Production and Remanufacturing of Vitrimer Matrix Composite Tubes

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Production Methods

2.2. Characterization

3. Results and Discussion

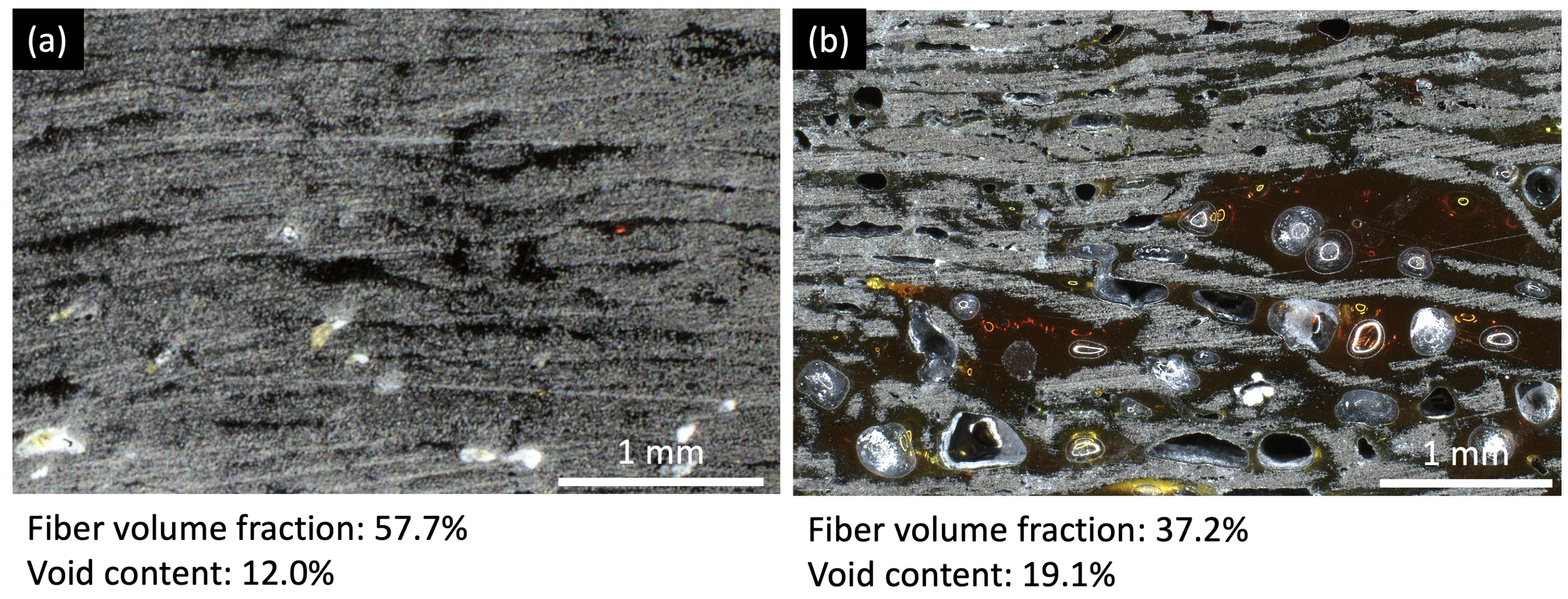

3.1. First-Generation Composites

3.2. Remanufactured Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| COPV | Composite overwrapped pressure vessel |

| CF | Carbon fiber |

| EOL | End of life |

| SEM | Scanning electron microscopy |

| CFRP | Carbon fiber-reinforced polymer |

| SBS | Short-beam shear |

Appendix A

| Fiber | Toray T700S | Teijin HTS40 |

|---|---|---|

| Tensile Strength (MPa) | 4900 | 4400 |

| Tensile Modulus (GPa) | 230 | 240 |

| Elongation (%) | 2.1 | 1.8 |

| Density (g/cm3) | 1.80 | 1.77 |

| Filament Count | 24K | 12K |

| Sizing | 50C (1%) | PU (1%) |

| Parameter | Value |

|---|---|

| Speed | 1.8 mm/s |

| Mandrel Rotation | 10 rpm |

| Mandrel Speed | 79.8 mm/s |

| Filament Width | 10 mm |

| Filament Thickness | 0.18 mm |

| Coupon | Diameter (mm) | Height (mm) | Layers |

|---|---|---|---|

| SBS | 152.4 | 38.1 | 14 |

| Dissolution | 31.75 | 50.8 | 2 |

References

- U.S. National Clean Hydrogen Strategy and Roadmap; U.S. Department of Energy: Washington, DC, USA, 2023. Available online: https://www.hydrogen.energy.gov/library/roadmaps-vision/clean-hydrogen-strategy-roadmap (accessed on 26 June 2025).

- National Aeronautics and Space Administration, Human Spaceflight Knowledge Sharing: Mitigating the High Risk of COPVs|APPEL Knowledge Services. Available online: https://appel.nasa.gov/2017/10/26/human-spaceflight-knowledge-sharing-mitigating-the-high-risk-of-copvs/ (accessed on 26 June 2025).

- Houchins, C.; James, B.D.; Acevedo, Y. Hydrogen Storage Cost Analysis. In Proceedings of the Technical Report, DOE Hydrogen Program 2021 Annual Merit Review and Peer Evaluation Meeting, Virtual, 7–11 June 2021. [Google Scholar]

- Mclaughlan, P.B.; Scott, P.E.; Forth, C.; Grimes-Ledesma, L.R. Composite Overwrapped Pressure Vessels, A Primer; Technical Report; Johnson Space Center: Houston, TX, USA, 2011.

- Taynton, P.; Ni, H.; Zhu, C.; Yu, K.; Loob, S.; Jin, Y.; Qi, H.J.; Zhang, W. Repairable woven carbon fiber composites with full recyclability enabled by malleable polyimine networks. Adv. Mater. 2016, 28, 2904–2909. [Google Scholar] [CrossRef] [PubMed]

- Hayashi, M.; Suzuki, M.; Kito, T. Understanding the Topology Freezing Temperature of Vitrimer-Like Materials through Complementary Structural and Rheological Analyses for Phase-Separated Network. ACS Macro Lett. 2025, 14, 182–187. [Google Scholar] [CrossRef] [PubMed]

- Ingrid Colleau. ECOHYDRO, Recyclable Composites for Hydrogen Storage. Available online: https://imtech.imt.fr/2023/12/05/ecohydro-composites-recyclables-pour-stockage-hydrogene/ (accessed on 17 December 2025).

- Mason, H. Recycling Hydrogen Tanks to Produce Automotive Structural Components. Available online: https://www.compositesworld.com/articles/recycling-hydrogen-tanks-to-produce-automotive-structural-components (accessed on 17 December 2025).

- Reynolds, S.; Longworth, B.; Norris, J.; Norris, P.; Reid, C.; Longworth, B.; Uk, L.; Millington, P. Deecom®: A Sustainable Process Used in Various Reclamation Processes; Technical Report. Available online: https://www.carolinapec.com/files/files/deecom-a-sustainable-process-used-in-various-reclamation-processes-2.pdf (accessed on 17 December 2025).

- Cygnet, Viritech Recover H2 Tank Continuous Carbon Fibers in Ford FCVGen2.0 project|CompositesWorld. Available online: https://www.compositesworld.com/news/cygnet-viritech-recover-h2-tank-continuous-carbon-fibers-in-ford-fcvgen20-project (accessed on 18 July 2025).

- D2344/D2344M-22; Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates. ASTM International: West Conshohocken, PA, USA, 2022.

- 11566:1996(E); Carbon Fibre—Determination of the Tensile Properties of Single-Filament Specimens. ISO: Geneva, Switzerland, 1996.

- Mohammadi, N.; Pouladvand, A.R.; Beheshty, M.H. Optimizing Towpreg Parameters for Filament Winding: A Comparison with Wet Winding. Polym. Compos. 2025, 46, 15331–15341. [Google Scholar] [CrossRef]

- Ghiorse, S.R. Effect of void content on the mechanical properties of carbon/epoxy laminates. SAMPE 1993, 24, 54–59. [Google Scholar]

- Lee, H.G.; Bae, J.S.; Hwang, H.Y. A normalization method of measured elastic properties of glass NCF composites with respect to fiber volume fraction based on periodic microstructure micromechanics. Mater. Today Commun. 2023, 36, 106767. [Google Scholar] [CrossRef]

- Broyles, N.S.; Verghese, K.N.; Davis, R.M.; Lesko, J.J.; Riffle, J.S. Pultruded Carbon Fiber/Vinyl Ester Composites Processed with Different Fiber Sizing Agents. Part I: Processing and Static Mechanical Performance. J. Mater. Civ. Eng. 2005, 17, 320–333. [Google Scholar] [CrossRef]

- Isa, A.; Nosbi, N.; Che Ismail, M.; Md Akil, H.; Wan Ali, W.F.F.; Omar, M.F. A Review on Recycling of Carbon Fibres: Methods to Reinforce and Expected Fibre Composite Degradations. Materials 2022, 15, 4991. [Google Scholar] [CrossRef] [PubMed]

- Hecker, M.D.; Longana, M.L.; Eloi, J.C.; Thomsen, O.; Hamerton, I. Recycling end-of-life sails by carbon fibre reclamation and composite remanufacture using the HiPerDiF fibre alignment technology. Compos. Part A Appl. Sci. Manuf. 2023, 173, 107651. [Google Scholar] [CrossRef]

- Pakdel, E.; Kashi, S.; Varley, R.; Wang, X. Recent progress in recycling carbon fibre reinforced composites and dry carbon fibre wastes. Resour. Conserv. Recycl. 2021, 166, 105340. [Google Scholar] [CrossRef]

- Hydrogen Storage; United States Department of Energy. Available online: https://www.energy.gov/eere/fuelcells/hydrogen-storage (accessed on 3 July 2024).

- Mallinda Inc. Our Responsibility; Mallinda Inc.: Denver, CO, USA, 2025; Available online: https://www.mallinda.com/responsibility (accessed on 7 October 2025).

| Method | Fiber Retention | Fiber Form | Process Temperature | Remanufacturing Demonstrated |

|---|---|---|---|---|

| This Work (Vitrimer) | 100% (p = 0.262) | Continuous tows | 90 °C | Yes |

| DEECOM (Decompression) | 94% | Variable length | 400 °C | Not reported |

| Voith (Pyrolysis) | 80–90% | 0.5–0.8 m segments | Not reported | Yes, down-cycled |

| ECOHYDRO (Thermoplastic) | Not reported | Continuous | Room temperature | Not reported |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Kennedy, A.; Ghafafian, C.; Nutt, S. Production and Remanufacturing of Vitrimer Matrix Composite Tubes. J. Compos. Sci. 2026, 10, 14. https://doi.org/10.3390/jcs10010014

Kennedy A, Ghafafian C, Nutt S. Production and Remanufacturing of Vitrimer Matrix Composite Tubes. Journal of Composites Science. 2026; 10(1):14. https://doi.org/10.3390/jcs10010014

Chicago/Turabian StyleKennedy, Alison, Carineh Ghafafian, and Steven Nutt. 2026. "Production and Remanufacturing of Vitrimer Matrix Composite Tubes" Journal of Composites Science 10, no. 1: 14. https://doi.org/10.3390/jcs10010014

APA StyleKennedy, A., Ghafafian, C., & Nutt, S. (2026). Production and Remanufacturing of Vitrimer Matrix Composite Tubes. Journal of Composites Science, 10(1), 14. https://doi.org/10.3390/jcs10010014