Comparative Study of Printed Multilayer OLED Fabrication through Slot Die Coating, Gravure and Inkjet Printing, and Their Combination

Abstract

1. Introduction

1.1. State of the Art of Printed Multilayer OLEDs

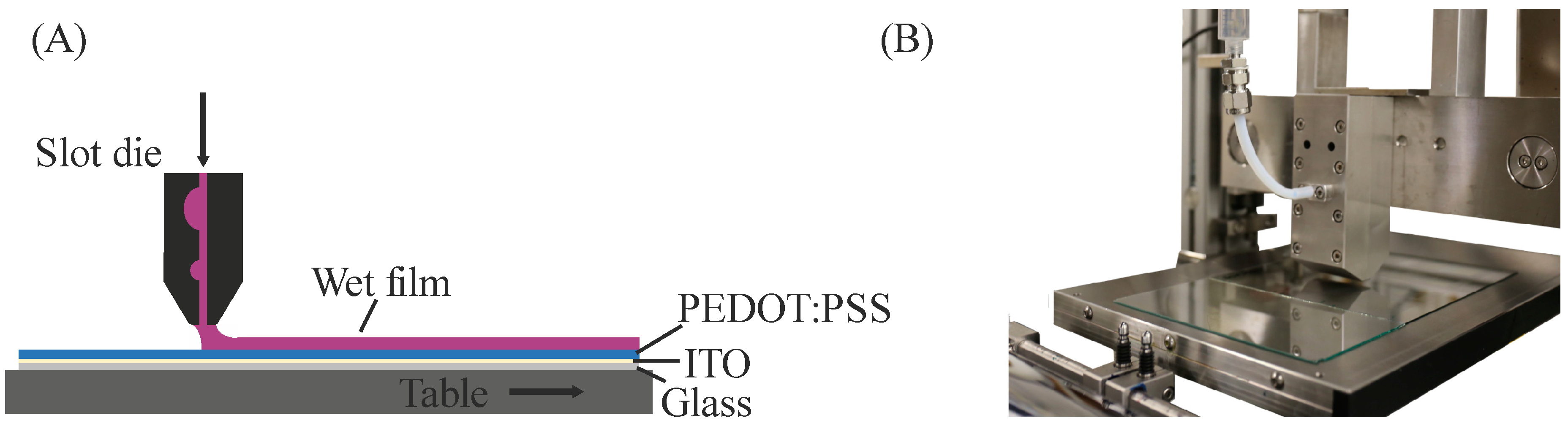

1.2. Slot Die Coating

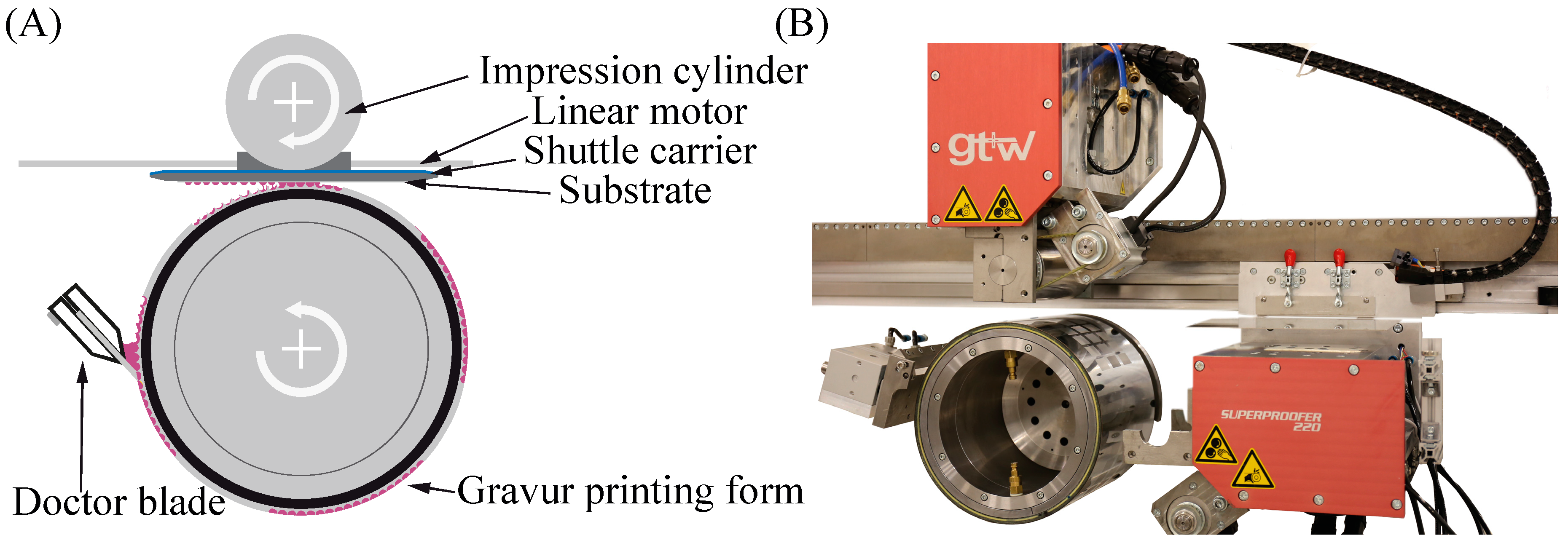

1.3. Gravure Printing

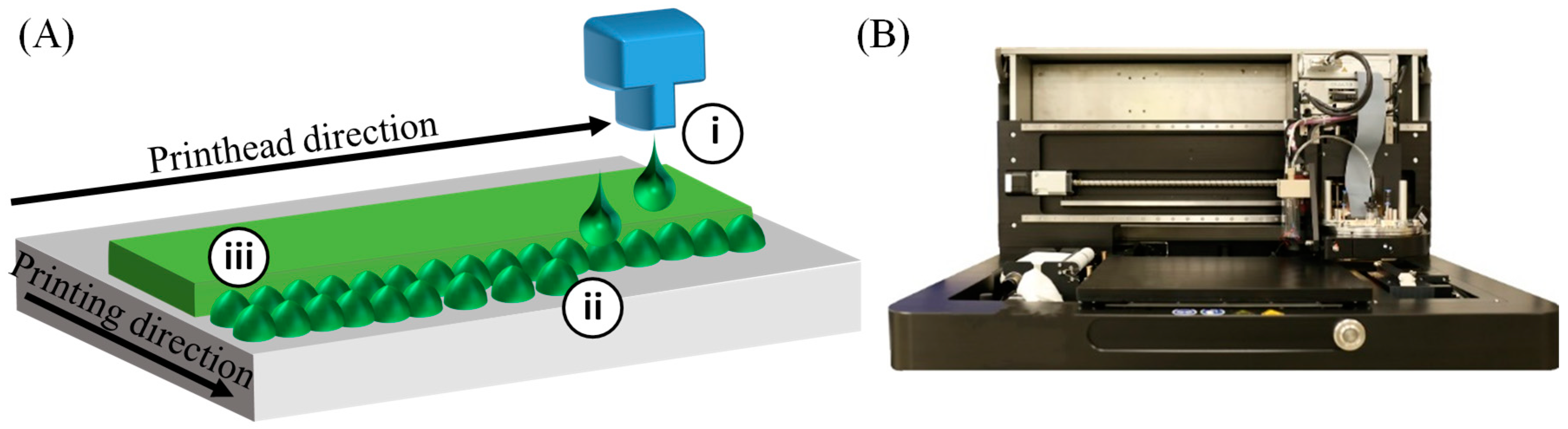

1.4. Inkjet Printing

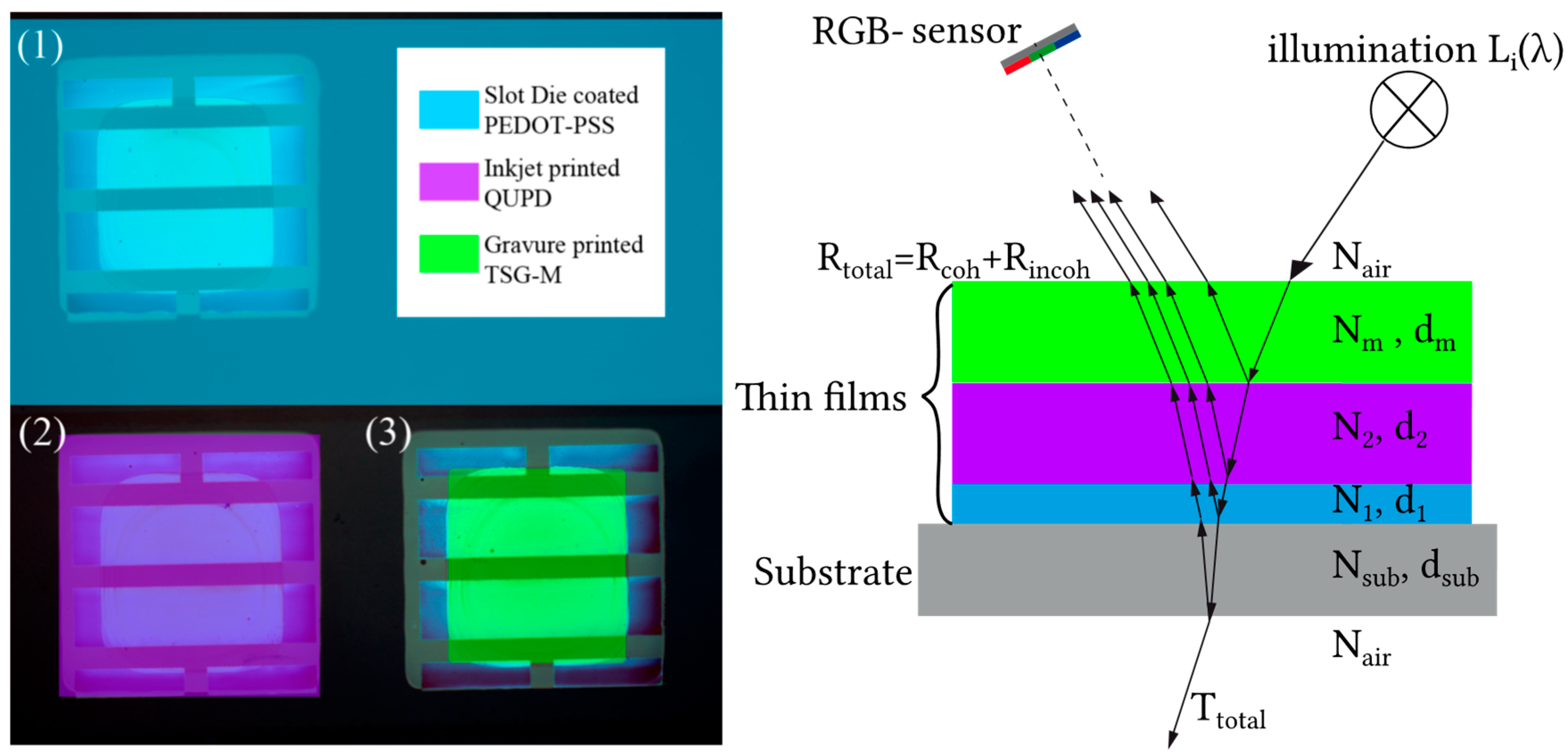

1.5. Imaging Color Reflectometry

2. Materials and Methods

2.1. Chemicals and Materials

2.2. Device Fabrication

2.3. Slot Die Coating

2.4. Gravure Printing

2.5. Inkjet Printing

2.6. Layer and Device Characterization

3. Results

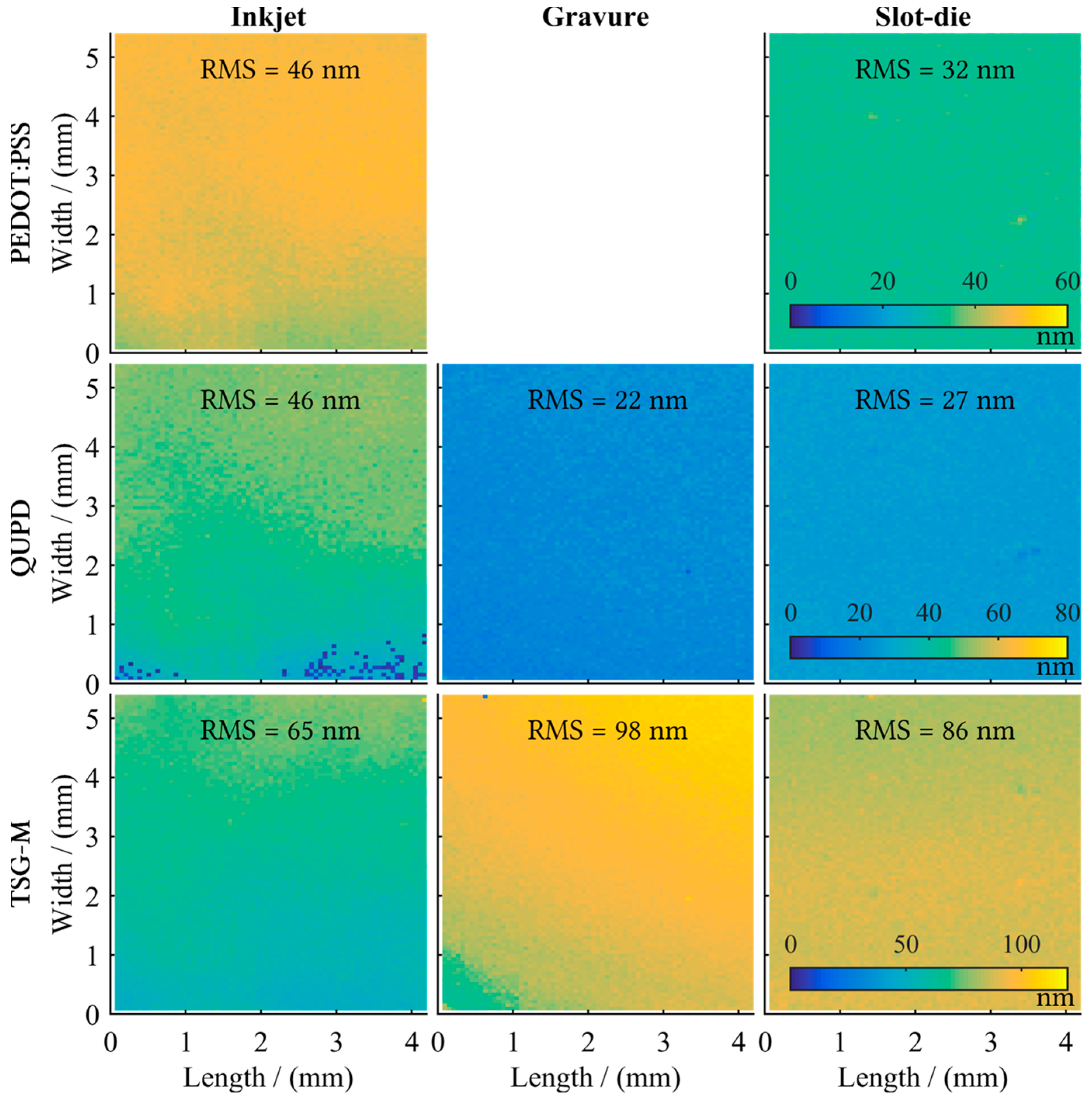

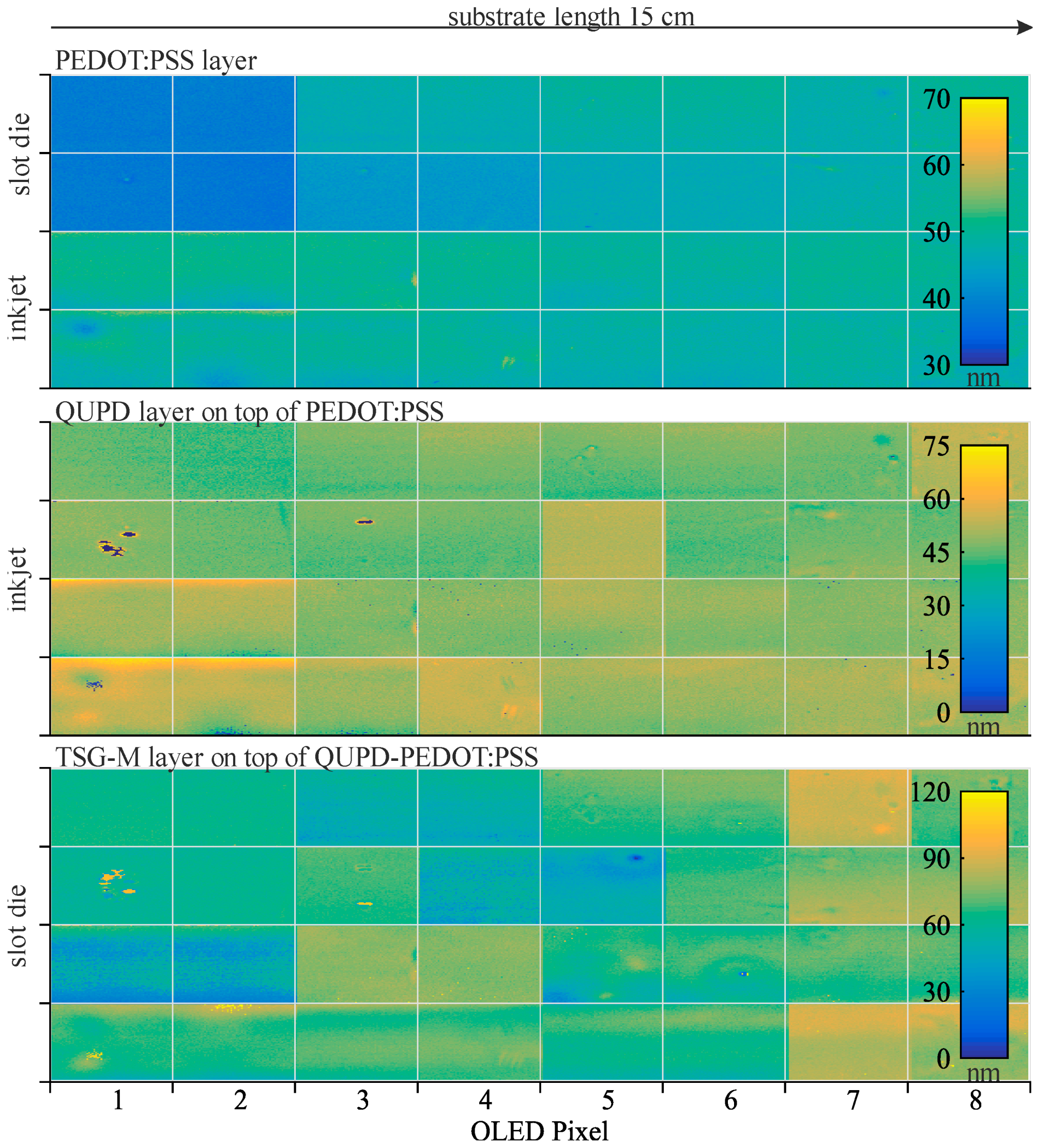

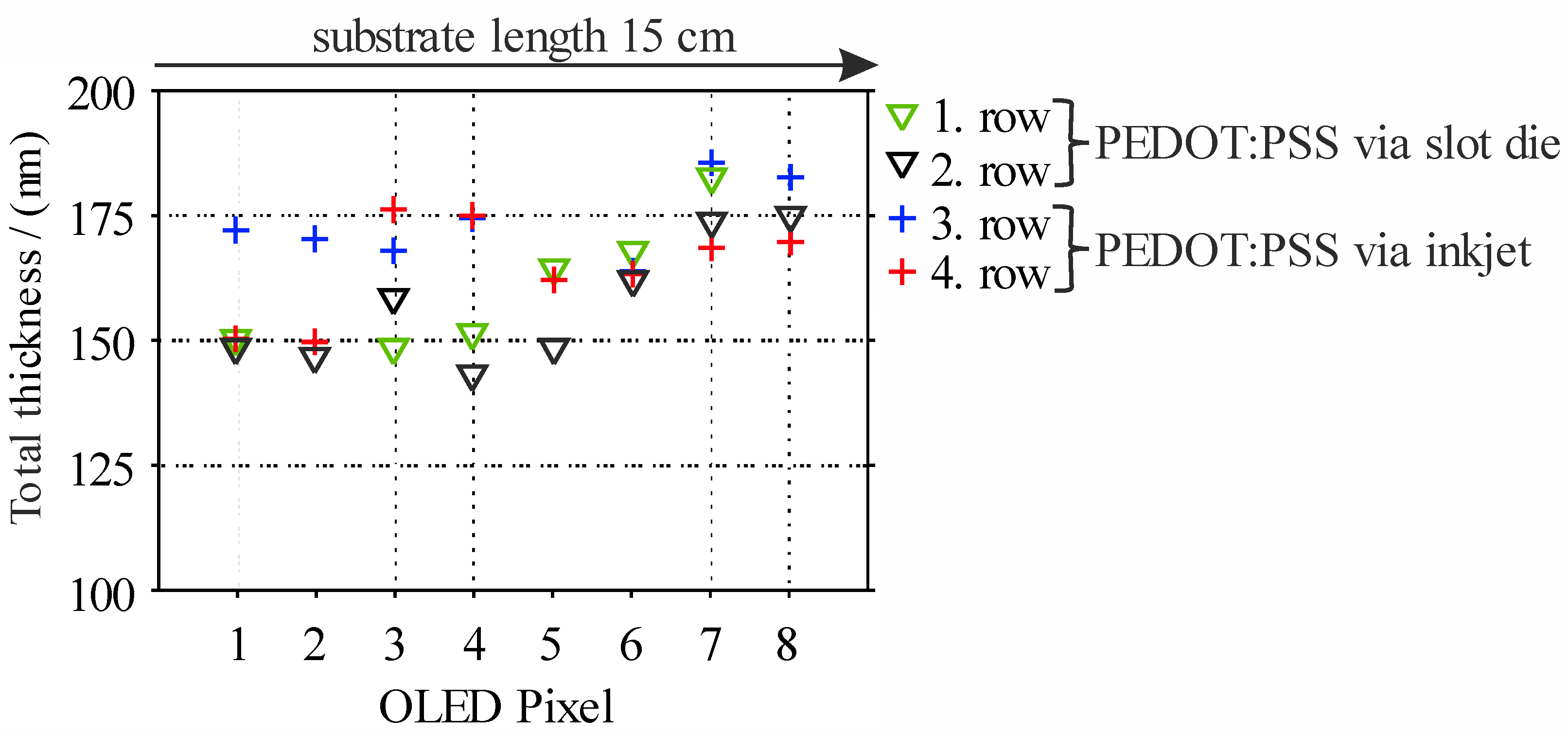

3.1. Influence of the Application Technique on Film Homogeneity

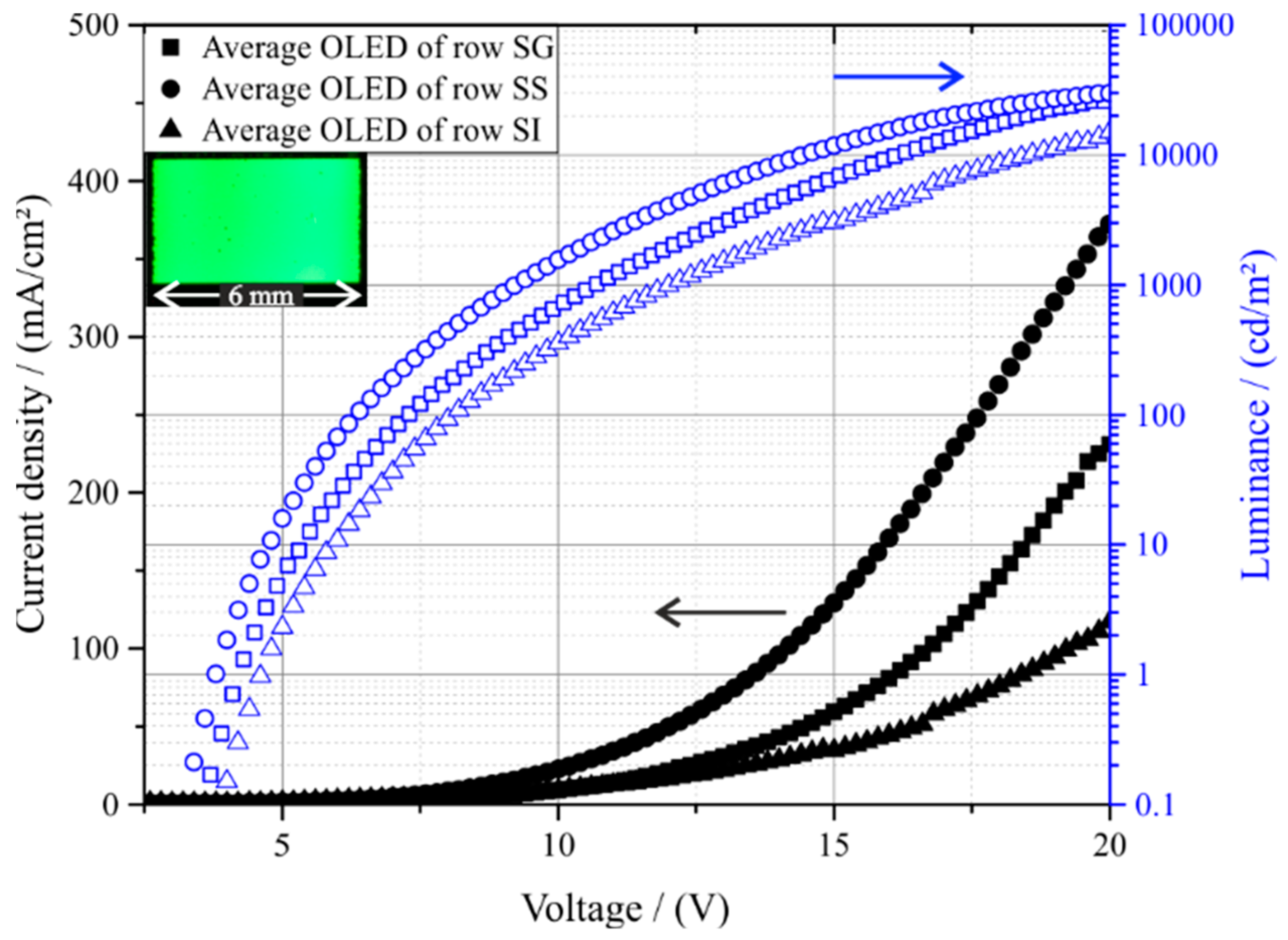

3.2. Influence of the Material/Technique Combination on OLED Performance

4. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- OE-A VDMA. The German Engineering Federation, 7th ed.; OE-A Roadmap: Washington, DC, USA, 2017. [Google Scholar]

- Duggal, A.R.; Heller, C.M.; Shiang, J.J.; Liu, J.; Lewis, L.N. Solution-Processed Organic Light-Emitting Diodes for Lighting. J. Display Technol. 2007, 3, 184–192. [Google Scholar] [CrossRef]

- Aizawa, N.; Pu, Y.-J.; Watanabe, M.; Chiba, T.; Ideta, K.; Toyota, N.; Igarashi, M.; Suzuri, Y.; Sasabe, H.; Kido, J. Solution-processed multilayer small-molecule light-emitting devices with high-efficiency white-light emission. Nat. Commun. 2014, 5, 5756. [Google Scholar] [CrossRef] [PubMed]

- Park, B.; Kwon, O.E.; Yun, S.H.; Jeon, H.G.; Huh, Y.H. Organic semiconducting layers fabricated by self-metered slot-die coating for solution-processable organic light-emitting devices. J. Mater. Chem. C 2014, 2, 8614–8621. [Google Scholar] [CrossRef]

- Chang, H.-W.; Lee, Y.-T.; Tseng, M.-R.; Jang, M.-H.; Yeh, H.-C.; Luo, F.-T.; Meng, H.-F.; Chen, C.-T.; Chi, Y.; Qiu, Y.; et al. General application of blade coating to small-molecule hosts for organic light-emitting diode. Synth. Met. 2014, 196, 99–109. [Google Scholar] [CrossRef]

- Søndergaard, R.R.; Hösel, M.; Krebs, F.C. Roll-to-Roll fabrication of large area functional organic materials. J. Polym. Sci. B Polym. Phys. 2013, 51, 16–34. [Google Scholar] [CrossRef]

- Krebs, F.C. Fabrication and processing of polymer solar cells: A review of printing and coating techniques. Solar Energy Mater. Solar Cells 2009, 93, 394–412. [Google Scholar] [CrossRef]

- Gather, M.C.; Kronenberg, N.M.; Meerholz, K. Monolithic integration of multi-color organic LEDs by grayscale lithography. Adv. Mater. 2010, 22, 4634–4638. [Google Scholar] [CrossRef] [PubMed]

- Chung, D.-Y.; Huang, J.; Bradley, D.D.C.; Campbell, A.J. High performance, flexible polymer light-emitting diodes (PLEDs) with gravure contact printed hole injection and light emitting layers. Org. Electron. 2010, 11, 1088–1095. [Google Scholar] [CrossRef]

- Hegemann, D.; Brunner, H.; Oehr, C. Plasma treatment of polymers for surface and adhesion improvement. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Int. Mater. Atoms 2003, 208, 281–286. [Google Scholar] [CrossRef]

- Kim, S.R. Surface modification of poly(tetrafluoroethylene) film by chemical etching, plasma, and ion beam treatments. J. Appl. Polym. Sci. 2000, 77, 1913–1920. [Google Scholar] [CrossRef]

- Choi, K.-J.; Lee, J.-Y.; Park, J.; Seo, Y.-S. Multilayer slot-die coating of large-area organic light-emitting diodes. Org. Electron. 2015, 26, 66–74. [Google Scholar] [CrossRef]

- Raupp, S.; Daume, D.; Tekoglu, S.; Merklein, L.; Lemmer, U.; Hernandez-Sosa, G.; Sauer, H.M.; Dörsam, E.; Scharfer, P.; Schabel, W. Slot Die Coated and Flexo Printed Highly Efficient SMOLEDs. Adv. Mater. Technol. 2016, 2, 1600230. [Google Scholar] [CrossRef]

- Duan, L.; Hou, L.; Lee, T.-W.; Qiao, J.; Zhang, D.; Dong, G.; Wang, L.; Qiu, Y. Solution processable small molecules for organic light-emitting diodes. J. Mater. Chem. 2010, 20, 6392–6407. [Google Scholar] [CrossRef]

- Choi, K.-J.; Lee, J.-Y.; Shin, D.-K.; Park, J. Investigation on slot-die coating of hybrid material structure for OLED lightings. J. Phys. Chem. Solids 2016, 95, 119–128. [Google Scholar] [CrossRef]

- Elschner, A.; Heuer, H.W.; Jonas, F.; Kirchmeyer, S.; Wehrmann, R.; Wussow, K. Gallium Complexes in Three-Layer Organic Electroluminescent Devices. Adv. Mater. 2001, 13, 1811–1814. [Google Scholar] [CrossRef]

- Abbel, R.; de Vries, I.; Langen, A.; Kirchner, G.; t’Mannetje, H.; Gorter, H.; Wilson, J.; Groen, P. Toward high volume solution based roll-to-roll processing of OLEDs. J. Mater. Res. 2017, 32, 2219–2229. [Google Scholar] [CrossRef]

- Tekoglu, S.; Hernandez-Sosa, G.; Kluge, E.; Lemmer, U.; Mechau, N. Gravure printed flexible small-molecule organic light emitting diodes. Org. Electron. 2013, 14, 3493–3499. [Google Scholar] [CrossRef]

- Olivier, S.; Ishow, E.; Della-Gatta, S.M.; Maindron, T. Inkjet deposition of a hole-transporting small molecule to realize a hybrid solution-evaporation green top-emitting OLED. Org. Electron. 2017, 49, 24–32. [Google Scholar] [CrossRef]

- Zhou, L.; Yang, L.; Yu, M.; Jiang, Y.; Liu, C.-F.; Lai, W.-Y.; Huang, W. Inkjet-Printed Small-Molecule Organic Light-Emitting Diodes: Halogen-Free Inks, Printing Optimization, and Large-Area Patterning. ACS Appl. Mater. Interfaces 2017, 9, 40533–40540. [Google Scholar] [CrossRef] [PubMed]

- Stolz, S.; Scherer, M.; Mankel, E.; Lovrinčić, R.; Schinke, J.; Kowalsky, W.; Jaegermann, W.; Lemmer, U.; Mechau, N.; Hernandez-Sosa, G. Investigation of solution-processed ultrathin electron injection layers for organic light-emitting diodes. ACS Appl. Mater. Interfaces 2014, 6, 6616–6622. [Google Scholar] [CrossRef] [PubMed]

- Verma, A.; Zink, D.M.; Fléchon, C.; Leganés Carballo, J.; Flügge, H.; Navarro, J.M.; Baumann, T.; Volz, D. Efficient, inkjet-printed TADF-OLEDs with an ultra-soluble NHetPHOS complex. Appl. Phys. A 2016, 122, 191. [Google Scholar] [CrossRef]

- Schmitt, M.; Scharfer, P.; Schabel, W. Slot die coating of lithium-ion battery electrodes: Investigations on edge effect issues for stripe and pattern coatings. J. Coat. Technol. Res. 2014, 11, 57–63. [Google Scholar] [CrossRef]

- Peters, K.; Wengeler, L.; Scharfer, P.; Schabel, W. Liquid film coating of small molecule OLEDs. J. Coat. Technol. Res. 2014, 11, 75–81. [Google Scholar] [CrossRef]

- Raupp, S.M.; Schmitt, M.; Walz, A.-L.; Diehm, R.; Hummel, H.; Scharfer, P.; Schabel, W. Slot die stripe coating of low viscous fluids. J. Coat. Technol. Res. 2018, 30, 363. [Google Scholar] [CrossRef]

- Schmitt, M.; Diehm, R.; Scharfer, P.; Schabel, W. An experimental and analytical study on intermittent slot die coating of viscoelastic battery slurries. J. Coat. Technol. Res. 2015, 12, 927–938. [Google Scholar] [CrossRef]

- Buerkin, C.K.; de Vries, I.; Raupp, S.M.; Scharfer, P.; Schabel, W.; Groen, P. Investigation of interfacial instabilities with a two-layer slide coating process. J. Coat. Technol. Res. 2017, 14, 991–1001. [Google Scholar] [CrossRef]

- Horiuchi, R.; Suszynski, W.J.; Carvalho, M.S. Simultaneous multilayer coating of water-based and alcohol-based solutions. J. Coat. Technol. Res. 2015, 12, 819–826. [Google Scholar] [CrossRef]

- Kistler, S.F.; Schweizer, P.M. Liquid Film Coating: Scientific Principles and Their Technological Implications; Chapman & Hall: London, UK, 1997. [Google Scholar]

- Gutoff, E.B.; Cohen, E.D.; Kheboian, G.I. Coating and Drying Defects: Troubleshooting Operating Problems, 2nd ed.; Wiley-Interscience: Hoboken, NJ, USA, 2006. [Google Scholar]

- Raupp, S.M.; Merklein, L.; Pathak, M.; Scharfer, P.; Schabel, W. An experimental study on the reproducibility of different multilayer OLED materials processed by slot die coating. Chem. Eng. Sci. 2017, 160, 113–120. [Google Scholar] [CrossRef]

- Raupp, S.M.; Merklein, L.; Hietzschold, S.; Zürn, M.; Scharfer, P.; Schabel, W. Slot die-coated blue SMOLED multilayers. J. Coat. Technol. Res. 2017, 10, 1029–1037. [Google Scholar] [CrossRef]

- Nisato, G.; Donald, L.; Simone, G. Organic and Printed Electronics: Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Bornemann, N. Characterization and Investigation of Large-Area, Ultra-Thin Gravure Printed Layers. Ph.D. Thesis, Technische Universität Darmstadt, Darmstadt, Germany, May 2014. [Google Scholar]

- Fields, R.J.; Ashby, M.F. Finger-like crack growth in solids and liquids. Philos. Mag. 1976, 33, 33–48. [Google Scholar] [CrossRef]

- Gingras, M.J.P.; Rácz, Z. Noise and the linear stability analysis of viscous fingering. Phys. Rev. A 1989, 40, 5960–5965. [Google Scholar] [CrossRef]

- Ben Amar, M. Viscous fingering in a wedge. Phys. Rev. A 1991, 44, 3673–3685. [Google Scholar] [CrossRef] [PubMed]

- Derby, B. Inkjet Printing of Functional and Structural Materials: Fluid Property Requirements, Feature Stability, and Resolution. Annu. Rev. Mater. Res. 2010, 40, 395–414. [Google Scholar] [CrossRef]

- Cummins, G.; Desmulliez, M.P.Y. Inkjet printing of conductive materials: A review. Circuit World 2012, 38, 193–213. [Google Scholar] [CrossRef]

- Eggenhuisen, T.M.; Galagan, Y.; Biezemans, A.F.K.V.; Slaats, T.M.W.L.; Voorthuijzen, W.P.; Kommeren, S.; Shanmugam, S.; Teunissen, J.P.; Hadipour, A.; Verhees, W.J.H.; et al. High efficiency, fully inkjet printed organic solar cells with freedom of design. J. Mater. Chem. A 2015, 3, 7255–7262. [Google Scholar] [CrossRef]

- Coenen, M.J.J.; Slaats, T.M.W.L.; Eggenhuisen, T.M.; Groen, P. Inkjet printing the three organic functional layers of two-colored organic light emitting diodes. Thin Solid Films 2015, 583, 194–200. [Google Scholar] [CrossRef]

- Morfa, A.J.; Rödlmeier, T.; Jürgensen, N.; Stolz, S.; Hernandez-Sosa, G. Comparison of biodegradable substrates for printed organic electronic devices. Cellulose 2016, 23, 3809–3817. [Google Scholar] [CrossRef]

- Inzelberg, L.; Pur, M.D.; Schlisske, S.; Rödlmeier, T.; Granoviter, O.; Rand, D.; Steinberg, S.; Hernandez-Sosa, G.; Hanein, Y. Printed facial skin electrodes as sensors of emotional affect. Flex. Print. Electron. 2018, 3, 045001. [Google Scholar] [CrossRef]

- Gao, M.; Li, L.; Song, Y. Inkjet printing wearable electronic devices. J. Mater. Chem. C 2017, 5, 2971–2993. [Google Scholar] [CrossRef]

- De Gans, B.-J.; Schubert, U.S. Inkjet printing of well-defined polymer dots and arrays. Langmuir ACS J. Surf. Colloids 2004, 20, 7789–7793. [Google Scholar] [CrossRef] [PubMed]

- Soltman, D.; Subramanian, V. Inkjet-printed line morphologies and temperature control of the coffee ring effect. Langmuir ACS J. Surf. Colloids 2008, 24, 2224–2231. [Google Scholar] [CrossRef] [PubMed]

- Bornemann, N.; Sauer, H.M.; Dörsam, E. Gravure Printed Ultrathin Layers of Small-Molecule Semiconductors on Glass. J. Imaging Sci. Technol. 2011, 55, 40201. [Google Scholar] [CrossRef]

- Rehmann, N.; Hertel, D.; Meerholz, K.; Becker, H.; Heun, S. Highly efficient solution-processed phosphorescent multilayer organic light-emitting diodes based on small-molecule hosts. Appl. Phys. Lett. 2007, 91, 103507. [Google Scholar] [CrossRef]

- Bayerl, M.S.; Braig, T.; Nuyken, O.; Müller, D.C.; Groß, M.; Meerholz, K. Crosslinkable hole-transport materials for preparation of multilayer organic light emitting devices by spin-coating. Macromol. Rapid Commun. 1999, 20, 224–228. [Google Scholar] [CrossRef]

| Inkjet | Gravure | Slot Die | |

|---|---|---|---|

| PEDOT:PSS | ✓ | agglomerate formation | ✓ |

| QUPD | cloudy layer | ✓ | ✓ |

| TSG-M | (✓) | thickness gradient | ✓ |

| Technique Combination | SS | IS | SG | IG | SI | II |

|---|---|---|---|---|---|---|

| PEDOT:PSS | SD | IJ | SD | IJ | SD | IJ |

| QUPD | SD | SD | GP | GP | IJ | IJ |

| TSG-M | SD | SD | SD | SD | SD | SD |

| Yield | 9/16 | 13/16 | 10/16 | 11/12 | 6/16 | 11/16 |

| Current effic. (cd A−1) | 10.9 ± 0.9 | 9.7 ± 0.9 | 12.9 ± 0.4 | 8.4 ± 0.8 | 10.6 ± 1.1 | 9.0 ± 0.9 |

| Power effic. (lm W−1) | 2.2 ± 0.1 | 1.7 ± 0.2 | 2.4 ± 0.1 | 1.4 ± 0.1 | 2.0 ± 0.1 | 1.7 ± 0.2 |

| Voltage at 1000 cd m−2 | 11.3 ± 0.8 | 12.0 ± 0.8 | 12.7 ± 0.6 | 13.6 ± 0.4 | 11.3 ± 0.7 | 10.5 ± 0.8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Merklein, L.; Daume, D.; Braig, F.; Schlisske, S.; Rödlmeier, T.; Mink, M.; Kourkoulos, D.; Ulber, B.; Di Biase, M.; Meerholz, K.; et al. Comparative Study of Printed Multilayer OLED Fabrication through Slot Die Coating, Gravure and Inkjet Printing, and Their Combination. Colloids Interfaces 2019, 3, 32. https://doi.org/10.3390/colloids3010032

Merklein L, Daume D, Braig F, Schlisske S, Rödlmeier T, Mink M, Kourkoulos D, Ulber B, Di Biase M, Meerholz K, et al. Comparative Study of Printed Multilayer OLED Fabrication through Slot Die Coating, Gravure and Inkjet Printing, and Their Combination. Colloids and Interfaces. 2019; 3(1):32. https://doi.org/10.3390/colloids3010032

Chicago/Turabian StyleMerklein, Lisa, Dominik Daume, Felix Braig, Stefan Schlisske, Tobias Rödlmeier, Marvin Mink, Dimitrios Kourkoulos, Benjamin Ulber, Manuela Di Biase, Klaus Meerholz, and et al. 2019. "Comparative Study of Printed Multilayer OLED Fabrication through Slot Die Coating, Gravure and Inkjet Printing, and Their Combination" Colloids and Interfaces 3, no. 1: 32. https://doi.org/10.3390/colloids3010032

APA StyleMerklein, L., Daume, D., Braig, F., Schlisske, S., Rödlmeier, T., Mink, M., Kourkoulos, D., Ulber, B., Di Biase, M., Meerholz, K., Hernandez-Sosa, G., Lemmer, U., Sauer, H. M., Dörsam, E., Scharfer, P., & Schabel, W. (2019). Comparative Study of Printed Multilayer OLED Fabrication through Slot Die Coating, Gravure and Inkjet Printing, and Their Combination. Colloids and Interfaces, 3(1), 32. https://doi.org/10.3390/colloids3010032