Environmentally Friendly PLA-Based Conductive Composites: Electrical and Mechanical Performance

Abstract

1. Introduction

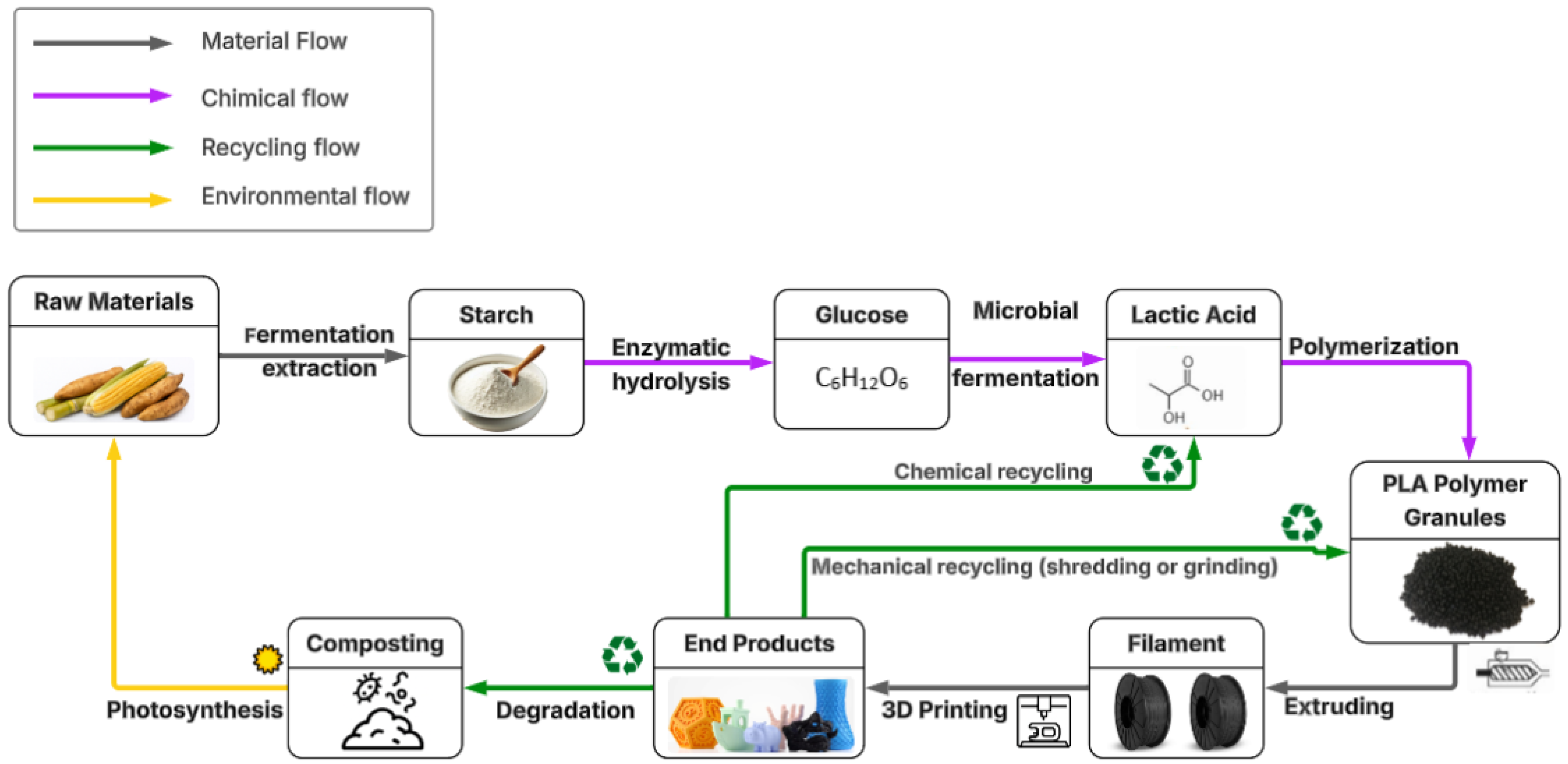

2. Polymer Matrix PLA

2.1. Process of PLA Fabrication

2.2. Mechanical Comparison of PLA with Common Basics Thermoplastics

2.3. Comparing 3D Printing Parameters of Common Thermoplastic Polymers

| Polymers | Extrusion Temperature (°C) | Bed Temperature (°C) | Print Speed Recommended (mm/s) | Printability & Bed Adhesion | Advantages | Limitations | Refs |

|---|---|---|---|---|---|---|---|

| PLA (Polylactic Acid) | ~190–210 | ~25–80 | ~40–80 | Easy to print | Ecological, rigid, printable at low T°. | Brittle, poor thermal resistance | [35,48,49] |

| ABS (Acrylonitrile Butadiene Styrene) | ~220–260 | ~90–110 | ~40–60 | Medium to difficult: Requires a heated bed, adhesive (e.g., glue stick), and a skirt | Resistant, Post-processable | Strong odor, prone to warping, requires enclosed chamber | [35,48,49] |

| PP (Polypropylene) | ~200–230 | ~90–110 | ~35–70 | Difficult to print: PP-specific tape recommended/poor bed adhesion, | Flexible and chemically resistant. | Difficult to print due to high shrinkage (warping risk) | [50] |

| PVC (Polyvinyl Chloride) | ~180–200 | ~50–60 | ~10–30 | Difficult to print/Poor natural adhesion (Glue or special adhesives are recommended) | Flame-retardant and mechanically strong | Toxic fumes HCl and degradation risk at elevated temperatures | [51,52] |

| HDPE (High-Density Polyethylene) | ~200–260 | ~60–130 | ~25–150 | Difficult to print: Significant shrinkage and warping/Poor bed adhesion | Flexible, chemically resistant, hydrophobic, lightweight: | Difficult to print due to high warping risk, needs a high bed temperature | [53,54] |

| PETG (Polyethylene Terephthalate Glycol) | ~220–250 | ~70–90 | ~40–60 | Easy to print with good interlayer adhesion/Bed adhesion may require a glue stick or adhesive | Good balance between rigidity and flexibility | Prone to stringing and sensitive to moisture. | [35,48,49] |

| PEEK (Polyether Ether Ketone) | ~350–420 | ~120–130 °C | ~20–60 | Difficult to print, requires a hot bed/closed chamber/good property if printed correctly | High thermal, mechanical, and chemical resistance | High cost, warping, thermal convection, difficult crystallization control, sometimes weak adhesion interface | [55,56,57] |

| Nylon (PA6: Polyamide 6) | ~230–260 | ~80–90 | ~40–60 | Needs high-temp bed, dries before print | Strong, durable, high mechanical resistance. | Warping, absorbs moisture, requires closed chamber | [58,59] |

| Nylon (PA12: Polyamide 12) | ~270 | ~90 | ~40–60 | Better adhesion than PA6, less warping | Chemically resistant, dimensionally stable | Still hygroscopic, requires dry storage & hotend > 250 °C | [60] |

3. PLA-Based Conductive Composites

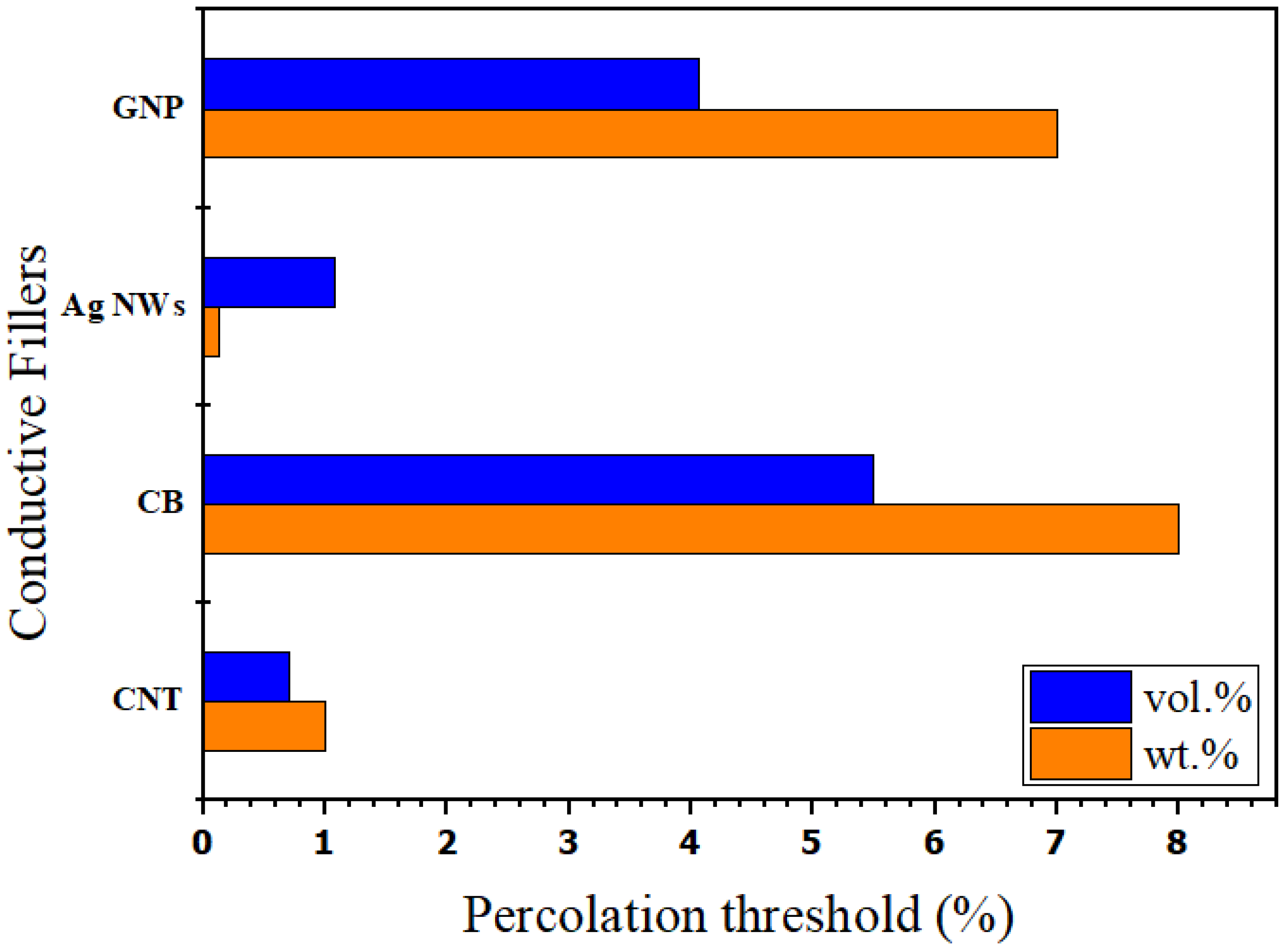

3.1. Percolation Threshold of Conductive Fillers in PLA Matrix

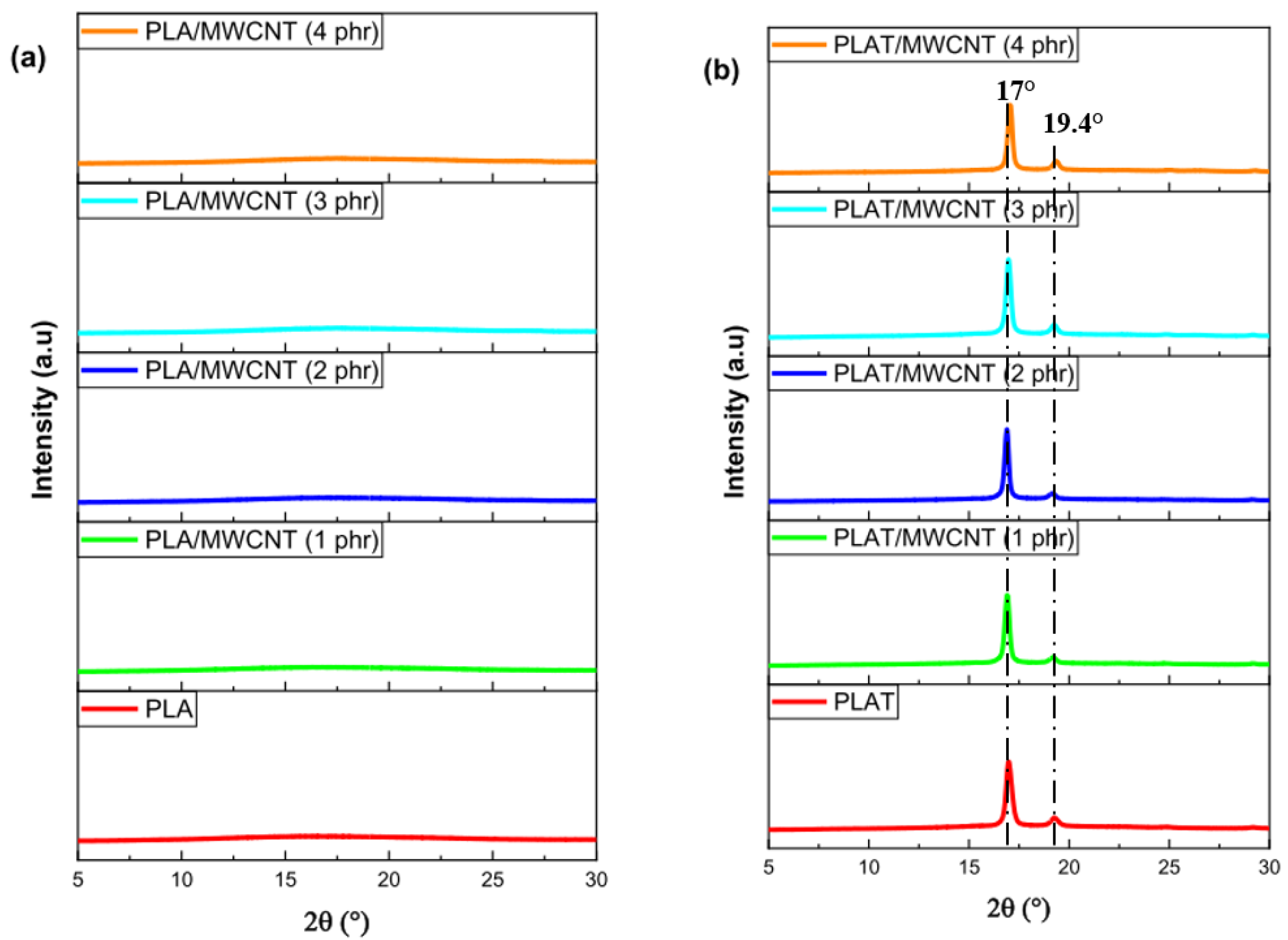

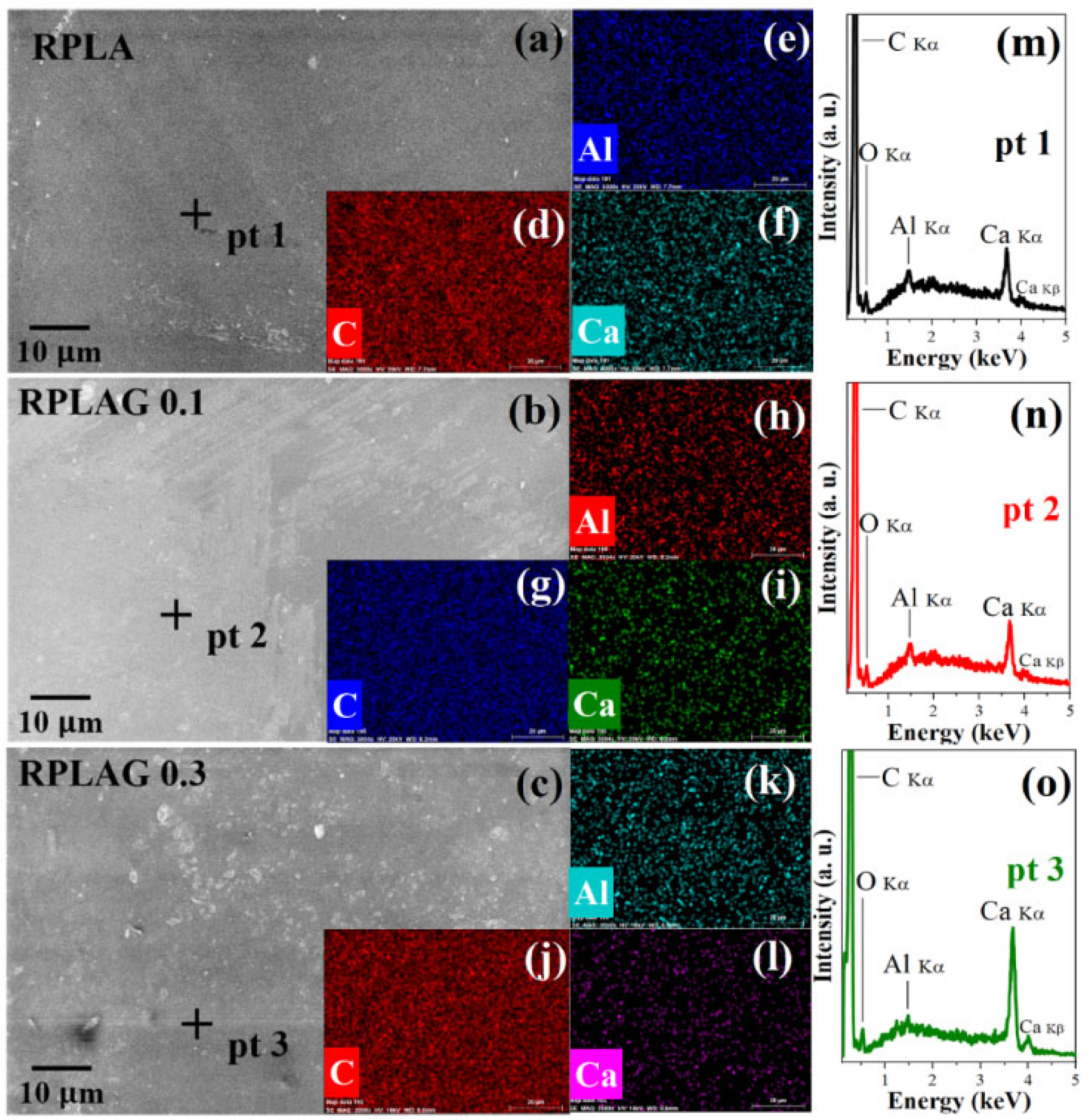

3.2. Structural and Morphological Characterization

3.3. Mechanical Characterization

3.4. Electrical Characterization

| Composites (PLA/Fillers) | Filler Content | Conductivity | Resistivity | Refs |

|---|---|---|---|---|

| PLA/CNTs | 12 wt% CNTs | 4.54 S/m | 0.22 Ohm.m | [86] |

| PLA/GNPs | 12 wt% GNPs | 6.27 S/m | 0.159 Ohm.m | |

| PLA/CNTs | 5.6 wt% CNT | 72.2 S/m | 1.38 × 10−2 Ohm.m | [80] |

| PLA/GNPs | 5 wt% GNPs | 10 S/m | 1.00 × 10−1 Ohm.m | [88] |

| 10 wt% GNPs | 16 S/m | 6.25 × 10−2 Ohm.m | ||

| 15 wt% GNPs | 116 S/m | 8.62 × 10−3 Ohm.m | ||

| PLA/GNPs | 1.5 wt% GNPs | 1.5 × 10−12 S/m | 6.67 × 1011 Ohm.m | [87] |

| 3 wt% GNPs | 1.7 × 10−12 S/m | 5.88 × 1011 Ohm.m | ||

| 6 wt% GNPs | 3.12 × 10−2 S/m | 3.21 × 101 Ohm.m | ||

| 9 wt% GNPs | 3.47 × 10−1 S/m | 2.88 Ohm.m | ||

| PLA/MWCNTs | 1.5 wt% MWCNTs | 1.08 × 10−8 S/m | 9.26 × 107 Ohm.m | |

| 3 wt% MWCNTs | 1.4 × 10−2 S/m | 7.14 × 101 Ohm.m | ||

| 6 wt% MWCNTs | 6.57 × 10−1 S/m | 1.52 Ohm.m | ||

| 9 wt% MWCNTs | 9.4 × 10−1 S/m | 1.06 Ohm.m | ||

| PLA/(MWCNTs + GNPs) | 1.5 wt% MWCNTs + 1.5 wt% GNPs | 2.70 × 10−1 S/m | 3.7 Ohm.m | |

| 3 wt% MWCNTs + 3 wt% GNPs | 3.52 × 10−1 S/m | 2.84 Ohm.m | ||

| 6 wt% MWCNTs + 6 wt% GNPs | 5.33 × 10−1 S/m | 1.88 Ohm.m | ||

| PLA/CB | 4 wt% CB | 0.6 S/m | 1.67 Ohm.m | [84] |

| 8 wt% CB | 12.5 S/m | 8 × 10−2 Ohm.m | ||

| 12 wt% CB | 13.5 S/m | 7.4 × 10−2 Ohm.m | ||

| 16 wt% CB | 13.8 S/m | 7.25 × 10−2 Ohm.m | ||

| 20 wt% CB | 14.3 S/m | 6.99 × 10−2 Ohm.m |

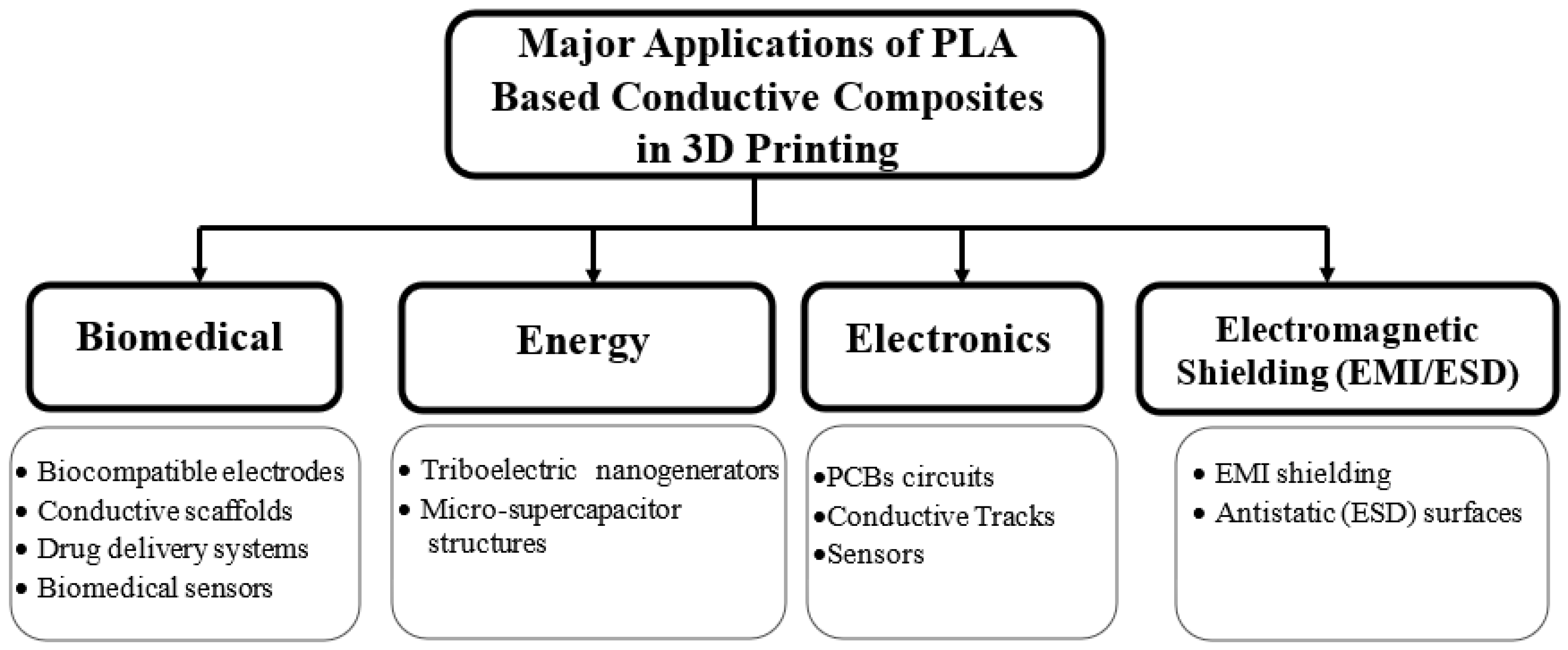

4. Applications of PLA-Based Electrically Conductive Composites

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Castro-Aguirre, E.; Iñiguez-Franco, F.; Samsudin, H.; Fang, X.; Auras, R. Poly(lactic acid)—Mass production, processing, industrial applications, and end of life. Adv. Drug Deliv. Rev. 2016, 107, 333–366. [Google Scholar] [CrossRef] [PubMed]

- Ranakoti, L.; Gangil, B.; Rakesh, P.K.; Agrawal, N. Synthesis and Utilization of Biodegradable Polymers. In Biobased Composites: Processing, Characterization, Properties, and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2021; pp. 167–174. [Google Scholar] [CrossRef]

- Maurya, A.K.; de Souza, F.M.; Dawsey, T.; Gupta, R.K. Biodegradable polymers and composites: Recent development and challenges. Polym. Compos. 2024, 45, 2896–2918. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef]

- Muller, J.; González-Martínez, C.; Chiralt, A. Combination of Poly(lactic) Acid and Starch for Biodegradable Food Packaging. Materials 2017, 10, 952. [Google Scholar] [CrossRef] [PubMed]

- Xiao, L.; Wang, B.; Yang, G.; Gauthier, M. Poly(Lactic Acid)-Based Biomaterials: Synthesis, Modification and Applications. In Biomedical Science, Engineering and Technology; Ghista, D.N., Ed.; IntechOpen: London, UK, 2012. [Google Scholar]

- Mozgova, O.; Chernyayeva, O.; Sroka-Bartnicka, A.; Pieta, P.; Nowakowski, R.; Pieta, I.S. Physicochemical Characterization of Biodegradable Polymers for Biomedical Applications: Insights from XPS, DRIFT, and AFM Techniques. J. Polym. Environ. 2025, 33, 3477–3511. [Google Scholar] [CrossRef]

- Khalifa, M.; Lammer, H.; Gadad, M.S.; Varsavas, S.D.; Weng, Z. Recent advances on copper/polymer nanocomposites: Processing strategies, mechanisms, and antibacterial efficacy. Eur. Polym. J. 2024, 223, 113637. [Google Scholar] [CrossRef]

- Arora, N.; Dua, S.; Singh, V.K.; Singh, S.K.; Senthilkumar, T. A comprehensive review on fillers and mechanical properties of 3D printed polymer composites. Mater. Today Commun. 2024, 40, 109617. [Google Scholar] [CrossRef]

- Navidfar, A.; Trabzon, L. Recent Advances in the Multifunctional Properties and Applications of Carbon Nanotube/Graphene Hybrid Polymer Nanocomposites. Polym. Compos. 2025, 1–23. [Google Scholar] [CrossRef]

- Beygisangchin, M.; Baghdadi, A.H.; Kamarudin, S.K.; Rashid, S.A.; Jakmunee, J.; Shaari, N. Recent progress in polyaniline and its composites; Synthesis, properties, and applications. Eur. Polym. J. 2024, 210, 112948. [Google Scholar] [CrossRef]

- Alli, Y.A.; Bamisaye, A.; Ejeromedoghene, O.; Jimoh, O.O.; Oni, S.O.; Ezeamii, G.C.; Ozoemezim, C.; Ogunlaja, A.S.; Rashid, S.A.; Kandola, B.K. Recent advancement in MXene-based nanomaterials for flame retardant polymers and composites. Adv. Ind. Eng. Polym. Res. 2025, 8, 322–340. [Google Scholar] [CrossRef]

- Naboulsi, N.; Majid, F.; Hachimi, T.; Barhoumi, N.; Khlifi, K.; Dadoun, S. Predicting the strength of 3D-printed conductive composite under tensile load: A probabilistic modeling and experimental study. Fract. Struct. Integr. 2025, 19, 247–262. [Google Scholar] [CrossRef]

- Naboulsi, N.; Majid, F.; Hmazi, F.A.; Baghaz, E.; El Alaoui-Belghiti, H.; Kechagias, J.D. Electrical conductivity and microstructural features of 3D-printed PLA-CB composites fabricated at different temperatures. Next Mater. 2025, 9, 101122. [Google Scholar] [CrossRef]

- Lopes, T.J.; de Azevedo, A.M.; Monteiro, S.N.; Araujo-Moreira, F.M. Electrical Properties of Composite Materials: A Comprehensive Review. J. Compos. Sci. 2025, 9, 438. [Google Scholar] [CrossRef]

- Shchegolkov, A.V.; Shchegolkov, A.V.; Parfimovich, I.D.; Komarov, F.F.; Novikov, L.S.; Chernik, V.N. Functional Characteristics of Conductive Polymer Composites with Built-In Carbon Nanotubes and Metallic Particles. J. Compos. Sci. 2025, 9, 429. [Google Scholar] [CrossRef]

- El Marouazi, H.; van der Schueren, B.; Favier, D.; Bolley, A.; Dagorne, S.; Dintzer, T.; Janowska, I. Great enhancement of mechanical features in PLA based composites containing aligned few layer graphene (FLG), the effect of FLG loading, size, and dispersion on mechanical and thermal properties. J. Appl. Polym. Sci. 2021, 138, 51300. [Google Scholar] [CrossRef]

- Tirado-Garcia, I.; Garcia-Gonzalez, D.; Garzon-Hernandez, S.; Rusinek, A.; Robles, G.; Martinez-Tarifa, J.; Arias, A. Conductive 3D printed PLA composites: On the interplay of mechanical, electrical and thermal behaviours. Compos. Struct. 2021, 265, 113744. [Google Scholar] [CrossRef]

- Rifa’i, A.F.; Kaavessina, M.; Distantina, S. Mechanical, Morphological, and Electrical Properties of Polylactic Acid-based Conductive Polymer Composites through Polyethylene Glycol and Carbon Nanotubes Integration. Period. Polytech. Chem. Eng. 2025, 69, 149–162. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, J.; Shao, M.; Liang, Y.; Li, H. Hybrid combinations of graphene nanoplatelet, carbon nanotube, and carbon black for tailored mechanical and triboelectric properties in polypropylene fibers. Adv. Compos. Hybrid Mater. 2025, 8, 259. [Google Scholar] [CrossRef]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-Based 3D Printing of Polymer and Associated Composite: A Review on Mechanical Properties, Defects and Treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef]

- Attallah, O.A.; Palkova, V.; Vij, R. Single Step Depolymerization of Multiple Polyesters in Poly(Lactic Acid) Mixed Plastics: Process Optimization, Pure Monomers Extraction and Kinetics Evaluation. J. Polym. Environ. 2025, 33, 1897–1915. [Google Scholar] [CrossRef]

- Hussain, M.; Khan, S.M.; Shafiq, M.; Abbas, N. A review on PLA-based biodegradable materials for biomedical applications. Giant 2024, 18, 100261. [Google Scholar] [CrossRef]

- Naboulsi, N.; Hachimi, T.; Majid, F.; Rhanim, R.; Zekriti, N.; Rhanim, H. Modeling and control of 3D filament extruder. Procedia Struct. Integr. 2021, 33, 989–995. [Google Scholar] [CrossRef]

- Hachimi, T.; Naboulsi, N.; Majid, F.; Rhanim, R.; Mrani, I.; Rhanim, H. Design and Manufacturing of a 3D printer filaments extruder. Procedia Struct. Integr. 2021, 33, 907–916. [Google Scholar] [CrossRef]

- Plamadiala, I.; Croitoru, C.; Pop, M.A.; Roata, I.C. Enhancing Polylactic Acid (PLA) Performance: A Review of Additives in Fused Deposition Modelling (FDM) Filaments. Polymers 2025, 17, 191. [Google Scholar] [CrossRef]

- Wang, X.; Huang, L.; Li, Y.; Wang, Y.; Lu, X.; Wei, Z.; Mo, Q.; Zhang, S.; Sheng, Y.; Huang, C.; et al. Research progress in polylactic acid processing for 3D printing. J. Manuf. Process. 2024, 112, 161–178. [Google Scholar] [CrossRef]

- Lim, L.-T.; Auras, R.; Rubino, M. Processing technologies for poly(lactic acid). Prog. Polym. Sci. 2008, 33, 820–852. [Google Scholar] [CrossRef]

- Dittrich, B.; Wartig, K.A.; Mülhaupt, R.; Schartel, B. Flame-retardancy properties of intumescent ammonium poly(phosphate) and mineral filler magnesium hydroxide in combination with graphene. Polymers 2014, 6, 2875–2895. [Google Scholar] [CrossRef]

- Campos, B.M.; Bourbigot, S.; Fontaine, G.; Bonnet, F. Thermoplastic matrix-based composites produced by resin transfer molding: A review. Polym. Compos. 2022, 43, 2485–2506. [Google Scholar] [CrossRef]

- Travieso-Rodriguez, J.A.; Jerez-Mesa, R.; Llumà, J.; Traver-Ramos, O.; Gomez-Gras, G.; Rovira, J.J.R. Mechanical Properties of 3D-Printing Polylactic Acid Parts subjected to Bending Stress and Fatigue Testing. Materials 2019, 12, 3859. [Google Scholar] [CrossRef]

- Fakhrurrozi, I.F.; Herliansyah, M.K. Characterization and mechanical properties of PLA/acetylated cellulose nanocrystals composites for dental crown prototype application. Results Eng. 2025, 25, 103903. [Google Scholar] [CrossRef]

- Oosthuizen, G.A.; Hagedorn-hansen, D.; Gerhold, T. Evaluation of Rapid Product Development Technologies for Production of Prosthesis in Developing Communities. 2013. Available online: https://hdl.handle.net/10210/13053 (accessed on 22 May 2025).

- Al-Mazrouei, N.; Ismail, A.; Ahmed, W.; Al-Marzouqi, A.H. ABS/Silicon Dioxide Micro Particulate Composite from 3D Printing Polymeric Waste. Polymers 2022, 14, 509. [Google Scholar] [CrossRef]

- Agócs, C.; Hanon, M.M.; Zsidai, L. A comprehensive review of Fused Deposition Modeling (FDM) method using PLA, ABS, and PET-G polymers. Gradus 2024, 11, 1–12. [Google Scholar] [CrossRef]

- Thabet, A.; Mobarak, Y.A. Predictable Models and Experimental Measurements for Electric Properties of Polypropylene Nanocomposite Films. Int. J. Electr. Comput. Eng. 2016, 6, 120–129. [Google Scholar] [CrossRef]

- Jia, P.; Hu, L.; Feng, G.; Bo, C.; Zhang, M.; Zhou, Y. PVC materials without migration obtained by chemical modification of azide-functionalized PVC and triethyl citrate plasticizer. Mater. Chem. Phys. 2017, 190, 25–30. [Google Scholar] [CrossRef]

- Varshney, D.; Debnath, K.; Singh, I. Mechanical Characterization of Polypropylene (PP) and Polyethylene (PE) Based Natural Fiber Reinforced Composites. Int. J. Surf. Eng. Mater. Technol. 2014, 4, 2249–7250. [Google Scholar]

- Saidi, M.A.A.; Hassan, A.; Wahit, M.U.; Choy, L.J.; Anuar, H. Thermal, dynamic mechanical analysis and mechanical properties of polybutylene terephthalate/polyethylene terephthalate blends. J. Teknol. 2020, 82, 73–83. [Google Scholar] [CrossRef]

- Patil, M.; Dongre, M.; Raut, D.; Naik, A. Multi-objective optimization of fused filament fabrication (FFF) parameters for rice husk reinforced PLA composites. Next Mater. 2025, 8, 100540. [Google Scholar] [CrossRef]

- Hachimi, T.; Hmazi, F.A.; Majid, F. Damage of additively manufactured polymer materials: Experimental and probabilistic analysis. Fract. Struct. Integr. 2025, 19, 236–255. [Google Scholar] [CrossRef]

- Syaefudin, E.A.; Kholil, A.; Hakim, M.; Wulandari, D.A.; Murtinugraha, E. The effect of orientation on tensile strength 3D printing with ABS and PLA materials. J. Phys. Conf. Ser. 2023, 2596, 012002. [Google Scholar] [CrossRef]

- Shergill, K.; Chen, Y.; Bull, S. An investigation into the layer thickness effect on the mechanical properties of additively manufactured polymers: PLA and ABS. Int. J. Adv. Manuf. Technol. 2023, 126, 3651–3665. [Google Scholar] [CrossRef]

- Kartal, F.; Kaptan, A. Response of PLA material to 3D printing speeds: A comprehensive examination on mechanical properties and production quality. Eur. Mech. Sci. 2024, 8, 137–144. [Google Scholar] [CrossRef]

- Adarsh, S.H.; Nagamadhu, M. Effect of Printing Parameters on Mechanical Properties and Warpage of 3D-Printed PEEK/CF-PEEK Composites Using Multi-Objective Optimization Technique. J. Compos. Sci. 2025, 9, 208. [Google Scholar] [CrossRef]

- Iftekar, S.F.; Aabid, A.; Amir, A.; Baig, M. Advancements and Limitations in 3D Printing Materials and Technologies: A Critical Review. Polymers 2023, 15, 2519. [Google Scholar] [CrossRef]

- Naboulsi, N.; Majid, F.; Zekriti, N. Experimental Analysis of Mechanical Properties of Polymeric Insulation in HV Underground Cables. J. Mater. Environ. Sci. 2025, 16, 1721–1730. [Google Scholar]

- Sepahi, M.T.; Abusalma, H.; Jovanovic, V.; Eisazadeh, H. Mechanical Properties of 3D-Printed Parts Made of Polyethylene Terephthalate Glycol. J. Mater. Eng. Perform. 2021, 30, 6851–6861. [Google Scholar] [CrossRef]

- Algarni, M.; Ghazali, S. Comparative Study of the Sensitivity of PLA, ABS, PEEK, and PETG’s Mechanical Properties to FDM Printing Process Parameters. Crystals 2021, 11, 995. [Google Scholar] [CrossRef]

- Spoerk, M.; Gonzalez-Gutierrez, J.; Lichal, C.; Cajner, H.; Berger, G.R.; Schuschnigg, S.; Cardon, L.; Holzer, C. Optimisation of the Adhesion of Polypropylene-Based Materials during Extrusion-Based Additive Manufacturing. Polymers 2018, 10, 490. [Google Scholar] [CrossRef]

- Aberoumand, M.; Soltanmohammadi, K.; Rahmatabadi, D.; Soleyman, E.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Bodaghi, M.; Baghani, M. 4D Printing of Polyvinyl Chloride (PVC): A Detailed Analysis of Microstructure, Programming, and Shape Memory Performance. Macromol. Mater. Eng. 2023, 308, 2200677. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Soltanmohammadi, K.; Aberoumand, M.; Soleyman, E.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Bodaghi, M.; Baghani, M. Development of Pure Poly Vinyl Chloride (PVC) with Excellent 3D Printability and Macro- and Micro-Structural Properties. Macromol. Mater. Eng. 2022, 308, 2200568. [Google Scholar] [CrossRef]

- Wampol, C. Additive Manufacturing with High Density Polyethylene: Mechanical Properties Evaluation. 2018, p. 2693. Available online: https://openprairie.sdstate.edu/etd/2693 (accessed on 16 June 2025).

- Schirmeister, C.G.; Hees, T.; Licht, E.H.; Mülhaupt, R. 3D printing of high density polyethylene by fused filament fabrication. Addit. Manuf. 2019, 28, 152–159. [Google Scholar] [CrossRef]

- El Magri, A.; Vanaei, S.; Vaudreuil, S. An overview on the influence of process parameters through the characteristic of 3D-printed PEEK and PEI parts. High Perform. Polym. 2021, 33, 862–880. [Google Scholar] [CrossRef]

- Zanjanijam, A.R.; Major, I.; Lyons, J.G.; Lafont, U.; Devine, D.M. Fused Filament Fabrication of PEEK: A Review of Process-Structure-Property Relationships. Polymers 2020, 12, 1665. [Google Scholar] [CrossRef]

- Vaezi, M.; Yang, S. Extrusion-based additive manufacturing of PEEK for biomedical applications. Virtual Phys. Prototyp. 2015, 10, 123–135. [Google Scholar] [CrossRef]

- Yilmaz, S. Comprehensive analysis of 3D printed PA6.6 and fiber-reinforced variants: Revealing mechanical properties and adhesive wear behavior. Polym. Compos. 2023, 45, 1446–1460. [Google Scholar] [CrossRef]

- Shakeri, Z.; Benfriha, K.; Zirak, N.; Shirinbayan, M. Mechanical strength and shape accuracy optimization of polyamide FFF parts using grey relational analysis. Sci. Rep. 2022, 12, 13142. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Moutsopoulou, A.; Papadakis, V.; Spiridaki, M.; Mountakis, N.; Charou, C.; Tsikritzis, D.; Maravelakis, E. Nanocomposites with Optimized Polytetrafluoroethylene Content as a Reinforcement Agent in PA12 and PLA for Material Extrusion Additive Manufacturing. Polymers 2023, 15, 2786. [Google Scholar] [CrossRef] [PubMed]

- Radzuan, N.A.M.; Samudin, I.M.; Sereshk, M.R.V.; Ma, Q.; Sulong, A.B.; Foudzi, F.M.; Royan, N.R.R. A comprehensive approach for the production of carbon fibre-reinforced polylactic acid filaments with enhanced wear and mechanical behaviour. e-Polymers 2025, 25, 20250002. [Google Scholar] [CrossRef]

- Çaylak, S.; Navidfar, A.; Trabzon, L. Review on polylactic acid and Polycaprolactone composites with Carbon-Based reinforcements: CNTs and GNPs integration. Emergent Mater. 2025, 1–24. [Google Scholar] [CrossRef]

- Xu, X.; Yang, L.; Zheng, W.; Zhang, H.; Wu, F.; Tian, Z.; Zhang, P.; Sun, Z. MXenes with applications in supercapacitors and secondary batteries: A comprehensive review. Mater. Rep. Energy 2022, 2, 100080. [Google Scholar] [CrossRef]

- Beltrán, F.R.; Aksas, H.; Salah, L.S.; Danlée, Y.; Huynen, I. Theoretical Prediction of Electrical Conductivity Percolation of Poly(lactic acid)—Carbon Nanotube Composites in DC and RF Regime. Materials 2023, 16, 5356. [Google Scholar] [CrossRef]

- Zhou, X.; Wu, L.; Wang, J. Recent developments in conductive polymer composites for fused deposition modeling. Compos. Part A Appl. Sci. Manuf. 2023, 174, 107739. [Google Scholar] [CrossRef]

- Masiuchok, O.; Iurzhenko, M.; Kolisnyk, R.; Mamunya, Y.; Godzierz, M.; Demchenko, V.; Yermolenko, D.; Shadrin, A. Polylactide/Carbon Black Segregated Composites for 3D Printing of Conductive Products. Polymers 2022, 14, 4022. [Google Scholar] [CrossRef]

- Cheong, K.L.; Pang, M.M.; Low, J.H.; Tshai, K.Y.; Koay, S.C.; Wong, W.Y.; Ch’ng, S.Y.; Buys, Y.F. Graphene Nanoplatelets/Polylactic Acid Conductive Polymer Composites: Tensile, Thermal and Electrical Properties. Chem. Eng. Technol. 2024, 47, e202300592. [Google Scholar] [CrossRef]

- Doganay, D.; Coskun, S.; Kaynak, C.; Unalan, H.E. Electrical, mechanical and thermal properties of aligned silver nanowire/polylactide nanocomposite films. Compos. B Eng. 2016, 99, 288–296. [Google Scholar] [CrossRef]

- Masarra, N.-A.; Quantin, J.-C.; Batistella, M.; El Hage, R.; Pucci, M.F.; Lopez-Cuesta, J.-M. Influence of Polymer Processing on the Double Electrical Percolation Threshold in PLA/PCL/GNP Nanocomposites. Sensors 2022, 22, 9231. [Google Scholar] [CrossRef]

- Lu, X.; Kang, B.; Shi, S. Selective Localization of Carbon Black in Bio-Based Poly (Lactic Acid)/Recycled High-Density Polyethylene Co-Continuous Blends to Design Electrical Conductive Composites with a Low Percolation Threshold. Polymers 2019, 11, 1583. [Google Scholar] [CrossRef] [PubMed]

- Giner-Grau, S.; Lazaro-Hdez, C.; Pascual, J.; Fenollar, O.; Boronat, T. Enhancing Polylactic Acid Properties with Graphene Nanoplatelets and Carbon Black Nanoparticles: A Study of the Electrical and Mechanical Characterization of 3D-Printed and Injection-Molded Samples. Polymers 2024, 16, 2449. [Google Scholar] [CrossRef] [PubMed]

- Haghgoo, M.; Ansari, R.; Hassanzadeh-Aghdam, M.K. Augmented electrical conductivity of hybrid graphene nanoplatelets carbon nanotubes polymer nanocomposites by the electro-magnetic field induced subbands. J. Mater. Res. Technol. 2025, 34, 2909–2918. [Google Scholar] [CrossRef]

- Seetala, K.; Clower, W.; Wilson, C.G. Electrochemical enhancement of carbon black-infused poly(lactic acid) filament for additive manufactured electronic applications. Addit. Manuf. 2022, 61, 103283. [Google Scholar] [CrossRef]

- Kilinc, F.B.; Turkoglu, T.; Guler, S.; Kilinc, A.C. Optimization of 3D printing parameters for enhanced tensile properties in continuous carbon fiber reinforced PLA composites. Mater. Res. Express 2025, 12, 045302. [Google Scholar] [CrossRef]

- Du, Y.-K.; Shi, Z.-X.; Dong, S.; Jin, H.; Ke, X.; Zhao, P.; Jiang, B.-B.; You, F. Recent Progress in Fabrication and Structural Design of Thermal Conductive Polymer Composites. Chin. J. Polym. Sci. 2023, 42, 277–291. [Google Scholar] [CrossRef]

- Iffelsberger, C.; Jellett, C.W.; Pumera, M. 3D Printing Temperature Tailors Electrical and Electrochemical Properties through Changing Inner Distribution of Graphite/Polymer. Small 2021, 17, 2101233. [Google Scholar] [CrossRef] [PubMed]

- da Silva, F.U.; Luna, C.B.B.; da Silva, F.S.; Barreto, J.V.M.; Schmitz, D.P.; Soares, B.G.; Wellen, R.M.R.; Araújo, E.M. Exploring the Effect of Annealing on PLA/Carbon Nanotube Nanocomposites: In Search of Efficient PLA/MWCNT Nanocomposites for Electromagnetic Shielding. Polymers 2025, 17, 246. [Google Scholar] [CrossRef]

- França, Á.R.S.; Batista, B.d.S.; Filho, J.F.S.D.; Sousa, R.M.V.; de Menezes, A.S.; dos Santos, C.C.; Santos-Oliveira, R.; Souza, P.F.N.; da Silva, L.M.; Alencar, L.M.R. Sustainable Graphene Synthesis and Analysis of Graphene-Based PLA Nanocomposites: Impacts of Polymer Functionalization and Potential Applications in Cancer Treatments. ACS Omega 2025, 10, 24520–24531. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-Rodríguez, C.; Avilés, M.-D.; Pamies, R.; Carrión-Vilches, F.-J.; Sanes, J.; Bermúdez, M.-D. Extruded PLA Nanocomposites Modified by Graphene Oxide and Ionic Liquid. Polymers 2021, 13, 655. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, C.; Xin, Z.; Luo, Y.; Wang, B.; Feng, X.; Mao, Z.; Sui, X. Poly(lactic acid)/carbon nanotube composites with enhanced electrical conductivity via a two-step dispersion strategy. Compos. Commun. 2022, 30, 101087. [Google Scholar] [CrossRef]

- Yang, L.; Li, S.; Zhou, X.; Liu, J.; Li, Y.; Yang, M.; Yuan, Q.; Zhang, W. Effects of carbon nanotube on the thermal, mechanical, and electrical properties of PLA/CNT printed parts in the FDM process. Synth. Met. 2019, 253, 122–130. [Google Scholar] [CrossRef]

- Younus, M.M.; Naguib, H.M.; Fekry, M.; Elsawy, M.A. Pushing the limits of PLA by exploring the power of MWCNTs in enhancing thermal, mechanical properties, and weathering resistance. Sci. Rep. 2023, 13, 16588. [Google Scholar] [CrossRef]

- Kumar, G.P.; Keshavamurthy, R.; Panigrahi, S.P.; Thomas, S.; Hebbar, G.S.; Prasad, C.D.; Aden, A.A. Enhanced mechanical properties of CNT/Graphene reinforced PLA-based composites fabricated via fused deposition modelling. Results Eng. 2025, 25, 104472. [Google Scholar] [CrossRef]

- Guo, J.; Tsou, C.-H.; Yu, Y.; Wu, C.-S.; Zhang, X.; Chen, Z.; Yang, T.; Ge, F.; Liu, P.; De Guzman, M.R. Conductivity and mechanical properties of carbon black-reinforced poly(lactic acid) (PLA/CB) composites. Iran. Polym. J. 2021, 30, 1251–1262. [Google Scholar] [CrossRef]

- Yu, B.; Zhao, Z.; Fu, S.; Meng, L.; Liu, Y.; Chen, F.; Wang, K.; Fu, Q. Fabrication of PLA/CNC/CNT conductive composites for high electromagnetic interference shielding based on Pickering emulsions method. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105558. [Google Scholar] [CrossRef]

- Lamberti, P.; Spinelli, G.; Kuzhir, P.P.; Guadagno, L.; Naddeo, C.; Romano, V.; Kotsilkova, R.; Angelova, P.; Georgiev, V. Evaluation of thermal and electrical conductivity of carbon-based PLA nanocomposites for 3D printing. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2018; Volume 1981, p. 020158. [Google Scholar] [CrossRef]

- Spinelli, G.; Lamberti, P.; Tucci, V.; Kotsilkova, R.; Ivanov, E.; Menseidov, D.; Naddeo, C.; Romano, V.; Guadagno, L.; Adami, R.; et al. Nanocarbon/Poly(Lactic) Acid for 3D Printing: Effect of Fillers Content on Electromagnetic and Thermal Properties. Materials 2019, 12, 2369. [Google Scholar] [CrossRef] [PubMed]

- Zeranska-Chudek, K.; Wróblewska, A.; Kowalczyk, S.; Plichta, A.; Zdrojek, M. Graphene Infused Ecological Polymer Composites for Electromagnetic Interference Shielding and Heat Management Applications. Materials 2021, 14, 2856. [Google Scholar] [CrossRef]

- Islam, M.S.; Elahee, G.M.F.; Fang, Y.; Yu, X.; Advincula, R.C.; Cao, C. Polylactic acid (PLA)-based multifunctional and biodegradable nanocomposites and their applications. Compos. B Eng. 2025, 306, 112842. [Google Scholar] [CrossRef]

- Singh, N.; Kaur, A.; Madhu, A.; Yadav, M. Advancements in nanotechnology for biomedical and wearable applications. Next Mater. 2025, 8, 100658. [Google Scholar] [CrossRef]

- Liu, Y.-Y.; Echeverry-Rendón, M. 3D-printed biodegradable polymer scaffolds for tissue engineering: An overview, current stage and future perspectives. Next Mater. 2025, 8, 100647. [Google Scholar] [CrossRef]

- Gasparotto, M.; Bellet, P.; Scapin, G.; Busetto, R.; Rampazzo, C.; Vitiello, L.; Shah, D.I.; Filippini, F. 3D Printed Graphene-PLA Scaffolds Promote Cell Alignment and Differentiation. Int. J. Mol. Sci. 2022, 23, 1736. [Google Scholar] [CrossRef]

- Dixon, D.T.; Gomillion, C.T. 3D-Printed conductive polymeric scaffolds with direct current electrical stimulation for enhanced bone regeneration. J. Biomed. Mater. Res. B Appl. Biomater. 2023, 111, 1351–1364. [Google Scholar] [CrossRef]

- González-Rodríguez, L.; Pérez-Davila, S.; Lama, R.; López-Álvarez, M.; Serra, J.; Novoa, B.; Figueras, A.; González, P. 3D printing of PLA:CaP:GO scaffolds for bone tissue applications. RSC Adv. 2023, 13, 15947–15959. [Google Scholar] [CrossRef]

- Ferguson, M.; Egorov, V.; Zhang, Y.; Gulzar, U.; O’Dwyer, C. Effect of Solvent Presoaking of FDM-Printed Conductive PLA Current Collectors in 3D-Printed Carbon Supercapacitors. ACS Appl. Eng. Mater. 2025, 3, 613–624. [Google Scholar] [CrossRef]

- Papavasileiou, A.V.; Děkanovský, L.; Chacko, L.; Wu, B.; Luxa, J.; Regner, J.; Paštika, J.; Koňáková, D.; Sofer, Z. Unraveling the Versatility of Carbon Black—Polylactic Acid (CB/PLA) 3D-Printed Electrodes via Sustainable Electrochemical Activation. Small Methods 2025, 9, 2402214. [Google Scholar] [CrossRef] [PubMed]

- Bera, T.; Mohanty, S. Design and Characterization of 3D-Printed Capacitors Using Conductive and Non-Conductive PLA Filaments. J. Appl. Polym. Sci. 2025, 142, e56965. [Google Scholar] [CrossRef]

- Mappoli, S.; Ghosh, K.; Pumera, M. Integrated free-standing WS 2 3D-printed carbon supercapacitor with solid state electrolyte. Virtual Phys. Prototyp. 2024, 19, e2326897. [Google Scholar] [CrossRef]

- Kalinke, C.; Neumsteir, N.V.; Aparecido, G.d.O.; Ferraz, T.V.d.B.; dos Santos, P.L.; Janegitz, B.C.; Bonacin, J.A. Comparison of activation processes for 3D printed PLA-graphene electrodes: Electrochemical properties and application for sensing of dopamine. Analyst 2019, 145, 1207–1218. [Google Scholar] [CrossRef] [PubMed]

- Jeon, J.G.; Hong, G.-W.; Park, H.-G.; Lee, S.K.; Kim, J.-H.; Kang, T.J. Resistance Temperature Detectors Fabricated via Dual Fused Deposition Modeling of Polylactic Acid and Polylactic Acid/Carbon Black Composites. Sensors 2021, 21, 1560. [Google Scholar] [CrossRef] [PubMed]

- Mappoli, S.; Sonigara, K.K.; Subhadarshini, S.; Pumera, M. 3D-Printed Nanocarbon Polymer Conductive Structures for Electromagnetic Interference Shielding. Small Methods 2025, 9, 2401822. [Google Scholar] [CrossRef]

- Liu, T.; Feng, H.; Zeng, W.; Jin, C.; Kuang, T. Facile Fabrication of Absorption-Dominated Biodegradable Poly(lactic acid)/Polycaprolactone/Multi-Walled Carbon Nanotube Foams towards Electromagnetic Interference Shielding. J. Compos. Sci. 2023, 7, 395. [Google Scholar] [CrossRef]

- Nan, X.; Zhang, Y.; Shen, J.; Liang, R.; Wang, J.; Jia, L.; Yang, X.; Yu, W.; Zhang, Z. A Review of the Establishment of Effective Conductive Pathways of Conductive Polymer Composites and Advances in Electromagnetic Shielding. Polymers 2024, 16, 2539. [Google Scholar] [CrossRef]

- Li, X.; Zeng, B.; Zheng, Y.; Zhou, J. Excellent mechanical and electromagnetic interference shielding properties of polylactic acid/polycaprolactone/multiwalled carbon nanotube composites enabled by a multilayer structure design. RSC Adv. 2024, 14, 20390–20397. [Google Scholar] [CrossRef]

- Abbas, R.; Rehman, U.U.; Bilal, A.; Sultan, N.; Ghazanfar, U.; Ali, T.; Nadeem, M. 3D printed lightweight honeycomb vent structures with subsequent coating of silver nanowires for efficient electromagnetic interference (EMI) shielding. Heliyon 2024, 10, e30429. [Google Scholar] [CrossRef]

| Polymers | Young Modulus (GPa) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation at Break (%) | Refs |

|---|---|---|---|---|---|

| PLA (Polylactic Acid) | ~3.6 | - | ~60 | ~6 | [31] |

| ~3.734 | ~49.58 | - | ~4.68 | [32] | |

| ~3.5 | ~59 | ~70 | 7 | [4,33] | |

| ABS (Acrylonitrile Butadiene Styrene) | ~2.1555 | ~36.10 | ~26.73 | ~30 Ductility: ~21.34 | [34,35] |

| From ~2.6 to ~3 | ~40 | - | ~50 | [33] | |

| PP (Polypropylene) | ~1.3 | - | ~32 | 70 | [36] |

| Soft PVC (Polyvinyl Chloride) | ~1.971 | ~26.6 | - | ~167.2 | [37] |

| PE (Polyethylene) | ~0.21 | ~11.7 | ~15.43 | [38] | |

| PET (Polyethylene Terephthalate) | ~1.094 | ~60.6 | - | ~8.1 | [39] |

| Composites (PLA/Fillers) | Filler Content | Tensile Strength | Yield Strength (MPa) | Elongation at Break (%) | Young Modulus | Method | Refs |

|---|---|---|---|---|---|---|---|

| PLA/CNT + Graphène | 0.5 wt% CNT + 0.5 wt% Graphene | 35 MPa | ~22 MPa | 0.8% | ~3 GPa | FDM | [83] |

| 1.0 wt% CNT + 0.5 wt% Graphene | 42 MPa | ~25 MPa | 0.7% | ~3.5 GPa | FDM | ||

| 1.5 wt% CNT + 0.5 wt% Graphène | 48 MPa | ~28 MPa | 0.5% | ~4 GPa | FDM | ||

| PLA/CNC/CNT | 4.3 wt% CNT | 45.52 MPa | ~45.52 MPa | 2.5% | ~3.152 GPa | Pickering emulsions | [85] |

| PLA/GNP | 1 wt% GNP | ~43 MPa | - | ~4.05% | ~4.1 GPa | Melt blending | [67] |

| 3 wt% GNP | ~47 MPa | - | ~3.4% | ~4.25 GPa | |||

| 7 wt% GNP | ~36 MPa | - | ~3.7% | ~3.35 GPa | |||

| 12 wt% GNP | ~27 MPa | - | ~3.9% | ~3.3 GPa | |||

| PLA/CNTs | 5.6 wt% CNT | ~71.4 MPa | ~35 MPa | ~1.75% | ~1.53 E (Young Modulus of neat PLA) | Melt blending | [80] |

| PLA/CNTs | 2 wt% CNT | ~48 MPa | ~26 MPa | ~5.5% | ~1.27 GPa | Melt blending | [81] |

| 4 wt% CNT | ~56 MPa | ~35 MPa | ~4.3% | ~1.65 GPa | |||

| 6 wt% CNT | ~68.5 MPa | ~42 MPa | ~4.25% | ~1.92 GPa | |||

| PLA/GNPs | 5 wt% GNP | ~37 MPa | - | ~1.5% | ~875 MPa | 3D printing | [71] |

| 10 wt% GNP | ~27 MPa | - | ~1.7% | ~1100 MPa | |||

| PLA/CB | 5 wt% CB | ~37.5 MPa | - | ~3.75% | ~875 MPa | ||

| 10 wt% CB | ~31 MPa | - | ~5% | ~1060 MPa | |||

| PLA/GNPs | 5 wt% GNP | ~34 MPa | - | ~5% | ~750 MPa | Injection Molding | |

| 10 wt% GNP | ~30 MPa | - | ~4.87% | ~825 MPa | |||

| PLA/CB | 5 wt% CB | ~38 MPa | - | ~9.75% | ~760 MPa | ||

| 10 wt% CB | ~33 MPa | - | ~11.25% | ~900 MPa | |||

| PLA/CNTs | 0.5 wt% CNTs | ~72.2 MPa | - | ~24.4% | ~3.9 GPa | Solution casting | [82] |

| 1 wt% CNTs | ~72 MPa | - | ~30.3% | ~3.86 GPa | |||

| 3 wt% CNTs | ~64 MPa | - | ~51.8% | ~3.3 GPa | |||

| 5 wt% CNTs | ~66.2 MPa | - | ~42.7% | ~3.19 GPa | |||

| PLA/CB | 4 wt% CB | ~54 MPa | - | ~5.3% | - | Melt-compounding | [84] |

| 8 wt% CB | ~60 MPa | - | ~5.1% | - | |||

| 12 wt% CB | ~63.5 MPa | - | ~4.8% | - | |||

| 16 wt% CB | ~43 MPa | - | ~3.2% | - | |||

| 20 wt% CB | ~38 MPa | - | ~2.9% | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naboulsi, N.; Majid, F.; Louzazni, M. Environmentally Friendly PLA-Based Conductive Composites: Electrical and Mechanical Performance. J. Compos. Sci. 2025, 9, 571. https://doi.org/10.3390/jcs9100571

Naboulsi N, Majid F, Louzazni M. Environmentally Friendly PLA-Based Conductive Composites: Electrical and Mechanical Performance. Journal of Composites Science. 2025; 9(10):571. https://doi.org/10.3390/jcs9100571

Chicago/Turabian StyleNaboulsi, Nassima, Fatima Majid, and Mohamed Louzazni. 2025. "Environmentally Friendly PLA-Based Conductive Composites: Electrical and Mechanical Performance" Journal of Composites Science 9, no. 10: 571. https://doi.org/10.3390/jcs9100571

APA StyleNaboulsi, N., Majid, F., & Louzazni, M. (2025). Environmentally Friendly PLA-Based Conductive Composites: Electrical and Mechanical Performance. Journal of Composites Science, 9(10), 571. https://doi.org/10.3390/jcs9100571