Inspection of Damaged Composite Structures with Active Thermography and Digital Shearography

Abstract

1. Introduction

2. Materials and Methods

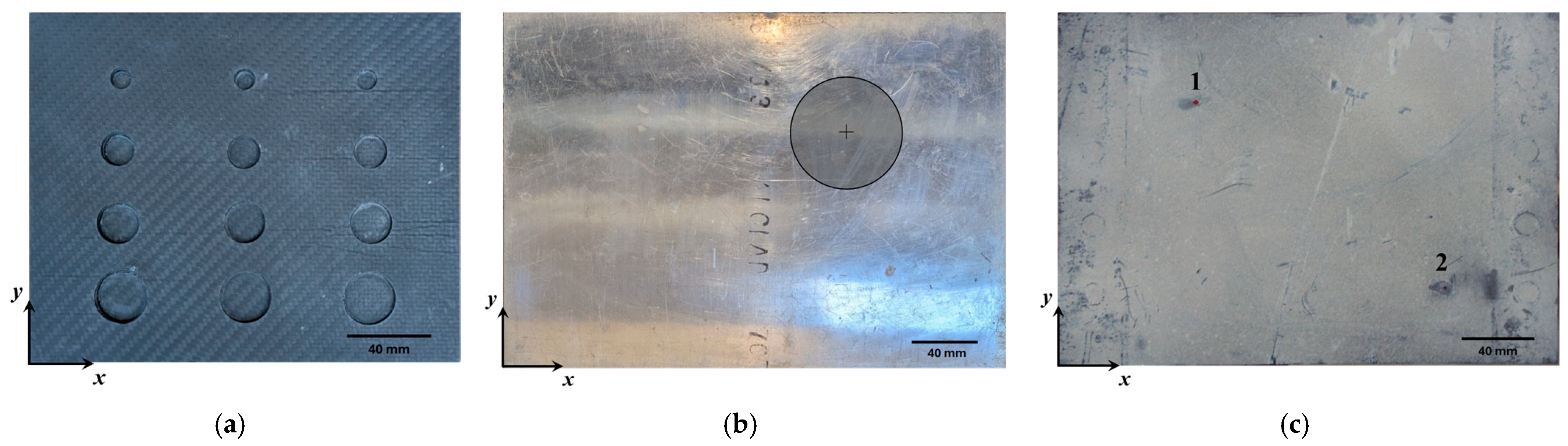

2.1. Inspected Structures

2.2. NDT Techniques Employed in Inspection

2.2.1. Active Thermography (AT)

2.2.2. Digital Shearography (DS)

2.3. Damage Identification Procedure

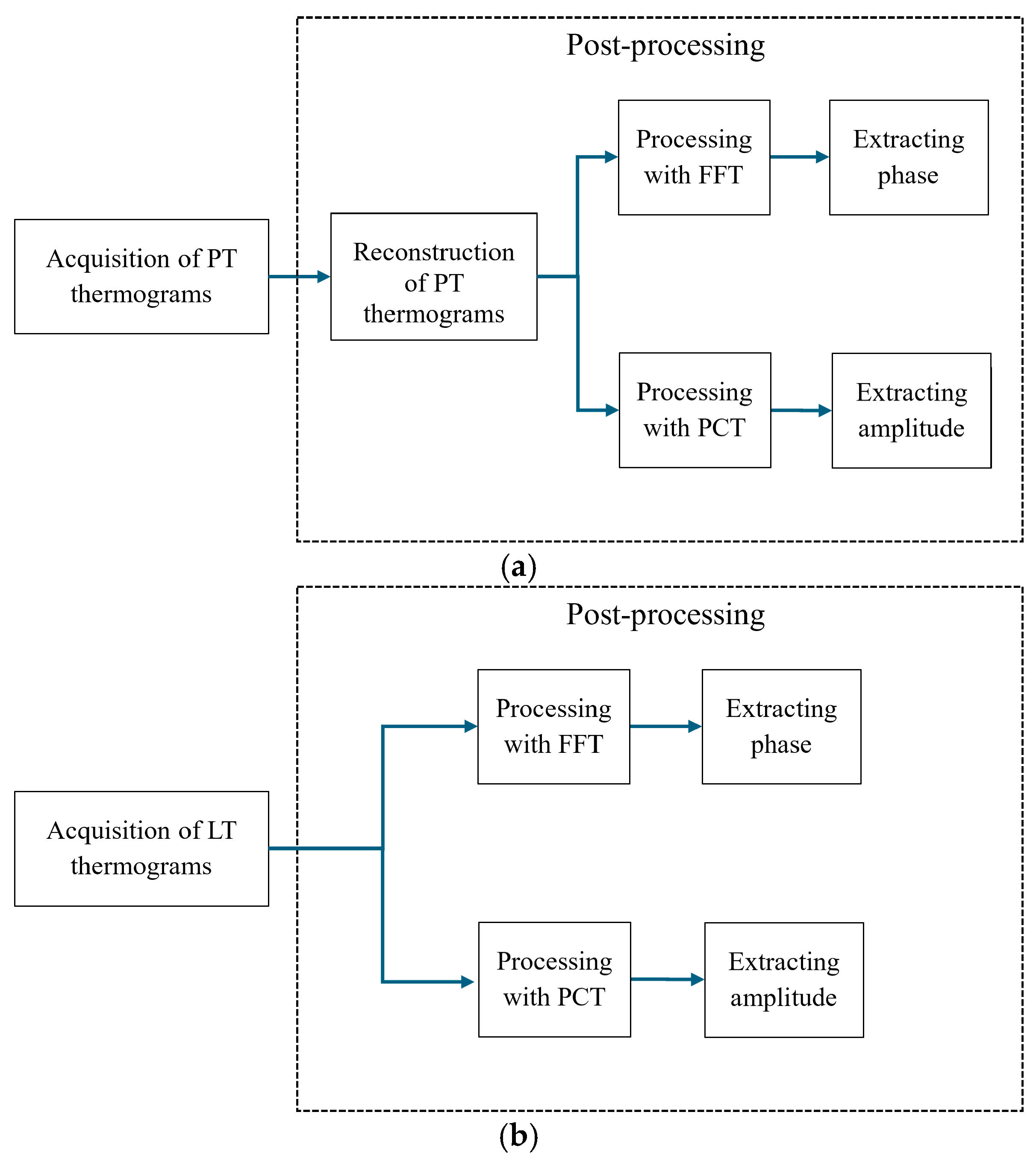

2.3.1. Post-Processing of Thermograms

2.3.2. Post-Processing of Phase Maps

3. Results

3.1. Active Thermography (AT)

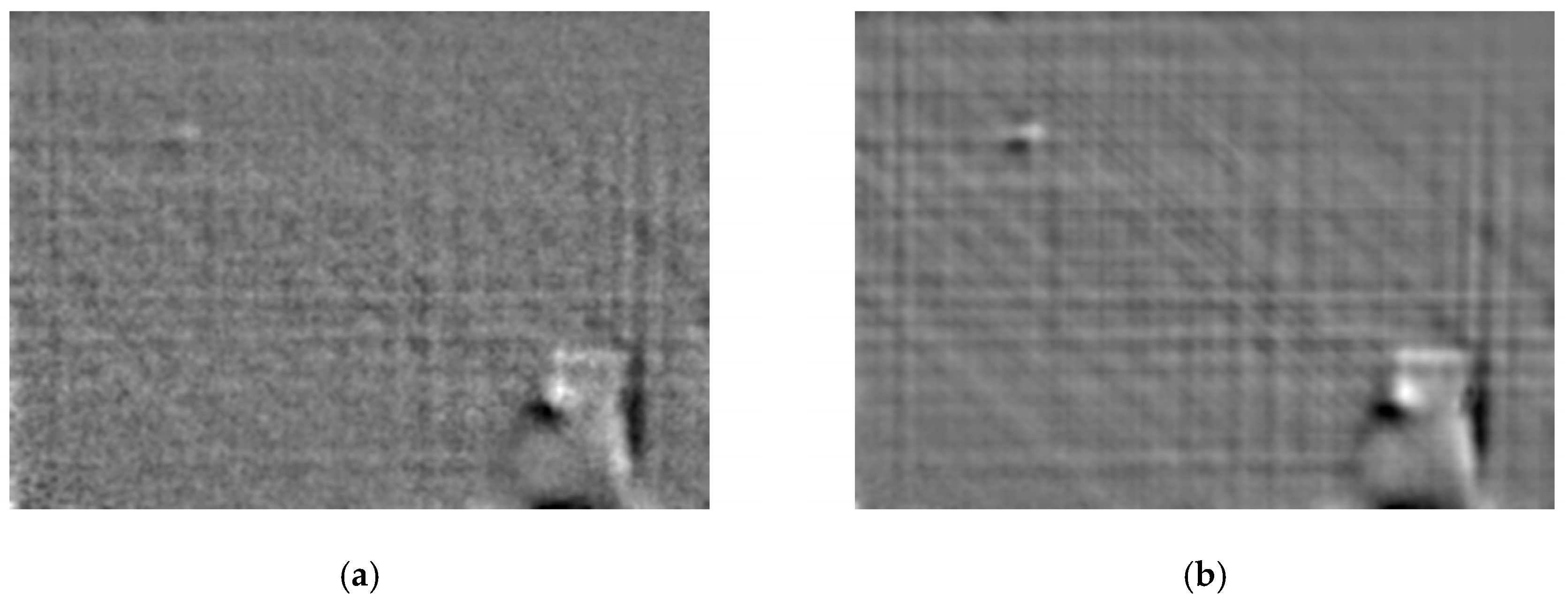

3.2. Digital Shearography (DS)

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AT | Active thermography |

| BVID | Barely visible impact damage |

| CFRP | Carbon-fiber-reinforced polymer |

| CW | Continuous wave |

| DFT | Discrete Fourier transform |

| DS | Digital shearography |

| FFT | Fast Fourier transform |

| LT | Lock-in thermography |

| LPT | Long pulse thermography |

| NDT | Non-destructive testing |

| PCT | Principal component thermography |

| PT | Pulsed thermography |

| SVD | Singular value decomposition |

| TSR | Thermographic signal reconstruction |

References

- Heslehurst, R.B. Defects and Damage in Composite Materials and Structures; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar] [CrossRef]

- Wang, B.; Zhong, S.; Lee, T.-L.; Fancey, K.S.; Mi, J. Non-destructive testing and evaluation of composite materials/structures: A state-of-the-art review. Adv. Mech. Eng. 2020, 12, 1687814020913761. [Google Scholar] [CrossRef]

- Aldave, I.J.; Bosom, P.V.; González, L.V.; de Santiago, I.L.; Vollheim, B.; Krausz, L.; Georges, M. Review of thermal imaging systems in composite defect detection. Infrared Phys. Techn. 2013, 61, 167–175. [Google Scholar] [CrossRef]

- Hashemi, A.; Jovicic, G.; Batentschuk, M.; Brabec, C.J.; Vetter, A. Contactless temperature determination using dual-channel lock-in phosphor thermometry. Meas. Sci. Technol. 2016, 28, 27001. [Google Scholar] [CrossRef]

- Gupta, R.; Mitchell, D.; Blanche, J.; Harper, S.; Tang, W.; Pancholi, K.; Baines, L.; Bucknall, D.G.; Flynn, D. A review of sensing technologies for non-destructive evaluation of structural composite materials. J. Compo. Sci. 2021, 5, 319. [Google Scholar] [CrossRef]

- Francis, D.; Tatam, R.P.; Groves, R.M. Shearography technology and applications: A review. Meas. Sci. Technol. 2010, 21, 102001. [Google Scholar] [CrossRef]

- Hung, Y.Y.; Chen, Y.S.; Ng, S.P.; Liu, L.; Huang, Y.H.; Luk, B.L.; Ip, R.W.L.; Wu, C.M.L.; Chung, P.S. Review and comparison of shearography and active thermography for nondestructive evaluation. Mater. Sci. Eng. R Rep. 2009, 64, 73–112. [Google Scholar] [CrossRef]

- Georges, M.; Srajbr, C.; Menner, P.; Koch, J.; Dillenz, A. Thermography and shearography inspection of composite hybrid sandwich structure made of CFRP and GFRP core and titanium skins. Proceedings 2018, 2, 484. [Google Scholar] [CrossRef]

- Wei, Y.; Xiao, Y.; Gu, X.; Ren, J.; Zhang, Y.; Zhang, D.; Chen, Y.; Li, H.; Li, S. Inspection of defects in composite structures using long pulse thermography and shearography. Heliyon 2024, 10, e33184. [Google Scholar] [CrossRef]

- Ochana, I.; Ducobu, F.; Homrani, M.K.; Notebaert, A.; Demarbaix, A. A comparative study of non-destructive testing techniques: Active thermography versus shearography for 3D-printed thermoplastic composites reinforced with continuous carbon fiber. J. Manuf. Mater. Process. 2024, 8, 227. [Google Scholar] [CrossRef]

- Castanie, B.; Bouvet, C.; Ginot, M. Review of composite sandwich structure in aeronautic applications. Compos. Part C-Open. 2020, 1, 100004. [Google Scholar] [CrossRef]

- Stergiou, V.; Konstantopoulos, G.; Charitidis, C.A. Carbon fiber reinforced plastics in space: Life cycle assessment towards improved sustainability of space vehicles. J. Compos. Sci. 2022, 6, 144. [Google Scholar] [CrossRef]

- Ahmad, H.; Markina, A.A.; Porotnikov, M.V.; Ahmad, F. A review of carbon fiber materials in automotive industry. IOP Conf. Ser. Mater. Sci. Eng. 2020, 971, 032011. [Google Scholar] [CrossRef]

- Martulli, L.M.; Diani, M.; Sabetta, G.; Bontumasi, S.; Colledani, M.; Bernasconi, A. Critical review of current wind turbine blades’ design and materials and their influence on the end-of-life management of wind turbines. Eng. Struct. 2025, 327, 119625. [Google Scholar] [CrossRef]

- Balageas, D.; Bourasseau, S.; Dupont, M.; Bocherens, E.; Dewynter-Marty, V.; Ferdinand, P. Comparison between non-destructive evaluation techniques and integrated fiber optic health monitoring systems for composite sandwich structures. J. Intell. Mater. Syst. Struct. 2000, 11, 426–437. [Google Scholar] [CrossRef]

- Poddar, B.; Bijudas, C.R.; Mitra, M.; Mujumdar, P.M. Damage detection in a woven-fabric composite laminate using time-reversed Lamb wave. Struct. Health Monit. 2012, 1, 602–612. [Google Scholar] [CrossRef]

- Bossi, R.H.; Giurgiutiu, V. 15—Nondestructive testing of damage in aerospace composites. In Polymer Composites in the Aerospace Industry; Irving, P.E., Soutis, C., Eds.; Woodhead Publishing: Cambridge, UK, 2015; pp. 413–448. [Google Scholar] [CrossRef]

- Li, H.; Zhou, Z. Detection and characterization of debonding defects in aeronautical honeycomb sandwich composites using noncontact air-coupled ultrasonic testing technique. Appl. Sci. 2019, 9, 283. [Google Scholar] [CrossRef]

- Yu, Q.; Zhou, S.; Cheng, Y.; Deng, Y. Research on delamination damage quantification detection of CFRP bending plate based on Lamb wave mode control. Sensors 2024, 24, 1790. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Jin, Y.; Chang, X.; Shang, Y.; Cai, D. On low-velocity impact response and compression after impact of hybrid woven composite laminates. Coatings 2024, 14, 986. [Google Scholar] [CrossRef]

- Mouzakis, D.E.; Charitidis, P.J.; Zaoutsos, S.P. Compression after impact response of Kevlar composites plates. J. Compos. Sci. 2024, 8, 299. [Google Scholar] [CrossRef]

- Akbari, D.; Soltani, N.; Farahani, M. Numerical and experimental investigation of defect detection in polymer materials by means of digital shearography with thermal loading. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2013, 227, 430–442. [Google Scholar] [CrossRef]

- Tao, N.; Anisimov, A.G.; Groves, R.M. FEM-assisted shearography with spatially modulated heating for non-destructive testing of thick composites with deep defects. Compos. Struct. 2022, 297, 115980. [Google Scholar] [CrossRef]

- Lopes, H.M.R.; dos Santos, J.V.A.; Soares, C.M.M.; Guedes, R.J.M.; Vaz, M.A.P. A numerical-experimental method for damage location based on rotation fields spatial differentiation. Comput. Struct. 2011, 89, 1754–1770. [Google Scholar] [CrossRef]

- Talreja, R.; Phan, N. Assessment of damage tolerance approaches for composite aircraft with focus on barely visible impact damage. Compos. Struct. 2019, 219, 1–7. [Google Scholar] [CrossRef]

- Yang, R.; He, Y. Optically and non-optically excited thermography for composites: A review. Infrared Phys. Techn. 2016, 75, 26–50. [Google Scholar] [CrossRef]

- Hidayat, Z.; Avdelidis, N.P.; Fernandes, H. Brief review of vibrothermography and optical thermography for defect quantification in CFRP material. Sensors 2025, 25, 1847. [Google Scholar] [CrossRef]

- Kreis, T. Digital holography for metrologic applications. In Interferometry in Speckle Light; Jacquot, P., Fournier, J.-M., Eds.; Springer: Berlin/Heidelberg, Germany, 2000; pp. 205–212. [Google Scholar]

- Shepard, S.M.; Lhota, J.R.; Rubadeux, B.A.; Wang, D.; Ahmed, T. Reconstruction and enhancement of active thermographic image sequences. Opt. Eng. 2003, 42, 1337–1342. [Google Scholar] [CrossRef]

- Maldague, X.; Marinetti, S. Pulse phase infrared thermography. J. Appl. Phys. 1996, 79, 2694–2698. [Google Scholar] [CrossRef]

- Rajic, N. Principal component thermography for flaw contrast enhancement and flaw depth characterisation in composite structures. Compos. Struct. 2002, 58, 521–528. [Google Scholar] [CrossRef]

- Ebrahimi, S.; Fleuret, J.; Klein, M.; Théroux, L.-D.; Georges, M.; Ibarra-Castanedo, C.; Maldague, X. Robust principal component thermography for defect detection in composites. Sensors 2021, 21, 2682. [Google Scholar] [CrossRef] [PubMed]

- dos Santos, J.V.A.; Lopes, H. 4—Assessment of impact damage of composite structures using digital shearography. In Non-destructive Testing of Impact Damage in Fiber-Reinforced Polymer Composites; Saeedifar, M., Saleh, M.N., Eds.; Woodhead Publishing: Cambridge, UK, 2024; pp. 87–113. [Google Scholar] [CrossRef]

| Specimen 1 | Specimen 2 | Specimen 3 | ||||

|---|---|---|---|---|---|---|

| Flat-bottom hole depths (mm) | Debonding | Impact of 13.5 J | Impact of 26.2 J | |||

| 2 | 4 | 6 | ||||

| PT | ✗ | ✓ | ✓✓ | ✓ | ✓ | ✓✓ |

| DS | ✗ | ✓✓ | ✓✓ | ✓✓ | ✓✓ | ✓✓ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Queirós, J.; Lopes, H.; Mourão, L.; dos Santos, V. Inspection of Damaged Composite Structures with Active Thermography and Digital Shearography. J. Compos. Sci. 2025, 9, 398. https://doi.org/10.3390/jcs9080398

Queirós J, Lopes H, Mourão L, dos Santos V. Inspection of Damaged Composite Structures with Active Thermography and Digital Shearography. Journal of Composites Science. 2025; 9(8):398. https://doi.org/10.3390/jcs9080398

Chicago/Turabian StyleQueirós, João, Hernâni Lopes, Luís Mourão, and Viriato dos Santos. 2025. "Inspection of Damaged Composite Structures with Active Thermography and Digital Shearography" Journal of Composites Science 9, no. 8: 398. https://doi.org/10.3390/jcs9080398

APA StyleQueirós, J., Lopes, H., Mourão, L., & dos Santos, V. (2025). Inspection of Damaged Composite Structures with Active Thermography and Digital Shearography. Journal of Composites Science, 9(8), 398. https://doi.org/10.3390/jcs9080398