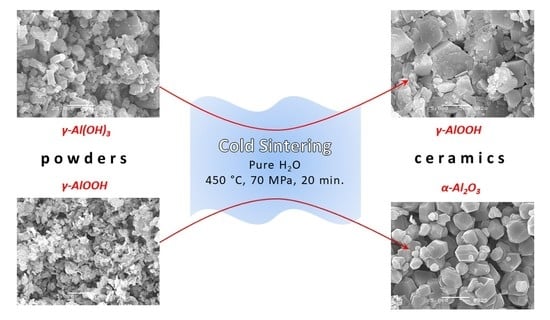

Water-Assisted Cold Sintering of Alumina Ceramics in SPS Conditions

Abstract

1. Introduction

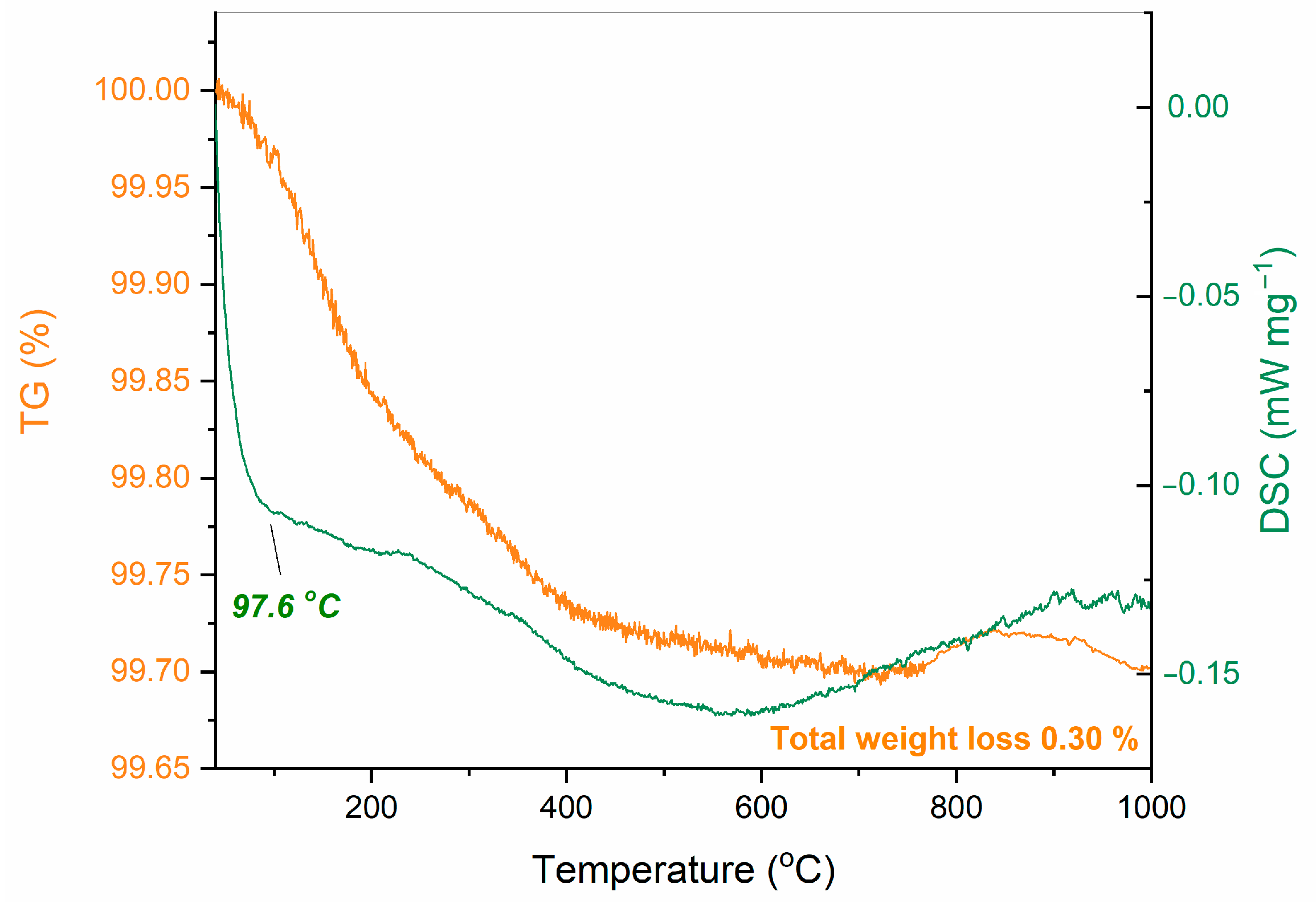

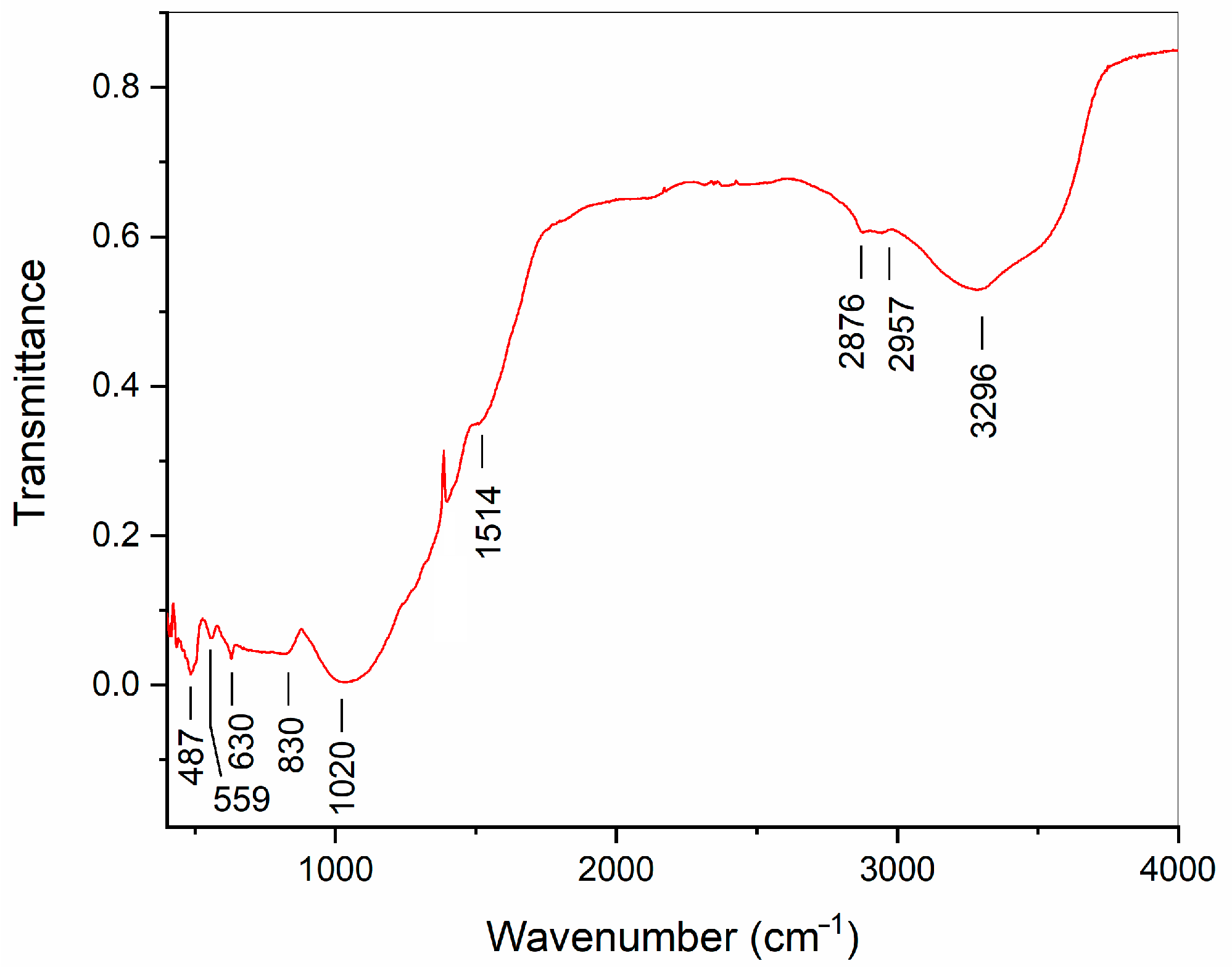

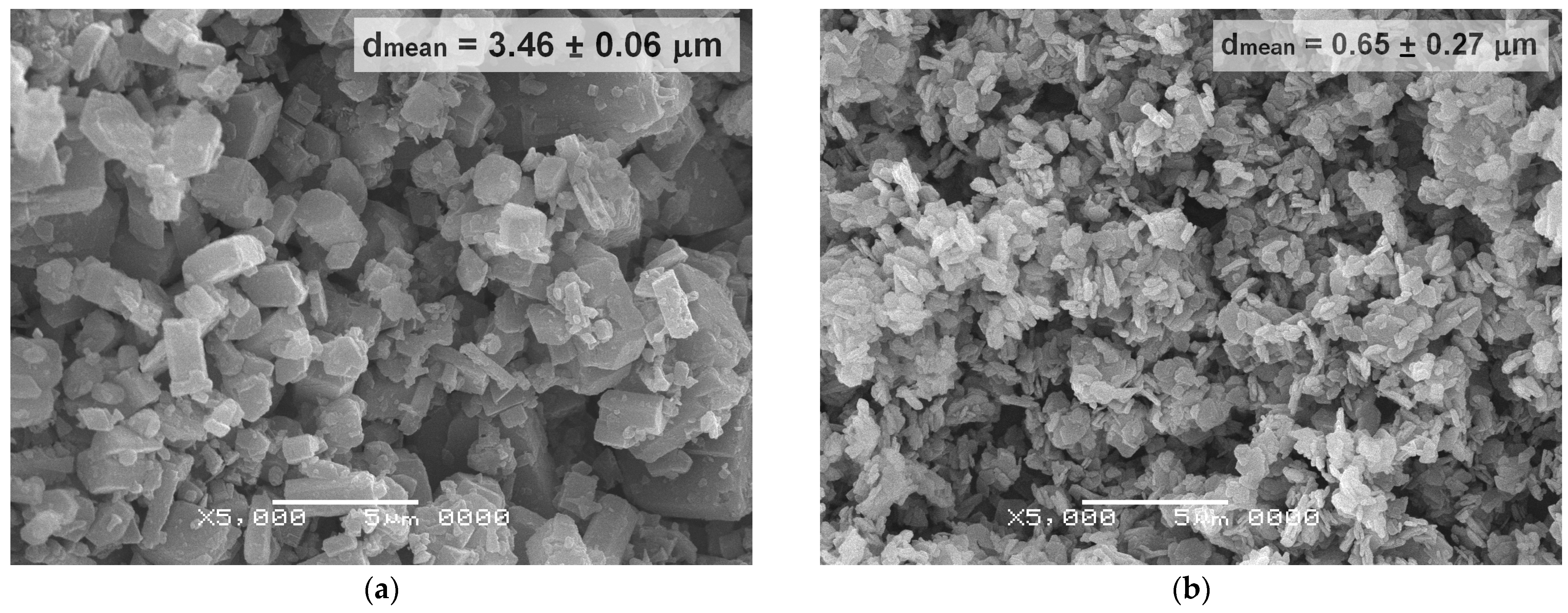

2. Materials and Methods

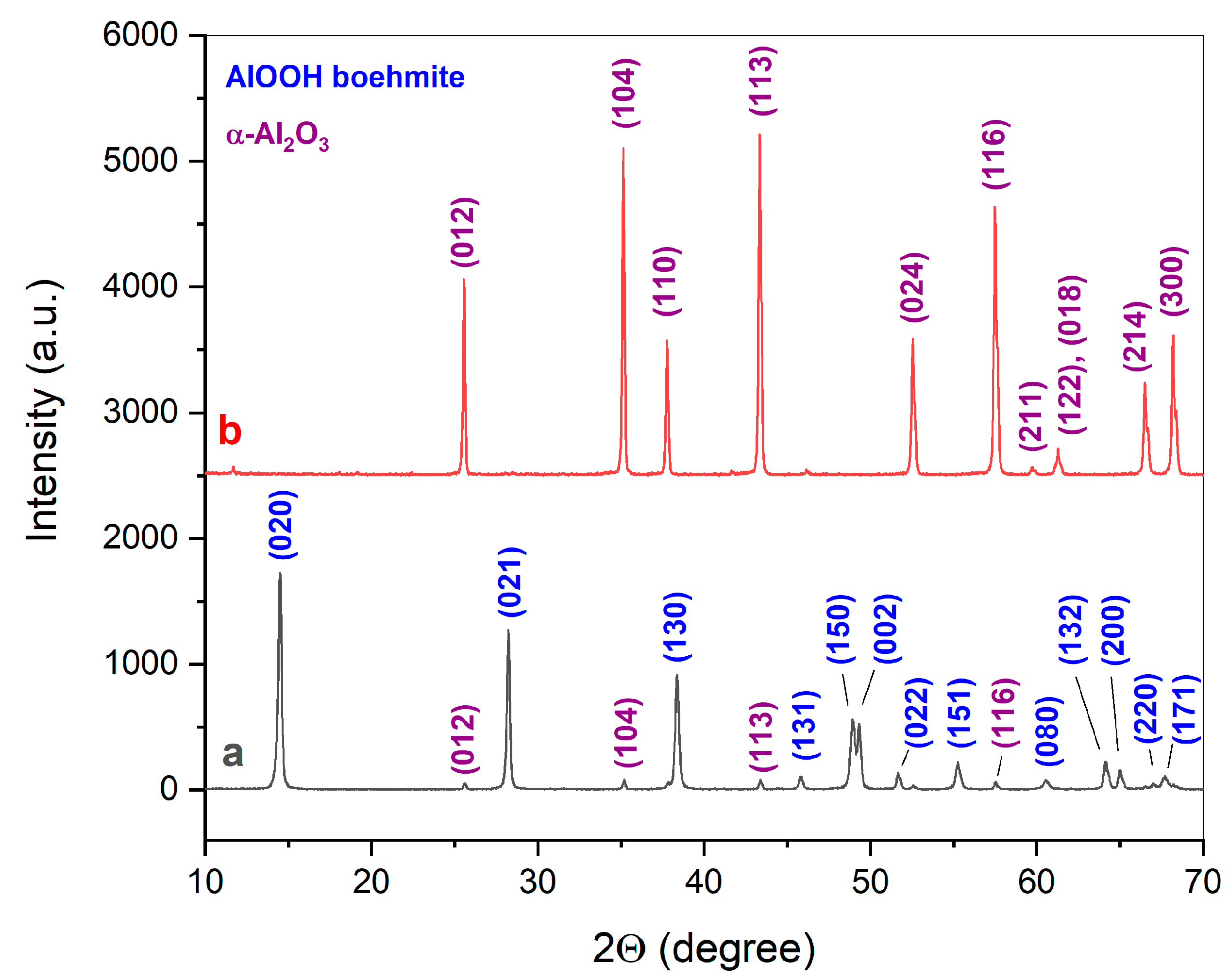

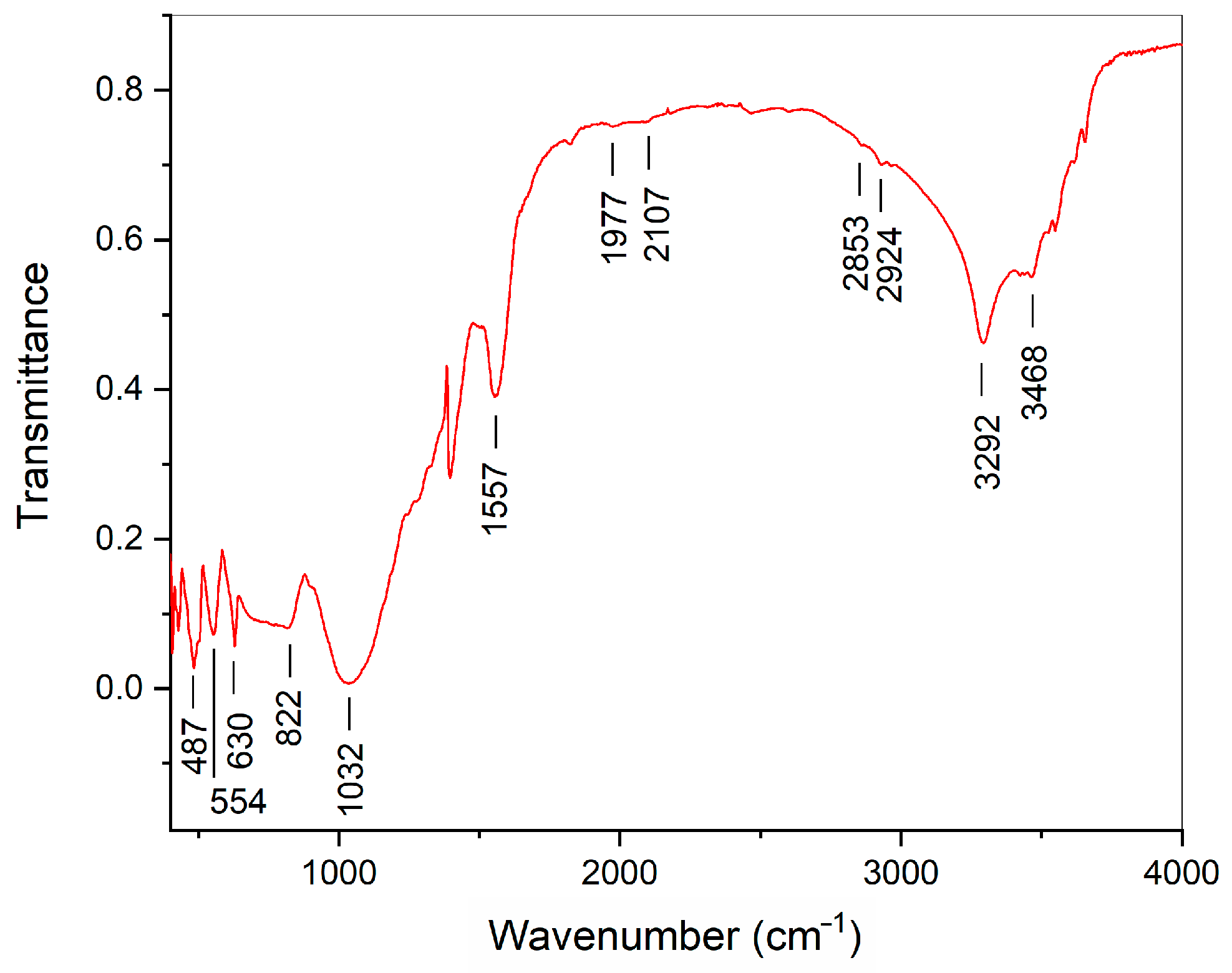

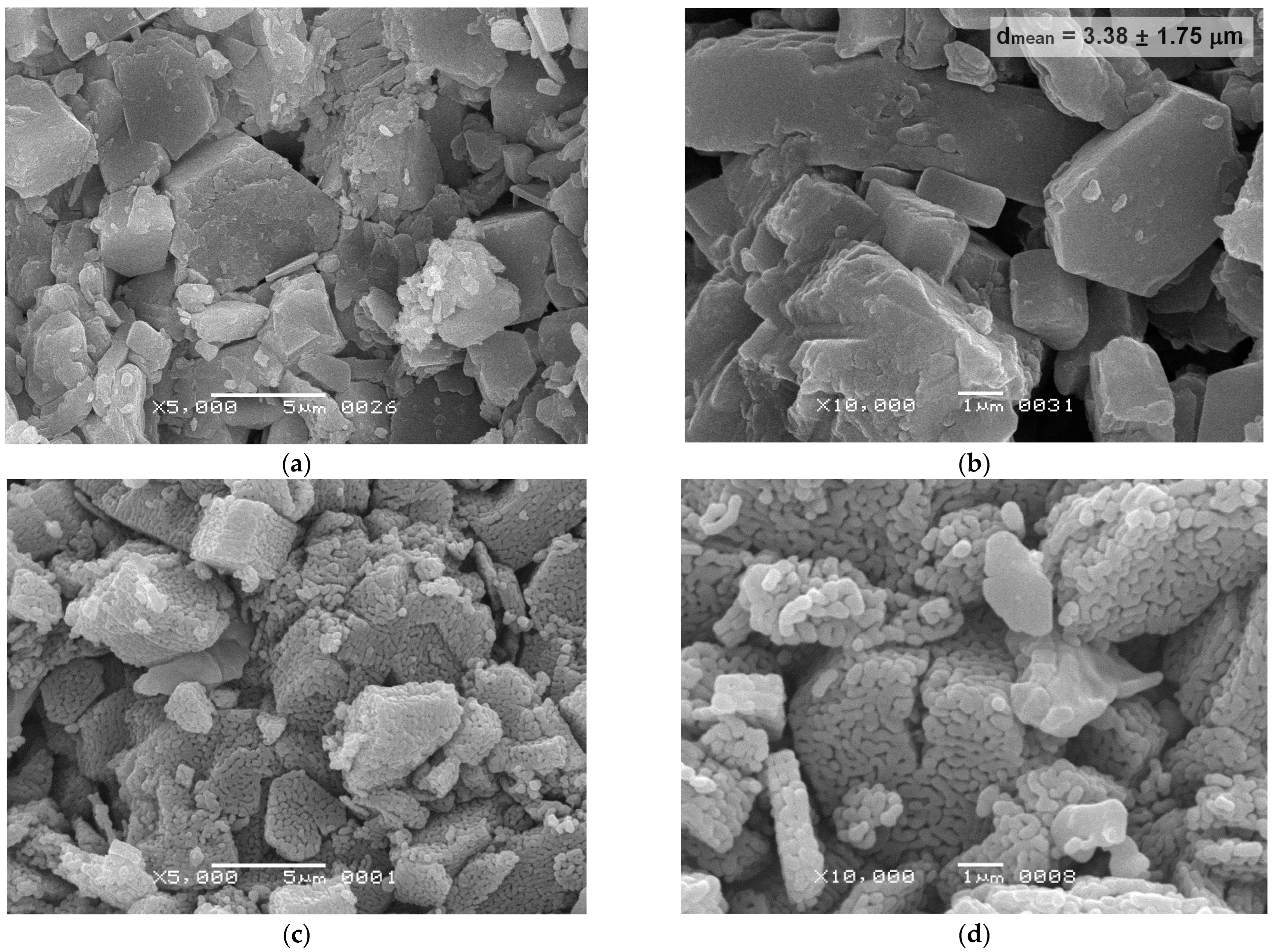

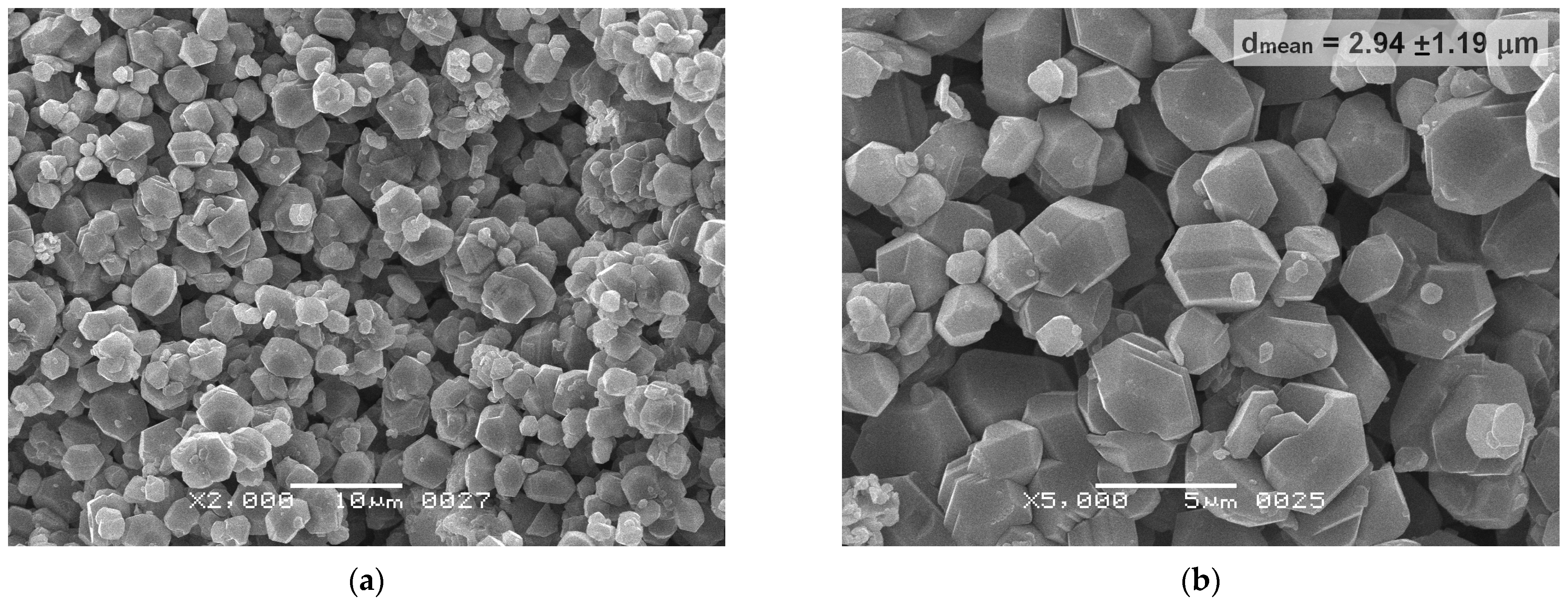

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Ohji, T.; Fukushima, M. Macro-Porous Ceramics: Processing and Properties. Int. Mater. Rev. 2012, 57, 115–131. [Google Scholar] [CrossRef]

- Hardy, D.; Green, D.J. Mechanical Properties of a Partially Sintered Alumina. J. Eur. Ceram. Soc. 1995, 15, 769–775. [Google Scholar] [CrossRef]

- Çelik, A.; Çağlar, G.; Çelik, Y. Fabrication of Porous Al2O3 Ceramics Using Carbon Black as a Pore Forming Agent by Spark Plasma Sintering. Ceram. Int. 2022, 48, 28181–28190. [Google Scholar] [CrossRef]

- González-Sánchez, M.; Rivero-Antúnez, P.; Cano-Crespo, R.; Morales-Flórez, V. Fabrication of Porous Alumina Structures by SPS and Carbon Sacrificial Template for Bone Regeneration. Materials 2022, 15, 1754. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Ding, X.; Wang, Y.; Luo, Z.; Zhai, P. Fractal Dimension Analysis of Structure and Bending Strength of Porous Alumina Prepared Using Starch and Carbon Fiber as Pore-Forming Agents. Fractal Fract. 2022, 6, 574. [Google Scholar] [CrossRef]

- Biggemann, J.; Stumpf, M.; Fey, T. Porous Alumina Ceramics with Multimodal Pore Size Distributions. Materials 2021, 14, 3294. [Google Scholar] [CrossRef] [PubMed]

- Schelm, K.; Fey, T.; Dammler, K.; Betke, U.; Scheffler, M. Hierarchical-Porous Ceramic Foams by a Combination of Replica and Freeze Technique. Adv. Eng. Mater. 2019, 21, 1801362. [Google Scholar] [CrossRef]

- Scheithauer, U.; Kerber, F.; Füssel, A.; Holtzhausen, S.; Beckert, W.; Schwarzer, E.; Weingarten, S.; Michaelis, A. Alternative Process Routes to Manufacture Porous Ceramics—Opportunities and Challenges. Materials 2019, 12, 663. [Google Scholar] [CrossRef][Green Version]

- He, X.; Zhou, X.; Su, B. 3D Interconnective Porous Alumina Ceramics via Direct Protein Foaming. Mater. Lett. 2009, 63, 830–832. [Google Scholar] [CrossRef]

- Devavarapu, S.; Chaudhuri, P.; Shrivastava, A.; Bhattacharyya, S. Processing of Porous Alumina by Foaming Method-Effect of Foaming Agent, Solid Loading and Binder. Ceram. Int. 2019, 45, 12264–12273. [Google Scholar] [CrossRef]

- Maria, J.-P.; Kang, X.; Floyd, R.D.; Dickey, E.C.; Guo, H.; Guo, J.; Baker, A.; Funihashi, S.; Randall, C.A. Cold Sintering: Current Status and Prospects. J. Mater. Res. 2017, 32, 3205–3218. [Google Scholar] [CrossRef][Green Version]

- Langer, J.; Hoffmann, M.J.; Guillon, O. Direct Comparison between Hot Pressing and Electric Field-Assisted Sintering of Submicron Alumina. Acta Mater. 2009, 57, 5454–5465. [Google Scholar] [CrossRef]

- Bocanegra-Bernal, M.H. Hot Isostatic Pressing (HIP) Technology and Its Applications to Metals and Ceramics. J. Mater. Sci. 2004, 39, 6399–6420. [Google Scholar] [CrossRef]

- Oghbaei, M.; Mirzaee, O. Microwave versus Conventional Sintering: A Review of Fundamentals, Advantages and Applications. J. Alloys Compd. 2010, 494, 175–189. [Google Scholar] [CrossRef]

- Munir, Z.A.; Quach, D.V.; Ohyanagi, M. Electric Current Activation of Sintering: A Review of the Pulsed Electric Current Sintering Process: Electric Current Activation of Sintering. J. Am. Ceram. Soc. 2011, 94, 1–19. [Google Scholar] [CrossRef]

- Munir, Z.A.; Anselmi-Tamburini, U.; Ohyanagi, M. The Effect of Electric Field and Pressure on the Synthesis and Consolidation of Materials: A Review of the Spark Plasma Sintering Method. J. Mater. Sci 2006, 41, 763–777. [Google Scholar] [CrossRef]

- Rubinovskii, N.A.; Shornikov, D.P.; Tenishev, A.V.; Zaluzhnui, A.G.; Zholnin, A.G. Effect of Aluminum Oxide Powder Particle Size on Spark Plasma Sintering Results. Glass Ceram. 2019, 76, 94–98. [Google Scholar] [CrossRef]

- Wang, S.W.; Chen, L.D.; Hirai, T. Densification of Al2O3 Powder Using Spark Plasma Sintering. J. Mater. Res. 2000, 15, 982–987. [Google Scholar] [CrossRef]

- Young, C.; Zhang, C.; Nisar, A.; Boesl, B.; Agarwal, A. Spark Plasma Sintered Porous Aluminum Oxide for Filtration Applications. Ceram. Int. 2021, 47, 21822–21827. [Google Scholar] [CrossRef]

- Roussel, N.; Lallemant, L.; Chane-Ching, J.-Y.; Guillemet-Fristch, S.; Durand, B.; Garnier, V.; Bonnefont, G.; Fantozzi, G.; Bonneau, L.; Trombert, S.; et al. Highly Dense, Transparent α-Al2O3 Ceramics From Ultrafine Nanoparticles Via a Standard SPS Sintering. J. Am. Ceram. Soc. 2013, 96, 1039–1042. [Google Scholar] [CrossRef]

- Guo, J.; Guo, H.; Baker, A.L.; Lanagan, M.T.; Kupp, E.R.; Messing, G.L.; Randall, C.A. Cold Sintering: A Paradigm Shift for Processing and Integration of Ceramics. Angew. Chem. Int. Ed. 2016, 55, 11457–11461. [Google Scholar] [CrossRef] [PubMed]

- Ibn-Mohammed, T.; Randall, C.A.; Mustapha, K.B.; Guo, J.; Walker, J.; Berbano, S.; Koh, S.C.L.; Wang, D.; Sinclair, D.C.; Reaney, I.M. Decarbonising Ceramic Manufacturing: A Techno-Economic Analysis of Energy Efficient Sintering Technologies in the Functional Materials Sector. J. Eur. Ceram. Soc. 2019, 39, 5213–5235. [Google Scholar] [CrossRef]

- Floyd, R.D.; Lowum, S.; Maria, J.-P. Cold Sintering Zinc Oxide with a Crystalline Zinc Acetate Dihydrate Mass Transport Phase. J. Mater. Sci. 2020, 55, 15117–15129. [Google Scholar] [CrossRef]

- Dargatz, B.; Gonzalez-Julian, J.; Bram, M.; Jakes, P.; Besmehn, A.; Schade, L.; Röder, R.; Ronning, C.; Guillon, O. FAST/SPS Sintering of Nanocrystalline Zinc Oxide—Part I: Enhanced Densification and Formation of Hydrogen-Related Defects in Presence of Adsorbed Water. J. Eur. Ceram. Soc. 2016, 36, 1207–1220. [Google Scholar] [CrossRef]

- Dargatz, B.; Gonzalez-Julian, J.; Bram, M.; Shinoda, Y.; Wakai, F.; Guillon, O. FAST/SPS Sintering of Nanocrystalline Zinc Oxide—Part II: Abnormal Grain Growth, Texture and Grain Anisotropy. J. Eur. Ceram. Soc. 2016, 36, 1221–1232. [Google Scholar] [CrossRef]

- Ivakin, Y.; Smirnov, A.; Kholodkova, A.; Vasin, A.; Kormilicin, M.; Kornyushin, M.; Stolyarov, V. Comparative Study of Cold Sintering Process and Autoclave Thermo-Vapor Treatment on a ZnO Sample. Crystals 2021, 11, 71. [Google Scholar] [CrossRef]

- Bang, S.H.; Tsuji, K.; Ndayishimiye, A.; Dursun, S.; Seo, J.; Otieno, S.; Randall, C.A. Toward a Size Scale-up Cold Sintering Process at Reduced Uniaxial Pressure. J. Am. Ceram. Soc. 2020, 103, 2322–2327. [Google Scholar] [CrossRef]

- Hérisson de Beauvoir, T.; Dursun, S.; Gao, L.; Randall, C. New Opportunities in Metallization Integration in Cofired Electroceramic Multilayers by the Cold Sintering Process. ACS Appl. Electron. Mater. 2019, 1, 1198–1207. [Google Scholar] [CrossRef]

- Jing, Y.; Luo, N.; Wu, S.; Han, K.; Wang, X.; Miao, L.; Wei, Y. Remarkably Improved Electrical Conductivity of ZnO Ceramics by Cold Sintering and Post-Heat-Treatment. Ceram. Int. 2018, 44, 20570–20574. [Google Scholar] [CrossRef]

- Funahashi, S.; Guo, J.; Guo, H.; Wang, K.; Baker, A.L.; Shiratsuyu, K.; Randall, C.A. Demonstration of the Cold Sintering Process Study for the Densification and Grain Growth of ZnO Ceramics. J. Am. Ceram. Soc. 2017, 100, 546–553. [Google Scholar] [CrossRef]

- Ma, J.-P.; Chen, X.-M.; Ouyang, W.-Q.; Wang, J.; Li, H.; Fang, J.-L. Microstructure, Dielectric, and Energy Storage Properties of BaTiO3 Ceramics Prepared via Cold Sintering. Ceram. Int. 2018, 44, 4436–4441. [Google Scholar] [CrossRef]

- Tsuji, K.; Ndayishimiye, A.; Lowum, S.; Floyd, R.; Wang, K.; Wetherington, M.; Maria, J.-P.; Randall, C.A. Single Step Densification of High Permittivity BaTiO3 Ceramics at 300 °C. J. Eur. Ceram. Soc. 2020, 40, 1280–1284. [Google Scholar] [CrossRef]

- Sada, T.; Ndayishimiye, A.; Fan, Z.; Fujioka, Y.; Randall, C.A. Surface Modification of BaTiO3 with Catechol Surfactant and Effects on Cold Sintering. J. Appl. Phys. 2021, 129, 184102. [Google Scholar] [CrossRef]

- Guo, N.; Shen, H.-Z.; Shen, P. One-Step Synthesis and Densification of BaTiO3 by Reactive Cold Sintering. Scr. Mater. 2022, 213, 114628. [Google Scholar] [CrossRef]

- Ma, J.; Li, H.; Wang, H.; Lin, C.; Wu, X.; Lin, T.; Zheng, X.; Yu, X. Composition, Microstructure and Electrical Properties of K0.5Na0.5NbO3 Ceramics Fabricated by Cold Sintering Assisted Sintering. J. Eur. Ceram. Soc. 2019, 39, 986–993. [Google Scholar] [CrossRef]

- Chi, M.; Ma, W.; Guo, J.; Wu, J.; Li, T.; Wang, S.; Zhang, P. Effect of NaCl on the Microstructure and Electrical Properties of K0.5Na0.5NbO3 Ceramics Prepared by Cold Sintering Process. J. Mater. Sci. Mater. Electron. 2019, 30, 21435–21443. [Google Scholar] [CrossRef]

- Cong, L.; Huajing, W.; Jianzhang, M.; Baoyu, D.; Xiao, W.; Tengfei, L.; Xinghua, Z.; Xing, Y. Effect of Dwell Time on Cold Sintering Assisted Sintering Based Highly Transparent 0.9K0.5Na0.5NbO3-0.1LiBiO3 Ceramics. J. Alloys Compd. 2020, 826, 154249. [Google Scholar] [CrossRef]

- Tsuji, K.; Fan, Z.; Bang, S.H.; Dursun, S.; Trolier-McKinstry, S.; Randall, C.A. Cold Sintering of the Ceramic Potassium Sodium Niobate, (K0.5Na0.5)NbO3, and Influences on Piezoelectric Properties. J. Eur. Ceram. Soc. 2022, 42, 105–111. [Google Scholar] [CrossRef]

- Wang, D.; Guo, H.; Morandi, C.S.; Randall, C.A.; Trolier-McKinstry, S. Cold Sintering and Electrical Characterization of Lead Zirconate Titanate Piezoelectric Ceramics. APL Mater. 2018, 6, 016101. [Google Scholar] [CrossRef][Green Version]

- Wang, D.; Tsuji, K.; Randall, C.A.; Trolier-McKinstry, S. Model for the Cold Sintering of Lead Zirconate Titanate Ceramic Composites. J. Am. Ceram. Soc. 2020, 103, 4894–4902. [Google Scholar] [CrossRef]

- Wang, D.; Dursun, S.; Gao, L.; Morandi, C.S.; Randall, C.A.; Trolier-McKinstry, S. Fabrication of Bimorph Lead Zirconate Titanate Thick Films on Metal Substrates via the Cold Sintering-Assisted Process. Acta Mater. 2020, 195, 482–490. [Google Scholar] [CrossRef]

- Induja, I.J.; Sebastian, M.T. Microwave Dielectric Properties of Cold Sintered Al2O3-NaCl Composite. Mater. Lett. 2018, 211, 55–57. [Google Scholar] [CrossRef]

- Suleiman, B.; Zhang, H.; Ding, Y.; Li, Y. Microstructure and Mechanical Properties of Cold Sintered Porous Alumina Ceramics. Ceram. Int. 2022, 48, 13531–13540. [Google Scholar] [CrossRef]

- Akmal, M.; Hassan, M.; Afzal, M.; Ryu, H.J. Novel Approach to Sintering Hydroxyapatite-Alumina Nanocomposites at 300 °C. Mater. Chem. Phys. 2021, 260, 124187. [Google Scholar] [CrossRef]

- Hérisson de Beauvoir, T.; Estournès, C. Translucent γ-AlOOH and γ-Al2O3 Glass-Ceramics Using the Cold Sintering Process. Scr. Mater. 2021, 194, 113650. [Google Scholar] [CrossRef]

- Kang, S.; Zhao, X.; Guo, J.; Liang, J.; Sun, J.; Yang, Y.; Yang, L.; Liao, R.; Randall, C.A. Thermal-Assisted Cold Sintering Study of Al2O3 Ceramics: Enabled with a Soluble γ-Al2O3 Intermediate Phase. J. Eur. Ceram. Soc. 2023, 43, 478–485. [Google Scholar] [CrossRef]

- Herisson de Beauvoir, T.; Sangregorio, A.; Cornu, I.; Elissalde, C.; Josse, M. Cool-SPS: An Opportunity for Low Temperature Sintering of Thermodynamically Fragile Materials. J. Mater. Chem. C 2018, 6, 2229–2233. [Google Scholar] [CrossRef][Green Version]

- Schwarz, S.; Thron, A.M.; Rufner, J.; Benthem, K.; Guillon, O. Low Temperature Sintering of Nanocrystalline Zinc Oxide: Effect of Heating Rate Achieved by Field Assisted Sintering/Spark Plasma Sintering. J. Am. Ceram. Soc. 2012, 95, 2451–2457. [Google Scholar] [CrossRef]

- Gonzalez-Julian, J.; Neuhaus, K.; Bernemann, M.; Pereira da Silva, J.; Laptev, A.; Bram, M.; Guillon, O. Unveiling the Mechanisms of Cold Sintering of ZnO at 250 °C by Varying Applied Stress and Characterizing Grain Boundaries by Kelvin Probe Force Microscopy. Acta Mater. 2018, 144, 116–128. [Google Scholar] [CrossRef][Green Version]

- Nur, K.; Mishra, T.P.; da Silva, J.G.P.; Gonzalez-Julian, J.; Bram, M.; Guillon, O. Influence of Powder Characteristics on Cold Sintering of Nano-Sized ZnO with Density above 99%. J. Eur. Ceram. Soc. 2021, 41, 2648–2662. [Google Scholar] [CrossRef]

- Liang, J.; Zhao, X.; Kang, S.; Guo, J.; Chen, Z.; Long, Y.; Zeng, Q.; Sun, J.; Yang, L.; Liao, R.; et al. Microstructural Evolution of ZnO via Hybrid Cold Sintering/Spark Plasma Sintering. J. Eur. Ceram. Soc. 2022, 42, 5738–5746. [Google Scholar] [CrossRef]

- Ivakin, Y.D.; Smirnov, A.V.; Kurmysheva, A.Y.; Kharlanov, A.N.; Solís Pinargote, N.W.; Smirnov, A.; Grigoriev, S.N. The Role of the Activator Additives Introduction Method in the Cold Sintering Process of ZnO Ceramics: CSP/SPS Approach. Materials 2021, 14, 6680. [Google Scholar] [CrossRef]

- Lazarev, V.B.; Panasyuk, G.P.; Voroshilov, I.L.; Boudova, G.P.; Danchevskaya, M.N.; Torbin, S.N.; Ivakin, Y.D. New Ecologically Pure Technologies of Fine-Crystalline Materials. Ind. Eng. Chem. Res. 1996, 35, 3721–3725. [Google Scholar] [CrossRef]

- Ivakin, Y.D.; Danchevskaya, M.N.; Muravieva, G.P. Induced Formation of Corundum Crystals in Supercritical Water Fluid. Russ. J. Phys. Chem. B 2015, 9, 1082–1094. [Google Scholar] [CrossRef]

- Gates-Rector, S.; Blanton, T. The Powder Diffraction File: A Quality Materials Characterization Database. Powder Diffr. 2019, 34, 352–360. [Google Scholar] [CrossRef][Green Version]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 Years of Image Analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef]

- Stevens, R. Beta-Alumina. In Concise Encyclopedia of Advanced Ceramic Materials; Elsevier: Amsterdam, The Netherlands, 1991; pp. 32–35. ISBN 978-0-08-034720-2. [Google Scholar]

- Danchevskaya, M.N.; Ivakin, Y.D.; Torbin, S.N.; Panasyuk, G.P.; Belan, V.N.; Voroshilov, I.L. Scientific Basis of Technology of Fine-Crystalline Quartz and Corundum. High Press. Res. 2001, 20, 229–239. [Google Scholar] [CrossRef]

- Sato, T. Thermal Decomposition of Aluminium Hydroxides. J. Therm. Anal. 1987, 32, 61–70. [Google Scholar] [CrossRef]

- Lamouri, S.; Hamidouche, M.; Bouaouadja, N.; Belhouchet, H.; Garnier, V.; Fantozzi, G.; Trelkat, J.F. Control of the γ-Alumina to α-Alumina Phase Transformation for an Optimized Alumina Densification. Bol. Soc. Esp. Ceram. Vidr. 2017, 56, 47–54. [Google Scholar] [CrossRef][Green Version]

- Panasyuk, G.P.; Kozerozhets, I.V.; Semenov, E.A.; Danchevskaya, M.N.; Azarova, L.A.; Belan, V.N. Thermodynamics and Kinetics of γ-Al2O3 and AlOOH Transformations under Hydrothermal Conditions. Inorg. Mater. 2019, 55, 920–928. [Google Scholar] [CrossRef]

- Kozerozhets, I.V.; Panasyuk, G.P.; Semenov, E.A.; Danchevskaya, M.N.; Azarova, L.A.; Simonenko, N.P. Transformations of Nanosized Boehmite and γ-Al2O3 upon Heat Treatment. Russ. J. Inorg. Chem. 2020, 65, 587–591. [Google Scholar] [CrossRef]

- Maryashkin, A.V.; Ivakin, Y.D.; Danchevskaya, M.N.; Murav’eva, G.P.; Kirikova, M.N. Synthesis of Corundum Doped with Cerium in Supercritical Water Fluid. Moscow Univ. Chem. Bull. 2011, 66, 290–298. [Google Scholar] [CrossRef]

- Kiss, A.B.; Keresztury, G.; Farkas, L. Raman and i.r. Spectra and Structure of Boehmite (y-AlOOH). Evidence for the Recently Discarded D172h Space Group. Spectrochim. Acta Part A 1980, 36A, 653–658. [Google Scholar] [CrossRef]

- Abdollahifar, M.; Zamani, R.; Beiygie, E.; Nekouei, H. Synthesis of Micro-Mesopores Flowerlike γ-Al2O3 Nano-Architectures. J. Serb. Chem. Soc. 2014, 79, 1007–1017. [Google Scholar] [CrossRef]

- Sun, T.; Zhuo, Q.; Chen, Y.; Wu, Z. Synthesis of Boehmite and Its Effect on Flame Retardancy of Epoxy Resin. High Perform. Polym. 2015, 27, 100–104. [Google Scholar] [CrossRef]

- Kloprogge, J.T.; Ruan, H.D.; Frost, R.L. Thermal Decomposition of Bauxite Minerals: Infrared Emission Spectroscopy of Gibbsite, Boehmite and Diaspore. J. Mater. Sci. 2002, 37, 1121–1129. [Google Scholar] [CrossRef][Green Version]

- Hajduchova, Z. Adsorption of Dodecylbenzenesulfonic Acid on the Alumina Particles in the Preparation of Alumina Foam. Ceram.–Silik. 2018, 62, 138–145. [Google Scholar] [CrossRef][Green Version]

- Santhiya, D.; Subramanian, S.; Natarajan, K.A.; Malghan, S.G. Surface Chemical Studies on Alumina Suspensions Using Ammonium Poly(Methacrylate). Colloids Surf. 2000, 164, 143–154. [Google Scholar] [CrossRef]

- Colomban, P. Vibrational Characterization of the Various Forms of (Solvated or Unsolvated) Mobile Proton in the Solid State. Advantages, Limitations and Open Questions. Solid State Ion. 2023, 393, 116187. [Google Scholar] [CrossRef]

- Wang, L.; Hu, J.; Cheng, Y.; Fu, Z.; Shen, Z.; Xiong, Y. Defect Formation by Order Coalescence in Vermicular Grains during Alumina Phase Transformation. Scr. Mater. 2015, 107, 59–62. [Google Scholar] [CrossRef]

- Jiménez-Morales, F.; Rivero-Antúnez, P.; González-Sánchez, M.; Garrido-Regife, L.; Morales-Flórez, V. The Evolution of Vermicular Structures and Sintering Behavior of Alumina. In Cellular Automata; Chopard, B., Bandini, S., Dennunzio, A., Arabi Haddad, M., Eds.; Lecture Notes in Computer Science; Springer International Publishing: Cham, Switzerland, 2022; Volume 13402, pp. 153–162. ISBN 978-3-031-14925-2. [Google Scholar]

- Dutta, S.; Kim, T.B.; Krentz, T.; Vinci, R.P.; Chan, H.M. Sol-Gel-Derived Single-Crystal Alumina Coatings with Vermicular Structure: Rapid Communications of the American Ceramic Society. J. Am. Ceram. Soc. 2011, 94, 340–343. [Google Scholar] [CrossRef]

- Guo, J.; Floyd, R.; Lowum, S.; Maria, J.-P.; Herisson de Beauvoir, T.; Seo, J.-H.; Randall, C.A. Cold Sintering: Progress, Challenges, and Future Opportunities. Annu. Rev. Mater. Res. 2019, 49, 275–295. [Google Scholar] [CrossRef]

- Grasso, S.; Biesuz, M.; Zoli, L.; Taveri, G.; Duff, A.I.; Ke, D.; Jiang, A.; Reece, M.J. A Review of Cold Sintering Processes. Adv. Appl. Ceram. 2020, 119, 115–143. [Google Scholar] [CrossRef][Green Version]

- Kholodkova, A.A.; Danchevskaya, M.N.; Ivakin, Y.D.; Muravieva, G.P.; Tyablikov, A.S. Crystalline Barium Titanate Synthesized in Sub- and Supercritical Water. J. Supercrit. Fluids 2016, 117, 194–202. [Google Scholar] [CrossRef]

- Ivakin, Y.D.; Danchevskaya, M.N.; Muravieva, G.P. Recrystallization of Zinc Oxide in a Sub- and Supercritical Water Medium. Russ. J. Phys. Chem. B 2019, 13, 1189–1200. [Google Scholar] [CrossRef]

- Kozawa, T.; Onda, A.; Yanagisawa, K. Accelerated Formation of Barium Titanate by Solid-State Reaction in Water Vapour Atmosphere. J. Eur. Ceram. Soc. 2009, 29, 3259–3264. [Google Scholar] [CrossRef][Green Version]

- Ivakin, Y.D.; Danchevskaya, M.N.; Muravieva, G.P. Influence of Molar Ratio Water Fluid/Al2O3 on Solid Phase Composition. In Proceedings of the 9th Meeting of Supercritical Fluids, Trieste, Italy, 13–16 June 2004. 24. [Google Scholar] [CrossRef]

- Okumiya, M.; Yamaguchi, G.; Yamada, O.; Ono, S. Formation of κ- and κ′-aluminium oxide from the dehydration of tohdite (5Al2O3·H2O). Bull. Chem. Soc. Jpn. 1971, 44, 418–423. [Google Scholar] [CrossRef][Green Version]

- De Bellis, J.; Ochoa-Hernández, C.; Farès, C.; Petersen, H.; Ternienden, J.; Weidenthaler, C.; Amrute, A.P.; Schüth, F. Surface and Bulk Chemistry of Mechanochemically Synthesized Tohdite Nanoparticles. J. Am. Chem. Soc. 2022, 144, 9421–9433. [Google Scholar] [CrossRef]

- Dong, Y.; Jiang, H.; Chen, A.; Yang, T.; Zou, T.; Xu, D. Porous Al2O3 Ceramics with Spontaneously Formed Pores and Enhanced Strength Prepared by Indirect Selective Laser Sintering Combined with Reaction Bonding. Ceram. Int. 2020, 46, 15159–15166. [Google Scholar] [CrossRef]

- Xu, C.; Liu, H.; Yang, H.; Yang, L. A Green Biocompatible Fabrication of Highly Porous Functional Ceramics with High Strength and Controllable Pore Structures. J. Mater. Sci. Technol. 2016, 32, 729–732. [Google Scholar] [CrossRef]

- Smirnov, A.V.; Kornyushin, M.V.; Kholodkova, A.A.; Melnikov, S.A.; Stepanov, A.D.; Fesik, E.V.; Ivakin, Y.D. Cold Sintering Process of Zinc Oxide Ceramics: Powder Preparation and Sintering Conditions Effects on Final Microstructure. Inorganics 2022, 10, 197. [Google Scholar] [CrossRef]

| Initial Powder | Samples after CSP-SPS | Samples after Annealing in Air |

|---|---|---|

| γ-Al(OH)3 (HA-P) | HA-CS | HA-CS-A |

| γ-AlOOH (BO-P) | BO-CS | - |

| Sample | Density after CSP-SPS (g cm−3) | Porosity after CSP-SPS (%) | Density after Annealing (g cm−3) | Porosity after Annealing (%) |

|---|---|---|---|---|

| HA-CS 1 | 1.57 | 51.9 | 1.52 | 60.5 |

| HA-CS 2 | 1.53 | 53.3 | 1.46 | 60.2 |

| HA-CS 3 | 1.53 | 52.9 | 1.50 | 60.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kholodkova, A.A.; Kornyushin, M.V.; Pakhomov, M.A.; Smirnov, A.V.; Ivakin, Y.D. Water-Assisted Cold Sintering of Alumina Ceramics in SPS Conditions. Ceramics 2023, 6, 1113-1128. https://doi.org/10.3390/ceramics6020066

Kholodkova AA, Kornyushin MV, Pakhomov MA, Smirnov AV, Ivakin YD. Water-Assisted Cold Sintering of Alumina Ceramics in SPS Conditions. Ceramics. 2023; 6(2):1113-1128. https://doi.org/10.3390/ceramics6020066

Chicago/Turabian StyleKholodkova, Anastasia A., Maxim V. Kornyushin, Mikhail A. Pakhomov, Andrey V. Smirnov, and Yurii D. Ivakin. 2023. "Water-Assisted Cold Sintering of Alumina Ceramics in SPS Conditions" Ceramics 6, no. 2: 1113-1128. https://doi.org/10.3390/ceramics6020066

APA StyleKholodkova, A. A., Kornyushin, M. V., Pakhomov, M. A., Smirnov, A. V., & Ivakin, Y. D. (2023). Water-Assisted Cold Sintering of Alumina Ceramics in SPS Conditions. Ceramics, 6(2), 1113-1128. https://doi.org/10.3390/ceramics6020066