Enhancing Axial Flow in Hydrokinetic Turbines via Multi-Slot Diffuser Design: A Computational Study

Abstract

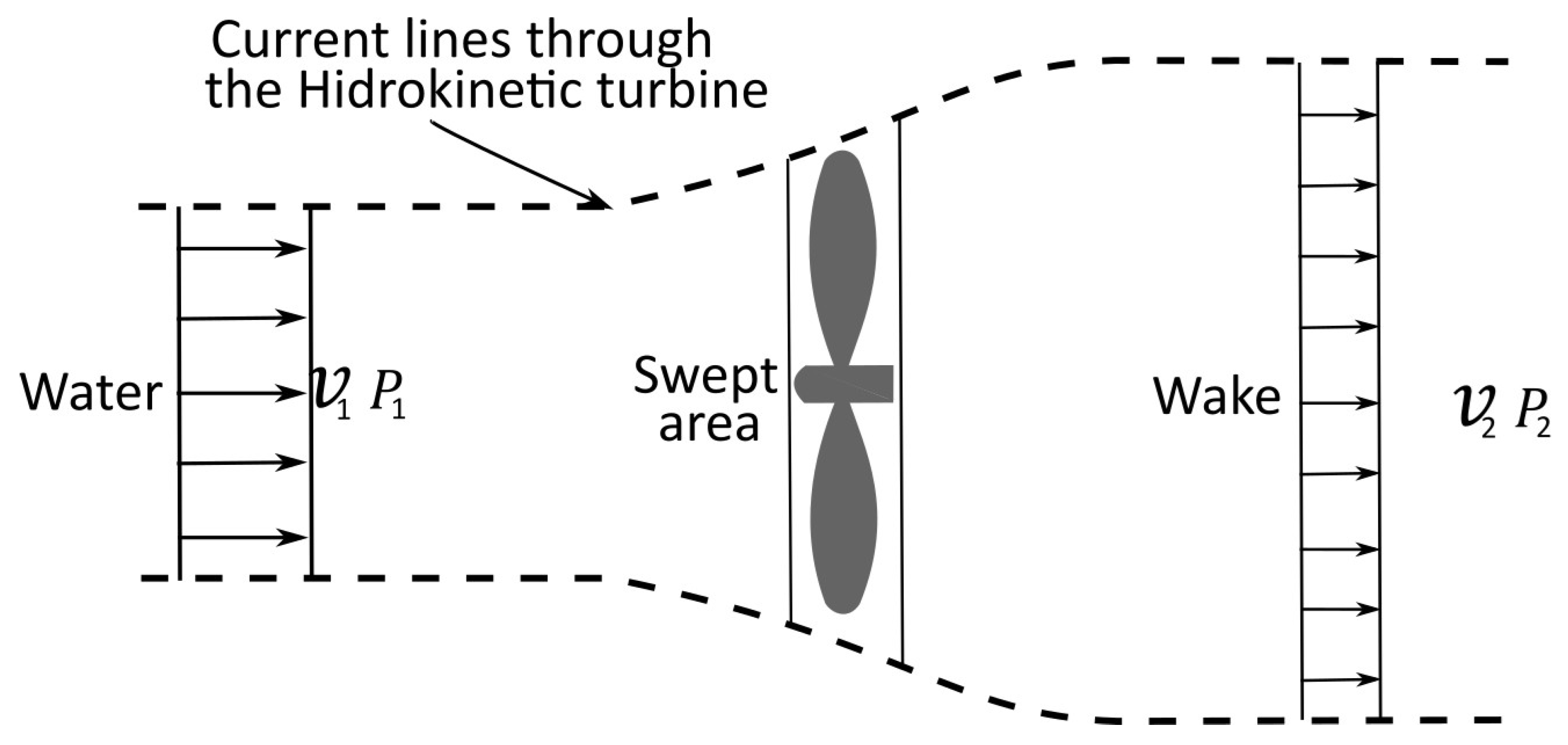

1. Introduction

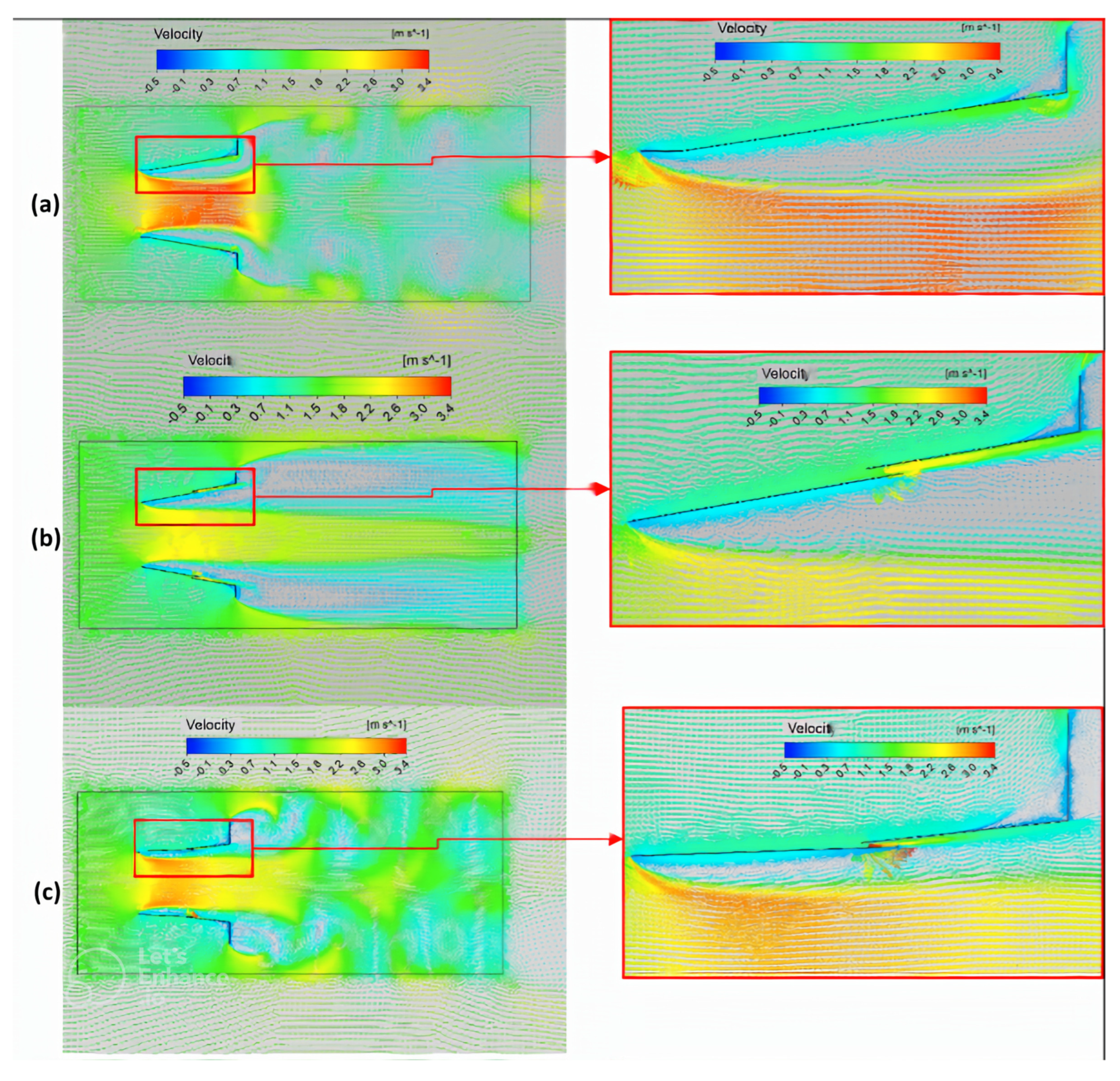

2. Methodology

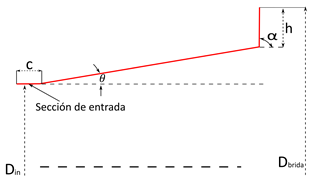

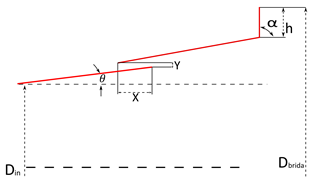

2.1. Diffuser Geometry and Experimental Designs

- Diffuser 1: Straight-walled slotless design (Silva et al. methodology [21]).

- Diffuser 2: Straight-walled with a single slot.

- Diffuser 3: Straight-walled with a single slot and two divergence angles.

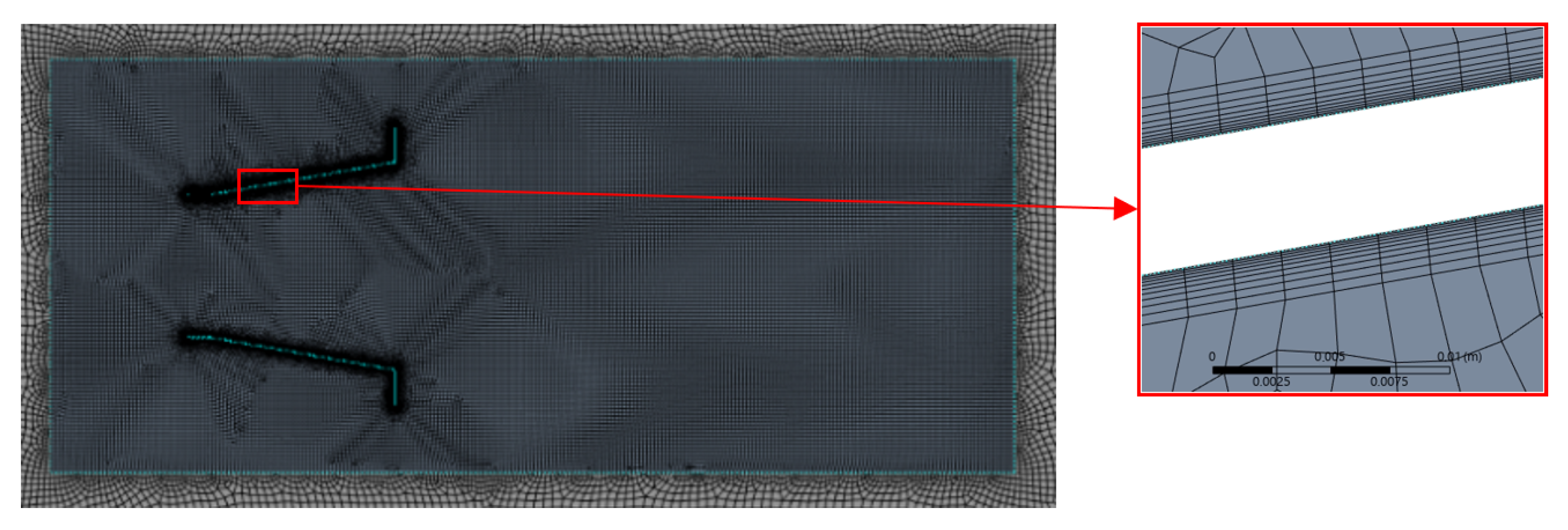

2.2. Computational Model

- Inlet: Uniform velocity m/s.

- Outlet: Gauge pressure set to 0 Pa.

- Walls: No-slip on diffuser and blade surfaces; slip (symmetry) on outer domain boundaries.

3. Results

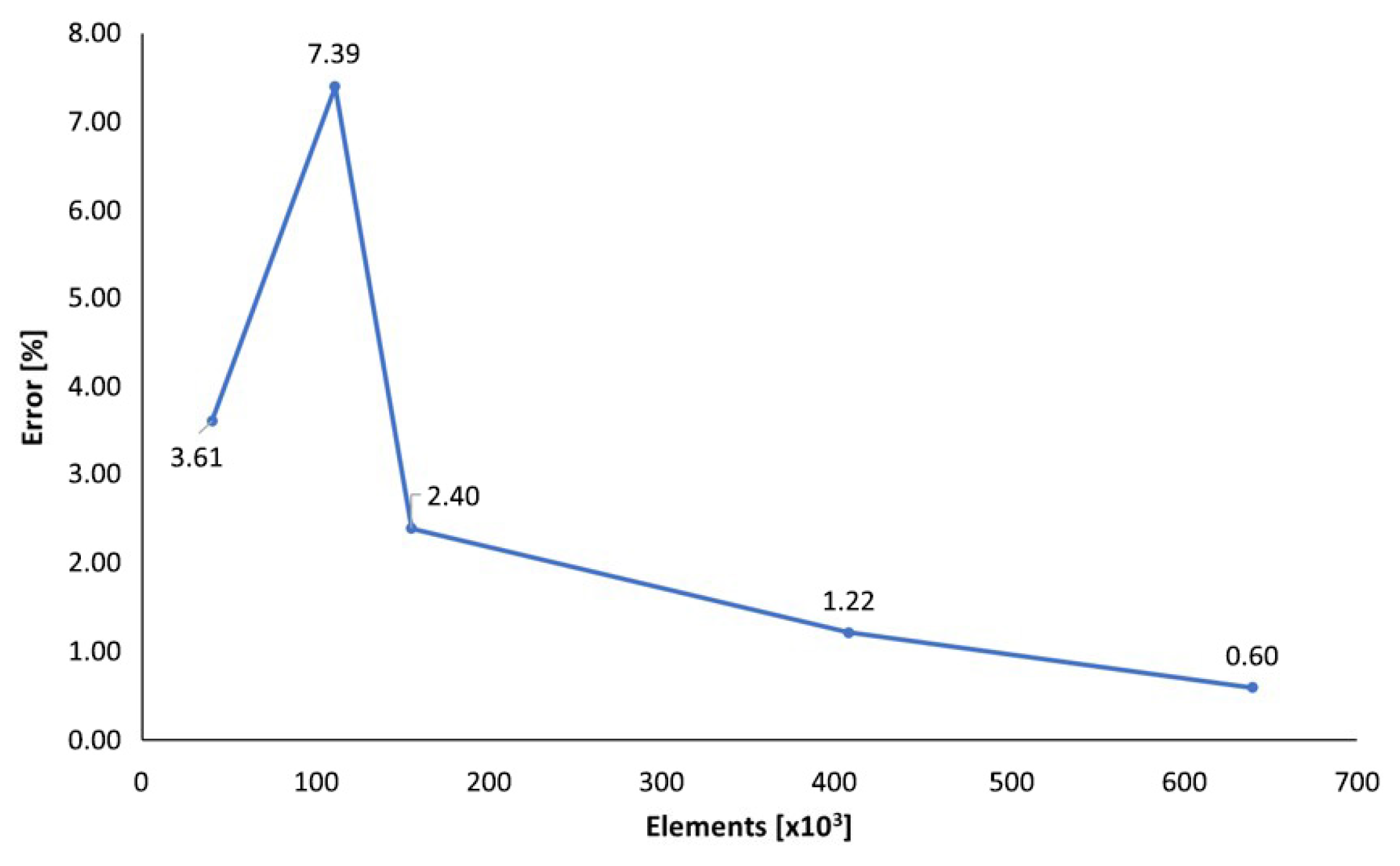

3.1. Numerical Validation

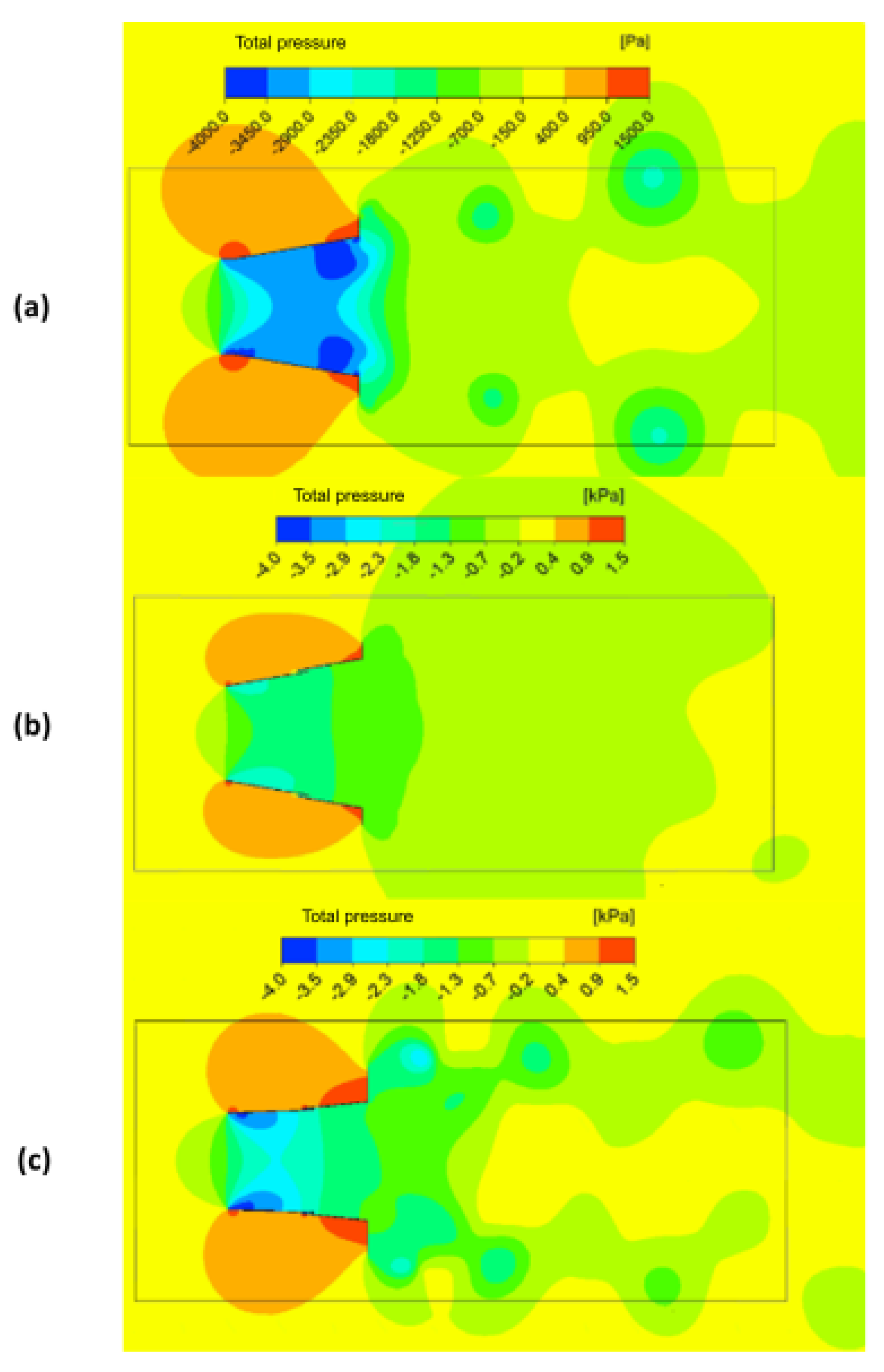

3.2. Numerical Results

4. Discussion

5. Conclusions

5.1. Key Conclusions

5.2. Limitations and Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sopian, K.; Ali, B.; Asim, N. Strategies for Renewable Energy Applications in the Organization of Islamic Conference (OIC) Countries. Renew. Sustain. Energy Rev. 2011, 15, 4706–4725. [Google Scholar] [CrossRef]

- International Energy Agency. World Energy Outlook 2006; IEA: Paris, France, 2006. [Google Scholar] [CrossRef]

- Dincer, I. Renewable Energy and Sustainable Development: A Crucial Review. Renew. Sustain. Energy Rev. 2000, 4, 157–175. [Google Scholar] [CrossRef]

- Elbatran, A.H.; Yaakob, O.B.; Ahmed, Y.M.; Shabara, H.M. Operation, Performance and Economic Analysis of Low Head Micro-Hydropower Turbines for Rural and Remote Areas: A Review. Renew. Sustain. Energy Rev. 2015, 43, 40–50. [Google Scholar] [CrossRef]

- Vermaak, H.J.; Kusakana, K.; Koko, S.P. Status of Micro-Hydrokinetic River Technology in Rural Applications: A Review of Literature. Renew. Sustain. Energy Rev. 2014, 29, 625–633. [Google Scholar] [CrossRef]

- Shahsavarifard, M.; Bibeau, E.L. Yaw operation of a shrouded horizontal axis hydrokinetic turbine. In Proceedings of the MTS/IEEE OCEANS 2015—Genova: Discovering Sustainable Ocean Energy for a New World, Genova, Italy, 18–21 May 2015; pp. 1–4. [Google Scholar] [CrossRef]

- Muñoz, A.H.; Chiang, L.E.; De la Jara, E.A. A Design Tool and Fabrication Guidelines for Small Low Cost Horizontal Axis Hydrokinetic Turbines. Energy Sustain. Dev. 2014, 22, 21–33. [Google Scholar] [CrossRef]

- Arrieta, E.L.C.; Cardona-Mancilla, C.; Slayton, J.; Romero, F.; Torres, E.; Agudelo, S.; Arbelaez, J.J.; Hincapié, D. Experimental Investigations and CFD Simulations of the Blade Section Pitch Angle Effect on the Performance of a Horizontal-Axis Hydrokinetic Turbine. Eng. J. 2018, 22, 141–154. [Google Scholar] [CrossRef]

- Shaabani, B.; Chatoorgoon, V.; Bibeau, E.L. Using numerical analysis to design and optimize river hydrokinetic turbines’ capacity factor to address seasonal velocity variations. Energies 2025, 18, 477. [Google Scholar] [CrossRef]

- Chica, E.; Aguilar, J.; Rubio-Clemente, A. Analysis of a Lift Augmented Hydrofoil for Hydrokinetic Turbines. Renew. Energy Power Qual. J. 2019, 17, 49–55. [Google Scholar] [CrossRef]

- Shen, C.; Han, Y.; Wang, S.; Wang, Z. Influence of airfoil curvature and blade angle on vertical axis hydraulic turbine performance in low flow conditions. Water 2025, 17, 11. [Google Scholar] [CrossRef]

- Gomez, M.A.; Guevara-Muñoz, A.; Zuluaga, D.H. A Numerical H-Darrieus Hydrokinetic Turbine Performance Assessment with the Application of Openings in Blade Geometry. Int. J. Renew. Energy Dev. 2025, 14, 1–9. [Google Scholar] [CrossRef]

- Kim, D.G.; Kim, J.; Jung, S.; Ko, J.H. Experimental investigation of the yaw misalignment effect on the power performance and system loading of a flapping-foil hydrokinetic turbine. Energy Sci. Eng. 2024, 12, 5555–5565. [Google Scholar] [CrossRef]

- Taborda, D.G.; Del Rio, J.S.; Perez-Alvarez, J.D.; Cardona-Vargas, A.; Sanin, D.S. CFD Analysis of the Needle Tip Angle in Pelton Injector on Jet Quality for the Power Generation. EUREKA Phys. Eng. 2021, 3, 45–59. [Google Scholar] [CrossRef]

- Sánchez, A.R.; Del Rio, J.A.S.; Quintana, E.C.; Sanín-Villa, D. Numerical Comparison of Savonius Turbine as a Rotor for Gravitational Vortex Turbine with Standard Rotor. J. Appl. Eng. Sci. 2023, 21, 204–211. [Google Scholar] [CrossRef]

- Del Rio, J.A.S.; Sánchez, A.R.; Sanín-Villa, D.; Quintana, E.C. Numerical Study of H-Darrieus Turbine as a Rotor for Gravitational Vortex Turbine. CFD Lett. 2022, 14, 1–11. [Google Scholar] [CrossRef]

- Kolekar, N.; Mukherji, S.S.; Banerjee, A. Numerical modeling and optimization of hydrokinetic. In Proceedings of the ASME 2011 5th International Conference on Energy Sustainability, Washington, DC, USA, 7–10 August 2011; pp. 1–8. [Google Scholar]

- Jamieson, P.M. Beating Betz: Energy extraction limits in a constrained flow field. J. Sol. Energy Eng. Trans. ASME 2009, 131, 031008. [Google Scholar] [CrossRef]

- Nunes, M.M.; Brasil Junior, A.C.P.; Oliveira, T.F. Systematic Review of Diffuser-Augmented Horizontal-Axis Turbines. Renew. Sustain. Energy Rev. 2020, 133, 110075. [Google Scholar] [CrossRef]

- Abdelwaly, M.; El-Batsh, H.; Bassily Hanna, M. Numerical Study for the Flow Field and Power Augmentation in a Horizontal Axis Wind Turbine. Sustain. Energy Technol. Assess. 2019, 31, 245–253. [Google Scholar] [CrossRef]

- Silva, P.A.S.F.; Rio Vaz, D.A.T.D.; Britto, V.; de Oliveira, T.F.; Vaz, J.R.P.; Brasil Junior, A.C.P. A New Approach for the Design of Diffuser-Augmented Hydro Turbines Using the Blade Element Momentum. Energy Convers. Manag. 2018, 165, 801–814. [Google Scholar] [CrossRef]

- Saha, G. Performance Improvement of Self-Rectifying Axial Impulse Turbines with a Diffuser Integration Strategy. In Proceedings of the 15th European Wave and Tidal Energy Conference (EWTEC 2023), Bilbao, Spain, 3–7 September 2023; University of Southampton: Southampton, UK, 2023. [Google Scholar] [CrossRef]

- Mehmood, N.; Liang, Z.; Khan, J. CFD Study of NACA 0018 for Diffuser Design of Tidal Current Turbines. Res. J. Appl. Sci. Eng. Technol. 2012, 4, 4552–4560. [Google Scholar]

- Tampier, G.; Troncoso, C.; Zilic, F. Numerical Analysis of a Diffuser-Augmented Hydrokinetic Turbine. Ocean Eng. 2017, 145, 138–147. [Google Scholar] [CrossRef]

- Song, K.; Wang, W.; Yan, Y. Numerical and Experimental Analysis of a Diffuser-Augmented Micro-Hydro Turbine. Ocean Eng. 2019, 171, 590–602. [Google Scholar] [CrossRef]

- Vaz, J.R.P.; Wood, D.H. Aerodynamic Optimization of the Blades of Diffuser-Augmented Wind Turbines. Energy Convers. Manag. 2016, 123, 35–45. [Google Scholar] [CrossRef]

- Park, J.; Lee, H.; Kim, S.; Choi, Y. CFD-Based Design Optimization of a 5 kW Ducted Hydrokinetic Turbine with Practical Constraints. arXiv 2024, arXiv:2411.13492. [Google Scholar] [CrossRef]

- Vaz, J.R.P.; de Lima, A.K.F.; Lins, E.F. Assessment of a Diffuser-Augmented Hydrokinetic Turbine Designed for Harnessing the Flow Energy Downstream of Dams. Sustainability 2023, 15, 7671. [Google Scholar] [CrossRef]

- Ng, C.Y.; Maldar, N.R.; Ong, M.C. Numerical Investigation on Performance Enhancement in a Drag-Based Hydrokinetic Turbine with a Diffuser. Ocean Eng. 2024, 298, 117179. [Google Scholar] [CrossRef]

- Arrieta-Gomez, M.; Vélez-García, S.; Hincapie, D.; Tejada, J.C.; Sanin-Villa, D. Efficiency Optimization of a Hybrid Savonius-Darrieus Hydrokinetic Turbine via Regression Modeling and CFD-Based Design of Experiments. Results Eng. 2025, 27, 105751. [Google Scholar] [CrossRef]

- Limacher, E.J.; da Silva, P.O.C.; Barbosa, P.E.S.; Vaz, J.R.P. Large Exit Flanges in Diffuser-Augmented Turbines Lead to Sub-Optimal Performance. J. Wind Eng. Ind. Aerodyn. 2020, 204, 104228. [Google Scholar] [CrossRef]

- Igra, O. Compact Shrouds for Wind Turbines. Energy Convers. 1977, 16, 149–157. [Google Scholar] [CrossRef]

- Rahmatian, M.A.; Hashemi Tari, P.; Mojaddam, M.; Majidi, S. Numerical and Experimental Study of the Ducted Diffuser Effect on Improving the Aerodynamic Performance of a Micro Horizontal Axis Wind Turbine. Energy 2022, 245, 123267. [Google Scholar] [CrossRef]

- Abe, K.I.; Ohya, Y. An Investigation of Flow Fields around Flanged Diffusers Using CFD. J. Wind Eng. Ind. Aerodyn. 2004, 92, 315–330. [Google Scholar] [CrossRef]

- Gilbert, B.L. Investigation of Diffuser-Augmented Wind Turbines. Part II. J. Wind Eng. Ind. Aerodyn. 1977, 2. [Google Scholar] [CrossRef]

- Sorribes-Palmer, F.; Sanz-Andrés, A.; Ayuso, L.; Sant, R.; Franchini, S. Mixed CFD–1D Wind Turbine Diffuser Design Optimization. Renew. Energy 2017, 105, 386–399. [Google Scholar] [CrossRef]

- Toshimitsu, K.; Nishikawa, K.; Haruki, W.; Oono, S.; Takao, M.; Ohya, Y. PIV Measurements of Flows around the Wind Turbines with a Flanged-Diffuser Shroud. J. Therm. Sci. 2008, 17, 375–380. [Google Scholar] [CrossRef]

- Foreman, K.M.; Gilbert, B.; Oman, R.A. Diffuser Augmentation of Wind Turbines; Technical Report Report 20; Oregon State University: Corvallis, OR, USA, 1976. [Google Scholar]

- Gilbert, B.L.; Oman, R.A.; Foreman, K.M. Investigation of Diffuser-Augmented Wind Turbines. Part I. J. Wind Eng. Ind. Aerodyn. 1977, 7, 541–559. [Google Scholar]

- Argyropoulos, C.D.; Markatos, N.C. Recent Advances on the Numerical Modelling of Turbulent Flows. Appl. Math. Model. 2015, 39, 693–732. [Google Scholar] [CrossRef]

- ANSYS Inc. Ansys Fluent User’s Guide; ANSYS Inc.: Canonsburg, PA, USA, 2021. [Google Scholar]

- Barbarić, M.; Guzović, Z. Investigation of the Possibilities to Improve Hydrodynamic Performances of Micro-Hydrokinetic Turbines. Energies 2020, 13, 4560. [Google Scholar] [CrossRef]

- Picanço, H.P.; de Lima, A.K.F.; Vaz, D.A.T.D.; Lins, E.F.; Vaz, J.R.P. Cavitation Inception on Hydrokinetic Turbine Blades Shrouded by Diffuser. Sustainability 2022, 14, 7067. [Google Scholar] [CrossRef]

- ANSYS Inc. Introduction to Ansys Meshing; ANSYS Inc.: Canonsburg, PA, USA, 2012. [Google Scholar]

- Leloudas, S.N.; Lygidakis, G.N.; Eskantar, A.I.; Nikolos, I.K. A Robust Methodology for the Design Optimization of Diffuser-Augmented Wind Turbine Shrouds. Renew. Energy 2020, 150, 722–742. [Google Scholar] [CrossRef]

- Khamlaj, T.A.; Rumpfkeil, M.P. Analysis and Optimization of Ducted Wind Turbines. Energy 2018, 162, 1234–1252. [Google Scholar] [CrossRef]

- Barbosa, D.L.M.; Vaz, J.R.P.; Figueiredo, S.W.O.; de Oliveira e Silva, M.; Lins, E.F.; Mesquita, A.L.A. An Investigation of a Mathematical Model for the Internal Velocity Profile of Conical Diffusers Applied to DAWTs. An. Acad. Bras. Ciênc. 2015, 87, 1133–1148. [Google Scholar] [CrossRef][Green Version]

| Parameter | Definition |

|---|---|

| Flange angle at diffuser outlet | |

| Divergence angle of first section | |

| Divergence angle of second section | |

| Inlet diameter | |

| Outlet flange diameter | |

| c | Length of straight inlet section |

| Total diffuser length | |

| Radial clearance between rotor and wall | |

| h | Flange height |

| X | Axial position of slot |

| Y | Radial position of slot |

| L | Distance from slot to diffuser outlet |

| DOE 1—Straight-Walled Diffuser | ||||

| Factor | Description | Level 1 | Level 2 | Refs. | |

| Divergence angle (°) | 10 | 16 | [31,32] | ||

| Flange angle (°) | 90 | 75 | [21,31,33] | ||

| Inlet section | With inlet | Without inlet | [21,33,34] | ||

| DOE 2—Single-Slot Diffuser | ||||

| Factor | Description | Level 1 | Level 2 | Refs. | |

| Divergence angle (°) | 10 | 16 | [31,32] | ||

| Slot Y-position | 0.0125 D | 0.04 D | [35,36] | ||

| Slot X-position | 0.250 D | 0.125 D | [35,36] | ||

| DOE 3—Dual-Angle Diffuser | ||||

| Factor | Description | Level 1 | Level 2 | Refs. | |

| Divergence angle 1 (°) | 2 | 4 | [21,37] | ||

| Divergence angle 2 (°) | 6 | 8 | [31,38] | ||

| Slot Y-position | 0.01 D | 0.06 D | [35,36,39] | ||

| Geometry | Divergence Angle (°) | Flange Angle (°) | Inlet Section | Average Normalised Axial Velocity |

|---|---|---|---|---|

| 5 | 16 | 90 | With inlet | 0.975 |

| 7 | 16 | 75 | With inlet | 0.906 |

| 8 | 16 | 75 | Without inlet | 0.889 |

| 3 | 10 | 75 | With inlet | 1.227 |

| 2 | 10 | 90 | Without inlet | 1.106 |

| 4 | 10 | 75 | Without inlet | 1.084 |

| 6 | 10 | 90 | With inlet | 0.897 |

| 1 | 16 | 90 | With inlet | 1.269 |

| Geometry | Divergence Angle (°) | Slot Y-Position | Slot X-Position | Average Normalised Axial Velocity |

|---|---|---|---|---|

| 8 | 16 | 0.0400 D | 0.125 D | 0.857 |

| 6 | 16 | 0.0400 D | 0.250 D | 0.835 |

| 3 | 10 | 0.0125 D | 0.125 D | 1.044 |

| 7 | 10 | 0.0400 D | 0.125 D | 1.046 |

| 2 | 16 | 0.0125 D | 0.250 D | 0.853 |

| 1 | 10 | 0.0125 D | 0.250 D | 1.044 |

| 5 | 10 | 0.0400 D | 0.250 D | 1.044 |

| 4 | 16 | 0.0125 D | 0.125 D | 0.848 |

| Geometry | Divergence Angle 1 (°) | Divergence Angle 2 (°) | Slot Y-Position | Average Normalised Axial Velocity |

|---|---|---|---|---|

| 8 | 4 | 10 | 0.06 D | 1.313 |

| 2 | 4 | 6 | 0.01 D | 1.329 |

| 5 | 2 | 6 | 0.06 D | 1.387 |

| 3 | 2 | 10 | 0.01 D | 1.394 |

| 4 | 4 | 10 | 0.01 D | 1.310 |

| 6 | 4 | 6 | 0.06 D | 1.304 |

| 1 | 2 | 6 | 0.01 D | 1.426 |

| 7 | 2 | 10 | 0.06 D | 1.387 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the International Institute of Knowledge Innovation and Invention. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sanin-Villa, D.; Sierra-Del Rio, J.; Hincapié Zuluaga, D.; Galvis-Holguin, S. Enhancing Axial Flow in Hydrokinetic Turbines via Multi-Slot Diffuser Design: A Computational Study. Appl. Syst. Innov. 2025, 8, 129. https://doi.org/10.3390/asi8050129

Sanin-Villa D, Sierra-Del Rio J, Hincapié Zuluaga D, Galvis-Holguin S. Enhancing Axial Flow in Hydrokinetic Turbines via Multi-Slot Diffuser Design: A Computational Study. Applied System Innovation. 2025; 8(5):129. https://doi.org/10.3390/asi8050129

Chicago/Turabian StyleSanin-Villa, Daniel, Jorge Sierra-Del Rio, Diego Hincapié Zuluaga, and Steven Galvis-Holguin. 2025. "Enhancing Axial Flow in Hydrokinetic Turbines via Multi-Slot Diffuser Design: A Computational Study" Applied System Innovation 8, no. 5: 129. https://doi.org/10.3390/asi8050129

APA StyleSanin-Villa, D., Sierra-Del Rio, J., Hincapié Zuluaga, D., & Galvis-Holguin, S. (2025). Enhancing Axial Flow in Hydrokinetic Turbines via Multi-Slot Diffuser Design: A Computational Study. Applied System Innovation, 8(5), 129. https://doi.org/10.3390/asi8050129