Hafnium-Zirconium Carbonitride (Hf,Zr)(C,N) by One Step Mechanically Induced Self-Sustaining Reaction: Powder Synthesis and Spark Plasma Sintering

Abstract

1. Introduction

2. Materials and Methods

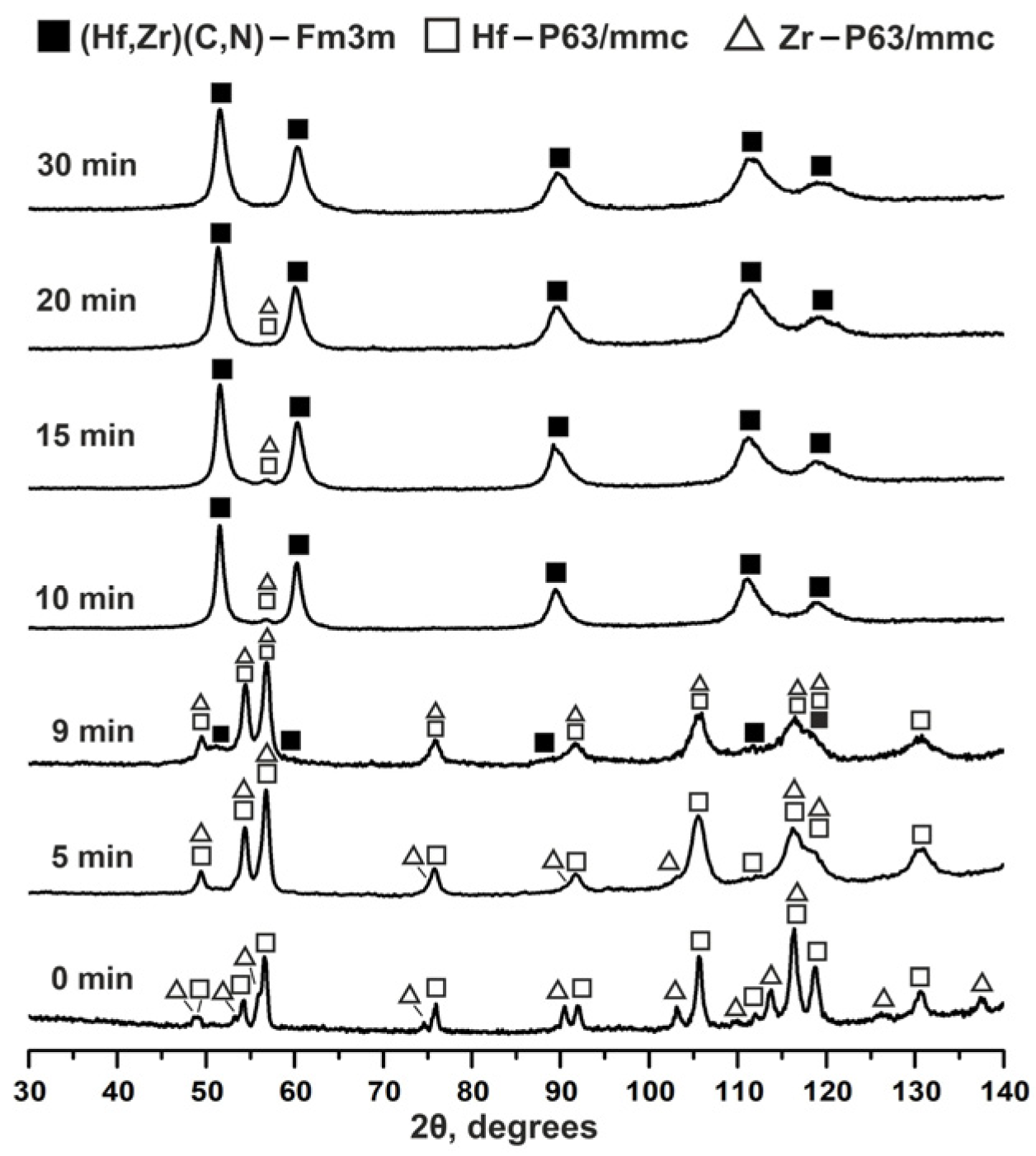

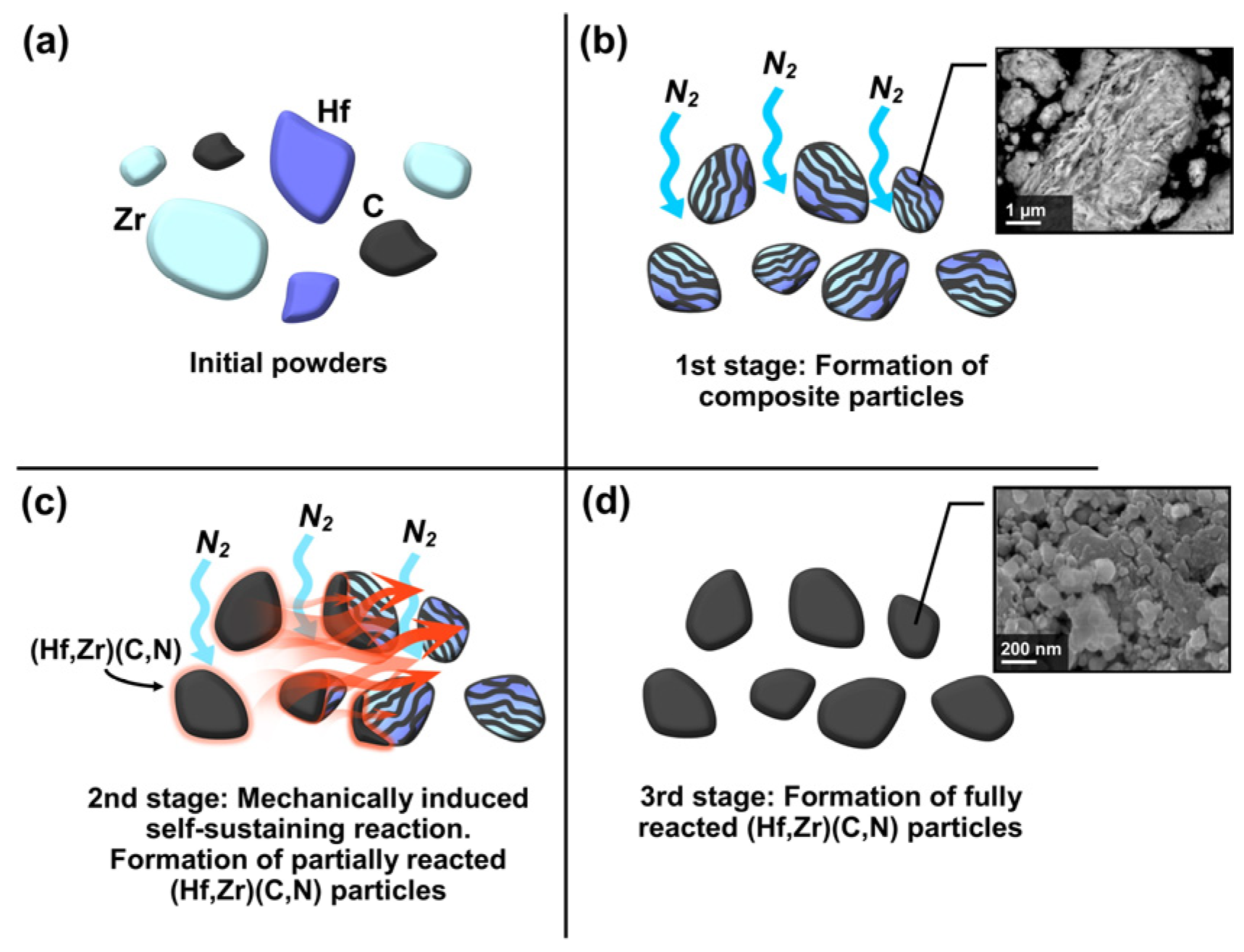

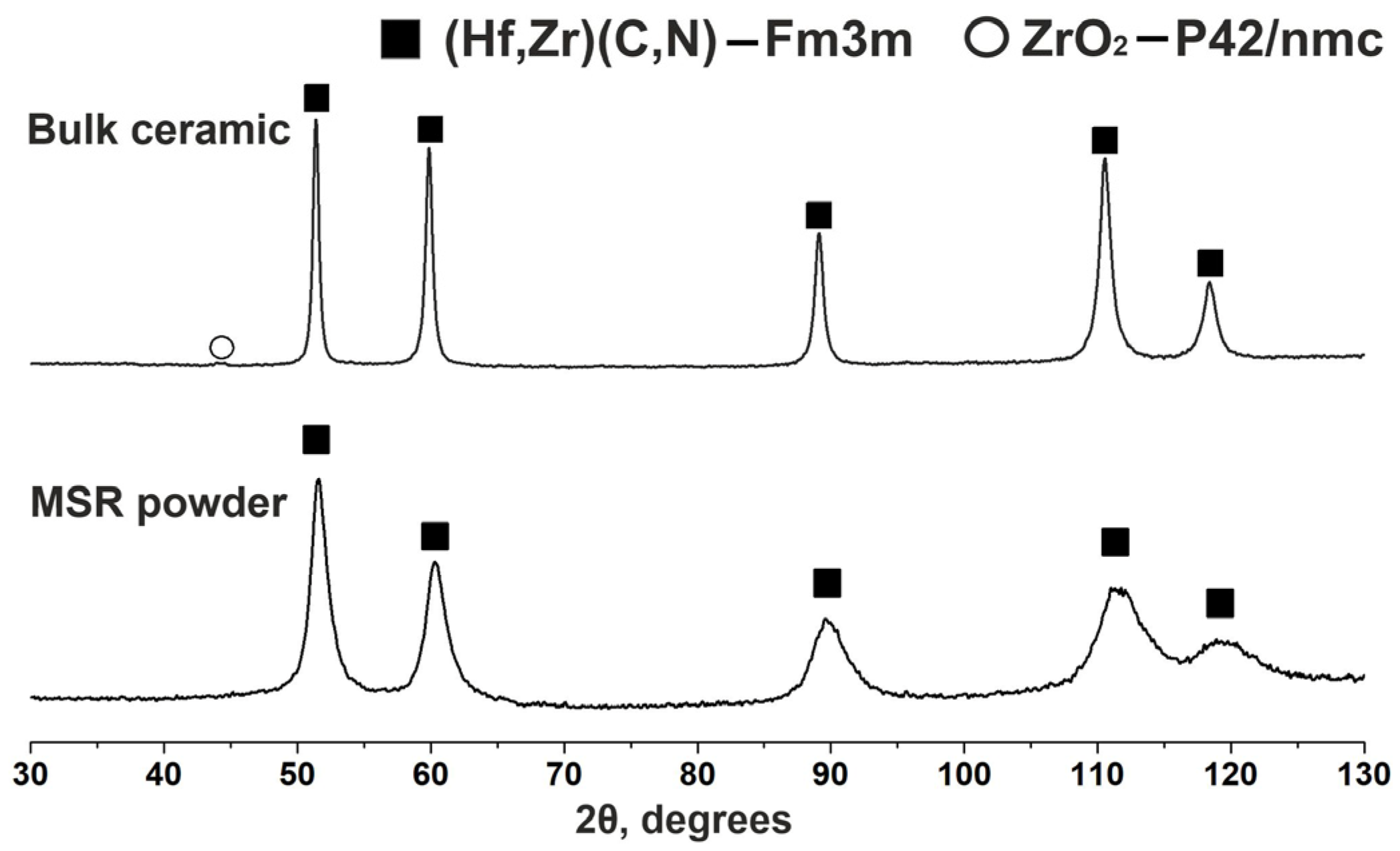

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Talmy, I.G.; Zaykoski, J.A.; Opeka, M.M. High-Temperature Chemistry and Oxidation of ZrB2Ceramics Containing SiC, Si3N4, Ta5Si3, and TaSi2. J. Am. Ceram. Soc. 2008, 91, 2250–2257. [Google Scholar] [CrossRef]

- Sciti, D.; Medri, V.; Silvestroni, L. Oxidation behaviour of HfB2–15 vol.% TaSi2 at low, intermediate and high temperatures. Scr. Mater. 2010, 63, 601–604. [Google Scholar] [CrossRef]

- Balaceanu, M.; Petreus, T.; Braic, V.; Zoita, C.N.; Vladescu, A.; Cotrutz, C.E.; Braic, M. Characterization of Zr-based hard coatings for medical implant applications. Surf. Coat. Technol. 2010, 204, 2046–2050. [Google Scholar] [CrossRef]

- Fahrenholtz, W.G.; Hilmas, G.E.; Talmy, I.G.; Zaykoski, J.A. Refractory Diborides of Zirconium and Hafnium. J. Am. Ceram. Soc. 2007, 90, 1347–1364. [Google Scholar] [CrossRef]

- Marschall, J.; Pejaković, D.A.; Fahrenholtz, W.G.; Hilmas, G.E.; Zhu, S.; Ridge, J.; Fletcher, D.G.; Asma, C.O.; Thoemel, J. Oxidation of ZrB2-SiC Ultrahigh-Temperature Ceramic Composites in Dissociated Air. J. Thermophys. Heat Transf. 2009, 23, 267–278. [Google Scholar] [CrossRef]

- Kurbatkina, V.V.; Patsera, E.I.; Levashov, E.A.; Vorotilo, S. SHS Processing and Consolidation of Ta–Ti–C, Ta–Zr–C, and Ta–Hf–C Carbides for Ultra-High-Temperatures Application. Adv. Eng. Mater. 2018, 20, 1701075. [Google Scholar] [CrossRef]

- Vogel, F.; Ngai, S.; Smith, C.J.; Holler, R.; Thompson, G.B. Complex evaporation behavior of a transition metal carbo-nitride (Hf(C,N)) studied by atom probe tomography. Ultramicroscopy 2018, 194, 154–166. [Google Scholar] [CrossRef]

- Yang, L.; Xiong, J.; Chen, X.; Li, X.; Deng, C.; Zhang, D.; Yi, L. Study on the growth and wear characters of CVD coating deposited on Ti(C, N)-based cermets with adding different C/N ratios of Ti(C, N) powders. Ceram. Int. 2023, 49, 18023–18034. [Google Scholar] [CrossRef]

- Harrison, R.; Ridd, O.; Jayaseelan, D.D.; Lee, W.E. Thermophysical characterisation of ZrCxNy ceramics fabricated via carbothermic reduction–nitridation. J. Nucl. Mater. 2014, 454, 46–53. [Google Scholar] [CrossRef]

- Liang, L.; Wei, B.; Wang, D.; Fang, W.; Chen, L.; Wang, Y. Densification, microstructures, and mechanical properties of (Zr, Ti)(C, N) ceramics fabricated by spark plasma sintering. J. Eur. Ceram. Soc. 2022, 42, 6445–6456. [Google Scholar] [CrossRef]

- Braic, M.; Balaceanu, M.; Vladescu, A.; Zoita, C.N.; Braic, V. Study of (Zr,Ti)CN, (Zr,Hf)CN and (Zr,Nb)CN films prepared by reactive magnetron sputtering. Thin Solid. Films 2011, 519, 4092–4096. [Google Scholar] [CrossRef]

- Miao, Q.; Fu, Y.; Chen, H.; Zhang, J.; Zhao, J.; Zhang, Y. Simultaneous enhancement of mechanical and ablation properties of C/C composites modified by (Hf-Ta-Zr)C solid solution ceramics. J. Eur. Ceram. Soc. 2023, 43, 3182–3190. [Google Scholar] [CrossRef]

- Wu, K.-H.; Jiang, Y.; Jiao, S.-Q.; Chou, K.-C.; Zhang, G.-H. Preparations of titanium nitride, titanium carbonitride and titanium carbide via a two-step carbothermic reduction method. J. Solid. State Chem. 2019, 277, 793–803. [Google Scholar] [CrossRef]

- Yudin, S.N.; Kasimtsev, A.V.; Volodko, S.S.; Alimov, I.A.; Markova, G.V.; Sviridova, T.A.; Tabachkova, N.Y.; Buinevich, V.S.; Nepapushev, A.A.; Moskovskikh, D.O. Low-temperature synthesis of ultra-high-temperature HfC and HfCN nanoparticles. Materialia 2022, 22, 101415. [Google Scholar] [CrossRef]

- Vasanthakumar, K.; Ghosh, S.; Koundinya, N.T.B.N.; Ramaprabhu, S.; Bakshi, S.R. Synthesis and mechanical properties of TiCx and Ti(C,N) reinforced Titanium matrix in situ composites by reactive spark plasma sintering. Mater. Sci. Eng. A 2019, 759, 30–39. [Google Scholar] [CrossRef]

- Li, Y.; Zeng, M.Q.; Liu, J.W.; Lu, Z.C. Evolution of metal nitriding and hydriding reactions during ammonia plasma-assisted ball milling. Ceram. Int. 2018, 44, 18329–18336. [Google Scholar] [CrossRef]

- Aisyah, I.S.; Wyszomirska, M.; Calka, A.; Wexler, D. Nitrogenation of hafnium carbide powders in AC and DC plasma by Electrical Discharge Assisted Mechanical Milling. J. Alloys Compd. 2017, 715, 192–198. [Google Scholar] [CrossRef]

- Nepapushev, A.A.; Buinevich, V.S.; Gallington, L.C.; Pauls, J.M.; Orlova, T.; Miloserdova, O.M.; Chapysheva, N.V.; Rogachev, A.S.; Mukasyan, A.S. Kinetics and mechanism of mechanochemical synthesis of hafnium nitride ceramics in a planetary ball mill. Ceram. Int. 2019, 45, 24818–24826. [Google Scholar] [CrossRef]

- Chicardi, E.; Gotor, F.J.; Alcalá, M.D.; Córdoba, J.M. Effects of additives on the synthesis of TiC N by a solid-gas mechanically induced self-sustaining reaction. Ceram. Int. 2018, 44, 7605–7610. [Google Scholar] [CrossRef]

- Córdoba, J.M.; Avilés, M.A.; Sayagués, M.J.; Alcalá, M.D.; Gotor, F.J. Synthesis of complex carbonitride powders TiyMT1−yCxN1−x (MT: Zr, V, Ta, Hf) via a mechanically induced self-sustaining reaction. J. Alloys Compd. 2009, 482, 349–355. [Google Scholar] [CrossRef]

- Oghenevweta, J.E.; Wexler, D.; Calka, A. Early stages of phase formation before the ignition peak during mechanically induced self-propagating reactions (MSRs) of titanium and graphite. Scr. Mater. 2016, 122, 93–97. [Google Scholar] [CrossRef]

- Córdoba, J.M.; Sayagués, M.J.; Alcalá, M.D.; Gotor, F.J. Monophasic TiyNb1−yCxN1−x nanopowders obtained at room temperature by MSR. J. Mater. Chem. 2006, 17, 650–653. [Google Scholar] [CrossRef]

- Lutterotti, L.; Chateigner, D.; Ferrari, S.; Ricote, J. Texture, residual stress and structural analysis of thin films using a combined X-ray analysis. Thin Solid. Films 2004, 450, 34–41. [Google Scholar] [CrossRef]

- Anstis, G.R.; Chantikul, P.; Lawn, B.R.; Marshall, D.B. A Critical Evaluation,of Indentation Techniques for Measuring Fracture Toughness: I, direct crack measurements. J. Am. Ceram. Soc. 1981, 64, 533–538. [Google Scholar] [CrossRef]

- Merzhanov, A.G.; Rogachev, A.S. Structural Macrokinetics of SHS Processes. Pure Appl. Chem. 1992, 64, 941–953. [Google Scholar] [CrossRef]

- Deevi, S.C. Structure of the Combustion Wave in the Combustion Synthesis of Titanium Carbides. J. Mater. Sci. 1991, 26, 2662–2670. [Google Scholar] [CrossRef]

- Zhu, J.F.; Ye, L.; Tong, H.; Wang, F. Synthesis of Nanocrystalline TiC1−XNx by High Energy Milling. In Advanced Materials Research; Trans Tech Publications Ltd.: Stafa-zuerich, Switzerland, 2011; Volume 194, pp. 458–461. [Google Scholar]

- Chicardi, E.; Gotor, F.J.; Alcalá, M.D.; Córdoba, J.M. Influence of milling parameters on the solid-gas synthesis of TiCxN1−x by mechanically induced self-sustaining reaction. Powder Technol. 2017, 319, 12–18. [Google Scholar] [CrossRef]

- Chicardi, E.; García-Garrido, C.; Beltran, A.M.; Sayagués, M.J.; Gotor, F.J. Synthesis of a cubic Ti(BCN) advanced ceramic by a solid-gas mechanochemical reaction. Ceram. Int. 2018, 45, 3878–3885. [Google Scholar] [CrossRef]

- Chen, L.; Wang, Y.; Li, Y.; Zhang, X.; Meng, Q. Microstructural evolution, mechanical and thermal properties of TiC-ZrC-Cr3C2 composites. Int. J. Refract. Met. Hard Mater. 2019, 80, 188–194. [Google Scholar] [CrossRef]

- Vorotilo, S.; Sidnov, K.; Sedegov, A.S.; Abedi, M.; Vorotilo, K.; Moskovskikh, D.O. Phase stability and mechanical properties of carbide solid solutions with 2–5 principal metals. Comput. Mater. Sci. 2021, 201, 110869. [Google Scholar] [CrossRef]

- Buinevich, V.S.; Nepapushev, A.A.; Moskovskikh, D.O.; Trusov, G.V.; Kuskov, K.V.; Mukasyan, A.S. Mechanochemical synthesis and spark plasma sintering of hafnium carbonitride ceramics. Adv. Powder Technol. 2021, 32, 385–389. [Google Scholar] [CrossRef]

- Buinevich, V.S.; Nepapushev, A.A.; Moskovskikh, D.O.; Kuskov, K.V.; Yudin, S.N.; Mukasyan, A.S. Ultra-high-temperature tantalum-hafnium carbonitride ceramics fabricated by combustion synthesis and spark plasma sintering. Ceram. Int. 2021, 47, 30043–30050. [Google Scholar] [CrossRef]

- Jing, C.; Zhou, S.-J.; Zhang, W.; Ding, Z.-Y.; Liu, Z.-G.; Wang, Y.-J.; Ouyang, J.-H. Low temperature synthesis and densification of (Ti,V,Nb,Ta,Mo)(C,N) high-entropy carbonitride ceramics. J. Alloys Compd. 2022, 927, 167095. [Google Scholar] [CrossRef]

- Zhang, M.; Wei, B.; Wang, D.; Fang, W.; Chen, L.; Wang, Y. Novel (Zr, Ti)(C, N)–SiC ceramics via reactive hot-pressing at low temperature. Ceram. Int. 2022, 48, 29641–29651. [Google Scholar] [CrossRef]

- Yun, S.-S.; Han, B.-D.; Park, D.-S.; Kim, H.-D.; Lim, D.-S. Friction and wear of pressureless sintered Ti(C,N)–WC ceramics. Wear 2003, 255, 682–685. [Google Scholar] [CrossRef]

| Sample | HEBM | (111) | (200) | (220) | (311) | (222) | a, nm |

|---|---|---|---|---|---|---|---|

| Duration, min | |||||||

| HfC (#39-1491) | - | 2.6776 | 2.3189 | 1.6401 | 1.3983 | 1.3389 | 0.4638 |

| ZrC (#35-0784) | - | 2.7089 | 2.3459 | 1.6592 | 1.4149 | 1.3547 | 0.4693 |

| HfN (#33-0592) | - | 2.6120 | 2.2620 | 1.6002 | 1.3641 | 1.3061 | 0.4525 |

| ZrN (#02-0956) | - | 2.64 | 2.29 | 1.62 | 1.38 | 1.32 | 0.456 |

| (Hf,Zr)(C,N) | 10 | 2.6342 | 2.2817 | 1.6273 | 1.3889 | 1.3296 | 0.4588 |

| 15 | 2.6332 | 2.2803 | 1.6268 | 1.3871 | 1.3289 | 0.4585 | |

| 20 | 2.6330 | 2.2801 | 1.6245 | 1.3863 | 1.3283 | 0.4583 | |

| 30 | 2.6328 | 2.2792 | 1.6225 | 1.3838 | 1.3268 | 0.4578 |

| Sample | ρh, g/cm3 | ρp, g/cm3 | ρ, % | HV, GPa | Fracture Toughness K1C, MPa∙m1/2 | Young’s Modulus, GPa |

|---|---|---|---|---|---|---|

| (Hf,Zr)(C,N) | 10.9 | 11.3 | 97 ± 1 | 17.3 ± 0.5 (30 N) | 4.5 ± 0.4 | 450 ± 20 |

| ZrC [30] | – | – | 98.2 | 16.4 ± 1.3 | 3.1 ± 0.7 | 210 ± 19 |

| HfZrC2 [31] | – | – | – | 19 ± 1.6 (100 mN) | 3.82 | 466 ± 81 |

| HfC0.5N0.2 [32] | – | – | 95.6 ± 1 | 20.8 ± 1 (10 N) | 3.5 ± 0.2 | ~460 |

| (Ta,Hf)CN [33] | – | – | 98 ± 1 | 19.4 ± 0.2 (30 N) | 5.4 ± 0.4 | 591 |

| (Ti,V,Nb,Ta,Mo)(C,N) [34] | – | – | 99.8 | 24.0 ± 0.7 (9.8 N) | 4.87 ± 0.25 | – |

| (Zr,Ti)(C,N)–SiC [35] | – | – | 98.5 ± 1 | 17.7–22.4 (9.8 N) | 3.0–4.4 | – |

| (Ti,W)(C,N) [36] | – | – | – | 15.9–17.8 (30 N) | 4.0–4.57 | 429–481 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khadyrova, I.; Suvorova, V.; Nepapushev, A.; Suvorov, D.; Kuskov, K.; Moskovskikh, D. Hafnium-Zirconium Carbonitride (Hf,Zr)(C,N) by One Step Mechanically Induced Self-Sustaining Reaction: Powder Synthesis and Spark Plasma Sintering. Ceramics 2023, 6, 1129-1138. https://doi.org/10.3390/ceramics6020067

Khadyrova I, Suvorova V, Nepapushev A, Suvorov D, Kuskov K, Moskovskikh D. Hafnium-Zirconium Carbonitride (Hf,Zr)(C,N) by One Step Mechanically Induced Self-Sustaining Reaction: Powder Synthesis and Spark Plasma Sintering. Ceramics. 2023; 6(2):1129-1138. https://doi.org/10.3390/ceramics6020067

Chicago/Turabian StyleKhadyrova, Irina, Veronika Suvorova, Andrey Nepapushev, Dmitrii Suvorov, Kirill Kuskov, and Dmitry Moskovskikh. 2023. "Hafnium-Zirconium Carbonitride (Hf,Zr)(C,N) by One Step Mechanically Induced Self-Sustaining Reaction: Powder Synthesis and Spark Plasma Sintering" Ceramics 6, no. 2: 1129-1138. https://doi.org/10.3390/ceramics6020067

APA StyleKhadyrova, I., Suvorova, V., Nepapushev, A., Suvorov, D., Kuskov, K., & Moskovskikh, D. (2023). Hafnium-Zirconium Carbonitride (Hf,Zr)(C,N) by One Step Mechanically Induced Self-Sustaining Reaction: Powder Synthesis and Spark Plasma Sintering. Ceramics, 6(2), 1129-1138. https://doi.org/10.3390/ceramics6020067