1. Introduction

The calculation of the stress–strain state of materials used in the design of structures for space satellites, unmanned aerial vehicles, aviation technical systems, and nano- and micro-class satellites, within the framework of linear elasticity theory, is often insufficient. This is due to the fact that most modern materials obey Hooke’s law only at small deformations, and in many cases, the investigated elements are operated under deformations that exceed the linear region. During the operation of such structures, even under small loads, the relationship between the resulting stress and strain in these materials follows a nonlinear law. Furthermore, such materials exhibit different elastic properties under tension and compression, and they are recognized as multimodular materials [

1].

For instance, graphene, the stiffest material with minimal resistance and frequently used in recent times, has a compressive elastic modulus several times greater than its tensile elastic modulus [

2,

3]. Similarly, certain popular composite materials, such as graphite epoxy resin used as a filler, possess different elastic moduli under tension and compression. Numerous experiments have established that the compressive elastic modulus of graphite material is four times greater than its tensile elastic modulus [

4].

To maximize the capabilities and communication connectivity of nano- and micro-class satellites and structures [

5,

6], which are constrained by size, weight, and high durability, mechanisms with a high deployable surface area relative to packaging volume are required. In this context, developing compact deployable mechanisms for this class of satellites becomes challenging without a thorough understanding of the mechanics of high-strength materials and structures. Previous studies [

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20] have presented a manufacturing process, experimental testing, and a progressive failure model to investigate the deformation of a composite rod in the form of an ultra-thin rod. Studies have examined the deformation modes of the rod and buckling failure in bending under eccentric torsion, subjected to cyclic pure bending loads using a four-point bending setup. A distributed (continuum) damage mechanics model for the rod was refined using experimental coupon testing and employed for open finite element analysis. It was demonstrated that the thin, highly rigid rod can sustain a bending radius of 14 mm without significant damage to the fiber or matrix. The results of the bending simulation were found to closely align with experimental outcomes, indicating that the simulation accurately describes deformation stages and predicts material damage. The research findings elucidate the structural properties of a system of ultra-thin, highly rigid rods with a progressive damage model, which can be utilized for designing complex deployable payloads for nano- and micro-class satellites. Further exploration in this field remains highly relevant.

Considering the relevance of the issue, the development of composite elements incorporating multimodular materials for nano- and micro-class satellites requires the creation of mathematical models capable of providing accurate results for durability issues under operating conditions relevant to the investigated structures. This necessitates first addressing the physically nonlinear problem of elasticity theory, as in cases involving material heterogeneity or damage. It is well-known that calculating structural elements beyond the limits of linear elasticity introduces challenges due to both complex mathematical computations and the inapplicability of certain principles of classical linear elasticity theory, particularly the impossibility of using the principle of load independence or the absence of a potential for internal forces. Additionally, the material’s structure significantly influences the failure process, which can be complex and unstable. The failure process also depends on external factors, such as the nature of loading, thermal conditions, turbulence, surface effects, and other factors, all of which affect the material’s stress state and, consequently, form the basis of the failure process.

One type of failure is associated with arbitrary defects that form and accumulate in materials, expressed by the general term “damage.” Such failure is referred to as distributed (continuum) failure. In cases of uniform stress (e.g., during rod tension), damage increases uniformly with respect to volume. However, when the stress field is non-uniform, the analysis of the failure process requires distinguishing two stages: the latent failure stage (incubation period) and the manifest failure stage. During the latent failure stage, microcracks and other defects form within a specific time interval (). At , localized failure occurs. Around these localized failure regions, distributed microcracks and other defects coalesce, forming macrocracks. For instance, experiments on material fatigue failure indicate that, in the initial stage, damage accumulates steadily and exhibits a distributed character. By the end of this stage, macrocracks form, which then develop intensively in subsequent moments.

The problem of studying the stress–strain states of multimodular materials has attracted the attention of researchers since the first models for such materials were proposed by Bert [

8] and other authors. Chen [

9] and others utilized the Timoshenko method to investigate the dynamic stability of a multimodular beam subjected to periodic uniaxial loading, with the instability zone in the beam identified using the Bolotin method.

In [

10,

11,

12], the problem of pure bending of a rectangular cross-section beam made from AK4-1T aviation alloy, exhibiting different tensile and compressive properties under a constant temperature and subjected to a pure bending moment, was investigated. The study addressed creep and long-term strength issues in the given structure, considering all stages of stress redistribution up to the onset of failure. The numerical solution of the problem, described by a system of differential algebraic equations, was performed using equations from the energy version of creep theory, along with methods for continuation of the solution with parameters and optimal parametrization. The system of ordinary differential equations was solved numerically using methods such as Euler, Euler–Cauchy, and fourth-order Runge–Kutta [

11,

12,

21]. Based on the results of the numerical calculations, a comparison of two methods for solving the problem was provided, along with a comparison of the obtained numerical solutions with experimental data. However, these results pose certain mathematical challenges for other materials with multimodular properties. Therefore, the development of a more advanced model is considered appropriate.

The analysis of existing classical approaches and previous research shows that the influence of accumulated damage over time and asymmetric elastic properties does not allow for a sufficiently realistic description of the physical and mechanical processes of material degradation. Therefore, the development of new mathematical models for predicting the durability of multimodular materials and providing a more accurate analysis of the failure process is considered a relevant and important task.

2. Problem Statement

The problem of distributed failure in the pure bending of a rectilinear rod made from a material with different elastic properties under tension and compression is considered. For this purpose, it is assumed that the investigated body is continuous, homogeneous, deformable, and isotropic. At the same time, the homogeneous material exhibits a distinct behavior: its properties are identical at all points, but at a given point, it possesses different elastic properties depending on the sign of the principal stresses (positive or negative).

It is assumed that when the principal stresses at a specific point or section of an element exhibit uniform signs (either tension, , or compression, , where i denotes the principal direction), the set of elastic constants aligns with those of the classical theory of elasticity. Conversely, in cases where the principal stresses differ in sign, two distinct sets of elastic constants are observed. The material possesses a modulus of elasticity under uniaxial tension and a modulus under uniaxial compression. Correspondingly, Poisson’s ratio characterizes transverse contraction under tension, while describes transverse expansion under compression. During simultaneous tension and compression in different directions, the elastic moduli and , and Poisson’s ratios and , respectively, remain constant.

It is also assumed that the material undergoes only small elastic deformations under any stress condition and obeys the general laws of a completely elastic medium.

As is known, in the pure bending of a homogeneous rod, the fibers parallel to its longitudinal axis deform and rotate with respect to the neutral axis. The fibers on the convex side of the rod elongate, and the fibers on the concave side shorten. There exists a layer between them, the length of which remains unchanged. This layer is called the neutral layer, and its intersection with the cross-section is known as the neutral axis. Tension occurs in fibers above this axis and compression below. Therefore, normal stresses arise throughout the cross-section except at the neutral axis (uniaxial stress state) [

13,

14,

15,

16,

17,

18,

19,

20,

21].

Let the initial cross-section of the bar be rectangular, with height

, width

b, and length

l (

). Assume the initial horizontal axis coincides with the neutral axis

, and let

denote the vertical coordinate from this axis. Suppose a constant bending moment

is applied. The resulting strain at a distance

from the axis is given as follows:

where

is the radius of curvature of the neutral axis. According to Hooke’s law, the longitudinal normal stresses are as follows:

For pure bending, the equilibrium condition must hold the following:

Substituting the above expressions and integrating, we obtain the following:

From Equations (5) and (6), the location of the neutral axis can be determined.

The total bending moment is given as follows:

Introducing moments of inertia generates the following:

The radius of curvature and stiffness of the bar are then described as follows:

Writing the integrals explicitly as follows:

Substituting into the following stress expressions:

Since the material has different viscoelastic and strength properties in tension and compression, the failure criteria are as follows [

14]:

where

and

are the tensile and compressive strength limits, respectively, and

and

are damage operators defined via viscoelastic integral kernels [

14,

15,

16,

17,

18,

19,

21]:

Here, and are the damage kernels.

3. Problem Solving

The maximum bending moment produced when a transverse force is applied

at a point on a bar of length

l is at

, and for simplicity it is assumed that the initial failure occurs in the tension layer. For this case, from Equation (

12), the tensile stress is written as follows:

Here, .

When the expression obtained in Equation (

18) is taken into account in the dispersion criterion (14), with

:

or clearly:

attitude is taken.

Of the integral operator

characterizing the damage

is specifically defined. This kernel

is obtained from (20) by adding the weak singular kernel in the form of an Abelian kernel (

):

The dimensionless quantity is included in the following figure:

In the case where the operator has a kernel

:

occurs.

From the analysis of the above formulas, it is clear that the longevity of the layer working in tension depends on the value of

n. As the value of

n increases, the value of

g also increases, which creates conditions for the increase in the bending capacity of the bar. At the same time, it can be seen from Formula (21) that the acceleration of the scattering front also sharply depends on the parameter

m, which is the singularity coefficient of the operator kernel. As the value of

m approaches unity, the value of

increases sharply. The development scheme of the failure front arising in the rod is shown in

Figure 1.

In the next stage, the layer adjacent to the collapsing layer will begin to collapse and

—a layer of varying thickness—will be formed as the collapse region expands. In this case, the neutral axis will shift downward. Assuming that the

x axis is directed in the direction of the neutral axis, since the

z coordinate decreases as the collapse region progresses, this coordinate will be calculated from that neutral axis. If we denote

as the thickness of the uncollapsing part of the rod,

will decrease as follows:

From Equation (

5),

is described as follows:

By writing (25) and (26) in (12), the following formula is obtained for the normal stress generated in a layer with varying thickness and tension:

or

The rupture front will expand and instantly pass through the fixed

coordinate of the region. Then,

—the dependence of the longitudinal stress generated at the rupture front on the

z coordinate—is as follows:

After substituting the

above relations (27) and (28) into the collapse criterion (14), the nonlinear integral equation characterizing the development of the collapse front formed in the beam and depending on its function is obtained as follows:

Before moving to dimensionless quantities in Equation (

30), the following transformation is performed:

Dimensionless quantities are introduced for variable time and variable thickness as follows:

Here,

is a constant quantity, the size of which is the inverse of the size of time. If the damage kernel is constant,

can be taken equal to 1. Taking (32) into account in (31), this equation is as follows:

where

.

To qualitatively characterize the decomposition process and make analytical evaluations, we can take

, i.e., the kernel of the damage operator is constant,

. In this case, Equation (

33) becomes the following:

Differentiating Equation (

34) with respect to dimensionless time

, the following equation is obtained:

In Equation (

35), for

and

,

, for dimensionless time

, it is

According to relation (24), the dimensionless value of the latent decay time when the kernel of the damage operator is fixed it is described as follows:

For this case, Equation (

36) becomes the following:

It is clear from relation (38) that with the increase of n (the increase in the stiffness of the tensile part), the speed of movement of the dispersion front decreases.

Again, the equation of motion of the scattering front is determined as follows:

As you can see, this equation is a second-order nonlinear differential equation. To solve it using the method of order reduction, a new function

is introduced:

Then,

If we substitute Equations (40) and (41) into (39), the following equation is obtained:

Since

, Equation (

42) can be written as follows:

The right-hand side of this equation is a homogeneous function of degree zero. Therefore, making the substitution

, the following separable differential equation is obtained:

After integration, the solution becomes the following:

Using this equation, the function

f is defined as follows:

After substituting Equation (

46) into Equation (

40), the equation becomes the following:

Using the initial condition from Equation (

38), the integral constant entering Equation (

47) is found as follows:

From (47) and (48), the equation of motion of the scattering front is as follows:

After integrating this equation within the initial condition

, the following equality is obtained:

For the formation of a rupture front, the limits of the values that the transverse force can take must be determined. The formation of a rupture front

P is possible when the condition in Equation (

38) is satisfied. For this

Using this condition and the last relation in (32), the transverse force can be estimated as follows:

Also, using Equation (

24), the value of the transverse force during the period before the initial collapse is obtained:

The dissipation occurs instantaneously at the values of

P for which

. When condition (49) is satisfied, from (49)

, and from (39)

.

Thus, when the above conditions are met, the collapse occurs and expands. At the moment of complete collapse, the speed of the collapse process increases infinitely (

). Using Equation (

49), the critical value of the dimensionless thickness of the rod at the moment of complete collapse is found as follows:

Also, by writing relation (54) in (50), the final dissipation time can be calculated as follows:

For the element with linear dimensions

,

,

, material tensile strength

, and transverse load

, the value

is obtained from the fourth factor of expression (32). Using Equation (

50), the curves were constructed for the function

characterizing the motion of the scattering front for three values of the parameter

n.

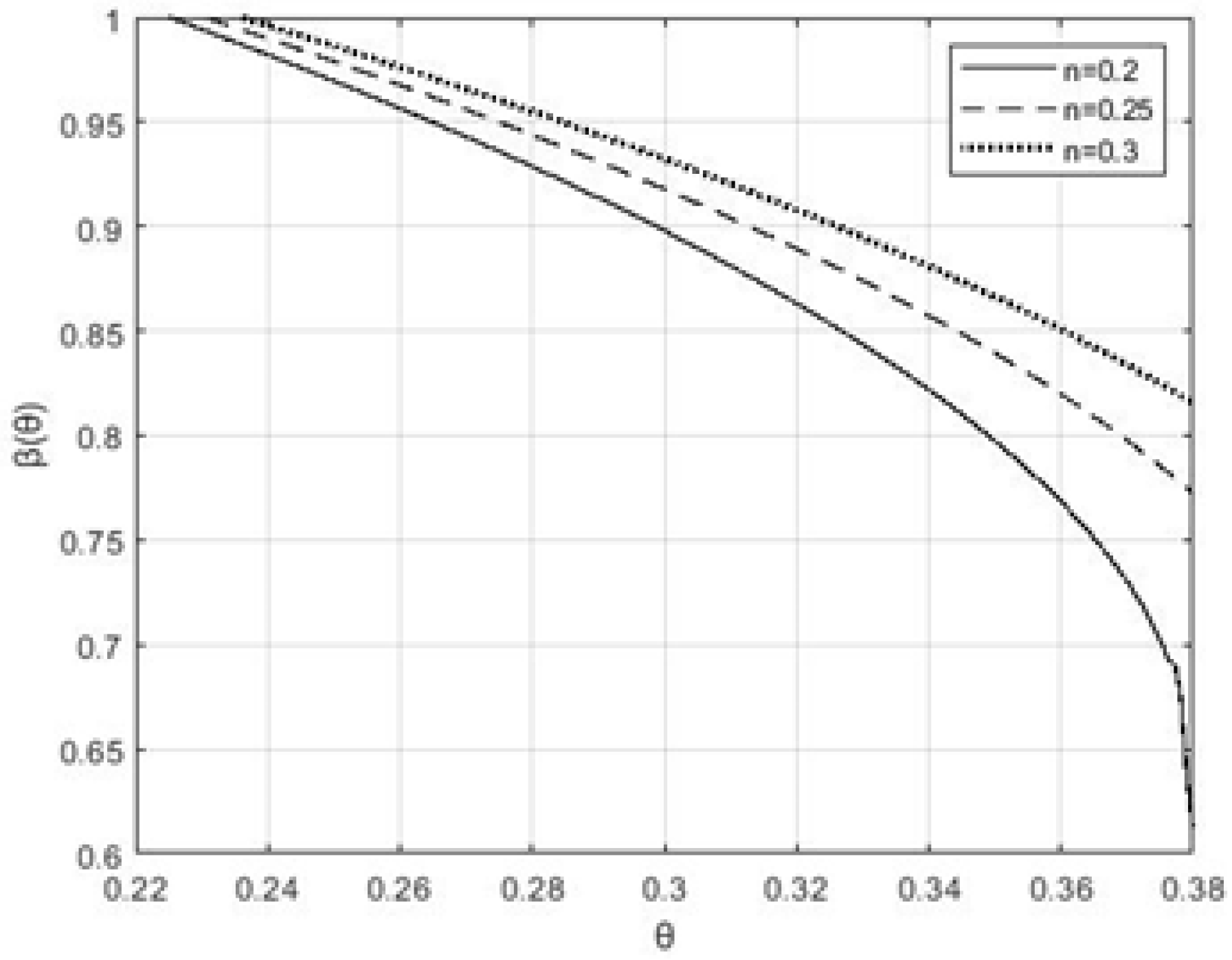

The analysis of the constructed curves (

Figure 2), the analysis of the constructed curves shows that as the value of the parameter

n increases, the critical moment of the decomposition time also increases. That is, the complete decomposition time (longevity) of the material increases.

To qualitatively analyze the damage process, an exponential kernel

is chosen for the kernel of the integral operator instead of a fixed kernel, where

m is referred to as the “memory decay” parameter. The “memory decay” effect is often used in materials with viscoelastic and nonlinear damage characteristics, and the intensity of this effect is typically modeled by a numerical parameter. In this case, the integral equation characterizing the motion of the rupture front takes the following form:

Each side of this equation is differentiated with respect to

:

Equation (

57) is differentiated again with respect to dimensionless time

, and the following differential equation is obtained:

The following markings are included as follows:

This equation is a second-order nonlinear differential equation and involves high degrees of the derivative of the unknown function. Since the analytical solution of the equation is complex, it is considered more convenient to use a numerical method (finite differences).

Since

takes small values, some simplifications can be made in the equation. Therefore, when (40) is taken into account in (59),

can be taken.

The results obtained from numerical calculations are presented in the following graphs:

The analysis of the constructed curves (

Figure 3 and

Figure 4) shows that, in the case of an exponential kernel, the effect of the parameters

m and

n on the speed of the dispersion is considerable. As the value of

m increases, the influence of the distant past decreases, which means that the damage does not accumulate, and therefore, the service life is extended.

The analysis of the constructed curves shows that the main factors affecting the durability of a bar made of a multimodulus material are physical and mechanical factors. These factors are mainly included in the obtained equations and are characterized by their parameters m, n, and .

4. Conclusions

A mathematical model has been developed and solved for the problem of the formation and development of the failure region during pure bending of a rod with a rectangular cross-section, made from a material exhibiting different properties under tension and compression, in the context of designing structures for space satellites, unmanned aerial vehicles, aviation technical systems, and nano- and micro-class satellites. The problem was investigated for various forms of the kernel of the damage operator (constant and exponential). For the exponential kernel, it was shown that an increase in the parameter expressing the “memory fading” effect accelerates the decay of mechanical stress influence, reduces damage accumulation, and prolongs the service life of the material. As the parameter m increases, the kernel function decays faster, the material “forgets” its past more quickly, and the memory effect weakens, reflecting an accelerated memory fading process.

Additionally, formulas for the incubation period and integral equations describing the motion of the failure front were derived. Qualitative analysis for special cases was provided. For the exponential kernel, curves representing the motion of the failure front were constructed using numerical computation methods. It was revealed that the variability of the ratio of elastic moduli has a significant effect on the propagation speed of the failure front.

The obtained results can be applied to predict the durability of materials with different stiffnesses under tension and compression, which are used in the design and production of structures for space satellites, unmanned aerial vehicles, aviation technical systems, and nano- and micro-class satellites.

The boundary conditions obtained from the developed mathematical model make it possible to predict the moment of material failure in advance. As a result, this is of great importance for the early detection of initial damage and for the assessment of the service life of the structural component. The performed numerical calculations and graphical analyses confirm that the proposed model is suitable for application using both analytical and numerical methods.