A Critical Analysis and Roadmap for the Development of Industry 4-Oriented Facilities for Education, Training, and Research in Academia

Abstract

1. Introduction

1.1. The Philosophy of Industry 4

1.2. Research Aims

- RQ1: Why is it important to build Industry 4 facilities in academia?

- RQ2: What features and characteristics of the Industry 4 system shall be considered in the development?

- RQ3: What Industry 4 technologies can be used in the development?

- RQ4: What challenges are expected during the development?

- RQ5: What are the current research gaps and solutions?

1.3. Research Contribution and Novelty

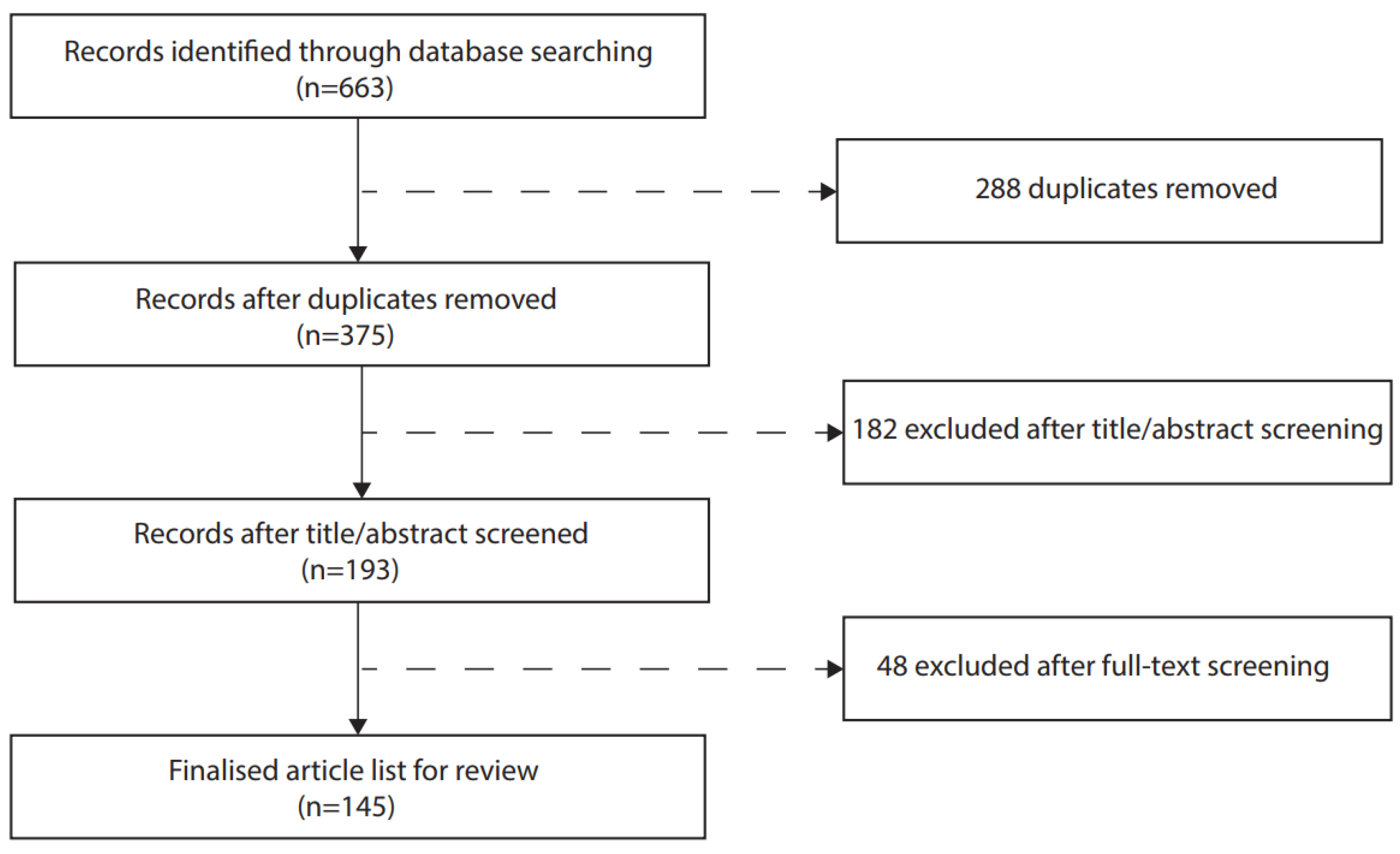

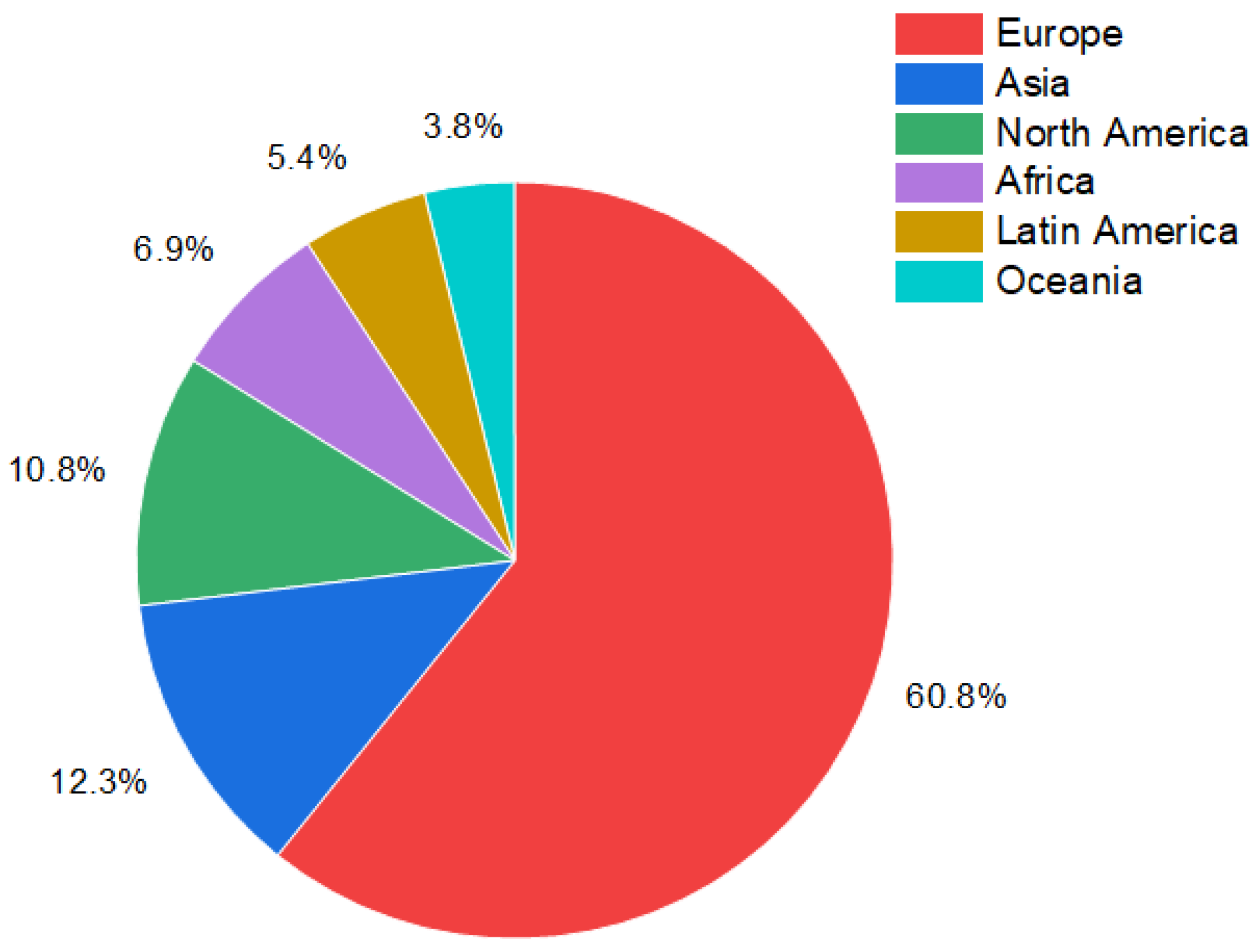

2. Review Methodology

2.1. Selection of Databases

2.2. Keyword Selection and Boolean Strings

2.3. Article Filtration and Selection

3. The Significance of Developing Industry 4 Facilities in Academia

3.1. Types of Industry 4 Facilities

3.2. Facilitating Academic Teaching and Research

3.3. Boosting Industrial Collaboration

4. The Design Principles

4.1. Interconnection

4.2. Information Transparency

4.3. Decentralised Decisions

4.4. Technical Assistance

5. The Technologies

5.1. Cyber–Physical Production Systems

5.2. Advanced Robotics

5.3. Additive Manufacturing

5.4. Digital Twin

5.5. Mixed-Reality Solution

5.6. Big Data Analytics

5.7. Industrial Internet-of-Things

5.8. Machine Vision

6. Challenges

6.1. Lack of Awareness

6.2. Technical Difficulties

6.3. Process Complexity

6.4. Resource Limitations

7. Discussion

7.1. Implementation Gaps

7.2. Bridging Design Principles and Key Technologies

7.3. Technology Maturity and Deployment Difficulty

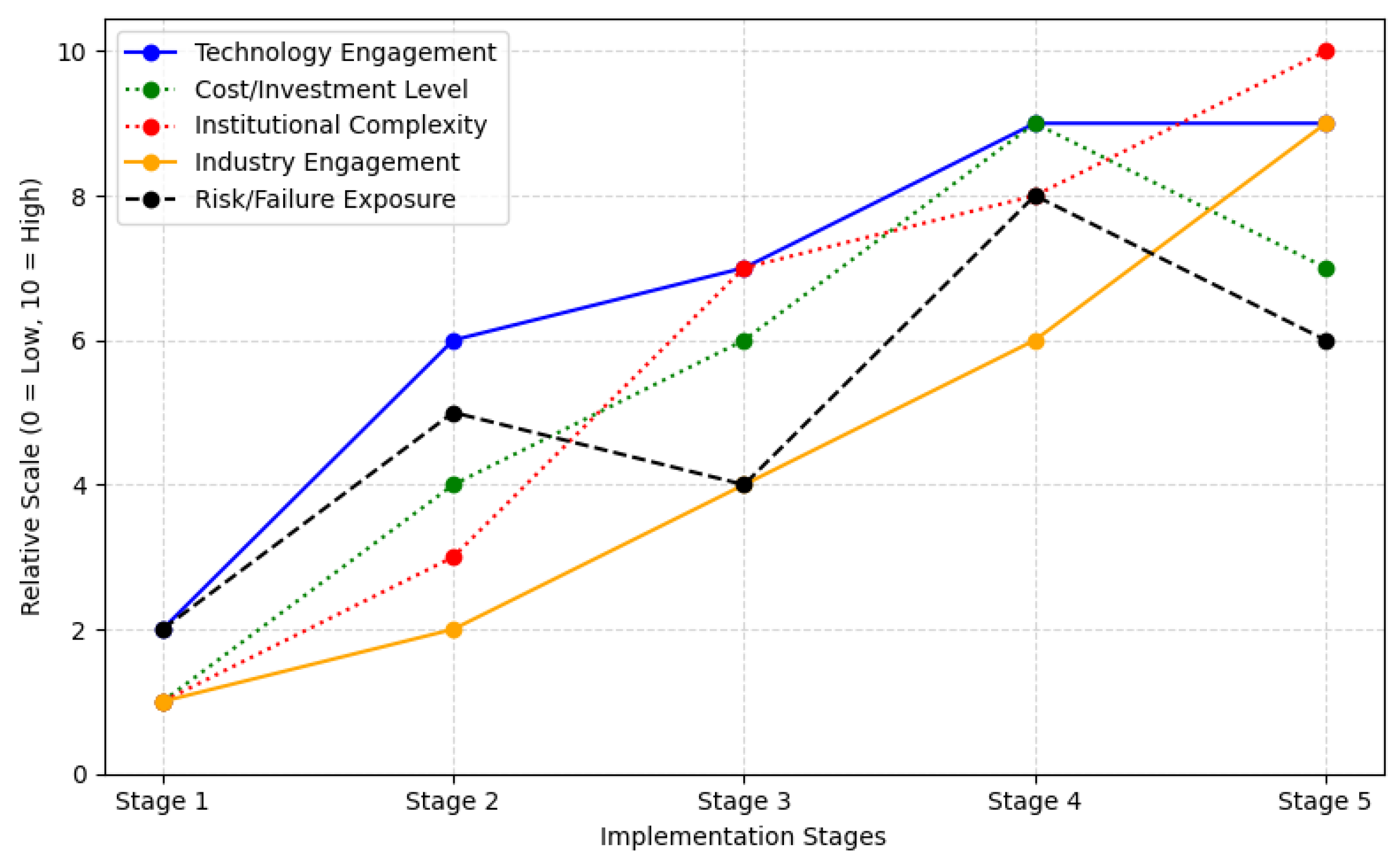

8. Strategic Roadmap and Future Trends for Industry 4 Facilities Development

8.1. Strategic Roadmap for Academic Implementation

8.2. Future Trend of the Industry 4 Facility Development

9. Research Limitations

10. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 3D | Three-Dimensional |

| 5G | Fifth Generation of Cellular Technology |

| AGV | Automated Guided Vehicles |

| AI | Artificial Intelligence |

| AM | Additive Manufacturing |

| AMQP | Advanced Message Queuing Protocol |

| AR | Augmented Reality |

| CAPP | Computer-Aided Process Planning |

| CPPS | Cyber–Physical Production System |

| CPS | Cyber–Physical system |

| DT | Digital Twin |

| ERP | Enterprise Resource Planning |

| IIoT | Industrial Internet-of-Things |

| IoT | Internet-of-Things |

| IT/OT | Information Technology/Operational Technology |

| LF | Learning Factory |

| LiFi | Light Fidelity |

| M2M | Machine-to-Machine |

| M2H | Machine-to-Human |

| MES | Manufacturing Execution System |

| MQTT | Message Queuing Telemetry Transport |

| MR | Mixed Reality |

| MV | Machine Vision |

| OPU UA | Open Platform Communications Unified Architecture |

| PDM | Product Data Management |

| RFID | Radio Frequency Identification |

| ROS | Robotic Operation System |

| TCP/IP | Transmission Control Protocol/Internet Protocol |

| USB | Universal Serial Bus |

| VR | Virtual Reality |

| VNC | Virtual Network Computing |

| Wi-Fi | Wireless Fidelity |

Appendix A

| Technology Group | No. of Articles | Linked Industry 4 Design Principles | Key Challenges | References |

|---|---|---|---|---|

| Cyber-physical Systems (CPS/CPPS) | 28 | Interconnection | Lack of awareness; Technical difficulty; Process complexity. | [2,4,6,7,8,10,15,16,17,18,24,35,37,41,47,49,80,84,93,96,115,117,118,119,140,157,158,166] |

| Industrial IoT (IoT/IIoT) | 26 | Interconnection | Technical difficulty. | [5,17,35,39,40,41,42,54,59,68,78,83,93,111,118,119,134,138,140,151,152,156,157,158,159,166] |

| Digital Twin (DT) | 18 | Information transparency | Lack of awareness; Technical difficulty. | [12,17,32,36,45,60,62,67,98,120,129,131,133,136,137,138,139,140] |

| Advanced Robotics | 20 | Technical assistance | Lack of awareness; Resource limitation. | [3,7,8,9,11,13,47,49,53,60,61,64,86,97,119,129,136,137,166,167] |

| Additive Manufacturing (AM) | 5 | Technical assistance | Resource limitation. | [51,69,97,111,140] |

| Mixed Reality (AR/VR) | 15 | Information transparency | Technical difficulty; Resource limitation. | [14,66,86,87,104,131,141,142,143,144,145,146,147,149] |

| Big Data Analytics | 12 | Decentralised decisions | Technical difficulty; Resource limitation. | [2,47,63,68,107,110,111,112,139,141,150,153] |

| Machine Vision (MV) | 5 | Technical assistance | Technical difficulty; Resource limitation. | [37,55,56,60,160] |

Appendix B

| Metric | Operational Definition with Example |

|---|---|

| Depth | A technology will be rated as 5 if it was discussed with architecture diagrams, detailed workflows, and performance data, e.g., the article [3] comprehensively discussed the details of establishing a robotic assembly cell to achieve a flexible assembly strategy. In contrast, a technology will be rated as 1 if it was only mentioned with conceptual ideas, instead of practical implementation details, e.g., all articles that mentioned 3D printing technology did not reveal technical details for the implementation. Numbers between 1 and 5 can be decided with qualitative analysis proportionally. |

| Breadth | A technology will be rated as 5 if it was discussed with different applications more than five times, e.g., DT has been discussed for the application of operational management [12,67], real-time monitoring [17], production virtualisation [32], pedagogical activity enhancement [45], virtual commissioning [60,62], production assistance [98], and more. In contrast, a technology will be rated as 1 if it was only mentioned with one application, e.g., AM technology was mentioned for two applications in the related articles, including rapid prototype and integration demonstration. So, the breadth for AM was rated as 2. Numbers between 1 and 5 can be decided with qualitative analysis proportionally. |

| Frequency | This metric refers to the proportion of a certain technology that is discussed in all the reviewed articles. It can be calculated by dividing the number of technology-related articles by the number of total articles reviewed, e.g., there are 14 articles that are related to mixed reality (AR and VR). Thus, the frequency equates to 14 over 145, which is 9.7%. |

| Technology Group | No. of Articles | Depth (1–5) | Breadth (1–5) | Frequency (0–100%) | TSn | Maturity Level |

|---|---|---|---|---|---|---|

| Cyber–physical Systems (CPS/CPPS) | 28 | 5 | 5 | 19.3% | 1 | High |

| Industrial IoT (IoT/IIoT) | 26 | 5 | 5 | 17.9% | 0.927 | High |

| Digital Twin (DT) | 18 | 4 | 5 | 12.4% | 0.508 | Medium |

| Advanced Robotics | 20 | 5 | 5 | 13.8% | 0.712 | Medium-High |

| Additive Manufacturing (AM) | 5 | 1 | 2 | 3.4% | 0 | Low |

| Mixed Reality (AR/VR) | 15 | 3 | 4 | 9.7% | 0.25 | Medium-Low |

| Big Data Analytics | 12 | 3 | 3 | 8.3% | 0.11 | Low |

| Machine Vision (MV) | 5 | 2 | 3 | 3.4% | 0.029 | Low |

| Technology Group | Technical Complexity (1–5) | Skills and Expertise (1–5) | Cost and Resource Intensity (1–5) | Total Score (TS) | TSn | Relative Deployment Difficulty |

|---|---|---|---|---|---|---|

| Cyber–physical Systems (CPS/CPPS) | 5 | 5 | 4 | 14 | 1 | High |

| Industrial IoT (IoT/IIoT) | 4 | 4 | 3 | 11 | 0.5 | Medium |

| Digital Twin (DT) | 4 | 5 | 3 | 12 | 0.667 | Medium-High |

| Advanced Robotics | 3 | 4 | 4 | 11 | 0.5 | Medium |

| Additive Manufacturing (AM) | 2 | 3 | 5 | 10 | 0.33 | Medium-Low |

| Mixed Reality (AR/VR) | 3 | 3 | 2 | 8 | 0 | Low |

| Big Data Analytics | 4 | 4 | 2 | 10 | 0.33 | Medium-Low |

| Machine Vision (MV) | 3 | 4 | 3 | 10 | 0.33 | Medium-Low |

Appendix C

| Publication Type | Percentage | |

|---|---|---|

| Peer-reviewed journal | Impact factor > 2: | 6.21% |

| Other: | 48.96% | |

| Peer-reviewed conference proceedings | 44.14% | |

| Book/book chapter | 0.69% | |

| Total | 100% | |

| Publication Country | Percentage |

|---|---|

| Germany | 33% |

| Austria | 9% |

| Canada | 8% |

| Other country | 50% |

| Total | 100% |

| Publication Source | Percentage |

|---|---|

| Procedia Manufacturing | 35.2% |

| Conference on Learning Factories | 26.9% |

| Other sources | 37.9% |

| Total | 100% |

References

- Schwab, K. The Fourth Industrial Revolution; World Economic Forum: Geneva, Switzerland, 2016; pp. 11–17. [Google Scholar]

- Seitz, K.F.; Nyhuis, P. Cyber-physical production systems combined with logistic models—A learning factory concept for an improved production planning and control. Procedia CIRP 2015, 32, 92–97. [Google Scholar] [CrossRef]

- Jin, Z.; Marian, R.M.; Chahl, J.S. Achieving batch-size-of-one production model in robot flexible assembly cells. Int. J. Adv. Manuf. Technol. 2023, 126, 2097–2116. [Google Scholar] [CrossRef]

- Schuhmacher, J.; Hummel, V. Decentralized control of logistic processes in cyber-physical production systems at the example of ESB logistics learning factory. Procedia CIRP 2016, 54, 19–24. [Google Scholar] [CrossRef]

- Gronau, N.; Ullrich, A.; Teichmann, M. Development of the industrial IoT competences in the areas of organization, process, and interaction based on the learning factory concept. Procedia Manuf. 2017, 9, 254–261. [Google Scholar] [CrossRef]

- Faller, C.; Feldmüller, D. Industry 4.0 learning factory for regional SMEs. Procedia CIRP 2015, 32, 88–91. [Google Scholar] [CrossRef]

- Gräßler, I.; Pöhler, A.; Pottebaum, J. Creation of a learning factory for cyber physical production systems. Procedia CIRP 2016, 54, 107–112. [Google Scholar] [CrossRef]

- Borangiu, T.; Răileanu, S.; Anton, F.; Iacob, I.; Anton, S. A systems engineering-oriented learning factory for Industry 4.0. In International Workshop on Service Orientation in Holonic and Multi-Agent Manufacturing; Borangiu, T., Trentesaux, D., Leitão, P., Eds.; Springer: Cham, Switzerland, 2022; Volume 1083, pp. 233–253. [Google Scholar]

- Aljinovic, A.; Crnjac, M.; Nikola, G.; Mladineo, M.; Basic, A.; Ivica, V. Integration of the human-robot system in the learning factory assembly process. Procedia Manuf. 2020, 45, 158–163. [Google Scholar] [CrossRef]

- Merkel, L.; Atug, J.; Merhar, L.; Schultz, C.; Braunreuther, S.; Reinhart, G. Teaching smart production: An insight into the learning factory for cyber-physical production systems (LVP). Procedia Manuf. 2017, 9, 269–274. [Google Scholar] [CrossRef]

- Mourtzis, D.; Angelopoulos, J.; Dimitrakopoulos, G. Design and development of a flexible manufacturing cell in the concept of learning factory paradigm for the education of generation 4.0 engineers. Procedia Manuf. 2020, 45, 361–366. [Google Scholar] [CrossRef]

- Küsters, D.; Praß, N.; Gloy, Y.S. Textile learning factory 4.0—Preparing Germany’s textile industry for the digital future. Procedia Manuf. 2017, 9, 214–221. [Google Scholar] [CrossRef]

- Jin, Z.; Marian, R.M.; Chahl, J.S. A new redundancy strategy for enabling graceful degradation in resilient robotic flexible assembly cells. Int. J. Adv. Manuf. Technol. 2024, 131, 3695–3711. [Google Scholar] [CrossRef]

- Eder, M.; Hulla, M.; Mast, F.; Ramsauer, C. On the application of augmented reality in a learning factory working environment. Procedia Manuf. 2020, 45, 7–12. [Google Scholar] [CrossRef]

- Simons, S.; Abé, P.; Neser, S. Learning in the AutFab—The fully automated Industrie 4.0 learning factory of the University of Applied Sciences Darmstadt. Procedia Manuf. 2017, 9, 81–88. [Google Scholar] [CrossRef]

- Zarte, M.; Pechmann, A. Implementing an energy management system in a learning factory—A project-based learning approach. Procedia Manuf. 2020, 45, 72–77. [Google Scholar] [CrossRef]

- Wank, A.; Adolph, S.; Anokhin, O.; Arndt, A.; Anderl, R.; Metternich, J. Using a learning factory approach to transfer Industrie 4.0 approaches to small- and medium-sized enterprises. Procedia CIRP 2016, 54, 89–94. [Google Scholar] [CrossRef]

- Leal, L.F.; Fleury, A.; Zancul, E. Starting up a Learning Factory focused on Industry 4.0. Procedia Manuf. 2020, 45, 436–441. [Google Scholar] [CrossRef]

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Oztemel, E.; Gursev, S. Literature review of Industry 4.0 and related technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Hermann, M.; Pentek, T.; Otto, B. Design principles for industrie 4.0 scenarios. In Proceedings of the 2016 49th Hawaii International Conference on System Sciences (HICSS), Koloa, HI, USA, 5–8 January 2016; pp. 3928–3937. [Google Scholar]

- Gilchrist, A. Introducing Industry 4.0. In Industry 4.0: The Industrial Internet of Things; Apress: Berkeley, CA, USA, 2016; pp. 195–215. [Google Scholar]

- Gökalp, E.; Şener, U.; Eren, P.E. Development of an assessment model for Industry 4.0: Industry 4.0-MM. In Software Process Improvement and Capability Determination: 17th International Conference, SPICE 2017, Palma de Mallorca, Spain, 4–5 October 2017; Mas, A., Mesquida, A., O’Connor, R., Rout, T., Dorling, A., Eds.; Springer International Publishing: Cham, Switzerland, 2017; Volume 770, pp. 128–142. [Google Scholar]

- Wengle, M.; Dalm, K.; Sahuji, R. Implementation of a Prototype Production Line based on concept of Industrial Digitalization in an existing Learning Factory environment. In Proceedings of the 13th Conference on Learning Factories (CLF 2023), Reutlingen, Germany, 9–11 May 2023. [Google Scholar]

- Zarte, M.; Wermann, J.; Heeren, P.; Pechmann, A. Concept, challenges, and learning benefits developing an Industry 4.0 learning factory with student projects. In Proceedings of the 2019 IEEE 17th International Conference on Industrial Informatics (INDIN), Helsinki, Finland, 22–25 July 2019; pp. 1133–1138. [Google Scholar]

- Schallock, B.; Rybski, C.; Jochem, R.; Kohl, H. Learning Factory for Industry 4.0 to provide future skills beyond technical training. Procedia Manuf. 2018, 23, 27–32. [Google Scholar] [CrossRef]

- Öztürk, E.; Hulla, M.; Prinz, C.; Kuhlenkötter, B.; Ramsauer, C. Digital transformation methods in learning factory based trainings. In Proceedings of the 12th Conference on Learning Factories (CLF 2022), Singapore, 11–13 April 2022. [Google Scholar]

- Behrendt, F.; Lehner, O.; Rettmann, A.; Schmidtke, N.; Wollert, T. Process analysis of a teaching and learning factory environment to demonstrate Industry 4.0 solutions by using the Smart Logistics Zone approach. In Proceedings of the 2022 IEEE 6th International Conference on Logistics Operations Management (GOL), Strasbourg, France, 29 June–1 July 2022; pp. 1–10. [Google Scholar]

- Dao, S.D.; Abhary, K.; Marian, R. Optimisation of partner selection and collaborative transportation scheduling in virtual enterprises using GA. Expert Syst. Appl. 2014, 41, 6701–6717. [Google Scholar] [CrossRef]

- Buergin, J.; Minguillon, F.E.; Wehrle, F.; Haefner, B.; Lanza, G. Demonstration of a concept for scalable automation of assembly systems in a learning factory. Procedia Manuf. 2017, 9, 33–40. [Google Scholar] [CrossRef]

- Nelson, S.X.; Khumbulani, M.; Innocent, R.B.; Aziz, C.; Thabiso, M.; Sinenhlanhla, N.; Thierry, Y. Development of a 3D interactive training platform for assembly of bogie unit in the railcar learning factory. Procedia Manuf. 2020, 45, 386–391. [Google Scholar] [CrossRef]

- Grube, D.; Malik, A.A.; Bilberg, A. SMEs can touch Industry 4.0 in the smart learning factory. Procedia Manuf. 2019, 31, 219–224. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Kaliszewski, N.; Marian, R.; Chahl, J. A reliability centred maintenance-oriented framework for modelling, evaluating, and optimising complex repairable flow networks. Complex Intell. Syst. 2025, 11, 223. [Google Scholar] [CrossRef]

- Elbestawi, M.; Centea, D.; Singh, I.; Wanyama, T. SEPT learning factory for Industry 4.0 education and applied research. Procedia Manuf. 2018, 23, 249–254. [Google Scholar] [CrossRef]

- Ralph, B.J.; Schwarz, A.; Stockinger, M. An implementation approach for an academic learning factory for the metal forming industry with special focus on digital twins and finite element analysis. Procedia Manuf. 2020, 45, 253–258. [Google Scholar] [CrossRef]

- Kumar, R.; Patil, O.; Nath, K.; Sangwan, K.S.; Kumar, R. A machine vision-based cyber-physical production system for energy efficiency and enhanced teaching-learning using a learning factory. Procedia CIRP 2021, 98, 424–429. [Google Scholar] [CrossRef]

- Kim, J.W.; Park, J.S.; Kim, S.K. Application of FlexSim software for developing cyber learning factory for smart factory education and training. Multimed. Tools Appl. 2020, 79, 16281–16297. [Google Scholar] [CrossRef]

- Louw, L.; Walker, M. Design and implementation of a low cost RFID track and trace system in a learning factory. Procedia Manuf. 2018, 23, 255–260. [Google Scholar] [CrossRef]

- Mladineo, M.; Veza, I.; Gjeldum, N.; Crnjac, M.; Aljinovic, A.; Basic, A. Integration and testing of the RFID-enabled Smart Factory concept within the Learning Factory. Procedia Manuf. 2019, 31, 384–389. [Google Scholar] [CrossRef]

- Centea, D.; Singh, I.; Elbestawi, M. SEPT approaches for education and training using a learning factory. Procedia Manuf. 2019, 31, 109–115. [Google Scholar] [CrossRef]

- Singh, I.; Centea, D.; Elbestawi, M. IoT, IIoT and cyber-physical systems integration in the SEPT learning factory. Procedia Manuf. 2019, 31, 116–122. [Google Scholar] [CrossRef]

- Baena, F.; Guarin, A.; Mora, J.; Sauza, J.; Retat, S. Learning factory: The path to Industry 4.0. Procedia Manuf. 2017, 9, 73–80. [Google Scholar] [CrossRef]

- Darun, M.R.; Al Adresi, A.; Turi, J.A.; Ghazali, M. Integrating blockchain technology for air purifier production system at FIM learning factory. Int. J. Control Autom. 2020, 13, 1112–1117. [Google Scholar]

- Rasovska, I.; Deniaud, I.; Marmier, F.; Michalak, J.L. Learning factory FleXtory: Interactive loops between real and virtual factory through digital twin. IFAC-PapersOnLine 2022, 55, 1938–1943. [Google Scholar] [CrossRef]

- de Albuquerque Felizola Romeral, P.A.; Leal, L.F.; Zancul, E. Mass customization demonstrator at an Industry 4.0 Learning Factory. In Proceedings of the 11th Conference on Learning Factories (CLF 2021), Graz, Austria, 1–2 July 2021. [Google Scholar]

- Louw, L. A Learning Factory Teaching Framework and Technology Demonstrator for Robotic Process Automation Application in Cyber-Physical Production Systems. In Proceedings of the 13th Conference on Learning Factories (CLF 2023), Reutlingen, Germany, 9–11 May 2023. [Google Scholar]

- Lindner, F.; Winkler, D.; Mühlan, K.; Wendt, U.; Keil, S. Learn to shape the digital transformation: The design approach of a learning factory for industrial engineers. In Proceedings of the 11th Conference on Learning Factories (CLF 2021), Graz, Austria, 1–2 July 2021. [Google Scholar]

- Kemény, Z.; Beregi, R.; Nacsa, J.; Kardos, C.; Horváth, D. Human–robot collaboration in the MTA SZTAKI learning factory facility at Győr. Procedia Manuf. 2018, 23, 105–110. [Google Scholar] [CrossRef]

- Hennig, M.; Reisinger, G.; Trautner, T.; Hold, P.; Gerhard, D.; Mazak, A. TU Wien pilot factory Industry 4.0. Procedia Manuf. 2019, 31, 200–205. [Google Scholar] [CrossRef]

- Centea, D.; Singh, I.; Yakout, M.; Boer, J.; Elbestawi, M. Opportunities and challenges in integrating additive manufacturing in the SEPT learning factory. Procedia Manuf. 2020, 45, 108–113. [Google Scholar] [CrossRef]

- Ahmad, M.H.; Moshood, T.D.; Nawanir, G. The influence of Industrial Revolution 4.0 in the implementation of the learning factory at the University of Malaysia Pahang. J. Appl. Res. High. Educ. 2024, 16, 89–103. [Google Scholar] [CrossRef]

- Ogbemhe, J.; Mpofu, K.; Tlale, N.; Ramatsetse, B. Application of robotics in rail car manufacturing learning factory: A case of welding complex joints. Procedia Manuf. 2019, 31, 316–322. [Google Scholar] [CrossRef]

- Perdana, R.H.Y.; Hidayati, N.; Yulianto, A.W.; Firdaus, V.A.H.; Sari, N.N.; Suprianto, D. Jig detection using scanning method base on internet of things for smart learning factory. In Proceedings of the 2020 IEEE International IOT, Electronics and Mechatronics Conference (IEMTRONICS), Vancouver, BC, Canada, 9–12 September 2020; pp. 1–5. [Google Scholar]

- Louw, L.; Droomer, M. Development of a low cost machine vision based quality control system for a learning factory. Procedia Manuf. 2019, 31, 264–269. [Google Scholar] [CrossRef]

- Zancul, E.; Martins, H.O.; Lopes, F.P.; da Silva Neto, F.A. Machine vision applications in a learning factory. Procedia Manuf. 2020, 45, 516–521. [Google Scholar] [CrossRef]

- Woldesemayat, W.; Hartmann, M. PV Technology-driven Learning Factory at Addis Ababa University Institute of Technology for Sustainable Engineering. In Proceedings of the 13th Conference on Learning Factories (CLF 2023), Reutlingen, Germany, 9–11 May 2023. [Google Scholar]

- Lang, S.; Reggelin, T.; Jobran, M.; Hofmann, W. Towards a modular, decentralized and digital Industry 4.0 learning factory. In Proceedings of the 2018 Sixth International Conference on Enterprise Systems (ES), Limassol, Cyprus, 1–2 October 2018; pp. 123–128. [Google Scholar]

- Centea, D.; Singh, I.; Boer, J. RFID in manufacturing: An implementation case in the SEPT learning factory. Procedia Manuf. 2020, 51, 543–548. [Google Scholar] [CrossRef]

- Schlette, C.; Buch, A.G.; Hagelskjær, F.; Iturrate, I.; Kraft, D.; Kramberger, A.; Lindvig, A.P.; Mathiesen, S.; Petersen, H.G.; Rasmussen, M.H.; et al. Towards robot cell matrices for agile production—SDU Robotics’ assembly cell at the WRC 2018. Adv. Robot. 2020, 34, 422–438. [Google Scholar] [CrossRef]

- Protic, A.; Jin, Z.; Marian, R.; Abd, K.; Campbell, D.; Chahl, J. Development of a novel control approach for collaborative robotics in i4 intelligent flexible assembling cells. In Proceedings of the 2020 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 12–14 December 2020; pp. 974–978. [Google Scholar]

- Protic, A.; Jin, Z.; Marian, R.; Abd, K.; Campbell, D.; Chahl, J. Implementation of a bi-directional digital twin for Industry 4 labs in academia: A solution based on OPC UA. In Proceedings of the 2020 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 12–14 December 2020; pp. 979–983. [Google Scholar]

- Zhang, W.; Cai, W.; Min, J.; Fleischer, J.; Ehrmann, C.; Prinz, C.; Kreimeier, D. 5G and AI technology application in the AMTC learning factory. Procedia Manuf. 2020, 45, 66–71. [Google Scholar] [CrossRef]

- Schulz, T.; Liu, S.; Peukert, C.; Toreini, P.; Maedche, A.; Weinhardt, C. An Immersive ‘Proto Learning Factory’ Concept for Teaching AI Competencies. In Proceedings of the 13th Conference on Learning Factories (CLF 2023), Reutlingen, Germany, 9–11 May 2023. [Google Scholar]

- Zarte, M.; Pechmann, A. Educational Concept and Application of Problem-Based Learning Using a Virtual Learning Factory. In Proceedings of the 12th Conference on Learning Factories (CLF 2022), Singapore, 11–13 April 2022. [Google Scholar]

- Mourtzis, D.; Siatras, V.; Angelopoulos, J.; Panopoulos, N. An augmented reality collaborative product design cloud-based platform in the context of learning factory. Procedia Manuf. 2020, 45, 546–551. [Google Scholar] [CrossRef]

- Brenner, B.; Hummel, V. Digital twin as enabler for an innovative digital shopfloor management system in the ESB Logistics Learning Factory at Reutlingen-University. Procedia Manuf. 2017, 9, 198–205. [Google Scholar] [CrossRef]

- Centea, D.; Singh, I.; Wanyama, T.; Magolon, M.; Boer, J.; Elbestawi, M. Using the SEPT learning factory for the implementation of Industry 4.0: Case of SMEs. Procedia Manuf. 2020, 45, 102–107. [Google Scholar] [CrossRef]

- Dalm, K.; Sahuji, R. Industrial Digitalization for Society—A Learning Factory Concept based on Four Pillars. In Proceedings of the 11th Conference on Learning Factories (CLF 2021), Graz, Austria, 1–2 July 2021. [Google Scholar]

- Gillani, S.A.; Abbasi, R.; Martinez, P.; Ahmad, R. Ontology-based Interactive Learning Approach for Transdisciplinary Teaching in Learning Factory. In Proceedings of the 12th Conference on Learning Factories (CLF 2022), Singapore, 11–13 April 2022. [Google Scholar]

- Savchenko, I.; Novotny, P.; Fleck, H.; Ropin, H. Learning Factory Concept for Technical and Economic Education: An I4.0 Solution with the Micro Factory Festo Mps404. In Proceedings of the 12th Conference on Learning Factories (CLF 2022), Singapore, 11–13 April 2022. [Google Scholar]

- Nixdorf, S.; Golec, M.; Hegedić, M.; Ansari, F. Work-Based Learning in South-East Europe: Example of a Learning Factory Industry 4.0 in Croatia. In Proceedings of the 13th Conference on Learning Factories (CLF 2023), Reutlingen, Germany, 9–11 May 2023. [Google Scholar]

- Oberc, H.; Reuter, M.; Wannöffel, M.; Kuhlenkötter, B. Development of a learning factory concept to train participants regarding digital and human centered decision support. Procedia Manuf. 2018, 23, 165–170. [Google Scholar] [CrossRef]

- Petrusch, N.; Schumacher, B.; Schwiethal, A.; Kohl, H. Evaluation of a Level-Based Industry 4.0 Competency Model by the Example of an Internationally Distributed Learning Factory. In Proceedings of the 11th Conference on Learning Factories (CLF 2021), Graz, Austria, 1–2 July 2021. [Google Scholar]

- Hulla, M.; Herstätter, P.; Sadaj, E.A.; Ramsauer, C. Procedure Model for the Configuration of Learning Factory-Based Training Modules to Promote the Digital Transformation in SMEs. In Proceedings of the 12th Conference on Learning Factories (CLF 2022), Singapore, 11–13 April 2022. [Google Scholar]

- Prasad, M.M.; Vijay, S.; Sutharsan, S.M. A conceptual approach for developing Industry 4.0 learning factory for Indian SMEs. Mater. Today Proc. 2020, 33, 2936–2939. [Google Scholar] [CrossRef]

- Hulla, M.; Herstätter, P.; Holly, M.; Brettschuh, S.; Pirker, J.; Wolf, M.; Ramsauer, C. Interdisciplinary Communication Training in a Learning Factory Environment to Enforce the Digital Transformation in Producing SMEs. In Proceedings of the 13th Conference on Learning Factories (CLF 2023), Reutlingen, Germany, 9–11 May 2023. [Google Scholar]

- Grøn, H.; Lassen, A.H.; Madsen, O.; ElMaraghy, H. Decision-making Learning Factory for SMEs via IIoT. In Proceedings of the 13th Conference on Learning Factories (CLF 2023), Reutlingen, Germany, 9–11 May 2023. [Google Scholar]

- Fink, K.; Sochor, R.; König, M.; Merkel, L.; Berg, J.; Reinhart, G. Dynamic value stream optimization for manual assembly in the learning factory for cyber-physical production systems. Procedia Manuf. 2020, 45, 78–83. [Google Scholar] [CrossRef]

- Brüggemann, H.; Stempin, S.; Meier, J.M. Consideration of digitalization for the purpose of resource efficiency in a learning factory. Procedia Manuf. 2020, 45, 140–145. [Google Scholar] [CrossRef]

- Wienbruch, T.; Leineweber, S.; Kreimeier, D.; Kuhlenkötter, B. Evolution of SMEs towards Industrie 4.0 through a scenario based learning factory training. Procedia Manuf. 2018, 23, 141–146. [Google Scholar] [CrossRef]

- Gyulai, T.; Wolf, P.; Kása, F.; Viharos, Z.J. Operational Structure for an Industry 4.0 oriented Learning Factory. In Proceedings of the 18th IMEKO TC10 Conference on Measurement for Diagnostics, Optimisation and Control to Support Sustainability and Resilience, Warsaw, Poland, 26–27 September 2022. [Google Scholar]

- Tan, H.S.; Oktarina, R.; Reynaldo, V.; Sharina, C. Conceptual development of learning factory for industrial engineering education in Indonesia context as an enabler of students’ competencies in Industry 4.0 era. IOP Conf. Ser. Earth Environ. Sci. 2019, 4426, 012123. [Google Scholar] [CrossRef]

- Merkel, L.; Atug, J.; Berger, C.; Braunreuther, S.; Reinhart, G. Mass customization and paperless assembly in the learning factory for cyber-physical-production systems: Learning module ‘from paperbased to paperless assembly’. In Proceedings of the 2018 IEEE 18th International Conference on Advanced Learning Technologies (ICALT), Mumbai, India, 9–13 July 2018; pp. 270–271. [Google Scholar]

- Meissner, A.; Müller, M.; Hermann, A.; Metternich, J. Digitalization as a catalyst for lean production: A learning factory approach for digital shop floor management. Procedia Manuf. 2018, 23, 81–86. [Google Scholar] [CrossRef]

- Sievers, T.S.; Neumann, F.; Tracht, K. Augmented virtuality in a digital learning factory for collaborative robotics. In Proceedings of the 11th Conference on Learning Factories (CLF 2021), Graz, Austria, 1–2 July 2021. [Google Scholar]

- Riemann, T.; Kreß, A.; Roth, L.; Metternich, J.; Grell, P. User-oriented design of virtual reality supported learning factory trainings: Methodology for the generation of suitable design elements. In Proceedings of the 11th Conference on Learning Factories (CLF 2021), Graz, Austria, 1–2 July 2021. [Google Scholar]

- Prinz, C.; Morlock, F.; Freit, S.; Kreggenfeld, N.; Kreimeier, D.; Kuhlenkötter, B. Learning factory modules for smart factories in Industrie 4.0. Procedia CIRP 2016, 54, 113–118. [Google Scholar] [CrossRef]

- Ast, J.; Möhle, J.; Bleckmann, M.; Nyhuis, P. Preliminary Study in a Learning Factory on Functional Flexibility of the Workforce. In Proceedings of the 12th Conference on Learning Factories (CLF 2022), Singapore, 11–13 April 2022. [Google Scholar]

- Cañas, H.; Mula, J.; Díaz-Madroñero, M.; Campuzano-Bolarín, F. Implementing Industry 4.0 principles. Comput. Ind. Eng. 2021, 158, 107379. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Prashar, A.; Carim, G., Jr.; Mostafa, S.; Barros, A.; Lima, R.M.; Hines, P. Organizational culture and Industry 4.0 design principles: An empirical study on their relationship. Prod. Plan. Control 2024, 35, 1263–1277. [Google Scholar] [CrossRef]

- Semeraro, C.; Alyousuf, N.; Kedir, N.I. A maturity model for evaluating the impact of Industry 4.0 technologies and principles in SMEs. Manuf. Lett. 2023, 37, 61–65. [Google Scholar] [CrossRef]

- Athinarayanan, R.; Newell, B.; Garcia, J.; Ostanek, J.; Diao, X.; Sundararajan, R.; Zhang, H.; Richards, G. Learning in context with horizontally & vertically integrated curriculum in a smart learning factory. Procedia Manuf. 2019, 31, 91–96. [Google Scholar] [CrossRef]

- Dikhanbayeva, D.; Shaikholla, S.; Suleiman, Z.; Turkyilmaz, A. Assessment of Industry 4.0 maturity models by design principles. Sustainability 2020, 12, 9927. [Google Scholar] [CrossRef]

- Habib, M.K.; Chimsom, C. Industry 4.0: Sustainability and design principles. In Proceedings of the 2019 20th International Conference on Research and Education in Mechatronics (REM), Wels, Austria, 23–24 May 2019; pp. 1–8. [Google Scholar]

- Sackey, S.M.; Bester, A.; Adams, D. Industry 4.0 learning factory didactic design parameters for industrial engineering education in South Africa. S. Afr. J. Ind. Eng. 2017, 28, 114–124. [Google Scholar] [CrossRef]

- Atmojo, U.D. Project-based Learning at Aalto Factory of the Future—A Flexible Production-based Industrie 4.0 Learning Factory. In Proceedings of the 11th Conference on Learning Factories (CLF 2021), Graz, Austria, 1–2 July 2021. [Google Scholar]

- Umeda, Y.; Goto, J.; Hongo, Y.; Shirafuji, S.; Yamakawa, H.; Kim, D.; Ota, J.; Matsuzawa, H.; Sukekawa, T.; Kojima, F.; et al. Developing a digital twin learning factory of automated assembly based on ‘digital triplet’ concept. In Proceedings of the 11th Conference on Learning Factories (CLF 2021), Graz, Austria, 1–2 July 2021. [Google Scholar]

- Bao, Y.; Zhang, W.; Jia, Z. 5G-based Cloud Learning Factory in AMTC. In Proceedings of the 12th Conference on Learning Factories (CLF 2022), Singapore, 11–13 April 2022. [Google Scholar]

- Vaidya, S.; Ambad, P.; Bhosle, S. Industry 4.0—A glimpse. Procedia Manuf. 2018, 20, 233–238. [Google Scholar] [CrossRef]

- Vogt, M.; Uhlig, B.; Sangwan, K.S.; Herrmann, C.; Thiede, S. Implementation of a cyber-physical cooling storage station in a learning factory. Procedia Manuf. 2019, 31, 142–147. [Google Scholar] [CrossRef]

- Semeraro, C.; Lezoche, M.; Panetto, H.; Dassisti, M. Digital twin paradigm: A systematic literature review. Comput. Ind. 2021, 130, 103469. [Google Scholar] [CrossRef]

- Vogt, L.; Pelzer, F.; Klose, A.; Khadyrov, V.; Lange, H.; Viedt, I.; Urbas, L.; Mädler, J. P2o-lab: A learning factory for digitalization and modularization. In Proceedings of the 13th Conference on Learning Factories (CLF 2023), Reutlingen, Germany, 9–11 May 2023. [Google Scholar]

- Marmier, F.; Rasovska, I.; Dubreuil, L.; Rose, B. Industry 4.0 Learning Factory: A canvas for specifications. In Proceedings of the 11th Conference on Learning Factories (CLF 2021), Graz, Austria, 1–2 July 2021. [Google Scholar]

- Schmid, J.; Pichler, R. Seamless data integration in the CAM-NC process chain in a learning factory. Procedia Manuf. 2020, 45, 31–36. [Google Scholar] [CrossRef]

- Cohen, Y.; Faccio, M.; Galizia, F.G.; Mora, C.; Pilati, F. Assembly system configuration through Industry 4.0 principles: The expected change in the actual paradigms. IFAC-PapersOnLine 2017, 50, 14958–14963. [Google Scholar] [CrossRef]

- Erdmann, J.G.; Hummela, V.; von Leipzig, K.; Schuhmacher, J. Development and implementation of an autonomous control system for target-optimised use of intralogistics transport systems in the Learning Factory Werk 150 at Reutlingen University. Procedia Manuf. 2020, 45, 405–410. [Google Scholar] [CrossRef]

- Li, L.; Lei, B.; Mao, C. Digital twin in smart manufacturing. J. Ind. Inf. Integr. 2022, 26, 100289. [Google Scholar] [CrossRef]

- Singh, M.; Srivastava, R.; Fuenmayor, E.; Kuts, V.; Qiao, Y.; Murray, N.; Devine, D. Applications of Digital Twin across Industries: A Review. Appl. Sci. 2022, 12, 5727. [Google Scholar] [CrossRef]

- Yang, S.; Liu, H.; Zhang, Y.; Arndt, T.; Hofmann, C.; Häfner, B.; Lanza, G. A data-driven approach for quality analytics of screwing processes in a global learning factory. Procedia Manuf. 2020, 45, 454–459. [Google Scholar] [CrossRef]

- Daniyan, I.; Mpofu, K.; Ramatsetse, B.; Muvunzi, R. Implementation of Digital Technology for Enhancing the Performance of the Rail Industry: A Learning Factory Approach. In Proceedings of the 13th Conference on Learning Factories (CLF 2023), Reutlingen, Germany, 9–11 May 2023. [Google Scholar]

- Yang, R.; Zhang, W.; Cai, W.; Xie, S.; Ehrmann, C. Machine tools’ running state monitoring in the learning factory—Based on machine learning method and vibration data. In Proceedings of the 11th Conference on Learning Factories (CLF 2021), Graz, Austria, 1–2 July 2021. [Google Scholar]

- Ketenci, A.; Wolf, M.; Rüdele, K.; Ramsauer, C. Impact analysis of a teaching module in a learning factory environment regarding energy efficiency potentials. In Proceedings of the 12th Conference on Learning Factories (CLF 2022), Singapore, 11–13 April 2022. [Google Scholar]

- Mahmood, K.; Otto, T.; Kuts, V.; Terkaj, W.; Urgo, M.; Haidegger, G. Development of virtual learning Factory toolkit for production engineering education. IOP Conf. Series Mater. Sci. Eng. 2021, 1140, 012039. [Google Scholar] [CrossRef]

- Pichler, R.; Gerhold, L.; Pichler, M. Seamless data integration in a CPPS with highly heterogeneous facilities-architectures and use cases executed in a learning factory. In Proceedings of the 2020 IEEE International Conference on Industrial Cyber-Physical Systems (ICPS 2020), Tampere, Finland, 10–12 June 2020; pp. 1–10. [Google Scholar]

- Rokoss, A.; Schmidt, M. Using Digitalization as An Enabler for Changeability in Production Systems in A Learning Factory Environment. In Proceedings of the 2nd Conference on Production Systems and Logistics (CPSL 2021), Hannover, Germany, 10–11 August 2021. [Google Scholar]

- Cimini, C.; Freti, E.; Lagorio, A. Design and test of a Human-Machine Interface for assembly lines in a learning factory. IFAC-PapersOnLine 2024, 58, 73–78. [Google Scholar] [CrossRef]

- de Paula Ferreira, W.; Palaniappan, A.; Armellini, F.; de Santa-Eulalia, L.A.; Mosconi, E.; Marion, G. Linking Industry 4.0, learning factory and simulation: Testbeds and proof-of-concept experiments. In Artificial Intelligence in Industry 4.0: A Collection of Innovative Research Case-Studies that are Reworking the Way We Look at Industry 4.0 Thanks to Artificial Intelligence; Dingli, A., Haddod, F., Klüver, C., Eds.; Springer: Cham, Switzerland, 2021; Volume 928, pp. 85–96. [Google Scholar]

- Hänggi, R.; Nyffenegger, F.; Ehrig, F.; Jaeschke, P.; Bernhardsgrütter, R. Smart learning factory–network approach for learning and transfer in a digital & physical set up. In Proceedings of the 17th IFIP WG 5.1 International Conference (PLM 2020), Rapperswil, Switzerland, 5–8 July 2020; pp. 15–25. [Google Scholar]

- Li, F.; Yang, J.; Wang, J.; Li, S.; Zheng, L. Integration of digitization trends in learning factories. Procedia Manuf. 2019, 31, 343–348. [Google Scholar] [CrossRef]

- Louw, L.; Deacon, Q. Teaching Industrie 4.0 technologies in a learning factory through problem-based learning: Case study of a semi-automated robotic cell design. Procedia Manuf. 2020, 45, 265–270. [Google Scholar] [CrossRef]

- Ferreira, E.; Louw, L. Teaching Human-Centered Design of Collaborative Robot Cells in a Learning Factory: A Study on Workload, Trust and Usability. In Proceedings of the 14th Conference on Learning Factories (CLF 2024), Enschede, The Netherlands, 17–19 April 2024; pp. 233–240. [Google Scholar]

- Veza, I.; Mladineo, M.; Kutlesa, M.; Gjeldum, N.; Bilic, B.; Zizic, M.C.; Meštrović, A.A.; Basic, A. Selection of the Cobot Workstation for the Learning Factory by using the Multi-Criteria Analysis. In Proceedings of the 12th Conference on Learning Factories (CLF 2022), Singapore, 11–13 April 2022. [Google Scholar]

- Busachi, A.; Erkoyuncu, J.; Colegrove, P.; Martina, F.; Watts, C.; Drake, R. A review of Additive Manufacturing technology and Cost Estimation techniques for the defence sector. CIRP J. Manuf. Sci. Technol. 2017, 19, 117–128. [Google Scholar] [CrossRef]

- Hendea, R.E.; Raducanu, D.; Nocivin, A.; Ivanescu, S.; Stanciu, D.; Trisca-Rusu, C.; Campian, R.S.; Drob, S.I.; Cojocaru, V.D.; Gălbinașu, B.M. Laser Powder Bed Fusion Applied to a New Biodegradable Mg-Zn-Zr-Ca Alloy. Materials 2022, 15, 2561. [Google Scholar] [CrossRef]

- Nielsen, C.P.; Malik, A.A.; Hansen, D.G.; Bilberg, A. Low-cost 3D scanning in a smart learning factory. Procedia Manuf. 2019, 38, 824–831. [Google Scholar] [CrossRef]

- Hendea, R.E.; Raducanu, D.; Claver, A.; García, J.A.; Cojocaru, V.D.; Nocivin, A.; Stanciu, D.; Serban, N.; Ivanescu, S.; Trisca-Rusu, C.; et al. Biodegradable Magnesium Alloys for Personalised Temporary Implants. J. Funct. Biomater. 2023, 14, 400. [Google Scholar] [CrossRef]

- Raducanu, D.; Cojocaru, V.D.; Nocivin, A.; Hendea, R.E.; Ivanescu, S.; Stanciu, D.; Trisca-Rusu, C.; Serban, N.; Drob, S.I.; Campian, R.S. Microstructure Evolution during Mechanical Alloying of a Biodegradable Magnesium Alloy. Crystals 2022, 12, 1641. [Google Scholar] [CrossRef]

- Al-Geddawy, T. A digital twin creation method for an opensource low-cost changeable learning factory. Procedia Manuf. 2020, 51, 1799–1805. [Google Scholar] [CrossRef]

- Marian, R.; Campbell, D.; Jin, Z.; Stumptner, M.; Chahl, J. Critical infrastructure for Industry 4 laboratories and learning factories in academia. In Proceedings of the 2019 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Macau, China, 15–18 December 2019; pp. 556–560. [Google Scholar]

- Tvenge, N.; Ogorodnyk, O.; Østbø, N.P.; Martinsen, K. Added value of a virtual approach to simulation-based learning in a manufacturing learning factory. Procedia CIRP 2020, 88, 36–41. [Google Scholar] [CrossRef]

- Savchenko, I.; Ropin, H.; Novotny, P.; Fleck, H. Data Science for Business Engineers: Using a Digital Twin Learning Factory and Cloud Solutions for Education. In Proceedings of the 13th Conference on Learning Factories (CLF 2023), Reutlingen, Germany, 9–11 May 2023. [Google Scholar]

- Kuts, V.; Modoni, G.E.; Otto, T.; Sacco, M.; Tähemaa, T.; Bondarenko, Y.; Wang, R. Synchronizing physical factory and its digital twin through an IIoT middleware: A case study. Proc. Est. Acad. Sci. 2019, 68, 364–370. [Google Scholar] [CrossRef]

- Mukku, V.D.; Lang, S.; Reggelin, T. Integration of LiFi technology in an Industry 4.0 learning factory. Procedia Manuf. 2019, 31, 232–238. [Google Scholar] [CrossRef]

- Celar, S.; Turic, M.; Dragicevic, S.; Veza, I. Digital learning factory at FESB–University of Split. In Proceedings of the 22nd YU INFO Conference 2016, Kopaonik, Serbia, 28 February–2 March 2016; pp. 1–6. [Google Scholar]

- Grinshpun, G.; Cichon, T.; Dipika, D.; Rossmann, J. From virtual testbeds to real lightweight robots: Development and deployment of control algorithms for soft robots, with particular reference to. In Proceedings of the ISR 2016: 47th International Symposium on Robotics, Munich, Germany, 21–22 June 2016; pp. 1–7. [Google Scholar]

- Kousi, N.; Gkournelos, C.; Aivaliotis, S.; Giannoulis, C.; Michalos, G.; Makris, S. Digital twin for adaptation of robots’ behavior in flexible robotic assembly lines. Procedia Manuf. 2019, 28, 121–126. [Google Scholar] [CrossRef]

- Häfner, P.; Bergmann, V.; Häfner, V.; Michels, F.L.; Grethler, M.; Karande, A. An Adaptive Learning Environment for Industry 4.0 Competencies Based on a Learning Factory and Its Immersive Digital Twin. In Proceedings of the 16th International Conference on Computer Supported Education, ERSeGEL, Angers, France, 2–4 May 2024; Volume 1, pp. 720–731. [Google Scholar]

- Durão, L.F.C.; Morgado, M.; de Deus Lopes, R.; Zancul, E. Middle of life digital twin: Implementation at a learning factory. In Proceedings of the 17th IFIP WG 5.1 International Conference (PLM 2020), Rapperswil, Switzerland, 5–8 July 2020; pp. 116–127. [Google Scholar]

- Leal, L.F.; Zancul, E.; Schützer, K. Industry 4.0 learning factory phased development. In Proceedings of the 11th Conference on Learning Factories (CLF 2021), Graz, Austria, 1–2 July 2021. [Google Scholar]

- Liu, S.; Schulz, T.; Toreini, P.; Maedche, A. An Immersive Learning Factory for AI & Data Literacy: An Exploratory Study in the Wild. In Proceedings of the Mensch und Computer 2023, Zurich, Switzerland, 3–6 September 2023. [Google Scholar]

- Maganha, I.; Pereira, T.F.; Pugliese, L.F.; Santos, A.C.O.; Andersen, A.L. A Learning Factory for Teaching the Transition from Conventional to Industry 4.0 Based Systems. In Proceedings of the 8th Changeable, Agile, Reconfigurable and Virtual Production Conference (CARV2021) and the 10th World Mass Customization & Personalization Conference (MCPC2021), Aalborg, Denmark, 1–2 November 2021; pp. 903–910. [Google Scholar]

- Weidig, C.; Menck, N.; Winkes, P.A.; Aurich, J.C. Virtual learning factory on VR-supported factory planning. In Proceedings of the 15th IFIP WG 5.5 Working Conference on Virtual Enterprises (PRO-VE 2014), Amsterdam, The Netherlands, 6–8 October 2014; pp. 455–462. [Google Scholar]

- Xie, Y.; Zhang, W.; Jia, Z.; Zhao, L. VR-Based Learning Platform for the Application of BPP Classification in 5G Learning Factory. In Proceedings of the 14th Conference on Learning Factories (CLF 2024), Enschede, The Netherlands, 17–19 April 2024; pp. 71–78. [Google Scholar]

- Prell, B.; Günther, N.; Wilbers, S.; van de Sand, R.; Reiff-Stephan, J. Transfer of Industry 4.0 Knowledge to SME Employing the Concept of a Learning Factory as a Roadshow. In Proceedings of the 14th Conference on Learning Factories (CLF 2024), Enschede, The Netherlands, 17–19 April 2024; pp. 286–293. [Google Scholar]

- Terkaj, W.; Urgo, M.; Kovács, P.; Tóth, E.; Mondellini, M. A framework for virtual learning in industrial engineering education: Development of a reconfigurable virtual learning factory application. Virtual Real. 2024, 28, 148. [Google Scholar] [CrossRef]

- Bjørnsten, T.B.; Wade, T.J.; Nellemann, C.; Christiansen, L. Extending the Learning Factory Through Virtual Reality. In Proceedings of the 14th Conference on Learning Factories (CLF 2024), Enschede, The Netherlands, 17–19 April 2024; pp. 79–86. [Google Scholar]

- Aqlan, F.; Zhao, R.; Yang, H.; Ramakrishnan, S. A virtual learning factory for advanced manufacturing. In Proceedings of the 2021 Winter Simulation Conference (WSC 2021), Phoenix, AZ, USA, 12–15 December 2021. [Google Scholar]

- Olearczyk, J.; Juraschek, M.; Effner, B.; Herrmann, C. System Architecture for Extended Reality and Hybrid Learning Factory Environments. In Proceedings of the 14th Conference on Learning Factories (CLF 2024), Enschede, The Netherlands, 17–19 April 2024; pp. 169–177. [Google Scholar]

- Orozco, E.; Cárdenas, P.C.; López, J.A.; Rodriguez, C.K. Low-cost desktop learning factory to support the teaching of artificial intelligence. HardwareX 2024, 18, e00528. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, W.; Jia, Z. Energy management with VR/AR technology in 5G learning factory. In Proceedings of the 13th Conference on Learning Factories (CLF 2023), Reutlingen, Germany, 9–11 May 2023. [Google Scholar]

- Cano-Suñén, E.; Martínez, I.; Fernández, Á.; Zalba, B.; Casas, R. Internet of Things (IoT) in Buildings: A Learning Factory. Sustainability 2023, 15, 12219. [Google Scholar] [CrossRef]

- Daniyan, I.; Mpofu, K.; Oyesola, M.; Ramatsetse, B.; Adeodu, A. Artificial intelligence for predictive maintenance in the railcar learning factories. Procedia Manuf. 2020, 45, 13–18. [Google Scholar] [CrossRef]

- Centea, D.; Singh, I.; Gadhrri, A.; Hodgins, S.; Schmidt, R. Integration of Software and Hardware AI Learning Models in the SEPT Learning Factory. In Proceeding of the 14th International Conference on Interactive Mobile Communication Technologies and Learning (IMCL 2021), Thessaloniki, Greece, 4–5 November 2021; pp. 322–330. [Google Scholar]

- Munirathinam, S. Industry 4.0: Industrial internet of things (IIOT). Adv. Comput. 2020, 117, 129–164. [Google Scholar]

- Zhang, Y.; Poulsen, C.; Liu, C.; Salling, L.J.H. Designing of an AM Learning Factory Using Interactive Videos as a Didactic Approach. In Proceedings of the 14th Conference on Learning Factories (CLF 2024), Enschede, The Netherlands, 17–19 April 2024; pp. 21–27. [Google Scholar]

- Gjeldum, N.; Mladineo, M.; Crnjac, M.; Veza, I.; Aljinovic, A. Performance analysis of the RFID system for optimal design of the intelligent assembly line in the learning factory. Procedia Manuf. 2018, 23, 63–68. [Google Scholar] [CrossRef]

- Gotthardt, S.; Hulla, M.; Eder, M.; Karre, H.; Ramsauer, C. Digitalized milk-run system for a learning factory assembly line. Procedia Manuf. 2019, 31, 175–179. [Google Scholar] [CrossRef]

- Xie, S.; Zhang, W.; Fleischer, J.; Kuhlenkötter, B.; Ehrmann, C.; Prinz, C.; Jia, Z.; Cai, W. Learning Factory of 5G-based Plug-and-play Application in Manufacturing. In Proceedings of the 11th Conference on Learning Factories (CLF 2021), Graz, Austria, 1–2 July 2021. [Google Scholar]

- Li, K.; Zhang, W.; Jia, Z. Visualization of Machine Vision Design Process in 5G Learning Factory. In Proceedings of the 13th Conference on Learning Factories (CLF 2023), Reutlingen, Germany, 9–11 May 2023. [Google Scholar]

- Geronymo, G.M. Smart Lab: An application of Industry 4.0 design principles to calibration laboratories. J. Phys. Conf. Ser. 2021, 1826, 012027. [Google Scholar] [CrossRef]

- Scholz, J.A.; Sieckmann, F.; Kohl, H. Implementation with agile project management approaches: Case Study of an Industrie 4.0 Learning Factory in China. Procedia Manuf. 2020, 45, 234–239. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Marian, R.; Campbell, D.; Jin, Z.; Stumptner, M.; Chahl, J. Challenges in implementing industry 4 laboratories and learning factories in academia. In Proceedings of the 2019 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Macau, China, 15–18 December 2019; pp. 506–510. [Google Scholar]

- Widiaty, I.; Ana, A.; Abdullah, A.G.; Karyono, T.; Suciati, S.; Mubaroq, S.R.; Martawijaya, D.H. Cyber Physical System vs Learning Factory: Perspective of Industry 4.0-based curriculum development. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1098, 032004. [Google Scholar] [CrossRef]

- Centea, D.; Elbestawi, M.; Singh, I.; Wanyama, T. SEPT learning factory framework. In Proceedings of the 15th International Conference on Remote Engineering and Virtual Instrumentation, Düsseldorf, Germany, 21–23 March 2018; pp. 354–362. [Google Scholar]

- Lawrence, J.; Dimashkie, B.; Centea, D.; Singh, I. The learning factory: Self-directed project-based education. In Proceedings of the 9th International Conference on Interactive Collaborative and Blended Learning (ICBL2020), Ontario, Canada, 14–16 October 2020; pp. 114–122. [Google Scholar]

| Database | Boolean Strings | No. of Articles |

|---|---|---|

| SpringerLink | (“Learning Factory” OR “Testlab” OR “Learning Laboratory”) AND (“Industry 4” OR “Digital Twin” OR “Smart Factory” OR “CPS” OR “CPPS” OR “IoT” OR “IIoT” OR “Intelligent Manufacturing” OR “AI” OR “Machine Vision” OR AR OR VR OR 5G) | 325 |

| Scopus | TITLE-ABS-KEY ((“Learning Factory” OR “Testlab” OR “Learning Laboratory”) AND (“Industry 4” OR “Digital Transformation” OR “Digitisation” OR “Smart Factory” OR “Intelligent Manufacturing” OR “Digital Twin” OR “CPS” OR “CPPS” OR “IoT” OR “IIoT” OR “Intelligent Robotics” OR “Machine-to-Machine” OR “AI” OR “Cloud Computing”)) | 218 |

| Web of Science | TS = ((“Learning Factory” OR “Testlab” OR “Learning Laboratory”) AND (“Industry 4” OR “Digital Transformation” OR “Digitisation” OR “Smart Factory” OR “Intelligent Manufacturing” OR “Digital Twin” OR “CPS” OR “CPPS” OR “IoT” OR “IIoT” OR “Intelligent Robotics” OR “Machine-to-Machine” OR “AI” OR “Cloud Computing”)) | 120 |

| Industry 4 Design Principles | Industry 4 Technologies | Intentions |

|---|---|---|

| Interconnection | CPPS | Establishing the integrations and interoperability by interconnecting hardware and software components. |

| IIoT | Capturing raw production data in real time from smart sensors across the interconnected networks. | |

| Information transparency | DT | Visualising physical assets in a digitised context. Simulating production workflows and equipment behaviour. |

| MR | Visualising physical assets in a virtualised context. Providing valuable information in manufacturing processes for human operators. | |

| Decentralised decisions | Big data analytics | Providing optimal decisions in production processes. |

| Technical assistance | Advanced robotics | Advanced manipulators to replace human operators. Fulfilling autonomous intralogistics. |

| AM | Fabricating products with an extremely complex structure in one go. Achieving a prompt prototype in the product development process. | |

| MV | Monitoring production processes in real time. |

| Technology | Maturity Level | Deployment Difficulty | Remarks |

|---|---|---|---|

| Cyber–physical systems (CPS) | High | High | Critical integration demands; software–hardware complexity. |

| Industrial IoT (IIoT) | High | Medium | Wide use, but requires sensor interfacing and network configuration. |

| Digital twin (DT) | Medium | Medium-High | Bi-directional integration remains immature. |

| Mixed reality (AR/VR) | Medium-Low | Low | Strong training usage, but the costs of employment can be challenging. |

| Big data analytics | Low | Medium-Low | Toolsets are maturing, but the talent gap persists. |

| Advanced robotics | Medium-High | Medium | Widely employed, especially the cobots. |

| Additive manufacturing | Low | Medium-Low | Ideal for prototyping and student projects. |

| Machine vision | Low | Medium-Low | Requires AI model training; resource-intensive. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the International Institute of Knowledge Innovation and Invention. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, Z.; Marian, R.M.; Chahl, J.S. A Critical Analysis and Roadmap for the Development of Industry 4-Oriented Facilities for Education, Training, and Research in Academia. Appl. Syst. Innov. 2025, 8, 106. https://doi.org/10.3390/asi8040106

Jin Z, Marian RM, Chahl JS. A Critical Analysis and Roadmap for the Development of Industry 4-Oriented Facilities for Education, Training, and Research in Academia. Applied System Innovation. 2025; 8(4):106. https://doi.org/10.3390/asi8040106

Chicago/Turabian StyleJin, Ziyue, Romeo M. Marian, and Javaan S. Chahl. 2025. "A Critical Analysis and Roadmap for the Development of Industry 4-Oriented Facilities for Education, Training, and Research in Academia" Applied System Innovation 8, no. 4: 106. https://doi.org/10.3390/asi8040106

APA StyleJin, Z., Marian, R. M., & Chahl, J. S. (2025). A Critical Analysis and Roadmap for the Development of Industry 4-Oriented Facilities for Education, Training, and Research in Academia. Applied System Innovation, 8(4), 106. https://doi.org/10.3390/asi8040106