Electrical Behavior and Microstructural Features of Electric Field-Assisted and Conventionally Sintered 3 mol% Yttria-Stabilized Zirconia

Abstract

:1. Introduction

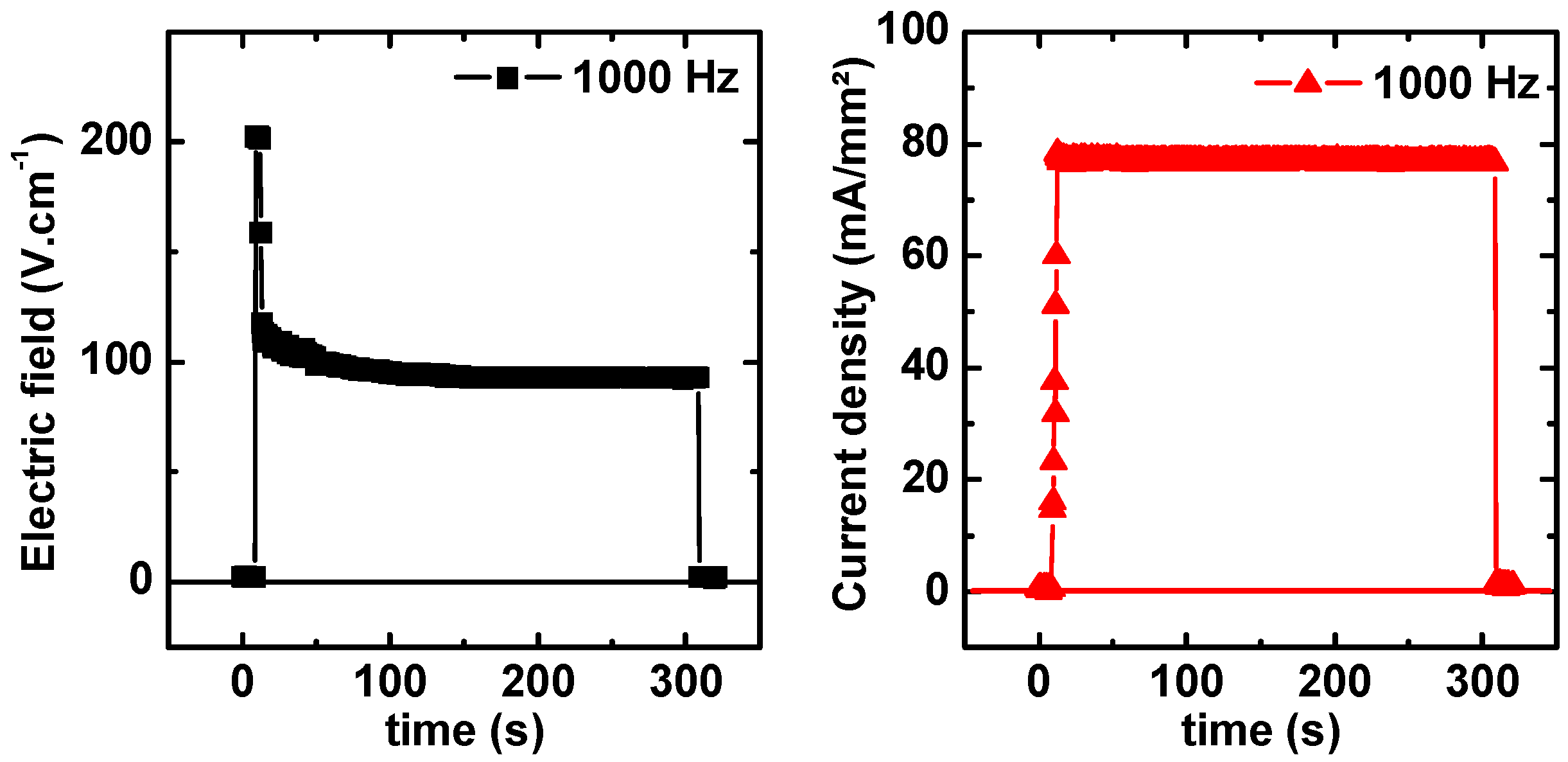

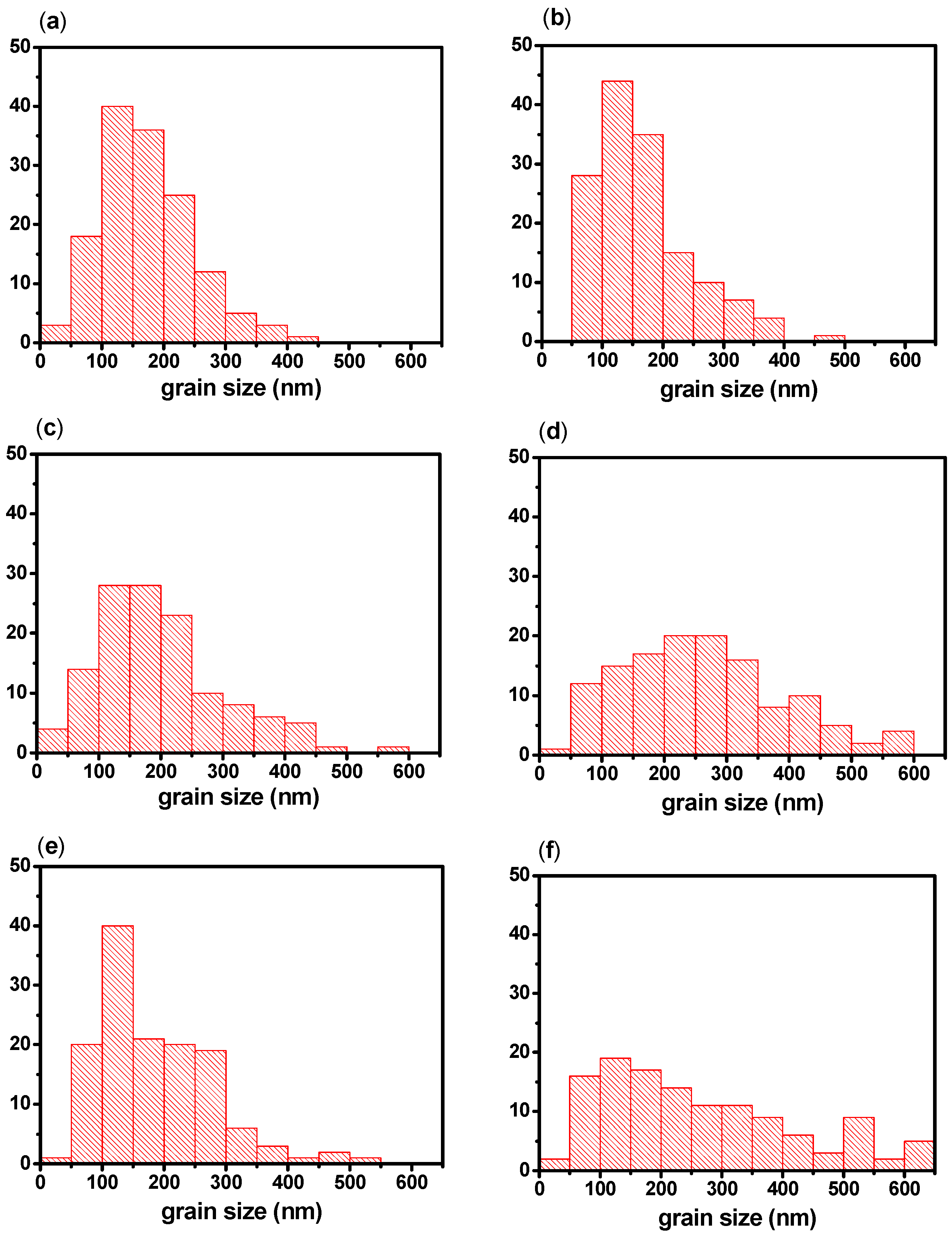

2. Materials and Methods

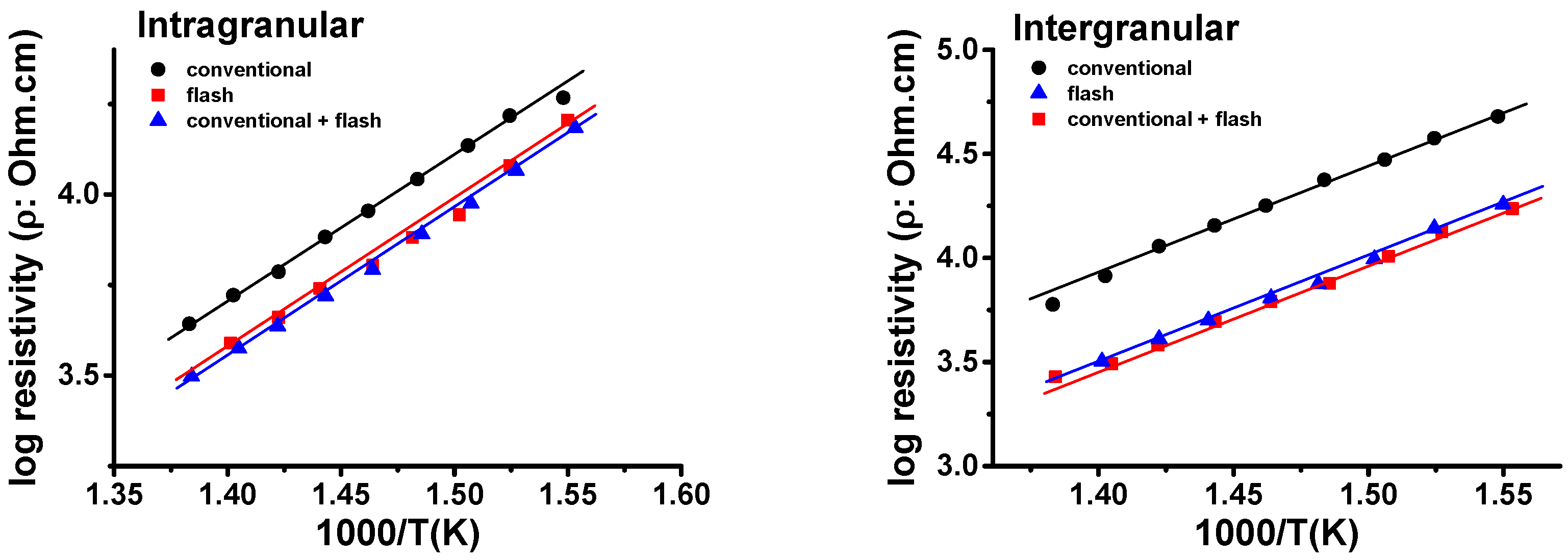

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kocjan, A.; Logar, S.M.; Shen, Z. The agglomeration, coalescence and sliding of nanoparticles, leading to the rapid sintering of zirconia nanoceramics. Sci. Rep. 2017, 7, 2541–2548. [Google Scholar] [CrossRef] [PubMed]

- Cologna, M.; Rashkova, B.; Raj, R. Flash sintering of nanograin zirconia in < 5 s at 850 °C. J. Am. Ceram. Soc. 2010, 93, 3556–3559. [Google Scholar] [CrossRef]

- Gosh, S.; Chokshi, A.H.; Lee, P.; Raj, R. A huge effect of week dc electrical fields on grain growth in zirconia. J. Am. Ceram. Soc. 2009, 92, 1856–1859. [Google Scholar] [CrossRef]

- Yang, D.; Conrad, H. Enhanced sintering rate of zirconia (3Y-TZP) by application of a small AC electric field. Scr. Mater. 2010, 63, 328–331. [Google Scholar] [CrossRef]

- Yang, D.; Raj, R.; Conrad, H. Enhanced sintering rate of zirconia (3Y-TZP) through the effect of a weak dc electric field on grain growth. J. Am. Ceram. Soc. 2010, 93, 2935–2937. [Google Scholar] [CrossRef]

- Cologna, M.; Prette, A.L.G.; Raj, R. Flash-Sintering of cubic yttria-stabilized zirconia at 750 °C for possible use in SOFC manufacturing. J. Am. Ceram. Soc. 2011, 94, 316–319. [Google Scholar] [CrossRef]

- Muccillo, R.; de Florio, D.Z.; Fonseca, F.C.; Muccillo, E.N.S. Electric field-assisted co-sintering of planar anode-supported solid oxide fuel cell. In Proceedings of the MRS Fall Meeting, Boston, MA, USA, November 30–December 5, 2014. [Google Scholar]

- Muccillo, R.; Kleitz, M.; Muccillo, E.N.S. Flash grain welding in yttria stabilized zirconia. J. Eur. Ceram. Soc. 2012, 31, 1517–1521. [Google Scholar] [CrossRef]

- Muccillo, R.; Muccillo, E.N.S. An experimental setup for shrinkage evaluation during electric field-assisted flash sintering: application to yttria-stabilized zirconia. J. Eur. Ceram. Soc. 2013, 33, 515–520. [Google Scholar] [CrossRef]

- Downs, J.A.; Sglavo, V.M. Electric field assisted sintering of cubic zirconia at 390 °C. J. Am. Ceram. Soc. 2014, 96, 1342–1344. [Google Scholar] [CrossRef]

- Steil, M.C.; Marinha, D.; Aman, Y.; Gomes, J.R.C.; Kleitz, M. From conventional ac flash sintering of YSZ to hyper-flash and double flash. J. Eur. Ceram. Soc. 2013, 33, 2093–2101. [Google Scholar] [CrossRef]

- Muccillo, R.; Muccillo, E.N.S. Shrinkage control of yttria-stabilized zirconia during ac electric field-assisted sintering. J. Eur. Ceram. Soc. 2014, 34, 3871–3877. [Google Scholar] [CrossRef]

- Muccillo, R.; Muccillo, E.N.S. Light emission during electric field-assisted sintering of electroceramics. J. Eur. Ceram. Soc. 2014, 35, 1653–1656. [Google Scholar] [CrossRef]

- da Silva, J.G.P.; Lebrun, J.-M.; Al-Qureshi, H.A.; Janssen, R.; Raj, R. Temperature distributions during flash sintering of 8% yttria-stabilized zirconia. J. Am. Ceram. Soc. 2015, 98, 3525–3528. [Google Scholar] [CrossRef]

- Du, Y.X.; Stevenson, A.J.; Vernat, D.; Diaz, M.; Marinha, D. Estimating Joule heating and ionic conductivity during flash sintering of 8YSZ. J. Eur. Ceram. Soc. 2016, 36, 749–759. [Google Scholar] [CrossRef]

- Naik, K.S.; Sglavo, V.M.; Raj, R. Field assisted sintering of ceramic constituted by alumina and yttria stabilized zirconia. J. Eur. Ceram. Soc. 2014, 34, 2435–2442. [Google Scholar] [CrossRef]

- Dancer, C.E.J. Flash sintering of ceramic materials. Mater. Res. Express 2016, 3, 102001. [Google Scholar] [CrossRef]

- Yu, M.; Grasso, S.; McKinnon, R.; Saunders, T.; Reece, M.J. Review of flash sintering: materials, mechanisms and modelling. Adv. Appl. Ceram. 2016, 116, 24–60. [Google Scholar] [CrossRef]

- Muccillo, R.; Muccillo, E.N.S. Electric field assisted sintering of electroceramics and in situ analysis by impedance spectroscopy. J. Electroceramics 2016, 38, 24–42. [Google Scholar] [CrossRef]

- Luo, J. Scientific questions and technological opportunities of flash sintering: from a case study of ZnO to other ceramics. Scr. Mater. 2018, 146, 260–266. [Google Scholar] [CrossRef]

- Prette, A.L.G.; Cologna, M.; Sglavo, V.; Raj, R. Flash-sintering of Co2MnO4 spinel for solid oxide fuel cell applications. J. Power Sources 2011, 196, 2061–2065. [Google Scholar] [CrossRef]

- Zapata-Solvas, E.; Bonilla, S.; Wilshaw, P.R.; Todd, R.I. Preliminary investigation of flash sintering of SiC. J. Eur. Ceram. Soc. 2013, 33, 2811–2816. [Google Scholar] [CrossRef]

- Gaur, A.; Sglavo, V.M. Flash-sintering of MnCo2O4 and its relation to phase stability. J. Eur. Ceram. Soc. 2014, 34, 2391–2400. [Google Scholar] [CrossRef]

- M’Peko, J.-C.; Francis, J.S.C.; Raj, R. Field-assisted sintering of undoped BaTiO3: Microstructure evolution and dielectric permittivity. J. Eur. Ceram. Soc. 2014, 34, 3655–3660. [Google Scholar] [CrossRef]

- Gaur, A.; Sglavo, V.M. Flash Sintering of (La, Sr)(Co, Fe)O3-Gd-Doped CeO2 Composite. J. Am. Ceram. Soc. 2015, 98, 1747–1752. [Google Scholar] [CrossRef]

- Biesuz, M.; Sglavo, V.M. Flash sintering of alumina: Effect of different operating conditions on densification. J. Eur. Ceram. Soc. 2016, 36, 2535–2542. [Google Scholar] [CrossRef]

- Biesuz, M.; Sglavo, V.M. Liquid phase flash sintering in magnesia silicate glass-containing alumina. J. Eur. Ceram. Soc. 2017, 37, 705–713. [Google Scholar] [CrossRef]

- Prado, M.O.; Biesuz, M.; Frasnelli, M.; Benedetto, F.E.; Sglavo, V.M. Viscous flow flash sintering of porous silica glass. J. Non-Cryst. Solids. 2017, 476, 60–66. [Google Scholar] [CrossRef]

- Frasnelli, M.; Sglavo, V.M. Flash sintering of tricalcium phosphate (TCP) bioceramics. J. Eur. Ceram. Soc. 2018, 38, 279–285. [Google Scholar] [CrossRef]

- Biesuz, M.; Abate, W.D.; Sglavo, V.M. Porcelain stoneware consolidation by flash sintering. J. Am. Ceram. Soc. 2018, 101, 71–81. [Google Scholar] [CrossRef]

- Francis, J.S.C.; Raj, R. Influence of the field and the current limit on flash sintering at isothermal furnace temperatures. J. Am. Ceram. Soc. 2013, 96, 2754–2758. [Google Scholar] [CrossRef]

- Francis, J.S.C.; Cologna, M.; Raj, R. Particle size effects in flash sintering. J. Am. Ceram. Soc. 2012, 32, 3129–3136. [Google Scholar] [CrossRef]

- Muccillo, E.N.S.; Carvalho, S.G.M.; Muccillo, R. Electric field-assisted pressureless sintering of zirconia-scandia-ceria solid electrolytes. J. Mater. Sci. 2018, 53, 1658–1671. [Google Scholar] [CrossRef]

- Raj, R. Joule heating during flash-sintering. J. Eur. Ceram. Soc. 2012, 32, 2293–2301. [Google Scholar] [CrossRef]

- Todd, R.I.; Zapata-Solvas, E.; Bonilla, R.S.; Sneddon, T.; Wilshaw, P.R. Electrical characteristics of flash sintering: thermal runaway of Joule heating. J. Eur. Ceram. Soc. 2015, 35, 1865–1877. [Google Scholar] [CrossRef]

- Narayan, J. A new mechanism for field-assisted processing and flash sintering of materials. Scr. Mater. 2013, 69, 107–111. [Google Scholar] [CrossRef]

- Naik, K.S.; Sglavo, V.M.; Raj, R. Flash sintering as a nucleation phenomenon and a model thereof. J. Eur. Ceram. Soc. 2014, 34, 4063–4067. [Google Scholar] [CrossRef]

- Chaim, R. Liquid film capillary mechanism for densification of ceramic powders during flash sintering. Materials 2016, 9, 280. [Google Scholar] [CrossRef] [PubMed]

- Biesuz, M.; Luchi, P.; Quaranta, A.; Sglavo, V.M. Theoretical and phenomenological analogies between flash sintering and dielectric breakdown in α-alumina. J. Appl. Phys. 2016, 120, 145107. [Google Scholar] [CrossRef]

- Chaim, R. Particle surface softening as universal behavior during flash sintering of oxide nanopowders. Materials 2017, 10, 179. [Google Scholar] [CrossRef] [PubMed]

- Mendelson, M.I. Average grain size in polycrystalline ceramics. J. Am. Ceram. Soc. 1969, 52, 443–446. [Google Scholar] [CrossRef]

- Image Processing and Analysis in Java. Available online: https://imagej.nih.gov/ij/ (accessed on 20 February 2018).

- Kleitz, M.; Kennedy, J.H. Fast Ion Transport in Solids; Vashishta, P., Mundy, J.N., Shenoy, G.K., Eds.; Elsevier: North Holland, The Netherlands, 1979; p. 185. [Google Scholar]

- Popovic, Z.; Popovic, B.D. Introductory Electromagnetics; Prentice Hall: Upper Saddle River, NJ, USA, 2000. [Google Scholar]

- Richerson, D.W. Modern Ceramic Engineering: Properties, Processing, and Use in Design, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2015; p. 436. [Google Scholar]

- Guo, X. Physical origin of the intrinsic grain-boundary resistivity of stabilized zirconia: Role of the space-charge layers. Solid State Ionics. 1995, 81, 235–242. [Google Scholar] [CrossRef]

- Gregori, G.; Merkle, R.; Maier, J. Ion conduction and redistribution at grain boundaries in oxide systems. Prog. Mater. Sci. 2017, 89, 252–305. [Google Scholar] [CrossRef]

- Guo, X.; Maier, J. Grain boundary blocking effect in zirconia: A Schottky barrier analysis. J. Electrochem. Soc. 2001, 148, E121–E126. [Google Scholar] [CrossRef]

| Sintering Technique | Activation Energy (eV) | |

|---|---|---|

| Bulk | Grain Boundary | |

| Conventional | 0.78 ± 0.02 | 1.07 ± 0.03 |

| Flash | 0.81 ± 0.04 | 1.01 ± 0.02 |

| Conventional + Flash | 0.80 ± 0.01 | 0.97 ± 0.02 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carvalho, S.G.M.; Muccillo, E.N.S.; Muccillo, R. Electrical Behavior and Microstructural Features of Electric Field-Assisted and Conventionally Sintered 3 mol% Yttria-Stabilized Zirconia. Ceramics 2018, 1, 3-12. https://doi.org/10.3390/ceramics1010002

Carvalho SGM, Muccillo ENS, Muccillo R. Electrical Behavior and Microstructural Features of Electric Field-Assisted and Conventionally Sintered 3 mol% Yttria-Stabilized Zirconia. Ceramics. 2018; 1(1):3-12. https://doi.org/10.3390/ceramics1010002

Chicago/Turabian StyleCarvalho, Sabrina G.M., Eliana N.S. Muccillo, and Reginaldo Muccillo. 2018. "Electrical Behavior and Microstructural Features of Electric Field-Assisted and Conventionally Sintered 3 mol% Yttria-Stabilized Zirconia" Ceramics 1, no. 1: 3-12. https://doi.org/10.3390/ceramics1010002

APA StyleCarvalho, S. G. M., Muccillo, E. N. S., & Muccillo, R. (2018). Electrical Behavior and Microstructural Features of Electric Field-Assisted and Conventionally Sintered 3 mol% Yttria-Stabilized Zirconia. Ceramics, 1(1), 3-12. https://doi.org/10.3390/ceramics1010002