Mechanical Properties of Highly Oriented Recycled Carbon Fiber Tapes Using Automated Fiber Placement

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

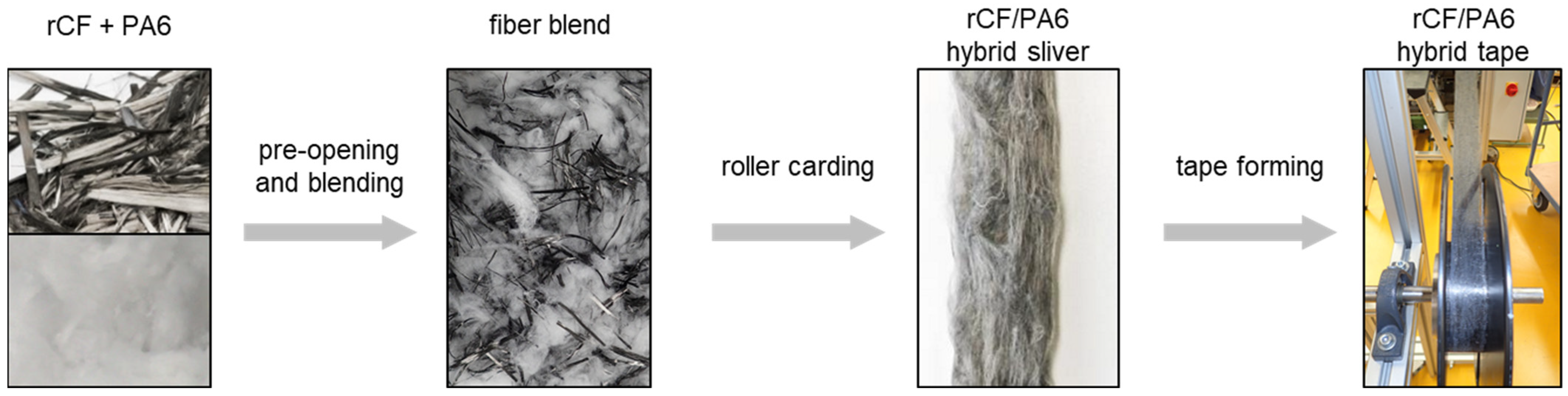

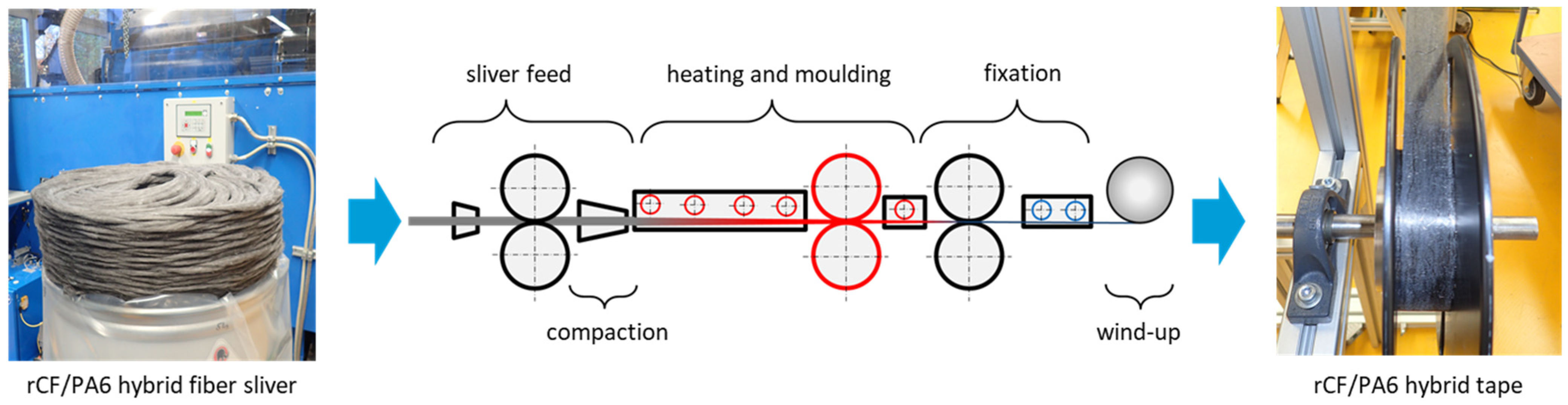

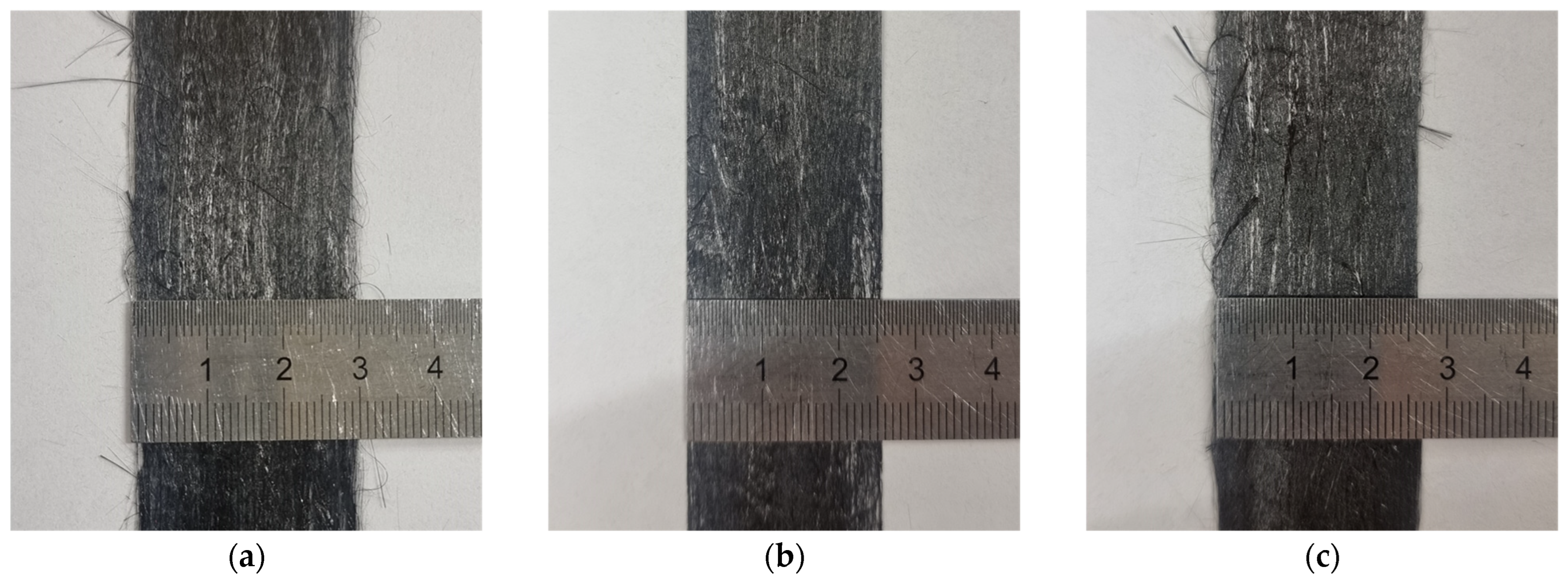

2.2. rCF-Tape Production

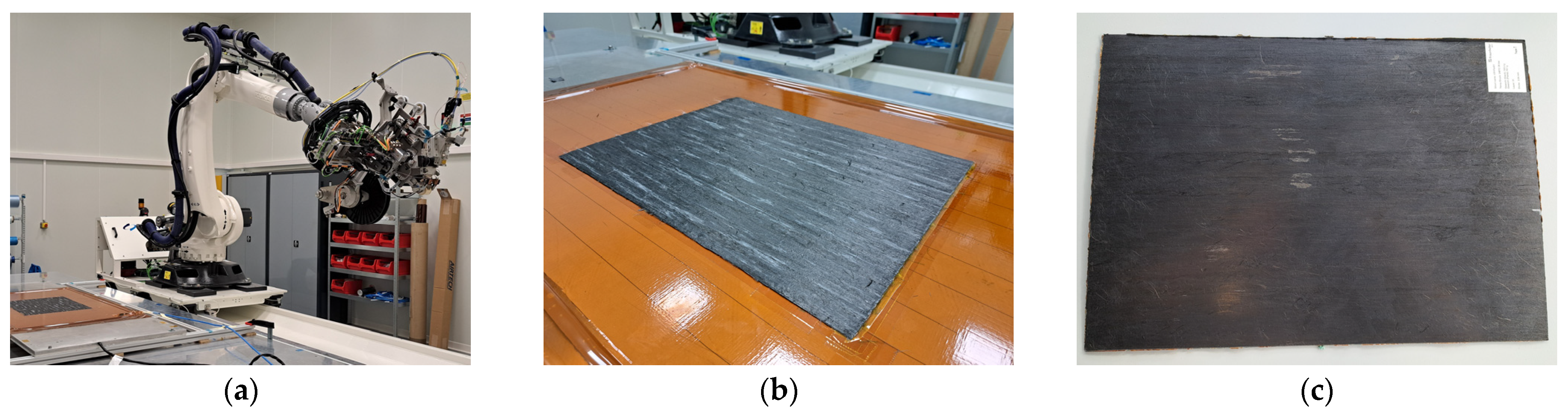

2.3. Production of Test Panels

2.4. Mechanical Evaluation

3. Results

3.1. Fiber Volume Content

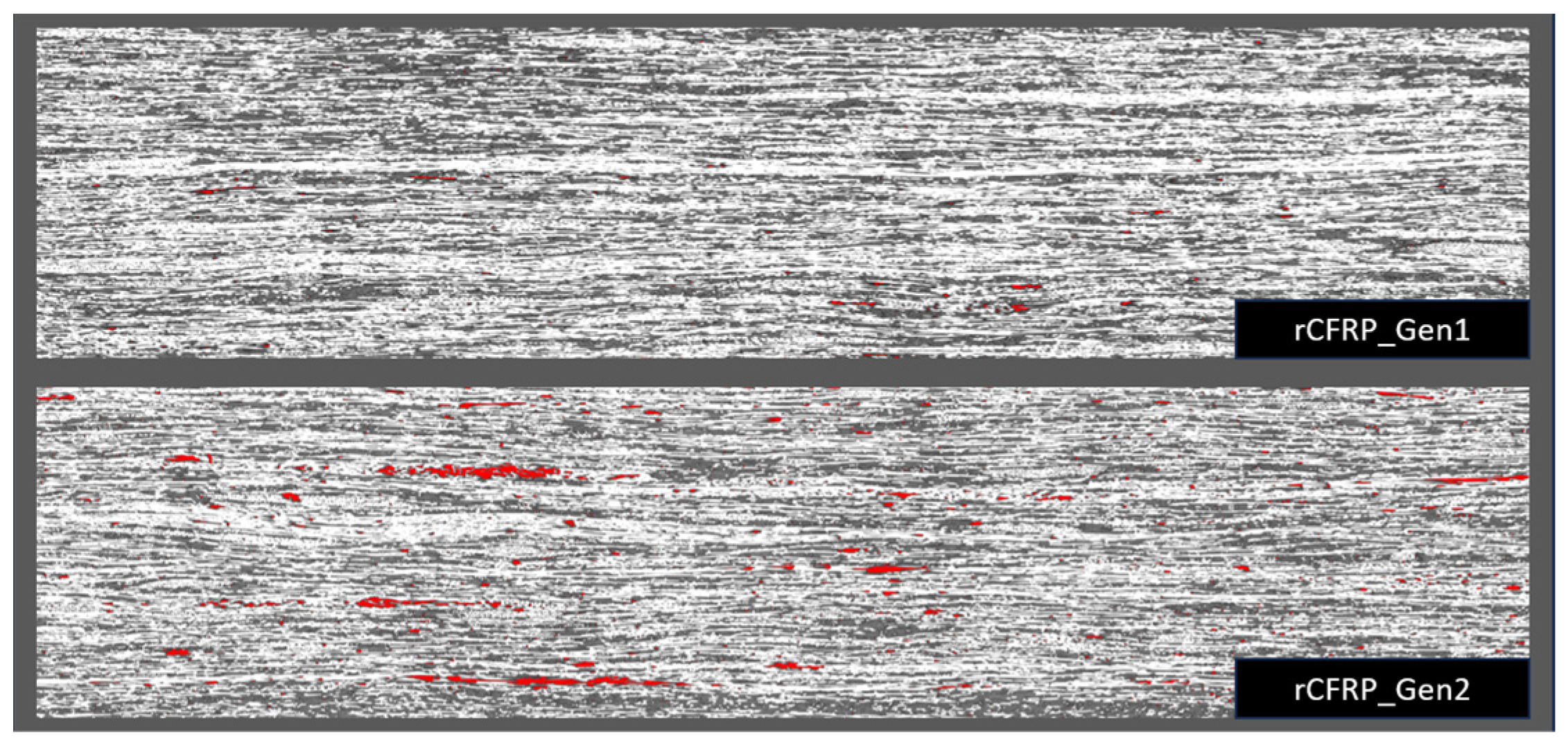

3.2. Tensile Tests of rCFRP_Gen1 Compared to rCFRP_Gen2

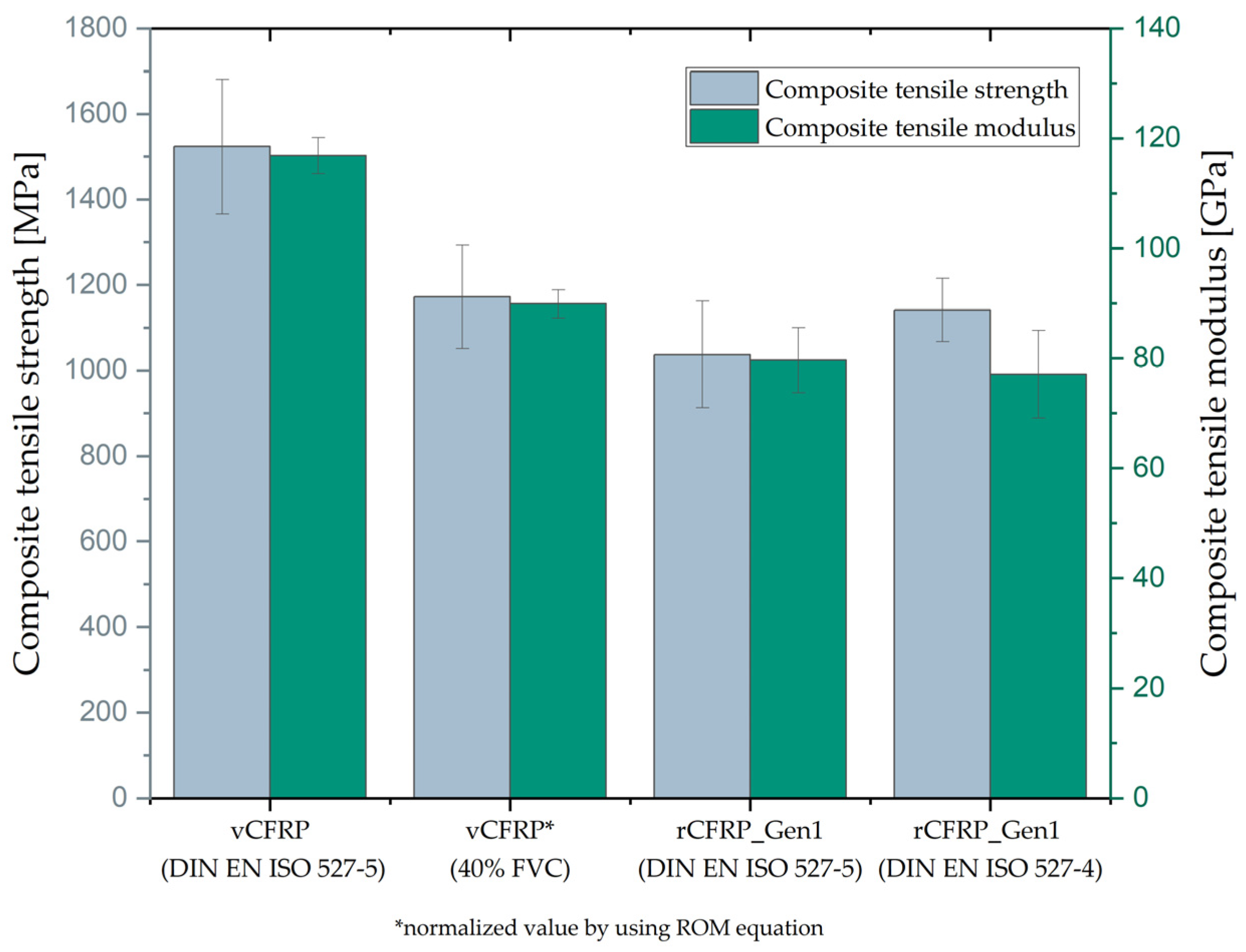

3.3. Tensile Tests of vCFRP Compared to rCFRP_Gen1

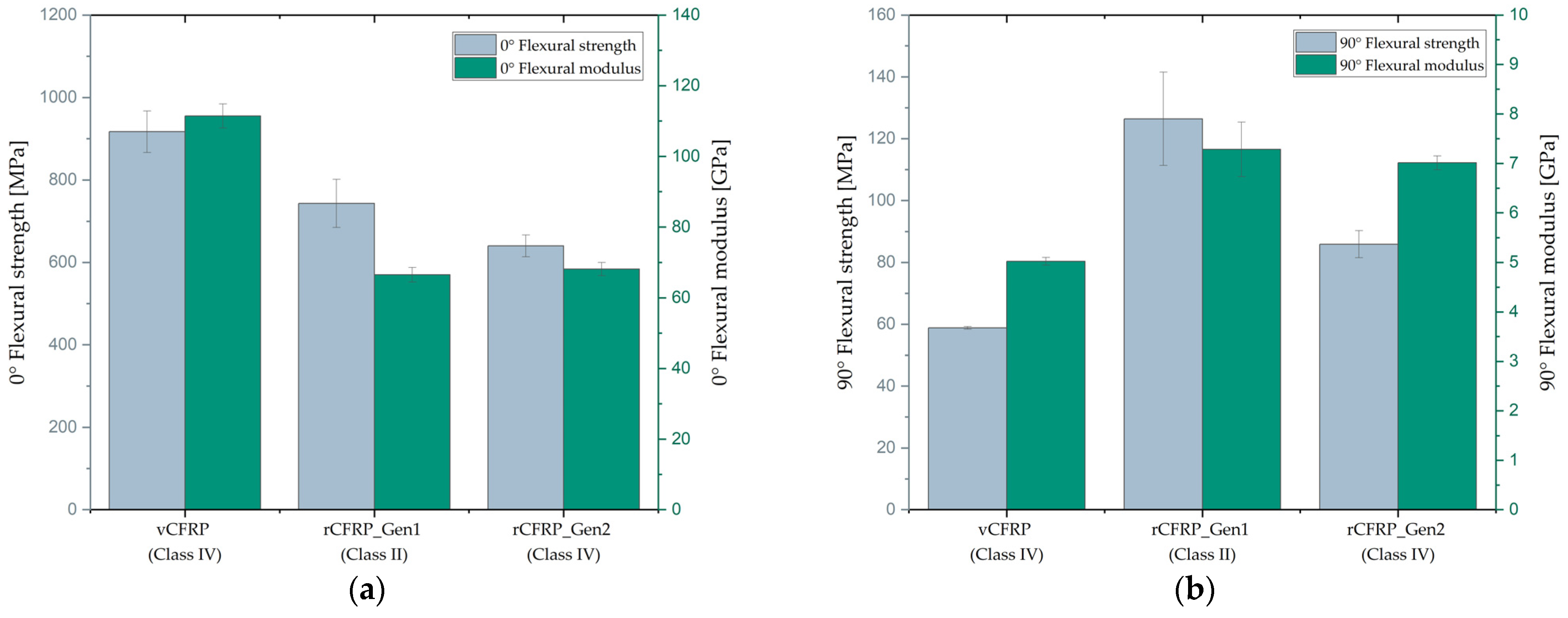

3.4. Flexural Tests of rCFRP Compared to vCFRP in 0° and 90°

4. Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Stieven Montagna, L.; Ferreira de Melo Morgado, G.; Lemes, A.P.; Roberto Passador, F.; Cerqueira Rezende, M. Recycling of carbon fiber-reinforced thermoplastic and thermoset composites: A review. J. Thermoplast. Compos. Mater. 2023, 36, 3455–3480. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Meng, F.; Olivetti, E.A.; Zhao, Y.; Chang, J.C.; Pickering, S.J.; McKechnie, J. Comparing Life Cycle Energy and Global Warming Potential of Carbon Fiber Composite Recycling Technologies and Waste Management Options. ACS. Sustain. Chem. Eng. 2018, 6, 9854–9865. [Google Scholar] [CrossRef]

- Liu, W.; Huang, H.; Liu, Y.; Li, L.; Cheng, H.; Liu, Z. Life cycle assessment and energy intensity of CFRP recycling using supercritical N-butanol. J. Mater. Cycles Waste Manag. 2021, 23, 1303–1319. [Google Scholar] [CrossRef]

- Nunes, A.O.; Viana, L.R.; Guineheuc, P.-M.; da Silva Moris, V.A.; de Paiva, J.M.F.; Barna, R.; Soudais, Y. Life cycle assessment of a steam thermolysis process to recover carbon fibers from carbon fiber-reinforced polymer waste. Int. J. Life Cycle Assess. 2018, 23, 1825–1838. [Google Scholar] [CrossRef]

- Prenzel, T.M.; Hohmann, A.; Prescher, T.; Angerer, K.; Wehner, D.; Ilg, R.; von Reden, T.; Drechsler, K.; Albrecht, S. Bringing Light into the Dark—Overview of Environmental Impacts of Carbon Fiber Production and Potential Levers for Reduction. Polymers 2023, 16, 12. [Google Scholar] [CrossRef] [PubMed]

- Hagnell, M.K.; Åkermo, M. The economic and mechanical potential of closed loop material usage and recycling of fibre-reinforced composite materials. J. Clean. Prod. 2019, 223, 957–968. [Google Scholar] [CrossRef]

- Meng, F.; Mckechnie, J.; Pickering, S.J. An assessment of financial viability of recycled carbon fibre in automotive applications. Compos. Part A Appl. Sci. Manuf. 2018, 109, 207–220. [Google Scholar] [CrossRef]

- Shehab, E.; Meiirbekov, A.; Amantayeva, A.; Tokbolat, S. Cost Modelling for Recycling Fiber-Reinforced Composites: State-of-the-Art and Future Research. Polymers 2023, 15, 150. [Google Scholar] [CrossRef] [PubMed]

- Vo Dong, P.A.; Azzaro-Pantel, C.; Cadene, A.-L. Economic and environmental assessment of recovery and disposal path-ways for CFRP waste management. Resour. Conserv. Recycl. 2018, 133, 63–75. [Google Scholar] [CrossRef]

- Pickering, S.J. Recycling technologies for thermoset composite materials—Current status. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Manis, F.; Stegschuster, G.; Paulus, H.; Seiwald, P.; Keller, S.; Osburg, H. MAI CC4 CaRinA: Carbonfaser Recyclingwerkstoffe für Industrielle Anwendungen: Fraunhofer-Gesellschaft, 2021. Available online: https://www.igcv.fraunhofer.de/de/forschung/referenzprojekte/CaRinA.html (accessed on 18 July 2025).

- Manis, F.; Stegschuster, G.; Wölling, J.; Schlichter, S. Influences on Textile and Mechanical Properties of Recycled Carbon Fiber Nonwovens Produced by Carding. J. Compos. Sci. 2021, 5, 209. [Google Scholar] [CrossRef]

- Khurshid, M.F.; Hengstermann, M.; Hasan, M.M.B.; Abdkader, A.; Cherif, C. Recent developments in the processing of waste carbon fibre for thermoplastic composites—A review. J. Compos. Mater. 2020, 54, 1925–1944. [Google Scholar] [CrossRef]

- Gandhi, U.N.; Osswald, T.A.; Goris, S.; Song, Y.Y. Discontinuous Fiber-Reinforced Composites: Fundamentals and Applications; Hanser Publications: Cincinnati, OH, USA, 2020. [Google Scholar]

- Zweifel, L.; Kupski, J.; Dransfeld, C.; Caglar, B.; Baz, S.; Cessario, D.; Gresser, G.T.; Brauner, C. Multiscale Characterisation of Staple Carbon Fibre-Reinforced Polymers. J. Compos. Sci. 2023, 7, 465. [Google Scholar] [CrossRef]

- Subhedar, K.; Chauhan, G.; Singh, B.P.; Dhakate, S. Effect of fibre orientation on mechanical properties of carbon fibre composites. Indian J. Eng. Mater. Sci. 2020, 27, 1100–1103. [Google Scholar] [CrossRef]

- Chen, A.Y.; Baehr, S.; Turner, A.; Zhang, Z.; Gu, G.X. Carbon-fiber reinforced polymer composites: A comparison of manufacturing methods on mechanical properties. Int. J. Light. Mater. Manuf. 2021, 4, 468–479. [Google Scholar] [CrossRef]

- Khurshid, M.F.; Hasan, M.M.B.; Abdkader, A.; Cherif, C. Processing of waste carbon and polyamide fibers for high performance thermoplastic composites: A novel manufacturing technology for unidirectional tapes structure. J. Ind. Text. 2022, 51, 7256S–7276S. [Google Scholar] [CrossRef]

- Reichert, O.; Ausheyks, L.; Baz, S.; Hehl, J.; Gresser, G.T. Innovative rC Staple Fiber Tapes—New Potentials for CF Recyclates in CFRP through Highly Oriented Carbon Staple Fiber Structures. Key Eng. Mater. 2019, 809, 509–514. [Google Scholar] [CrossRef]

- Teichmann, F.; Schumm, V.; Klemm, C.; Sauer, M.; Cetin, M. Demonstration and testing of a process chain for the realignment of discontinuous random-oriented recycled carbon fibers into unidirectional tape. In Proceedings of the 21st European Conference on Composite Materials, Nantes, France, 2–5 July 2024. [Google Scholar]

- Akonda, M.H.; Stefanova, M.; Potluri, P.; Shah, D.U. Mechanical properties of recycled carbon fibre/polyester thermoplastic tape composites. J. Compos. Mater. 2017, 51, 2655–2663. [Google Scholar] [CrossRef]

- Rimmel, O.; May, D.; Goergen, C.; Poeppel, A.; Mitschang, P. Development and validation of recycled carbon fiber-based binder tapes for automated tape laying processes. J. Compos. Mater. 2019, 53, 3257–3268. [Google Scholar] [CrossRef]

| Fiber Properties | rCF (T700S) | Polymer Fibers (PA6) |

|---|---|---|

| Mean Staple length [mm] | 84.6 ± 88.7 | 60 |

| Linear Density [dtex] | 0.68 ± 0.06 | 3.3 |

| Density [g/cm3] | 1.8 | 1.14 |

| Tensile Strength [GPa] | 4.01 ± 0.87 | 0.1 |

| Tensile Modulus [GPa] | 212.45 ± 5.38 | 0.75 |

| Initial Modulus [GPa] | 254.24 ± 7.33 | |

| Tenacity [cN/tex] | 226.71 ± 49.1 | 46 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Theiss, J.; Haj Ahmad, P.; Manis, F.; Preinfalck, M.; Baz, S. Mechanical Properties of Highly Oriented Recycled Carbon Fiber Tapes Using Automated Fiber Placement. J. Compos. Sci. 2025, 9, 425. https://doi.org/10.3390/jcs9080425

Theiss J, Haj Ahmad P, Manis F, Preinfalck M, Baz S. Mechanical Properties of Highly Oriented Recycled Carbon Fiber Tapes Using Automated Fiber Placement. Journal of Composites Science. 2025; 9(8):425. https://doi.org/10.3390/jcs9080425

Chicago/Turabian StyleTheiss, Julian, Perwan Haj Ahmad, Frank Manis, Miriam Preinfalck, and Stephan Baz. 2025. "Mechanical Properties of Highly Oriented Recycled Carbon Fiber Tapes Using Automated Fiber Placement" Journal of Composites Science 9, no. 8: 425. https://doi.org/10.3390/jcs9080425

APA StyleTheiss, J., Haj Ahmad, P., Manis, F., Preinfalck, M., & Baz, S. (2025). Mechanical Properties of Highly Oriented Recycled Carbon Fiber Tapes Using Automated Fiber Placement. Journal of Composites Science, 9(8), 425. https://doi.org/10.3390/jcs9080425