Mechanical Performance of Pultruded and Compression-Molded CFRTP Laminates: A Comparative Study

Abstract

1. Introduction

2. Materials and Methods

3. Tensile Testing

3.1. Tensile Testing Methodology

3.2. Tensile Testing Results

3.3. Discussion of Tensile Testing Results

4. Compression Testing

4.1. Compression Testing Methodology

4.2. Compression Testing Results

4.3. Discussion of Compression Testing Results

5. Short Beam Strength Testing

5.1. Short Beam Strength Testing Methodology

5.2. Short Beam Strength Testing Results

5.3. Discussion of Short Beam Strength Testing Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ASCC | Advanced Structures and Composites Center |

| ATL | Automated tape layup |

| AFP | Automated fiber placement |

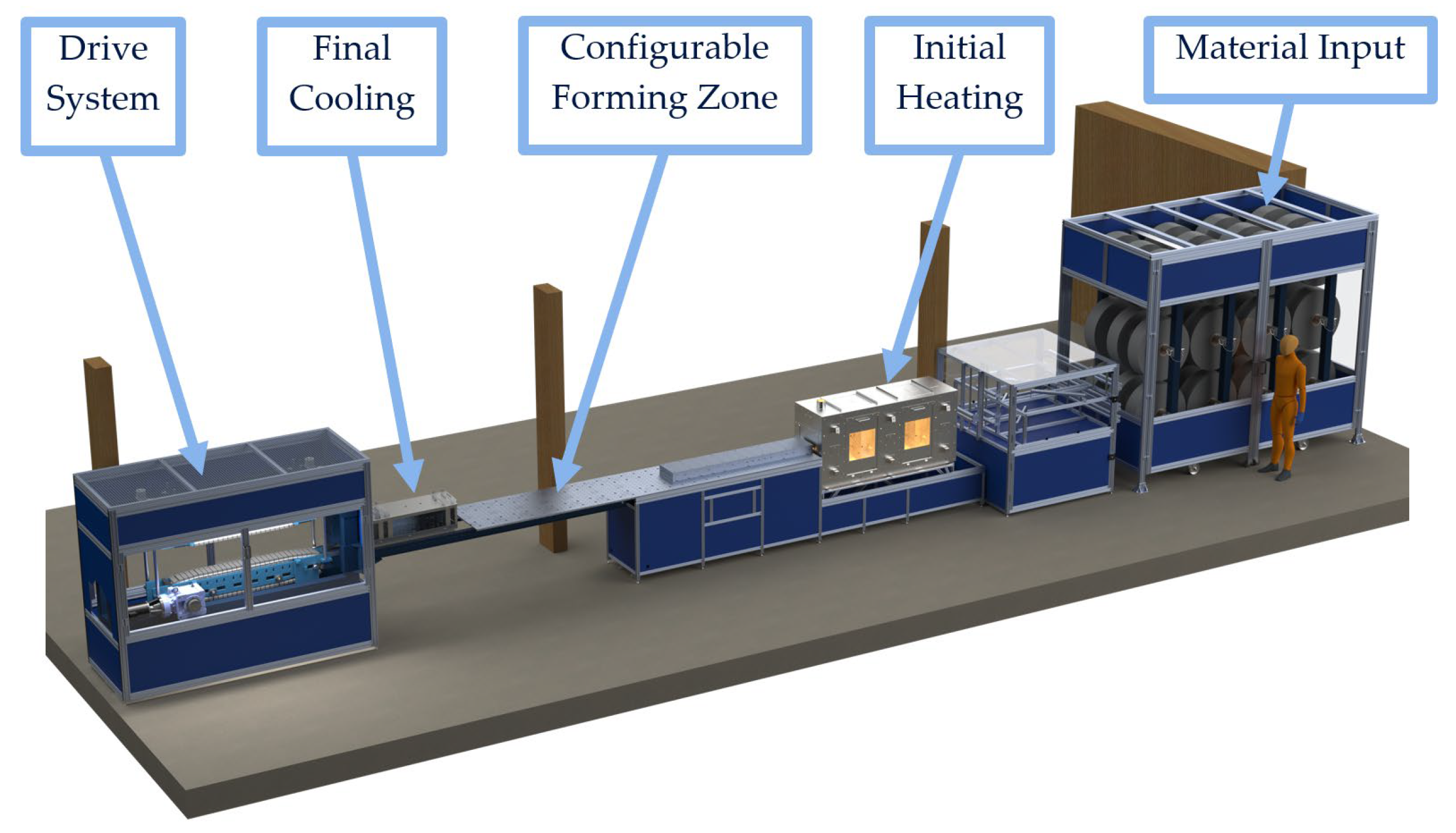

| CFM | Continuous forming machine |

| CFRTP | Continuous fiber-reinforced thermoplastic |

| CoV | Coefficient of variation |

| PCT | Pre-consolidated tape |

| Rebar | Reinforcement bar |

| TPL | Alfond Advanced Manufacturing Lab for Structural Thermoplastics |

Appendix A

References

- Kravtsova, V.; Minchenkov, K.; Gusev, S.; Evlashin, S.; Bondareva, J.; Alajarmeh, O.; Safonov, A. Recyclability of unidirectional reinforced pultruded thermoplastic profiles in composite laminates. Compos. Commun. 2024, 46, 101843. [Google Scholar] [CrossRef]

- Danzi, F.; Silva Campos, P.J.; Arteiro, A.; Dalli, D.; Furtado, C.; Chevalier, J.; Tavares, R.P.; Lani, F.; Camanho, P.P. Longitudinal failure mechanisms and crack resistance curves of unidirectional thermoplastic composites. Eng. Fract. Mech. 2023, 282, 109147. [Google Scholar] [CrossRef]

- Zoller, A.; Escalé, P.; Gérard, P. Pultrusion of Bendable Continuous Fibers Reinforced Composites with Reactive Acrylic Thermoplastic ELIUM® Resin. Front. Mater. 2019, 6, 290. [Google Scholar] [CrossRef]

- Dagher, H.J.; Bannon, D.J.; Davids, W.G.; Lopez-Anido, R.A.; Nagy, E.; Goslin, K. Bending behavior of concrete-filled tubular FRP arches for bridge structures. Constr. Build. Mater. 2012, 37, 432–439. [Google Scholar] [CrossRef]

- Davids, W.G.; Diba, A.; Dagher, H.J.; Guzzi, D.; Schanck, A.P. Development, assessment, and implementation of a novel FRP composite girder bridge. Constr. Build. Mater. 2022, 340, 127818. [Google Scholar] [CrossRef]

- Bechtold, G.; Wiedmer, S.; Friedrich, K. Pultrusion of Thermoplastic Composites—New Developments and Modelling Studies. Thermoplast. Compos. Mater. 2002, 15, 443–465. [Google Scholar] [CrossRef]

- Margossian, A.; Bel, S.; Hinterhoelzl, R. On the characterization of transverse tensile properties of molten unidirectional thermoplastic composite tapes for thermoforming simulations. Compos. Part A 2016, 88, 48–58. [Google Scholar] [CrossRef]

- Ambrogio, G.; Conte, R.; Gagliardi, F.; De Napoli, L.; Filice, L.; Russo, P. A new approach for forming polymeric composite structures. Compos. Struct. 2018, 204, 445–453. [Google Scholar] [CrossRef]

- Vaidya, U.K.; Chawla, K.K. Processing of fibre reinforced thermoplastic composites. Int. Mater. Rev. 2008, 53, 185–218. [Google Scholar] [CrossRef]

- Khurshid, M.F.; Hengstermann, M.; Badrul Hasan, M.M.; Abdkader, A.; Cherif, C. Recent developments in the processing of waste carbon fibre for thermoplastic composites—A review. Compos. Mater. 2020, 54, 1925–1944. [Google Scholar] [CrossRef]

- Donough, M.J.; Shafaq; St John, N.A.; Philips, A.W.; Gangadhara Prusty, B. Process modelling of In-situ consolidated thermoplastic composite by automated fibre placement—A review. Compos. Part A 2022, 163, 107179. [Google Scholar] [CrossRef]

- Chadwick, A.R.; Doll, G.; Christ, U.; Maier, S.; Lansky, S. Performance of In-situ Automated Fibre Placement Parts. Compos. Part A 2025, 192, 108725. [Google Scholar] [CrossRef]

- Fairuz, A.M.; Sapuan, S.M.; Zainudin, E.S.; Jaafar, C.N.A. Polymer composite manufacturing using a pultrusion process: A review. Am. J. Appl. Sci. 2014, 11, 1798–1810. [Google Scholar] [CrossRef]

- Suratno, B.R.; Ye, L.; Mai, Y.W. Simulation of temperature and curing profiles in pultruded composite rods. Compos. Sci. Technol. 1998, 58, 191–197. [Google Scholar] [CrossRef]

- Vedernikov, A.N.; Safonov, A.A.; Askhatov, I.S. Modelling and experimental validation of thermoset resin curing during pultrusion. In Proceedings of the 32th International Conference of Young Scientists and Students Topical Problems of Mechanical Engineering 2020, Moscow, Russia, 2–4 December 2020. [Google Scholar] [CrossRef]

- Joshi, S.C.; Lam, Y.C.; Win Tun, U. Improved cure optimization in pultrusion with pre-heating and die-cooler temperature. Compos. Part A 2003, 34, 1151–1159. [Google Scholar] [CrossRef]

- Udipi, K.; Dave, R.S.; Kruse, R.L.; Stebbins, L.R. Anionic Polymerization of Lactams: Some Industrial Applications. In Applications of Anionic Polymerization Research; American Chemical Society: Washington, DC, USA, 1998; pp. 255–266. [Google Scholar]

- Luisier, A.; Bourban, P.-E.; Månson, J.-A.E. Reaction injection pultrusion of PA12 composites: Process and modelling. Compos. Part A 2003, 34, 583–595. [Google Scholar] [CrossRef]

- Minchenkov, K.; Vedernikov, A.; Safonov, A.; Akhatov, I. Thermoplastic Pultrusion: A Review. Polymers 2021, 13, 180. [Google Scholar] [CrossRef] [PubMed]

- Devlin, B.J.; Williams, M.D.; Quinn, J.A.; Gibson, A.G. Pultrusion of unidirectional composites with thermoplastic matrices. Compos. Manuf. 1991, 2, 203–207. [Google Scholar] [CrossRef]

- Nunes, J.P.; Van Hattum, F.W.J.; Bernardo, C.A.; Silva, J.F.; Marques, A.T. Advances in Thermoplastic Matrix Towpregs Processing. Thermoplast. Compos. Mater. 2004, 17, 523–544. [Google Scholar] [CrossRef]

- Novo, P.J.; Silva, J.F.; Nunes, J.P.; Marques, A.T. Pultrusion of fibre reinforced thermoplastic pre-impregnated materials. Compos. Part B 2016, 89, 328–339. [Google Scholar] [CrossRef]

- Esfandiari, P.; Silva, J.F.; Novo, P.J.; Nunes, J.P.; Marques, A.T. Production and processing of pre-impregnated thermoplastic tapes by pultrusion and compression moulding. Compos. Mater. 2022, 56, 1667–1676. [Google Scholar] [CrossRef]

- Vedernikov, A.; Minchenkov, K.; Gusev, S.; Sulimov, A.; Zhou, P.; Li, C.; Xian, G.; Akhatov, I.; Safonov, A. Effects of the Pre-Consolidated Materials Manufacturing Method on the Mechanical Properties of Pultruded Thermoplastic Composites. Polymers 2022, 14, 2246. [Google Scholar] [CrossRef]

- Haller, J.C., Jr.; Clark, J.C.; Gayton, J.T.; Hunter, M.S.; Schanck, A.P.; Sheltra, C.A.; Davids, W.G.; Lopez-Anido, R.A.; Lapp, J.L. Novel Field-Manufacturing Methods for Long-Fiber Thermoplastic Composites. SAMPE J. 2025, 61, 30–39. [Google Scholar] [CrossRef]

- A+ Composites GmbH. UD-Tape GF-PA12-53-103-186: Technical Data Sheet; A+ Composites GmbH: Gugelingen, Germany, 2023. [Google Scholar]

- Avient Corporation. Polystrand™ IE 7034B: Technical Data Sheet. 2022. Available online: https://catalog.ides.com/Datasheet.aspx?I=19843&FMT=PDF&CULTURE=en-US&E=416164&SKEY=19843.1484624.250860989%3A2957a163-5667-415a-acf8-48857b600e0f& (accessed on 20 June 2025).

- Avient Corporation. Polystrand™ IE 5843.1: Technical Data Sheet. 2022. Available online: https://catalog.ides.com/Datasheet.aspx?I=19843&FMT=PDF&CULTURE=en-US&E=426853&SKEY=19843.1484624.250860989%3A2957a163-5667-415a-acf8-48857b600e0f& (accessed on 20 June 2025).

- A+ Composites GmbH. UD-Tape GF-PC-51-103-193: Technical Data Sheet; A+ Composites GmbH: Gugelingen, Germany, 2023. [Google Scholar]

- A+ Composites GmbH. UD-Tape GF-HDPE-46-51-296: Technical Data Sheet; A+ Composites GmbH: Gugelingen, Germany, 2021. [Google Scholar]

- Victrex plc. Victrex AE™ 250 UDT (Provisional): Technical Data Sheet; Victrex plc: Thornton-Cleveleys, UK, 2020. [Google Scholar]

- ASTM Standard D3039/D3039M-17; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM Standard D618-21; Standard Practice for Conditioning Plastics for Testing. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- ASTM Standard D6641-23; Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Compression (CLC) Test Fixutre. ASTM International: West Conshohocken, PA, USA, 2023. [CrossRef]

- ASTM Standard D2344-22; Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- Hao, Z.; Wang, X.; Ke, H.; Wei, G.; Kardomateas, G.; Liu, L. Experimental and numerical investigation on the size effect of interlaminar shear strength for thick composites. Compos. Struct. 2025, 353, 118710. [Google Scholar] [CrossRef]

| Material System (Polymer/Fiber Abbreviation) | Material Supplier (Vendor’s Product Code) | Technical Data Sheet |

|---|---|---|

| Polyamide 12, Glass Fiber-Reinforced (PA12-GF) | A+ Composites (GF-PA12-53-103-186) | [26] |

| Polypropylene, Glass Fiber-Reinforced (PP-GF) | Avient Corporation (PolystrandTM IE 7034BU) | [27] |

| Polyethylene Terephthalate Glycol, Glass Fiber-Reinforced (PETG-GF) | Avient Corporation (PolystrandTM IE 5843.1) | [28] |

| Polycarbonate, Glass Fiber-Reinforced (PC-GF) | A+ Composites (GF-PC-51-103-193) | [29] |

| High-Density Polyethylene, Glass Fiber-Reinforced (HDPE-GF) | A+ Composites (GF-HDPE-46-51-296) | [30] |

| Low-Melt Polyaryletherketone, Carbon Fiber-Reinforced (LMPAEK-CF) | Victrex plc (Victrex AETM 250 UDT) | [31] |

| Material System | Number of Tows Used |

|---|---|

| PA12-GF | 15 tows at 5.04 cm widths |

| PP-GF | 14 tows at 5.04 cm widths |

| PETG-GF | 13 tows at 5.04 cm widths plus 1 tow at 2.54 cm width |

| PC-GF | 15 tows at 5.04 cm widths plus 4 tows at 0.635 cm widths |

| HDPE-GF | 9 tows at 5.04 cm widths plus 1 tow at 2.54 cm width |

| LMPAEK-CF | 21 tows at 5.04 cm widths |

| Material System | PA12-GF | PP-GF | PETG-GF | PC-GF | HDPE-GF | LMPAEK-CF |

|---|---|---|---|---|---|---|

| Line Speed (m/min) | 0.457 | 0.305 | 0.610 | 0.305 | 0.305 | 0.305 |

| Heater Zone 1 (°C) | 119.2 | 80.2 | 72.2 | 80.1 | 119.8 | 290.9 |

| Heater Zone 2 (°C) | 200.9 | 99.4 | 100.3 | 140.2 | 136.9 | 289.7 |

| Heater Zone 3 (°C) | 229.8 | 164.2 | 158.3 | 179.6 | 136.1 | 349.9 |

| Forming Zone 1 (Guide Plate) (°C) | 185.0 | 167.0 | 127.6 | 159.9 | 134.4 | 279.7 |

| Forming Zone 2 (Preformer) (°C) | 152.1 | 140.1 | 122.9 | 160.0 | 110.1 | 274.2 |

| Forming Zone 3 (°C) | 120.3 | 120.0 | 81.6 | 132.0 | 74.1 | 266.0 |

| Forming Zone 4 (°C) | 58.1 | 94.2 | 70.2 | 101.4 | 50.6 | 256.1 |

| Forming Zone 5 (°C) | 22.2 | 50.9 | 45.9 | 51.2 | 29.6 | 230.1 |

| Material System | CFM | Compression Molded | Technical Data Sheet |

|---|---|---|---|

| PA12-GF | 71.7 | 71.3 | 74 |

| PP-GF | 73.0 | 70.1 | 70 |

| PETG-GF | 58.0 | 59.1 | 58 |

| PC-GF | 68.3 | 68.8 | 69 |

| HDPE-GF | 70.0 | 68.9 | 69 |

| LMPAEK-CF | 66.9 | 68.7 | 66 |

| CFM-Pultruded Specimens | Compression-Molded Specimens | ||||||

|---|---|---|---|---|---|---|---|

| Material System | Average (GPa) | Standard Deviation (GPa) | CoV (%) | Average (GPa) | Standard Deviation (GPa) | CoV (%) | TDS Value (GPa) |

| PA12-GF | 42 | 0.8 | 1.9 | 44 | 1.3 | 2.9 | 45 |

| PP-GF | 42 | 2.3 | 5.5 | 42 | 4.5 | 10.7 | 34.5 |

| PETG-GF | 34 | 5.2 | 15.4 | 37 | 1.2 | 3.2 | 30.3 |

| PC-GF | 47 | 5.5 | 11.6 | 47 | 3.6 | 7.7 | 44 |

| HDPE-GF | 38 | 4.3 | 11.2 | 37 | 5.2 | 14.2 | 35 |

| LMPAEK-CF | 122 | 2.9 | 2.4 | 135 | 15.1 | 11.2 | >150 |

| Source of Data | Longitudinal Tensile Modulus (GPa) | Fiber Mass Fraction (%) |

|---|---|---|

| CFM-Pultruded PP-GF | 42 | 73.0 |

| Compression-Molded PP-GF | 42 | 70.1 |

| Novo et al. [22] | 33.9 | 69.3 |

| Esfandiari et al. [23] | 39.4 | 71.0 |

| Vedernikov et al. [24] | 26.2 | 60.3 |

| CFM Pultruded Specimens | Compression-Molded Specimens | ||||||

|---|---|---|---|---|---|---|---|

| Material System | Average (GPa) | Standard Deviation (GPa) | CoV (%) | Average (GPa) | Standard Deviation (GPa) | CoV (%) | TDS Value (GPa) |

| PA12-GF | 358 | 47.1 | 13.2 | 280 | 26.6 | 9.5 | n/a |

| PP-GF | 214 | 14.0 | 6.5 | 228 | 23.3 | 10.2 | 357 |

| PETG-GF | 291 | 31.4 | 10.8 | 315 | 29.5 | 9.4 | 621 |

| PC-GF | 386 | 79.5 | 20.6 | 351 | 46.6 | 13.3 | n/a |

| HDPE-GF | 171 | 16.0 | 9.3 | 172 | 10.8 | 6.3 | n/a |

| LMPAEK-CF | 643 | 44.4 | 6.9 | 668 | 125.6 | 18.8 | >1200 |

| CFM-Pultruded Specimens | Compression-Molded Specimens | ||||||

|---|---|---|---|---|---|---|---|

| Material System | Average (MPa) | Standard Deviation (MPa) | CoV (%) | Average (MPa) | Standard Deviation (MPa) | CoV (%) | TDS Value (MPa) |

| PA12-GF | 48.6 | 2.09 | 4.3 | 34.6 | 6.64 | 19.2 | n/a |

| PP-GF | 28.1 | 1.25 | 4.4 | 22.5 | 5.56 | 24.7 | 26 |

| PC-GF | 46.6 | 3.41 | 7.3 | 47.8 | 1.40 | 2.9 | n/a |

| LMPAEK-CF | 85.5 | 4.40 | 5.2 | 83.1 | 6.49 | 7.8 | n/a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haller, J.C., Jr.; Clark, J.C.; Gayton, J.T. Mechanical Performance of Pultruded and Compression-Molded CFRTP Laminates: A Comparative Study. J. Compos. Sci. 2025, 9, 572. https://doi.org/10.3390/jcs9100572

Haller JC Jr., Clark JC, Gayton JT. Mechanical Performance of Pultruded and Compression-Molded CFRTP Laminates: A Comparative Study. Journal of Composites Science. 2025; 9(10):572. https://doi.org/10.3390/jcs9100572

Chicago/Turabian StyleHaller, James C., Jr., Jacob C. Clark, and James T. Gayton. 2025. "Mechanical Performance of Pultruded and Compression-Molded CFRTP Laminates: A Comparative Study" Journal of Composites Science 9, no. 10: 572. https://doi.org/10.3390/jcs9100572

APA StyleHaller, J. C., Jr., Clark, J. C., & Gayton, J. T. (2025). Mechanical Performance of Pultruded and Compression-Molded CFRTP Laminates: A Comparative Study. Journal of Composites Science, 9(10), 572. https://doi.org/10.3390/jcs9100572