Abstract

Reinforcing PLA composites with natural fibres is a prominent strategy for improving PLA’s properties while benefiting from its intrinsic biodegradation. However, these composites may be susceptible to an inefficient stress-transferring process due to the weak intermolecular interactions between PLA and natural fibres. A well-known practice is to incorporate coupling agents to improve polymer–fibre adhesion, such as carboxylic acids (CAs) and grafted copolymers. CAs are a more affordable and biodegradable option for improving PLA/natural fibre interface strength, resulting in a material with superior mechanical and thermal properties. In this context, this research discusses the potential use of mono (C6 and C8) and di (CC6 and CC8) carboxylic acids as coupling agents in PLA/pecan nutshells (PN) composites. PLA/PN composites with four different CAs were processed in a twin-screw extruder and subsequently injection moulded. The results indicated an increase in the flexural strength of the PLA due to the presence of PN in the neat composite. The use of CAs increased the storage modulus of PLA/PN composites, while C6 and CC8 reduced the PLA composite tan δ peak height. The PLA’s Tg in PLA/PN composite shifted to lower temperatures after the incorporation of CAs while increasing the PLA crystallinity degree. These results strongly suggested that besides acting as efficient coupling agents, these acids also exerted roles as nucleating agents and plasticisers.

1. Introduction

Poly (lactic acid) (PLA) has been one of the most important biodegradable polymers (BDPs) over the last decades, given the aim of environment friendliness [1,2,3,4], while posing as a potential replacement for applications in which non-BDPs are commonly employed, such as HDPE, LDPE, PS, PP, PET, and PVC [5]. PLA is a synthetic aliphatic polyester produced from renewable biomass resources, particularly sugarcane, maize, cassava, and corn [6]. Unlike many other BDPs, PLA is a rigid thermoplastic at room temperature due to its relatively high Tg (around 60 °C) [7], resulting in low toughness and limited deformation at break [8].

PLA has repeatedly been chosen as a matrix in the production of green polymer composites. Its choice is justified by a compelling combination of properties, including a high elastic modulus (2.0–4.0 GPa) [9,10,11,12], tensile strength (40–60 MPa) [10,13], and flexural strength (80–110 MPa) [11,13], along with intrinsic biodegradability and a low density (1.24–1.26 g·cm−3) [5]. This combination yields lightweight PLA composites with superior mechanical performance compared to commodity non-BDP thermoplastic composites. Oksman et al. [14] compared PLA/flax to PP/flax composites, reporting that PLA stiffness increased from 3.4 to 8.4 GPa while PP stiffness increased from 1.6 to 7.6 GPa after incorporating 30 wt.% flax fibres.

A frequent concern in the composite manufacturing using biodegradable polymers and fibres is the poor interfacial adhesion, which arises due to the difference in polarity between the phases and affects the mechanical and thermal properties [15,16,17]. The interfacial strength between polymer and fibre can be tailored and adjusted by routes like interface modifier agents (such as coupling agents and plasticisers), which increase the intermolecular interaction forces between matrix-fibre [18,19,20]. Compatibilizer (or coupling) agents are typically homopolymers (or copolymers) with grafted polar groups, such as maleic anhydride (MA) [21] and acrylic acid (AA) [22]. This unique polymer architecture contributes to increasing the intermolecular forces density between matrix and fibre, resulting in a stronger interface [23] and better mechanical and thermal properties. For instance, Yang et al. [24] evaluated wheat straw/PLA composites using silane as a coupling agent, observing that silane significantly enhanced wheat straw/PLA tensile and impact strength from 3.03 to 15.07 MPa and 3.73 to 9.95 kJ·m−2, respectively. Similarly, Oliver-Ortega et al. [23] characterised PLA/cellulose fibre composites with PLA-g-MA as a coupling agent. They reported that incorporating 10% cellulose fibres increased PLA tensile strength from 49.8 to 57.1 MPa, while PLA-g-MA improved the tensile strength to 61.7 MPa.

The remarkable efficiency of many synthetic coupling agents is also counterweighted by their poor and slow biodegradability, contributing to environmental problems. Therefore, adopting biodegradable additives is essential to balancing environmental responsibility and the manufacturing of polymer composites and blends. Biodegradable additives are frequently overshadowed by synthetic plasticisers and interface modifier agents in the industry of polymer composites and blends. Nonetheless, several works in the literature have highlighted the potential of natural additives, such as natural oils and triacetin [19,25,26,27,28], as biobased interface modifier additives. Their use represents a valuable strategy for mitigating environmental impact and carbon footprint while enabling the development of biobased materials with enhanced properties. Belyamani et al. [29] assessed the combination of glycerol and clove essential oil on PLA/PHBV blends, observing that the mixture of these oils increased PLA/PHBV thermal stability and improved this polymer blend’s miscibility and morphology. Khan et al. [30], for instance, assessed the use of maleic and citric acids as plasticisers for TPS, revealing that all formulations were thermally stable up to 170 °C and the use of maleic acid slightly improved TPS flexibility when compared to citric acid.

The potential of lignocellulosic fibres as reinforcement agents for polymer composites, like flax, sisal, and jute [31], as well as hemp, ramie, and kenaf [32] has been evaluated over the last decades. Lignocellulosic fibres are well known for their high specific strength and modulus and low cost [33], offering the possibility of a replacement of synthetic fibres in the manufacture of polymer composites. Moreover, the conversion of biobased waste residues into lignocellulosic materials has also been investigated, contributing to aspects of circular economy, sustainability, and carbon footprint. The evaluation of residues like sugarcane bagasse [34], pineapple crown [35], coconut husk [36], and pecan nutshells (PN) [37] highlights their potential as valuable lignocellulosic materials. The conversion offers a more sustainable approach to conventional use in low-value applications, such as animal feeding or energy generation [38,39,40] or their disposal in landfills [9].

Pecan nutshell (PN) is an important industrial residue, with the shell waste representing 40–50% of the nut’s total mass, and is a rich source of fibres, carbohydrates, water, protein, minerals, and lipids [41]. Recently, PN has also been reported as a potential lignocellulosic material [15,16,17]. In our previous study [37], we assessed the morphology and thermal stability of PN to determine its potential as a lignocellulosic material. PN is thermally stable in a non-reactive atmosphere up to 250 °C and has high extractive and holocellulose contents (12.6% and 55.7%, respectively). Álvarez-Chávez et al. [42] characterised extruded PLA reinforced with 5 and 7.5% PN. The increase in %PN led to a gradual reduction in PLA’s tensile strength, from 47.3 MPa (neat PLA) to 38.7 MPa, and a significant decrease in elongation at break (from 43.2 to 3.1%) (composite with 7.5% PN). However, the tensile elastic modulus slightly increased from 1902 MPa to 2108 MPa with 7.5% PN. Moreover, PN did not negatively interfere with the thermal stability of PLA/PN composites during extrusion. Agustin-Salazar et al. [15] also studied the potential of PN as a reinforcement agent for PLA composites. The presence of PN reduced the PLA T5% from 308.7 to 294 °C; however, it increased PLA flexural modulus from 4063 to 4520 MPa while the deformation at break was barely affected.

The use of biodegradable or non-biodegradable interface modifiers in polymer blends and composites is an expected practice, usually if the components do not present adequate chemical affinity between themselves [43]. These additives enhance the interfacial strength by promoting a more effective interaction between the phases [44], resulting in a material with better physical and mechanical properties [45]. Martins et al. [46] assessed the use of the carboxylic acids C6, C10, and C16 as coupling agents for LLDPE/TPS 70/30 blends. The use of C10 acid, for instance, remarkably increased LLDPE/TPS blend strain at break from 114.44% to 430.35%. Yang and Sun evaluated the mechanical properties of straw-PLA composites. The use of a silane coupling agent increased the composite tensile and flexural strengths from 3.03 to 15.07 MPa and from 9.12 to 30.83 MPa, respectively [24].

Previously, we compared some carboxylic acids (C6, C8, C10, and C12) and PP-g-MA efficiencies as interface modifier agents for PP/wood flour (PWF) composites [26]. The mechanical tests showed that the PP/PWF composite with octanoic acid (C8) had the same flexural modulus as the one with PP-g-MA (2.2 GPa). The use of dodecanoic acid (C12) increased the PP/PWF impact strength from 29.3 to 35.3 J·m−1, while PP-g-MA reduced it from 29.3 to 26.7 J·m−1. The thermal stability results indicated that the type of coupling agent (biodegradable or non-biodegradable) did not affect the thermal stability of the PP composites during their manufacturing. Although intermediate and long-chain carboxylic acids are commonly used as interface modifiers, the use of shorter-chain mono and di-carboxylic acids for this purpose in PLA composites remains, to the best of our knowledge, largely underexplored. This research paper aims to evaluate the potential of mono- and dicarboxylic acids (hexanoic acid (C6), hexanedioic acid (CC6), octanoic acid (C8), and octanodioic acid (CC8)) as biodegradable coupling agents in the development of injection-moulded PLA/PN composites.

2. Materials and Methods

2.1. Materials

Poly (lactic acid) (PLA) was supplied by NatureWorks (Plymouth, MN, USA) (grade: PLA3001D; ρ = 1.24 g·cm−3; MFI = 22 g/10 min at 210 °C). The pecan nutshells (PN) were kindly provided by Produtora de Nozes Pitol (Anta Gorda, Brazil) (ρ = 1.30 g·cm−3; average particle size = 200 µm). The carboxylic acids (CAs), hexanoic acid (C6) (ρ20 °C = 0.93 g·cm−3; Tb = 206 °C), hexanedioic acid (CC6) (ρ20 °C = 1.36 g·cm−3; Tb = 265 °C), octanoic acid (C8) (ρ20 °C = 0.91 g·cm−3; Tb = 237 °C), and octanodioic acid (CC8) (ρ20 °C = 1.27 g·cm−3; Tb = 229 °C) were supplied by Sigma Aldrich (St. Louis, MO, USA).

2.2. Methods

2.2.1. Composite Preparation

Table 1 presents the nomenclature and compositions of the PLA/PN composites (in wt. %). The composites were prepared either without (PLA/PN) or with carboxylic acids (CAs). PLA and PN were dried in an oven at 60 °C for 48 h to remove residual moisture prior to processing.

Table 1.

Nomenclature and compositions (wt.%) of the PLA/PN composites.

The PLA/PN composite components were simultaneously added into a MH Equipment co-rotating twin-screw extruder (model MH-COR-20–32; L/D = 44; screw speed = 120 rpm). The temperature profile (feed to die) was 100–160–175–175-175–175-175–175 °C. The extruded material was pelletized in a Seibet pelletizer (model PS 50; frequency: 50 Hz) and dried in an oven (60 °C for 12 h). Finally, the composites were injection moulded in an in HIMACO injection moulding machine (model LH150–80, L/D = 18.3, temperature profile: 165 °C).

2.2.2. Composite Characterisation

- Surface fracture morphology

The surface morphology of PLA and PLA/PN composites was examined using a Mira 3 Tescan field emission scanning electron microscope (FE-SEM) operated at an acceleration voltage of 15 kV. Prior to imaging, all samples were cryofractured and subsequently coated with a thin layer of gold. The micrographs of PLA and PLA/PN composites were captured at magnifications of 500× (available in the Supplementary Data) and 2000×.

- DSC analysis

DSC measurements were carried out on a DSC 300 Classic calorimeter (Netzsch). Approximately 15 mg of each sample was analysed under N2 atmosphere. The thermal programme consisted of an initial heating from 25 to 180 °C (1st run) at a rate of 10 °C·min−1, followed by a 2 min isothermal hold at 180 °C. The samples were then cooled to 0 °C at the same rate and subsequently reheated to 180 °C (2nd run) at 10 °C·min−1.

The cold crystallisation and melting processes and their respective temperature peaks and changes in the enthalpies were measured from the second heating cycle. The PLA crystallinity degree (Xc) of PLA was estimated as

where and are, respectively, the change in the enthalpy of melting and cold crystallisation, wPLA is the PLA weight fraction in the sample, and is change in the enthalpy of melting of a 100% crystalline PLA (93 J·g−1).

- Flexural Strength Test

Three-point flexural tests were conducted using a DL 3000 testing machine (EMIC) equipped with a 200 kg load cell, operating at a crosshead speed of 1.5 mm·min−1, according to the ASTM D790 standard [47]. The flexural properties were determined as the average values from seven specimens for each sample.

- Dynamic Mechanical Analysis (DMA)

The viscoelastic behaviour of PLA and PLA composites was evaluated by measuring the storage modulus (E’) and damping factor (tan δ) using a Q800 AT dynamic mechanical analyser (TA Instruments). The tests were conducted over a temperature range of 30–120 °C, with a heating rate of 3 °C·min−1, a constant deformation of 0.1%, and a frequency of 1 Hz. The sample dimensions were 30 mm × 12.5 mm × 3.5 mm.

- Thermogravimetric Analysis (TGA)

The thermal stability of PLA and its composites was assessed through TGA, using a TGA-50 thermogravimetric analyser (Shimadzu) under N2 atmosphere. Approximately 10 mg of each sample was analysed from 25 to 600 °C at a heating rate of 10 °C·min−1, using approximately 10 mg per sample. The mass loss (TG) and mass loss rate (DTG) were recorded. The corresponding temperature to 5% of mass loss (T5%) and the peak temperature of the DTG curve (Tp) were determined for all samples.

3. Results and Discussion

3.1. Surface Fracture Morphology of PLA Composites

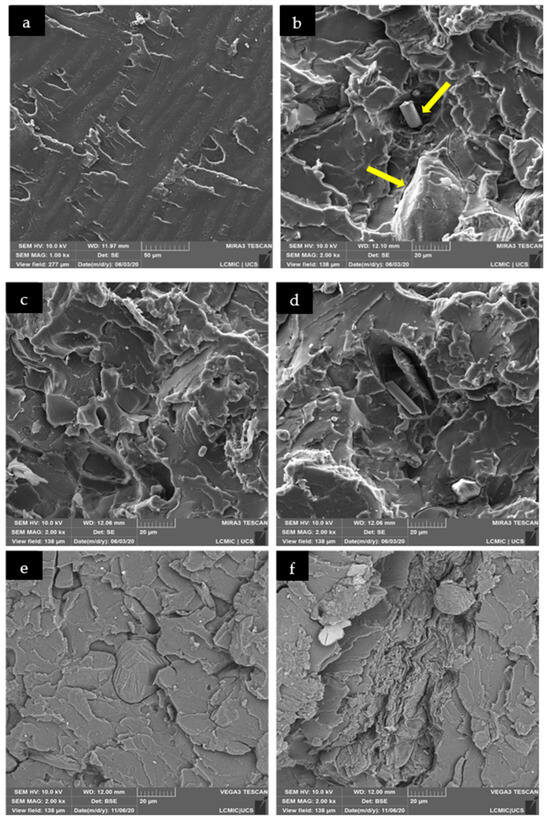

Figure 1 shows the surface fracture morphology of the PLA (Figure 1a) and PLA/PN composites (Figure 1b–f). PLA is well-known for its brittleness, with no or very low plastic deformation, showing a smooth surface in the surface fracture (Figure 1a), as also observed by Zhang et al. [48], Gao and Qiang [49], and Bernardes et al. [50]. The incorporation of PN modified the morphology of PLA surface fracture from smooth to rough (Figure 1b). The addition of hydrophilic PN fibres generates poor interfacial adhesion within the hydrophobic PLA matrix (pinpointed by the yellow arrows in the micrograph). These characteristics suggested weak intermolecular forces between PLA and PN, which may lead to an inefficient stress-transferring mechanism. Chun et al. [51] evaluated the fracture morphology of PLA/chrysanthemum waste (CWF) composites, also reporting a poor interfacial bonding between PLA and CWF and void presence in the absence of a coupling agent.

Figure 1.

Surface fracture micrograph of PLA (a), PLA/PN (b), PLA/PN/C6 (c), PLA/PN/CC6 (d), PLA/PN/C8 (e), and PLA/PN/CC8 (f).

Figure 1c–f shows the morphology of the surface fracture of PLA/PN composites with CAs. The presence of CA did not significantly change the morphology of the composites, which still presented a platelet-like morphology with a rough surface. The nature of the CA (mono- or dicarboxylic acid) exerted a minor influence on the PN embedment by the PLA matrix. The use of PN enhanced the adhesion of PN fibres on the PLA matrix in comparison with the neat PLA/PN composite (Figure 1b), irrespective of the type of CA used. This behaviour was similarly noticed by Chun and Husseinsyah [52] in their research about PLA/corn cub (CC) composites with coconut oil coupling agent (COCA). The presence of COCA resulted in better dispersion of CC particles and enhanced their embedment in the PLA matrix, which was attributed to a better matrix–filler interaction. Chun et al. [51] studied PLA/chrysanthemum waste (CWF) composites with PE-g-MA, noticing an improvement of the CWF adhesion and particle embedment for the PLA matrix as a result of the presence of PE-g-MA.

The surface fracture morphology is also a valuable and predictive tool for assessing the mechanical properties of multiphase materials, such as polymer composites. For instance, the transition from a smooth to a rough surface in the PLA/PN composite may indicate an enhanced flexural strength in contrast to neat PLA. This improvement could be explained by PN being more rigid than PLA, which would be corroborated by an increase in the composite’s molten viscosity. However, suppose the interfacial adhesion between PLA and PN is weak. In that case, the composite could exhibit an increase in flexural strength and modulus, but only a slight increase in strain at break. This observation is supported by Ramirez et al. [53], who studied the morphology and mechanical properties of PLA/natural fibres (sisal, coir, and fique) composites. The change in PLA surface morphology (from smooth to rough) was attributed to a plastic deformation of the PLA matrix caused by the presence of natural fibres. Moreover, the presence of natural fibres increased PLA’s elastic modulus and reduced its strain at break, which may be indicative of poor interfacial adhesion between PLA and natural fibres.

On the other hand, the addition of a coupling agent is expected to increase the intermolecular interaction between PLA/PN, resulting in a stronger interface and a more efficient stress-transferring mechanism. As a result, the mobility of the PLA chains may be reduced, increasing PLA melt viscosity, flexural strength, and modulus, as well as strain at break. This observation is supported by the research of Chun and Husseinsyah [52] about PLA/corn cub (CC) composites with a coconut oil coupling agent (COCA). The presence of COCA increased the tensile strength, elongation at break, and modulus of elasticity of PLA/CC composites regardless of CC content. This improvement is justified by a better embedding of CC particles within the PLA matrix due to the presence of COCA. Saeed et al. [54] studied PLA/softwood kraft nanocellulose fibril (NCF) composites with HDPE-g-MA, observing that the presence of HDPE-g-MA improved NCF adhesion on PLA matrix as well as reduced its debonding.

3.2. Influence of PN and CA on PLA Thermal Transitions

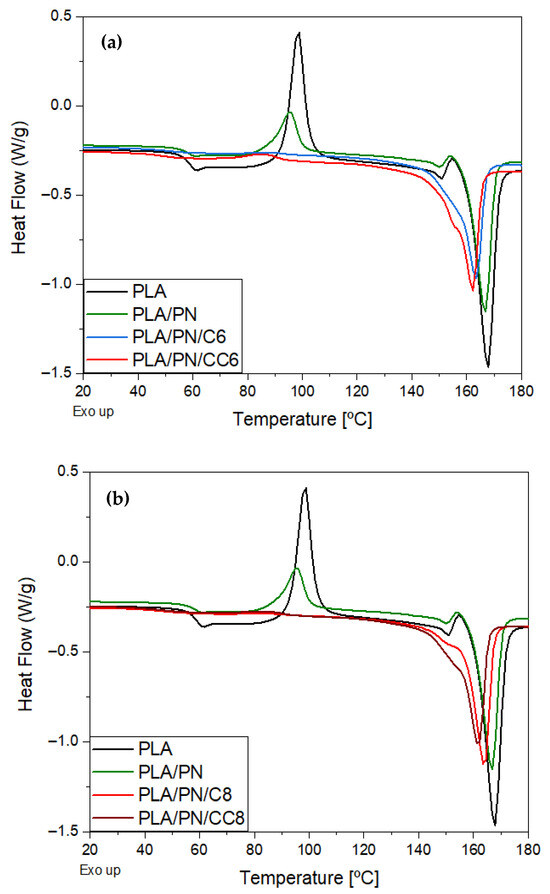

Figure 2 shows the DSC thermograms of PLA/PN composites with C6/CC6 (Figure 2a) and C8/CC8 (Figure 2b) carboxylic acids in the temperature range of 25–180 °C. The PLA main thermal transition is available in Table 2.

Figure 2.

DSC thermograms of PLA and PLA/PN composites with C6 and CC6 (a) and C8 and CC8 (b) carboxylic acids.

Table 2.

Main thermal transitions (second run) of PLA and PLA/PN composites.

An endothermic event is observed in the 90–130 °C range, which is attributed to the cold crystallisation of PLA [55,56,57]. Cold crystallisation is commonly identified in polyesters such as PET [58], PBT [59], PTT, and PLA [60], as well as in polyethers like PEG [61] and PEEKK [62]. When these polymers are quenched, they are unable to crystallise [63], resulting in an amorphous microstructure. Upon reheating between Tg and Tm, the increased thermal energy promotes chain mobility, contributing to the formation and stabilisation of crystallites. The comparison of the cold crystallisation processes of PLA and PLA/PN composite suggested that PN acted as a nucleating agent to PLA, shifting PLA cold crystallisation onset to lower temperatures. This conjecture is supported by the broadening of the PLA melting curve (Figure 2a,b) and the increase in the PLA crystallinity degree (Table 2). A similar result was observed by Alonso-González et al. [64] while evaluating the effect of rice bran on PLA crystallisation. The presence of 30% wt. rice bran also shifted PLA cold crystallisation onset to lower temperatures, while broadening the PLA melting curve. Conversely, the use of CA, irrespective of the number of carboxylic groups and the aliphatic chain length, hindered the cold crystallisation process. Mysiukiewicz and Barczewski [65] identified the same trend in their studies about the crystallisation of PLA reinforced with linseed cake (LC) (a byproduct of oil extraction from linseed). The authors varied LC content from 0.39 to 39.8% in the PLA/LC composites, reporting that the increase in LC% reduced the intensity of PLA cold crystallisation peak, eventually suppressing the phenomenon entirely. This behaviour was possibly affected by the choice of cooling rate (10 °C·min−1), which may have been sufficient to inhibit cold crystallisation in PLA.

A small exothermic phenomenon was observed in the 150–160 °C range (prior to PLA melting) in both neat PLA and PLA/PN composite. According to Tábi et al. [66], the temperature of cold crystallisation affects the type of crystallites formed in PLA. When this crystallisation occurs below 100 °C, PLA predominantly forms α’ crystallites (a less ordered structure than the more stable α form). The small exothermic peak before melting is likely due to the solid-phase transformation from α’ → α crystallites. The presence of PN reduced the height of this transformation peak without affecting its temperature. A possible explanation can be found in the increased viscosity caused by PN, which limits chain mobility. Notably, the presence of CA did not influence this transformation, as PLA/PN/CA composites did not show cold crystallisation.

The melting process of PLA was observed in the 140–180 °C range. Both the width and height of the melting curve were significantly influenced by the presence of pecan nut (PN) and carboxylic acids. The incorporation of PN affected the formation of the PLA crystallites, reducing their size, as inferred from the melting curve profile. Concomitantly, PN acted as a nucleating agent and increased the PLA crystallinity degree, as shown in Table 2. A similar trend was reported by Vitiello et al. in their evaluation of the effect of hemp on the PLA crystallinity process, in which the PLA Xc (%) increased from nearly 2.5 to approximately 17% after the incorporation of 30% wt. hemp [67]. Ramirez et al. [53] assessed the influence of sisal on the PLA crystallisation process by varying sisal content from 1 to 5% wt. The increase in sisal content in the PLA/sisal composite shifted PLA cold crystallisation from 121 (neat PLA) to 116 °C (PLA + 5% wt. sisal) while increasing the melting curve width.

The presence of carboxylic acid led to a wider melting temperature range, suggesting a nucleating effect, which was corroborated by the increase in the PLA Xc (Table 2). The number of carboxylic groups significantly played a key role on the nucleation of the PLA crystallites. Irrespective of chain length, PLA/PN composites containing mono-CAs exhibited narrower melting curves compared to those with di-CAs. This result suggested that while all CAs enhanced the crystallite population, they also reduced their size. This effect was more pronounced in di-CAs, which could be attributed to a stronger intermolecular interaction between PLA/di-CA/PN molecules.

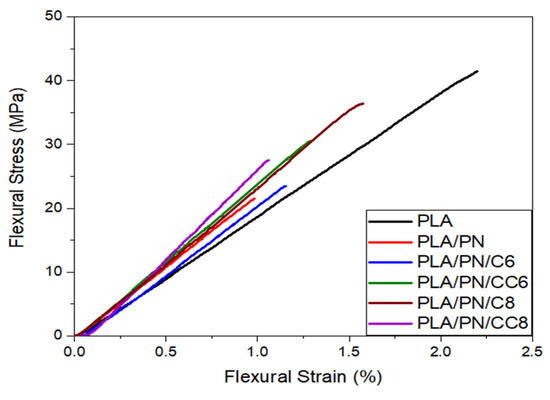

3.3. Flexural Behaviour of PLA/PN Composites

The flexural behaviour of PLA and PLA/PN composites is shown in Figure 3 as flexural stress vs. strain curves, and their main flexural properties data are displayed in Table 3. PLA is a glassy polymer at 23 °C, resulting in a material with both high flexural modulus and strength at the cost of low flexural strain at break. Saeed et al. [54] reported a similar behaviour while studying PLA/softwood kraft nanocellulose fibril (NCF) composites, in which neat PLA exhibited a tensile strain at break around 2%.

Figure 3.

Flexural stress vs. strain curves of PLA and PLA/PN composites.

Table 3.

PLA and PLA/PN composites’ main flexural properties data.

The addition of the PN dramatically reduced the strain at break and increased the flexural modulus of the PLA/PN composite. This trade-off could be justified by a combination of PN fibre’s rigidity, PLA/PN interfacial strength, and higher crystallinity degree (as evidenced by Table 2 data). The PN rigidity could have reduced the PLA molecule’s mobility during the flexural tests, resulting in a gain of modulus at the cost of lowering the flexural strain at break. This reduction is likely due to a weak PLA/PN interface, affecting the stress-transferring mechanism, which corroborates the results from Figure 1b. This result agrees with Stoia and Linul’s [68] study on 3D printed PLA composites with synthetic fibres (glass and carbon fibres). PLA composites presented a significantly higher flexural modulus than neat PLA (especially for PLA/carbon fibre composite), but lower flexural strength. Reverte et al. [69] evaluated the influence of carbon fibres (CF) on PLA flexural behaviour. The authors noticed an identical pattern to our research, in which CF increased PLA flexural modulus at the cost of reducing the flexural strain at break.

The use of CA (irrespective of the number of carboxylic groups) significantly increased the PLA composite’s modulus as well as strain at break. These results highlighted a triple effect promoted by the CA additives—plasticisation of PLA molecules, strengthening of the PLA/PN interface, and nucleating agent (evidenced by the increase in PLA crystallinity degree in Table 2). The plasticisation effect was identified based on a higher strain at break of PLA/PN/CA composites vs. the neat PLA/PN composite, which was attributed to CA increasing the chain slipperiness between PLA molecules. The interface modifier role was corroborated by higher flexural modulus and stress at break, evidencing a more efficient stress-transferring mechanism, possibly by a stronger intermolecular interaction between PLA-PN structures through Hydrogen bonds [70,71]. For instance, the composites with six-carbon carboxylic acid (C6 and CC6) presented a higher flexural strength compared to the neat composite, reaching an increment of 53% (PLA/PN/CC6 composite). The same behaviour was verified on PLA/PN/C8 and CC8 composites, in which PLA/PN/C8 achieved a higher flexural strength than other composites (72% higher than the neat composite). These results also agreed with the predictions made based on the morphology of the surface fracture from SEM micrographs (Figure 1c–f), which indicated better PN embedding by PLA matrix as well as lower fibre pull-out. Ermeydan et al. [72] reported a similar trend in their study about PLA/beech wood biocomposites, in which neat PLA exhibited a higher flexural strength than its composites, and the use of a coupling agent improved the PLA composite’s flexural strength. Gorgun et al. [73] studied PLA/microcrystalline cellulose (MCC) composites with and without maleated coupling agents. The use of the maleated coupling agent increased the PLA/MCC composite’s tensile strength from approximately 12 to nearly 16 MPa, while its elongation at break increased from nearly 3 to approximately 5.5%.

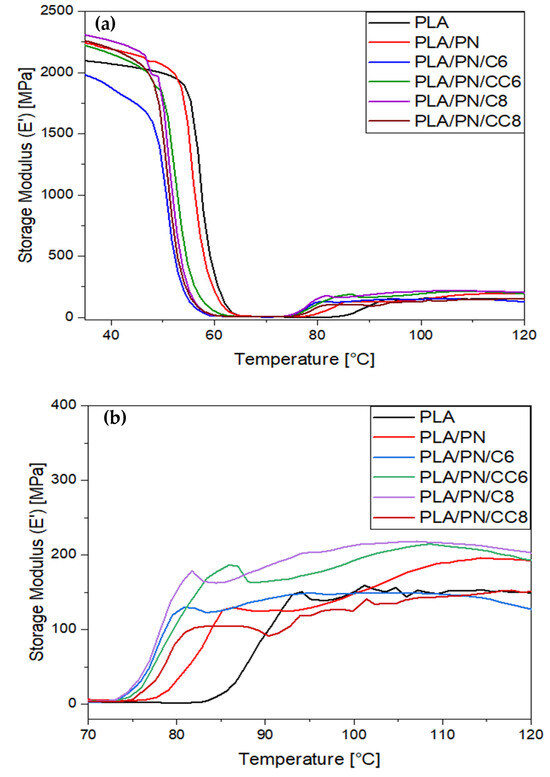

3.4. Influences of PN and CAs on the PLA/PN Composites’ Viscoelastic Behaviour

Figure 4a shows the variation in the storage modulus (E’) as a function of temperature for PLA and PLA composites, while Figure 4b evidences the cold crystallisation process of PLA. Table 4 shows the different E’ measured at 35 and 50 °C, PLA Tg (determined by the tan δ peak temperature), and the tan δ peak height (measured at Tg). All samples presented a drastic E’ reduction in the temperature range of 50–75 °C, which was attributed to the PLA glass transition and a probable low crystallinity degree. These results agreed with Badia et al. [74] and Copolla et al.’s [75] studies of PLA, which also reported a remarkable reduction in PLA storage modulus in the same temperature range. The incorporation of PN enhanced PLA’s storage modulus, irrespective of temperature. This effect is attributed to a decrease in PLA chain mobility caused by the PN rigid phase, which was already reported in the literature [76,77,78,79]. Yoganandam et al. [80] evaluated the effect of Calotropis procera (CP) particles on PLA viscoelastic behaviour, observing an increase in PLA’s storage modulus after the incorporation of CP particles. Sánchez Acosta et al. [81] also evaluated the role of PN on PLA viscoelasticity, reporting an increase in PLA’s storage modulus attributed to the use of PN as a reinforcing agent.

Figure 4.

PLA and PLA/PN composites’ storage modulus (E’) as a function of temperature (a) and zoomed-in view highlighting the PLA cold crystallisation (b).

Table 4.

PLA and PLA/PN composites’ main viscoelastic properties data.

The use of CA as a biodegradable coupling agent increased the storage modulus of the PLA composites, except for the composite with C6. The enhancement is justified by a stronger intermolecular interaction between PLA-PN phases. Consequently, the overlap of PN and CA presences reduced PLA chain mobility and increased its storage modulus. PLA/PN/C6 composite indicated a different behaviour, which could be attributed to the possible evaporation of C6 during PLA processing [79]. Saeed et al. [54] evaluated the effectiveness of HDPE-g-MA as a coupling agent for PLA/softwood kraft nanocellulose fibrils (NCF) composites. The PLA/NCF composite exhibited greater E’ than neat PLA, and the use of 3% wt. HDPE-g-MA in this composite further enhanced its storage modulus, which was attributed to an improvement of PLA/NCF interfacial adhesion.

The PLA cold crystallisation temperature onset (TCC, Onset) was determined based in the variation in PLA storage modulus in the 70–120 °C range (Figure 4b). PLA Tcc is commonly observed between 100 and 115 °C [56,65,82]. PLA TCC, Onset was identified around 85 °C, and the presence of PN shifted this temperature to approximately 80 °C in the PLA/PN composite. Yang et al. [82] reported a similar trend when assessing the effect of graphene oxide on PLA cold crystallisation. The use of CAs, irrespective of their nature, further shifted TCC, Onset from 80 to nearly 75–77 °C. The comparison of PLA and PLA composites’ TCC, Onset indicated that PN possibly acts as a heterogeneous nucleation site for PLA crystallites. The use of CAs synergically improves the effect of PN, which can be attributed to a combination of the low molecular weight of CAs and a stronger intermolecular interaction between PLA and PN.

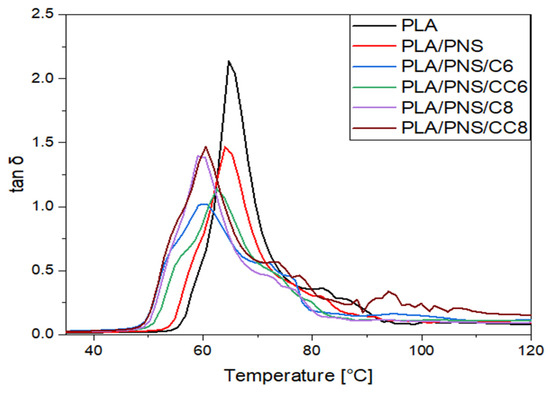

Figure 5 illustrates the change in tan δ as a function of temperature for PLA and its composites. PLA exhibited a sharp tan δ peak around 55–70 °C, which was considered as its glass transition temperature [83,84,85]. In DMA analyses, the height of the tan δ peak is directly related to the material’s damping, i.e., its capacity to dissipate energy over the temperature [86]. A high damping coefficient indicates that the viscous component of the polymer’s viscoelasticity overcomes the elastic component, resulting in a material with an energy-dissipating characteristic. On the other hand, a low damping coefficient indicates a material with an elastic behaviour, thus with better energy storage capability.

Figure 5.

PLA and PLA/PN composites’ tan δ as a function of temperature.

According to Figure 5 and Table 4 data, the presence of PN reduced PLA’s tan δ peak height, which was attributed to a weak PLA-PN interface and an easier detachment of PN particles from the PLA matrix. This result diverged from Álvarez-Chávez et al.’s [42] findings, in which the use of PN shifted PLA Tg to lower temperatures. Gupta and Singh [78] evaluated the effect of sisal on PLA viscoelasticity, reporting that the use of sisal reduced the PLA damping coefficient. Abatti et al. [87] assessed the potential of PN as a biobased replacement for carbon black in elastomer formulations, reporting that increasing the content of PN in the rubber formulation also reduced the rubber damping. The presence of CA also reduced the PLA tan δ peak height, and the nature of the carboxylic acid (short vs. long aliphatic chain and presence of one or two carboxylic groups) did not significantly affect this parameter. This trend can be explained by an improvement in the energy transferring from the PN to the PLA phase due to a stronger interface, which was corroborated by the flexural results and SEM micrographs.

The presence of PN practically did not affect PLA Tg (see Table 4), which was also observed in other studies about PLA composites [78,88,89]. The use of CA in PLA/PN composites resulted in further reduction in PLA Tg. This influence depended on the molecular characteristics of the CA, which suggested that this additive may have exerted a dual role on PLA composites (lubricant and coupling agent). For instance, evaluating the effect of the aliphatic chain length. The PLA/PN composites with C8 and CC8 presented lower Tgs than the ones with C6 and CC6 (especially for C8). In this scenario, the longer the chain length, the more significant the lubricant effect was, as proved by the reduction in the PLA Tg. Despite the presence of the PN, in this case, it is possible that these additives acted as plasticisers for PLA [90]. Moreover, the number of carboxyl groups also influenced the PLA Tg. The PLA composites with dicarboxylic CAs exhibited higher Tgs than the monocarboxylic ones, which indicates a reduction in the PLA chain mobility due to stronger intermolecular forces. In this case, these additives acted as coupling agents for the PLA composites.

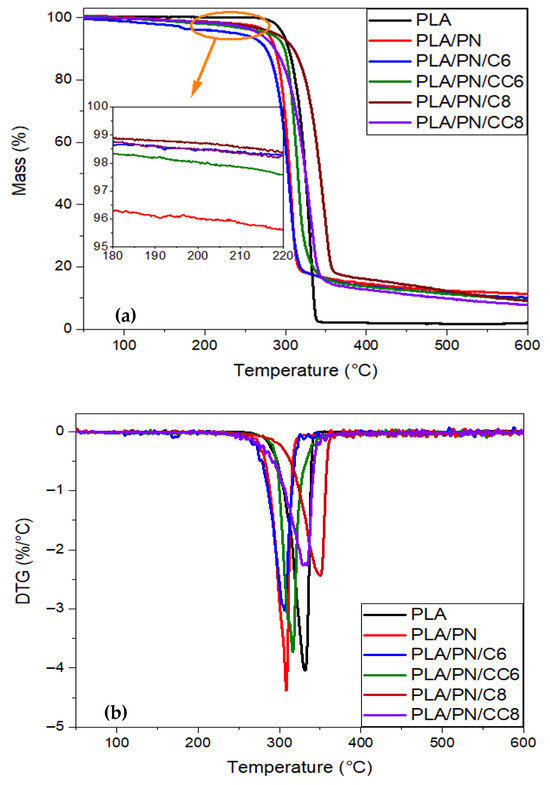

3.5. Influences of PN and CAs on the PLA/PN Composites’ Thermal Stability

Figure 6 shows the TG (Figure 6a) and DTG (Figure 6b) as functions of temperature for PLA and PLA composites. All data regarding PLA and its composites T5% and Tp are available in Table 5. The PLA thermal degradation process occurred as a single event (T5% = 296 °C), and it is characterised by random chain scission or transesterification reactions [91]. The thermal degradation of pecan nutshell (PN) was previously evaluated by our group [37]. PN presented a T5% around 250 °C and a percentage of residue of 40.6% at 600 °C, with a three-stage thermal degradation process. The first stage (around 100 °C) involved water elimination and extractive degradation, followed by hemicellulose and cellulose degradations (around 300 °C), and, finally, lignin degradation. Lignin features aromatic rings in its polymer backbone, which enhances the thermal stability of this polymer and requires a higher energy input to initiate its thermal decomposition. In our study of the thermal degradation of pineapple crown fibre (PCF) [35], the PCF exhibited a similar thermal degradation process to PN. At 100 °C, water molecules evaporated, followed by the degradation of cellulose around 250–400 °C, while lignin degraded from 200 to 600 °C.

Figure 6.

PLA and PLA composites’ mass (a) and DTG (b) as functions of temperature.

Table 5.

TG and DTG parameters of PLA and PLA/PN composites.

The incorporation of PN reduced the PLA/PN composite thermal stability in contrast to neat PLA, as evidenced in Figure 6 and Table 5. The PLA/PN exhibited a two-stage thermal decomposition process, in which the first stage (around 100 °C) was attributed to the elimination of the residual humidity of PN. The second stage (250–330 °C) was characterised by the elimination of hemicellulose, followed by an overlap of PLA and cellulose and lignin degradations. Chaitanya et al. [92] observed a similar behaviour in their studies of the thermal degradation of PLA/sisal composites, in which an overlap between PLA and cellulose (and some part of lignin) occurred between 260 and 365 °C. These results highlighted that lignocellulosic materials may potentially accelerate the thermal degradation of a composite compared to its neat polymer, which could be considered a drawback in terms of thermal stability. However, from a processing perspective, neither neat PLA nor its composites exhibited significant mass loss within the typical PLA processing window (200–220 °C) [93,94,95]. This suggests that the use of PN does not affect the thermal stability of PLA during processing.

The thermal stabilities of C6 and C8 were previously assessed [70], revealing a single decomposition event for both acids and T5% and Tp values of 104 and 176 °C (C6) and 131 and 198 °C (C8). In this research, we assessed the thermal stability of CC6 and CC8, which also revealed a single decomposition event for each acid, with T5% and Tp values of 210 and 275 °C (CC6) and 214 and 275 °C (CC8). The presence of CA did not modify the number of thermal decomposition events in the PLA/PN composites. This result can be attributed to the low CA content used in PLA/PN/CA composites and the overlap between CA’s thermal decomposition range and those of PLA and certain PN decomposition stages. Conversely, as evidenced in Table 5, the type and nature (mono- or dicarboxylic acid) of the CA exerted a major role in the thermal stability of the PLA/PN composites. For instance, the C6 and C8 acids have the lowest boiling point (Tb), suggesting that these mono-CAs could have been evaporated during the PLA processing due to the combined influences of pressure, temperature, and shear. This hypothesis was confirmed for the PLA/PN/C6 composite but not for PLA/PN/C8, based on the T5% and Tp values. The divergence can be explained by the molecular structure of carboxylic acids, which consist of a -CH2- sequence terminated by a carboxyl group (-COOH). The -C-C- and -C-H bonds are thermally stable, and a longer -CH2- sequence can enhance the thermal stability of the acid. On the other hand, the use of the di-CAs improved the thermal stability of the PLA/PN composite, shifting its T5% and Tp to higher temperatures. This superior performance, when compared to mono-CAs, is attributed to stronger intermolecular forces originating from a higher number of carboxyl groups in the acid molecule, promoting higher intermolecular interaction between PLA-PN.

4. Conclusions

In general, the carboxylic acids in our study showed promising results, playing a multifunctional role as coupling agents, plasticisers, and nucleating agents. The results highlight their versatility and may have indicated unexplored functionalities, which can contribute to the manufacture of novel polymer composites with improved properties. The use of CAs improved the mechanical, dynamic mechanical, and thermal properties of PLA/PN composites in comparison to neat PLA. The presence of CA reduced the PLA Tg in the PLA/PN composites (a possible plasticising effect), and increased PLA crystallinity degree (attributed to an enhanced nucleating effect when combined with the pecan nut fibres). The incorporation of CA increased the PLA/PN composite E’ at 35 °C and reduced the tan δ peak height. The use of these additives also significantly enhanced the PLA composite flexural strength. PLA/PN/CC8 presented the best results, probably due to a better interaction between fibre and matrix.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/jcs9080422/s1, Figure S1: Surface fracture micrograph of PLA (a), PLA/PN (b), PLA/PN/C6 (c), PLA/PN/CC6 (d), PLA/PN/C8 (e), PLA/PN/CC8 (f) at 500× magnification.

Author Contributions

Conceptualization, G.P.B. and M.P.; methodology, M.d.P.A.; software, M.d.P.A.; validation, G.P.B., M.d.P.A. and M.P.; formal analysis, G.P.B. and M.d.P.A.; investigation, G.P.B.; resources, M.P.; data curation, G.P.B.; writing—original draft preparation, G.P.B.; writing—review and editing, M.d.P.A. and M.P.; visualisation, M.P.; supervision, M.P.; project administration, M.P.; funding acquisition, M.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by CNPq, grant number 304647/2022-5. The APC was funded by CNPq.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed at the corresponding author.

Acknowledgments

The authors would like to thank Produtora de Nozes Pitol for donating the pecan nutshell. Poletto M. thanks CNPq.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Kaiser, M.R.; Anuar, H.B.; Samat, N.B.; Razak, S.B.A. Effect of Processing Routes on the Mechanical, Thermal and Morphological Properties of PLA-Based Hybrid Biocomposite. Iran. Polym. J. 2013, 22, 123–131. [Google Scholar] [CrossRef]

- Fahim, I.S.; Chbib, H.; Mahmoud, H.M. The Synthesis, Production & Economic Feasibility of Manufacturing PLA from Agricultural Waste. Sustain. Chem. Pharm. 2019, 12, 100142. [Google Scholar] [CrossRef]

- Fowlks, A.C.; Narayan, R. The Effect of Maleated Polylactic Acid (PLA) as an Interfacial Modifier in PLA-Talc Composites. J. Appl. Polym. Sci. 2010, 118, 2810–2820. [Google Scholar] [CrossRef]

- Tsou, C.H.; Suen, M.C.; Yao, W.H.; Yeh, J.T.; Wu, C.S.; Tsou, C.Y.; Chiu, S.H.; Chen, J.C.; Wang, R.Y.; Lin, S.M.; et al. Preparation and Characterization of Bioplastic-Based Green Renewable Composites from Tapioca with Acetyl Tributyl Citrate as a Plasticizer. Materials 2014, 7, 5617–5632. [Google Scholar] [CrossRef] [PubMed]

- Freeland, B.; McCarthy, E.; Balakrishnan, R.; Fahy, S.; Boland, A.; Rochfort, K.D.; Dabros, M.; Marti, R.; Kelleher, S.M.; Gaughran, J. A Review of Polylactic Acid as a Replacement Material for Single-Use Laboratory Components. Materials 2022, 15, 2989. [Google Scholar] [CrossRef] [PubMed]

- Trivedi, A.K.; Gupta, M.K.; Singh, H. PLA Based Biocomposites for Sustainable Products: A Review. Adv. Ind. Eng. Polym. Res. 2023, 6, 382–395. [Google Scholar] [CrossRef]

- Suder, J.; Bobovsky, Z.; Safar, M.; Mlotek, J.; Vocetka, M.; Zeman, Z. Experimental Analysis of Temperature Resistance of 3d Printed PLA Components. MM Sci. J. 2021, 2021, 4322–4327. [Google Scholar] [CrossRef]

- Wu, Y.; Gao, X.; Wu, J.; Zhou, T.; Nguyen, T.T.; Wang, Y. Biodegradable Polylactic Acid and Its Composites: Characteristics, Processing, and Sustainable Applications in Sports. Polymers 2023, 15, 3096. [Google Scholar] [CrossRef] [PubMed]

- Crupano, W.; Adrover-Monserrat, B.; Llumà, J.; Jerez-Mesa, R.; Travieso-Rodriguez, J.A. Investigating Mechanical Properties of 3D Printed Polylactic Acid/Poly-3-Hydroxybutyrate Composites. Compressive and Fatigue Performance. Heliyon 2024, 10, e38066. [Google Scholar] [CrossRef]

- Pinto, V.C.; Ramos, T.; Alves, S.; Xavier, J.; Tavares, P.; Moreira, P.M.G.P.; Guedes, R.M. Comparative Failure Analysis of PLA, PLA/GNP and PLA/CNT-COOH Biodegradable Nanocomposites Thin Films. Procedia. Eng. 2015, 114, 635–642. [Google Scholar] [CrossRef]

- Pepelnjak, T.; Karimi, A.; Maček, A.; Mole, N. Altering the Elastic Properties of 3D Printed Poly-Lactic Acid (PLA) Parts by Compressive Cyclic Loading. Materials 2020, 13, 4456. [Google Scholar] [CrossRef]

- Pszczółkowski, B.; Nowak, K.W.; Rejmer, W.; Bramowicz, M.; Dzadz, Ł.; Gałęcki, R. A Comparative Analysis of Selected Methods for Determining Young’s Modulus in Polylactic Acid Samples Manufactured with the FDM Method. Materials 2021, 15, 149. [Google Scholar] [CrossRef]

- Mazur, K.E.; Borucka, A.; Kaczor, P.; Gądek, S.; Bogucki, R.; Mirzewiński, D.; Kuciel, S. Mechanical, Thermal and Microstructural Characteristic of 3D Printed Polylactide Composites with Natural Fibers: Wood, Bamboo and Cork. J. Polym. Environ. 2022, 30, 2341–2354. [Google Scholar] [CrossRef]

- Oksman, K.; Skrifvars, M.; Selin, J.F. Natural Fibres as Reinforcement in Polylactic Acid (PLA) Composites. Compos. Sci. Technol. 2003, 63, 1317–1324. [Google Scholar] [CrossRef]

- Agustin-Salazar, S.; Cerruti, P.; Medina-Juárez, L.Á.; Scarinzi, G.; Malinconico, M.; Soto-Valdez, H.; Gamez-Meza, N. Lignin and Holocellulose from Pecan Nutshell as Reinforcing Fillers in Poly(Lactic Acid) Biocomposites. Int. J. Biol. Macromol. 2018, 115, 727–736. [Google Scholar] [CrossRef] [PubMed]

- Frone, A.N.; Berlioz, S.; Chailan, J.F.; Panaitescu, D.M.; Donescu, D. Cellulose Fiber-Reinforced Polylactic Acid. Polym. Compos. 2011, 32, 976–985. [Google Scholar] [CrossRef]

- Balart, J.F.; Fombuena, V.; Fenollar, O.; Boronat, T.; Sánchez-Nacher, L. Processing and Characterization of High Environmental Efficiency Composites Based on PLA and Hazelnut Shell Flour (HSF) with Biobased Plasticizers Derived from Epoxidized Linseed Oil (ELO). Compos. Part B Eng. 2016, 86, 168–177. [Google Scholar] [CrossRef]

- Orue, A.; Eceiza, A.; Arbelaiz, A. Preparation and Characterization of Poly(Lactic Acid) Plasticized with Vegetable Oils and Reinforced with Sisal Fibers. Ind. Crops. Prod. 2018, 112, 170–180. [Google Scholar] [CrossRef]

- Brambilla, V.C.; Beltrami, L.V.R.; Pelegrini, K.; Zimmermann, M.V.G.; Brandalise, R.N.; Zattera, A.J. Development and Characterization of PLA/Buriti Fibre Composites—Influence of Fibre and Coupling Agent Contents. Polym. Polym. Compos. 2017, 25, 143–152. [Google Scholar] [CrossRef]

- Avolio, R.; Castaldo, R.; Avella, M.; Cocca, M.; Gentile, G.; Fiori, S.; Errico, M.E. PLA-Based Plasticized Nanocomposites: Effect of Polymer/Plasticizer/Filler Interactions on the Time Evolution of Properties. Compos. Part B Eng. 2018, 152, 267–274. [Google Scholar] [CrossRef]

- Mahendra, I.P.; Wirjosentono, B.; Tamrin; Ismail, H.; Mendez, J.A.; Causin, V. The Influence of Maleic Anhydride-Grafted Polymers as Compatibilizer on the Properties of Polypropylene and Cyclic Natural Rubber Blends. J. Polym. Res. 2019, 26, 215. [Google Scholar] [CrossRef]

- Vudjung, C.; Nuinu, P.; Yupas, P.; Seelakun, R.; Saengsuwan, S. Styrene-Assisted Acrylic Acid Grafting onto Polypropylene Surfaces: Preparation, Characterization, and an Automatically Latex-Coagulating Application. Polym. Bull. 2023, 80, 5123–5147. [Google Scholar] [CrossRef]

- Oliver-Ortega, H.; Reixach, R.; Espinach, F.X.; Méndez, J.A. Maleic Anhydride Polylactic Acid Coupling Agent Prepared from Solvent Reaction: Synthesis, Characterization and Composite Performance. Materials 2022, 15, 1161. [Google Scholar] [CrossRef]

- Yang, Z.; Sun, K. Enhanced Characterization of Wheat Straw-PLA Composites with Silane Coupling Agent and Alkali Pretreatment. Ecotoxicol. Environ. Saf. 2025, 290, 117612. [Google Scholar] [CrossRef]

- Liminana, P.; Garcia-Sanoguera, D.; Quiles-Carrillo, L.; Balart, R.; Montanes, N. Development and Characterization of Environmentally Friendly Composites from Poly(Butylene Succinate) (PBS) and Almond Shell Flour with Different Compatibilizers. Compos. Part B Eng. 2018, 144, 153–162. [Google Scholar] [CrossRef]

- Poletto, M. Natural Oils as Coupling Agents in Recycled Polypropylene Wood Flour Composites: Mechanical, Thermal and Morphological Properties. Polym. Polym. Compos. 2020, 28, 443–450. [Google Scholar] [CrossRef]

- Martins, A.B.; Santana, R.M.C. Effect of Carboxylic Acids as Compatibilizer Agent on Mechanical Properties of Thermoplastic Starch and Polypropylene Blends. Carbohydr. Polym. 2016, 135, 79–85. [Google Scholar] [CrossRef] [PubMed]

- Castro, D.O.; Passador, F.; Ruvolo-Filho, A.; Frollini, E. Use of Castor and Canola Oils in “Biopolyethylene” Curauá Fiber Composites. Compos. Part A Appl. Sci. Manuf. 2017, 95, 22–30. [Google Scholar] [CrossRef]

- Belyamani, I.; Najemi, L.; Wilson, K.; Abdullah Alhadhrami, M.; Al-Badi, N. Influence of Glycerol and Clove Essential Oil on the Properties and Biodegradability of Poly(Lactic Acid)/Poly(Hydroxybutyrate-Co-Hydroxyvalerate) Blends. Int. J. Biol. Macromol. 2025, 308, 142698. [Google Scholar] [CrossRef]

- Khan, B.; Niazi, M.B.K.; Hussain, A.; Jahan, Z. Influence of Carboxylic Acids on Mechanical Properties of Thermoplastic Starch by Spray Drying. Fibers Polym. 2017, 18, 64–73. [Google Scholar] [CrossRef]

- Benkhelladi, A.; Laouici, H.; Bouchoucha, A. Tensile and Flexural Properties of Polymer Composites Reinforced by Flax, Jute and Sisal Fibres. Int. J. Adv. Manuf. Technol. 2020, 108, 895–916. [Google Scholar] [CrossRef]

- Kamarudin, S.H.; Mohd Basri, M.S.; Rayung, M.; Abu, F.; Ahmad, S.; Norizan, M.N.; Osman, S.; Sarifuddin, N.; Desa, M.S.Z.M.; Abdullah, U.H.; et al. A Review on Natural Fiber Reinforced Polymer Composites (NFRPC) for Sustainable Industrial Applications. Polymers 2022, 14, 3698. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T. A Review of Natural Fiber Composites: Properties, Modification and Processing Techniques, Characterization, Applications. J. Mater. Sci. 2020, 55, 829–892. [Google Scholar] [CrossRef]

- Hiranobe, C.T.; Gomes, A.S.; Paiva, F.F.G.; Tolosa, G.R.; Paim, L.L.; Dognani, G.; Cardim, G.P.; Cardim, H.P.; dos Santos, R.J.; Cabrera, F.C. Sugarcane Bagasse: Challenges and Opportunities for Waste Recycling. Clean Technol. 2024, 6, 662–699. [Google Scholar] [CrossRef]

- Bernardes, G.P.; de Prá Andrade, M.; Poletto, M. Effect of Alkaline Treatment on the Thermal Stability, Degradation Kinetics, and Thermodynamic Parameters of Pineapple Crown Fibres. J. Mater. Res. Technol. 2023, 23, 64–76. [Google Scholar] [CrossRef]

- Abraham, E.; Deepa, B.; Pothen, L.A.; Cintil, J.; Thomas, S.; John, M.J.; Anandjiwala, R.; Narine, S.S. Environmental Friendly Method for the Extraction of Coir Fibre and Isolation of Nanofibre. Carbohydr. Polym. 2013, 92, 1477–1483. [Google Scholar] [CrossRef] [PubMed]

- de Prá Andrade, M.; Piazza, D.; Poletto, M. Pecan Nutshell: Morphological, Chemical and Thermal Characterization. J. Mater. Res. Technol. 2021, 13, 2229–2238. [Google Scholar] [CrossRef]

- Lijó, L.; González-García, S.; Bacenetti, J.; Moreira, M.T. The Environmental Effect of Substituting Energy Crops for Food Waste as Feedstock for Biogas Production. Energy 2017, 137, 1130–1143. [Google Scholar] [CrossRef]

- Surendra, K.C.; Olivier, R.; Tomberlin, J.K.; Jha, R.; Khanal, S.K. Bioconversion of Organic Wastes into Biodiesel and Animal Feed via Insect Farming. Renew. Energy 2016, 98, 197–202. [Google Scholar] [CrossRef]

- Nassary, E.K.; Nasolwa, E.R. Unravelling Disposal Benefits Derived from Underutilized Brewing Spent Products in Tanzania. J. Environ. Manag. 2019, 242, 430–439. [Google Scholar] [CrossRef]

- do Prado, A.C.P.; da Silva, H.S.; da Silveira, S.M.; Barreto, P.L.M.; Vieira, C.R.W.; Maraschin, M.; Ferreira, S.R.S.; Block, J.M. Effect of the Extraction Process on the Phenolic Compounds Profile and the Antioxidant and Antimicrobial Activity of Extracts of Pecan Nut [Carya Illinoinensis (Wangenh) C. Koch] Shell. Ind. Crops. Prod. 2014, 52, 552–561. [Google Scholar] [CrossRef]

- Álvarez-Chávez, C.R.; Sánchez-Acosta, D.L.; Encinas-Encinas, J.C.; Esquer, J.; Quintana-Owen, P.; Madera-Santana, T.J. Characterization of Extruded Poly(Lactic Acid)/Pecan Nutshell Biocomposites. Int. J. Polym. Sci. 2017, 2017, 3264098. [Google Scholar] [CrossRef]

- Miao, M.; Wei, C.; Wang, Y.; Qian, Y. Effect of Compatibilizer on the Interface Bonding of Graphene Oxide/Polypropylene Composite Fibers. Polymers 2018, 10, 1283. [Google Scholar] [CrossRef]

- Chen, Q.; Li, F.; Zhai, Z.; Li, S.; Cai, Y.; Li, Q. Effect of Interfacial Compatibility on Mechanical Property of Polyamide 6 Modified by Polyborosiloxane. Polymers 2025, 17, 392. [Google Scholar] [CrossRef]

- Rao, J.; Zhou, Y.; Fan, M. Revealing the Interface Structure and Bonding Mechanism of Coupling Agent Treated WPC. Polymers 2018, 10, 266. [Google Scholar] [CrossRef]

- Martins, A.B.; Cattelan, A.K.; Santana, R.M.C. How the Compatibility between Polyethylene and Thermoplastic Starch Can Be Improved by Adding Organic Acids? Polym. Bull. 2018, 75, 2197–2212. [Google Scholar] [CrossRef]

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- Zhang, X.; Chen, L.; Mulholland, T.; Osswald, T.A. Characterization of Mechanical Properties and Fracture Mode of PLA and Copper/PLA Composite Part Manufactured by Fused Deposition Modeling. SN Appl. Sci. 2019, 1, 616. [Google Scholar] [CrossRef]

- Gao, H.; Qiang, T. Fracture Surface Morphology and Impact Strength of Cellulose/PLA Composites. Materials 2017, 10, 624. [Google Scholar] [CrossRef]

- Bernardes, G.P.; da Rosa Luiz, N.; Santana, R.M.C.; de Camargo Forte, M.M. Rheological Behavior and Morphological and Interfacial Properties of PLA/TPE Blends. J. Appl. Polym. Sci. 2019, 136, 47962. [Google Scholar] [CrossRef]

- Chun, K.S.; Yeng, C.M.; May, C.P.; Yeow, T.K.; Kiat, O.T.; How, C.K. Effect of Coupling Agent Content on Properties of Composites Made from Polylactic Acid and Chrysanthemum Waste. J. Vinyl. Addit. Technol. 2020, 26, 10–16. [Google Scholar] [CrossRef]

- Chun, K.S.; Husseinsyah, S. Polylactic Acid/Corn Cob Eco-Composites. J. Thermoplast. Compos. Mater. 2014, 27, 1667–1678. [Google Scholar] [CrossRef]

- Ramirez, C.; Agaliotis, E.; Pettarin, V. Fracture Toughness and Overall Characterization of PLA Based Biocomposites with Natural Fibers: A Comparative Study. Polymer 2024, 307, 127309. [Google Scholar] [CrossRef]

- Saeed, U.; Rathur, S.U.; Alturaif, H.; Bamufleh, H. Effect of Coupling Agent on Softwood Kraft Nanocellulose Fibril-Reinforced Polylactic Acid Biocomposite. J. Nanomater. 2021, 2021, 9076170. [Google Scholar] [CrossRef]

- Day, M.; Nawaby, A.V.; Liao, X. A DSC Study of the Crystallization Behaviour of Polylactic Acid and Its Nanocomposites. J. Therm. Anal. Calorim. 2006, 86, 623–629. [Google Scholar] [CrossRef]

- Hesami, M.; Jalali-Arani, A. Cold Crystallization Behavior of Poly(Lactic Acid) in Its Blend with Acrylic Rubber; the Effect of Acrylic Rubber Content. Polym. Int. 2017, 66, 1564–1571. [Google Scholar] [CrossRef]

- Tarani, E.; Pušnik Črešnar, K.; Zemljič, L.F.; Chrissafis, K.; Papageorgiou, G.Z.; Lambropoulou, D.; Zamboulis, A.; Bikiaris, D.N.; Terzopoulou, Z. Cold Crystallization Kinetics and Thermal Degradation of PLA Composites with Metal Oxide Nanofillers. Appl. Sci. 2021, 11, 3004. [Google Scholar] [CrossRef]

- Sago, T.; Itagaki, H.; Asano, T. Onset of Forming Ordering in Uniaxially Stretched Poly(Ethylene Terephthalate) Films Due to π-π Interaction Clarified by the Fluorescence Technique. Macromolecules 2014, 47, 217–226. [Google Scholar] [CrossRef]

- Pyda, M.; Nowak-Pyda, E.; Heeg, J.; Huth, H.; Minakov, A.A.; Di Lorenzo, M.L.; Schick, C.; Wunderlich, B. Melting and Crystallization of Poly(Butylene Terephthalate) by Temperature-Modulated and Superfast Calorimetry. J. Polym. Sci. Part B Polym. Phys. 2006, 44, 1364–1377. [Google Scholar] [CrossRef]

- Zhang, J.; Li, J.; Zhai, G.; Chen, Y.; Christiansen, J.d.C.; Yu, D.; Jiang, S. Cold Crystallization of Polytrimethylene Terephthalate and Copolymers. Polymer 2024, 300, 126967. [Google Scholar] [CrossRef]

- Hatakeyma, T.; Kasuga, H.; Tanaka, M.; Hatakeyama, H. Cold Crystallization of Poly(Ethylene Glycol)–Water Systems. Thermochim. Acta 2007, 465, 59–66. [Google Scholar] [CrossRef]

- Liu, T.; Mo, Z.; Wang, S.; Zhang, H. Nonisothermal Melt and Cold Crystallization Kinetics of Poly(Aryl Ether Ether Ketone Ketone). Polym. Eng. Sci. 1997, 37, 568–575. [Google Scholar] [CrossRef]

- Yu, L.; Liu, H.; Dean, K.; Chen, L. Cold Crystallization and Postmelting Crystallization of PLA Plasticized by Compressed Carbon Dioxide. J. Polym. Sci. Part B Polym. Phys. 2008, 46, 2630–2636. [Google Scholar] [CrossRef]

- Alonso-González, M.; Felix, M.; Romero, A.; Aliotta, L.; Gigante, V.; Sergi, C.; Bavasso, I.; Sarasini, F. Innovative Approaches to Bioplastic Development: Rice Bran/PLA Blends via Extrusion Combined with Injection Molding and 3D Printing. J. Environ. Manag. 2025, 389, 126081. [Google Scholar] [CrossRef]

- Mysiukiewicz, O.; Barczewski, M. Crystallization of Polylactide-Based Green Composites Filled with Oil-Rich Waste Fillers. J. Polym. Res. 2020, 27, 374. [Google Scholar] [CrossRef]

- Tábi, T.; Hajba, S.; Kovács, J.G. Effect of Crystalline Forms (A′ and α) of Poly(Lactic Acid) on Its Mechanical, Thermo-Mechanical, Heat Deflection Temperature and Creep Properties. Eur. Polym. J. 2016, 82, 232–243. [Google Scholar] [CrossRef]

- Vitiello, L.; Carroccio, S.C.; Ambrogi, V.; Podda, E.; Filippone, G.; de Luna, M.S. Degradation Kinetics of PLA/Hemp Biocomposites: Tradeoff between Nucleating Action and pro-Hydrolytic Effect of Natural Fibers. Compos. Sci. Technol. 2024, 257, 110806. [Google Scholar] [CrossRef]

- Stoia, D.I.; Linul, E. Tensile, Flexural and Fracture Properties of MEX-Printed PLA-Based Composites. Theor. Appl. Fract. Mech. 2024, 132, 104478. [Google Scholar] [CrossRef]

- Reverte, J.M.; Caminero, M.Á.; Chacón, J.M.; García-Plaza, E.; Núñez, P.J.; Becar, J.P. Mechanical and Geometric Performance of PLA-Based Polymer Composites Processed by the Fused Filament Fabrication Additive Manufacturing Technique. Materials 2020, 13, 1924. [Google Scholar] [CrossRef]

- Poletto, M.; Zattera, A.J.; Santana, R.M.C. Effect of Natural Oils on the Thermal Stability and Degradation Kinetics of Recycled Polypropylene Wood Flour Composites. Polym. Compos. 2014, 35, 1935–1942. [Google Scholar] [CrossRef]

- Spiridon, I.; Darie, R.N.; Kangas, H. Influence of Fiber Modifications on PLA/Fiber Composites. Behavior to Accelerated Weathering. Compos. Part B Eng. 2016, 92, 19–27. [Google Scholar] [CrossRef]

- Ermeydan, M.A.; Aykanat, O.; Altın, Y. Preparation and Characterization of Hybrid PLA Biocomposites Reinforced by Wood and Silane Treated Basalt Fibers or Compatibilized by Maleic Anhydride-Grafted Polypropylene (MAPP). Polym. Compos. 2024, 45, 9831–9844. [Google Scholar] [CrossRef]

- Gorgun, E.; Ali, A.; Islam, M.S. Biocomposites of Poly(Lactic Acid) and Microcrystalline Cellulose: Influence of the Coupling Agent on Thermomechanical and Absorption Characteristics. ACS Omega 2024, 9, 11523–11533. [Google Scholar] [CrossRef]

- Badia, J.D.; Strömberg, E.; Karlsson, S.; Ribes-Greus, A. Material Valorisation of Amorphous Polylactide. Influence of Thermo-Mechanical Degradation on the Morphology, Segmental Dynamics, Thermal and Mechanical Performance. Polym. Degrad. Stab. 2012, 97, 670–678. [Google Scholar] [CrossRef]

- Coppola, B.; Cappetti, N.; Maio, L.D.; Scarfato, P.; Incarnato, L. 3D Printing of PLA/Clay Nanocomposites: Influence of Printing Temperature on Printed Samples Properties. Materials 2018, 11, 1947. [Google Scholar] [CrossRef]

- Lee, J.-M. The Current Concepts of Total Hip Arthroplasty. Hip Pelvis 2016, 28, 191–200. [Google Scholar] [CrossRef] [PubMed]

- Chee, S.S.; Jawaid, M.; Sultan, M.T.H.; Alothman, O.Y.; Abdullah, L.C. Thermomechanical and Dynamic Mechanical Properties of Bamboo/Woven Kenaf Mat Reinforced Epoxy Hybrid Composites. Compos. Part B Eng. 2019, 163, 165–174. [Google Scholar] [CrossRef]

- Gupta, M.K.; Singh, R. Flexural and Dynamic Mechanical Analysis (DMA) of Polylactic Acid (PLA) Coated Sisal Fibre Reinforced Polyester Composite. Mater. Today Proc. 2018, 5, 6109–6114. [Google Scholar] [CrossRef]

- Poletto, M.; Zattera, A.J.; Santana, R.M.C. Thermal Decomposition of Wood: Kinetics and Degradation Mechanisms. Bioresour. Technol. 2012, 126, 7–12. [Google Scholar] [CrossRef] [PubMed]

- Yoganandam, K.; Shanmugam, V.; Vasudevan, A.; Vinodh, D.; Nagaprasad, N.; Stalin, B.; Karthick, A.; Malla, C.; Bharani, M. Investigation of Dynamic, Mechanical, and Thermal Properties of Calotropis Procera Particle-Reinforced PLA Biocomposites. Adv. Mater. Sci. Eng. 2021, 2021, 2491489. [Google Scholar] [CrossRef]

- Sánchez-Acosta, D.; Rodriguez-Uribe, A.; Álvarez-Chávez, C.R.; Mohanty, A.K.; Misra, M.; López-Cervantes, J.; Madera-Santana, T.J. Physicochemical Characterization and Evaluation of Pecan Nutshell as Biofiller in a Matrix of Poly(Lactic Acid). J. Polym. Environ. 2019, 27, 521–532. [Google Scholar] [CrossRef]

- Yang, S.; Li, S.R.; Zhou, S.Y.; Yang, H.R.; Xu, L.; Zhong, G.J.; Xu, J.Z.; Li, Z.M.; Tao, X.M.; Mai, Y.W. Cold Crystallization Behavior of Poly(Lactic Acid) Induced by Poly(Ethylene Glycol)-Grafted Graphene Oxide: Crystallization Kinetics and Polymorphism. Compos. Sci. Technol. 2024, 258, 110871. [Google Scholar] [CrossRef]

- Cristea, M.; Ionita, D.; Iftime, M.M. Dynamic Mechanical Analysis Investigations of PLA-Based Renewable Materials: How Are They Useful? Materials 2020, 13, 5302. [Google Scholar] [CrossRef] [PubMed]

- Bernardes, G.P.; da Rosa Luiz, N.; Santana, R.M.C.; de Camargo Forte, M.M. Influence of the Morphology and Viscoelasticity on the Thermomechanical Properties of Poly(Lactic Acid)/Thermoplastic Polyurethane Blends Compatibilized with Ethylene-Ester Copolymer. J. Appl. Polym. Sci. 2020, 137, 48926. [Google Scholar] [CrossRef]

- Mofokeng, J.P.; Luyt, A.S.; Tábi, T.; Kovács, J. Comparison of Injection Moulded, Natural Fibre-Reinforced Composites with PP and PLA as Matrices. J. Thermoplast. Compos. Mater. 2012, 25, 927–948. [Google Scholar] [CrossRef]

- Manral, A.; Ahmad, F.; Chaudhary, V. Static and Dynamic Mechanical Properties of PLA Bio-Composite with Hybrid Reinforcement of Flax and Jute. Mater. Today Proc. 2020, 25, 577–580. [Google Scholar] [CrossRef]

- Abatti, L.; Vieira, E.R.; da Silva Crespo, J. Thermal Evaluation of Rubber Compounds Containing Pecan Nutshell Powder for Tire Treads. J. Therm. Anal. Calorim. 2019, 138, 3673–3678. [Google Scholar] [CrossRef]

- Dembri, I.; Belaadi, A.; Lekrine, A.; Boumaaza, M.; Jawaid, M.; Ismail, A.S.; Ghernaout, D. Structural and Thermal Properties of Alkali-Treated Biomass Fibers and W. Robusta Waste Reinforced PLA Hybrid Biocomposites. Case Stud. Therm. Eng. 2025, 70, 106170. [Google Scholar] [CrossRef]

- Lekrine, A.; Belaadi, A.; Dembri, I.; Jawaid, M.; Ismail, A.S.; Ghernaout, D. Fiber Treatment Impact on the Thermal Behavior of Biomass/Palm-Fibers Polylactic-Acid Hybrid Biocomposites. Mater. Chem. Phys. 2025, 338, 130651. [Google Scholar] [CrossRef]

- Ortega-Toro, R.; López-Córdoba, A.; Avalos-Belmontes, F. Epoxidised Sesame Oil as a Biobased Coupling Agent and Plasticiser in Polylactic Acid/Thermoplastic Yam Starch Blends. Heliyon 2021, 7, e06176. [Google Scholar] [CrossRef]

- Kopinke, F.D.; Remmler, M.; Mackenzie, K.; Möder, M.; Wachsen, O. Thermal Decomposition of Biodegradable Polyesters—II. Poly (Lactic Acid). Polym. Degrad. Stab. 1996, 53, 329–342. [Google Scholar] [CrossRef]

- Chaitanya, S.; Singh, I.; Song, J.I. Recyclability Analysis of PLA/Sisal Fiber Biocomposites. Compos. Part B Eng. 2019, 173, 106895. [Google Scholar] [CrossRef]

- Shekhar, N.; Mondal, A. Synthesis, Properties, Environmental Degradation, Processing, and Applications of Polylactic Acid (PLA): An Overview. Polym. Bull. 2024, 81, 11421–11457. [Google Scholar] [CrossRef]

- Lim, L.T.; Auras, R.; Rubino, M. Processing Technologies for Poly(Lactic Acid). Prog. Polym. Sci. 2008, 33, 820–852. [Google Scholar] [CrossRef]

- Swetha, T.A.; Bora, A.; Mohanrasu, K.; Balaji, P.; Raja, R.; Ponnuchamy, K.; Muthusamy, G.; Arun, A. A Comprehensive Review on Polylactic Acid (PLA)—Synthesis, Processing and Application in Food Packaging. Int. J. Biol. Macromol. 2023, 234, 123715. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).