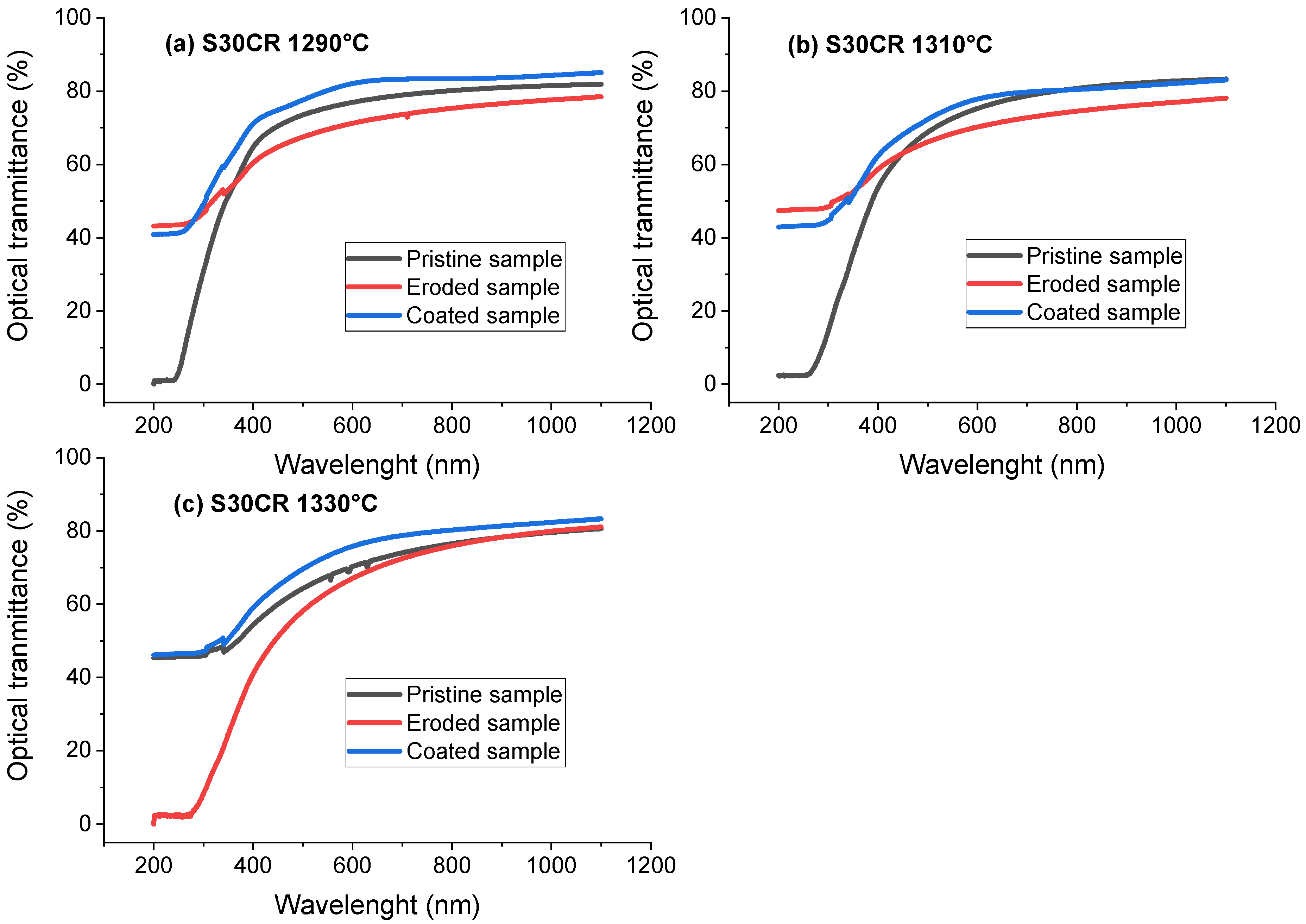

- In the pristine state, the optical transmission presents the best transmission values (85% at 1000 nm) for the S25CRX12 powder, followed by the S30CR then the S25CRX14. This good result can be attributed to the significant difference which lies in the high purity of this powder, particularly the sulfur content.

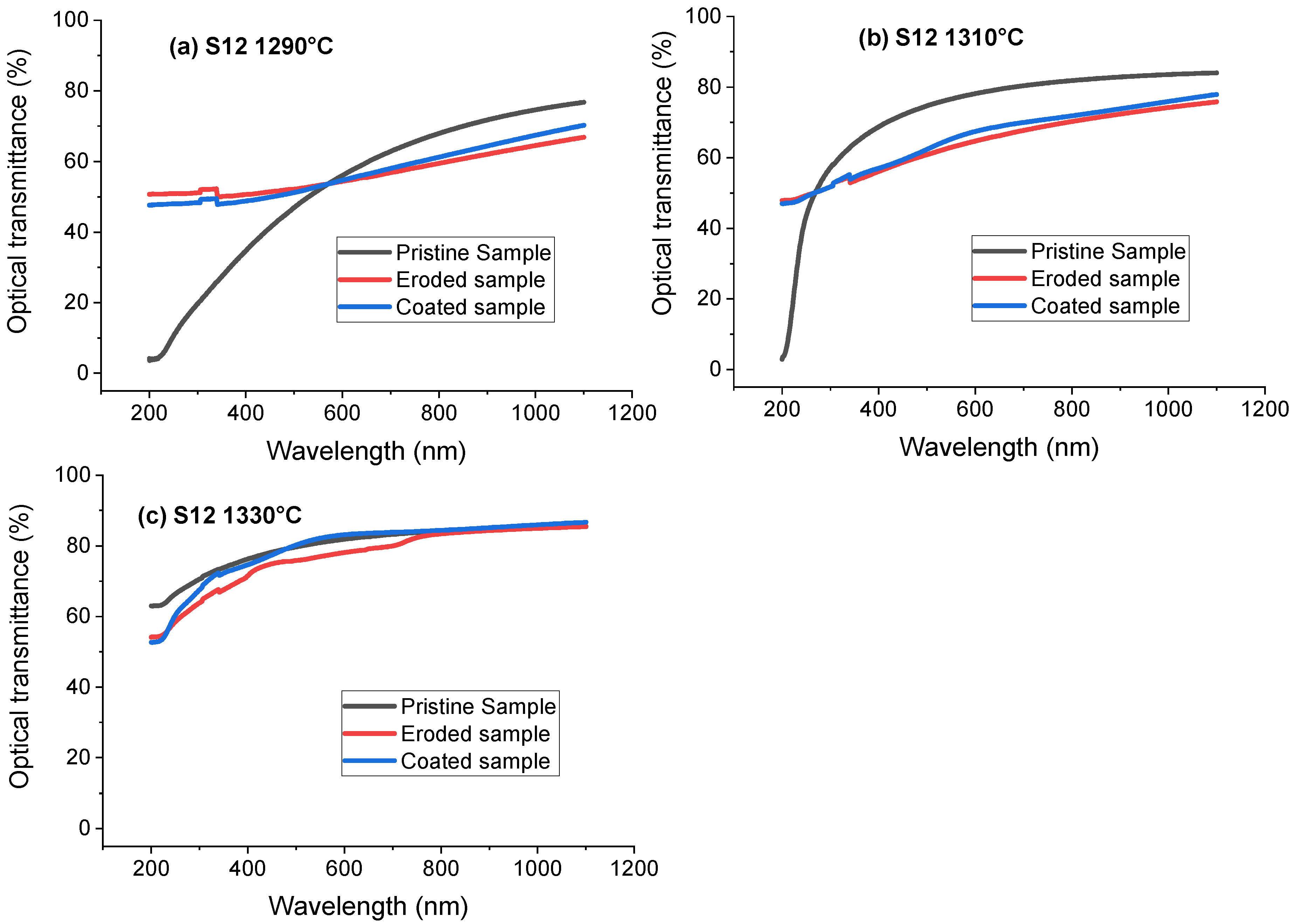

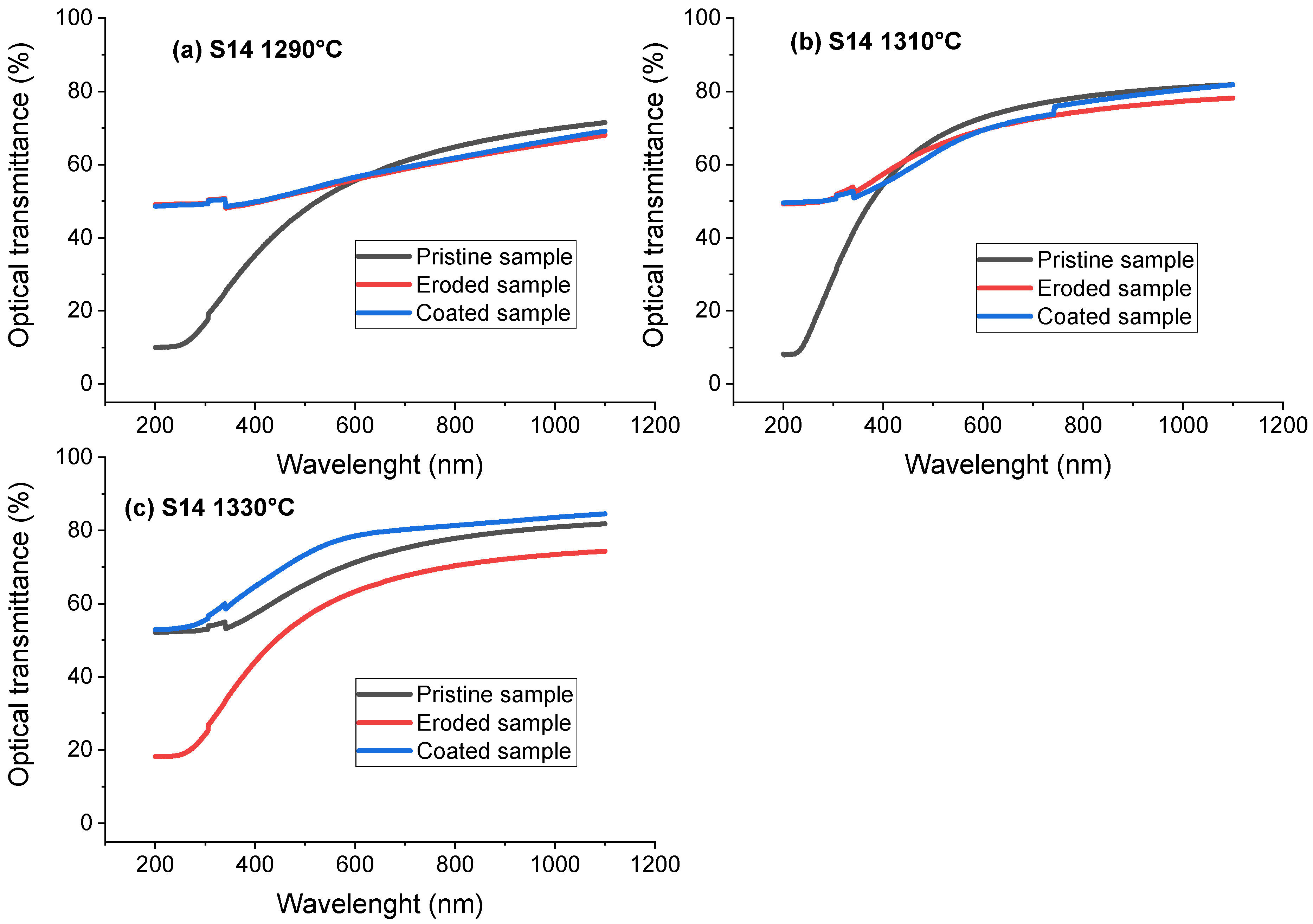

- At 200 nm wavelength, sandblasting tends to improve the transmission of spinel samples (nearly 40%) for the specimens exhibiting a low transmission in the pristine state. This behavior can be attributed to the healing of small superficial defects responsible for the degradation of transmission, such as pores or flaws, for instance. Evenly, when the pristine transmission at 200 nm is high, the sandblasting worsens the transmission, which can be due to the formation of impact flaws.

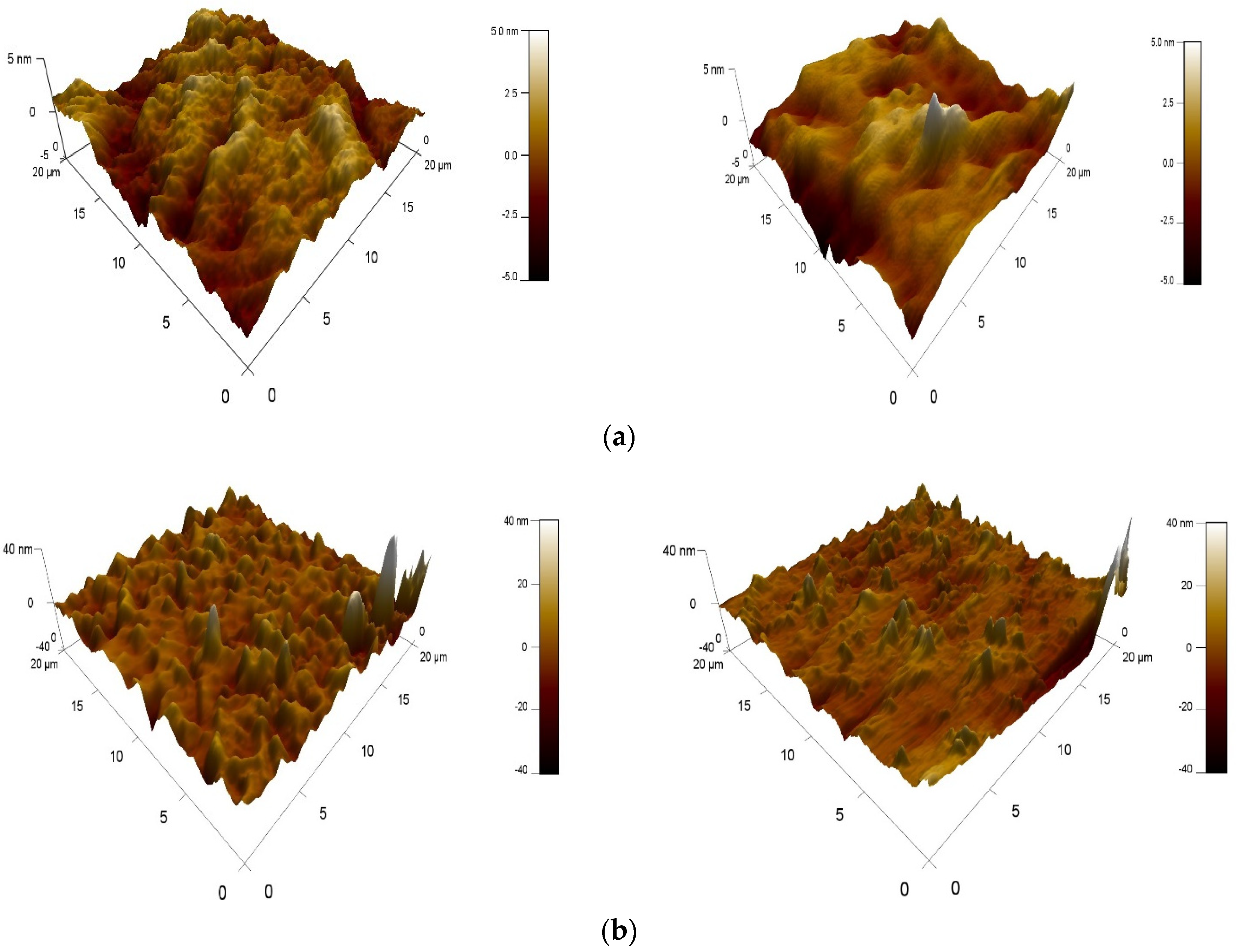

- Sandblasting reduces slightly the transmission values for long wavelengths due to the formation of large superficial defects like chipping by creation and propagation of lateral cracks. Furthermore, sandblasting degrades the surface of the samples, starting with a roughness Ra of around 8 nm in the pristine state to a significant roughness after sandblasting around 25 nm.

- Using a silica-based coating can largely restore the initial roughness and optical transmission of the eroded spinel samples by repairing the superficial defects and filling flaws or cracks tips. After coating, the optical transmission is restored, and sometimes it is higher than the initial value.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Telling, R.H.; Jilbert, G.H.; Field, J.E. Erosion of aerospace materials by solid-particle impact. In Proceedings Volume 3060, Window and Dome Technologies and Materials V; SPIE: Bellingham, WA, USA, 1997. [Google Scholar] [CrossRef]

- Lallemant, L.; Garnier, V.; Bonnefont, G.; Marouani, A.; Fantozzi, G.; Bouaouadja, N. Effect of solid particle impact on light transmission of transparent ceramics: Role of the microstructure. Opt. Mater. 2014, 37, 352–357. [Google Scholar] [CrossRef]

- DiGiovanni Anthony, A.; Fehrenbacher, L.; Roy, D.W. Hard transparent domes and windows from magnesium aluminate spinel. In Proceedings Volume 5786, Window and Dome Technologies and Materials IX; SPIE: Bellingham, WA, USA, 2005. [Google Scholar] [CrossRef]

- Von Helden, S.; Malzbender, J.; Krüger, M. Mechanical properties, wear resistance and surface damage of glasses and MgAl2O4 spinel ceramic after abrasion and scratch exposure. Ceram. Int. 2019, 45, 10765–10775. [Google Scholar] [CrossRef]

- Lindsley, B.A.; Marder, A.R. The effect of velocity on the solid particle erosion rate of alloys. Wear 1999, 225–229, 510–516. [Google Scholar] [CrossRef]

- Wellman, R.G.; Allen, C. The effects of angle of impact and material properties on the erosion rates of ceramics. Wear 1995, 186–187, 117–122. [Google Scholar] [CrossRef]

- Krell, A.; Klimke, J.; Hutzler, T. Advanced spinel and sub-μm Al2O3 for transparent armor applications. J. Eur. Ceram. Soc. 2009, 29, 275–281. [Google Scholar] [CrossRef]

- Tokariev, O.; Schnetter, L.; Beck, T.; Malzbender, J. Grain size effect on the mechanical properties of transparent spinel ceramics. J. Eur. Ceram. Soc. 2013, 33, 749–757. [Google Scholar] [CrossRef]

- Zegadi, A.; Kolli, M.; Hamidouche, M.; Fantozzi, G. Transparent MgAl2O4 spinel fabricated by spark plasma sintering from commercial powders. Ceram. Int. 2018, 44, 18828–18835. [Google Scholar] [CrossRef]

- Swab, J.J.; Pavlacka, R.; Gilde, G.; Kilczewski, S.; Wright, J.; Harris, D. Determining the Strength of Coarse-Grained ALON and Spinel. J. Am. Ceram. Soc. 2014, 97, 592–600. [Google Scholar] [CrossRef]

- Tustison, R.W. Window and Dome Technologies and Materials XI. Orlando, Florida, United States. Proceedings of SPIE, 7302; SPIE: Bellingham, WA, USA, 2009. [Google Scholar]

- Pellice, S.; Gilabert, U.; Solier, C.; Castro, Y.; Durán, A. Mechanical behavior of glass reinforced with SiO2 hybrid sol–gel coatings. J. Non-Cryst. Solids 2004, 348, 172–179. [Google Scholar] [CrossRef]

- Gallardo, J.; Durán, A.; Di Martino, D.; Almeida, R.M. Structure of inorganic and hybrid SiO2 sol–gel coatings studied by variable incidence infrared spectroscopy. J. Non-Cryst. Solids 2002, 298, 219–225. [Google Scholar] [CrossRef]

- Innocenzi, P.; Abdirashid, M.O.; Guglielmi, M. Structure and properties of sol-gel coatings from methyltriethoxysilane and tetraethoxysilane. J. Sol-Gel Sci. Technol. 1994, 3, 47–55. [Google Scholar] [CrossRef]

- García-Heras, M.; Rincón, J.M.; Romero, M.; Villegas, M.A. Indentation properties of ZrO2–SiO2 coatings on glass substrates. Mater. Res. Bull. 2003, 38, 1635–1644. [Google Scholar] [CrossRef]

- Endres, K.; Mennig, M.; Amlung, M.; Gier, A.; Schmidt, H. Enhancement of fracture strength of cutted plate glass by the application of SiO2 sol-gel coatings. Thin Sol. Films 1999, 351, 132–136. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, X.; Shen, J.; Wu, G.; Wang, J.; Chen, L. ZrO2 thin films and ZrO2-SiO2 optical reflection filters deposited by sol–gel method. Mat. Lett. 2000, 45, 311–314. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, J.-H.; Zhang, Q.-L.; Yang, H. Mechanical and Optical Properties of Ion-exchange Strengthened Glass Coated with Sol-Gel Derived ZrO2-SiO2 Film. J. Inorg. Mater. 2013, 28, 779–785. [Google Scholar] [CrossRef]

- Ma, K.J.; Chien, H.H.; Huang, S.W.; Chen, S.C.; Chao, C.L. Crack Filling of Cover Glasses by Sol-Gel Coatings. Adv. Mater. 2013, 797, 700–705. [Google Scholar] [CrossRef]

- Nogami, M. Glass preparation of the ZrO2-SiO2 system by the sol-gel process from metal alkoxides. J. Non-Crys Solids 1985, 69, 415–423. [Google Scholar] [CrossRef]

- Bonnefont, G.; Fantozzi, G.; Trombert, S.; Bonneau, L. Fine-grained transparent MgAl2O4 spinel obtained by spark plasma sintering of commercially available nano powders. Ceram. Int. 2012, 38, 131–140. [Google Scholar] [CrossRef]

- Apetz, R.; Van Bruggen, M.P.B. Transparent Alumina: A Light-Scattering Model. J. Am. Ceram. Soc. 2003, 86, 480–486. [Google Scholar] [CrossRef]

- DIN 50332; Strahlverschleiβprufung (Ray of Schleiβ Test). DIN: Berlin, Germany, 1984.

- ASTM G76-04; Standard Test Method for Conducting Erosion Tests by Solid Particle Impingement Using Gas Jets. ASTM International: West Conshohocken, PA, USA, 2004.

- Oka, Y.I.; Mihara, S.; Yoshida, T. Impact-angle dependence and estimation of erosion damage to ceramic materials caused by solid particle impact. Wear 2009, 267, 129–135. [Google Scholar] [CrossRef]

- Ayadi, A.; Bouaouadja, N.; Durán, A.; Castro, Y. Hybrid SiO2–ZrO2 coatings for restoring and repairing glasses damaged by sandblasting. Ceram. Int. 2020, 46, 10634–10640. [Google Scholar] [CrossRef]

- Brinker, C.J.; Scherer, G.W. Sol-Gel Science, The Physics and Chemistry of Sol-Gel Processing; Academic Press: Cambridge, MA, USA, 1990; 463p, ISBN 13:978-0-12-134970-7. [Google Scholar]

- Al-Oweini, R.; El-Rassy, H. Synthesis and characterization by FTIR spectroscopy of silica aerogels prepared using several Si(OR)4 and R″Si(OR′)3 precursors. J. Mol. Struct 2009, 919, 140–145. [Google Scholar] [CrossRef]

- Gopal, N.O.; Narasimhulu, K.V.; Rao, J.L. EPR, optical, infrared and Raman spectral studies of Actinolite mineral. Spectrochim. Acta. Mol. Biomol. Spectrosc. 2004, 60, 2441–2448. [Google Scholar] [CrossRef] [PubMed]

- Bertoluzza, A.; Fagnano, C.; Antonietta Morelli, M.; Gottardi, V.; Guglielmi, M. Raman and infrared spectra on silica gel evolving toward glass. J. Non-Cryst. Solids 1982, 48, 117–128. [Google Scholar] [CrossRef]

- Socrates, G. Infrared and Raman Characteristic Group Frequencies: Tables and Charts, 3rd ed.; Wiley: Abingdon, UK, 2004; 368p, ISBN 978-0-470-09307-8. [Google Scholar]

- Gonçalves, R.R.; Guimarães, J.J.; Ferrari, J.L.; Maia, L.J.Q.; Ribeiro, S.J.L. Active planar waveguides based on sol–gel Er3+-doped SiO2–ZrO2 for photonic applications: Morphological, structural and optical properties. J. Non-Cryst. Solids 2008, 354, 4846–4851. [Google Scholar] [CrossRef]

- Chmel, A. Vibrational spectra and defect structure of silica prepared by non-organic sol-gel process. J. Non-Cryst. Solids 1990, 122, 285–290. [Google Scholar] [CrossRef]

- Sakka, S. Handbook of Sol-Gel Science and Technology: Processing, Characterization and Applications, Volume I: Sol-Gel Processing; Kluwer Academic Publishers: Boston, MA, USA; Springer Science and Business Media: New York, NY, USA, 2005; 680p, ISBN 1402079664/9781402079665. [Google Scholar]

- Ćurković, L.; Kumić, I.; Grilec, K. Solid particle erosion behavior of high purity alumina ceramics. Ceram. Int. 2011, 37, 29–35. [Google Scholar] [CrossRef]

| Chemical Composition Weight (ppm) | Crystallite Size (nm) | SSA (m2/g) | ||||||

|---|---|---|---|---|---|---|---|---|

| Na | K | Fe | Si | Ca | S | |||

| S 12 | 11 | 14 | 8.1 | 13 | 4.3 | 200 | 29 | 17.1 |

| S 14 | 11 | 13 | 6.5 | 14 | 6.9 | 300 | 60 | 27.4 |

| S30CR | 13 | 35 | 1 | 36 | <1 | 600 | 73 | 31 |

| Grain Size (nm) | |||

|---|---|---|---|

| Sintering temperature (°C) | 1290 | 1310 | 1330 |

| S 12 | 338 | 500 | 835 |

| S 14 | 366 | 628 | 805 |

| S30CR | 408 | 614 | 964 |

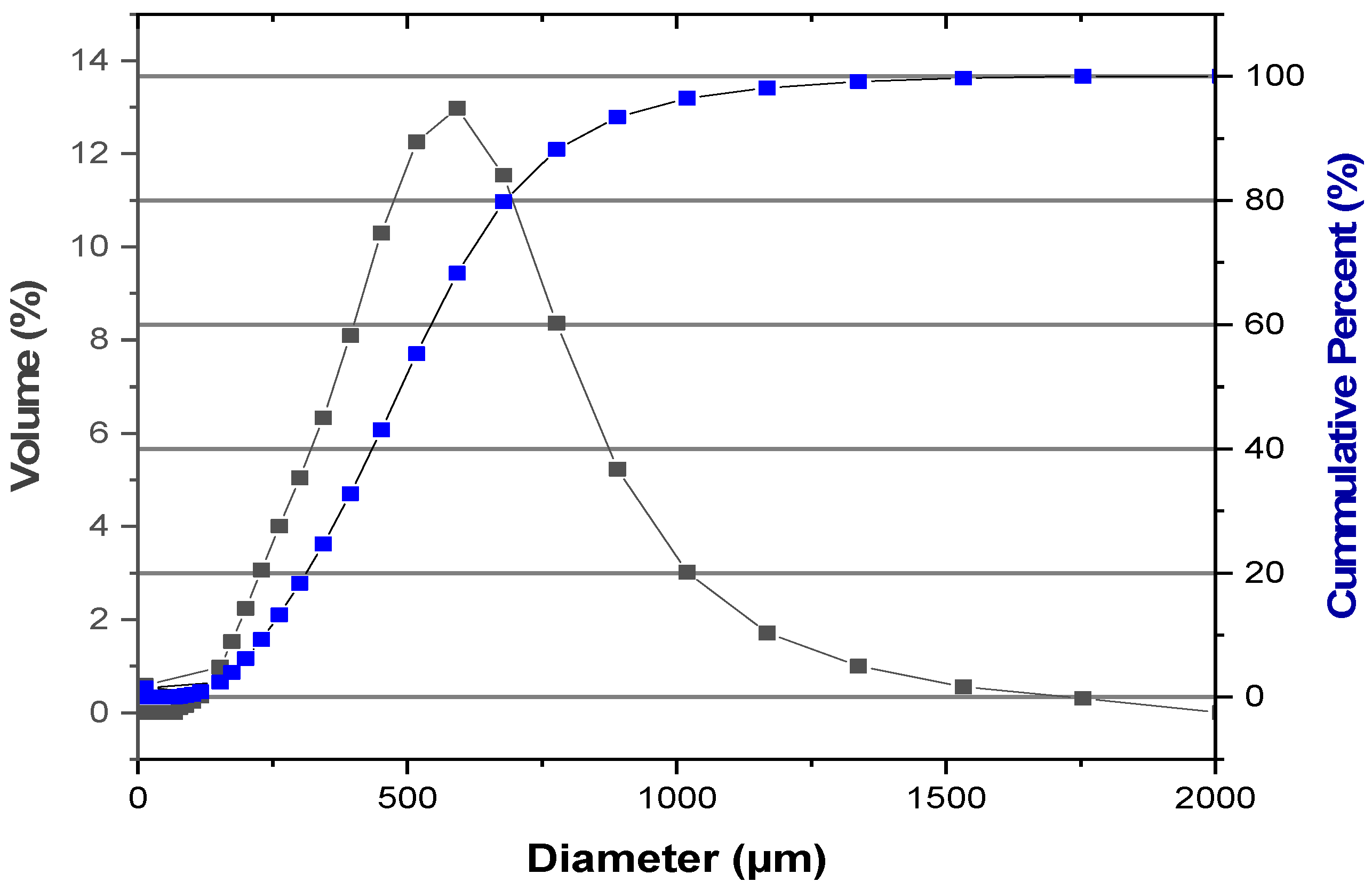

| Diameter (D) | Particles Size (µm) |

|---|---|

| D (0.1) minimum diameter | 235 |

| D (0.5) average diameter | 515 |

| D (0.9) maximum diameter | 815 |

| N° | Wave Number (cm−1) | Vibration | Structure | References |

|---|---|---|---|---|

| 1 | 3323 | Stretching O-H and Si-O-H | H-O-H/H2O | [27] |

| 2 | 2973 | νs C-H | Si-CH3/-CH3 | [28] |

| 3 | 1262 | δs C-H | Si-CH3 | [29] |

| 4 | 1042 | νas Si-O-Si | Si-O-Si | [30] |

| 5 | 940 | νβ Si-O | ≡Si-OH Si-O-Zr | [31] [32] |

| 6 | 878 | νβ Si-O | Si-O | [33] |

| 7 | 432 | δ O-Si-O | O-Si-O | [30] |

| Transmittance at λ = 200 nm | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Sintering Temperature | Pristine (%) | Eroded (%) | Coated (%) | ||||||

| S 12 | S 14 | S30CR | S 12 | S 14 | S30CR | S 12 | S 14 | S30CR | |

| 1290 °C | 4.2 | 10 | 0 | 50.7 | 49.0 | 43.1 | 47.6 | 48.5 | 40.8 |

| 1310 °C | 2.8 | 8.1 | 2.47 | 47.8 | 49.1 | 47.4 | 47.0 | 49.5 | 42.9 |

| 1330 °C | 62.9 | 52.1 | 45.34 | 54.1 | 18.2 | 0 | 52.6 | 52.8 | 46.1 |

| Transmittance at λ = 550 nm | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Sintering Temperature | Pristine (%) | Eroded (%) | Coated (%) | ||||||

| S 12 | S 14 | S30CR | S 12 | S 14 | S30CR | S 12 | S 14 | S30CR | |

| 1290 °C | 51.8 | 52.1 | 75.5 | 53.2 | 54.3 | 69.5 | 52.9 | 54.9 | 80.2 |

| 1310 °C | 76.6 | 70.2 | 72.6 | 62.9 | 67.4 | 68.4 | 65.2 | 66.6 | 75.6 |

| 1330 °C | 80.9 | 68.5 | 67.6 | 76.9 | 60.2 | 63.2 | 82.1 | 76.5 | 73.1 |

| Transmittance at λ = 1000 nm | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Sintering Temperature | Pristine (%) | Eroded (%) | Coated (%) | ||||||

| S 12 | S 14 | S30CR | S 12 | S 14 | S30CR | S 12 | S 14 | S30CR | |

| 1290 °C | 74.6 | 69.7 | 81.4 | 64.5 | 65.9 | 77.6 | 67.4 | 66.2 | 84.3 |

| 1310 °C | 83.5 | 81.1 | 82.7 | 74.2 | 77.3 | 77.0 | 75.9 | 80.4 | 82.1 |

| 1330 °C | 85.2 | 80.9 | 79.5 | 84.9 | 73.4 | 79.9 | 86 | 83.5 | 82.3 |

| Ra (nm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Sintering Temperature | Pristine | Eroded | Coated | ||||||

| S 12 | S 14 | S30CR | S 12 | S 14 | S30CR | S 12 | S 14 | S30CR | |

| 1290 °C | 6.3 | 4.6 | 8.6 | 15 | 14.9 | 27.6 | 12 | 6.7 | 5.7 |

| 1310 °C | 8.3 | 7.6 | 10.1 | 25.3 | 16.7 | 19.2 | 6.7 | 8.6 | 7 |

| 1330 °C | 6.4 | 5.5 | 12 | 23.1 | 39.2 | 22.5 | 8.8 | 8.3 | 8.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zegadi, A.; Ayadi, A.; Khellaf, I.; Hamidouche, M.; Fantozzi, G.; Durán, A.; Castro, Y. Improving the Transparency of a MgAl2O4 Spinel Damaged by Sandblasting through a SiO2-ZrO2 Coating. Ceramics 2024, 7, 743-758. https://doi.org/10.3390/ceramics7020049

Zegadi A, Ayadi A, Khellaf I, Hamidouche M, Fantozzi G, Durán A, Castro Y. Improving the Transparency of a MgAl2O4 Spinel Damaged by Sandblasting through a SiO2-ZrO2 Coating. Ceramics. 2024; 7(2):743-758. https://doi.org/10.3390/ceramics7020049

Chicago/Turabian StyleZegadi, Akram, Abdelwahhab Ayadi, Ikram Khellaf, Mohamed Hamidouche, Gilbert Fantozzi, Alicia Durán, and Yolanda Castro. 2024. "Improving the Transparency of a MgAl2O4 Spinel Damaged by Sandblasting through a SiO2-ZrO2 Coating" Ceramics 7, no. 2: 743-758. https://doi.org/10.3390/ceramics7020049

APA StyleZegadi, A., Ayadi, A., Khellaf, I., Hamidouche, M., Fantozzi, G., Durán, A., & Castro, Y. (2024). Improving the Transparency of a MgAl2O4 Spinel Damaged by Sandblasting through a SiO2-ZrO2 Coating. Ceramics, 7(2), 743-758. https://doi.org/10.3390/ceramics7020049