Residual Stress Evolution of Graphene-Reinforced AA2195 (Aluminum–Lithium) Composite for Aerospace Structural Hydrogen Fuel Tank Application

Abstract

1. Introduction

2. Materials and Methods

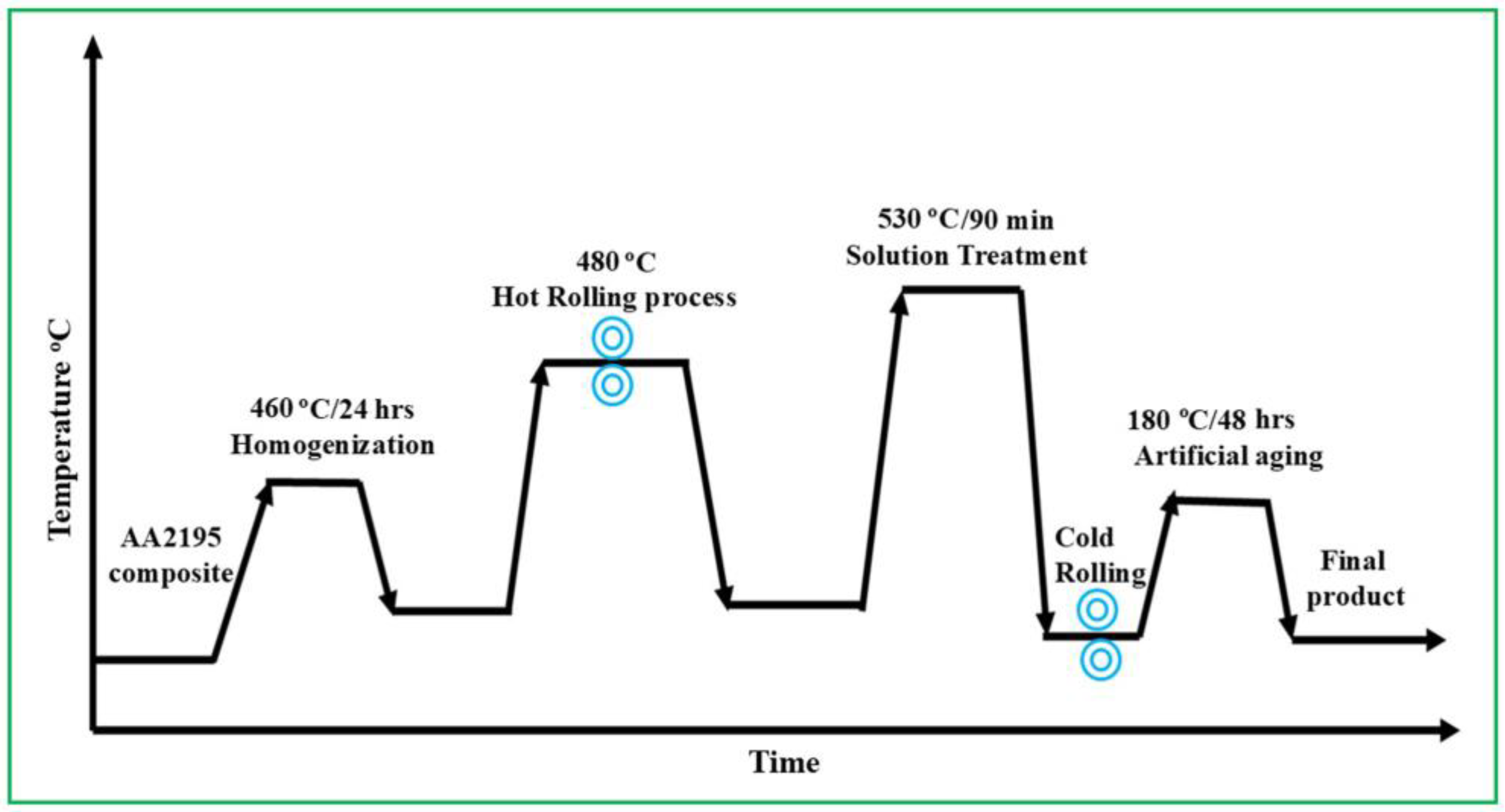

2.1. Fabrication of AA2195–Graphene Composite

2.2. Hot Rolling Process

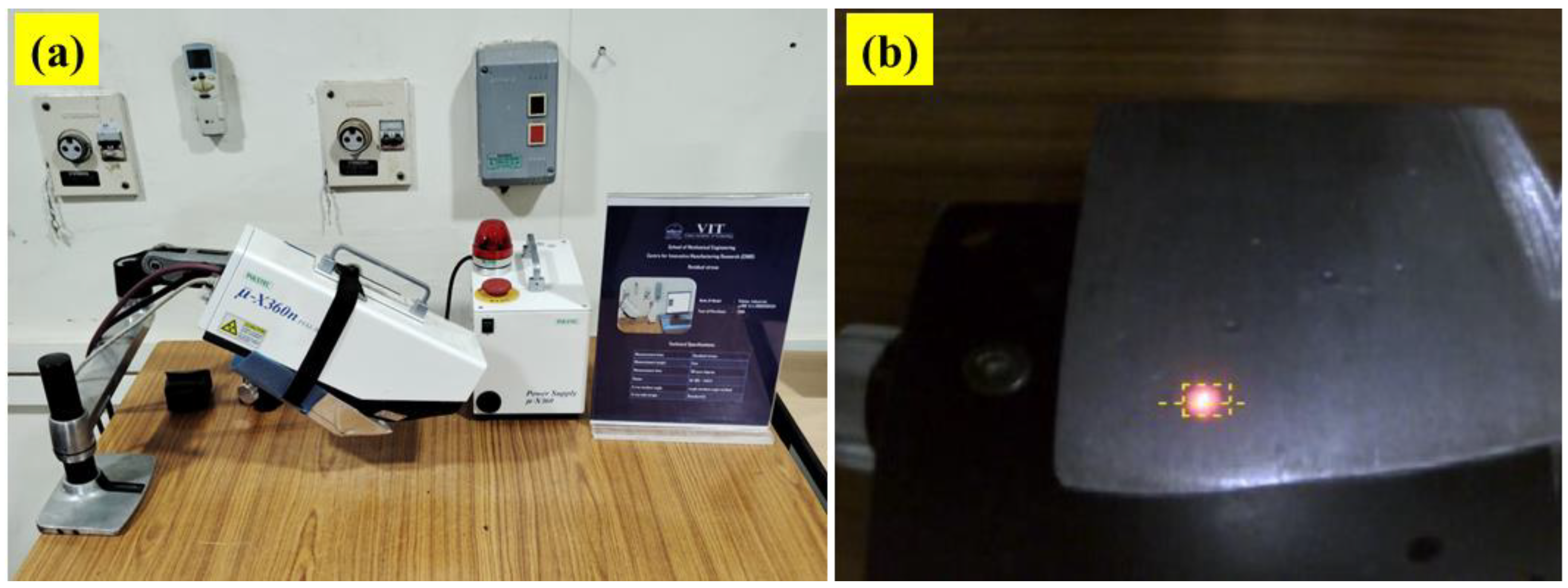

2.3. Residual Stress Analysis

3. Result and Discussion

3.1. Microstructural Analysis of the Fabricated Composite

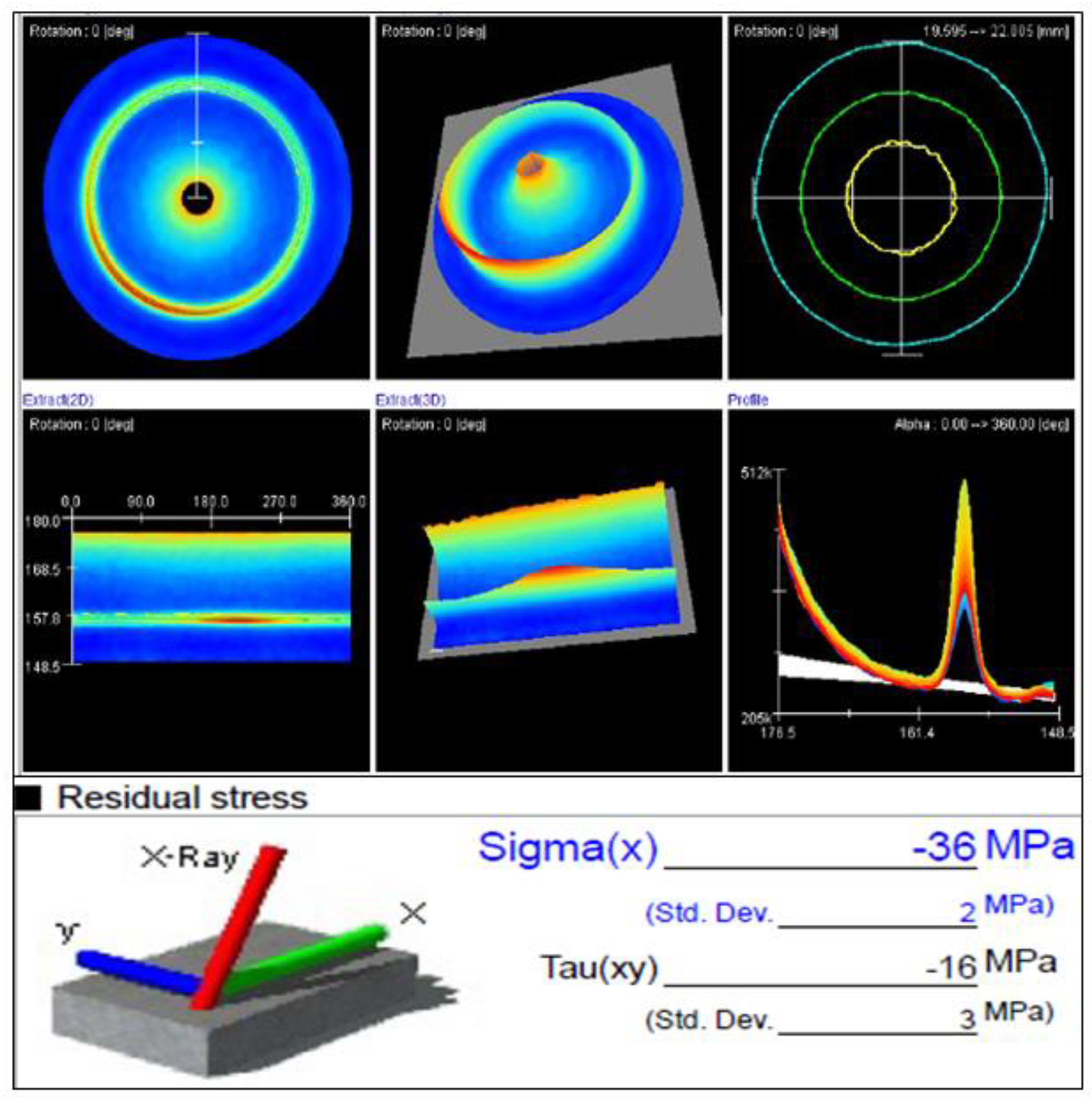

3.2. Residual Stress Analysis of AA2195 in the As-Received Condition

3.3. Residual Stress Analysis of AA2195–Graphene Composite in the As-Cast Condition

3.4. Residual Stress Analysis of AA2195–Graphene Composite After First Pass of Hot Rolling

3.5. Residual Stress Analysis of AA2195–Graphene Composite After Second Pass of Hot Rolling

3.6. Residual Stress Analysis of AA2195–Graphene Composite After Third Pass of Hot Rolling

3.7. Residual Stress Analysis of AA2195–Graphene Composite After Fourth Pass of Hot Rolling

3.8. Residual Stress Analysis of AA2195–Graphene Composite After Fifth Pass of Cold Rolling

3.9. Residual Stress Analysis of AA2195–Graphene Composite in the Artificially Aged (T8) Condition

4. Conclusions

- ➢

- A novel 0.5 wt.% graphene-reinforced AA2195 composite was successfully fabricated using squeeze casting, followed by multi-pass hot rolling and T8 heat treatment, resulting in a homogeneously strengthened aluminum matrix composite.

- ➢

- Microstructural analysis of SEM images confirmed the uniform distribution of graphene particles within the AA2195 matrix, accompanied by significant grain refinement and the formation of fine precipitates such as θ’ (Al2Cu) and T1 (Al2CuLi).

- ➢

- The addition of graphene particles significantly influenced the residual stress behavior of the composite. The final stage of the T8 condition exhibited compressive residual stress (−23 MPa), in contrast to the parent alloy, due to the thermal expansion mismatch and interfacial constraint effects induced by graphene.

- ➢

- Throughout the rolling passes, residual stress was carefully monitored. The fifth pass, conducted under cold rolling conditions, increased the strain hardening and dislocation density, which subsequently relaxed during artificial aging. The overall reduction in residual stress (from −68 MPa to −23 MPa) confirmed effective stress stabilization without compromising strength.

- ➢

- Compared to the unreinforced parent alloy, the graphene-reinforced AA2195 composite exhibited enhanced compressive residual stress characteristics, making it a promising candidate for lightweight, high-strength aerospace applications, especially in components that are subjected to cyclic loading and fatigue.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hajjioui, E.A.; Bouchaâla, K.; Faqir, M.; Essadiqi, E. A Review of Manufacturing Processes, Mechanical Properties and Precipitations for Aluminum Lithium Alloys Used in Aeronautic Applications. Heliyon 2023, 9, e12565. [Google Scholar] [CrossRef] [PubMed]

- Eswara Prasad, N.; Gokhale, A.A.; Wanhill, R.J.H. Aluminium–Lithium Alloys. In Aerospace Materials and Material Technologies; Springer: Singapore, 2017; Volume 1, pp. 53–72. [Google Scholar]

- Chen, W.; Yang, T.; Dong, L.; Elmasry, A.; Song, J.; Deng, N.; Elmarakbi, A.; Liu, T.; Lv, H.B.; Fu, Y.Q. Advances in Graphene Reinforced Metal Matrix Nanocomposites: Mechanisms, Processing, Modelling, Properties and Applications. Nanotechnol. Precis. Eng. 2020, 3, 189–210. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, Y.; Zhang, H.; Yang, J. Mechanical Properties of Graphene-Reinforced Aluminium Composite with Modified Substrate Surface: A Molecular Dynamics Study. Nanotechnology 2021, 32, 085712. [Google Scholar] [CrossRef] [PubMed]

- Ghodrati, H.; Ghomashchi, R. Effect of Graphene Dispersion and Interfacial Bonding on the Mechanical Properties of Metal Matrix Composites: An Overview. FlatChem 2019, 16, 100113. [Google Scholar] [CrossRef]

- Hu, Z.; Wu, Z.; Luo, S.; Wang, X.; Nian, Q.; Chen, Y.; Nagaumi, H. Large Scale Production of Graphene Aluminum Composites by Stir Casting: Process, Microstructure and Properties. J. Mater. Res. Technol. 2023, 27, 681–691. [Google Scholar] [CrossRef]

- Lou, S.M.; Qu, C.D.; Guo, G.X.; Ran, L.W.; Liu, Y.Q.; Zhang, P.P.; Su, C.J.; Wang, Q.B. Effect of Fabrication Parameters on the Performance of 0.5 Wt.% Graphene Nanoplates-Reinforced Aluminum Composites. Materials 2020, 13, 3483. [Google Scholar] [CrossRef] [PubMed]

- Venkatraman, M.; Xavior, M.A. Microstructural Study and Property Evaluation of Graphene Reinforced AA2195 Metal Matrix Composites. Results Eng. 2025, 25, 104492. [Google Scholar] [CrossRef]

- Ashwath, P.; Venkatraman, M.; Patel, A.; Xavior, M.A.; Batako, A. Innovation in Sustainable Composite Research: Investigating Graphene-Reinforced MMCs for Liquid Hydrogen Storage Tanks in Aerospace and Space Exploration. J. Mater. Res. Technol. 2024, 33, 4313–4331. [Google Scholar] [CrossRef]

- Withers, P.J.; Bhadeshia, H.K.D.H. Residual Stress. Part 2—Nature and Origins. Mater. Sci. Technol. 2001, 17, 366–375. [Google Scholar] [CrossRef]

- Hosseini, S.; Farajollahi, M.; Ebrahimi, M. Residual Stress, Fatigue Behavior, and Mechanical Properties of Equal-Channel Angular Pressed Commercial Pure Titanium. J. Mater. Res. Technol. 2024, 28, 3297–3305. [Google Scholar] [CrossRef]

- Wong, C.S.; Pramanik, A.; Basak, A.K. Residual Stress Generation in Metal Matrix Composites after Cooling. Mater. Sci. Technol. 2018, 34, 1388–1400. [Google Scholar] [CrossRef]

- Wang, X.; Rong, Q.; Shi, Z.; Li, Y.; Cao, J.; Chen, B.; Lin, J. Investigation of Stress Effect on Creep, Precipitation and Dislocation Evolution of Al–Li Alloy during Creep Age Forming. Mater. Sci. Eng. A 2022, 836, 142723. [Google Scholar] [CrossRef]

- Algendy, A.Y.; Rometsch, P.; Chen, X.-G. Impact of Hot Rolling Temperature on the Mechanical Properties and Microstructural Evolution of Hot/Cold-Rolled AA5083 with Sc and Zr Microalloying. Mater. Sci. Eng. A 2024, 896, 146275. [Google Scholar] [CrossRef]

- Xu, X.; Wu, G.; Zhang, L.; Tong, X.; Zhang, X.; Sun, J.; Li, L.; Xiong, X. Effects of Heat Treatment and Pre-Stretching on the Mechanical Properties and Microstructure Evolution of Extruded 2050 Al–Cu–Li Alloy. Mater. Sci. Eng. A 2022, 845, 143236. [Google Scholar] [CrossRef]

- Li, Y.; Gan, W.; Zhou, W.; Li, D. Review on Residual Stress and Its Effects on Manufacturing of Aluminium Alloy Structural Panels with Typical Multi-Processes. Chin. J. Aeronaut. 2023, 36, 96–124. [Google Scholar] [CrossRef]

- Ammar, M.M.A.; Shirinzadeh, B.; Zhao, P.; Shi, Y. Optimization of Process-Induced Residual Stresses in Automated Manufacturing of Thermoset Composites. Aerosp. Sci. Technol. 2022, 123, 107443. [Google Scholar] [CrossRef]

- Abd Rahim, M.N.; Salleh, M.S.; Yahaya, S.H.; Subramonian, S.; Jun, L.P.; Abdul Rashid, A.H.; Syed Ahmad, S.N.A.; Al-Zubaidi, S.S. Effect of Graphene Addition on Microstructure and Mechanical Properties of Cast Aluminium Alloy Composite. J. Adv. Res. Micro Nano Eng. 2024, 25, 66–75. [Google Scholar] [CrossRef]

- Duan, S.; Liu, Z.; Guo, F.; Pan, Y.; Matsuda, K.; Zou, Y. Precipitates Evolution during Artificial Aging and Their Influence on Mechanical Properties of a Cast Al–Cu–Li Alloy. J. Mater. Res. Technol. 2023, 22, 2502–2517. [Google Scholar] [CrossRef]

- Li, M.; Yang, W.; Tian, X.; Chen, L.; Hou, H.; Zhao, Y. Precipitation and Refining of Al2Cu in Graphene Nanoplatelets Reinforced 2024 Al Composites. Mater. Charact. 2023, 200, 112854. [Google Scholar] [CrossRef]

- Zhang, Y.; Yi, Y.; Huang, S.; Dong, F. Influence of Quenching Cooling Rate on Residual Stress and Tensile Properties of 2A14 Aluminum Alloy Forgings. Mater. Sci. Eng. A 2016, 674, 658–665. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Ghanei Mohammadi, A.R. 1 - The importance of measuring residual stresses in composite materials. In Residual Stresses in Composite Materials; Shokrieh, M.M., Ed.; Woodhead Publishing: Oxford, UK, 2014; pp. 3–14. ISBN 9780857092700. [Google Scholar] [CrossRef]

- Teixeira-Dias, F.; Menezes, L.F. Thermal Residual Stresses in Aluminium Matrix Composites; Springer: Berlin/Heidelberg, Germany, 2010; pp. 33–62. [Google Scholar]

- Iqbal, A.A.; Arai, Y.; Araki, W. Influence of Residual Stress on the Fatigue Crack Growth Mechanism in the Al-Alloy/Hybrid MMC Bi-Material. J. Fail. Anal. Prev. 2022, 22, 1468–1477. [Google Scholar] [CrossRef]

- Huang, H.; Xiong, W.; Jiang, Z.; Zhang, J. A Quasi In-Situ Study on the Microstructural Evolution of 2195 Al-Cu-Li Alloy during Homogenization. Materials 2022, 15, 6573. [Google Scholar] [CrossRef] [PubMed]

- Dixit, U.S.; Dixit, P.M. A Study on Residual Stresses in Rolling. Int. J. Mach. Tools Manuf. 1997, 37, 837–853. [Google Scholar] [CrossRef]

- Withers, J.P.; Roy, J.M. 4.10 Residual Stresses in Metal Matrix Composites. In Comprehensive Composite Materials II; Beaumont, P.W.R., Zweben, C.H., Eds.; Elsevier: Oxford, UK, 2018; pp. 275–286. ISBN 9780081005347. [Google Scholar] [CrossRef]

- Yang, Z.; Ni, Z.; Yan, J.; Fan, L.; Zhang, J.; Chen, X.; Guan, R. Towards High Performance Nano Multilayered Graphene/5052 Al Composite: In Situ Interfacial Tailoring via Accumulative Roll Bonding. Carbon 2025, 238, 120213. [Google Scholar] [CrossRef]

- Mukherjee, S.; Ananth, C.R.; Chandra, N. Effect of Residual Stresses on the Interfacial Fracture Behavior of Metal-Matrix Composites. Compos. Sci. Technol. 1997, 57, 1501–1512. [Google Scholar] [CrossRef]

- Yan, Y.; Zhao, J.; Chen, L.; Zhao, H.; Klimova-Korsmik, O.; Tolochko, O.V.; Yin, F.; Ji, P.; Kang, S. Effect of Strain Rate on Compressive Properties of Aluminium-Graphene Composites. Metals 2023, 13, 618. [Google Scholar] [CrossRef]

- Wang, M.; Sheng, J.; Wang, L.-D.; Yang, Z.-Y.; Shi, Z.-D.; Wang, X.-J.; Fei, W.-D. Hot Rolling Behavior of Graphene/Cu Composites. J. Alloys Compd. 2020, 816, 153204. [Google Scholar] [CrossRef]

- Yang, K.M.; Ma, Y.C.; Zhang, Z.Y.; Zhu, J.; Sun, Z.B.; Chen, J.S.; Zhao, H.H.; Song, J.; Li, Q.; Chen, N.Q.; et al. Anisotropic Thermal Conductivity and Associated Heat Transport Mechanism in Roll-to-Roll Graphene Reinforced Copper Matrix Composites. Acta. Mater. 2020, 197, 342–354. [Google Scholar] [CrossRef]

- Jang, J.-H.; Nam, D.-G.; Park, Y.-H.; Park, I.-M. Effect of Solution Treatment and Artificial Aging on Microstructure and Mechanical Properties of Al–Cu Alloy. Trans. Nonferrous Met. Soc. China 2013, 23, 631–635. [Google Scholar] [CrossRef]

- Zhou, C.; Zhan, L.; Liu, C.; Huang, M. Influence of Dislocation Morphology on T1 Precipitation of an Al-Cu-Li Alloy. J. Alloys Compd. 2023, 947, 169463. [Google Scholar] [CrossRef]

- Rashidi, M.; Tayebi, P.; Hashemi, R. Stress Relief Treatment of Aluminum/Magnesium Laminates Fabricated by Roll Bonding Technique. Heliyon 2025, 11, e41639. [Google Scholar] [CrossRef] [PubMed]

- Requena, G.; Yubero, D.C.; Corrochano, J.; Repper, J.; Garcés, G. Stress Relaxation during Thermal Cycling of Particle Reinforced Aluminium Matrix Composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1981–1988. [Google Scholar] [CrossRef]

- Xu, X.; Wu, G.; Zhang, L.; Tong, X.; Qi, F.; Guo, Y.; Li, L.; Xiong, X.; Wang, C. Regulation of Precipitation Behavior among T1, S’, and θ’ Phases in Al–Cu–Li-(Mg–Ag) Alloys by Optimizing Ag/Mg Ratios. Mater. Sci. Eng. A 2023, 876, 145158. [Google Scholar] [CrossRef]

- Tsai, S.-D.; Mahulikar, D.; Marcus, H.L.; Noyan, I.C.; Cohen, J.B. Residual Stress Measurements on Al-Graphite Composites Using X-Ray Diffraction. Mater. Sci. Eng. 1981, 47, 145–149. [Google Scholar] [CrossRef]

- Abd-Elaziem, W.; Khedr, M.; Elsheikh, A.H.; Liu, J.; Zeng, Y.; Sebae, T.A.; Abd El-Baky, M.A.; Darwish, M.A.; Daoush, W.M.; Li, X. Influence of Nanoparticles Addition on the Fatigue Failure Behavior of Metal Matrix Composites: Comprehensive Review. Eng. Fail. Anal. 2024, 155, 107751. [Google Scholar] [CrossRef]

| Rolling Pass | 1st | 2nd | 3rd | 4th | Solution Treatment | 5th |

| Entrance (mm) | 12 | 11.9 | 11.8 | 11.7 | 11.6 | |

| Exit (mm) | 11.9 | 11.8 | 11.7 | 11.6 | 11.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manokaran, V.; Michael, A.X.; Pazhani, A.; Batako, A. Residual Stress Evolution of Graphene-Reinforced AA2195 (Aluminum–Lithium) Composite for Aerospace Structural Hydrogen Fuel Tank Application. J. Compos. Sci. 2025, 9, 369. https://doi.org/10.3390/jcs9070369

Manokaran V, Michael AX, Pazhani A, Batako A. Residual Stress Evolution of Graphene-Reinforced AA2195 (Aluminum–Lithium) Composite for Aerospace Structural Hydrogen Fuel Tank Application. Journal of Composites Science. 2025; 9(7):369. https://doi.org/10.3390/jcs9070369

Chicago/Turabian StyleManokaran, Venkatraman, Anthony Xavior Michael, Ashwath Pazhani, and Andre Batako. 2025. "Residual Stress Evolution of Graphene-Reinforced AA2195 (Aluminum–Lithium) Composite for Aerospace Structural Hydrogen Fuel Tank Application" Journal of Composites Science 9, no. 7: 369. https://doi.org/10.3390/jcs9070369

APA StyleManokaran, V., Michael, A. X., Pazhani, A., & Batako, A. (2025). Residual Stress Evolution of Graphene-Reinforced AA2195 (Aluminum–Lithium) Composite for Aerospace Structural Hydrogen Fuel Tank Application. Journal of Composites Science, 9(7), 369. https://doi.org/10.3390/jcs9070369