Seawater Ageing Effects on the Mechanical Performance of Basalt Fibre-Reinforced Thermoplastic and Epoxy Composites

Abstract

1. Introduction

2. Materials and Methods

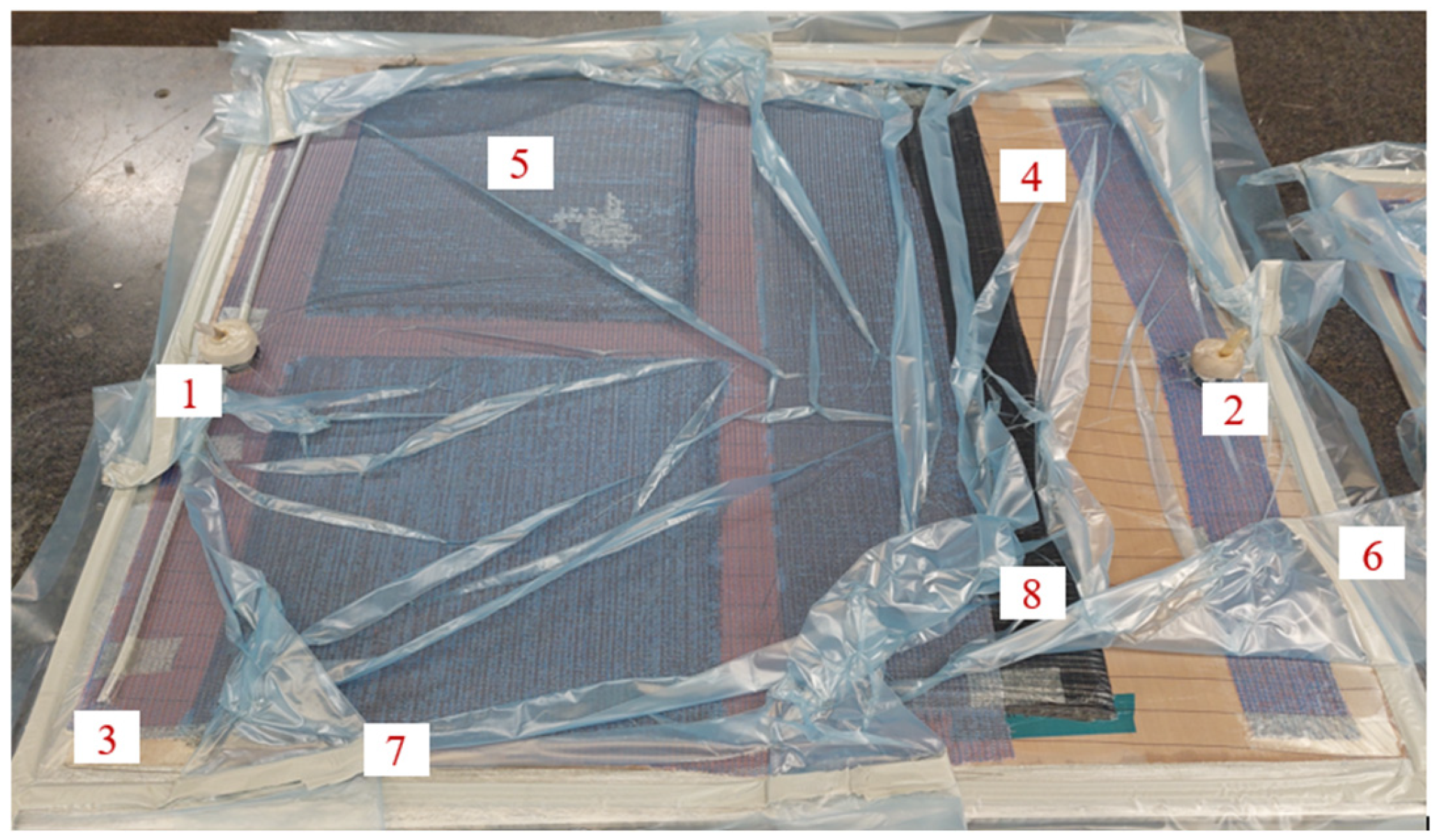

2.1. Materials and Manufacturing Process

2.2. Physical Testing

2.3. Tensile and Flexural Testing

3. Results and Discussion

3.1. Physical and Chemical Performance

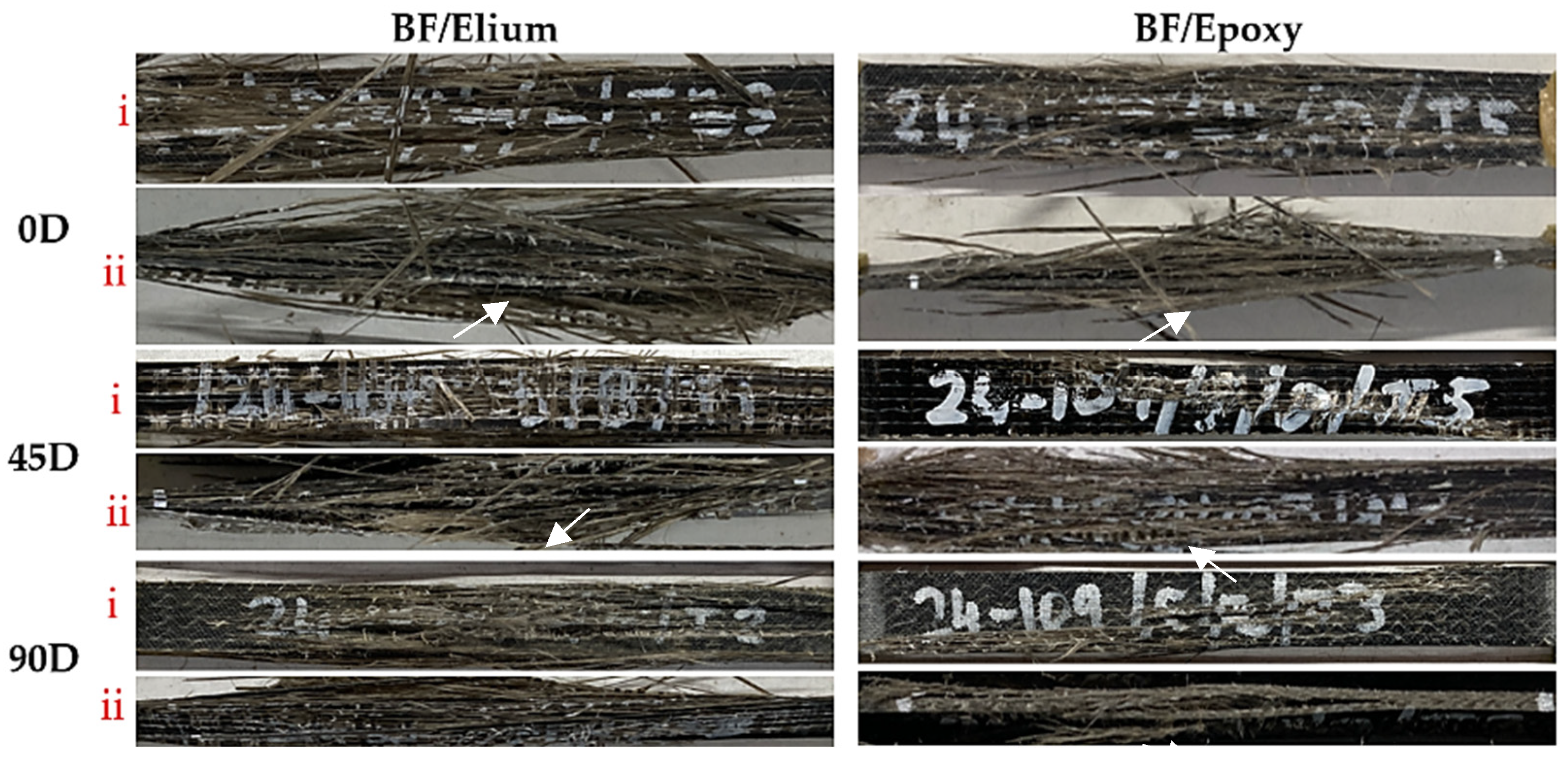

3.2. Tensile Performance in 0° Direction

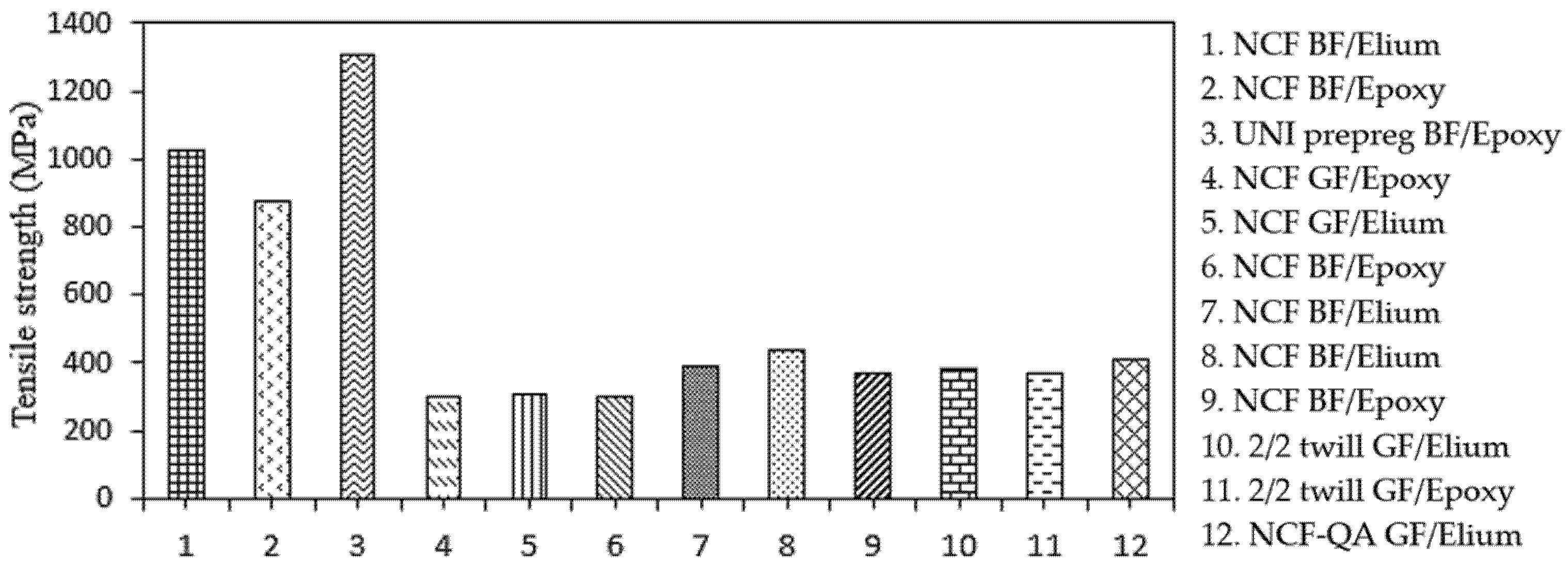

3.3. Effect of Manufacturing Method and Reinforcement on Tensile Performance

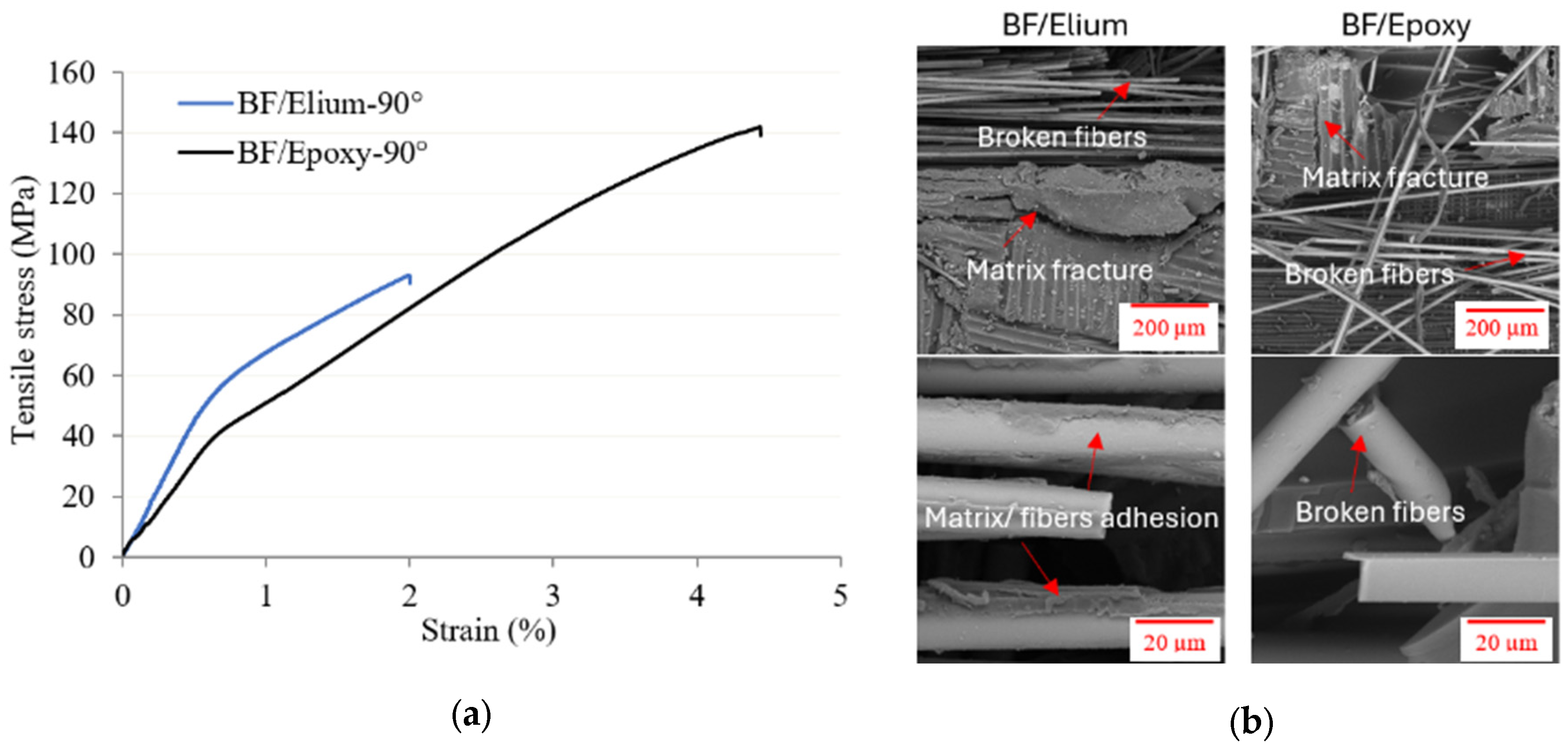

3.4. Tensile Performance at 90° Fibre Orientation Angle

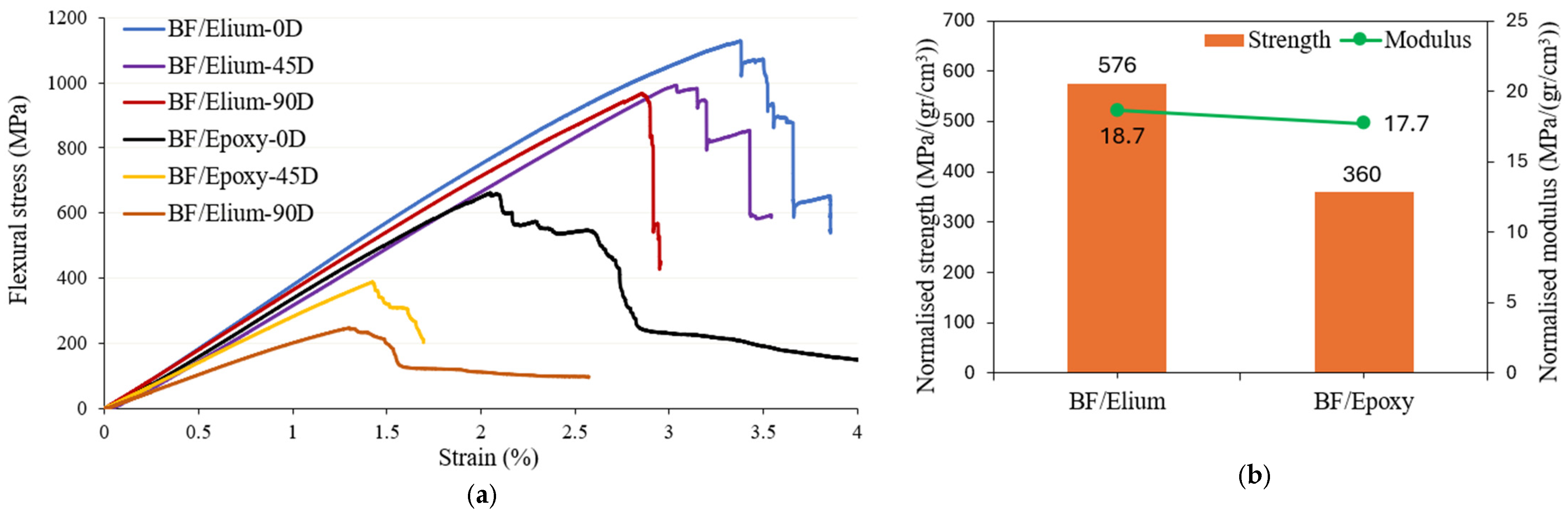

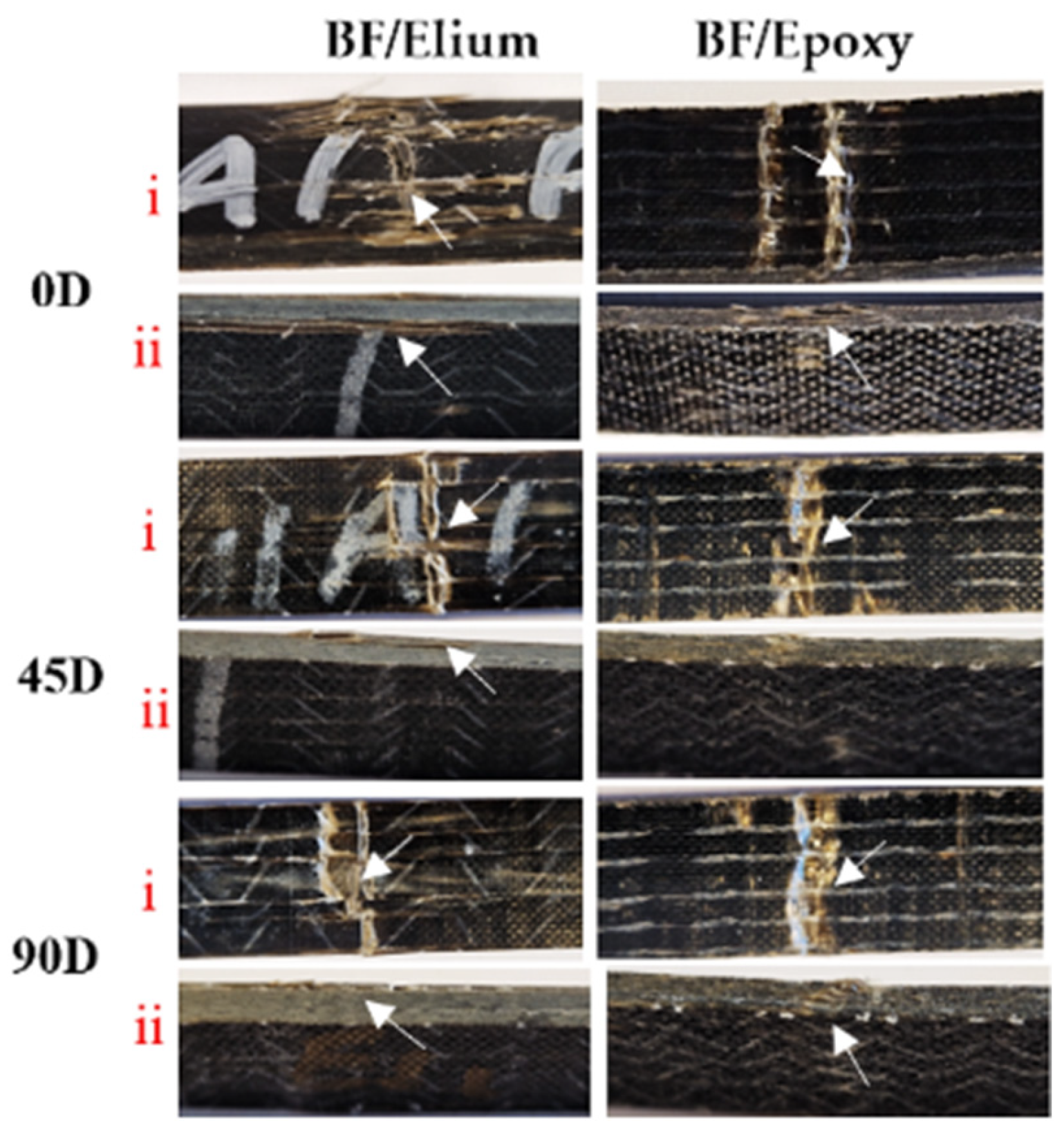

3.5. Flexural Performance

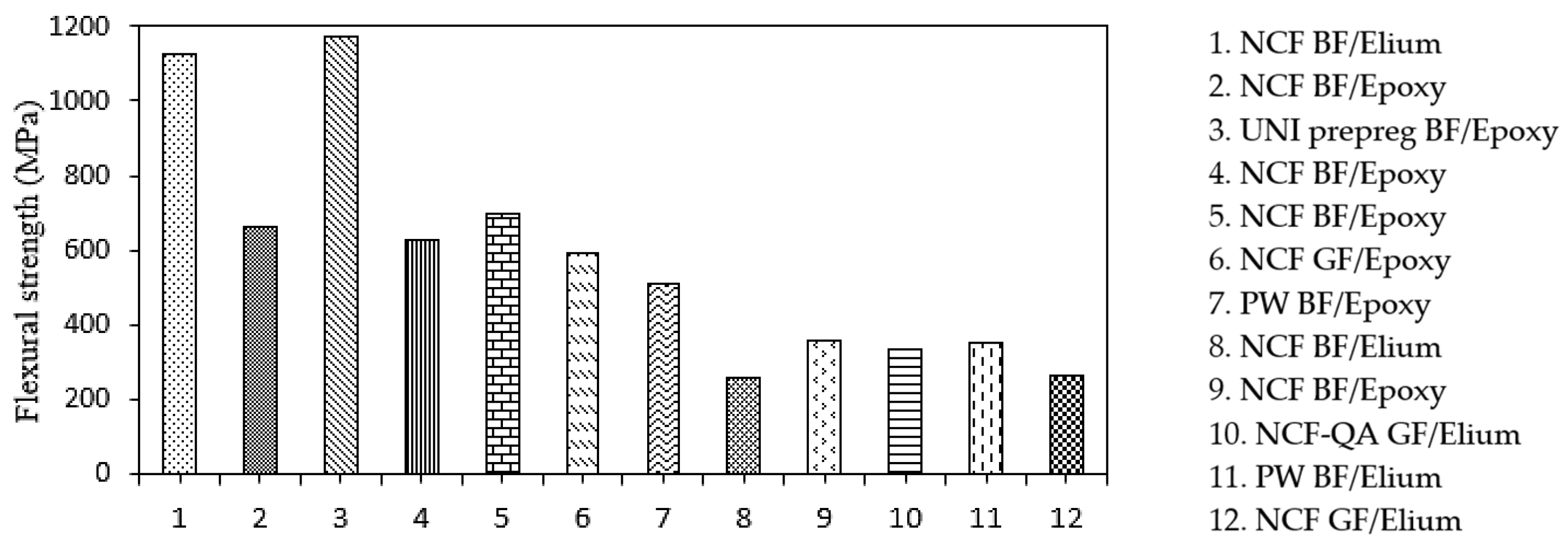

3.6. Effect of Manufacturing Method and Reinforcement on Flexural Performance

4. Conclusions

- The density and fibre volume fraction values of BF/Elium were 1.96 g/cm3 and 53%, while those of the BF/Epoxy composite were 1.84 g/cm3 and 48%, respectively. Hydrothermal ageing increased the thickness and density of both thermoset and thermoplastic composites, attributed to moisture uptake and swelling.

- The peak intensity levels of the thermoplastic BF/Elium composites decreased after hydrothermal ageing due to microstructural relaxation. The opposite behaviour occurred for the thermoset BF/Epoxy composites, as the peak intensity levels increased after seawater ageing due to plasticisation.

- Hydrothermal seawater ageing acted as a plasticiser for the polymer matrices in both thermoplastic and thermoset composites, leading to deformation under lower applied loads. As a result, the stiffness, strength, and failure strain of both BF/Elium and BF/Epoxy composites were reduced during tensile and flexural testing.

- The tensile and flexural strength values of the BF/Elium composite were 1165 MPa and 1128 MPa, which are 33% and 71% higher than those of the BF/Epoxy composite, respectively. The strength values exhibited a reduction for both composites after the coupons reached saturation in seawater.

- The tensile and flexural modulus values of the BF/Elium composite were 44.1 GPa and 38.2 GPa, respectively, representing increases of 30% and 12% compared with the BF/Epoxy composite. Both composites exhibited stiffness reduction when the coupons reached saturation after 90 days of seawater ageing.

- The strain-at-fracture values of the tensile and flexural tests were significantly reduced under the effect of hydrothermal ageing.

- The failed tensile samples indicated that the size of the fibre diffused in BF/Elium is greater than that in BF/Epoxy, attributed to the higher stored elastic energy.

- The G values were affected more by the stiffness reduction than by the increase in Poisson’s ratio values due to hydrothermal ageing, and both parameters resulted in a decrease in the G values.

- The 90° tensile strength was 57% higher and the modulus 57% lower compared with the BF/Elium composite. In both composites, matrix fracture was dominant due to the effect of the 10 g/m2 BF density in the 90° direction.

- The strength and modulus values of the tensile and flexural tests for both composites were normalised with respect to the density of each composite laminate. Even after normalising, the strength and stiffness values of the BF/Elium composite were higher than those of the BF/Epoxy composite.

- In general, the flexural properties were degraded more than the tensile properties due to hydrothermal seawater ageing at 45 °C for 45 and 90 days.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, P.; Barlow, C.Y. Wind Turbine Blade Waste in 2050. Waste Manag. 2017, 62, 229–240. [Google Scholar] [CrossRef]

- Martinez-Marquez, D.; Florin, N.; Hall, W.; Majewski, P.; Wang, H.; Stewart, R.A. State-of-the-Art Review of Product Stewardship Strategies for Large Composite Wind Turbine Blades. Resour. Conserv. Recycl. Adv. 2022, 15, 200109. [Google Scholar] [CrossRef]

- European Commission. Circular Economy Action Plan. Introduction. Available online: https://Environment.Ec.Europa.Eu/Strategy/Circular-Economy-Action-Plan_en (accessed on 11 April 2025).

- Esposito, B.; Smaldone, F.; Raimo, N.; Sica, D.; Vitolla, F. Enhancing Circular Economy Disclosure towards Net Zero: The Role of Circular Economy Capabilities. Int. J. Product. Perform. Manag. 2025. ahead of print. [Google Scholar] [CrossRef]

- Utekar, S.; V K, S.; More, N.; Rao, A. Comprehensive Study of Recycling of Thermosetting Polymer Composites – Driving Force, Challenges and Methods. Compos. Part B Eng. 2021, 207, 108596. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Mavinkere Rangappa, S.; Siengchin, S.; Puttegowda, M.; Thiagamani, S.M.K.; Rajeshkumar, G.; Hemath Kumar, M.; Oladijo, O.P.; Fiore, V.; Moure Cuadrado, M.M. Sustainable Recycling Technologies for Thermoplastic Polymers and Their Composites: A Review of the State of the Art. Polym. Compos. 2022, 43, 5831–5862. [Google Scholar] [CrossRef]

- Devine, M.; Bajpai, A.; Obande, W.; Ó Brádaigh, C.M.; Ray, D. Seawater Ageing of Thermoplastic Acrylic Hybrid Matrix Composites for Marine Applications. Compos. Part B Eng. 2023, 263, 110879. [Google Scholar] [CrossRef]

- Kazemi, M.E.; Shanmugam, L.; Lu, D.; Wang, X.; Wang, B.; Yang, J. Mechanical Properties and Failure Modes of Hybrid Fiber Reinforced Polymer Composites with a Novel Liquid Thermoplastic Resin, Elium®. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105523. [Google Scholar] [CrossRef]

- Alsaadi, M.; Bandaru, A.K.; Flanagan, T.; Devine, D.M. Off-Axis Fabric Orientation Angle Effect on the Flexural Characterisation of Mineral Basalt-Fibre-Reinforced Novel Acrylic Thermoplastic Composites. J. Compos. Sci. 2025, 9, 347. [Google Scholar] [CrossRef]

- Demski, S.; Misiak, M.; Majchrowicz, K.; Komorowska, G.; Lipkowski, A.; Stankiewicz, K.; Dydek, K.; Waśniewski, B.; Boczkowska, A.; Ehrlich, H. Mechanical Recycling of CFRPs Based on Thermoplastic Acrylic Resin with the Addition of Carbon Nanotubes. Sci. Rep. 2024, 14, 11550. [Google Scholar] [CrossRef]

- Bel Haj Frej, H.; Léger, R.; Perrin, D.; Ienny, P.; Gérard, P.; Devaux, J.-F. Recovery and Reuse of Carbon Fibre and Acrylic Resin from Thermoplastic Composites Used in Marine Application. Resour. Conserv. Recycl. 2021, 173, 105705. [Google Scholar] [CrossRef]

- Shamass, R.; Limbachiya, V.; Ajibade, O.; Rabi, M.; Lopez, H.U.L.; Zhou, X. Carbonated Aggregates and Basalt Fiber-Reinforced Polymers: Advancing Sustainable Concrete for Structural Use. Buildings 2025, 15, 775. [Google Scholar] [CrossRef]

- Pavlović, A.; Donchev, T.; Petkova, D.; Staletović, N. Sustainability of Alternative Reinforcement for Concrete Structures: Life Cycle Assessment of Basalt FRP Bars. Constr. Build. Mater. 2022, 334, 127424. [Google Scholar] [CrossRef]

- Acumen Research and Consulting, Basalt Fibre Market Size. 2025. Available online: https://www.Acumenresearchandconsulting.Com/Pressreleases/Basalt-Fibre-Market/Amp (accessed on 26 January 2025).

- Yaghoobi, H.; Taheri, F. Mechanical Performance of a Novel Environmentally Friendly Basalt-Elium® Thermoplastic Composite and Its Stainless Steel-Based Fiber Metal Laminate. Polym. Compos. 2021, 42, 4660–4672. [Google Scholar] [CrossRef]

- Chilali, A.; Zouari, W.; Assarar, M.; Kebir, H.; Ayad, R. Analysis of the Mechanical Behaviour of Flax and Glass Fabrics-Reinforced Thermoplastic and Thermoset Resins. J. Reinf. Plast. Compos. 2016, 35, 1217–1232. [Google Scholar] [CrossRef]

- Davies, P.; Verbouwe, W. Evaluation of Basalt Fibre Composites for Marine Applications. Appl. Compos. Mater. 2018, 25, 299–308. [Google Scholar] [CrossRef]

- Chowdhury, I.R.; Pemberton, R.; Summerscales, J. Developments and Industrial Applications of Basalt Fibre Reinforced Composite Materials. J. Compos. Sci. 2022, 6, 367. [Google Scholar] [CrossRef]

- Liao, D.; Gu, T.; Liu, J.; Chen, S.; Zhao, F.; Len, S.; Dou, J.; Qian, X.; Wang, J. Degradation Behavior and Ageing Mechanism of E-Glass Fiber Reinforced Epoxy Resin Composite Pipes under Accelerated Thermal Ageing Conditions. Compos. Part B Eng. 2024, 270, 111131. [Google Scholar] [CrossRef]

- Fitriah, S.N.; Abdul Majid, M.S.; Ridzuan, M.J.M.; Daud, R.; Gibson, A.G.; Assaleh, T.A. Influence of Hydrothermal Ageing on the Compressive Behaviour of Glass Fibre/Epoxy Composite Pipes. Compos. Struct. 2017, 159, 350–360. [Google Scholar] [CrossRef]

- Luo, X.; Wei, Y.; Ma, L.; Tian, W.; Zhu, C. Effect of Corrosive Aging Environments on the Flexural Properties of Silane-Coupling-Agent-Modified Basalt-Fiber-Reinforced Composites. Materials 2023, 16, 1543. [Google Scholar] [CrossRef]

- Davies, P.; Le Gac, P.-Y.; Le Gall, M. Influence of Sea Water Aging on the Mechanical Behaviour of Acrylic Matrix Composites. Appl. Compos. Mater. 2017, 24, 97–111. [Google Scholar] [CrossRef]

- Bel Haj Frej, H.; Léger, R.; Perrin, D.; Ienny, P. A Novel Thermoplastic Composite for Marine Applications: Comparison of the Effects of Aging on Mechanical Properties and Diffusion Mechanisms. Appl. Compos. Mater. 2021, 28, 899–922. [Google Scholar] [CrossRef]

- Barbosa, L.C.M.; Santos, M.; Oliveira, T.L.L.; Gomes, G.F.; Ancelotti Junior, A.C. Effects of Moisture Absorption on Mechanical and Viscoelastic Properties in Liquid Thermoplastic Resin/Carbon Fiber Composites. Polym. Eng. Sci. 2019, 59, 2185–2194. [Google Scholar] [CrossRef]

- Arkema. Liquid Thermoplastic Resin for Tougher Composites. Available online: https://www.arkema.com/global/en/resources/post/elium-resin-breakthrough-innovation/ (accessed on 21 April 2025).

- Coastal Enterprises. Epoxy PrimeTM 37 Technical Data Sheet; Coastal Enterprises Co.: Orange, CA, USA, 2022. [Google Scholar]

- ASTM D792; Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D3171-22 (Reapproved 2022); Standard Test Methods for Constituent Content of Composite Materials. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D5229; Standard Test Method for Moisture Absorption Properties and Equilibrium Conditioning of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2014.

- Ladaci, N.; Saadia, A.; Belaadi, A.; Boumaaza, M.; Chai, B.X.; Abdullah, M.M.S.; Al-Khawlani, A.; Ghernaout, D. ANN and RSM Prediction of Water Uptake of Recycled HDPE Biocomposite Reinforced with Treated Palm Waste W. filifera. J. Nat. Fibers 2024, 21, 2356697. [Google Scholar] [CrossRef]

- Bulut, M.; Alsaadi, M.; Erkliğ, A. The Effects of Nanosilica and Nanoclay Particles Inclusions on Mode II Delamination, Thermal and Water Absorption of Intraply Woven Carbon/Aramid Hybrid Composites. Int. Polym. Process. 2020, 35, 367–375. [Google Scholar] [CrossRef]

- Zeng, J.-J.; Zhuge, Y.; Liang, S.-D.; Bai, Y.-L.; Liao, J.; Zhang, L. Durability Assessment of PEN/PET FRP Composites Based on Accelerated Aging in Alkaline Solution/Seawater with Different Temperatures. Constr. Build. Mater. 2022, 327, 126992. [Google Scholar] [CrossRef]

- ASTM D3039; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D790; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- Bandaru, A.K.; Hickey, S.; Singh, D.; Gujjala, R.; Pichandi, S. Influence of Hygrothermal Ageing on the Novel Infusible Thermoplastic Resin Reinforced with Quadriaxial Non-Crimp Glass Fabrics. J. Thermoplast. Compos. Mater. 2023, 36, 3813–3836. [Google Scholar] [CrossRef]

- Das, S.C.; Srivastava, C.; Goutianos, S.; La Rosa, A.D.; Grammatikos, S. On the Response to Hygrothermal Ageing of Fully Recyclable Flax and Glass Fibre Reinforced Polymer Composites. Materials 2023, 16, 5848. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Chen, P.; Yan, C.; Cai, C.; Shi, Y. Four-Dimensional Printing of a Novel Acrylate-Based Shape Memory Polymer Using Digital Light Processing. Mater. Des. 2019, 171, 107704. [Google Scholar] [CrossRef]

- Li, C.; Zhang, L.; Wang, H.; Song, Y.; Wang, J. Study of Hygrothermal Aging for Basalt Fiber/Epoxy Resin Composites Modified with CeCl3. Polymers 2024, 16, 819. [Google Scholar] [CrossRef]

- Boos, D.D.; Stefanski, L.A. P-Value Precision and Reproducibility. Am. Stat. 2011, 65, 213–221. [Google Scholar] [CrossRef]

- Fagerland, M.W. T-Tests, Non-Parametric Tests, and Large Studies—A Paradox of Statistical Practice? BMC Med. Res. Methodol. 2012, 12, 78. [Google Scholar] [CrossRef]

- Oliveira, M.; da Luz, F.; Pereira, A.; Costa, U.; Bezerra, W.; da Cunha, J.; Lopera, H.; Monteiro, S. Water Immersion Aging of Epoxy Resin and Fique Fabric Composites: Dynamic–Mechanical and Morphological Analysis. Polymers 2022, 14, 3650. [Google Scholar] [CrossRef]

- Zhang, W.; Zou, J.; Liu, M.; Han, Z.; Xiong, Y.; Liang, B.; Hu, N.; Zhang, W. Investigating the Role of Fibre-Matrix Interfacial Degradation on the Ageing Process of Carbon Fibre-Reinforced Polymer under Hydrothermal Conditions. Compos. Sci. Technol. 2025, 259, 110922. [Google Scholar] [CrossRef]

- Bergeret, A.; Ferry, L.; Ienny, P. Influence of the Fibre/Matrix Interface on Ageing Mechanisms of Glass Fibre Reinforced Thermoplastic Composites (PA-6,6, PET, PBT) in a Hygrothermal Environment. Polym. Degrad. Stab. 2009, 94, 1315–1324. [Google Scholar] [CrossRef]

- Plappert, D.; Ganzenmüller, G.C.; May, M.; Beisel, S. Mechanical Properties of a Unidirectional Basalt-Fiber/Epoxy Composite. J. Compos. Sci. 2020, 4, 101. [Google Scholar] [CrossRef]

- Al-Furjan, M.S.H.; Shan, L.; Shen, X.; Zarei, M.S.; Hajmohammad, M.H.; Kolahchi, R. A Review on Fabrication Techniques and Tensile Properties of Glass, Carbon, and Kevlar Fiber Reinforced Rolymer Composites. J. Mater. Res. Technol. 2022, 19, 2930–2959. [Google Scholar] [CrossRef]

- Taheri, F.; Llanos, J.R.J.G. Comparative Performance of Kevlar, Glass and Basalt Epoxy- and Elium-Based Composites under Static-, Low- and High-Velocity Loading Scenarios—Introduction to an Effective Recyclable and Eco-Friendly Composite. Polymers 2024, 16, 1494. [Google Scholar] [CrossRef]

- Idrisi, A.H.; Mourad, A.-H.I.; Sherif, M.M. Impact of Prolonged Exposure of Eleven Years to Hot Seawater on the Degradation of a Thermoset Composite. Polymers 2021, 13, 2154. [Google Scholar] [CrossRef]

- El Hawary, O.; Boccarusso, L.; Ansell, M.P.; Durante, M.; Pinto, F. An Overview of Natural Fiber Composites for Marine Applications. J. Mar. Sci. Eng. 2023, 11, 1076. [Google Scholar] [CrossRef]

- Chowdhury, I.R.; Rao, P.S.; O’Dowd, N.P.; Comer, A.J. Hygrothermal Ageing Effects on Failure Behaviour of Fibre-Reinforced Polymer Composite Materials under in-Situ SEM Testing. Compos. Part B Eng. 2025, 294, 112148. [Google Scholar] [CrossRef]

- Wang Mingchao; Zhang Zuoguang; Li Yubin; Li Min; Sun Zhijie Chemical Durability and Mechanical Properties of Alkali-Proof Basalt Fiber and Its Reinforced Epoxy Composites. J. Reinf. Plast. Compos. 2008, 27, 393–407. [CrossRef]

- Chowdhury, I.R.; O’Dowd, N.P.; Comer, A.J. Experimental Study of Hygrothermal Ageing Effects on Failure Modes of Non-Crimp Basalt Fibre-Reinforced Epoxy Composite. Compos. Struct. 2021, 275, 114415. [Google Scholar] [CrossRef]

- Lopresto, V.; Leone, C.; De Iorio, I. Mechanical Characterisation of Basalt Fibre Reinforced Plastic. Compos. Part B Eng. 2011, 42, 717–723. [Google Scholar] [CrossRef]

- Bandaru, A.K.; Pothnis, J.R.; Portela, A.; Gujjala, R.; Ma, H.; O’Higgins, R.M. Flexural and Interlaminar Shear Response of Novel Methylmethacrylate Composites Reinforced with High-Performance Fibres. Polym. Test. 2024, 140, 108578. [Google Scholar] [CrossRef]

- Hussnain, S.M.; Shah, S.Z.H.; Megat-Yusoff, P.S.M.; Choudhry, R.S.; Hussain, M.Z. Hygrothermal Effects on the Durability of Resin-infused Thermoplastic E-glass Fiber-reinforced Composites in Marine Environment. Polym. Compos. 2024, 45, 13901–13923. [Google Scholar] [CrossRef]

| Property | Elium®191 XO/SA | Epoxy PrimeTM 37 |

|---|---|---|

| Viscosity (cP) at 25 °C | 100 | 181 |

| Density (g/cm3) at RT | 1.01 | 1.10 |

| Gel Time (min) at 25 °C | 210–260 | 240 |

| Curing Process at RT * | 24 h infusion and curing | 24 h infusion and curing |

| Post-Curing | 2 h at 80 °C | 16 h at 50 °C |

| Tensile Strength (MPa) | 47.10 | 72.50 |

| Tensile Modulus (GPa) | 2.68 | 3.21 |

| Flexural Strength (MPa) | 80.51 | 113 |

| Flexural Modulus (GPa) | 2.77 | 3.01 |

| Composite | Basalt Fibre Structure | Polymer Matrix |

|---|---|---|

| BF/Elium | BAS-UNI 550:

| Elium®191 XO/SA, three parts: 191 XO acrylic resin (50 wt%), 191 SA accelerator (50 wt%), and methyl ethyl ketone peroxide (MEKP) initiator (2 wt%) |

| BF/Epoxy | BAS-UNI 350:

| Epoxy PrimeTM 37, two parts: Epoxy resin (100 wt%) and slow hardener Ampreg 3X (29 wt%) |

| Composite | FVF (%) | h (mm) | Increment (%) | ρc (g/cm3) | Increment (%) | Mm (%) |

|---|---|---|---|---|---|---|

| BF/Elium-0D | 53.5 ± 0.01 | 2.46 ± 0.05 | - | 1.96 ± 0.02 | - | - |

| BF/Elium-45D | - | 2.47 ± 0.02 | 0.41 | 1.99 ± 0.03 | 1.6 | 0.85 ± 0.03 |

| BF/Elium-90D | - | 2.49 ± 0.09 | 1.22 | 2.01 ± 0.02 | 2.4 | 1.12 ± 0.01 |

| BF/Epoxy-0D | 47.8 ± 0.01 | 2.29 ± 0.07 | - | 1.89 ± 0.01 | - | - |

| BF/Epoxy-45D | - | 2.32 ± 0.04 | 1.31 | 1.87 ± 0.03 | 1.75 | 1.20 ± 0.02 |

| BF/Epoxy-90D | - | 2.33 ± 0.06 | 1.75 | 1.90 ± 0.04 | 3.2 | 1.48 ± 0.03 |

| Composite | σt (MPa) | Change% | Et (GPa) | Change% | σtn (MPa/(gr/cm3)) | Etn (GPa/(gr/cm3)) | µ (-) | G (GPa) |

|---|---|---|---|---|---|---|---|---|

| BF/Elium-0D | 1165 ± 49 | - | 44.1 ± 03 | - | 594 | 22.5 | 0.202 | 18.4 |

| BF/Elium-45D | 1009 ± 38 | −13.4 | 40.5 ± 02 | −8.3 | 507 | 20.3 | 0.207 | 16.8 |

| BF/Elium-90D | 933 ± 53 | −19.9 | 40.3 ± 02 | −8.6 | 465 | 20.1 | 0.208 | 16.7 |

| BF/Epoxy-0D | 880 ± 57 | - | 34.9 ± 02 | - | 478 | 17.9 | 0.189 | 14.3 |

| BF/Epoxy-45D | 622 ± 14 | −29.3 | 33.4 ± 02 | −4.2 | 332 | 18.1 | 0.193 | 14.0 |

| BF/Epoxy-90D | 538 ± 18 | −38.9 | 31.9 ± 01 | −8.5 | 283 | 16.8 | 0.197 | 13.3 |

| Composite | σf (MPa) | Reduction (%) | Ef (GPa) | Reduction (%) | σfn (MPa/(gr/cm3)) | Efn (GPa/(gr/cm3)) |

|---|---|---|---|---|---|---|

| BF/Elium-0D | 1128 ± 06 | - | 36.6 ± 1.49 | - | 576 | 18.7 |

| BF/Elium-45D | 992 ± 24 | −12 | 34.8 ± 1.66 | −4.8 | 499 | 17.8 |

| BF/Elium-90D | 952 ± 84 | −15.6 | 35.7 ± 0.46 | −2.4 | 474 | 18.2 |

| BF/Epoxy-0D | 662 ± 43 | - | 32.6 ± 3.08 | - | 360 | 17.7 |

| BF/Epoxy-45D | 390 ± 33 | −41.1 | 26.2 ± 1.44 | −19.4 | 208 | 14.0 |

| BF/Epoxy-90D | 244 ± 49 | −63.1 | 22.9 ± 1.07 | −29.8 | 129 | 18.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alsaadi, M.; Flanagan, T.; Devine, D.M. Seawater Ageing Effects on the Mechanical Performance of Basalt Fibre-Reinforced Thermoplastic and Epoxy Composites. J. Compos. Sci. 2025, 9, 368. https://doi.org/10.3390/jcs9070368

Alsaadi M, Flanagan T, Devine DM. Seawater Ageing Effects on the Mechanical Performance of Basalt Fibre-Reinforced Thermoplastic and Epoxy Composites. Journal of Composites Science. 2025; 9(7):368. https://doi.org/10.3390/jcs9070368

Chicago/Turabian StyleAlsaadi, Mohamad, Tomas Flanagan, and Declan M. Devine. 2025. "Seawater Ageing Effects on the Mechanical Performance of Basalt Fibre-Reinforced Thermoplastic and Epoxy Composites" Journal of Composites Science 9, no. 7: 368. https://doi.org/10.3390/jcs9070368

APA StyleAlsaadi, M., Flanagan, T., & Devine, D. M. (2025). Seawater Ageing Effects on the Mechanical Performance of Basalt Fibre-Reinforced Thermoplastic and Epoxy Composites. Journal of Composites Science, 9(7), 368. https://doi.org/10.3390/jcs9070368