1.1. The Freeze-Foaming Process and Recent Achievements

The Freeze-Foaming process can be classified into direct foaming methods in which suspensions are foamed either by turbulent mixing with surfactants [

1] or by in situ gas and vapor developing reactions [

2,

3]. The two other industrially relevant techniques are based on polyurethane (PU) foam replication, i.e., the Replica/Schwartzwalder approach [

4], and pore forming substances, e.g., polymeric beads, starch, carbon black, wax or sawdust [

5,

6]. Polymeric scaffolds and pore formers later need to be burned out in order to achieve the desired porous body. No burnout of organic volatile pore formers and polymer scaffolds is needed with so-called Freeze Foaming, which allows the direct foaming of almost any desired material (diverse ceramics, metals, etc.) as long as it can be prepared as an aqueous suspension. The Freeze-Foaming process is triggered by ambient pressure reduction of an aqueous suspension in a freeze dryer. The applied vacuum initiates an inflation of the suspension medium by rising processing air and water vapor. During this foaming step, only a couple of seconds long, the Freeze Foam’s macroporosity evolves (foam cell development). Further foaming takes place with the aqueous system moving along the vapor–liquid equilibrium line towards the triple point (referring to the p,T-diagram of water). After crossing the triple point, the generated protofoam instantaneously freezes and dries via sublimation [

7,

8]. This freezing step can result in cryogenic structures (discussed in more detail in [

9]) similar to typical freeze cast structures [

10,

11] and accounts for the microporosity of foamed structures. Therefore, the Freeze Foam’s only pore formers are rising bubbles of processing air and water vapor as well as sublimated frozen water. After debindering and sintering, the particularly typical ceramic properties can be achieved.

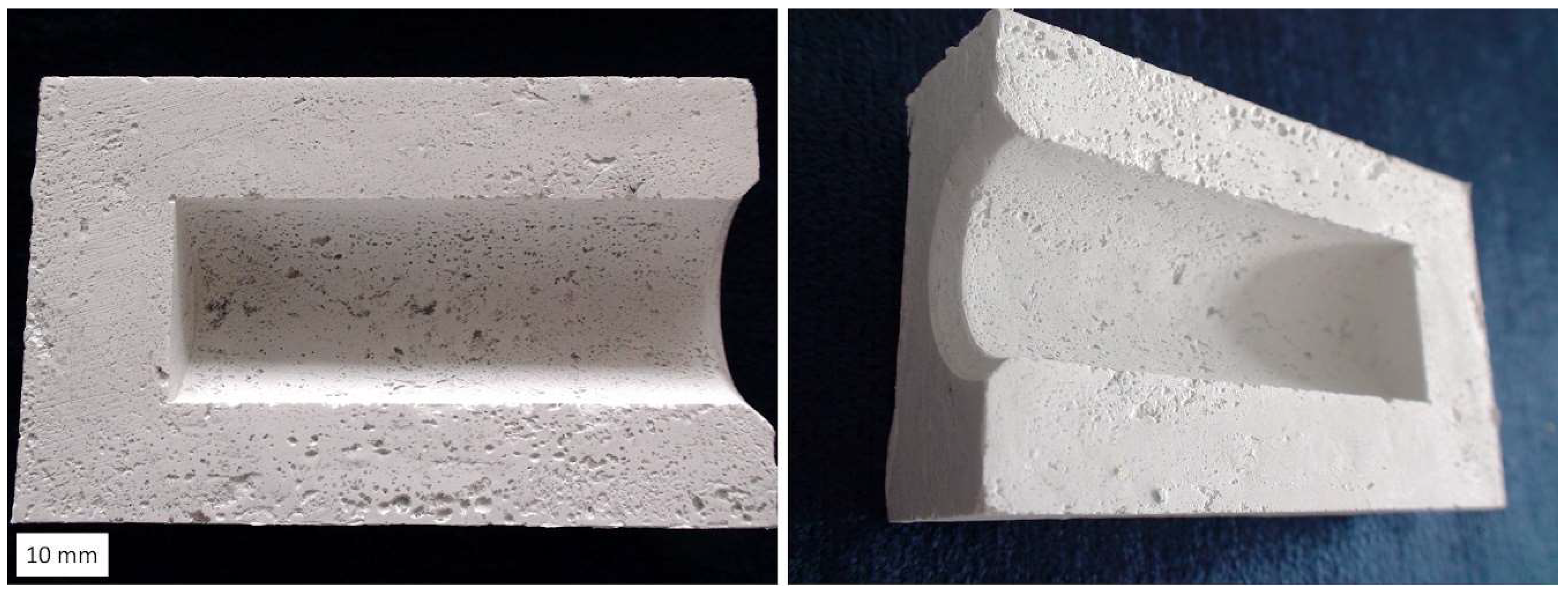

The manifold possibilities concerning material choice and, up until now, basic opportunities to tune the overall porosity of Freeze Foams, allowed the development of potential insulating refractory bricks made of mullite. It has been shown that, by altering the amount of binder, surfactant, solid content and suspension temperature, a different pore morphology as well as different thermomechanical characteristics can be achieved [

12]. The conclusion had been reached that manufacturing refractory bricks by this method is within reach. Although only at a small batch scale, especially near net shaped complex structures (

Figure 1) were obtained. Further research has been undertaken concerning the material composition, but adjustment of the optimal pore size is the most crucial variable for sophisticated application.

The main interest, though, lies in the sector of biomedical technology. With changing the material to bioceramics, the field of synthetic implants and bone replacement material is being addressed. Mainly open porous and interconnected cellular structures have been achieved, which are applicable as biocompatible components when made of hydroxyapatite (HAp), ZrO

2 or a composite mixture [

13,

14,

15]. Recent research is concerned with a hybrid shaping method: First, three-dimensional, complex-shaped hollow shell geometries are manufactured, for instance by Additive Manufacturing processes. In a second step, those shell structures are filled with a ceramic suspension with the Freeze-Foaming process commenced in situ. That process allows for connecting porous/cellular features provided by the Freeze Foaming with the dense and complex features provided by 3D printing methods like LCM (Lithography-based Ceramic Manufacturing). Bioactive femoral bone model demonstrators and dense-porous segmental components (

Figure 2) were successfully co-sintered to one composite part [

16,

17]. This hybrid shaping technology therefore offers a wide range of application potential for personalized and surface customizable implant structures for application in the field of biomedical technology and engineering.

However, Freeze Foaming and hybrid shaping so far do not exceed the laboratory scale. Upscaling this process requires large batches of reproducible ceramic suspensions. Applications require cellular scaffolds to either have a closed or open as well as often homogeneous pore morphology in order to provide the targeted properties in a predictable manner. With regard to refractories, homogeneously distributed small pores of typically closed porosity (in the range of 100 nm to 1 mm for proper isolation capability) are required [

18]. In contrast, bioceramic scaffolds for bone replacement material require sufficiently large pores (at least 100–500 µm) for cell attachment [

19,

20], interconnectivity [

21] and microporosity [

11], as well a general porosity greater than 40% [

22,

23,

24]. Thus, Freeze Foaming indeed allows for producing open and microporous, as well as interconnected scaffolds. From the example in

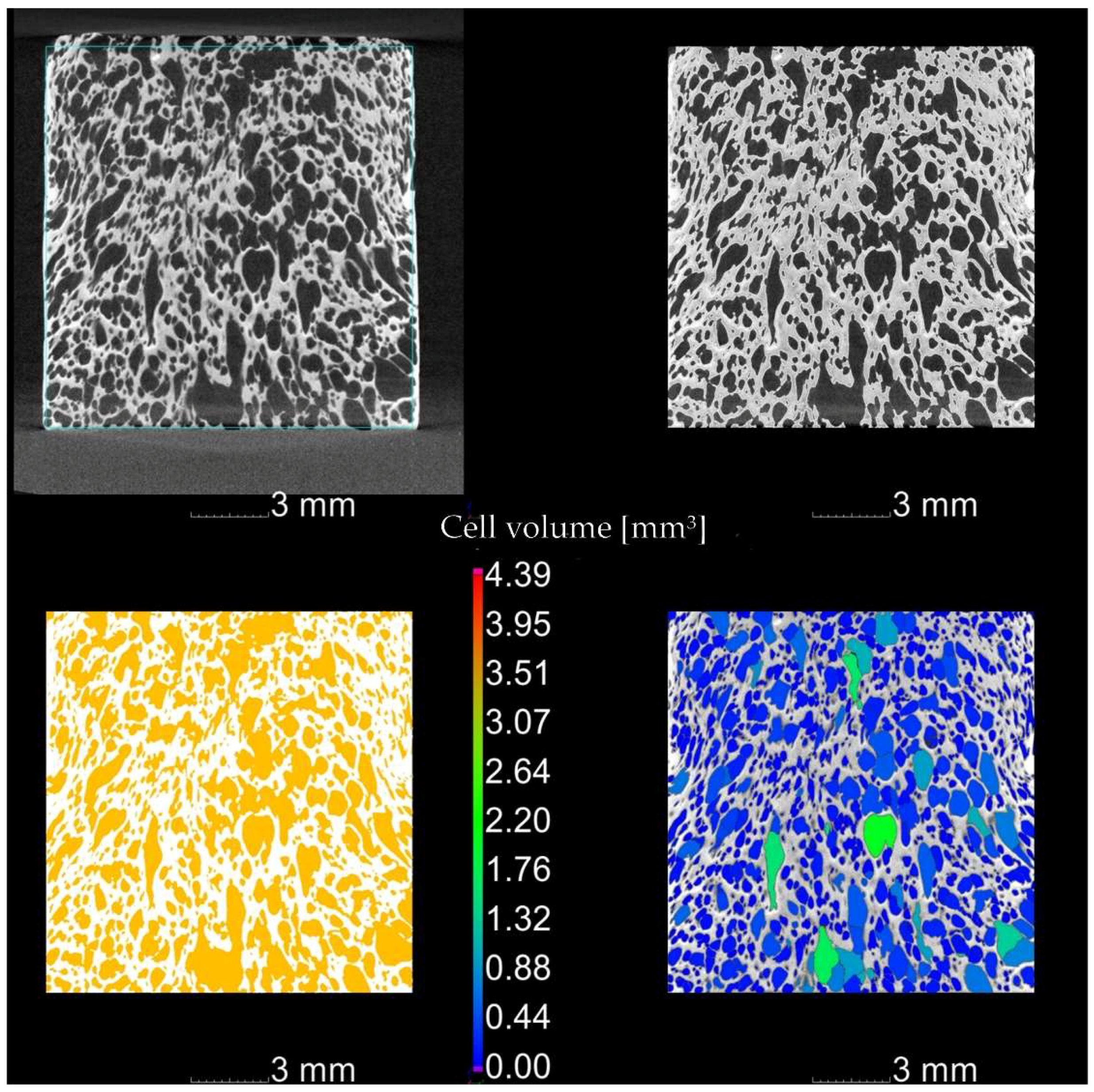

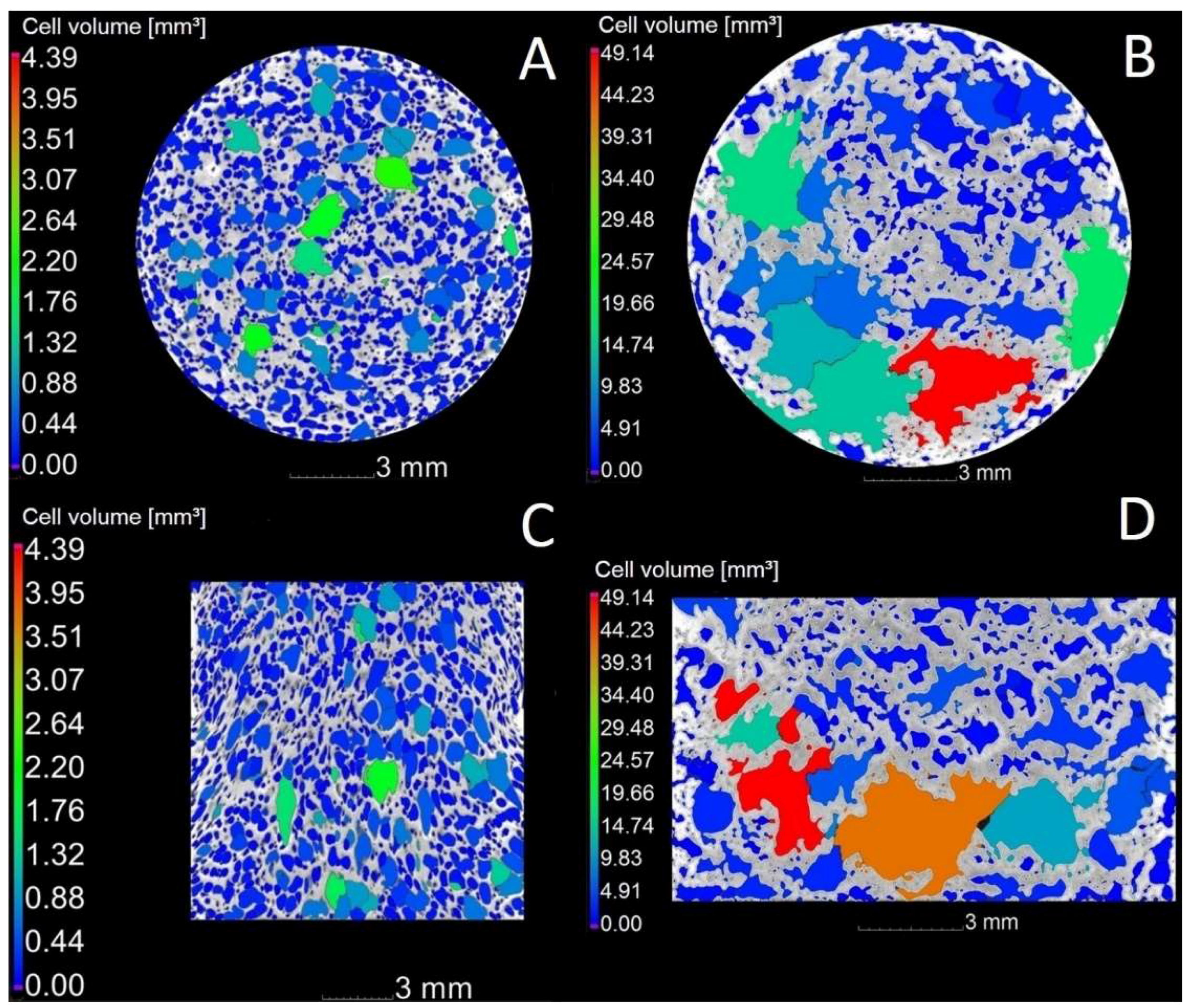

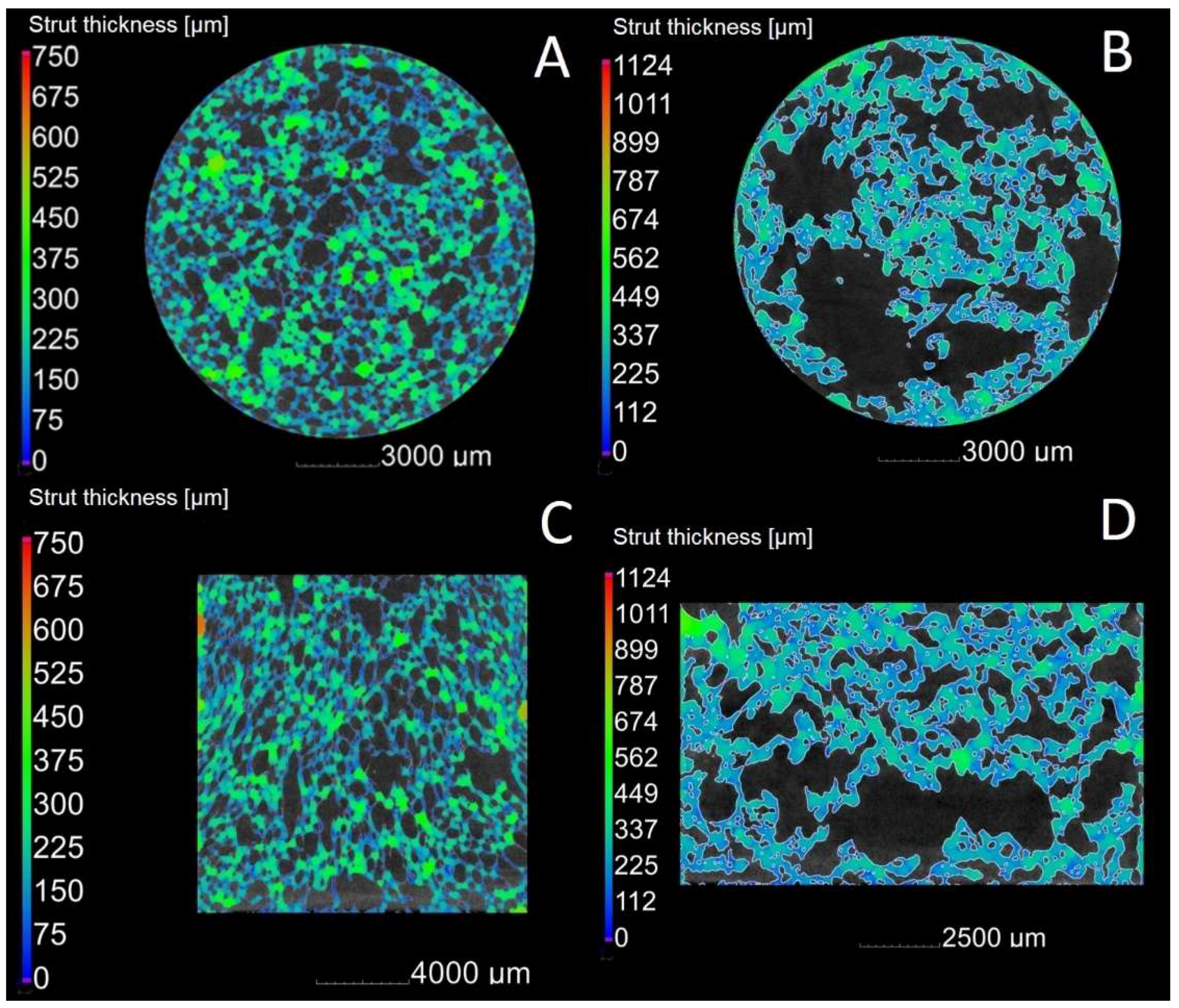

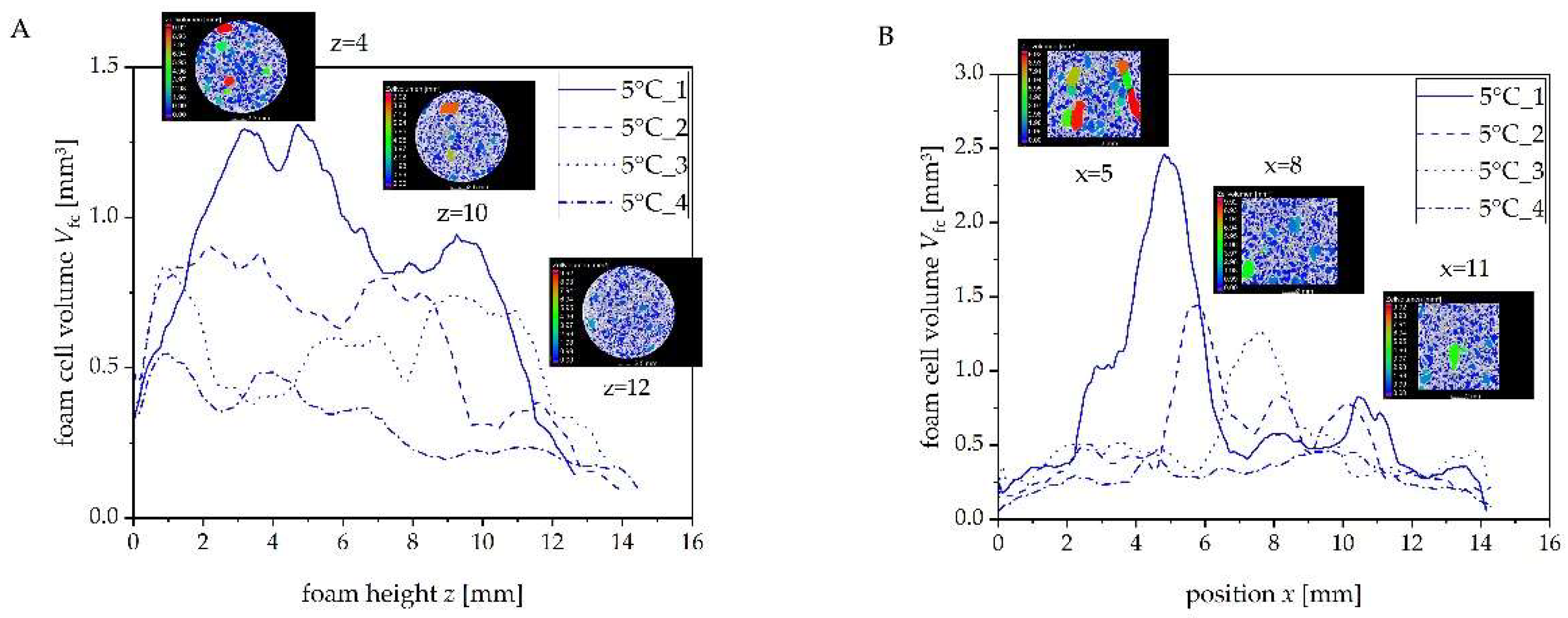

Figure 2, though, it becomes obvious that cellular Freeze Foams are typically heterogeneous. This makes estimations and assessments of the reproducibility of biocompatibility or mechanical strength very difficult.

Intense basic research into Freeze Foaming’s principles with a consideration of the material and processing aspects is needed. A material preparation and process approach must be found that allows for a controlled tuning of the pore morphology and evaluation of pore evolving activities by monitoring the foaming process itself. One solution that allows insights into processes and influence on materials is being provided by computed tomography (CT), which has become a sophisticated tool for improved damage and degradation analyses as well as structural evaluations in the field of material sciences [

25,

26,

27,

28].

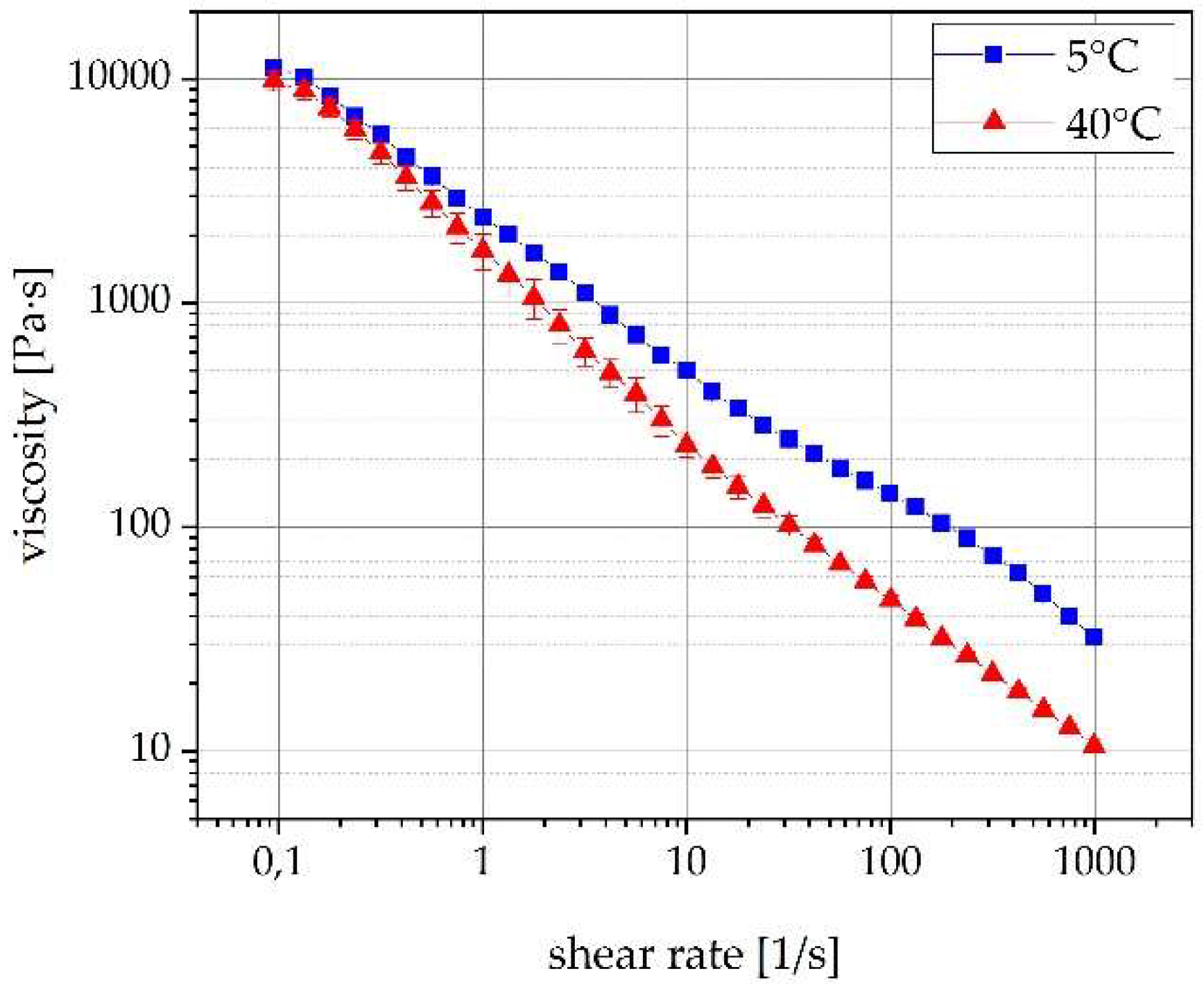

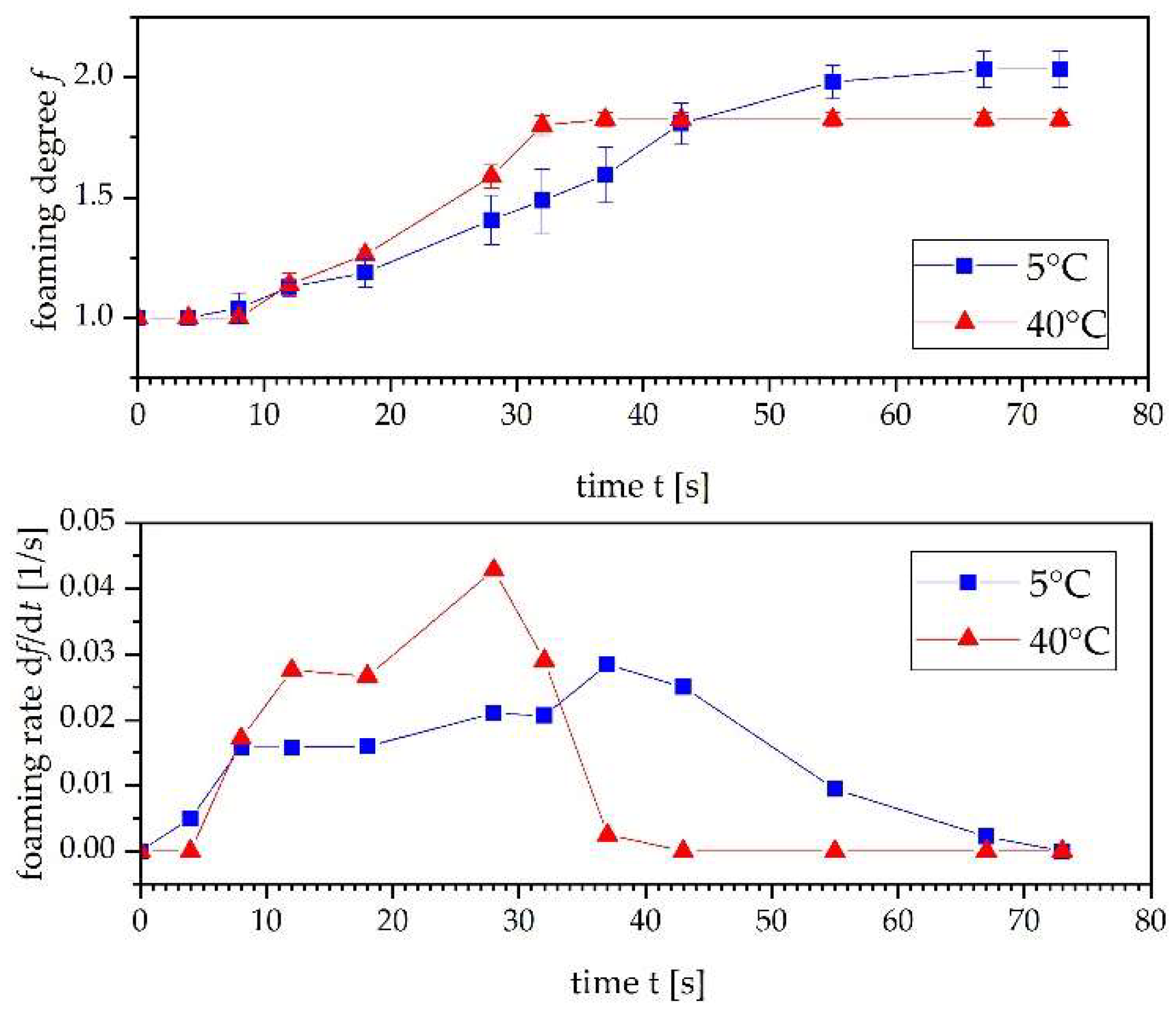

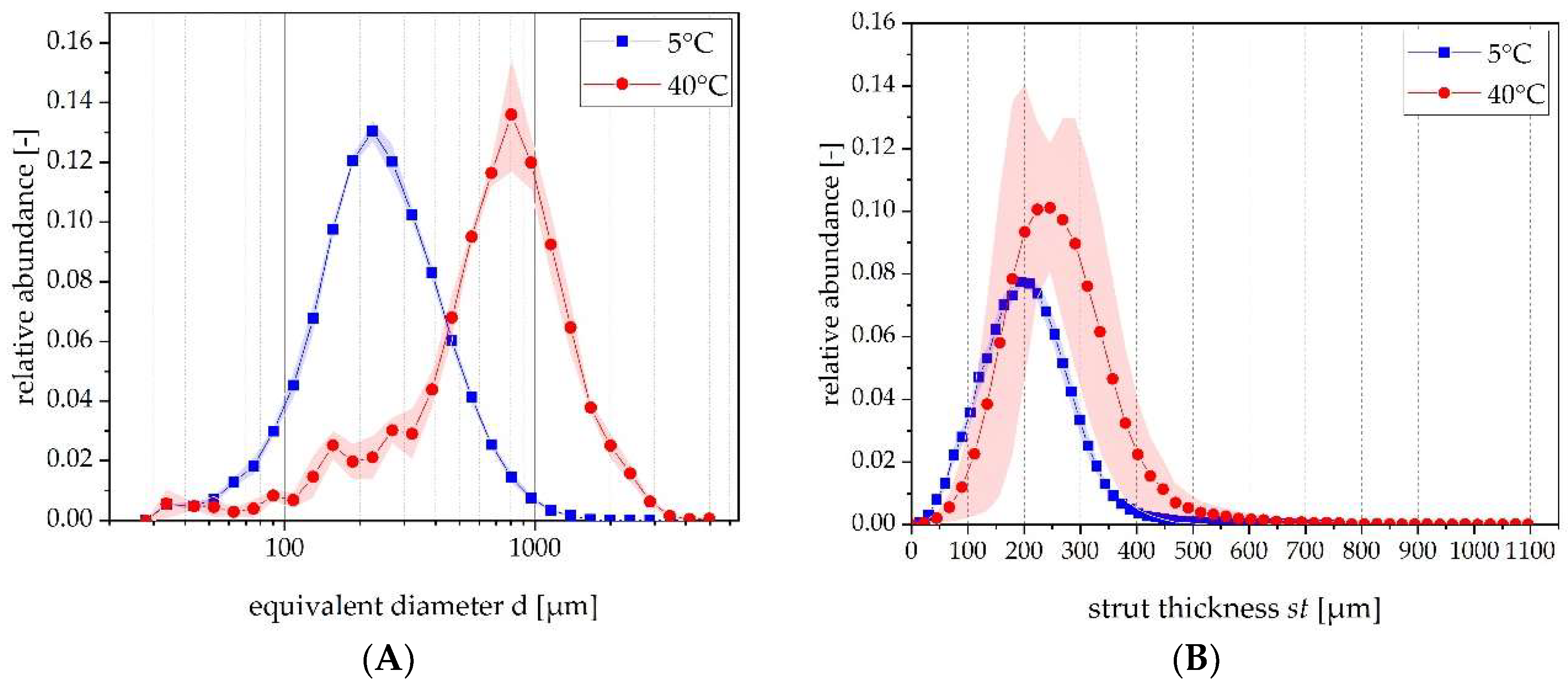

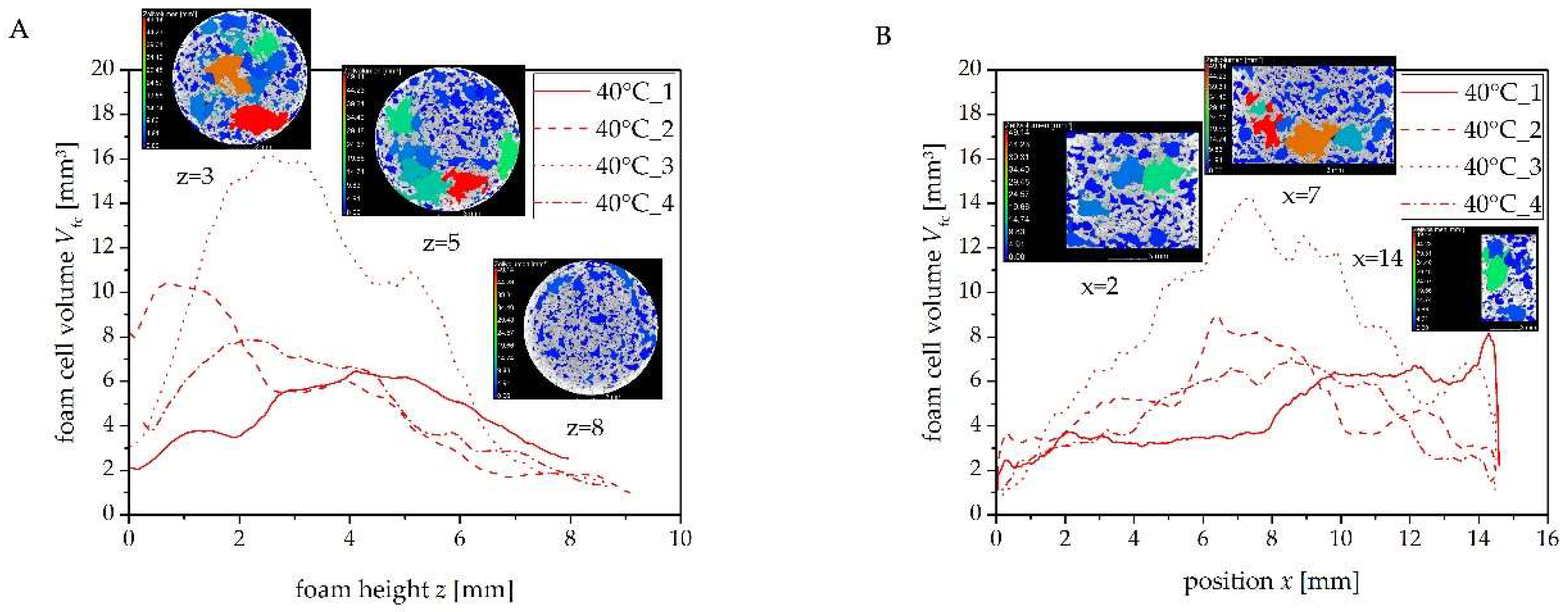

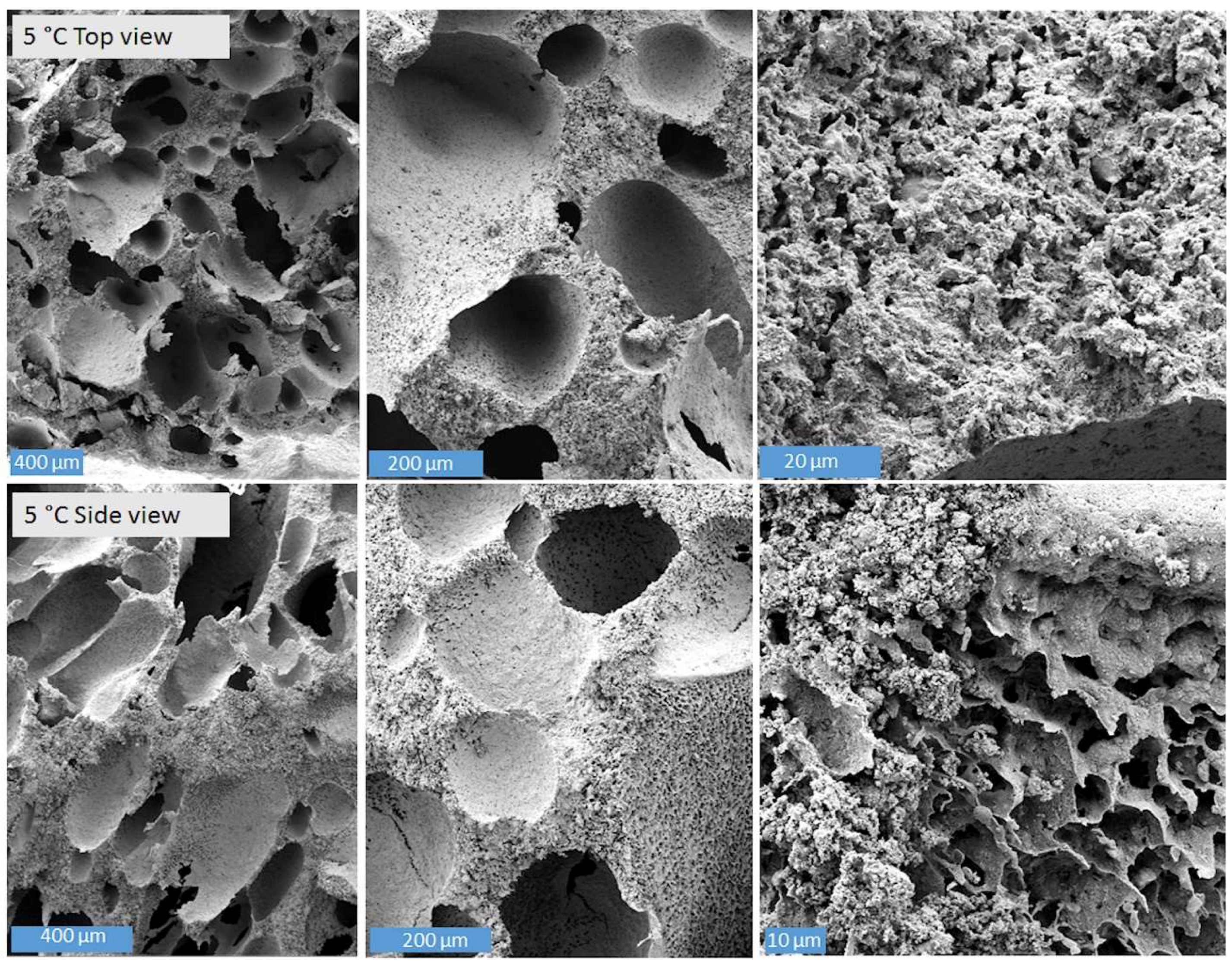

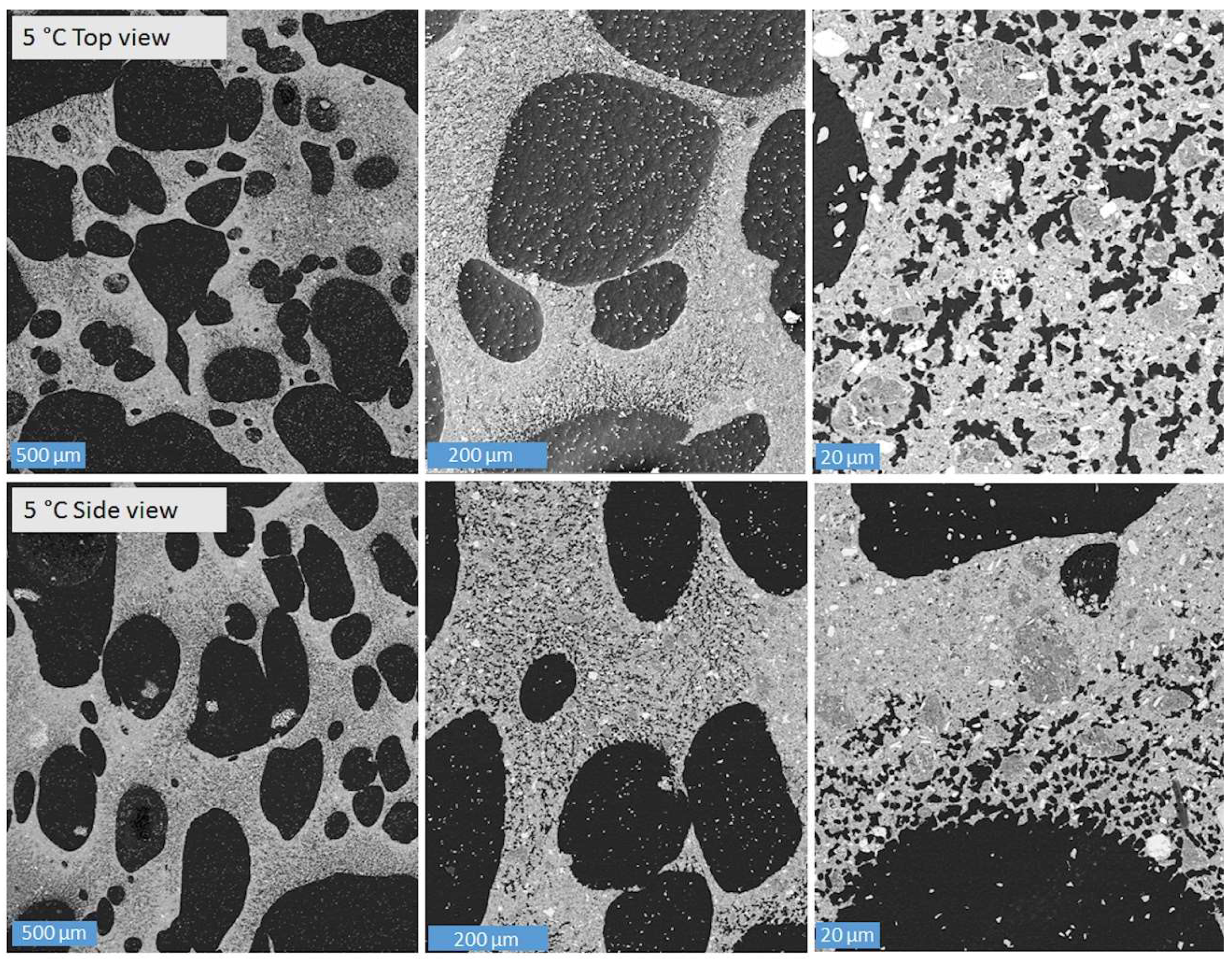

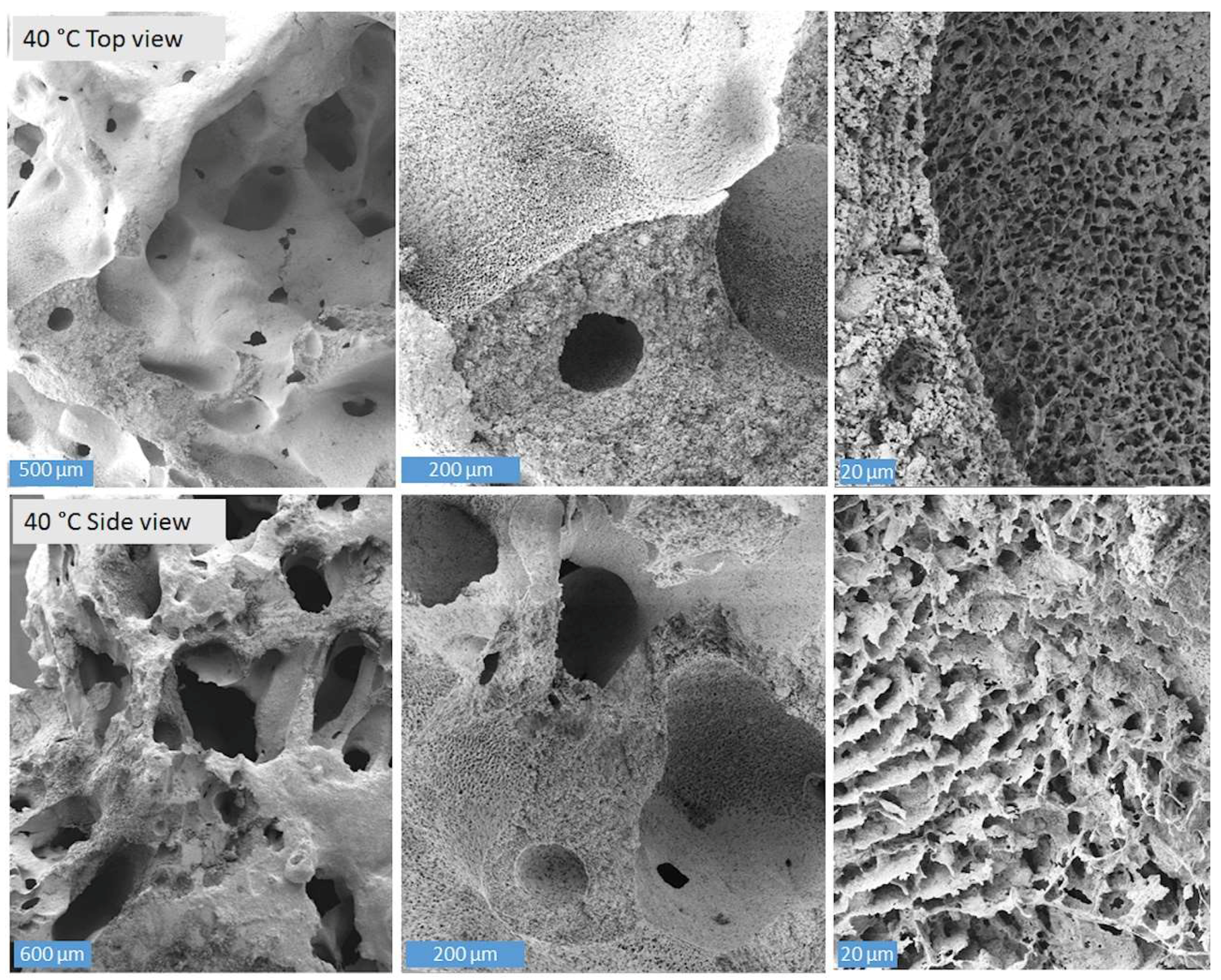

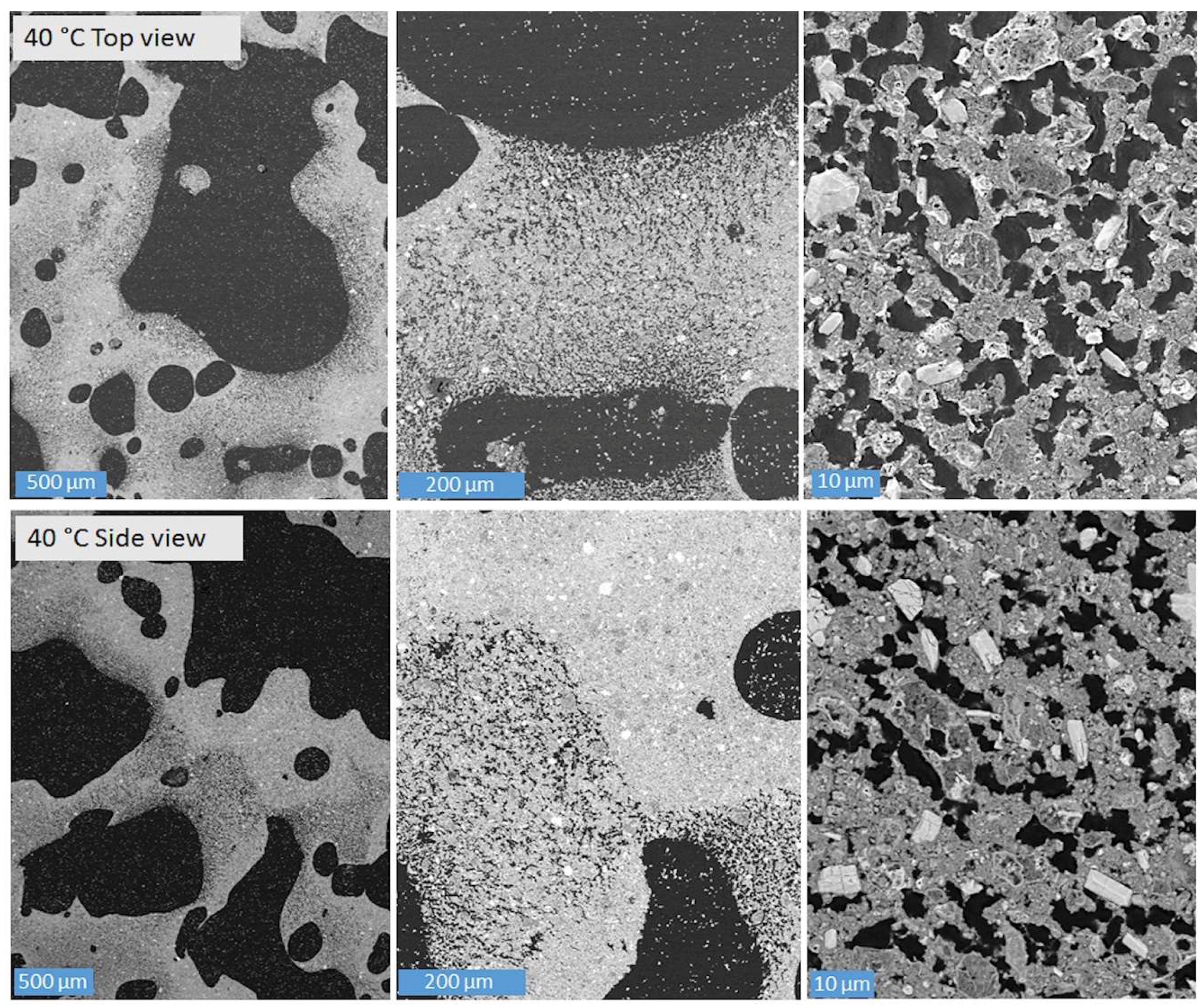

Already detailed in the previous contribution [

9], CT analyses were used for the first time to monitor the Freeze-Foaming process and allow for evaluation of foam structuring phenomena. The first results report the successful manufacturing of a model suspension, of reproducible foam structures foamed at room temperature and the dependence of the porosity, pore size and the shape from the pressure reduction rate of the freeze dryer used. In addition, the first indications of a strong influence of the amount of water with regard to the abundance of occurring cryogenic structures were discovered. The task of the related project’s next period was to vary the suspension temperature and monitor the tempered suspension’s foaming behavior as well as evaluate the resulting pore morphologies. Reproducible ceramic cellular structures were created with 5 °C and 40 °C tempered suspensions. The focus was not on achieving one defined pore size but rather observing and clarifying the phenomena of the Freeze-Foaming process. Since biomaterial application is one of the higher aims, hydroxyapatite was used, which is well known for its similarities to the mineral fraction of bone and its high osteoconductive potential [

29,

30,

31]. We aimed at reaching a pore size of around 100–700 μm as well as a distribution of pores that was as homogenous as possible. The porosity should be greater than 40% in order to achieve pore morphologic properties that generally meet the requirements for bone replacement material, as stated above. Since only the green state of manufactured Freeze Foams directly reflects the foaming process’s effects on the foam structure, the present contribution focuses on green-state ceramic material only. Analyses of the debinded and sintered foams will follow as soon as the results are available.