The Feature Resolution and Dimensional Control in Freeform Solidification of Alumina Systems by Stereolithography

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Materials

2.2. Suspensions Preparation

2.3. Suspension Characterization

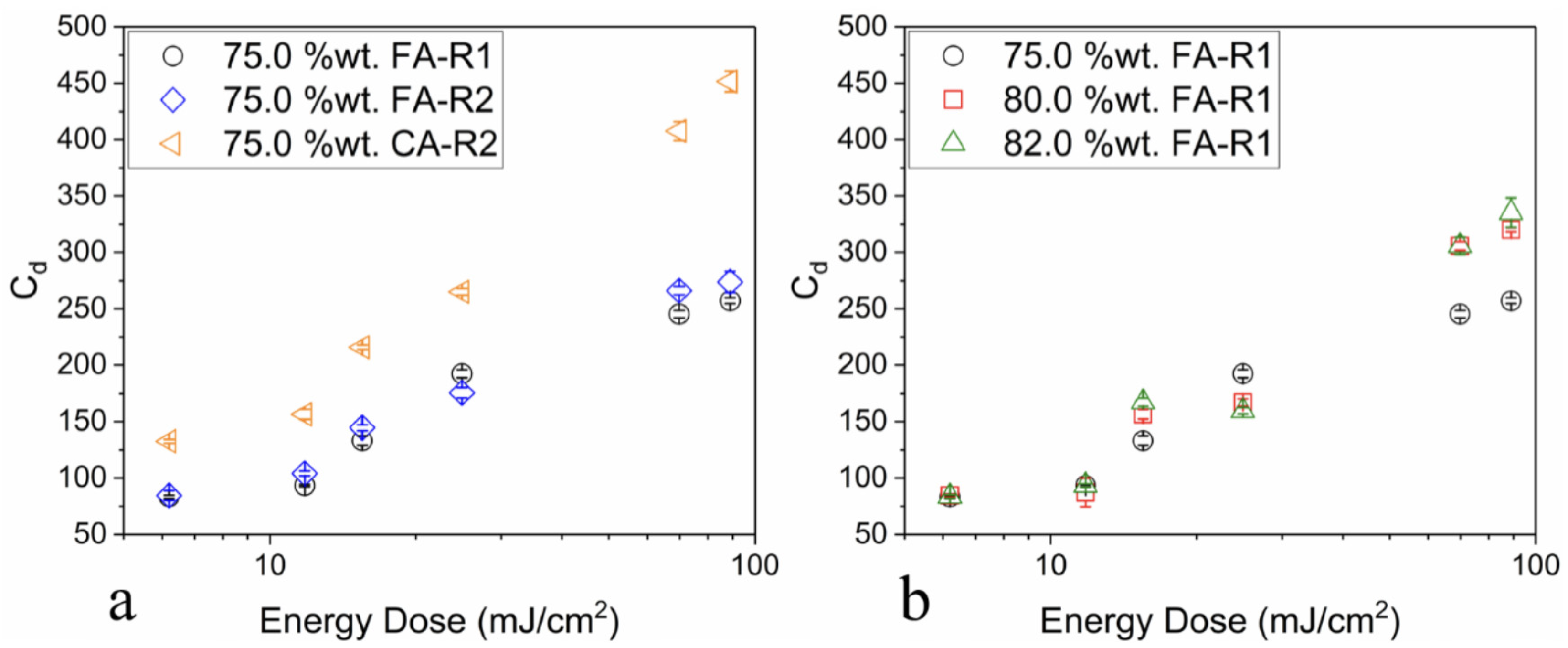

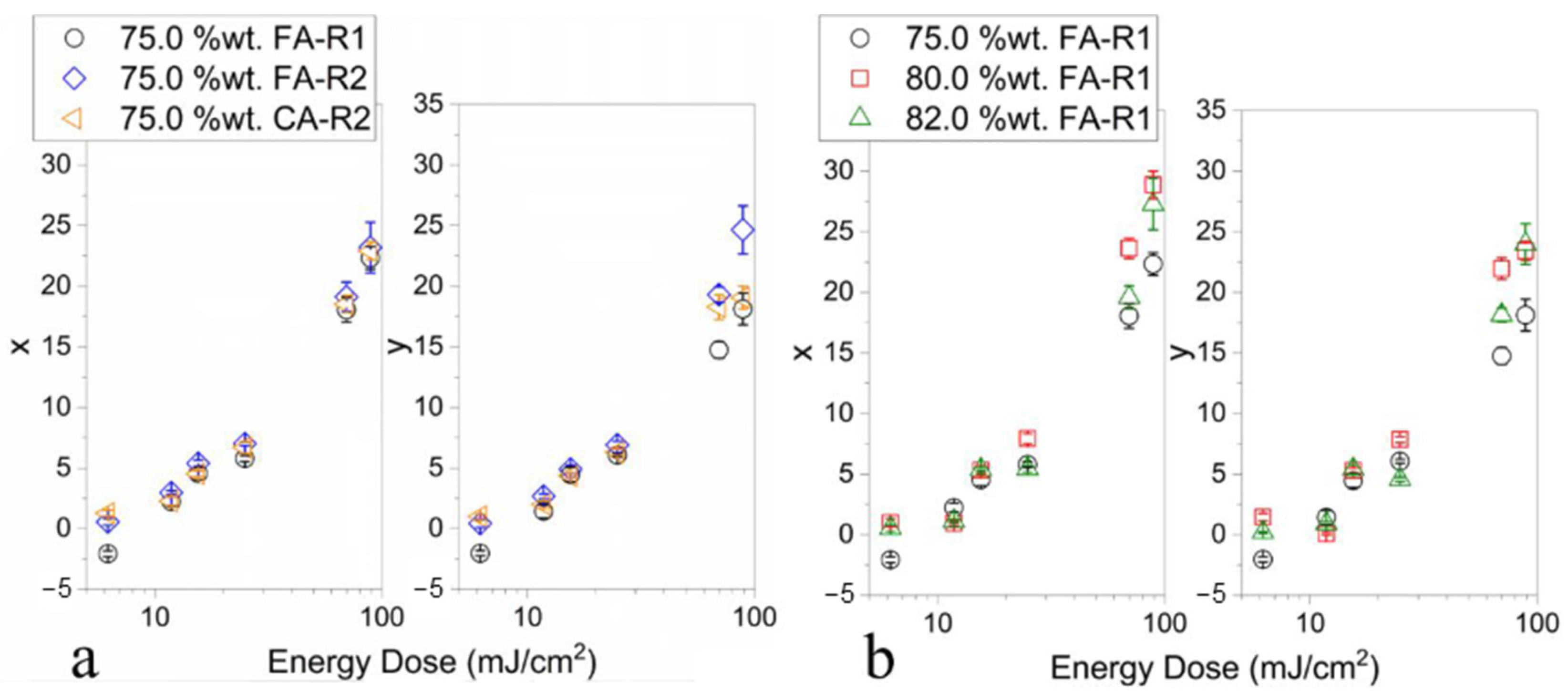

2.4. Cure Depth and Width Changes Measurements

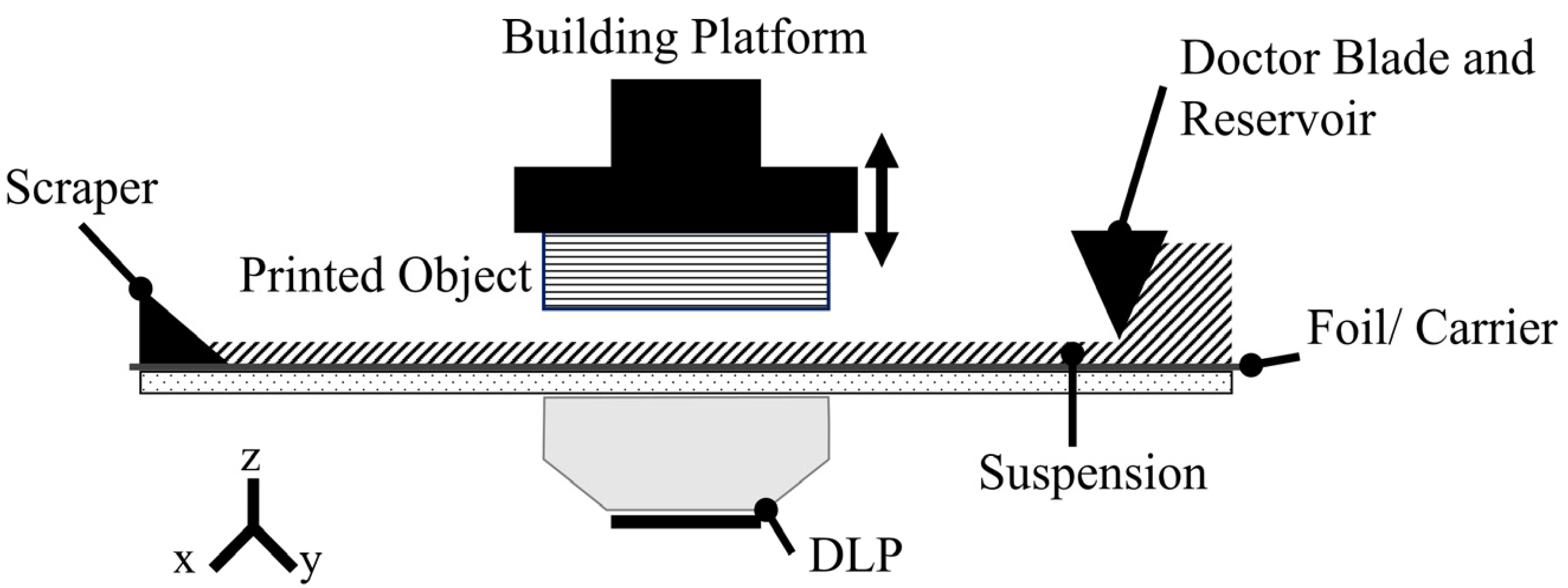

2.5. Printing and Dimensional Measurements

2.6. Microstructure Visualization

3. Results and Discussion

3.1. Suspension Characterization

3.2. Cure Depth and Width Changes

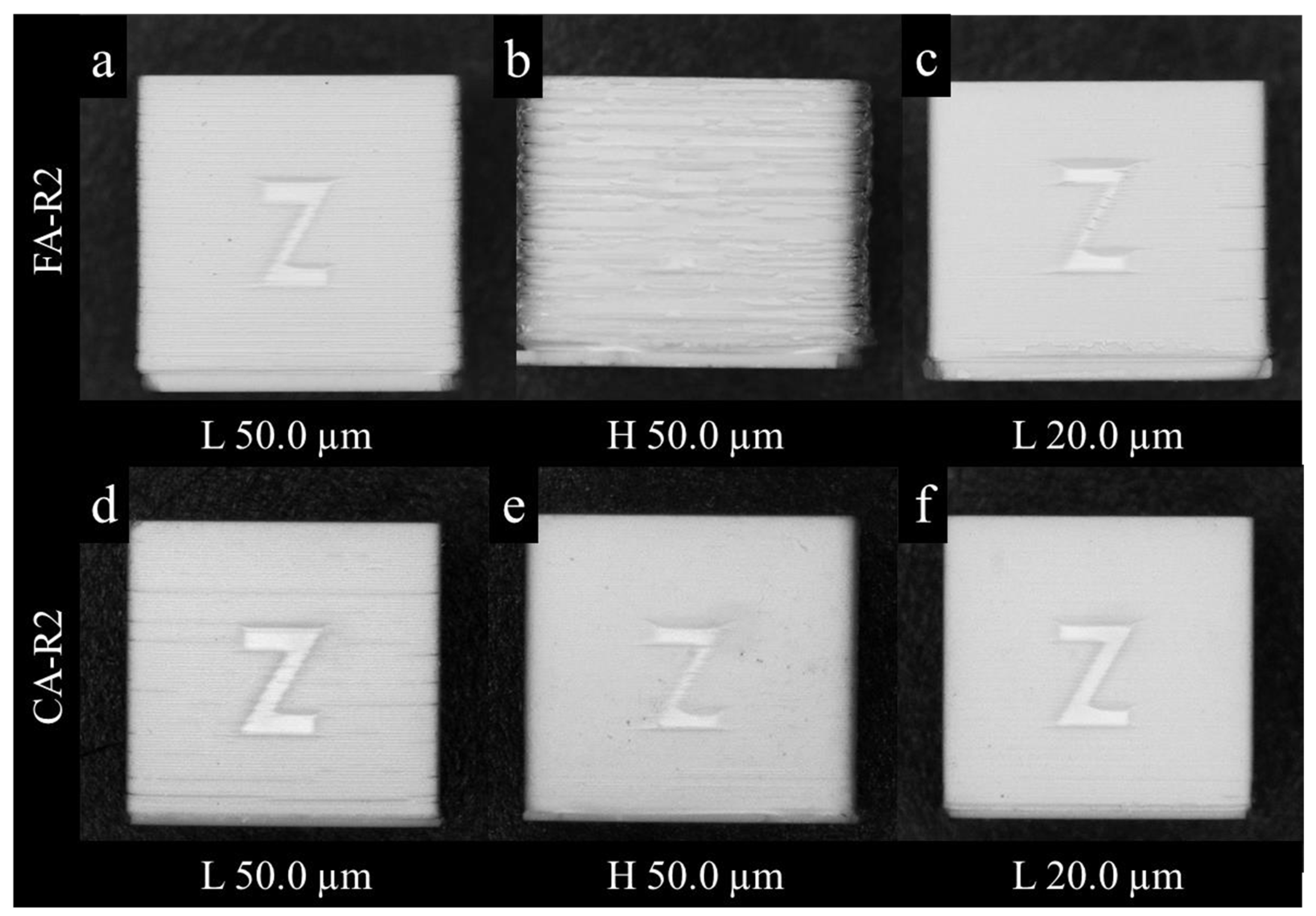

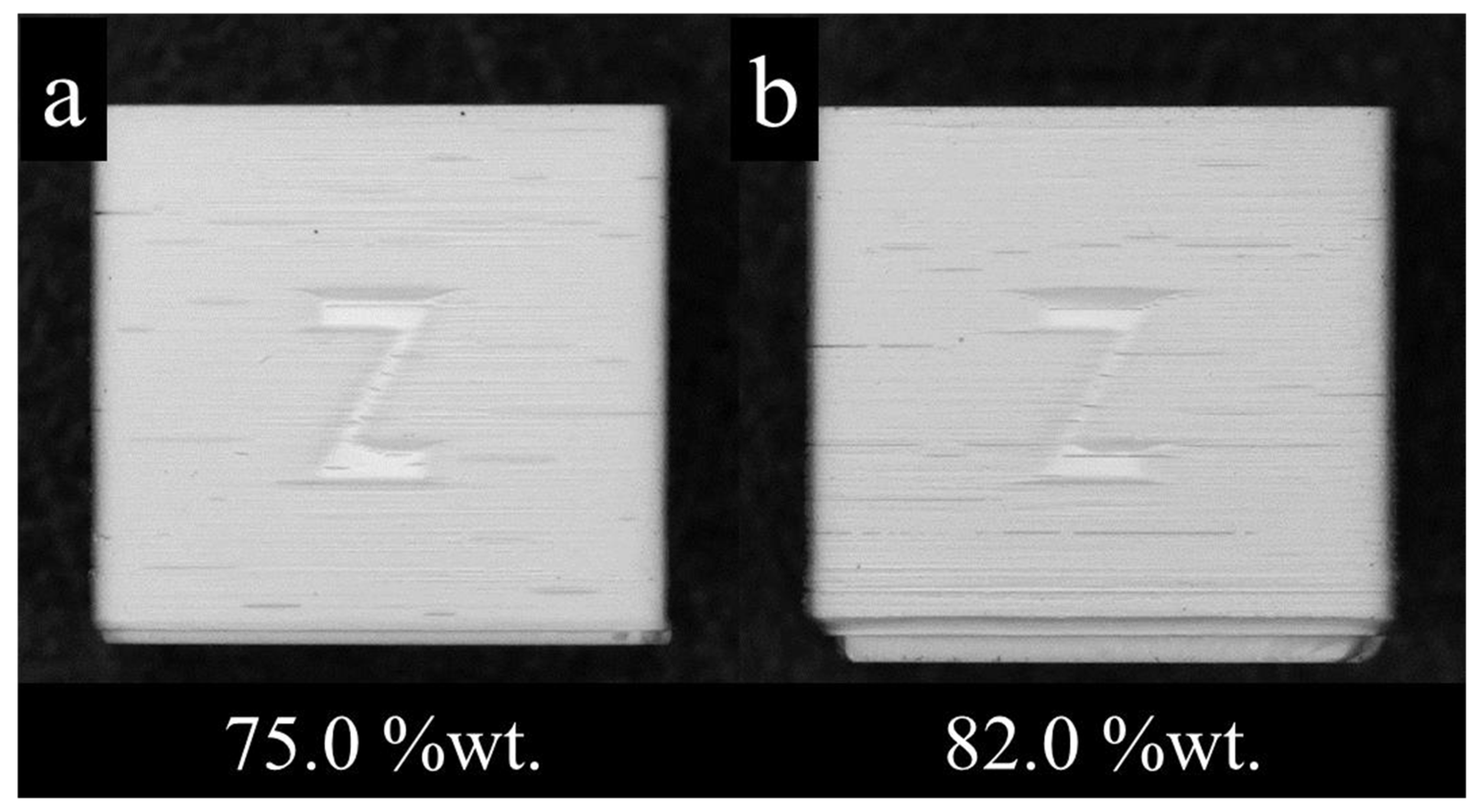

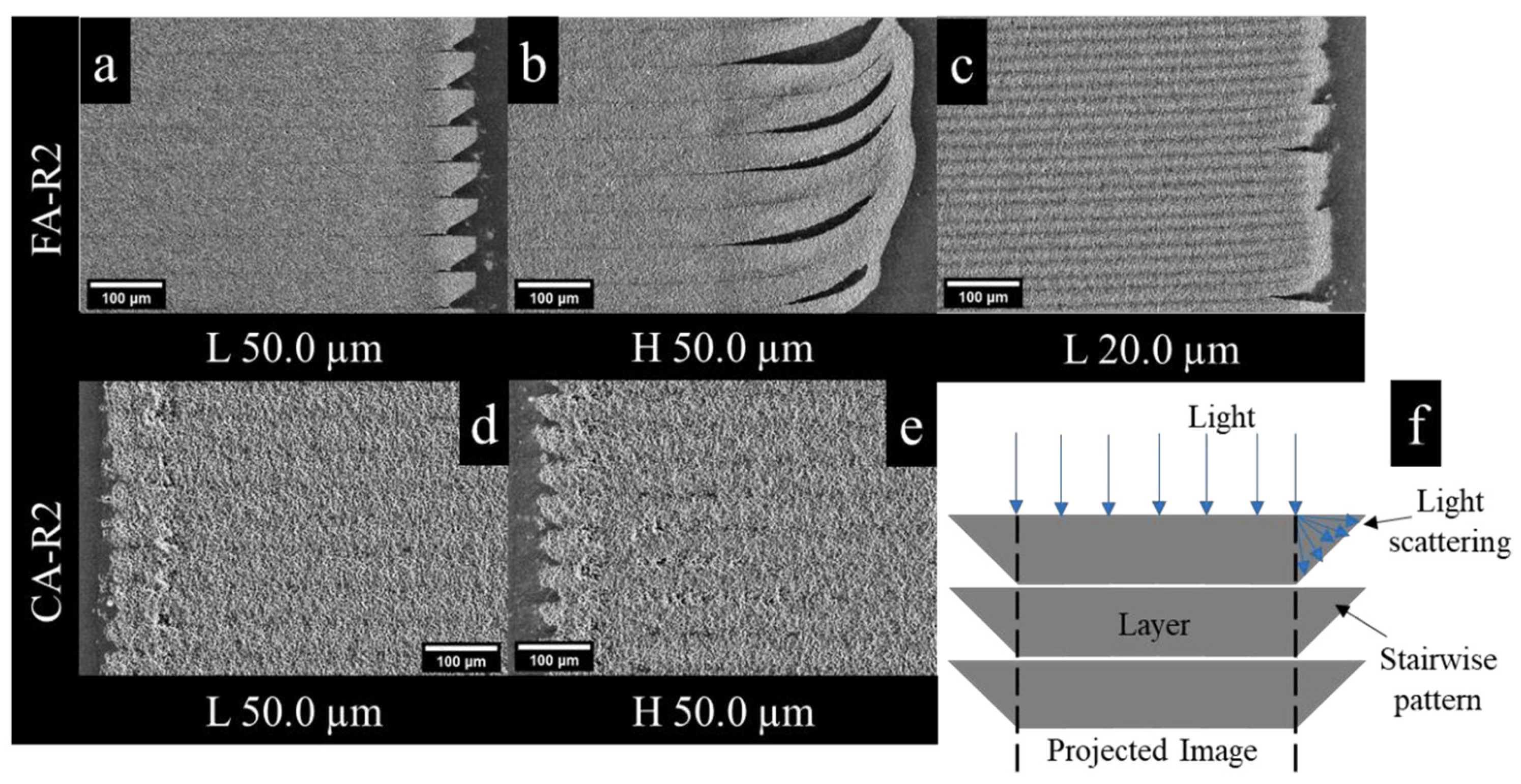

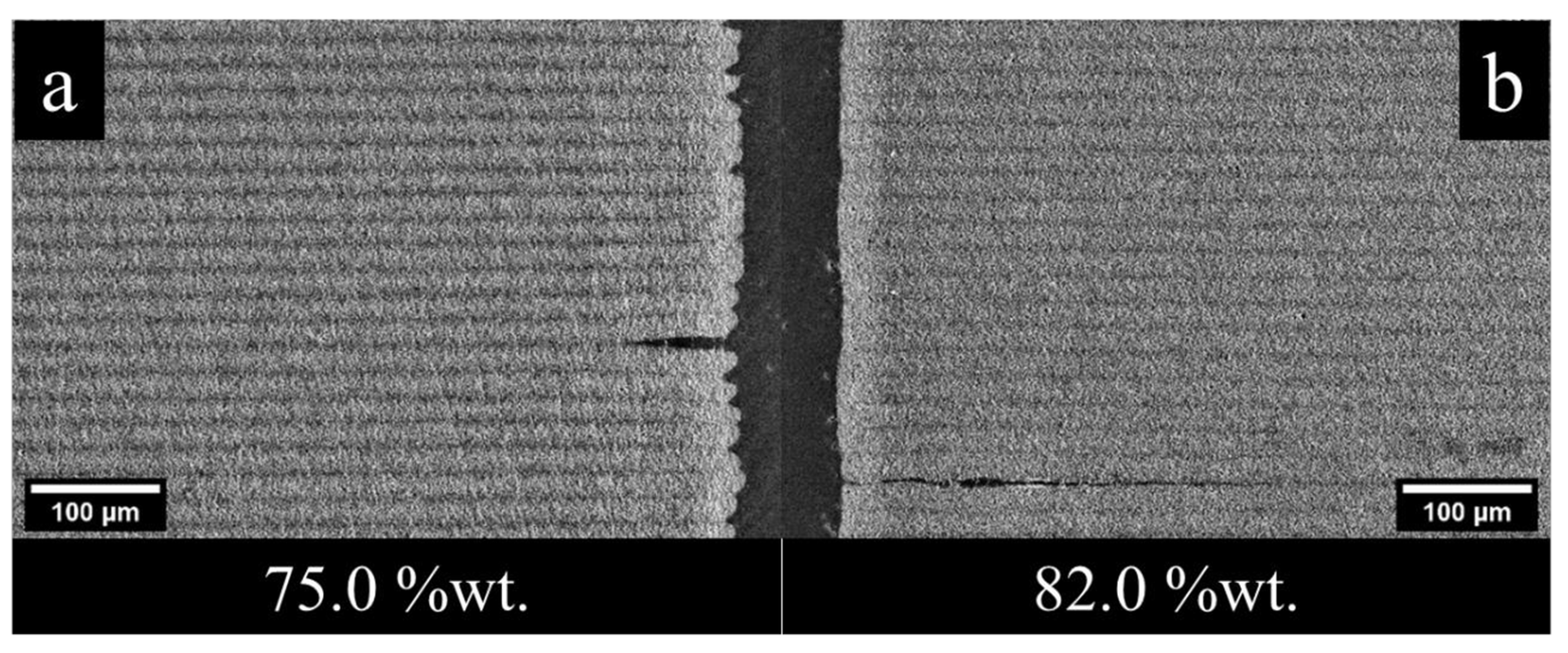

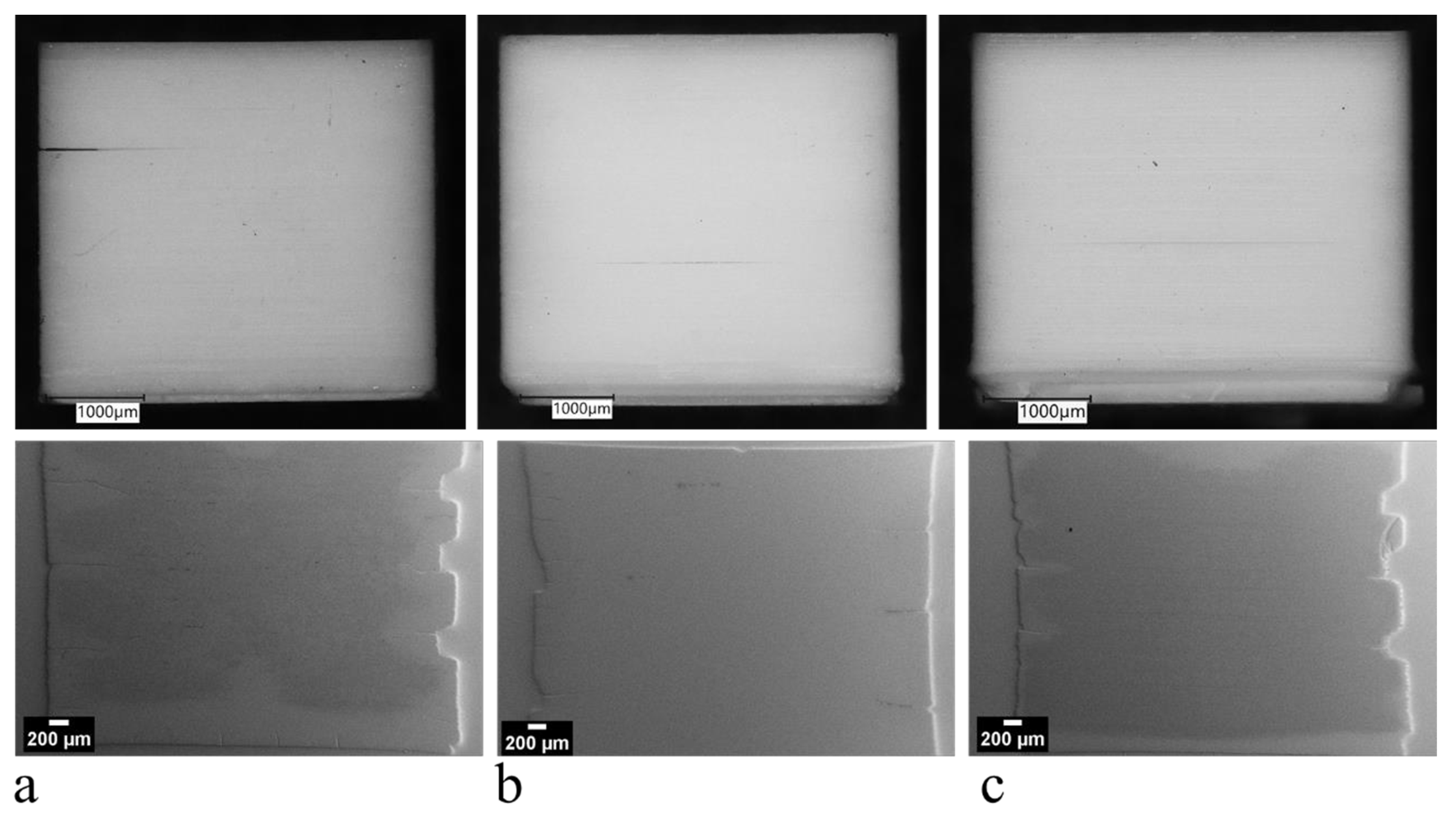

3.3. Feature Resolution

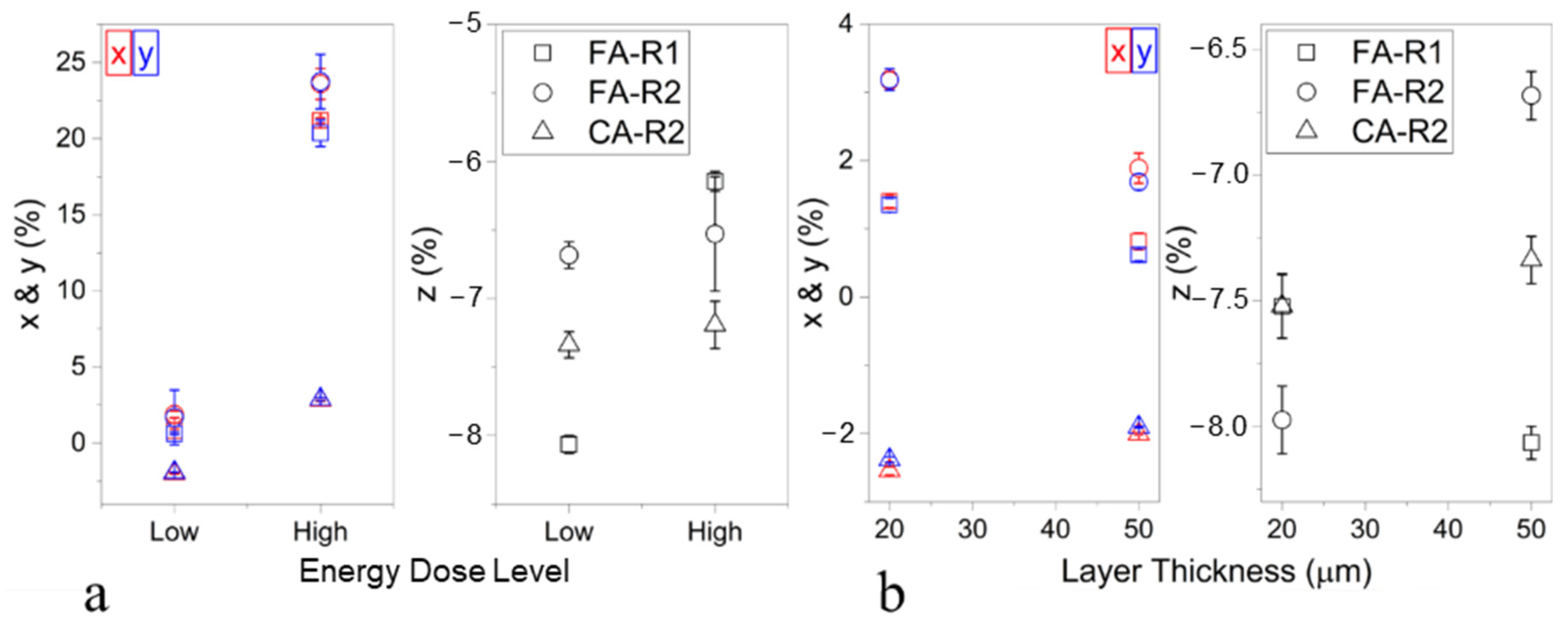

3.4. Dimensional Changes after Printing

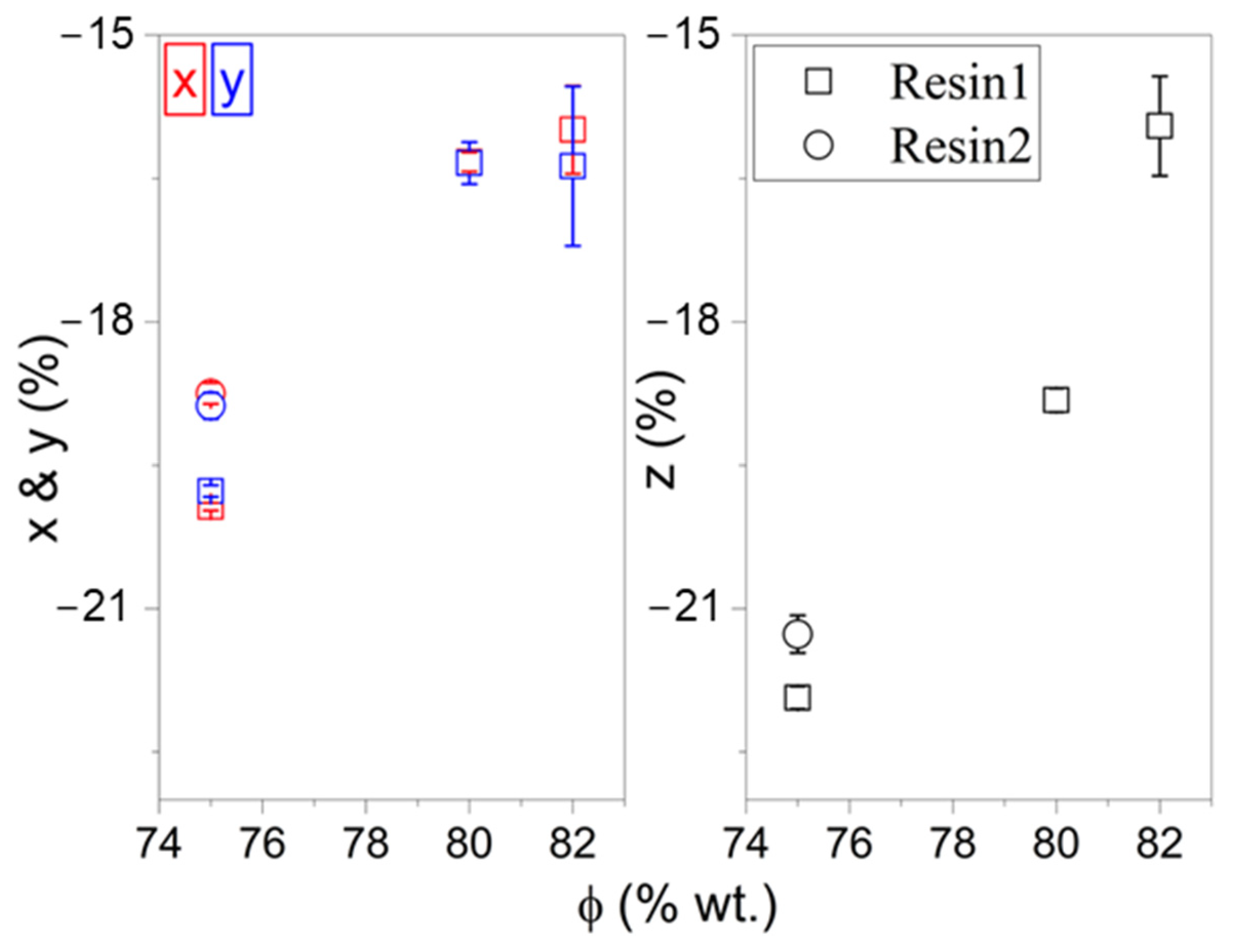

3.5. Dimensional Changes after Sintering

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Osman, R.B.; van der Veen, A.J.; Huiberts, D.; Wismeijer, D.; Alharbi, N. 3D-printing zirconia implants; a dream or a reality? An in-vitro study evaluating the dimensional accuracy, surface topography and mechanical properties of printed zirconia implant and discs. J. Mech. Behav. Biomed. Mater. 2017, 75, 521–528. [Google Scholar] [CrossRef]

- Tahayeri, A.; Morgan, M.; Fugolin, A.P.; Bompolaki, D.; Athirasala, A.; Pfeifer, C.S.; Ferracane, J.L.; Bertassoni, L.E. 3D printed versus conventionally cured provisional crown and bridge dental materials. Dent. Mater. 2018, 34, 192–200. [Google Scholar] [CrossRef]

- Bae, C.J.; Halloran, J.W. Integrally cored ceramic mold fabricated by ceramic stereolithography. Int. J. Appl. Ceram. Technol. 2011, 8, 1255–1262. [Google Scholar] [CrossRef]

- Conti, L.; Bienenstein, D.; Borlaf, M.; Graule, T. Effects of the Layer Height and Exposure Energy on the Lateral Resolution of Zirconia Parts Printed by Lithography-Based Additive Manufacturing. Materials 2020, 13, 1317. [Google Scholar] [CrossRef]

- Dehurtevent, M.; Robberecht, L.; Hornez, J.-C.; Thuault, A.; Deveaux, E.; Béhin, P. Stereolithography: A new method for processing dental ceramics by additive computer-aided manufacturing. Dent. Mater. 2017, 33, 477–485. [Google Scholar] [CrossRef]

- Borlaf, M.; Serra-Capdevila, A.; Colominas, C.; Graule, T. Development of UV-curable ZrO2 slurries for additive manufacturing (LCM-DLP) technology. J. Eur. Ceram. Soc. 2019, 39, 3797–3803. [Google Scholar] [CrossRef]

- Griffith, M.L.; Halloran, J.W. Ultraviolet curing of highly loaded ceramic suspensions for stereolithography of ceramics. In Proceedings of the 1994 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 8–10 August 1994; pp. 396–403. [Google Scholar]

- Johansson, E.; Lidström, O.; Johansson, J.; Lyckfeldt, O.; Adolfsson, E. Influence of resin composition on the defect formation in alumina manufactured by stereolithography. Materials 2017, 10, 138. [Google Scholar] [CrossRef]

- Griffith, M.L.; Halloran, J.W. Freeform fabrication of ceramics via stereolithography. J. Am. Ceram. Soc. 1996, 79, 2601–2608. [Google Scholar] [CrossRef]

- Halloran, J.W.; Griffith, M.; Chu, T.-M. Stereolithography Resin for Rapid Prototyping of Ceramics and Metals. US Patent 6117612A, 12 September 2000. [Google Scholar]

- Zhang, K.; Xie, C.; Wang, G.; He, R.; Ding, G.; Wang, M.; Dai, D.; Fang, D. High solid loading, low viscosity photosensitive Al2O3 slurry for stereolithography based additive manufacturing. Ceram. Int. 2019, 45, 203–208. [Google Scholar] [CrossRef]

- Hinczewski, C.; Corbel, S.; Chartier, T. Stereolithography for the fabrication of ceramic three-dimensional parts. Rapid Prototyp. J. 1998, 4, 104–111. [Google Scholar] [CrossRef]

- Gentry, S.P.; Halloran, J.W. Depth and width of cured lines in photopolymerizable ceramic suspensions. J. Eur. Ceram. Soc. 2013, 33, 1981–1988. [Google Scholar] [CrossRef]

- Gentry, S.P.; Halloran, J.W. Light scattering in absorbing ceramic suspensions: Effect on the width and depth of photopolymerized features. J. Eur. Ceram. Soc. 2015, 35, 1895–1904. [Google Scholar] [CrossRef]

- Hinczewski, C.; Corbel, S.; Chartier, T. Ceramic suspensions suitable for stereolithography. J. Eur. Ceram. Soc. 1998, 18, 583–590. [Google Scholar] [CrossRef]

- Chartier, T.; Hinczewski, C.; Corbel, S. UV curable systems for tape casting. J. Eur. Ceram. Soc. 1999, 19, 67–74. [Google Scholar] [CrossRef]

- Griffith, M.L.; Halloran, J.W. Scattering of ultraviolet radiation in turbid suspensions. J. Appl. Phys. 1997, 81, 2538–2546. [Google Scholar] [CrossRef]

- Tomeckova, V.; Halloran, J.W. Critical energy for photopolymerization of ceramic suspensions in acrylate monomers. J. Eur. Ceram. Soc. 2010, 30, 3273–3282. [Google Scholar] [CrossRef]

- Mitteramskogler, G.; Gmeiner, R.; Felzmann, R.; Gruber, S.; Hofstetter, C.; Stampfl, J.; Ebert, J.; Wachter, W.; Laubersheimer, J. Light curing strategies for lithography-based additive manufacturing of customized ceramics. Addit. Manuf. 2014, 1–4, 110–118. [Google Scholar] [CrossRef]

- Tomeckova, V.; Halloran, J.W. Predictive models for the photopolymerization of ceramic suspensions. J. Eur. Ceram. Soc. 2010, 30, 2833–2840. [Google Scholar] [CrossRef]

- Tomeckova, V.; Halloran, J.W. Cure depth for photopolymerization of ceramic suspensions. J. Eur. Ceram. Soc. 2010, 30, 3023–3033. [Google Scholar] [CrossRef]

- Li, K.; Zhao, Z. The effect of the surfactants on the formulation of UV-curable SLA alumina suspension. Ceram. Int. 2017, 43, 4761–4767. [Google Scholar] [CrossRef]

- Adake, C.V.; Bhargava, P.; Gandhi, P. Effect of surfactant on dispersion of alumina in photopolymerizable monomers and their UV curing behavior for microstereolithography. Ceram. Int. 2015, 41, 5301–5308. [Google Scholar] [CrossRef]

- Wang, W.; Feng, M.; Wang, Z.; Jiang, Y.; Xing, B.; Zhao, Z. Precision control in vat photopolymerization based on pure copper paste: Process parameters and optimization strategies. Materials 2023, 16, 5565. [Google Scholar] [CrossRef] [PubMed]

- Arora, P.; Mostafa, K.G.; Russell, E.; Dehgahi, S.; Butt, S.U.; Talamona, D.; Qureshi, A.J. Shrinkage compensation and effect of building orientation on mechanical properties of ceramic stereolithography parts. Polymers 2023, 15, 3877. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Sutejo, I.A.; Kim, J.; Choi, Y.-J.; Gal, C.W.; Yun, H.-s. Fabrication of complex three-dimensional structures of mica through digital light processing-based additive manufacturing. Ceramics 2022, 5, 562–574. [Google Scholar] [CrossRef]

- Lin, C.; Xu, W.; Liu, B.; Wang, H.; Xing, H.; Sun, Q.; Xu, J. Three-dimensional printing of large objects with high resolution by dynamic projection scanning lithography. Micromachines 2023, 14, 1700. [Google Scholar] [CrossRef]

- Alazzawi, M.K.; Beyoglu, B.; Haber, R.A. A study in a tape casting based stereolithography apparatus: Role of layer thickness and casting shear rate. J. Manuf. Process. 2021, 64, 1196–1203. [Google Scholar] [CrossRef]

- Polyanskiy, M.N. Refractive Index Database. Available online: https://refractiveindex.info (accessed on 17 August 2020).

- Alazzawi, M.K. Stereolithography of Alumina Systems: Cure Depth and Dimensional Control; Rutgers University-School of Graduate Studies: New Brunswick, NJ, USA, 2021. [Google Scholar]

- Alazzawi, M.K.; Beyoglu, B.; Maniaci, F.F.; Haber, R.A. Degree of dispersion assessments of highly filled stereolithography suspension using fineness of grind measurement. Powder Technol. 2021, 382, 318–330. [Google Scholar] [CrossRef]

- Xing, H.; Zou, B.; Liu, X.; Wang, X.; Chen, Q.; Fu, X.; Li, Y. Effect of particle size distribution on the preparation of ZTA ceramic paste applying for stereolithography 3D printing. Powder Technol. 2020, 359, 314–322. [Google Scholar] [CrossRef]

- Song, S.Y.; Park, M.S.; Lee, J.W.; Yun, J.S. A study on the rheological and mechanical properties of photo-curable ceramic/polymer composites with different silane coupling agents for SLA 3D printing technology. Nanomaterials 2018, 8, 93. [Google Scholar] [CrossRef]

- Schwentenwein, M.; Homa, J. Additive manufacturing of dense alumina ceramics. Int. J. Appl. Ceram. Technol. 2015, 12, 1–7. [Google Scholar] [CrossRef]

- Chartier, T.; Badev, A.; Abouliatim, Y.; Lebaudy, P.; Lecamp, L. Stereolithography process: Influence of the rheology of silica suspensions and of the medium on polymerization kinetics–cured depth and width. J. Eur. Ceram. Soc. 2012, 32, 1625–1634. [Google Scholar] [CrossRef]

- Li, X.; Zhong, H.; Zhang, J.; Duan, Y.; Bai, H.; Li, J.; Jiang, D. Dispersion and properties of zirconia suspensions for stereolithography. Int. J. Appl. Ceram. Technol. 2020, 17, 239–247. [Google Scholar] [CrossRef]

- Gonzalez, P.; Schwarzer, E.; Scheithauer, U.; Kooijmans, N.; Moritz, T. Additive manufacturing of functionally graded ceramic materials by stereolithography. J. Vis. Exp. 2019, 143, e57943. [Google Scholar]

- Tomeckova, V.; Halloran, J. Flow behavior of polymerizable ceramic suspensions as function of ceramic volume fraction and temperature. J. Eur. Ceram. Soc. 2011, 31, 2535–2542. [Google Scholar] [CrossRef]

- Alazzawi, M.K.; Kondapalli, S.S.; Haber, R.A. Degree of dispersion and cure depth of photocurable ceramic and metal suspensions. J. Mater. Res. 2021, 36, 4275–4286. [Google Scholar] [CrossRef]

| Samples | Solid Content (%wt.) | Powder | Particle Size, d50 (µm) | Density (g/cm3) | Refractive Index Difference | Resin |

|---|---|---|---|---|---|---|

| FA-R1 | 75–82 | AA07 | 1.35 | 4.01 | 0.275 | Resin1 |

| FA-R2 | 0.269 | Resin2 | ||||

| CA-R2 | 75.0 | AA3 | 2.76 | 4.06 | Resin2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alazzawi, M.K.; Hwang, C.; Tsarkova, V.R.; Haber, R.A. The Feature Resolution and Dimensional Control in Freeform Solidification of Alumina Systems by Stereolithography. Ceramics 2023, 6, 2036-2052. https://doi.org/10.3390/ceramics6040125

Alazzawi MK, Hwang C, Tsarkova VR, Haber RA. The Feature Resolution and Dimensional Control in Freeform Solidification of Alumina Systems by Stereolithography. Ceramics. 2023; 6(4):2036-2052. https://doi.org/10.3390/ceramics6040125

Chicago/Turabian StyleAlazzawi, Mustafa K., Chawon Hwang, Victoria R. Tsarkova, and Richard A. Haber. 2023. "The Feature Resolution and Dimensional Control in Freeform Solidification of Alumina Systems by Stereolithography" Ceramics 6, no. 4: 2036-2052. https://doi.org/10.3390/ceramics6040125

APA StyleAlazzawi, M. K., Hwang, C., Tsarkova, V. R., & Haber, R. A. (2023). The Feature Resolution and Dimensional Control in Freeform Solidification of Alumina Systems by Stereolithography. Ceramics, 6(4), 2036-2052. https://doi.org/10.3390/ceramics6040125