Abstract

This study evaluated the effects of conventional cigarette smoke compared to aerosol from a heat-non-burn tobacco product on the color stability of two UDMA-based dental composite resins, namely a monochromatic (Omnichroma) and a polychromatic (Vittra APS) resin. Twenty disc-shaped specimens were prepared, divided into two groups of ten, and exposed to 105 cigarettes or 105 aerosol tobacco sticks via a custom-made smoking chamber. Puff duration was 2 s, with a 60 s interval between puffs in which smoke saturated the chamber for 30 s; then, clean air was introduced into the chamber for 30 s. Six puffs and six intervals were simulated. Color parameters were measured before and after exposure and following brushing of each specimen with 15 strokes. Color differences were determined based on the CIEDE2000 formula. Significant color change was found in all specimens exposed to cigarette and tobacco aerosol. The highest color-change mean value was obtained from composite resin exposed to cigarette smoke. Although both cigarette and thermal heating systems cause discoloration, the aerosol causes reduced composite resin discoloration, which compromises aesthetics and increases patient dissatisfaction, impacting the overall dental care. Color stability is the hallmark of success, as it is the main reason for replacing dental restorations.

1. Introduction

Living in the age of “images”, patients’ esthetic demands increase day by day. To achieve such goals, dental professionals use restorative materials that reproduce the optical properties of dental tissues [1]. Resin-based composites (RBCs) have gained broad acceptance because of their cost-effectiveness, conservative approach, easy handling, and esthetic properties [2]. A great number of RBCs with different characteristics are available in the market, and color stability is the hallmark of success, as it is considered to be one of the main reasons for replacement of dental restorations [2,3].

Both internal and external factors contribute to the discoloration of resin-based composites (RBCs). Internal factors are associated with the material’s composition, including the resin matrix, inorganic fillers, and initiators. External factors involve the adsorption of pigmented molecules from external sources like foods and beverages [2,4,5,6]. One of the main contributors to discoloration is the buildup of plague, which facilitates the retention of these pigments [7].

Cigarette smoke (CS) has been recognized as one of the factors causing stain and discoloration of composite resins since the early years of development of these dental restorative materials [8]. According to the World Health Organization, almost 1.3 billion people around the world have smoking habits [2,9]. When a conventional cigarette is lit and puffed, the tobacco is burned at temperatures between 600 °C and 900 °C, generating a mixed gas–particulate phase [3]. Tobacco smoke is a complex mixture of almost 4000 different components. The gas phase consists of nitrogen, oxygen, carbon dioxide, nitric oxide, carbon monoxide, and other components [10]. The particulate phase contains solid particles and liquid droplets with a diameter ranging from 0.1 mm to 1 mm, suspended in a gas phase [2,3]. When the particulate phase is trapped in a filter and the amount of water and nicotine present is isolated, the remaining content is referred to as “tar” [3,11]. Tobacco leaves contain pigmented compounds [10], and cigarette smoke includes metal ions such as lead and cadmium [3,12]. These substances are found in the tar produced during smoking and can either adhere to the surface or infiltrate the matrix of dental hard tissues and resin composite materials, leading to discoloration. The brown pigments in the particulate phase are primarily responsible for staining; however, the specific mechanisms by which smoking causes discoloration have not been fully explored [3,10,13]. The extent of discoloration is largely influenced by the number of brown deposits formed during the high-temperature combustion of tobacco. Consequently, reducing the tar content in cigarette smoke could potentially lessen the effects of smoking on the color stability of composite resins [3].

Electronic cigarettes (e-cigarettes) first appeared on the global market in the early 2000s. These devices can be categorized into two main types: Tobacco Heating Systems (THSs) and Electronic Nicotine Delivery Systems (ENDSs). THSs are specifically engineered to deliver nicotine extracted from tobacco leaves without the need for combustion [14]. This “heat-not-burn” approach utilizes a controlled heating system to avoid burning the tobacco.

The Tobacco Heating System 2.2 (THS 2.2), marketed as IQOS, is a heat-not-burn (HNB) tobacco product that has been successfully introduced to the global market. Despite its expanding market, few independent and systematic studies have been carried out to date [15]. THS 2.2 (IQOS) is a system based on specifically designed tobacco sticks which are heated using a blade and reach maximum temperatures of 350 °C to generate an aerosol [3,16,17]. The released aerosol consists of suspended liquid droplets, thus eliminating the production of solid particles while having a much different chemical composition than cigarette smoke. Most of the potentially harmful elements are more than 90% reduced in the heated tobacco sticks as compared to the combusted cigarettes [3,18,19]. The particulate matter (TPM) contained in the aerosol of THS 2.2 exhibits a substantially different chemical content compared to cigarette smoke, composed mainly of water and glycerin [3,19]. In addition, the particulate phase of THS 2.2 does not contain carbon-based solid particles in contrast to conventional smoke, which has been estimated to contain up to 10 [11] particles per 11 cigarette puffs [3,20]. E-cigarettes are claimed to be safer than conventional cigarettes and able to help in smoking cessation [2].

Unfortunately, very few studies [2,3,21] have examined the effects of these products on dental materials, and the possibility of the color change has not been fully investigated. To the best of our knowledge, recent research efforts are limited to the CS and electronic cigarette exposure to gingiva-colored porcelain and indirect composite resins [22], as well as to the CS and THS aerosol effect on the color stability of CAD/CAM restorative materials [23]. However, there is no literature data comparing the color-change result due to the exposure of contemporary dental composite resins to CS and aerosol of the new generation THS 2.2.

This study aims to evaluate the effect of conventional cigarette smoke (Marlboro red, Phillip Morris) compared to the aerosol derived from THS 2.2 (IQOS) on the color stability of two widely used dental composite resins. For this purpose, the studied composites will be exposed to the emitted smoke and aerosol into a customized chamber through a designed process imitating the dental restorative aging induced by the common smoking procedure. The null hypothesis was as follows:

- Such exposure mechanisms do affect the color stability of the resin composites;

- THS 2.2 tobacco aerosol causes less composite resin discoloration than the conventional cigarette smoke.

The findings will help educate dental practitioners on the long-term implications of smoking on color stability, as well as the impact on dental esthetics and support initiatives focused on the harm tobacco can cause, leading to smoking reduction.

2. Materials and Methods

2.1. Materials

Two different resin composites were tested for this study: the Vittra APS, Shade EA2 (FGM Dental Group, Joinville, Santa Catarina, 89219-501, Brazil); and the Omnichroma (Tokuyama Dental Corporation, Tokyo, Japan). Their composition is described in Table 1. Marlboro Red cigarettes (Papastratos, Athens, Greece, affiliated Company of Philip Morris International), tobacco sticks (TEREA Amber, Smartcore Sticks, Neuchatel, Switzerland), and THS 2.2 (IQOS Iluma Smartcore Induction System, Lausanne, Switzerland) were supplied from the Greek market.

Table 1.

Description of the studied resin composites’ content according to the manufacturer’s SDS data.

2.2. Specimen Preparation

Twenty disc-shaped specimens (8 mm × 2 mm) were prepared for each type of tested composite resin [13,24] and were divided into 2 subgroups (n = 10) exposed to conventional cigarette smoke and aerosol from THS 2.2 (IQOS), respectively.

The composite resin materials were initially placed into a Teflon matrix (8 mm in diameter and 2 mm in thickness) in two increments with a plastic spatula. The increments were then covered with a polyester strip and glass plates from both sides, and light pressure was applied to remove any excess material and to make the outer layer as smooth as possible. The specimens were then light-cured with an LED polymerization unit (Faro, Poliled 1200 mw/cm2) for 20 s each side. The discs were removed from the Teflon matrix and polished for 60 s with medium and fine light wet-polishing discs (Super-Snap, SHOFU). For each sample, a different disc was used. Specimens were stored to dry conditions before being mounted on two separate Styrofoam rectangular bases with marked positions to help us differentiate between the samples.

2.3. Specimen Exposure

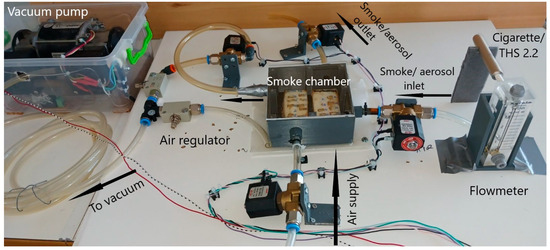

A custom-designed 3D-printed smoke chamber (dimensions: 12 × 12 × 5 cm) was constructed to simulate the smoking process under controlled laboratory conditions. The chamber featured four openings—one on each side—fitted with a low-pressure electrovalve (D263 DVG, 2/2, Nc, 1/4″, M&M, Bedford, UK) enabling precise control of air and smoke movement into and out of the chamber (Figure 1).

Figure 1.

Picture of the smoking apparatus, with each component labeled (smoking chamber, air supply, smoke/aerosol inlet, smoke/aerosol outlet, vacuum pump, and flowmeter).

The first opening was used as the smoke/aerosol inlet. A vertical flowmeter (EK-2NR, Kytola Instruments, Muurame, Finland) was placed between either the conventional cigarette or the Tobacco Heating System (THS 2.2), allowing accurate monitoring and regulation of flow rates during exposure. On the opposite side of the chamber, the second valve was connected to a vacuum pump (Type 90/30, RPM 1300/1600 Maraz Motor, Sant Boi de Llobregat, Spain), which was regulated via an external air regulator system. The third opening was connected to a clean air supply to flush the chamber between puffs, while the fourth served as the smoke/aerosol outlet following each exposure cycle.

The Styrofoam rectangular base with composite resins was mounted centrally on the bottom of the chamber (Figure 2), ensuring the horizontal exposure of all test samples to the incoming smoke/aerosol stream. Once the specimens were in place, the chamber was then sealed airtight with a transparent removable lid, which allowed for visual monitoring while preventing external contamination or loss of aerosol density. To accurately replicate the process of smoking, a pneumatic circuit controlled the puffing cycle. Each puff was set to last for 2 s, followed by a 60 s interval between puffs [25,26]. The chamber was filled with smoke or aerosol by applying negative pressure for 2 s [27] to ensure a constant flow of 1.8 mL/min and a uniform delivery across all specimens. After each puff, the chamber was left saturated with smoke or aerosol for 30 s to allow for adequate interaction with the composite surfaces. Subsequently, a clean-air airstream was introduced into the chamber for 30 s to purge the chamber before the next puff began. A cycle of 6 puffs and 6 corresponding intervals was administrated for both conventional cigarette and THS 2.2. Each conventional cigarette was allowed to burn to a standard distance of approximately 10 mm from the filter—ensuring consistency in smoke production across samples. The sequence and duration of each procedure—valve activation, puff duration, saturation, and flushing—were controlled by custom-developed software running on a single board computer (Raspberry Pi 4). This ensured repeatability, minimized operator variability, and allowed for precise control of exposure parameters.

Figure 2.

Specimens (a) before and after exposure to (b) Marlboro cigarette and (c) IQOS THS 2.2.

A total of 105 cigarettes and 105 tobacco sticks were consumed based on the simulation of smoking 15 cigarettes/tobacco sticks daily for 7 days [14]. When a total of 52 cigarettes/sticks were consumed, the Styrofoam bases were positioned in reverse to ensure equivalent smoke/aerosol exposure throughout the entire process. Following exposure, all specimens were carefully brushed under running water using a soft-bristled manual toothbrush applying 15 strokes to simulate daily oral hygiene practices.

2.4. Color Measurements

Color analysis was performed for all discs before (baseline) and after exposure in both conventional cigarette smoke and THS 2.2 aerosol (Figure 2). Color measurements were taken using a UV-2401PC ultraviolet–visible spectrophotometer from Shimadzu (Tokyo, Japan), which was operated with its accompanying software (UVPROBE v2.21, Shimadzu). The data collection was based on the illuminant D65 standard, representing average daylight conditions, with a 10-degree observation angle in reflectance mode on a black background corresponding to the basis of the sample holder. This process utilizes color measurement software (UVPC Color Analysis Ver. 3.02, Shimadzu). The spectrophotometer featured an integrating sphere (ISR-240 A, Shimadzu) with a 7 mm aperture that directed light perpendicularly (0 degrees) onto the specimen. Color-change values were computed using the CIEDE2000 color difference formula, as shown below:

where ΔE00 represents the color difference; and ΔL′, ΔC′, and ΔH′ are the differences in lightness (L), chroma (C), and hue (H) between two samples in the CIEDE2000 model. The term RT is a rotation factor that accounts for the interaction between chroma and hue differences, particularly in the blue region. The weighting functions, SL, SC, and SH, adjust the color differences based on their position in the L*, a*, and b* coordinates of the CIELab color space, where L* indicates lightness (ranging from 0 for black to 100 for white), a* denotes the red–green axis (a* > 0 for red, a* < 0 for green), and b* signifies the yellow–blue axis (b* > 0 for yellow, b* < 0 for blue). The parametric factors, KL, KC, and KH, are specific to experimental conditions, and in this study, these factors were set to 1 [28].

2.5. Statistical Analysis

Descriptive statistics were calculated using mean value and standard deviation (SD). Τhe assumption of normal distribution was investigated using the Shapiro–Wilkinson test (Appendix A). Two-way analysis of variance (two-way ANOVA) was performed to evaluate the effect on color change (ΔE00) of dental composite resins from cigarette-smoke exposure and heated cigarette’s aerosol and the difference of CIE (L*a*b*) values (Δ = after–before). Paired samples t-test was used to compare CIE (L*a*b*) values before and after smoke exposure. Statistical analysis was performed using “SPSS Statistics v.28”, and statistical significance level was set up at p-value ≤ 0.05. A rigorous power analysis using the G*Power software (3.1.9.7 version) was performed to determine the appropriate sample size for the study. The analysis was based on achieving 80% power at a significance level of 0.05.

3. Results

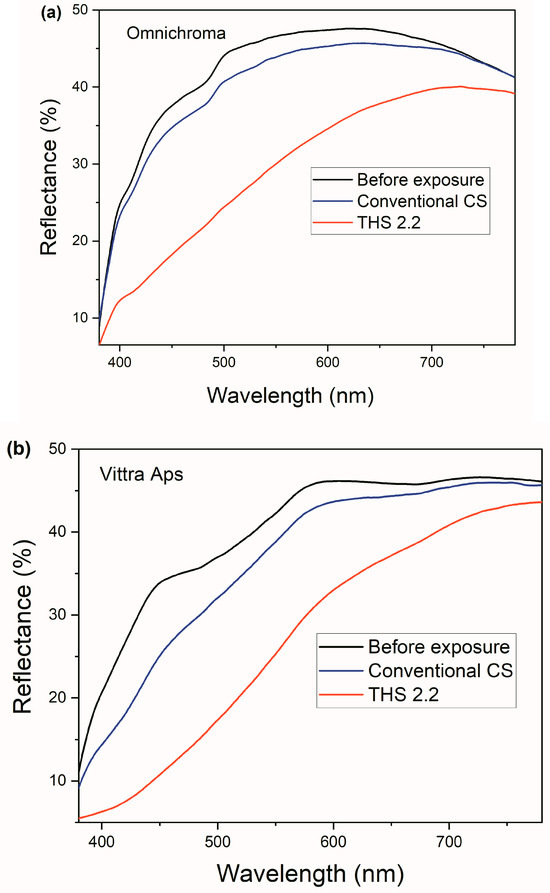

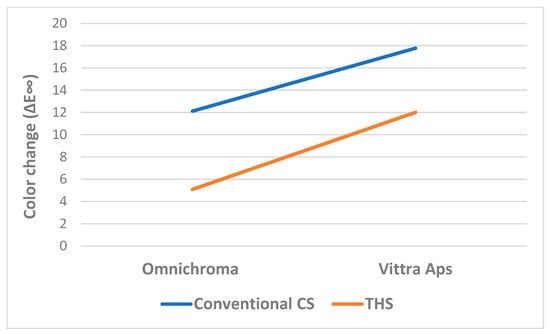

Typical UV-Vis spectra obtained for Omnichroma and Vittra APS composite resins before and after cigarette smoke and THS 2.2 exposure are presented in Figure 2. It is obvious that the pattern of both dental restorative materials exhibited substantial changes over the whole acquisition range, especially when the composites were subjected to cigarette smoke-aging conditions. Table 2 lists the color-change values (ΔE00) calculated for the studied dental restorative materials after their exposure to conventional cigarette smoke or THS 2.2 aerosol. The observed tendencies among the tested dental composites under the selected smoking conditions are also illustrated in Figure 3. It is clear that there was a significant effect for both types of composite resins and the type of smoke exposure on the acquired ΔE00 values. In particular, exposure to conventional cigarette smoke resulted in greater ΔE00 change compared to heated cigarette’s aerosol whether Omnichroma (p-value = 0.012) or Vittra APS resin (p-value = 0.037) was used.

Table 2.

ΔE00 values (mean ± SD) for both composite resins exposed to conventional cigarette and heated-tobacco aerosol.

Figure 3.

Representative UV-Vis spectra recorded for (a) Omnichroma and (b) Vittra APS composite resins before and after specimen’s exposure to conventional CS (Marlboro) and THS 2.2 (IQOS).

Additionally, the use of Vittra APS resin induced a statistically significant higher change in color (ΔE00) than the use of Omnichroma resin, whether there was exposure to conventional cigarette smoke (p-value = 0.041) or to a heated cigarette’s aerosol (p-value = 0.014).

The interaction plot (Figure 4) shows that the midpoint values between the two edges of the presented straight lines correspond to significant ΔE00 differences, namely 8.61 and 14.90 for Omnichroma and Vittra APS, respectively, verifying that there is a main effect of the type of dental composite resin on the color change. Moreover, the midpoints on the lines of the conventional CS (ΔE00 = 14.95) and THS (ΔE00 = 8.55) differ considerably, hence highlighting the main effect of the smoke exposure on the color change. Since the lines of the plot cross each other, there is no interaction effect between the type of smoke exposure and composite resin.

Figure 4.

Interaction plot indicating the mean color change by smoking exposure and dental-composite resin.

The CIE (L*a*b*) values extracted by the manipulation of the recorded UV-Vis spectra are given in Table 3. It can be seen that there is a significant effect for both types of composite resins and the type of smoke exposure on the change (Δ = after–before) of CIE (L*a*b*) values.

Table 3.

Mean ± standard deviation and color change (Δ = after − before) of CIE (L*, a*, and b*) values for the two dental composite resins after exposure to conventional cigarette smoke (CS) and THS 2.2 tobacco aerosol.

More specifically, exposure of Omnichroma composite resin to conventional cigarette smoke resulted in a statistically significant increase in a* (Δa* = 2.95, p < 0.001) and b* (Δb* = 12.11, p < 0.001), while exposure to a heated cigarette’s aerosol did not cause significant change in L*, a*, and b* parameters. In terms of the Vittra APS composite resin, the presence of conventional cigarette smoke led to a significant reduction of L* (ΔL* = −17.74, p < 0.001), but a significantly increased value of a* (Δa* = 3.81, p < 0.001) and b* (Δb* = 14.49, p < 0.001). On the other hand, when it was subjected to THS 2.2 aerosol, a significant decrease in L* (ΔL* = −11.24, p = 0.007) and a* (Δa* = −1.15, p < 0.001) was recorded, unlike the value of b*, which was significantly decreased (Δb* = 5.30, p < 0.001).

Regarding the differences in change (Δ) of CIE (L*a*b*) values between the type of composite resin and the type of smoke exposure, it can be stated that exposure to conventional cigarette smoke induced a higher decrease in L* value (ΔL* = after–before) in Vittra APS resin in comparison to Omnichroma resin (−17.74 vs. −2.37, p < 0.001), and it led to a greater increase in a* value (Δa* = after–before) in Vittra Apps resin than in Omnichroma resin (3.81 vs. 2.95, p = 0.006). In addition, the presence of a heated cigarette’s aerosol reduced the L* value (ΔL* = after–before) in Vittra Apps resin, while it increased the L* value in Omnichroma resin (−11.24 vs. 1.31, p = 0.003). This resulted in a decrease in the a* value (Δa* = after–before) in Vittra APS resin, while the a* value was increased in Omnichroma resin (−1.15 vs. 0.19, p < 0.001). Finally, the increase in b* value (Δb* = after–before) in Vittra APS resin was higher than that in Omnichroma resin (14.49 vs. 12.11, p = 0.039). Regarding the Omnichroma resin, conventional cigarette-smoke exposure yielded a greater increase in the a* value in comparison to THS 2.2 aerosol (2.95 vs. 0.19, p < 0.001). In addition, conventional cigarette-smoke composite aging resulted in a higher increase in b* value than the exposure to THS 2.2 (12.11 vs. 1.10, p < 0.001). When the Vittra Apps resin was exposed to conventional cigarette smoke, the a* value was raised, while the exposure to a heated cigarette’s aerosol reduced this value (3.81 vs. −1.15, p < 0.001). Furthermore, the resulting increase in b* value due to exposure to conventional cigarette smoke was higher in comparison to the one produced from THS 2.2 aerosol (14.49 vs. 5.30, p < 0.001).

4. Discussion

The findings of this study presented significant differences in the color change in dental composite resins for both exposure methods. The results indicated that THS 2.2 tobacco aerosol led to less discoloration than conventional cigarette smoke. Therefore, the null hypothesis was not rejected.

This study evaluated and compared the effects of exposure from conventional cigarettes and THS 2.2 on color change in two different composite resins. Vittra APS was commercially introduced as a Bisphenol A (BPA)-free and Advanced Polymerization System (APS), containing low concentration of camphorquinone, capable of amplifying its curing capacity and providing longer working time (8 min). On the other hand, Omnichroma is a one-shade universal composite reinforced with uniformly sized 260 nm spherical fillers (SiO2-ZrO2) that generate red-to-yellow color without the need of added pigments or dyes. The latter combines with the reflected color of the patient’s surrounding dentition, creating the perfect match from A1 to D4 and beyond.

The rationale behind selecting these two types of composite resins lies in their properties, which influence their color stability when exposed to conventional and tobacco aerosols. One composite resin is monochromatic, meaning it has a uniform color and lacks additional layering effects, while the other is polychromatic, designed to mimic the natural gradient and translucency of dental enamel and dentin.

The advanced CIEDE2000 formula was used to quantify the color differences, providing an accurate approach to human perception by applying positional corrections in the CIE (L*a*b*) color space. The calculated ΔE00 parameter is considered as a standardized tool for evaluation and comparison of color change in color science. According to the established criteria in aesthetic restorations, when ΔE < 1, any color alteration cannot be detected by the human visual perception; if 1 < ΔE < 3.3, it can be detected only by an experienced dentist; and ΔE > 3.3 changes can be easily detected by anyone and are clinically unacceptable [29,30]. The results of this study revealed significant change in color (ΔE00 > 3.3) for both the tested restorative materials after exposure, regardless of the selected type of smoking. Consequently, the null hypothesis that exposure of dental composite resins to smoke from conventional cigarettes and aerosol of THS 2.2 does affect their color stability was verified. The specimens became darker and obtained their brown coloration after their exposure, and the coloration was readily noticeable to the naked eye. It was also revealed that the combination Vittra APS–conventional cigarette was the most vulnerable to discoloration (ΔE00 = 17.78 ± 4.19, p = 0.041), while the most color-stable combination was Omnichroma–THS 2.2 aerosol (ΔE00 = 5.09 ± 5.71, p = 0.012). Though Omnichroma showed less discoloration after exposure to both types of smoking than Vittra APS, its color change was visible to the naked eye. The role of each dental composite resin’s organic matrix and its interaction with volatile components originated from smoke and aerosol may be possible contributors to the results observed. In particular, the oxidation potential of aerosol components and their chemical reactivity with unreacted monomers or initiators could be involved in the discoloration mechanism. Similarly, the interaction of hygroscopic components in aerosols (e.g., glycerin) with the hydrophilic monomers in the composite matrix might affect the color instability. As color stability is the hallmark of success in esthetic dental materials, smoking is a factor that can lead to color mismatch between the tooth and the restoration and, subsequently, failure of the restoration.

Regarding the discoloration process based on the conventional cigarette smoke, the decreased values of the L* coordinate for Omnichroma and Vittra APS are consistent with the results of previous studies, which showed that cigarette smoke causes alterations to RBC’s color due to the reduction of luminosity [10,13,31]. This is of the utmost importance, as the human eye can perceive the variations in the L* axis more clearly than in the a* and b* axes because the quantity of the rods, namely the cells responsible for vision in black and white, is much higher than the cells which are responsible for color vision, in a ratio of 20:1 (cones). This verifies the significance of luminosity for clinical success of dental restorative materials [2,13]. It is believed that cigarette smoke induces alterations in composite resins by adsorption of external pigments which interact with unreacted resin monomers and might be correlated with surface degradation [32]. This explains the observed dark brown staining of dental composite resins that is generally attributed to the pigments contained in tobacco leaves or in the tar which is the tobacco particulate phase [2]. Moreover, the exposure to cigarette smoke increased the redness and yellowness (a* and b* coordinates) of the composite resins studied, an observation which is in agreement with the possible deposition of brown pigments from tobacco leaves.

The ΔE00 data comparisons between the two types of smoking (Omnichroma: p < 0.012, Vittra APS: p < 0.037) align with previous reports revealing that color change in composite resins exposed to THS 2.2 aerosol was significantly less pronounced than in samples exposed to cigarette smoke [3,21]. These observations also agree with the second part of the null hypothesis. According to the literature data [3], aerosol from THS 2.2 caused only a slight increase in yellowness of the tested samples, while the cigarette smoke resulted in a 6–8-times-higher ΔΕ. In the present study, exposure to THS 2.2 aerosol decreased lightness and increased yellowness in Vittra APS significantly, but it did not have the same effect with Omnichroma. A previous study [21] showed that discoloration caused by THS 2.2 did not even reach the clinically unacceptable threshold (ΔΕ < 3.3). However, the color changes, as determined here, exceeded the clinically acceptable limit not only for Vittra APS (ΔE00 = 12.02) but also for the Omnichroma (ΔE00 = 5.09) composite resin after exposure to THS 2.2. Another study [15] reported that although carbonyl compounds, ammonia, and N-nitrosoanabasine (NAB) released from THS 2.2 were much lower than the standard reference cigarette (3R4F), the measured levels of tar and nicotine were similar [33]. Since tar is the main cause of discoloration, this would explain the change in color of the composite resins under both kinds of exposure. Moreover, although nicotine is colorless in its original state, oxidized nicotine can cause yellowish discoloration [14,21]. Considering the observed large standard deviations of ΔE00, especially in the aerosol-exposed composites, possible causes of variability could be uneven surface finishing, heterogeneity in polymerization, or inconsistencies in specimen handling.

The lightness parameter (L*) level dropped significantly for the Vittra APS composite resin for both types of exposure. For the THS 2.2 group, the red–green coordinate (a*) shifted toward green (Δa* < 0), and the yellow–blue coordinate (b*) shifted toward yellow (Δb* > 0). The Vittra APS–cigarette smoke group showed an increase in a* (Δa* > 0) and b* (Δb* > 0), shifting toward red and yellow, respectively. Τhe corresponding CIE (L*a*b*) coordinates were found to alter to a lower degree for Omnichroma regardless of the selected exposure mechanism. In particular, the a* and b* parameters turned red and yellow in each case. The differentiated color tendencies among the tested composite resins could be attributed to their specific composition. According to manufacturers’ data (Table 1), the higher monomer content of UDMA and TEGDMA for Vittra APS can contribute to more unreacted double bonds, even after curing, along with the availability for hydrogen bonding, leading to stronger interactions with compounds derived from either cigarette smoke or THS 2.2 aerosol. Furthermore, the different sizes of fillers within Vittra APS and Omnichroma (Table 1) and, more specifically, a possible distinct size distribution of inorganic fillers on the composite surface could also account for the observed diversity of color parameters.

It is worth pointing out, in regard to study limitations, that there are several parameters which could have affected the produced outcome, such as the size of the utilized chamber, the distance from the smoke inlet, the type and the number of puffed cigarettes, the flow of the smoke, and the time dental composite resins were exposed. The type of composite resins, and the finishing and polishing of the surfaces are important festures that may affect the color-stability results [34,35]. Τhe different amount and width of the air voids incorporated during layering and micro-cracks generated during finishing and polishing may lead to the retention of colored agents [2]. In addition, mouth conditions are difficult to simulate, as tongue and saliva play an important role in mechanical cleaning of teeth and dental restorations [13]. Discoloration can be influenced by real-life oral environments involving dynamic salivary flow, enzymatic activity, thermal cycling, mechanical stress from mastication, and biofilm formation. Future investigations could also explore longer-term exposures, including a broader range of resin materials, and incorporate surface roughness and gloss measurements. Evaluating the impact of saliva, thermal cycling, and bacterial biofilms through in situ studies would provide more clinically relevant data, contributing to a better understanding of how different smoking alternatives influence the longevity and esthetics of dental restorations. Recent work by Szczesio-Wlodarczyk et al. [36] demonstrates how combining hydrolytic aging with thermomechanical challenges can better predict material degradation. And while the 2 mm thickness enabled standardized comparisons, it does not reflect the optical behavior of thinner restorations (e.g., 0.5 mm veneers), as underlying tooth structure and adhesive layers influence perceived color. Future studies should incorporate gradient thickness models (0.5–2.0 mm) to evaluate how discoloration scales with depth, particularly for polychromatic materials like Omnichroma, mimicking protocols using dentin or enamel analogs beneath composites to simulate clinical light interactions and performing multilayer restorations to assess interfacial staining risks, as suggested by recent work on aesthetic longevity [36].

The discoloration caused by cigarette smoke and aerosol exposure highlights the need for ways to improve the color stability of composite resins in patients that use tobacco on a daily basis. Future research could investigate the possibility of using stain-resistant composite formulations, protective surface sealants or ceramic coatings to protect color stability of composite resins, along with clinicians reinforcing proper oral hygiene practices to prolong the aesthetic performance of restorations. Addressing such factors may reduce restoration replacement rates and improve long-term patient satisfaction in restorative dentistry.

5. Conclusions

Two dental restorative materials were exposed to conventional cigarette smoke and THS 2.2 tobacco aerosol. It was found that both types of selected aging procedures can affect the color of the tested composite resins and cause discoloration beyond the clinically acceptable limit. However, it was also shown that THS 2.2 aerosol has reduced composite resin discoloration in comparison to conventional cigarette smoke. The exact mechanism by which tobacco smoke and aerosol affect the interaction of resin surfaces with ambient light is not well known, and further investigation needs to be carried out, especially under in vivo conditions. The observed discoloration of composite resin restorations may not only affect the esthetic longevity of dental restorations but also lead to patient dissatisfaction and lack of confidence in their dental care.

The present study directly compares the discoloration effects of conventional cigarette smoke and heat-not-burn tobacco aerosol on both monochromatic (Vittra APS) and polychromatic (Omnichroma) UDMA-based composite resins under standardized experimental conditions. It provides evidence that while both exposure types cause clinically unacceptable discoloration, aerosol from heat-not-burn products induces comparatively less color change, unlike previous studies which focused solely on tobacco products and helping understand the impact of modern tobacco products on dental materials.

Author Contributions

Conceptualization, M.G.M., O.G., A.K.N., C.G. and E.A.K.; methodology, A.K.N., C.G. and E.A.K.; software, C.G.; validation, M.G.M., O.G. and A.K.N.; formal analysis, M.G.M., O.G. and A.K.N.; resources, A.K.N., C.G. and E.A.K.; data curation, M.G.M., O.G. and A.K.N.; writing—original draft preparation, M.G.M.; writing—review and editing, O.G. and A.K.N.; supervision, O.G., A.K.N., C.G. and E.A.K.; project administration, C.G. and E.A.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data will be available upon request.

Acknowledgments

The experimental procedures were performed at the Department of Basic Dental Sciences, Division of Dental Tissues Pathology and Therapeutics, School of Dentistry, Aristotle University of Thessaloniki, Greece.

Conflicts of Interest

The authors declare no conflicts of interest. The authors do not have any financial interest in the companies whose materials are included in this article.

Abbreviations

The following abbreviations are used in this manuscript:

| RBCs | Resin-based composites |

| CS | Cigarette smoke |

| THS | Tobacco Heating System |

| ENDS | Electronic Nicotine Delivery System |

| HNB | Heat-not-burn |

| TPM | The particulate matter |

Appendix A

Statistical analysis—Assumptions

- (1)

- For each combination of smoke exposure and resin, the assumption of normal distribution for L*, a*, b*, and Δ values was investigated using the Shapiro–Wilk test.

Table A1.

This is a table caption.

Table A1.

This is a table caption.

| Omnichroma | Vittra Apps | ||||||

|---|---|---|---|---|---|---|---|

| Before | After | Δ (After–Before) | Before | After | Δ (After–Before) | ||

| Conventional cigarette’s smoke (Marlboro) | L* | 0.235 | 0.173 | 0.743 | - a | 0.063 | 0.050 |

| a* | 0.674 | 0.745 | 0.869 | - a | 0.192 | 0.192 | |

| b* | 0.240 | 0.680 | 0.052 | - a | 0.079 | 0.079 | |

| Heated cigarette’s smoke (IQOS) | L* | 0.303 | 0.051 | 0.050 | 0.947 | 0.136 | 0.178 |

| a* | 0.532 | 0.948 | 0.308 | 0.336 | 0.403 | 0.219 | |

| b* | 0.305 | 0.658 | 0.155 | 0.785 | 0.083 | 0.050 | |

a Constant value in this combination of smoke exposure and resin.

All p-values are equal or greater than 0.050, so the assumption of the normal distribution is valid for all the combinations of resin + smoke exposure.

- (2)

- For the two-way ANOVA test, the assumption of normality is valid (as shown in the above table). The assumption of homogeneity of variances across groups (resin*smoke exposure) was examined using Levene’s test.

| p-Value from Levene’s Test | |

| L* before | <0.001 |

| a* before | <0.001 |

| b* before | <0.001 |

| L* after | 0.084 |

| a* after | 0.194 |

| b* after | 0.203 |

| ΔL* (after–before) | 0.443 |

| Δa* (after–before) | 0.219 |

| Δb* (after–before) | 0.224 |

References

- Barbosa, G.F.; Santos, S. Effects of cigarette smoke on color change of resin composites. Am. J. Dent. 2018, 31, 3–6. [Google Scholar]

- Paolone, G.; Pavan, F.; Mandurino, M.; Baldani, S.; Guglielmi, P.C.; Scotti, N.; Cantatore, G.; Vichi, A. Color stability of resin-based composites exposed to smoke. A systematic review. J. Esthet. Restor. Dent. 2023, 35, 309–321. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Zanetti, F.; Majeed, S.; Pan, J.; Malmstrom, H.; Peitsch, M.C.; Hoeng, J.; Ren, Y.-F. Effects of cigarette smoking on color stability of dental resin composites. Am. J. Dent. 2017, 30, 316–322. [Google Scholar] [PubMed]

- Ertas, E.; Gueler, A.U.; Yuecel, A.C.; Koepruelue, H.; Gueler, E. Color stability of resin composites after immersion in different drinks. Dent. Mater. J. 2006, 25, 371–376. [Google Scholar] [CrossRef]

- Belli, S.; Tanriverdi, F.F.; Belli, E. Colour stability of three esthetic laminate materials against to different staining agents. J. Marmara Univ. Dent. Fac. 1997, 2, 643–648. [Google Scholar] [PubMed]

- Paolone, G.; Formiga, S.; De Palma, F.; Abbruzzese, L.; Chirico, L.; Scolavino, S.; Goracci, C.; Cantatore, G.; Vichi, A. Color stability of resin-based composites: Staining procedures with liquids—A narrative review. J. Esthet. Restor. Dent. 2022, 34, 865–887. [Google Scholar] [CrossRef]

- Asmussen, E.; Hansen, E.K. Surface discoloration of restorative resins in relation to surface softening and oral hygiene. Scand J. Dent. Res. 1986, 94, 174–177. [Google Scholar] [CrossRef]

- Raptis, C.N.; Powers, J.M.; Fan, P.L.; Yu, R. Staining of composite resins by cigarette smoke. J. Oral Rehabil. 1982, 9, 367–371. [Google Scholar] [CrossRef]

- Stratton, K.; Shetty, P.; Wallace, R.; Bondurant, S. Clearing the smoke: The science base for tobacco harm reduction—Executive summary. Tob. Control 2001, 10, 189–195. [Google Scholar] [CrossRef]

- Mathias, P.; Rossi, T.A.; Cavalcanti, A.N.; Lima, M.J.P.; Fontes, C.M.; Nogueira-Filho, G.D.R. Cigarette smoke combined with staining beverages decreases luminosity and increases pigmentation in composite resin restorations. Compend. Contin. Educ. Dent. 2011, 32, 66–70. [Google Scholar]

- Thielen, A.; Klus, H.; Müller, L. Tobacco smoke: Unraveling a controversial subject. Exp. Toxicol. Pathol. 2008, 60, 141–156. [Google Scholar] [CrossRef] [PubMed]

- Takeuchi, C.Y.G.; Corrêa-Afonso, A.M.; Pedrazzi, H.; Dinelli, W.; Palma-Dibb, R.G. Deposition of lead and cadmium released by cigarette smoke in dental structures and resin composite. Microsc. Res. Tech. 2011, 74, 287–291. [Google Scholar] [CrossRef] [PubMed]

- Wasilewski, M.D.; Takahashi, M.K.; Kirsten, G.A.; de Souza, E.M. Effect of cigarette smoke on color stability and surface roughness of dental composites. J. Dent. 2013, 41 (Suppl. S3), e73–e79. [Google Scholar]

- Wang, Y.; Ryu, R.; Seo, J.-M.; Lee, J.-J. Effects of conventional and heated tobacco product smoking on discoloration of artificial denture teeth. J. Prosthet. Dent. 2022, 128, 206–210. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Luo, Y.; Jiang, X.; Zhang, H.; Zhu, F.; Hu, S.; Hou, H.; Hu, Q.; Pang, Y. Chemical Analysis and Simulated Pyrolysis of Tobacco Heating System 2.2 Compared to Conventional Cigarettes. Nicotine Tob. Res. 2019, 21, 111–118. [Google Scholar] [CrossRef] [PubMed]

- Smith, M.R.; Clark, B.; Lüdicke, F.; Schaller, J.-P.; Vanscheeuwijck, P.; Hoeng, J.; Peitsch, M.C. Evaluation of the Tobacco Heating System 2.2. Part 1: Description of the system and the scientific assessment program. Regul. Toxicol. Pharmacol. 2016, 81 (Suppl. S2), S17–S26. [Google Scholar] [CrossRef]

- Schaller, J.-P.; Pijnenburg, J.P.M.; Ajithkumar, A.; Tricker, A.R. Evaluation of the Tobacco Heating System 2.2. Part 3: Influence of the tobacco blend on the formation of harmful and potentially harmful constituents of the Tobacco Heating System 2.2 aerosol. Regul. Toxicol. Pharmacol. 2016, 81 (Suppl. S2), S48–S58. [Google Scholar] [CrossRef]

- Phillips, B.; Veljkovic, E.; Boué, S.; Schlage, W.K.; Vuillaume, G.; Martin, F.; Titz, B.; Leroy, P.; Buettner, A.; Elamin, A.; et al. An 8-month systems toxicology inhalation/cessation study in Apoe−/− mice to investigate cardiovascular and respiratory exposure effects of a candidate modified risk tobacco product, THS 2.2, compared with conventional cigarettes. Toxicol. Sci. 2016, 149, 411–432. [Google Scholar] [CrossRef]

- Schaller, J.-P.; Keller, D.; Poget, L.; Pratte, P.; Kaelin, E.; McHugh, D.; Cudazzo, G.; Smart, D.; Tricker, A.R.; Gautier, L.; et al. Evaluation of the Tobacco Heating System 2.2. Part 2: Chemical composition, genotoxicity, cytotoxicity, and physical properties of the aerosol. Regul. Toxicol. Pharmacol. 2016, 81 (Suppl. S2), S27–S47. [Google Scholar] [CrossRef]

- Pratte, P.; Cosadney, S.; Goujon, G.C. Investigation of solid particles in the mainstream aerosol of the tobacco heating system THS2.2 and mainstream smoke of a 3R4F reference cigarette. Hum. Exp. Toxicol. 2017, 36, 1115–1120. [Google Scholar] [CrossRef]

- Zanetti, F.; Zhao, X.; Pan, J.; Peitsch, M.C.; Hoeng, J.; Ren, Y. Effects of cigarette smoke and tobacco heating aerosol on color stability of dental enamel, dentin, and composite resin restorations. Quintessence Int. 2019, 50, 156–166. [Google Scholar] [CrossRef] [PubMed]

- Erdogan, M.A.; Kalyoncuoğlu, Ü.T.; Erdemli, B.Y. Comparative effects of conventional and electronic cigarettes on discoloration and surface roughness of gingiva-colored dental materials. J. Prosthodont. 2025, 34, 511–519. [Google Scholar] [CrossRef]

- Makkeyah, F.; El Sergany, O.; Shamel, M.; Al Ankily, M. Effect of conventional cigarette smoking and recent heated tobacco products on CAD/CAM restorative materials. BMC Oral Health 2024, 24, 765. [Google Scholar] [CrossRef]

- Paolone, G.; Pavan, F.; Guglielmi, P.C.; Scotti, N.; Cantatore, G.; Vichi, A. In vitro procedures for color stability evaluation of dental resin-based composites exposed to smoke: A scoping review. Dent. Mater. J. 2022, 41, 791–799. [Google Scholar] [CrossRef] [PubMed]

- Cooperation Centre for Scientific Research Relative to Tobacco. Coresta Guide No 22, Technical Guide for the Selection of Appropriate Intense Vaping Regimes for E-Vapour Devices; Version 2-Systematic Revision; Cooperation Centre for Scientific Research Relative to Tobacco: Knoxville, TN, USA, 2024. [Google Scholar]

- Patil, S.S.; Dhakshaini, M.R.; Gujjari, A.K. Effect of cigarette smoke on acrylic resin teeth. J. Clin. Diagn. Res. 2013, 7, 2056–2059. [Google Scholar]

- Cerami, C.; Founds, H.; Nicholl, I.; Mitsuhashi, T.; Giordano, D.; Vanpatten, S.; Lee, A.; Al-Abed, Y.; Vlassara, H.; Bucala, R.; et al. Tobacco smoke is a source of toxic reactive glycation products. Proc. Natl. Acad. Sci. USA 1997, 94, 13915–13920. [Google Scholar] [CrossRef]

- Şahin, O.; Koroglu, A.; Dede, D.Ö.; Yilmaz, B. Effect of surface sealant agents on the surface roughness and color stability of denture base materials. J. Prosthet. Dent. 2016, 116, 610–616. [Google Scholar] [CrossRef]

- Alnasser, H.A.; Elhejazi, A.A.; Al-Abdulaziz, A.A.; Alajlan, S.S.; Habib, S.R. Effect of Conventional and Electronic Cigarettes Smoking on the Color Stability and Translucency of Tooth Colored Restorative Materials: An In Vitro Analysis. Coatings 2021, 11, 1568. [Google Scholar] [CrossRef]

- Mathias, P.; Costa, L.; Saraiva, L.O.; Rossi, T.A.; Cavalcanti, A.N.; Nogueira-Filho, G.D.R. Morphologic Texture Characterization Allied to Cigarette Smoke Increase Pigmentation in Composite Resin Restorations. J. Esthet. Restor. Dent. 2010, 22, 252–259. [Google Scholar] [CrossRef] [PubMed]

- Wasilewski, M.D.S.A.; Takahashi, M.K.; Kirsten, G.A.; De Souza, E.M. Effect of cigarette smoke and whiskey on the color stability of dental composites. Am. J. Dent. 2010, 23, 4–8. [Google Scholar] [PubMed]

- Theobaldo, J.D.; Vieira Junior, W.F.; Cortellazzi, K.L.; Marchi, G.M.; Nunes Leite Lima, D.A.; Aguiar, F.H.B. Effects of cigarette smoke on color, roughness and gloss of high-viscosity bulk-fill resin composites. Am. J. Dent. 2020, 33, 83–88. [Google Scholar]

- Kentucky Tobacco Research & Development Center. 3R4F Preliminary Analysis. Available online: https://ctrp.uky.edu/assets/pdf/webdocs/3R4F%20Preliminary%20Analysis.pdf (accessed on 5 June 2025).

- Jefferies, S.R. The art and science of abrasive finishing and polishing in restorative dentistry. Dent. Clin. N. Am. 1998, 42, 613–627. [Google Scholar] [CrossRef]

- Gonulol, N.; Yilmaz, F. The effects of finishing and polishing techniques on surface roughness and color stability of nano-composites. J. Dent. 2012, 40 (Suppl. S2), e64–e70. [Google Scholar] [CrossRef]

- Szczesio-Wlodarczyk, A.; Kopacz, K.; Ranoszek-Soliwoda, K.; Sokolowski, J.; Bociong, K. Towards the Standardization of Artificial Aging Protocols for Dental Composites: Evaluation of Proposed Methods. J. Funct. Biomater. 2025, 16, 49. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).