Optimization of Yb:CaF2 Transparent Ceramics by Air Pre-Sintering and Hot Isostatic Pressing

Abstract

1. Introduction

2. Materials and Methods

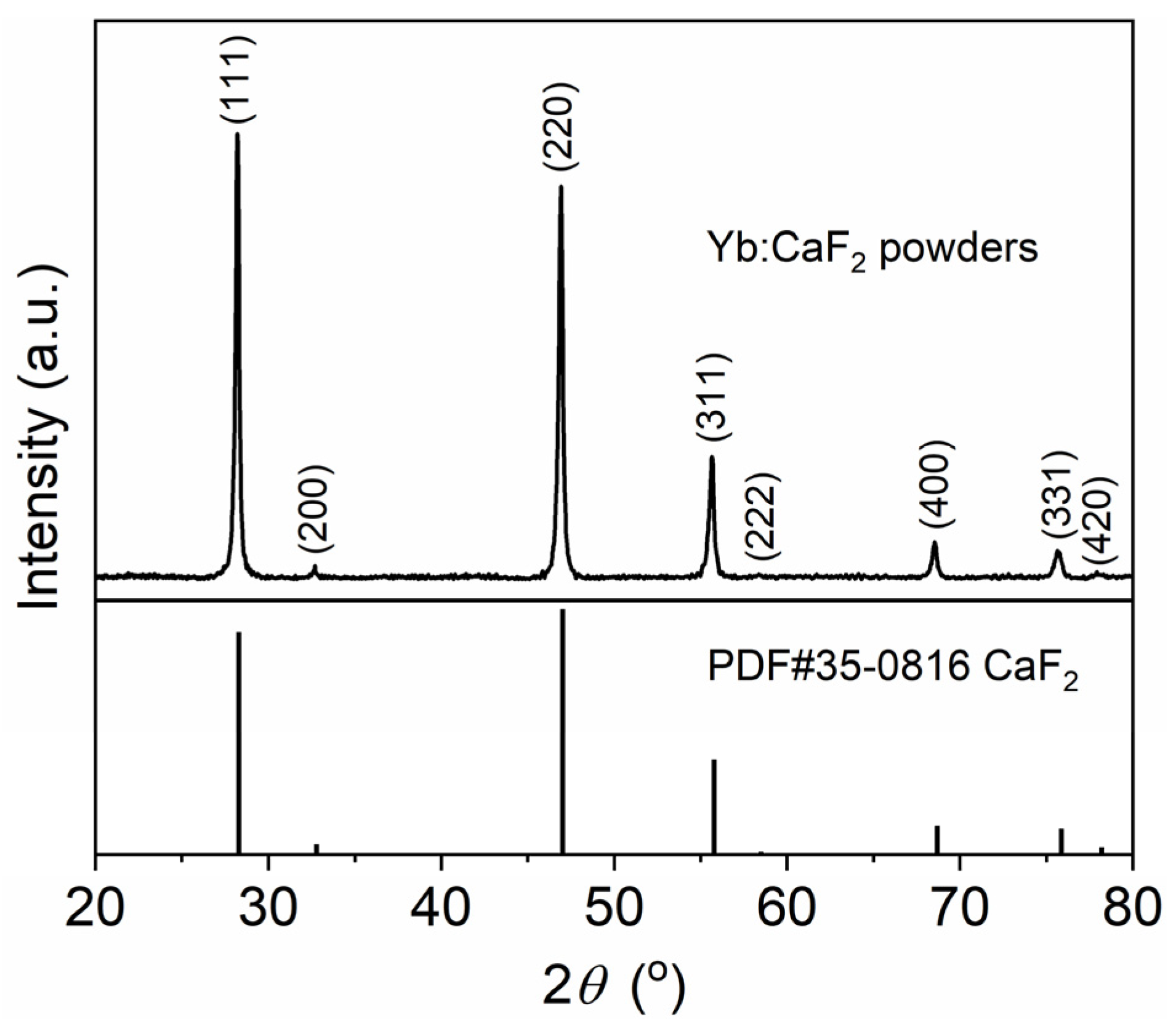

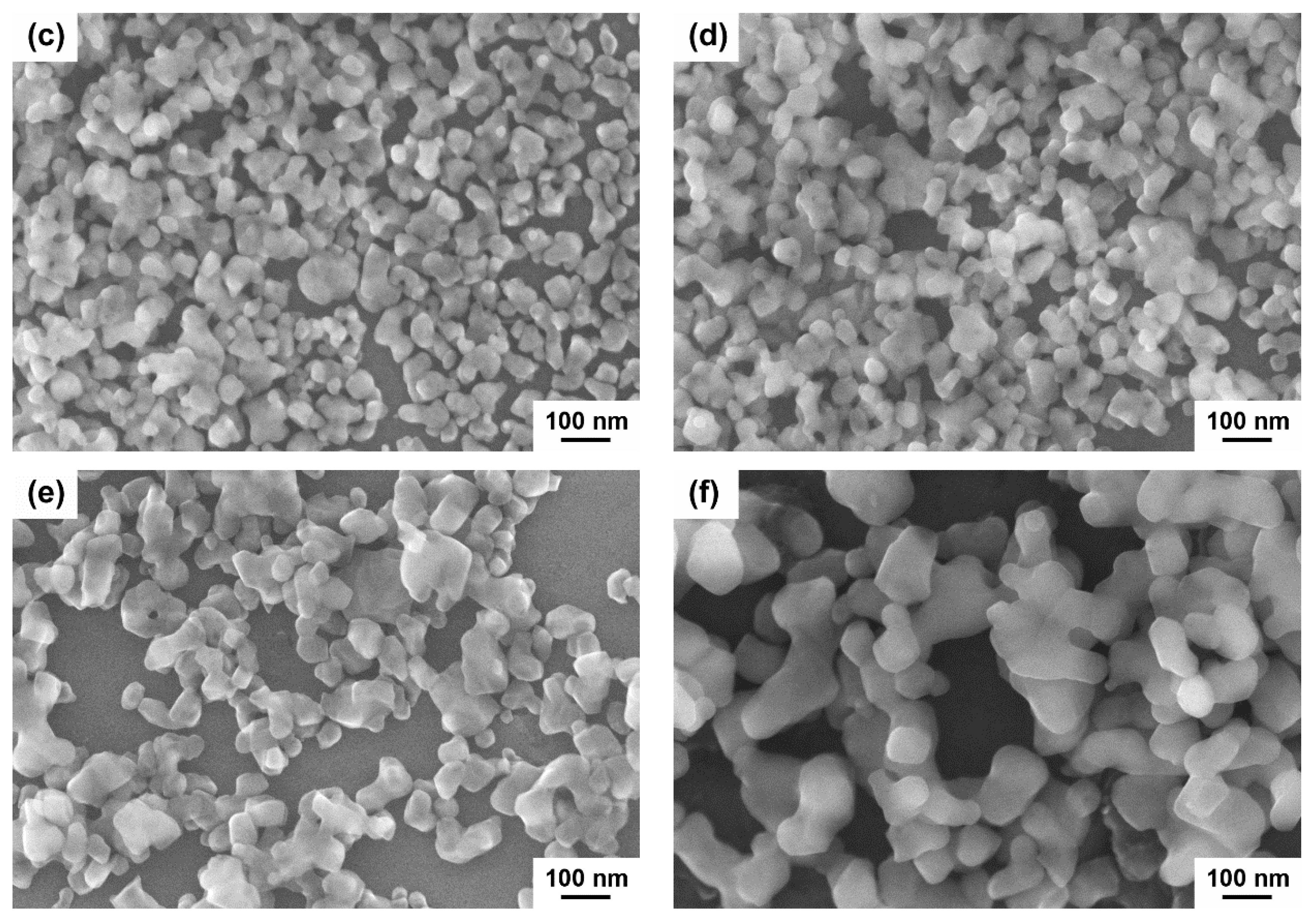

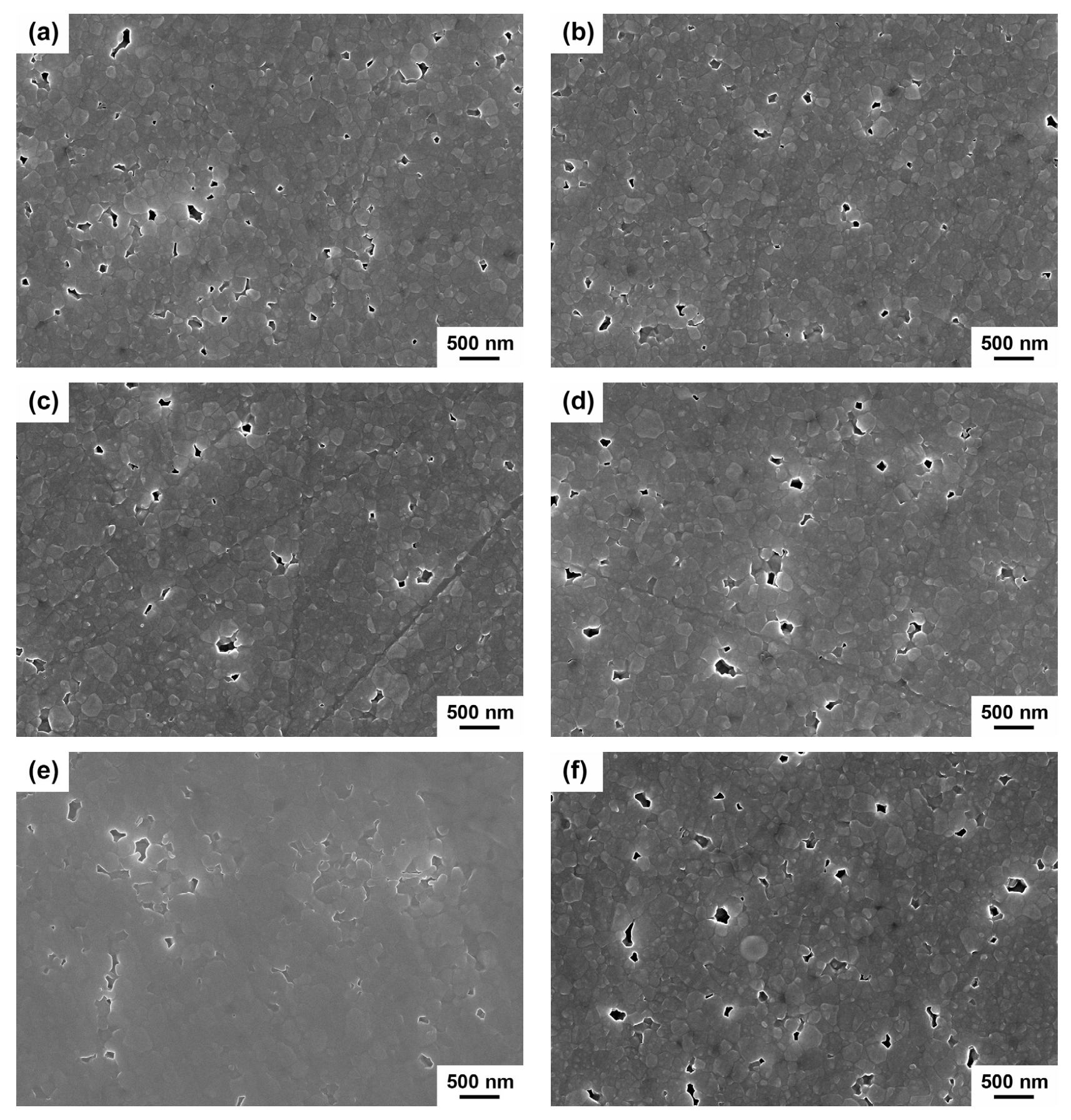

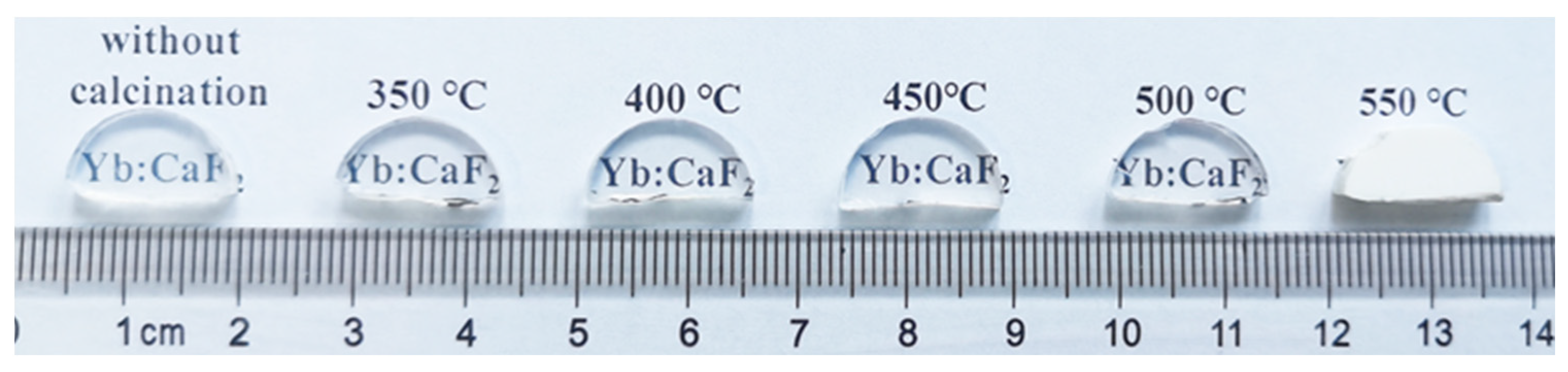

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guo, F.F.; Rong, W.L.; Chen, L.J.; Hu, F.A.; Wang, S.P.; Tao, X.T.; Gao, Z.L. Novel laser crystal Nd:LiY(MoO4)2: Crystal growth, characterization, and orthogonally polarized dual-wavelength laser. Cryst. Growth Des. 2024, 24, 1421–1428. [Google Scholar] [CrossRef]

- Ji, Y.Y.; Hu, M.; Xv, M.M.; Li, H.Z.; Gao, L.; Li, Q.; Bi, M.H.; Zhou, X.F.; Pan, S.Q.; Liu, C. Exploring the spatial hole burning effect on the mode-locking characteristics of self-mode-locked Nd:YVO4 lasers. Opt. Commun. 2023, 549, 129883. [Google Scholar] [CrossRef]

- Zhang, L.X.; Hu, D.J.; Snetkov, I.L.; Balabanov, S.; Palashov, O.; Li, J. A review on magneto-optical ceramics for Faraday isolators. J. Adv. Ceram. 2023, 12, 873–915. [Google Scholar] [CrossRef]

- Dong, J.S.; Wang, Q.G.; Xu, J.; Xue, Y.Y.; Wang, W.D.; Cao, X.; Tang, H.L.; Wu, F.; Luo, P. Growth and spectral properties of Ho,Y:CaF2 crystal grown with porous crucible TGT method. J. Synth. Cryst. 2022, 51, 200–207. [Google Scholar]

- Danson, C.N.; Haefner, C.; Bromage, J.; Butcher, T.; Chanteloup, J.-C.F.; Chowdhury, E.A.; Galvanauskas, A.; Gizzi, L.A.; Hein, J.; Hillier, D.I.; et al. Petawatt and exawatt class lasers worldwide. High Power Laser Sci. Eng. 2019, 7, e54. [Google Scholar] [CrossRef]

- Papadopoulos, D.N.; Friebel, F.; Pellegrina, A.; Hanna, M.; Camy, P.; Doualan, J.L.; Moncorgé, R.; Georges, P.; Druon, F.P.H.J. High repetition rate Yb:CaF2 multipass amplifiers operating in the 100-mJ range. IEEE J. Sel. Top. Quantum Electron. 2015, 21, 464–474. [Google Scholar] [CrossRef]

- Xuan, L.L.; Pisch, A.; Duffar, T. Thermodynamic calculations of Ti ion concentrations and segregation coefficients during Ti:Sapphire crystal growth. Cryst. Growth Des. 2022, 22, 2407–2416. [Google Scholar] [CrossRef]

- Ma, B.Y.; Zhang, W.; Luo, H.; Yuan, F.; Cheng, B.T.; Bai, L.Y.; Tang, Y.; Song, H.Z. Growth of Cr,Yb:YAG single crystals for self-Q-switched monolithic solid-state lasers. Opt. Mater. 2023, 143, 114218. [Google Scholar] [CrossRef]

- Chen, J.M.; Jiang, Y.E.; Wang, X.; Du, L.F.; Xiao, Q.; Pan, X.; Zhou, L.; Zhou, S.L.; Peng, J.H.; Li, X.C.; et al. High-stability, high-power diode-pumped mode-locked laser with a novel Nd:Glass. Opt. Commun. 2024, 558, 130380. [Google Scholar] [CrossRef]

- Liu, K.X.; Dong, Y.; Zhang, Z.H.; Duan, X.H.; Guo, R.H.; Zhai, Z.J.; Wang, J.L. MHz repetition rate femtosecond radially polarized vortex laser direct writing Yb:CaF2 waveguide laser operating in continuous-wave and pulsed regimes. Nanophotonics. 2024, 13, 9–18. [Google Scholar] [CrossRef]

- Püschel, S.; Mauerhoff, F.; Kränkel, C.; Tanaka, H. Solid-state laser cooling in Yb:CaF2 and Yb:SrF2 by anti-Stokes fluorescence. Opt. Lett. 2022, 47, 333–336. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.Y.; Li, R.X.; Li, K.; Xu, H.; Zhang, B.; Niu, J.; Sui, Y.; Yuan, M.H.; Liu, X.P.; Ma, Y.J.; et al. 10-mJ 300-fs 1-kHz cryogenically cooled Yb:CaF2 regenerative amplifier. Opt. Commun. 2024, 565, 130687. [Google Scholar] [CrossRef]

- Zhao, C.C.; Zhang, P.X.; Li, S.M.; Fang, Q.N.; Xu, M.; Cheng, Z.Q.; Hang, Y. Development of rare-earth ion doped fluoride laser crystal. J. Synth. Cryst. 2022, 51, 1573–1587. [Google Scholar]

- Petit, V.; Doualan, J.L.; Camy, P.; Ménard, V.; Moncorgé, R. CW and tunable laser operation of Yb3+ doped CaF2. Appl. Phys. B 2004, 78, 681–684. [Google Scholar] [CrossRef]

- Hornung, M.; Liebetrau, H.; Keppler, S.; Kessler, A.; Hellwing, M.; Schorcht, F.; Becker, G.A.; Reuter, M.; Polz, J.; Körner, J.; et al. 54 J pulses with 18 nm bandwidth from a diode-pumped chirped-pulse amplification laser system. Opt. Lett. 2016, 41, 5413–5416. [Google Scholar] [CrossRef]

- Wentsch, K.S.; Weichelt, B.; Guenster, S.; Druon, F.; Georges, P.; Ahmed, M.A.; Graf, T. Yb:CaF2 thin-disk laser. Opt. Express 2014, 22, 1524–1532. [Google Scholar] [CrossRef]

- Akchurin, M.S.; Basiev, T.T.; Demidenko, A.A.; Doroshenko, M.E.; Fedorov, P.P.; Garibin, E.A.; Gusev, P.E.; Kuznetsov, S.V.; Krutov, M.A.; Mironov, I.A.; et al. CaF2:Yb laser ceramics. Opt. Mater. 2013, 35, 444–450. [Google Scholar] [CrossRef]

- Liu, Y.; Qin, X.P.; Gan, L.; Zhou, G.H.; Zhang, T.J.; Wang, S.W.; Chen, H.T. Preparation of sub-micron spherical Y2O3 particles and transparent ceramics. J. Inorg. Mater. 2024, 39, 691–696. [Google Scholar] [CrossRef]

- Feng, S.W.; Guo, Y.C.; Sun, X.M.; Fu, J.; Li, J.Q.; Jiang, J.; Qin, H.M.; Wang, H.; Yang, Y.F. Elevating photoluminescence properties of Y3MgAl3SiO12:Ce3+ transparent ceramics for high-power white lighting. J. Rare Earth 2023, 41, 649–657. [Google Scholar] [CrossRef]

- Wang, D.W.; Wang, J.P.; Yuan, H.C.; Liu, Z.; Zhou, J.; Deng, J.J.; Wang, X.; Wu, B.H.; Zhang, J.; Wang, S.W. Metre-scale Y3Al5O12 (YAG) transparent ceramics by vacuum reactive sintering. J. Inorg. Mater. 2023, 38, 1483–1484. [Google Scholar] [CrossRef]

- Rakov, N.; Matias, F.; Maciel, G.S. Temperature sensing performance of Er3+:Yb3+ co-doped CaF2 ceramic powders using near-infrared light. J. Rare Earth. 2024, in press. [CrossRef]

- Jin, X.H.; Dong, M.J.; Kan, Y.M.; Liang, B.; Dong, S.M. Fabrication of transparent AlON by gel casting and pressureless sintering. J. Inorg. Mater. 2023, 38, 193–198. [Google Scholar] [CrossRef]

- Yang, C.L.; Huang, J.Q.; Huang, Q.F.; Deng, Z.H.; Wang, Y.; Li, X.Y.; Zhou, Z.H.; Chen, J.; Liu, Z.G.; Guo, W. Optical, thermal, and mechanical properties of (Y1−xScx)2O3 transparent ceramics. J. Adv. Ceram. 2022, 11, 901–911. [Google Scholar] [CrossRef]

- Basiev, T.T.; Doroshenko, M.E.; Fedorov, P.P.; Konyushkin, V.A.; Kuznetsov, S.V.; Osiko, V.V.; Akchurin, M.S. Efficient laser based on CaF2-SrF2-YbF3 nanoceramics. Opt. Lett. 2008, 33, 521–523. [Google Scholar] [CrossRef]

- Jiang, Y.G.; Jiang, B.X.; Zhang, P.D.; Chen, S.L.; Gan, Q.J.; Fan, J.T.; Mao, X.J.; Jiang, N.; Su, L.B.; Li, J.; et al. Transparent Nd-doped Ca1−xYxF2+x ceramics prepared by the ceramization of single crystals. Mater. Des. 2017, 113, 326–330. [Google Scholar] [CrossRef]

- Yang, Y.; Zhou, Z.; Mei, B.; Zhang, Y.; Liu, X. Fabrication and upconversion luminescence properties of Er:SrF2 transparent ceramics compared with Er:CaF2. Ceram. Int. 2021, 47, 17139–17146. [Google Scholar] [CrossRef]

- Chen, X.; Zhao, B.; Chen, N.; Cheng, J.; Dang, M.; Wang, F.; Xu, X.; Wang, H. Low temperature fired CaF2-based microwave dielectric ceramics with enhanced microwave properties. J. Eur. Ceram. Soc. 2022, 42, 4969–4973. [Google Scholar] [CrossRef]

- Liu, Z.D.; Shen, Q.L.; Fu, S.C.; Yang, L.T.; Chen, X.; Li, S.Y.; Cao, Y.; Liu, B.; Yu, Y.S.; Jing, Q.S.; et al. Effects of LiF sintering additive on the microstructure and mechanical properties of hot-pressed CaF2 transparent ceramics. Opt. Mater. 2022, 14, 100147. [Google Scholar] [CrossRef]

- Wang, P.; Huang, Z.F.; Morita, K.; Li, Q.Z.; Yang, M.J.; Zhang, S.; Goto, T.; Tu, R. Influence of spark plasma sintering conditions on microstructure, carbon contamination, and transmittance of CaF2 ceramics. J. Eur. Ceram. Soc. 2022, 42, 245–257. [Google Scholar] [CrossRef]

- Yang, Y.; Zhou, Z.; Mei, B.; Li, W.; Zhang, Y.; Liu, X. Energy transfer and controllable colors of upconversion emission in Er3+ and Dy3+ co-doped CaF2 transparent ceramics. J. Eur. Ceram. Soc. 2021, 41, 7835–7844. [Google Scholar] [CrossRef]

- Chen, L.; Mei, B.C.; Li, W.W.; Zhou, Z.W.; Yang, Y.; Zhang, Y.Q. Effect of reactive raw materials and pre-loading pressure on the microstructure and transmittance of pure CaF2 transparent ceramics. Mater. Chem. Phys. 2023, 297, 127315. [Google Scholar] [CrossRef]

- Kuznetsov, S.V.; Alexandrov, A.A.; Fedorov, P.P. Optical Fluoride Nanoceramics. Inorg. Mater. 2021, 57, 555–578. [Google Scholar] [CrossRef]

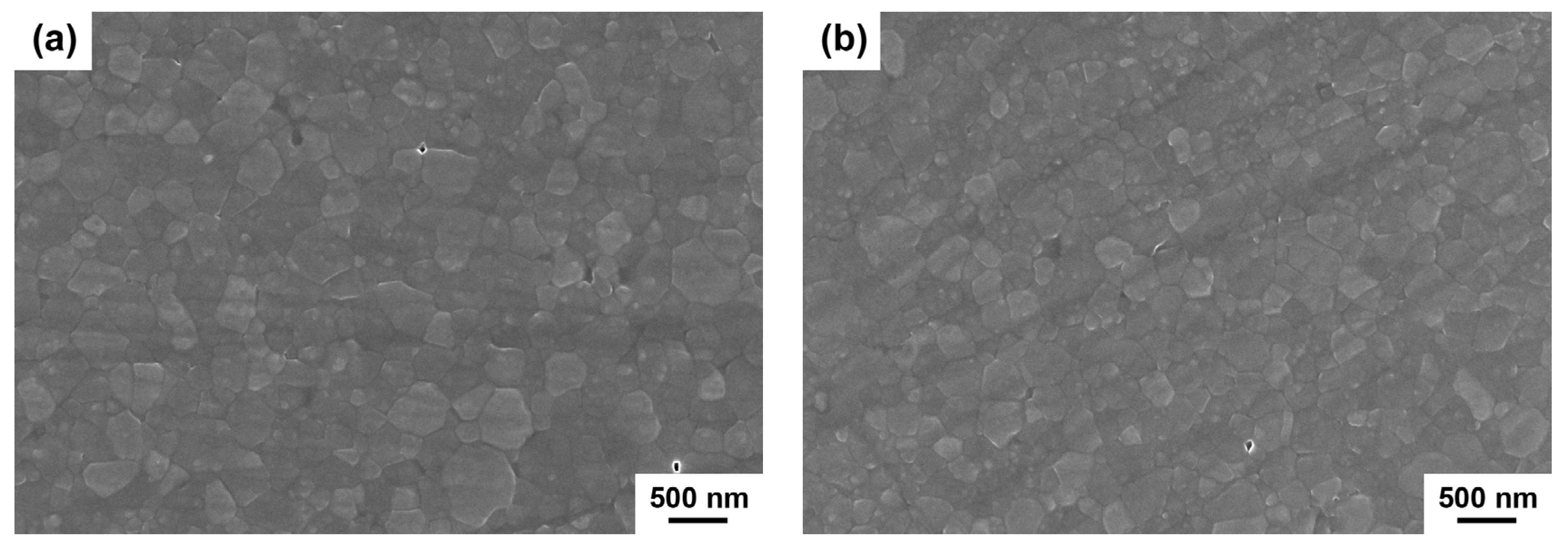

- Li, W.W.; Huang, H.J.; Mei, B.C.; Wang, C.; Liu, J.; Wang, S.Z.; Jiang, D.P.; Su, L.B. Effect of Yb concentration on the microstructures, spectra, and laser performance of Yb:CaF2 transparent ceramics. J. Am. Ceram. Soc. 2020, 103, 5787–5795. [Google Scholar] [CrossRef]

- Sarthou, J.; Aballea, P.; Patriarche, G.; Serier-Brault, H.; Suganuma, A.; Gredin, P.; Mortier, M.; Riman, R. Wet-route synthesis and characterization of Yb:CaF2 optical ceramics. J. Am. Ceram. Soc. 2016, 99, 1992–2000. [Google Scholar] [CrossRef]

- Aballea, P.; Suganuma, A.; Druon, F.; Hostalrich, J.; Georges, P.; Gredin, P.; Mortier, M. Laser performance of diode-pumped Yb:CaF2 optical ceramics synthesized using an energy-efficient process. Optica 2015, 2, 288–291. [Google Scholar] [CrossRef]

- Li, W.W.; Jing, W.; Mei, B.C.; Zhai, P.F.; Yang, Y.; Song, J.H. Effect of NaF doping on the transparency, microstructure and spectral properties of Yb3+:CaF2 transparent ceramics. J. Eur. Ceram. Soc. 2020, 40, 4572–4577. [Google Scholar] [CrossRef]

- Li, W.W.; Huang, H.J.; Mei, B.C.; Wang, C.; Liu, J.; Wang, S.Z.; Jiang, D.P.; Su, L.B. Fabrication, microstructure and laser performance of Yb3+ doped CaF2-YF3 transparent ceramics. Ceram. Int. 2020, 46, 19530–19536. [Google Scholar] [CrossRef]

- Liu, X.Q.; Hao, Q.Q.; Liu, J.; Liu, D.H.; Li, W.W.; Su, L.B. Yb:CaF2–YF3 transparent ceramics ultrafast laser at dual gain lines. Chin. Phys. B 2022, 31, 114205. [Google Scholar] [CrossRef]

- Wei, J.B.; Toci, G.; Pirri, A.; Patrizi, B.; Feng, Y.G.; Vannini, M.; Li, J. Fabrication and property of Yb:CaF2 laser ceramics from co-precipitated nanopowders. J. Inorg. Mater. 2019, 34, 1341–1348. [Google Scholar] [CrossRef]

- Huang, X.Y.; Chen, G.M.; Wei, J.B.; Liu, Z.Y.; Feng, Y.G.; Tian, F.; Xie, T.F.; Li, J. Fabrication of Yb,La:CaF2 transparent ceramics by air pre-sintering with hot isostatic pressing. Opt. Mater. 2021, 116, 111108. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Wei, J.B.; Toci, G.; Pirri, A.; Patrizi, B.; Feng, Y.G.; Xie, T.F.; Hreniak, D.; Vannini, M.; Li, J. Microstructure and laser emission of Yb:CaF2 transparent ceramics fabricated by air pre-sintering and hot isostatic pressing. Opt. Mater. 2022, 129, 112540. [Google Scholar] [CrossRef]

- Kitajima, S.; Yamakado, K.; Shirakawa, A.; Ueda, K.I.; Ezura, Y.; Ishizawa, H. Yb3+-doped CaF2-LaF3 ceramics laser. Opt. Lett. 2017, 42, 1724–1727. [Google Scholar] [CrossRef] [PubMed]

- Guo, L.H.; Shi, Y.; Tian, F.; Chen, H.H.; Toci, G.; Pirri, A.; Patrizi, B.; Vannini, M.; Li, J. Microstructure and laser performance of fine-grained Yb:CaF2 transparent ceramics prepared by two-step sintering. Opt. Mater. 2023, 140, 113841. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Y.; Wang, J.; Ma, J.; Ni, M.; Lin, H.; Zhang, J.; Liu, P.; Xu, X.D.; Tang, D.Y. High transparency Pr:Y2O3 ceramics: A promising gain medium for red emission solid-state lasers. J. Adv. Ceram. 2022, 11, 874–881. [Google Scholar] [CrossRef]

- Li, X.; Yin, J.; Lai, Y.M.; Zhang, X.; Yu, S.Q. Improved microstructure and optical properties of Nd:YAG ceramics by hot isostatic pressing. Ceram. Int. 2023, 49, 31939–31947. [Google Scholar] [CrossRef]

- Zhang, L.X.; Li, X.Y.; Hu, D.J.; Liu, Z.Y.; Xie, T.F.; Wu, L.X.; Yang, Z.X.; Li, J. Fabrication and properties of non-stoichiometric Tb2(Hf1−xTbx)2O7−x magneto-optical ceramics. J. Adv. Ceram. 2022, 11, 784–793. [Google Scholar] [CrossRef]

- Li, W.W.; Huang, H.J.; Mei, B.C.; Song, J.H. Comparison of commercial and synthesized CaF2 powders for preparing transparent ceramics. Ceram. Int. 2017, 43, 10403–10409. [Google Scholar] [CrossRef]

- Akinribide, O.J.; Mekgwe, G.N.; Akinwamide, S.O.; Gamaoun, F.; Abeykoon, C.; Johnson, O.T.; Olubambi, P.A. A review on optical properties and application of transparent ceramics. J. Mater. Res. Technol. 2022, 21, 712–738. [Google Scholar] [CrossRef]

- Liu, Z.D.; Ji, Y.M.; Xu, C.Y.; Wang, Y.; Liu, Y.; Shen, Q.; Yi, G.; Yu, Y.; Mei, B.; Liu, P.; et al. Microstructural, spectroscopic and mechanical properties of hot-pressed Er:SrF2 transparent ceramics. J. Eur. Ceram. Soc. 2021, 41, 4907–4914. [Google Scholar] [CrossRef]

- Yi, G.Q.; Liu, Z.D.; Li, W.W.; Mei, B.C.; Yin, S.M.; Xue, L.H.; Yan, Y.W. Gd3+ doping induced microstructural evolution and enhanced visible luminescence of Pr3+ activated calcium fluoride transparent ceramics. Ceram. Int. 2023, 49, 7333–7340. [Google Scholar] [CrossRef]

- Chen, J.M.; Mei, B.C.; Li, W.W.; Zhang, Y.Q. Fabrication and spectral performance of Ndx:(La0.05Lu0.05Gd0.05Y0.05)Ca0.8−xF2.2+x High-entropy transparent fluoride ceramics. Ceram. Int. 2024, 50, 6128–6134. [Google Scholar] [CrossRef]

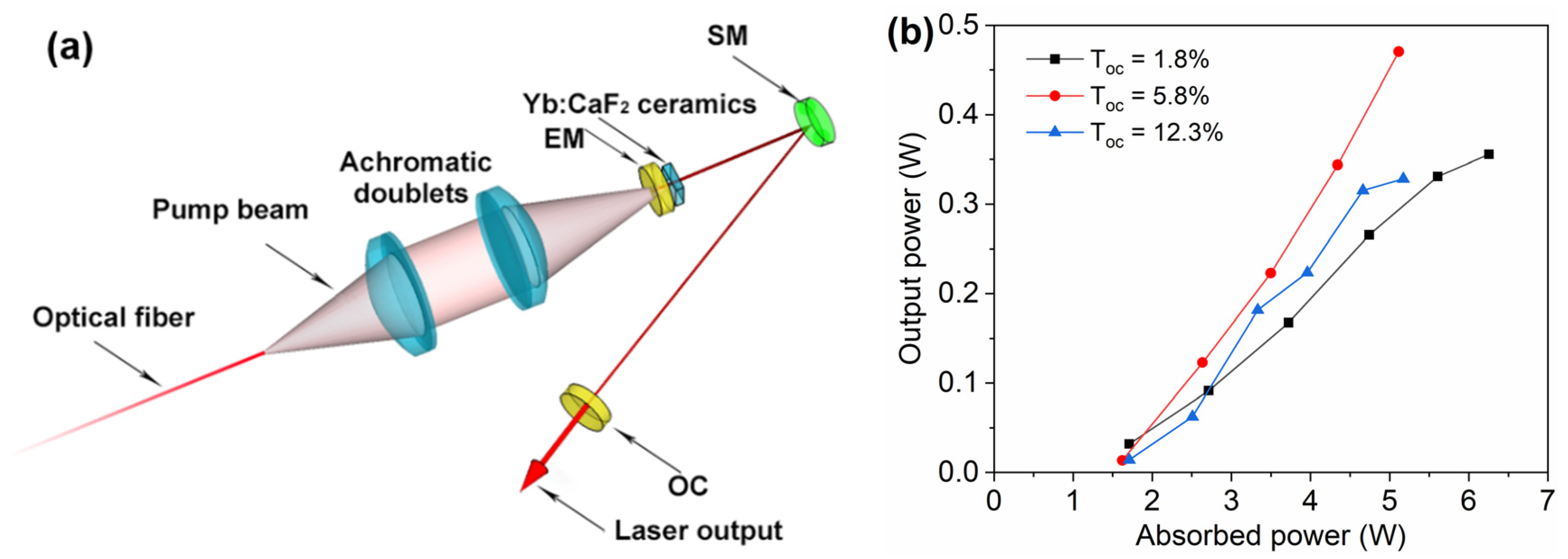

| Output Coupler Transmission/% | Maximum Power/W | Slope Efficiency/% | Optical Efficiency/% | Lasing Wavelength/nm |

|---|---|---|---|---|

| 1.8 | 0.36 | 7.6 | 5.7 | 1028.9 |

| 5.8 | 0.47 | 9.2 | 8.1 | 1029.0 |

| 12.3 | 0.33 | 8.9 | 6.4 | 1030.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Hu, C.; Guo, L.; Wu, J.; Toci, G.; Pirri, A.; Patrizi, B.; Vannini, M.; Liu, Q.; Hreniak, D.; et al. Optimization of Yb:CaF2 Transparent Ceramics by Air Pre-Sintering and Hot Isostatic Pressing. Ceramics 2024, 7, 1053-1065. https://doi.org/10.3390/ceramics7030069

Li X, Hu C, Guo L, Wu J, Toci G, Pirri A, Patrizi B, Vannini M, Liu Q, Hreniak D, et al. Optimization of Yb:CaF2 Transparent Ceramics by Air Pre-Sintering and Hot Isostatic Pressing. Ceramics. 2024; 7(3):1053-1065. https://doi.org/10.3390/ceramics7030069

Chicago/Turabian StyleLi, Xiang, Chen Hu, Lihao Guo, Junlin Wu, Guido Toci, Angela Pirri, Barbara Patrizi, Matteo Vannini, Qiang Liu, Dariusz Hreniak, and et al. 2024. "Optimization of Yb:CaF2 Transparent Ceramics by Air Pre-Sintering and Hot Isostatic Pressing" Ceramics 7, no. 3: 1053-1065. https://doi.org/10.3390/ceramics7030069

APA StyleLi, X., Hu, C., Guo, L., Wu, J., Toci, G., Pirri, A., Patrizi, B., Vannini, M., Liu, Q., Hreniak, D., & Li, J. (2024). Optimization of Yb:CaF2 Transparent Ceramics by Air Pre-Sintering and Hot Isostatic Pressing. Ceramics, 7(3), 1053-1065. https://doi.org/10.3390/ceramics7030069