Abstract

Background. Physicomechanical properties and clinical service of bulk-fill composites depend on their adequate polymerization and depth of cure. Some manufacturers claim that these composites can be adequately cured when used in bulks exceeding 4 mm. Objective. The aim of this study was to compare Vickers microhardness (VMH) and depth of cure (DOC) of six contemporary bulk-fill resin composites at depths of 4 mm and 6 mm. Material and methods. Six bulk-fill composites were evaluated in this study: 1. Tetric EvoCeram Bulk (Ivoclar Vivadent, Schaan, Liechtenstein), (TEC); 2. Filtek Bulk Fill Posterior (3M ESPE Dental Products Division, St. Paul, MN, USA), (FBF); 3. Filtek One Bulk Fill (3M ESPE Dental Products Division, St. Paul, MN, USA, (FOB); 4. SonicFill 2 (Kerr, Orange, CA, USA), (SF2); 5. Admira Fusion X-tra (Voco, GmbH, Cuxhaven, Germany), (AFX); 6. GrandioSO X-tra (Voco, GmbH, Cuxhaven, Germany), (GSX). The 18 specimens (3 of each composite) were prepared in split Teflon moulds of 4 mm diameter and 6 mm thickness. All composites were cured in standard mode for 20 s using LED LCU (D-Light Duo, RF-Pharmaceuticals Sarl, Geneva, Switzerland; 1200–1300 mW/cm). The VMH was measured using a digital Micro Hardness Tester Shimadzu (HMV-2T E, Shimadzu Corporation, Kyoto, Japan). A 50 g (0.5 N) load force was applied for 30 s. Each specimen was measured at five places selected by chance at each level (N = 15). The hardness ratio or DOC was calculated for all samples as the ratio of bottom and surface microhardness at levels of 4 and 6 mm. Data were analysed using one-way ANOVA and Tukey’s post hoc test. Results. Significant reduction in VMH was observed for all tested materials when comparing top surface and bottom (p < 0.01). The highest VMH was obtained for GSX and AFX, and the lowest for TEC. The results show that the degree of polymerization was adequate for all tested materials at a depth of 6 mm, since the hardness ratio exceeded 0.80 in all cases. The hardness ratio at 4 mm was high for all tested composites ranging from 0.91 for TEC to 0.98 for GSX. All composites showed adequate DOC at the bottom of the 6 mm bulk samples. However, the hardness ratio was the highest for Admira Fusion X-tra (0.96) and GrandioSO X-tra (0.97). Conclusions. All tested materials showed a significant decrease in microhardness from the top surface to the bottom. The DOC was adequate for all bulk-fill composites at a depth of 6 mm cured under standard mode for 20 s. All bulk-fill resin composites evaluated in this study can be used in bulk, up to 6 mm.

1. Introduction

Resin-based composites are the most frequently used filling materials for direct restorations of teeth. They provide highly aesthetic results and longevity of restorations. Clinical paediatric dentistry requires reliable dental materials and techniques to provide confident and lasting restorations. Conventional composite resins require an incremental insertion of material in 2 mm layers, which can be time-consuming in deeper cavities. At the same time, their use is technique-sensitive and longer manipulations can lead to mistakes and failures [1,2].

Bulk-fill composites have become more popular in clinical practice due to being less time consuming for handling and the possibility to be used in one increment for the restoration of lateral teeth. The idea of the introduction of bulk-fill composites was to provide easier handling. While traditional composites need to be applied and cured in increments up to 2 mm, bulk-fill composites provide application in bulk, up to 4 or even 7 mm, making the clinical procedure simple and less environment-sensitive [1,2]. Numerous studies reported on the adequate polymerization of bulk-fill composites at different depths. An ideal bulk-fill material should display a high degree of conversion, low polymer shrinkage, deep curing, and long-term durability [3].

The physicomechanical properties and clinical performance of composite restorations depend on the adequate polymerization and degree of conversion (DC) of the resin matrix. The microhardness of bulk-fill composites shows a gradual decrease from the top toward the bottom of the composite specimen. It is related to the degree of cure of the composite resin. Measurement of composite hardness represents an indirect method of assessing the degree of conversion (DC). A decrease in microhardness along the surface of the specimen from top to bottom represents a decrease in the degree of conversion of the RBCs with increasing distance from the source of polymerization light source to the bottom of the specimen. It has been shown that the surface hardness of light-cured composite resin does not necessarily correlate with depth of cure (DOC). However, the bottom-to-top hardness ratio provides a practical and commonly used method for indirectly determining the degree of monomer conversion in resin composite materials [4,5].

Depth of cure, as a measure of adequate polymerization, was used to assess the behaviour of different bulk-fill resin composites according to the manufacturer’s recommendations, or even deeper. It is defined as the depth at which the hardness is equal to 80% of the surface hardness [6]. The DOC is usually expressed as the bottom-to-top hardness ratio or as a percentage of the maximum hardness measured at the surface of the sample. It also serves as an indirect measure of the degree of conversion. DOC depends on many factors, such as the resin composite’s colour and translucency, filler size and type, material thickness, type of monomer, photo-initiator system, and the curing light’s time and intensity [7,8].

Bulk-fill resin composites show a comparable hardness ratio to the conventional composites if used in bulks according to the manufacturer’s recommendation [9]. It is considered that bottom-to-top hardness ratio or DOC of 4 mm thick bulk-fill specimens should be close to 1 or 100%. However, many studies consider a hardness ratio of 0.80 or higher as a standard of clinically acceptable depth of cure [10,11,12,13,14].

Manufacturers of contemporary bulk-fill composites claim that these products can be successfully cured up to 4 mm or more [7,11,15,16]. Kuraray Noritake, Japan, claims that Clearfil PhotoCore can be used and successfully polymerized in a layer thickness of 7 mm [2]. It was observed that the highest microhardness of bulk-fill resin composites does not correlate only with the percentage of filler particles.

Analysis of microhardness and depth of cure of some bulk-fill resin composites at manufacturer’s recommended thicknesses delivered values comparable to the conventional composite materials [9,16]. Several studies displayed conflicting findings regarding the adequate depth of curing of currently available bulk-fill resin composites at a depth of 4 mm [1,7,16].

The purpose of this research was to establish some mechanical properties of bulk-fill composites depending on the degree of monomer conversion. The aim was to determine Vickers microhardness (VMH) and the depth of cure of six bulk-fill resin composites using standard curing methods at depths of 4 mm and 6 mm. The particular aim was to compare the microhardness of resin composites having different monomer compositions and different filler characteristics.

2. Materials and Methods

2.1. Materials

Six bulk-fill composites were evaluated in this study (Table 1). The following composites were analysed: 1. Tetric EvoCeram Bulk (Ivoclar Vivadent, Schaan, Liechtenstein; Lot: S45466) (TEC); 2. Filtek Bulk Fill Posterior (3M ESPE Dental Products Division, St. Paul, MN, USA; Lot: N604393) (FBF); 3. Filtek One Bulk Fill (3M ESPE Dental Products Division, St. Paul, MN, USA; Lot: N851522) (FOB); 4. SonicFill 2 (Kerr, Orange, CA, USA; Lot: 6076513) (SF2); 5. Admira Fusion X-tra (Voco, GmbH, Cuxhaven, Germany; Lot: 1514493) (AFX); 6. GrandioSO X-tra (Voco, GmbH, Cuxhaven, Germany; Lot: V64944) (GSX). The shades of the composites were chosen to be as close as possible to minimise the effect on light curing and DOC.

Table 1.

Description of composites used in this study.

2.2. Specimen Preparation

The 18 cylindrical specimens were prepared in split Teflon moulds of 4 mm diameter and 6 mm thickness. Each mould was filled in a 6 mm single increment. The Teflon moulds were placed on a polyester matrix strip and microscopic glass. Another polyester matrix strip was placed on the top of the sample to prevent oxygen from interfering with the polymerization. The microscopic glass was pressed over the polyester matrix strip at the top of the composite to extrude the access of the material. The specimens were photo-polymerized in standard mode using LED LCU (D-Light Duo, RF-Pharmaceuticals Sarl, Geneva, Switzerland; 1200–1300 mW/cm) for 20 s at room temperature (23 ± 1 °C). The light intensity was periodically measured by radiometer, Demetron Research, Model 100, SDS Kerr, Orange, CA, USA. The battery of the curing device was fully charged before each light curing. After polymerization the samples were carefully separated from the moulds, marked at the bottom side, and stored in distilled water at 37 °C for 24 h.

2.3. Vickers Microhardness and Depth of Cure

Vickers microhardness (VMH) was measured using a digital Micro Hardness Tester Shimadzu (HMV-2T E, NO. 163034601445, Shimadzu Corporation, Kyoto, Japan). A 50 g (0.5 N) load was applied using the indenter for 30 s. The sample comprised 3 specimens of each composite. All measurements were performed in a sequential pattern starting from the surface, over the lateral surface, and to the bottom. The specimens were measured at 5 places selected by chance at the top and at 1 mm, 2 mm, 3 mm, 4 mm, 5 mm, and 6 mm, or at the bottom. In total, five measurements were taken at each level of the specimen, obtaining a final mean for each sample (N = 15).

The depth of cure as a ratio of bottom and top surface microhardness was obtained at 4 mm and 6 mm of depth.

2.4. Statistical Analysis

Statistical analysis was performed by using the software Statistica 7.0 (StatSoft, Dell Inc., Tulsa, OK, USA). Factorial ANOVA was used to analyse the higher-order interactive effects of multiple categorical independent variables. The measurements of Vickers microhardness at 7 levels and depths of curing (DOCs) were compared for all composites at depths of 4 mm and 6 mm. Significant differences between groups were identified using Tukey’s post hoc analysis at a significance level of p < 0.05.

3. Results

Mean values and standard deviations of Vickers hardness numbers for the tested materials at the top, lateral (1 mm to 5 mm), and bottom (6 mm) are presented in Table 2. In most of the tested materials, the difference in microhardness (VHN) between the top surface and the bottom (6 mm of depth) ranged from 9.2 to 14.93 micro-Vickers. The GSX (Voco) showed a smaller difference of only 7.54 micro-Vickers, while the best polymerization was shown for AFX (Voco) at 6.8 micro-Vickers, with a difference between surface and bottom (6 mm) hardness.

Table 2.

Microhardness of bulk-fill composites used in this study.

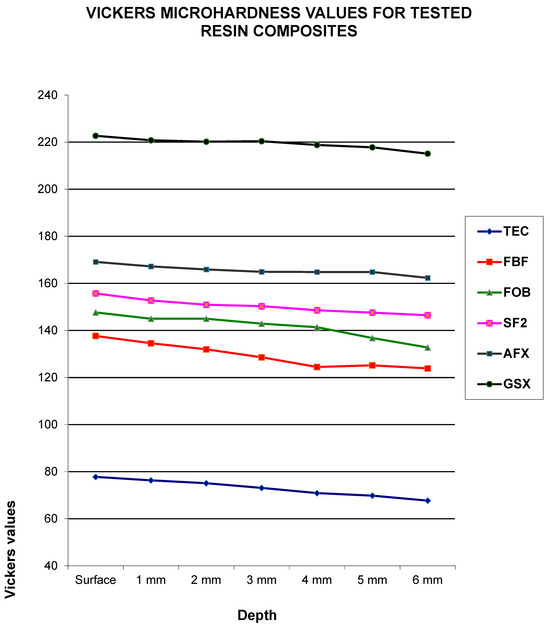

Two-factor ANOVA revealed significant differences in the hardness values among the six composites examined. Differences in microhardness between the surface and different depths were significant for all tested material. All composites showed significant differences in Vickers microhardness at the surface and at different depths from the surface (p < 0.01). The results are presented in Figure 1. Regarding microhardness, GSX presented the highest values followed by AFX, while TEC showed the lowest surface microhardness. All bulk-fill composites showed significantly higher hardness at the top surface than at the bottom (p < 0.01) (Table 2 and Figure 1).

Figure 1.

Vickers microhardness values for tested bulk-fill resin composites (TEC—Tetric EvoCeram Bulk, FBF—Filtek Bulk Fill Posterior, FOB—Filtek One Bulk Fill, SF2—SonicFill 2, AFX—Admira Fusion X-tra, GSX—GrandioSO X-tra).

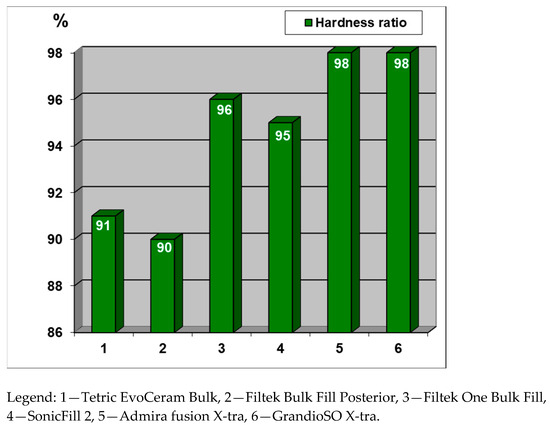

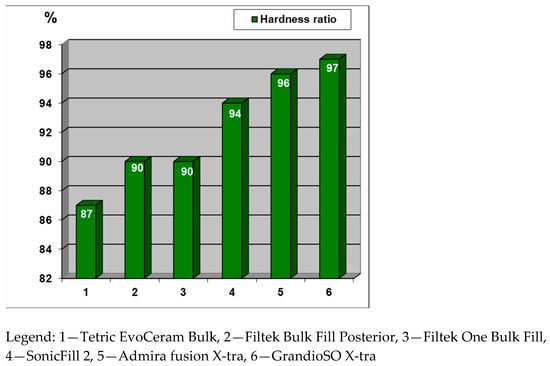

All bulk-fill composites showed significantly higher hardness at the top surface than at depths of 4 mm or 6 mm (Table 3 and Table 4; Figure 2 and Figure 3). In spite of drastic differences between microhardness numbers on the top and on the bottom surfaces, all tested materials showed hardness ratios higher than 0.80, which is considered as a minimum in the literature. A high hardness ratio was found for all composites at a depth of 4 mm and 6 mm. The differences between tested materials were significant (p < 0.01) (Table 3).

Table 3.

Differences between top and bottom (4 mm depth) microhardness of the samples and depth of cure (hardness ratio).

Table 4.

Differences between top and bottom (6 mm depth) microhardness of the samples in this study.

Figure 2.

Depth of cure (hardness ratio) at 4 mm.

Figure 3.

Depth of cure (hardness ratio) at 6 mm.

The lowest DOC was observed for TEC (0.9116) and FBF (0.9042). The highest hardness ratio of DOC was displayed by Admira Fusion X-tra and GrandioSO X-tra (0.9752 and 0.9829, respectively). While the first composites (TEC and FBC) displayed hardness ratios of about 0.90 at 4 mm, the AFX and GSX showed a DOC of about 98% (Figure 2).

It is interesting that all tested bulk-fill RBCs displayed a DOC higher than 80% at a depth of 6 mm (Table 4). TBC showed a border DOC at this depth of 0.8699, while AFX and GSX displayed a DOC of about 96%. The obtained DOC for the analysed composites ranged from 87% for TEC as the lowest value, to 97% for GSX as the highest value (Figure 3).

4. Discussion

The bulk-fill composites were developed to enhance clinical practice and reduce working time. They provide application of composite resin in increments of 4 mm or more and simple curing with a reliable degree of conversion. The manufacturers of bulk-fill composite resins claim a DOC of at least 4 mm up to 7 mm [2].

The Vickers microhardness (VMH) of the samples was measured after 24 h storage in distilled water at 37 °C. This is important because it was established that post-irradiation microhardness at the bottom and top of the specimen increases during the first hours after polymerization without any increase after 24 h [17]. Microhardness of resin composites depends on the degree of cure and shows a gradual decrease from the top to the bottom of composite specimens [18]. For the success of dental restorations, it is important to achieve adequate curing at the bottom surface of a composite filling. DOC is correlated to the DC. A ratio of 80% or higher is considered as a minimum acceptable value of bottom-to-top hardness ratio [10,18]. Based on this, all bulk-fill composites tested in this study could be used up to 6 mm depth. TEC is the only material that shows a border value at a depth of 6 mm. Some other studies show that TEC can be used at least in 4 mm thick increments to be satisfactorily cured [7,16].

Proper polymerization of composite resins is of key importance for their mechanical properties, wear resistance, and the clinical longevity of restorations [19,20]. Studies have shown that surface microhardness alone cannot reflect the depth of cure [4]. A suitable indirect method for assessing the depth of cure is the determination of the bottom-to-top microhardness ratio. This method is simple to use and correlates well with the degree of conversion of resin composites [21].

Hardness depends on the filler volume, but not on the average inorganic filler size [17,22]. It is also influenced by the degree of monomer conversion, which plays a key role in determining the performance of dental restorations under clinical conditions [23]. Furthermore, microhardness is affected by the composition of the resin matrix [24]. Based on individual microhardness measurements at the top and bottom surfaces of the samples, the depth of cure was calculated as the ratio of bottom-to-top microhardness.

The depth of polymerization or depth of curing in light-cured composites depends on filler (type, size, and load), resin composition, shade of composite material, intensity of curing light, and exposure time [25]. Filler size and type as well as type of matrix monomer play a key role in composite curing. The composition of the resin matrix and filler characteristics strongly influence the microhardness of composite materials [11,25,26]. Larger filler particles create more interfaces that scatter light. A study using spherical silica showed that increasing particle size significantly reduces transmitted light, cure depth, and bottom hardness. Composites with smaller filler particles display decreased light scattering and reflection, resulting in an increased depth of cure. This allows deeper light penetration and higher hardness at greater depths. An increase in filler content increases the microhardness of composites [26,27,28,29]. Bulk-fill composites with smaller-sized nano-fillers and a high load of fillers display increased light scattering [11]. Although nano-clusters still allow adequate curing, finer fillers generally perform better in bulk-fill materials [26].

Matrix monomers also influence cure depth. For example, UDMA-based composites typically cure deeper than Bis-GMA/Bis-EMA ones because of lower viscosity and higher light transmission. More filler reduces resin volume and can enhance surface hardness. Higher microhardness of composites was observed in materials with base monomers like UDMA compared to those with Bis-GMA monomers [26].

In our study the highest DOC values at 6 mm were shown by GSK and AFX composites, while the lowest value was displayed by the TEC bulk-fill composite. A possible explanation lies in the nano-sized filler particles and high filler loading, which gives high hardness to both GSK and AFK bulk-fill composites. In addition, a specific resin matrix of GSK and AFX contributes to the highest hardness, while the Bis-GMA resin matrix in TEC contributes to the lowest microhardness.

The shade of bulk-fill composite influences optical properties of the composite in use. The depth of cure considerably depends on the shade of composite material [30]. Translucency of a composite plays a key role in depth of cure. Increased translucency of composite materials allows additional light penetration and deeper cure. When the refractive index of filler closely matches the resin, light scattering reduces significantly. Bulk-fill composites often employ matched refractive-index fillers to increase translucency and thus cure depth [31]. The shade of the composites in this study was standardised to A3 or the closest available equivalent to minimise any influence on the depth of curing of the tested materials.

The depth of cure (DOC) is strongly influenced by the energy output of the curing light. Studies have shown that devices with higher energy density generally achieve greater curing depths [32]. Most bulk-fill composites demonstrate satisfactory curing up to a depth of 4 mm. According to Thomaidis et al. [33], there is no significant difference in curing effectiveness between monowave LED and polywave LED curing devices for the tested materials.

Different studies could not find a positive correlation between surface hardness and depth of cure. The effectiveness of curing cannot be assessed by top surface hardness only because even inferior curing units can polymerize the surface layer properly [4,34]. There is no also direct relation between the degree of conversion and microhardness of the bulk-fill composites [35].

Bucuta and Ilie [7] showed that the bottom-to-top Vickers hardness ratio of many bulk-fill RBCs is higher than 80% in 4 mm increments. Analysis of seven bulk-fill composites showed that the hardness ratio was higher than 80% at 4 mm increments in six materials, and at 6 mm increments in four bulk-fill materials, including TEC. They observed that bulk-fill composites are more translucent for blue light than conventional resin composites.

In the present study all samples were polymerized by using an LED light curing unit with 1200–1300 mW/cm in standard mode for 20 s at room temperature (23 ± 1 °C). According to Schattenberg et al. [12], all resin composites cured by LED devices are sufficiently polymerized with 20 s irradiation time.

The manufacturers of bulk-fill composites have changed the nature of composites to achieve a better depth of cure by decreasing the filler content, increasing the filler volume and composite translucency, and adding new photo-initiators to enhance polymerization [36].

The degree of conversion (DC) evaluated through microhardness as an indirect method gives results comparable to those obtained by much more sophisticated direct methods such as Fourier infrared spectroscopy [18]. Regarding data on the DC, there are conflicting findings in the literature [28,29,30]. Yap et al. [37] reported that none of the five examined bulk-fill RBCs had a DOC ratio of 0.80 or higher. The methods they used were ISO 4049 for depth of cure or a scraping method, and the Knoop hardness method. Other studies confirmed that bulk-fill composites display sufficient polymerization properties at a 4 mm depth [8,38,39,40].

The bottom-to-top surface microhardness ratio of composite resins reflects a bottom-to-top degree of conversion [10]. The hardness ratio should be greater than 0.80 for light-polymerized composite resins if adequately polymerized [17].

In the present study the Vickers hardness values were used to evaluate the DOC of six bulk-fill composite resins. The values of the Vickers hardnesses were obtained with an applied force of 50 g for 30 s. This method is easy to perform and provides reliable assessment of the DC [10,18,41].

Comba et al. [38] tested six bulk-fill composites and established that all of them can be placed in 4 mm thick layers, as recommended by manufacturers. Filtek Bulk Fill, Sonic Fill, and Tetric Bulk Fill showed hardness adequate for placement in 4 mm layers.

All bulk-fill composite resins in this study were polymerized by LED light in standard mode for 20 s and showed DOCs higher than 80% for a 4 mm depth of cure and 6 mm depth of cure (Table 3 and Table 4). It should be stressed that all tested materials in this study showed DOCs higher than 0.80 at a depth of 4 mm, but the highest values were displayed by GSX (0.98) and AFX (0.97). The lowest DOCs were displayed by TEC (0.91) and FBF (0.90). GrandioSO X-tra (GSX) is a nanohybrid with 84% w/w of filler. Close to this is a second Voco resin composite AFX, also nano-hybrid, with 84% w/w of filler. Just opposite, TEC showed the lowest DOC. TEC showed also the lowest DOC in the study performed by Parasher et al. [42]. It was explained by smaller filler size and a different photo-initiator, leading to a higher light reflection and decreased translucency [34].

A previous study on the microhardness and DOC of AFX and GSX (Voco, Dusseldorf, Germany) showed the highest hardness ratio for GrandioSO X-tra, with a value of 0.95 at a depth of 4 mm [8]. In that study, DOC was assessed using the bottom-to-top hardness ratio. In our study, the hardness ratio of GrandioSO X-tra was 0.98 at 4 mm depth and 0.96 at 6 mm, which is close to the results obtained by Colombo et al. [8]. For AFX, our results showed a hardness ratio of 0.97 at 4 mm and 0.96 at 6 mm. In comparison, Colombo et al. reported hardness ratios of 0.86 for AFX, and 0.92 for GSX at 4 mm [8]. All tested materials in our study showed a gradual decrease in hardness from the top to the bottom surface of the samples. Nevertheless, they all maintained depth of cure ratios above the clinically acceptable threshold of 0.80 at both 4 mm and 6 mm depths. These findings have clinical relevance, as they suggest that all tested materials could be applied in a single-layer bulk increment up to 6 mm. Such findings justify simplifying of clinical procedures in posterior restorations, particularly in paediatric dentistry, where shorter curing times and enhanced clinical efficiency are crucial due to limited patient cooperation and treatment time constraints.

5. Conclusions

The microhardness and DOC of all tested bulk-fill resin composites showed differences. GrandioSO X-tra (GSX) showed the highest Vickers microhardness and DOC, followed by Admira Fusion X-tra (AFX), while Tetric EvoCeram Bulk (TEC) exhibited the lowest Vickers microhardness and DOC. In this study, all tested bulk-fill composite resins achieved sufficient curing at a depth of 6 mm, indicating their suitability for use in single-layer applications at that depth. The obtained results can be helpful in the selection of bulk-fill composite material for direct restorations on the posterior teeth.

Author Contributions

Conceptualization, T.S. and K.G.; methodology, T.S. and K.G.; validation, T.S., K.G., P.B.S. and J.S.; formal analysis, K.G. and J.B.; investigation, T.S. and K.G.; resources, P.B.S. and J.S.; data curation, J.B.; P.B.S. and J.S.; writing—original draft preparation, T.S.; writing—review and editing, K.G. and L.A.M.M.; visualisation, K.G. and P.B.S.; supervision, K.G. and L.A.M.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| TEC | Tetric EvoCeram Bulk |

| FBF | Filtek Bulk Fill Posterior |

| FOB | Filtek One Bulk Fill |

| SF2 | SonicFill 2 |

| AFX | Admira Fusion X-tra |

| GSX | GrandioSO X-tra |

References

- Czasch, P.; Ilie, N. In vitro comparison of mechanical properties and degree of cure of bulk fill composites. Clin. Oral Investig. 2012, 17, 227–235. [Google Scholar] [CrossRef]

- Van Ende, A.; De Munck, J.; Lise, D.P.; Van Meerbeek, B. Bulk-fill composites a review of the current literature. J. Adhes. Dent. 2017, 19, 95–109. [Google Scholar]

- Furness, A.; Tadros, M.Y.; Looney, S.W.; Rueggeberg, F.A. Effect of bulk/incremental fill on internal gap formation of bulk-fill composites. J. Dent. 2014, 42, 439–449. [Google Scholar] [CrossRef] [PubMed]

- Hansen, E.K.; Asmussen, E. Correlation between depth of cure and surface hardness of a light-activated resin. Scand. J. Dent. Res. 1993, 101, 62–64. [Google Scholar] [CrossRef] [PubMed]

- Finan, L.; Palin, W.M.; Moskwa, N.; McGinley, E.L.; Fleming, G.J. The influence of irradiation potential on the degree of conversion and mechanical properties of two bulk-fill flowable resin composite base materials. Dent. Mater. 2013, 29, 906–912. [Google Scholar] [CrossRef]

- Musanje, L.; Darvell, B. Curing-light attenuation in filled-resin restorative materials. Dent. Mater. 2006, 22, 804–817. [Google Scholar] [CrossRef]

- Bucuta, S.; Ilie, N. Light transmittance and micro-mechanical properties of bulk fill vs. conventional resin-based composites. Clin. Oral Investig. 2014, 18, 1991–2000. [Google Scholar] [CrossRef]

- Colombo, M.; Gallo, S.; Poggio, C.; Ricaldone, V.; Arciola, C.R.; Scribante, A. New resin-based bulk-fill composites: In vitro evaluation of micro-hardness and depth of cure as infection risk indexes. Materials 2020, 13, 1308. [Google Scholar] [CrossRef]

- Alshali, R.Z.; Salim, N.A.; Satterthwaite, J.D.; Silikas, N. Post-irradiation hardness development, chemical softening, and thermal stability of bulk-fill and conventional resin-composites. J. Dent. 2015, 43, 209–218. [Google Scholar] [CrossRef]

- Bouschlicher, M.R.; Rueggeberg, F.A.; Wilson, B.M. Correlation of bottom-to-top surface microhardness and conversion ratios for a variety of resin composite compositions. Oper. Dent. 2004, 29, 698–704. [Google Scholar]

- Moore, B.K.; Platt, J.A.; Borges, G.; Chu, T.M.; Katsilieri, I. Depth of cure of dental resin composites: ISO 4049 depth and microhardness of types of materials and shades. Oper. Dent. 2008, 33, 408–412. [Google Scholar] [CrossRef]

- Schattenberg, A.; Lichtenberg, D.; Stender, E.; Willershausen, B.; Ernst, C.-P. Minimal exposure time of different LED-curing devices. Dent. Mater. 2008, 24, 1043–1049. [Google Scholar] [CrossRef]

- Yap, A.U.; Soh, M.S.; Siow, K.S. Effectiveness of composite cure with pulse activation and soft-start polymerization. Oper. Dent. 2002, 27, 44–49. [Google Scholar] [PubMed]

- Jadhav, S.; Hegde, V.; Aher, G.; Fajandar, N. Influence of light curing units on failure of direct composite restorations. J. Conserv. Dent. 2011, 14, 225–227. [Google Scholar] [CrossRef]

- Itota, T.; Carrick, T.E.; Yoshiyama, M.; McCabe, J.F. Fluoride release and recharge in giomer, compomer and resin composite. Dent. Mater. 2004, 20, 789–795. [Google Scholar] [CrossRef] [PubMed]

- Alrahlah, A.; Silikas, N.; Watts, D.C. Post-cure depth of cure of bulk fill dental resin-composites. Dent. Mater. 2014, 30, 149–154. [Google Scholar] [CrossRef] [PubMed]

- Pilo, R.; Cardash, H.S. Post-irradiation polymerization of different anterior and posterior visible light-activated resin composites. Dent. Mater. 1992, 8, 299–304. [Google Scholar] [CrossRef]

- Flury, S.; Hayoz, S.; Peutzfeldt, A.; Hüsler, J.; Lussi, A. Depth of cure of resin composites: Is the ISO 4049 method suitable for bulk fill materials? Dent. Mater. 2012, 28, 521–528. [Google Scholar] [CrossRef]

- Da Silva, E.M.; Poskus, L.T.; Guimarães, J.G.; de Araújo Lima Barcellos, A.; Fellows, C.E. Influence of light polymerization modes on degree of conversion and crosslink density of dental composites. J. Mater. Sci. Mater. Med. 2008, 19, 1027–1032. [Google Scholar] [CrossRef]

- Moon, H.J.; Lee, Y.K.; Lim, B.S.; Kim, C.W. Effects of various light curing methods on the leachability of uncured substances and hardness of a composite. J. Oral Rehabil. 2004, 31, 258–264. [Google Scholar] [CrossRef]

- Ferracane, J.L. Correlation between hardness and degree of conversion during the setting reaction of unfilled dental restorative resins. Dent. Mater. 1985, 1, 11–14. [Google Scholar] [CrossRef]

- Manhart, J.; Kunzelmann, K.H.; Chen, H.Y.; Hickel, R. Mechanical properties and wear behavior of light-cured packable composite resins. Dent. Mater. 2000, 16, 33–40. [Google Scholar] [CrossRef] [PubMed]

- Uhl, A.; Mills, R.W.; Jandt, K.D. Polymerization and light-induced heat of dental composites cured with LED and halogen technology. Biomaterials 2003, 24, 1809–1820. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Li, H.; Fok, A.S.; Watts, D.C. Multiple correlations of material parameters of light-cured dental composites. Dent. Mater. 2009, 25, 829–836. [Google Scholar] [CrossRef] [PubMed]

- Jang, J.H.; Park, S.H.; Hwang, I.N. Polymerization shrinkage and depth of cure of bulk-fill resin composites and highly filled flowable resin. Oper. Dent. 2015, 40, 172–180. [Google Scholar] [CrossRef]

- Del Rio, D.L.; Johnston, W.M. Effect of monomer composition and filler fraction on surface microhardness and depth of cure of experimental resin composites. Eur. J. Oral Sci. 2023, 131, e12933. [Google Scholar] [CrossRef]

- Shah, P.K.; Stansbury, J.W. Role of filler and functional group conversion in the evolution of properties in polymeric dental restoratives. Dent. Mater. 2014, 30, 586–593. [Google Scholar] [CrossRef]

- Wang, R.; Habib, E.; Zhu, X.X. Evaluation of the filler packing structures in dental resin composites: From theory to practice. Dent. Mater. 2018, 34, 1014–1023. [Google Scholar] [CrossRef]

- Nakanishi, L.; Kaizer, M.R.; Brandeburski, S.; Cava, S.S.; Della Bona, A.; Zhang, Y.; Moraes, R.R. Non-silicate nanoparticles for improved nanohybrid resin composites. Dent. Mater. 2020, 36, 1314–1321. [Google Scholar] [CrossRef]

- Koupis, N.S.; Vercuysse, C.W.J.; Marks, L.A.M.; Martens, L.C.; Verbeeck, R.M.H. Curing depth of (polyacid-modified) composite resins determined by scraping and a penetrometer. Dent. Mater. 2004, 20, 908–914. [Google Scholar] [CrossRef]

- Margeas, R.C. Bulk-fill materials: Simplify restorations, reduce chairtime. Compend. Contin. Educ. Dent. 2015, 36, e1–e4. [Google Scholar]

- Vandenbulcke, J.D.E.; Marks, L.A.M.; Martens, L.C.; Verbeeck, R.M.H. Comparison of curing depth of a colored polyacid-modified composite resin with different light-curing units. Quintessence Int. 2010, 41, 787–794. [Google Scholar]

- Thomaidis, S.; Kampouropoulos, D.; Antoniadou, M.; Kakaboura, A. Evaluation of the Depth of Cure by Microhardness of Bulk-Fill Composites with Monowave and Polywave LED Light-Curing Units. Appl. Sci. 2024, 14, 11532. [Google Scholar] [CrossRef]

- Neo, B.J.; Soh, M.S.; Teo, J.W.; Yap, A.U.J. Effectiveness of composite cure associated with different light-curing regimes. Oper. Dent. 2005, 30, 671–675. [Google Scholar] [PubMed]

- Pirmoradian, M.; Hooshmand, T.; Jafari-Semnani, S.; Fadavi, F. Degree of conversion and microhardness of bulk-fill dental composites polymerized by LED and QTH light curing units. J. Oral Biosci. 2020, 62, 107–113. [Google Scholar] [CrossRef] [PubMed]

- Gan, J.K.; Yap, A.U.; Cheong, J.W.; Arista, N.; Tan, C.B. Bulk-fill composites: Effectiveness of cure with poly-and monowave curing lights and modes. Oper. Dent. 2018, 43, 136–143. [Google Scholar] [CrossRef]

- Yap, A.U.J.; Pandya, M.; Toh, W.S. Depth of cure of contemporary bulk-fill resin-based composites. Dent. Mater. J. 2016, 35, 503–510. [Google Scholar] [CrossRef]

- Comba, A.; Scotti, N.; Maravić, T.; Mazzoni, A.; Carossa, M.; Breschi, L.; Cadenaro, M. Vickers hardness and shrinkage stress evaluation of low and high viscosity bulk-fill resin composite. Polymers 2020, 12, 1477. [Google Scholar] [CrossRef]

- Zorzin, J.; Maier, E.; Harre, S.; Fey, T.; Belli, R.; Lohbauer, U.; Petschelt, A.; Taschner, M. Bulk-fill resin composites: Polymerization properties and extended light curing. Dent. Mater. 2015, 31, 293–301. [Google Scholar] [CrossRef]

- Moharam, L.M.; El-Hoshy, A.Z.; Abou-Elenein, K. The effect of different insertion techniques on the depth of cure and vickers surface microhardness of two bulk-fill resin composite materials. J. Clin. Exp. Dent. 2017, 9, e266–e271. [Google Scholar]

- Watts, D.C. Reaction kinetics and mechanics in photo-polymerised networks. Dent. Mater. 2005, 21, 27–35. [Google Scholar] [CrossRef]

- Parasher, A.; Ginjupalli, K.; Somayaji, K.; Kabinale, P. Comparative evaluation of the depth of cure and surface roughness of bulk-fill composites: An in vitro study. Dent. Med. Probl. 2020, 57, 39–44. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).