In this section, results obtained using the so called 3D-u-

-

model are proposed. This acronym aims to shortly collect the main peculiarities of the model: a three-dimensional (3D) formulation where primary variables are displacement components (

u), electric potential (

) and magnetic potential (

) (and their first derivatives in

z). In the first subsection, the 3D-u-

-

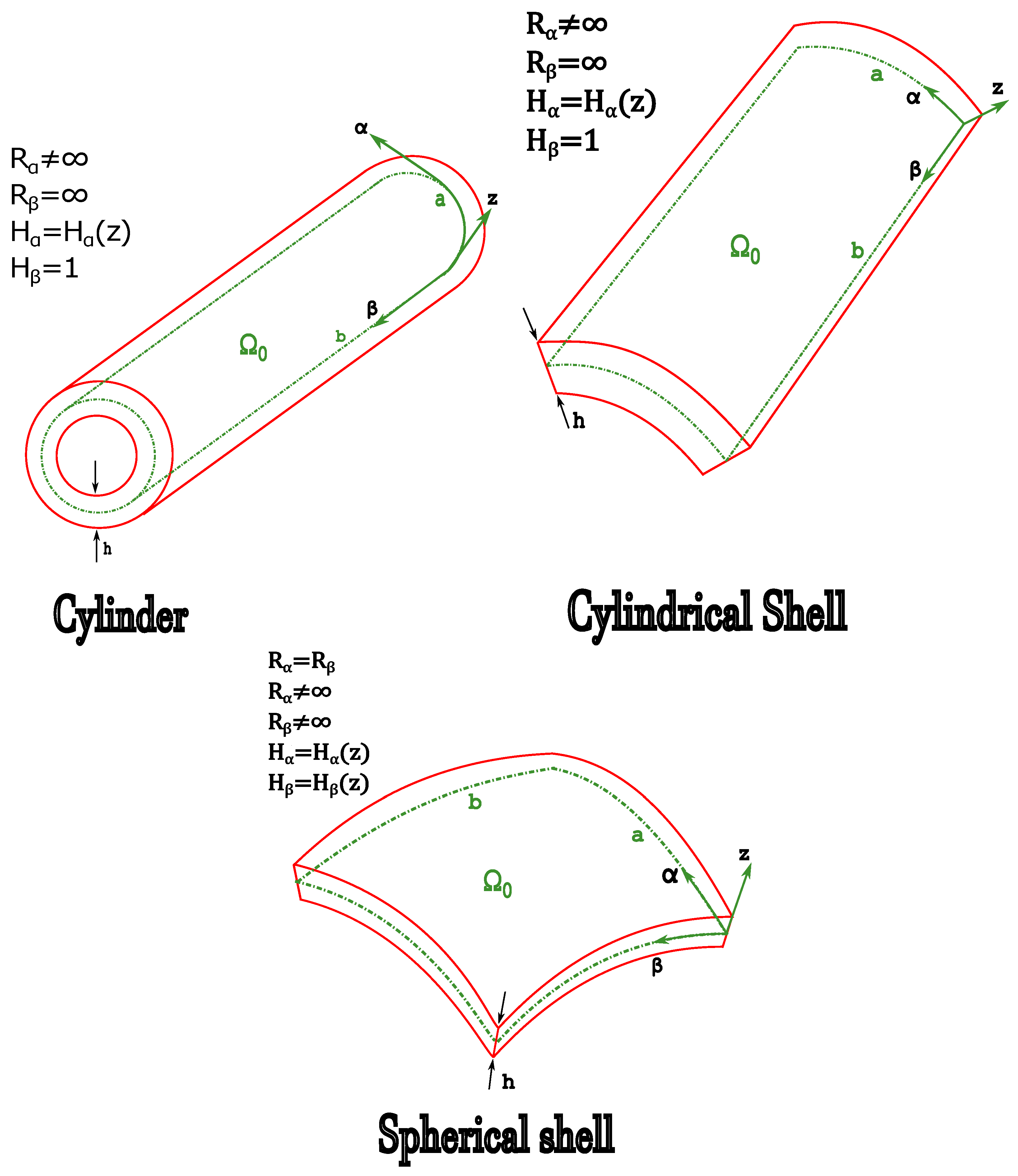

model is validated using other 3D analytical theories available in the literature. Validation is performed to understand if all possible involved effects in MEE curved structures are correctly depicted (magneto-electro-elastic coupling, material-layer effects, thickness-layer effects and curvature effects). In [

36], a convergence analysis for free elastic vibrations suggests

mathematical layers and

as an exponential matrix expansion in order to obtain correct results for each thickness ratio. The small number of 3D magneto-electro-elastic shell models available in the literature is compensated for by the use of a 3D electro-elastic shell model (3D-u-

) and a 3D magneto-elastic shell model (3D-u-

) to separately validate the electro-elastic coupling and the magneto-elastic coupling in the 3D-u-

-

model. Validation cases are presented considering different

half-wave couples couples and

thickness ratios. Therefore, new benchmark cases involving a multilayered cylinder, a multilayered cylindrical panel and a multilayered spherical shell are proposed considering different

couples, thickness ratios (from thick to thin shells) and load boundary conditions (open- and closed-circuit configurations). When the couple (

) is imposed, the 3D model provides a huge number of frequencies and thickness vibration modes (theoretically, from I to infinite). In the Results, the first three frequencies (from I to III) are presented for each imposed (

) couple.

3.1. Validation Cases

In the first validation case, a multilayered, simply supported spherical shell panel is analyzed. The multilayered configuration is PZT-4/

/

/

/PZT-4. The thickness of each PZT-4 external face is

; the thickness of each composite layer is

.

h is the total thickness of the spherical shell. Geometrical data are collected in

Table 1 under the first column; material data are presented in

Table 2 under the first two columns. The solution used as a reference is the 3D-u-

model in [

32], where only the electro-elastic coupling is evaluated. Both closed-circuit (

=

and

=

) and open-circuit (

=

and

=

) configurations are considered for different

couples and thickness ratios (from thin to thick structures). Results presented in

Table 3 (for the closed circuit configuration) and

Table 4 (for the open circuit configuration) in terms of the first three circular frequencies (

) attest to the perfect accordance for each considered

. Results are perfectly coincident in both configurations. Thanks to this assessment, electro-elastic coupling in closed- and open-circuit configurations was verified, together with the thickness-layer effect, the material-layer effect and the curvature effect.

The second validation case is devoted to a single-layered cylindrical panel made of a CoFe

2O

4 magnetostrictive material. Geometrical data can be seen in

Table 1 (second column). Material data are in the third column of

Table 2. In the present validation case, magnetic permittivity coefficients

and

have a negative sign in order to be consistent with the reference solution. The reference solution is the 3D-u-

model proposed in [

33], where only the magneto-elastic coupling is evaluated. Comparison results regarding the open-circuit configuration (

=

and

=

) are presented in

Table 5 considering the first three circular frequencies for several

couples and

thickness ratios (from thick to thin shells). Results collected in

Table 5, in terms of circular frequencies, show an accordance for each proposed thickness ratio (thick, moderately thick and thin shells). This assessment is presented in order to separately validate the magneto-elastic coupling in terms of thickness-layer effects, material-layer effects and curvature effects.

3.2. Benchmarks

Thanks to the subsection previously discussed, the 3D-u-

-

model is considered validated when

fictitious layers and

for the exponential matrix expansion order are employed. In fact, with these values, all the involved effects in curved MEE smart structures are correctly depicted. New benchmark cases are now proposed and discussed in order to evaluate the full coupling between elastic, magnetic and electric fields. The three proposed benchmarks have the same lamination scheme, i.e.,B Adaptive Wood/

/

/

/Adaptive Wood. A single adaptive wood external face is

thick, and a single composite lamina is

thick, where

h is the total thickness of the structure. Material properties for composite material and adaptive wood are presented in the second and fourth columns of

Table 2. For each benchmark, the closed-circuit configuration states

=

and

=

, and the open-circuit configuration states

=

and

=

. Adaptive wood laminae have the same magnetic properties as the CoFe

2O

4 material but with permittivity magnetic coefficients

and

with positive signs, as justified by Pan in [

38]. All the other material coefficients are obtained from Tornabene’s book [

37].

Benchmark number one (B1) is devoted to a multilayered, simply supported cylinder. Geometrical data on the cylinder are presented in the first column of

Table 6.

Table 7 and

Table 8 show the first three circular frequencies for several

thickness ratios and

couples in closed-circuit and open-circuit configurations, respectively. For each imposed (

m,

n) couple, the first three vibration modes are discussed. For the closed-circuit configuration, it is possible to notice a slight decrease for the first circular frequency as the thickness ratio increases. This feature is due to the decreasing stiffness of the cylinder. On the contrary, for the second and third circular frequencies, the

value increases for thin structures. This particular behavior is possible thanks to the curvature effect. This described trend of

values is valid for all

couples, except for

. The same considerations mentioned above are also valid for the open-circuit configuration. In

Figure 2 and

Figure 3, the first three vibration modes in terms of normalized

,

,

,

,

,

,

and

values are presented along the

z thickness direction for the closed-circuit configuration and the open-circuit configuration. In

Figure 2, the first two vibration modes are flexural, as

is symmetrical along the thickness direction, while the third vibration mode is membranal due to the antisymmetrical trend along the thickness direction of

. In addition, the antisymmetrical trend of

and

must be noted for each vibration mode. This behavior is typical for such smart structures involving adaptive wood, as piezoelectric and piezomagnetic coefficients

and

have opposite signs. These antisymmetric trends along the thickness direction are also reflected onto the normalized variables (

and

). Concerning

Figure 3, the first two vibration modes are flexural, and the third one is membranal as well, considering the same trends along the thickness direction for

. Electric and magnetic variables also present the same antisymmetric trend along the thickness direction, as described for the closed-circuit configuration. Normalization is performed considering the maximum value of each variable. The zigzag effect along the thickness direction is evident for both closed-circuit (

Figure 2) and open-circuit (

Figure 3) configurations. Slopes of variables change in correspondence with each physical interface. A layerwise approach is correctly implemented in the model, as trends along the thickness direction are continuous. For the open-circuit configuration,

=

and

=

are correctly imposed; for the closed-circuit configuration,

=

and

=

are opportunely imposed on external surfaces. In

Figure 2 and

Figure 3, the magneto-electro-elastic coupling, material-layer effects and curvature effects are clearly shown. The differences, in terms of

, are very small between open-circuit and closed-circuit configurations.

In benchmark number two (B2), a multilayered cylindrical panel with simply supported boundary conditions is shown. Geometrical data can be seen in

Table 6.

Table 9 and

Table 10 show the first three circular frequencies (

) for closed- and open-circuit configurations, respectively. Thick and thin (from

to

) structures are presented. In both open- and closed-circuit configurations, the first circular frequency tends to decrease as the cylindrical shell panel becomes thinner (this is true from

to

half-wave couples). On the contrary, for a

half-wave couple, the first

increases for thinner structures, but the other two frequencies decrease due to the curvature effect. In addition,

values for

and

are quite similar when the thickness ratio changes. For these two half-wave couples, the vibration modes occur at the same frequencies in both closed- and open-circuit configurations. Results for half-wave couples (0, 1) and (0, 2) are the same for cylinders (benchmark 1) and cylindrical panels (benchmark 2) because

in the

direction means that it is not important if the

a dimension be equal to

or equal to

. In

Figure 4 (closed-circuit configuration) and

Figure 5 (open-circuit configuration), the same eight normalized variables seen in B1 are proposed in the

z thickness direction. In

Figure 4, the first vibration mode for

is flexural, the second and the third are membranal due to the fact that

has a symmetrical first vibration mode and antisymmetrical trends for the second and third vibration modes along the thickness direction. The particular trends presented in

Figure 4 are also influenced by the thickness-layer effect. In addition, the antisymmetrical nature of the normalized electric potential and the normalized magnetic potential is confirmed. In

Figure 5, the first vibration mode is purely flexural as

is constant, while the second and third vibration modes are purely membranous. The antisymmetrical nature of

and

is confirmed. The differences between open- and closed-circuit configurations are quite small in terms of

, but they are much more evident in terms of vibration modes through the thickness direction. In both configurations, the change in slope in each different physical layer clearly states the correct depiction of zigzag effects. Interlaminar continuity conditions are correctly imposed, as no discontinuities occur in either interface. Both closed- and open-circuit configurations are properly modeled because, on the external surfaces, the zero value is correctly imposed for electric and magnetic potentials (closed-circuit configuration) and for transverse normal electric displacement and transverse normal magnetic induction (open-circuit configuration). Magneto-electro-elastic effects, curvature effects, material-layer effects and thickness-layer effects are clearly visualized in

Figure 4 and

Figure 5.

Benchmark number three (B3) proposes a simply supported, multilayered spherical shell. Geometrical data are collected in the third column of

Table 6.

Table 11 presents the first three circular frequencies for different

couples and different thickness ratios. The first circular frequency for each

couple decreases as the spherical shell becomes thinner. On the other hand, the second and third circular frequencies increase as the geometry becomes thinner. The same behavior is shown for the open-circuit configuration in

Table 12. In

Figure 6 and

Figure 7, all the effects involved in a magneto-electro-elastic smart structure can be seen in both closed- and open-circuit configurations: magneto-electro-elastic coupling, material-layer effects, thickness-layer effects and curvature effects. In

Figure 6, thanks to the considerations regarding the trend along the thickness direction of the normalized variable (

), it is possible to state that the first vibration mode is a flexural mode, while the second and third ones are membrane modes. The same consideration is also valid for vibration modes depicted in

Figure 7. For both open-circuit and closed-circuit configurations, normalized trends of electric and magnetic potential are antisymmetrical with respect to each other. In addition, a zigzag effect is clearly depicted as the slope changes in each physical layer. A layerwise approach is correctly implemented in the model, as no discontinuities occur in correspondence with each physical interface. Configuration conditions on the external surfaces are correctly imposed in both closed-circuit (see top and bottom values in

Figure 6 for

and

variables) and open-circuit (see top and bottom values in

Figure 7 for

and

variables) configurations.