Lightweight Textile and Fiber-Reinforced Composites for Soft Body Armor (SBA): Advances in Panel Design, Materials, and Testing Standards

Abstract

1. Introduction

2. Review Methodology

3. Frontal Soft Body Armor (SBA) Panel Design for Females

3.1. Design and Production

3.1.1. Traditional Cutting and Stitching Method

3.1.2. Folding Method

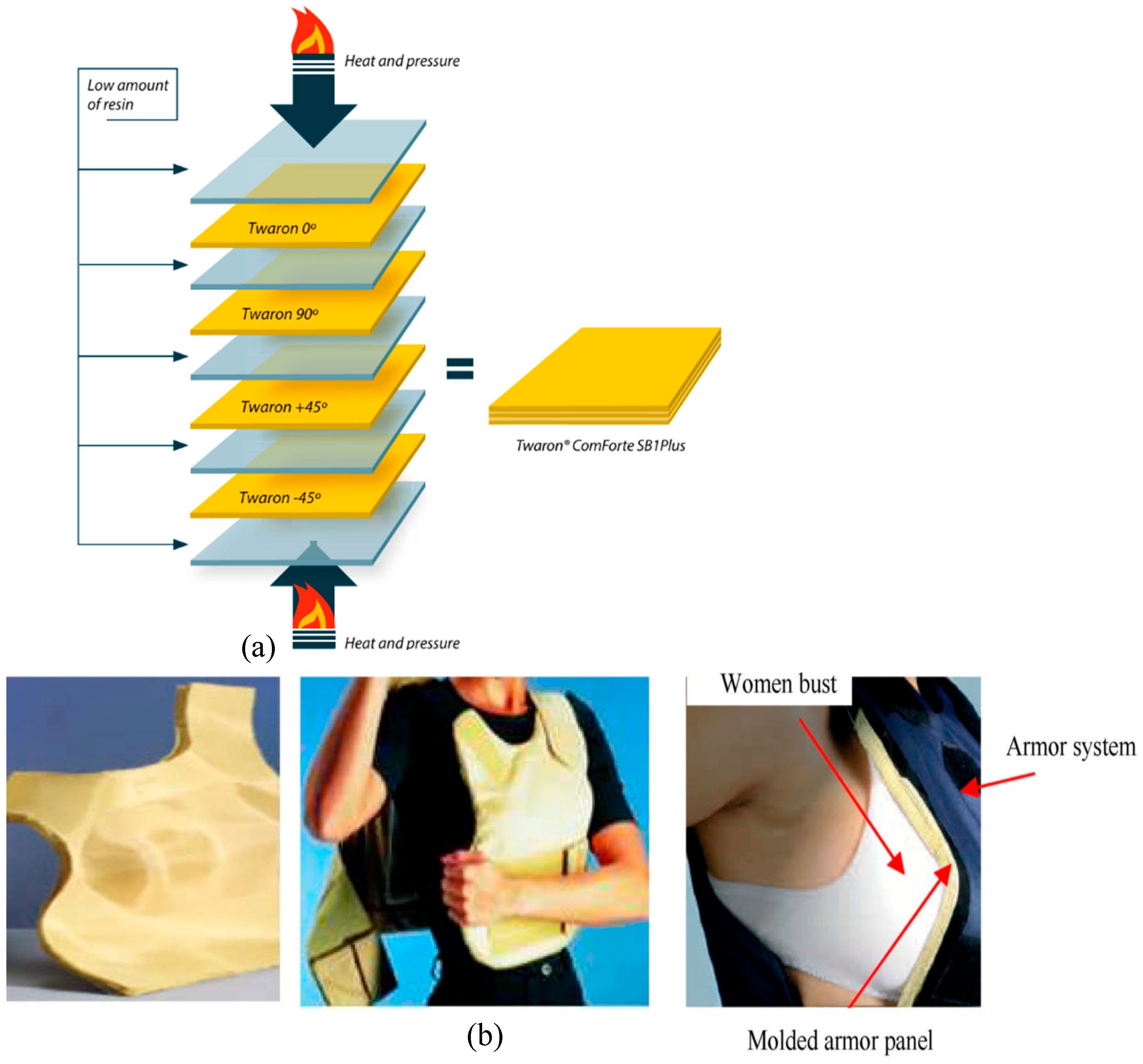

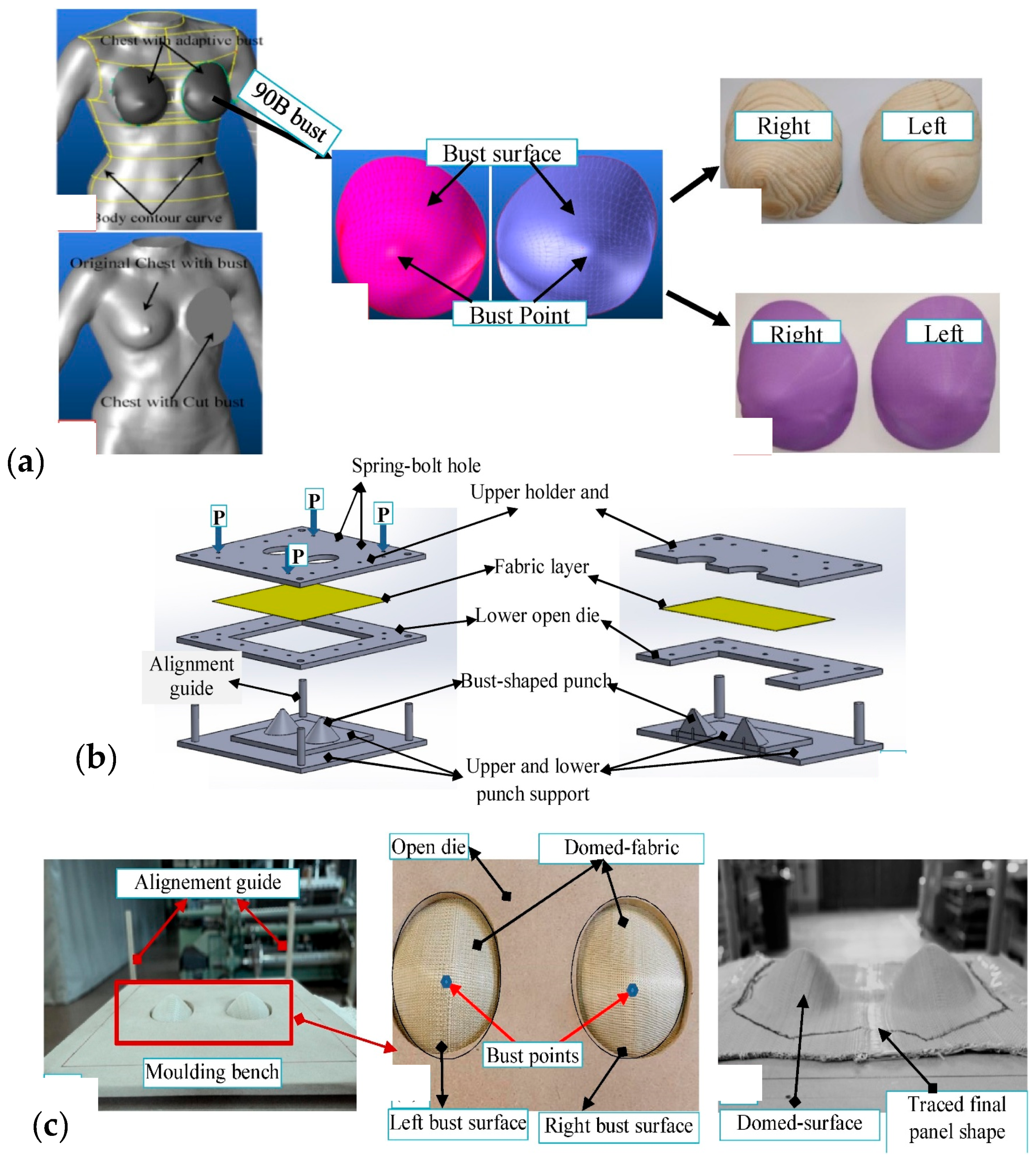

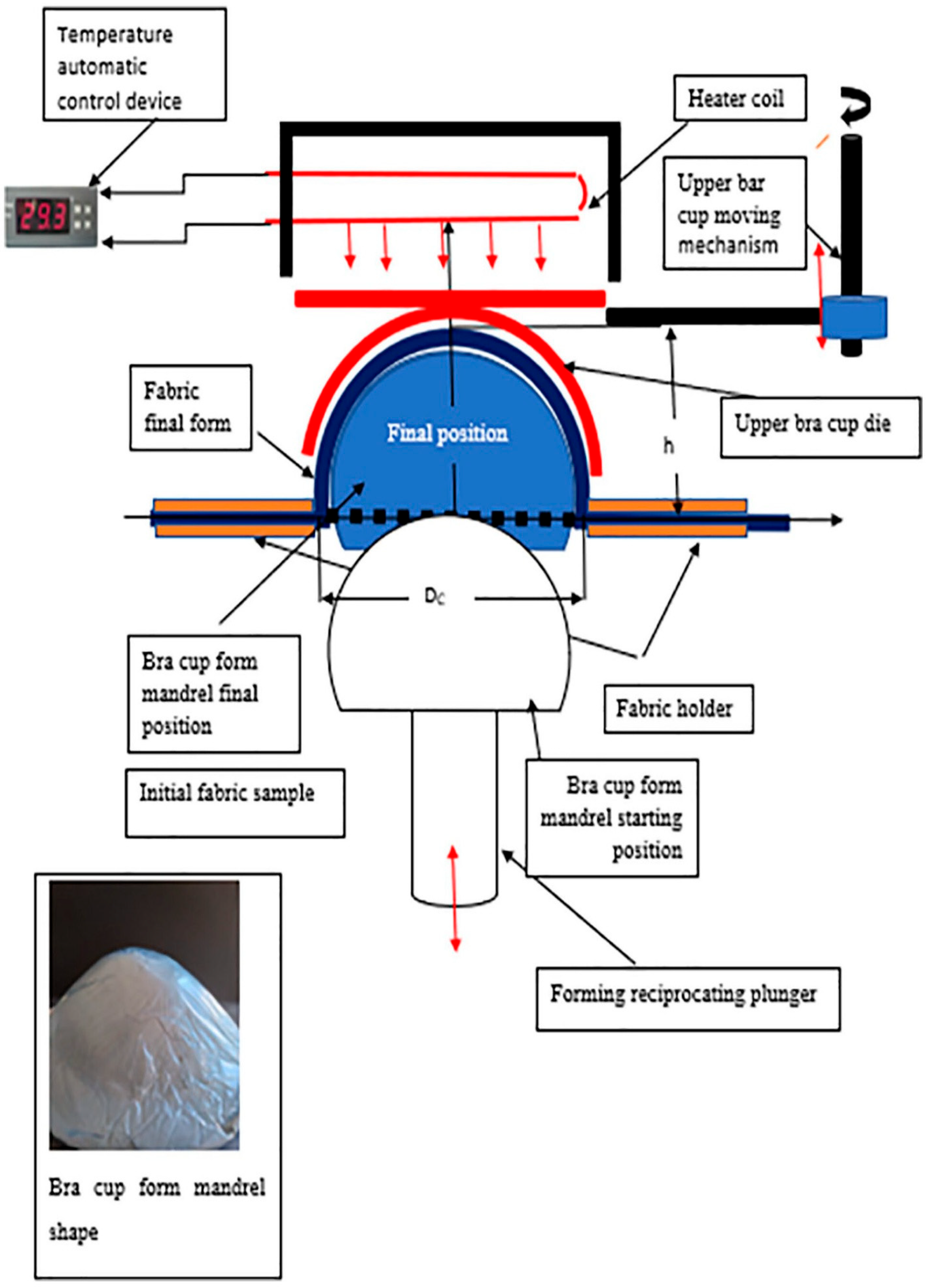

3.1.3. Molding Method

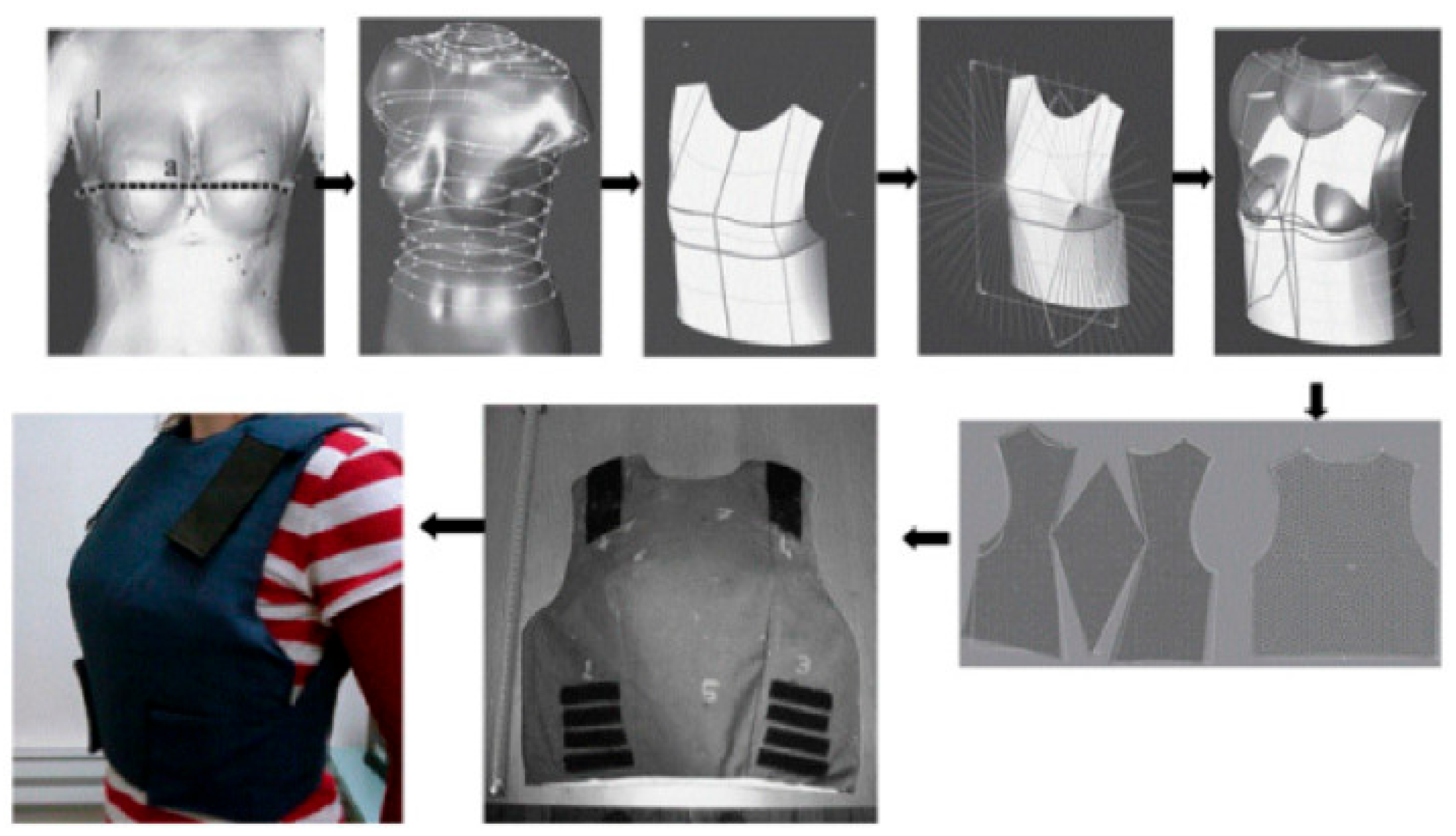

3.1.4. Technological Development in Panel Design

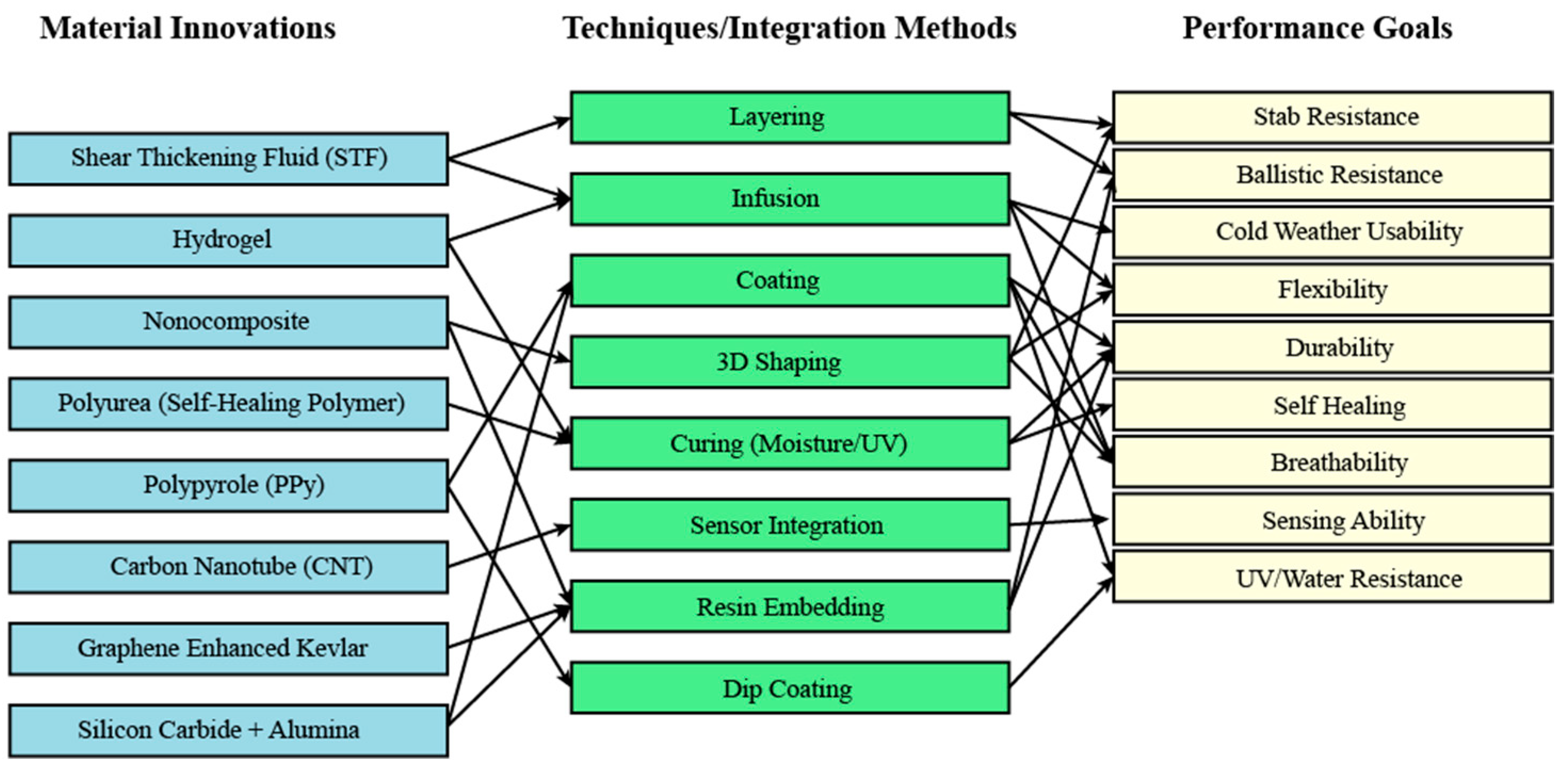

4. Materials Used for Developing Soft Body Armor

4.1. Evolution of Materials Used for Body Armor

4.2. Commonly Used Materials for Lightweight Body Armor

4.3. Recent Dry and Fiber-Reinforced Composite Materials for SBA Development

5. Evolutions of Standards and Regulations for Ballistic Testing

5.1. Overview of Different Body Armor Standards

5.1.1. National Institute of Justice (NIJ) Standards

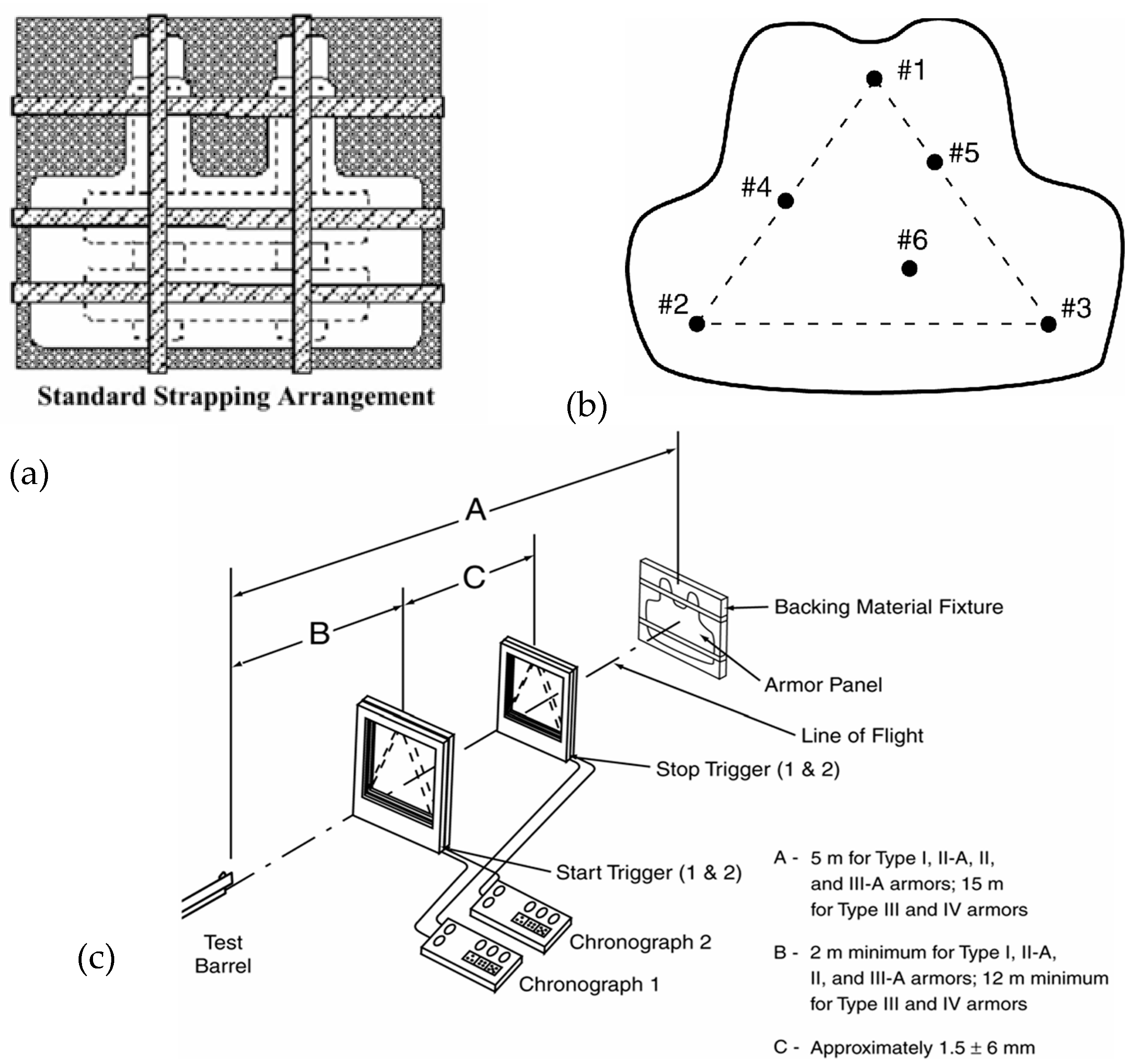

NIJ Standard 0101.01 and NIJ Standard 0101.04

NIJ Standard 0101.06

NIJ Standard 0101.07

5.1.2. HOSDB/CAST (UK) Standard

5.1.3. VPAM Standard

5.1.4. ISO/FDIS 14876-1

5.2. Improved Body Armor Standards for Female-Oriented Body Armor

6. Challenges and Future Implications

6.1. Challenges

6.1.1. Challenges of Female Soft Body Armor Panel Design

6.1.2. Challenges of Soft Body Armor Materials

6.2. Future Implications

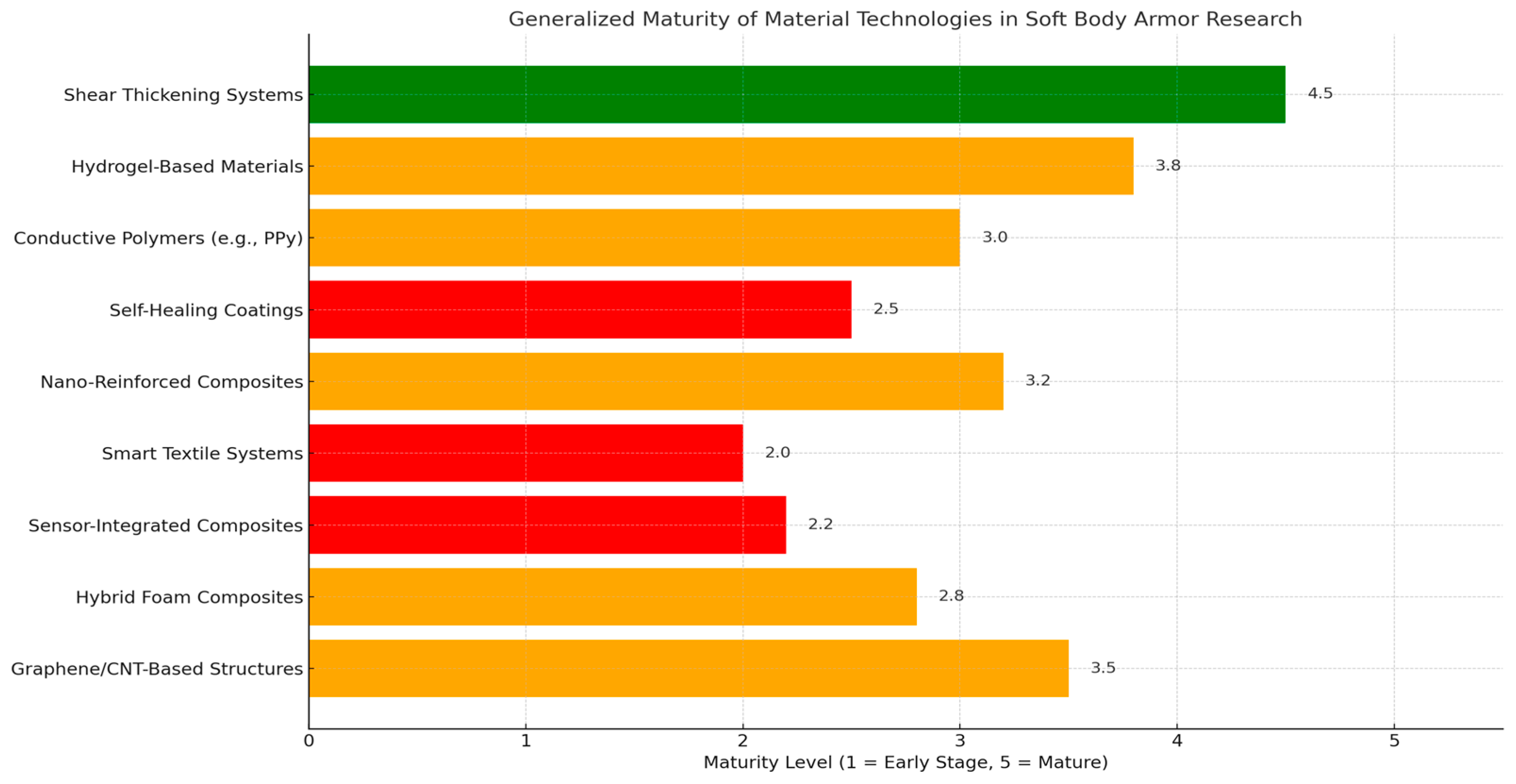

6.2.1. Technological Advances and Research Priorities

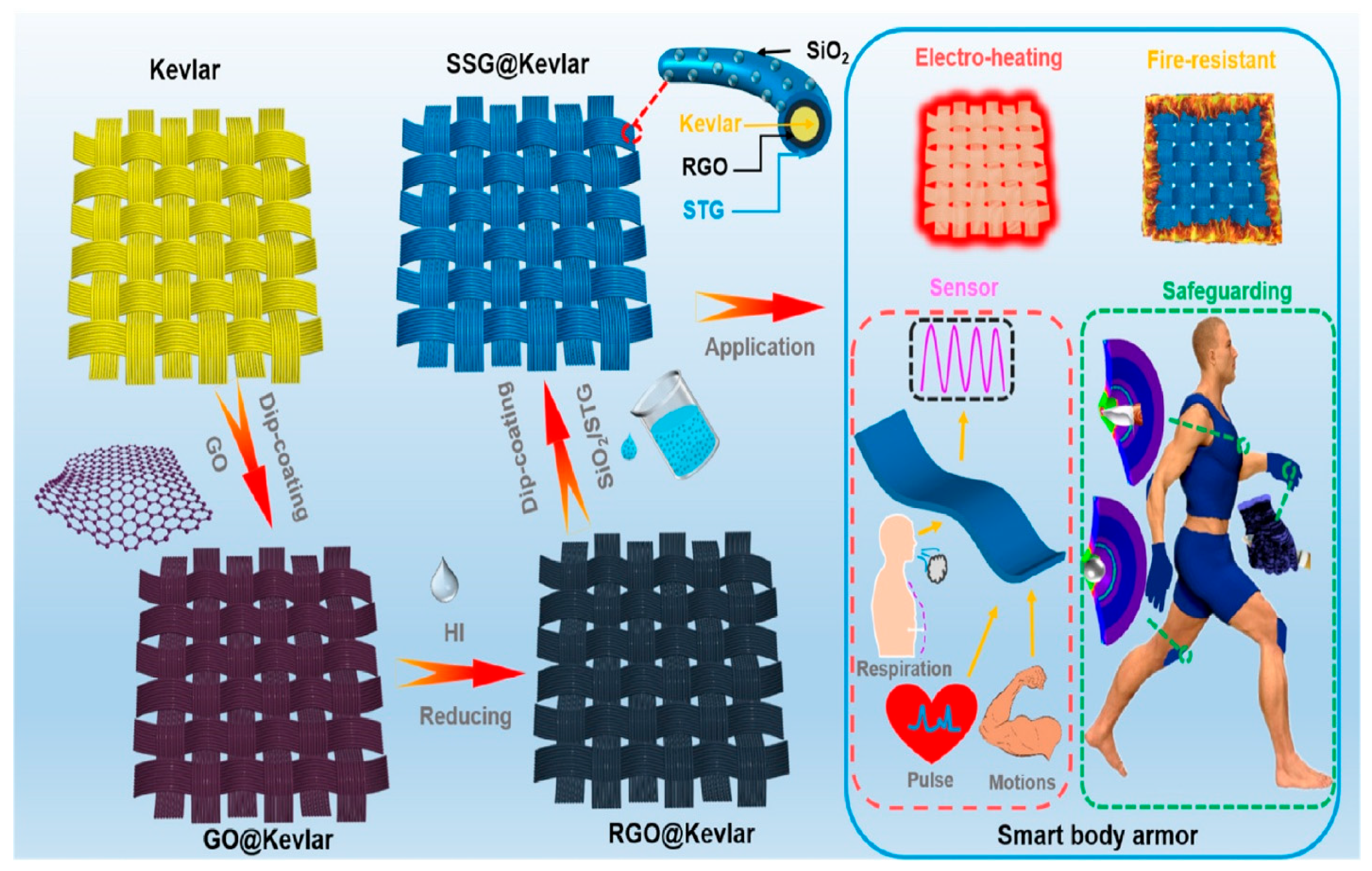

6.2.2. Smart Textiles and Functional Coatings

6.2.3. Industrial Scalability, Economic Feasibility, and Sustainability

7. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Knecht, C.; Kosuru, R.K. Protecting the First Responders: Improving FR Situational Awareness Through Multi-Modal Interfaces Leveraging the Ubiquitous Personal Smartphone. Saf. Manag. Hum. Factors 2024, 151, 78–87. [Google Scholar] [CrossRef]

- Haugen, P.T.; Evces, M.; Weiss, D.S. Treating posttraumatic stress disorder in first responders: A systematic review. Clin. Psychol. Rev. 2012, 32, 370–380. [Google Scholar] [CrossRef]

- Hsiao, H.; Kau, T.-Y.; Bradtmiller, B. A cluster-based law enforcement body armor sizing system: Concept, procedure, and design practice. Appl. Ergon. 2024, 117, 104201. [Google Scholar] [CrossRef]

- Davis, E. A Qualitative Study of How Body Armor Impacts Risk-Taking of Prehospital Providers; Capella University: Minneapolis, MN, USA, 2020. [Google Scholar]

- Tyakoff, A.; Garis, L.; Thomas, L. Firefighter Injuries in British Columbia: An Examination of Frequency, Severity, Locational and Temporal Aspects; University of the Fraser Valley: Abbotsford, BC, Canada, 2015; pp. 1–19. [Google Scholar] [CrossRef]

- Marino, M.; Delaney, J.; Atwater, P.; Smith, R. To Save Lives and Property: High Threat Response. Homel. Secur. Aff. 2015, 11, 5. Available online: https://www.hsaj.org/articles/4530 (accessed on 1 May 2025).

- Purushothaman, A.; Coimbatore, G.; Ramkumar, S.S. Soft body armor for law enforcement applications. J. Eng. Fiber. Fabr. 2013, 8, 97–103. [Google Scholar] [CrossRef]

- McQuerry, M. A Review of Ballistic, Slash, and Stab Protection for Integration in First Responder Personal Protective Clothing. J. Text. Sci. Fash. Technol. 2019, 2, 1–5. [Google Scholar] [CrossRef]

- Frazer, H.; Van Hooff, M.; Lawrence-Wood, E.; Searle, A. Factors influencing the recruitment and retention of female first responders: A mixed methods systematic review protocol. JBI Evid. Synth. 2021, 19, 721–726. [Google Scholar] [CrossRef]

- Korhonen, V. Gender Distribution of Full-Time Law Enforcement Employees in the United States in 2023, Staista. Available online: https://www.statista.com/statistics/195324/gender-distribution-of-full-time-law-enforcement-employees-in-the-us/#:~:text=Publishedby,lawenforcementofficersweremale (accessed on 1 May 2025).

- Fahy, R.; Evarts, B.; Stein, G.P. U.S. Fire Department Profile 2020. Available online: https://www.nfpa.org/News-and-Research/Data-research-and-tools/Emergency-Responders/US-fire-department-profile (accessed on 21 February 2025).

- Women in EMS: Breaking Barriers and Achieving Success, UnitekEMT. Available online: https://www.unitekemt.com/blog/women-in-ems-breaking-barriers-and-achieving-success/#:~:text=Currentstatisticsshowagrowing,lessreliableincriticalsituations (accessed on 1 May 2025).

- Tomes, C.; Orr, R.M.; Pope, R. The impact of body armor on physical performance of law enforcement personnel: A systematic review. Ann. Occup. Environ. Med. 2017, 29, 14. [Google Scholar] [CrossRef]

- Choi, H.J.; Mitchell, K.B.; Garlie, T.; McNamara, J.; Hennessy, E.; Carson, J. Effects of Body Armor Fit on Marksmanship Performance. In Advance in Physical Egronomics and Human Factors, Proceedeings of the AHFE 2016 International Conference on Physical Egronimics and Human Factor, Walt Disney, FL, USA, 27–31 July 2016; Springer: Berlin/Heidelberg, Germany, 2016; pp. 341–354. [Google Scholar] [CrossRef]

- Epstein, Y.; Yanovich, R.; Moran, D.S.; Heled, Y. Physiological employment standards IV: Integration of women in combat units physiological and medical considerations. Eur. J. Appl. Physiol. 2013, 113, 2673–2690. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Bruniaux, P. Dynamic impact protective body armour: A comprehensive appraisal on panel engineering design and its prospective materials. Def. Technol. 2021, 17, 2027–2049. [Google Scholar] [CrossRef]

- Edwards, M.; Furnell, A.; Coleman, J.; Davis, S. A Preliminary Anthropometry Standard for Australian Army Equipment Evaluation, Dsto-Tr-3006. Available online: https://www.dst.defence.gov.au/sites/default/files/publications/documents/DSTO-TR-3006.pdf (accessed on 21 February 2025).

- Park, H.; Park, J.; Lin, S.H.; Boorady, L.M. Assessment of Firefighters’ needs for personal protective equipment. Fash. Text. 2014, 1, 8. [Google Scholar] [CrossRef]

- Niemczyk, S.E.; Arnold, L.; Wang, L. Qualitative Observations on the Design of Sports Bras for Wear Under Body Armour. KnE Eng. 2017, 2, 342. [Google Scholar] [CrossRef]

- Coltman, C.E.; Steele, J.R.; Spratford, W.A.; Molloy, R.H. Are female soldiers satisfied with the fit and function of body armour? Appl. Ergon. 2020, 89, 103197. [Google Scholar] [CrossRef]

- Coppola, M. Body Armor for Female Officers: What’s Next? Techbeat 2014, 3–8. Available online: https://nij.ojp.gov/library/publications/body-armor-female-officers-whats-next (accessed on 1 May 2025).

- Bhatia, D.; Jaswal, P.; Sinha, S.K. Women’s body armor: A comprehensive review of design, performance, and ergonomics. J. Eng. Fiber. Fabr. 2024, 19, 15589250241232151. [Google Scholar] [CrossRef]

- Yang, D. Design, Performance and Fit of Fabrics for Female Body Armour; The University of Manchester (United Kingdom): Manchester, UK, 2011. [Google Scholar]

- Wendland, R.; Bossi, L.; Nakaza, E.; Oliver, M. Comparison of In-service Reduced vs. Full Torso Coverage Armor for Females. Mil. Med. 2023, 188, e3102–e3111. [Google Scholar] [CrossRef]

- Arora, S.; Ghosh, A. Evolution of soft body armor. In Advanced Textile Engineering Materials; Ul-Islam, S., Butola, B.S., Eds.; Scrivener Publishing LLC: Beverly, MA, USA, 2018; Chapter 13; pp. 499–552. [Google Scholar] [CrossRef]

- Yang, D.; Chen, X. Multi-layer pattern creation for seamless front female body armor panel using angle-interlock woven fabrics. Text. Res. J. 2017, 87, 381–386. [Google Scholar] [CrossRef]

- Mica, M.T.; Peksoz, S. Fit Problems and Design Modifications of the Ballistic Vest for Female Police Officers. In Pivoting for the Pandemic; Iowa State University Digital Press: Ames, IA, USA, 2020. [Google Scholar] [CrossRef]

- Tung, T.-Y. Design Criteria of Type IV Body Armor for Women. Master’s Thesis, Oregon State University, Corvallis, OR, USA, 2008. Available online: https://ir.library.oregonstate.edu/concern/graduate_thesis_or_dissertations/2f75r9931 (accessed on 1 May 2025).

- Coltman, C.E.; Brisbine, B.R.; Steele, J.R. Bra-body armour integration, breast discomfort and breast injury associated with wearing body armour. Ergonomics 2021, 64, 1623–1633. [Google Scholar] [CrossRef]

- Coltman, C.E.; Brisbine, B.R.; Molloy, R.H.; Steele, J.R. Can smaller body armour improve thoracolumbar range of motion and reduce interference when female soldiers perform dynamic tasks? Appl. Ergon. 2022, 98, 103602. [Google Scholar] [CrossRef]

- Coltman, C.E.; Brisbine, B.R.; Molloy, R.H.; Steele, J.R. Effect of Torso and Breast Characteristics on the Perceived Fit of Body Armour Systems Among Female Soldiers: Implications for Body Armour Sizing and Design. Front. Sport. Act. Living 2022, 4, 821210. [Google Scholar] [CrossRef]

- Boussu, F.; Bruniaux, P. Customization of a lightweight bullet-proof vest for the female form. In Advances in Military Textiles and Personal Equipment; Elsevier: Amsterdam, The Netherlands, 2012; pp. 167–195. [Google Scholar] [CrossRef]

- Coltman, C.E.; Brisbine, B.R.; Molloy, R.H.; Ball, N.B.; Sfile, W.A. Identifying problems that female soldiers experience with current-issue body armour. Appl. Ergon. 2021, 94, 103384. [Google Scholar] [CrossRef] [PubMed]

- Park, H.; Nolli, G.; Branson, D.; Peksoz, S.; Petrova, A.; Goad, C. Impact of wearing body armor on lower body mobility. Cloth. Text. Res. J. 2011, 29, 232–247. [Google Scholar] [CrossRef]

- Lenton, G.; Aisbett, B.; Neesham-Smith, D.; Carvajal, A.; Netto, K. The effects of military body armour on trunk and hip kinematics during performance of manual handling tasks*. Ergonomics 2016, 59, 806–812. [Google Scholar] [CrossRef][Green Version]

- Mahbub, R.F. Comfort and Stab-Resistant Performance of Body Armour Fabrics and Female Vests. Ph.D. Thesis, RMIT University, Melbourne, VIC, Australia, 2015. [Google Scholar]

- McQuerry, M.; Kwon, C.; Johnson, H. A critical review of female firefighter protective clothing and equipment workplace challenges. Res. J. Text. Appar. 2019, 23, 94–110. [Google Scholar] [CrossRef]

- Stuivinga, M.; Carton, E.P.; Verbeek, H.J.; van Bree, J.L.M.J. Energy transfer mitigation using foam at porojectile defeat by body armour. In Proceedings of the 11th Personal Armour Systems Symposium, Nurnberg, Germany, 17–21 September 2012. [Google Scholar]

- Dearden, L. Women now allowed to apply for royal marines and all other frontline military roles, defence secretary announces. The Independent. 25 October 2018. Available online: https://www.independent.co.uk/news/uk/home-news/women-soldiers-army-military-sas-defence-government-infantry-frontline-gavin-williamson-female-a8601371.html (accessed on 1 May 2025).

- Chen, X.; Yang, D. Use of Three-dimensional Angle-interlock Woven Fabric for Seamless Female Body Armor: Part II: Mathematical Modeling. Text. Res. J. 2010, 80, 1589–1601. [Google Scholar] [CrossRef]

- Kitano, H.A.K.; Hamaguchi, S.; Aoki, H. Pleated Ballistic Package for Soft Body Armor. U.S. Patent US2010/0313321 A1, 28 January 2010. Available online: https://patentimages.storage.googleapis.com/3b/c9/82/c283c7b24afe69/US20100019677A1.pdf (accessed on 13 February 2025).

- Mcqueer, P.S.; Classification, P. Woman’s bullet resistant undergarment. U.S. Patent US2011/0277202 A1, 2011. [Google Scholar]

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Loghin, C.; Cristian, I.; Chen, Y.; Wang, L. Forming characteristics and surface damages of stitched multi-layered para-aramid fabrics with various stitching parameters for soft body armour design. Compos. Part A Appl. Sci. Manuf. 2018, 109, 517–537. [Google Scholar] [CrossRef]

- Armellino, R.A. Lightweight Armor and Method of Fabrication. U.S. Patent 3, 1976. [Google Scholar]

- Abtew, M.A.; Bruniaux, P.; Boussu, F.; Loghin, C.; Crist, I. Pattern Engineering for Customized Women Seamless Ballistic Protection Vest on 3D Virtual Mannequin. J. Fiber Bioeng. Inform. 2022, 15, 17–25. [Google Scholar] [CrossRef]

- Abtew, M.A.; Bruniaux, P.; Boussu, F.; Loghin, C.; Cristian, I.; Chen, Y.; Wang, L. Female seamless soft body armor pattern design system with innovative reverse engineering approaches. Int. J. Adv. Manuf. Technol. 2018, 98, 2271–2285. [Google Scholar] [CrossRef]

- Aramid, T. Ballistic Materials Handbook; Arnhem, The Netherlands, 2018; Available online: https://www.teijinaramid.com/ (accessed on 15 February 2025).

- Abtew, M.A.; Bruniaux, P.; Boussu, F.; Loghin, C.; Cristian, I.; Chen, Y.; Wang, L. A systematic pattern generation system for manufacturing customized seamless multi-layer female soft body armour through dome-formation (moulding) techniques using 3D warp interlock fabrics. J. Manuf. Syst. 2018, 49, 61–74. [Google Scholar] [CrossRef]

- Boussu, F.; Legrand, X.; Nauman, S.; Binetruy, C.; Composites, T.D.P.E.; Mécanique, I. Mouldability of Angle Interlock Fabrics. In Proceedings of the FPCM-9, the 9th International Conference on Flow Processes in Composite Materials, Montréal, QC, Canada, 8–10 July 2008. [Google Scholar]

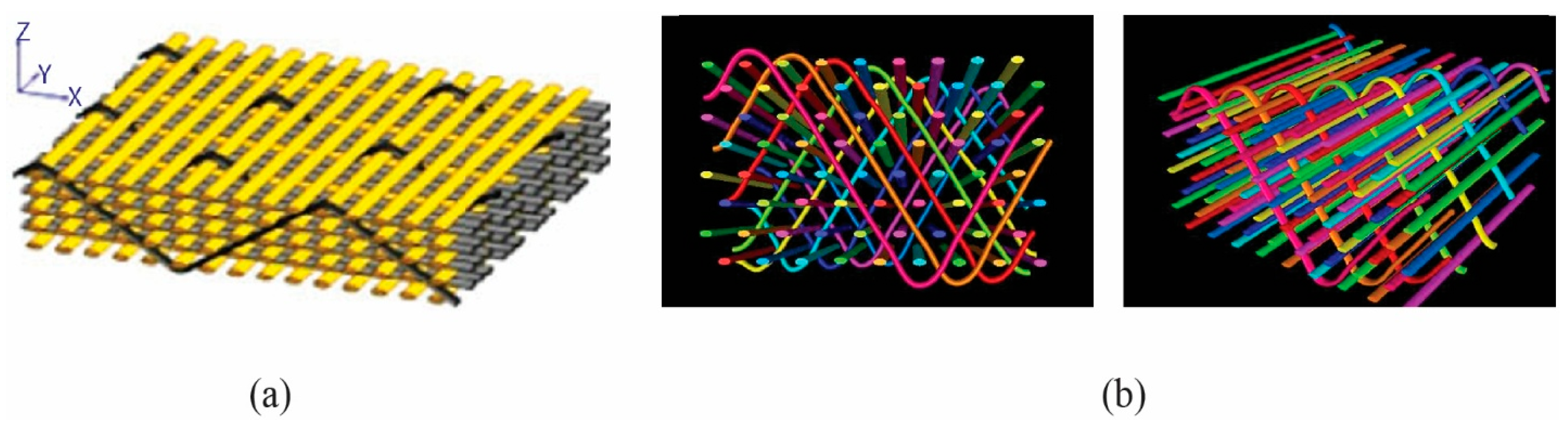

- Boussu, F.; Abtew, M.A.; Bruniaux, P. 3D Warp Interlock Fabric Structure and their Applications in Soft and Hard Armour Protections. Appl. Compos. Mater. 2022, 29, 65–82. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Loghin, C.; Cristian, I.; Chen, Y.; Wang, L. Ballistic impact performance and surface failure mechanisms of two-dimensional and three-dimensional woven p-aramid multi-layer fabrics for lightweight women ballistic vest applications. J. Ind. Text. 2021, 50, 1351–1383. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Hong, Y. Dynamic Impact Surface Damage Analysis of 3D Woven Para-Aramid Armour Panels Using NDI Technique. Polymers 2021, 13, 877. [Google Scholar] [CrossRef] [PubMed]

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Loghin, C.; Cristian, I. Effect of Structural Parameters on the Deformational Behaviors of Multiply 3D Layer-by-Layer Angle-Interlock Para-Aramid Fabric for Fiber-Reinforcement Composite. J. Compos. Sci. 2020, 4, 145. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Liu, H. Fabrication and Mechanical Characterization of Dry Three-Dimensional Warp Interlock Para-Aramid Woven Fabrics: Experimental Methods toward Applications in Composite Reinforcement and Soft Body Armor. Materials 2020, 13, 4233. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Loghin, C.; Cristian, I. Enhancing the Ballistic Performances of 3D Warp Interlock Fabric Through Internal Structure as New Material for Seamless Female Soft Body Armor Development. Appl. Sci. 2020, 10, 4873. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Loghin, C.; Cristian, I. Engineering of 3D warp interlock p-aramid fabric structure and its energy absorption capabilities against ballistic impact for body armour applications. Compos. Struct. 2019, 225, 111179. [Google Scholar] [CrossRef]

- Mahbub, R.; Wang, L.; Arnold, L. Design of knitted three-dimensional seamless female body armour vests. Int. J. Fash. Des. Technol. Educ. 2014, 7, 198–207. [Google Scholar] [CrossRef]

- El Messiry, M.; Mohamed, A. Innovative technique in sheet forming of feminine personal protective armor by combined cyclic stretching and deep drawing method. J. Eng. Fiber. Fabr. 2022, 17, 15589250221144009. [Google Scholar] [CrossRef]

- Purnomo, H.; Kurnia, F. An analysis of body armor sizing and the development of an existing sizing system for the indonesian national army. Eng. Lett. 2020, 28, 206–212. [Google Scholar]

- Fenne, P. Protection against knives and other weapons. In Textiles for Protection; Elsevier: Amsterdam, The Netherlands, 2005; pp. 648–677. [Google Scholar] [CrossRef]

- Horsfall, I. Osteoartritli Hastaların Evde Egzersiz Yapma ve Yarar Görme Durumları. Türkiye Fiz. Tıp Rehabil. Derg. 2012, 58, 288–293. [Google Scholar] [CrossRef]

- Bellis, M. History of Body Armor and Bullet Proof Vests. ThoughtCo. Available online: https://www.thoughtco.com/history-of-body-armor-and-bullet-proof-vests-1991337 (accessed on 13 May 2025).

- King, L. Lightweight Body Armor. The Quartermaster Review. Available online: https://www.quartermasterfoundation.org/lightweight-body-armor/ (accessed on 13 February 2025).

- Reiners, P. Investigation About the Stab Resistance of Textile Structures, Methods for Their Testing and Improvement. Ph.D. Thesis, Université de Haute Alsace, Mulhouse, France, 2017. Available online: https://theses.hal.science/tel-01527362v1 (accessed on 5 May 2025).

- Bajya, M.; Majumdar, A.; Butola, B.S. A review on current status and development possibilities of soft armour panel assembly. J. Mater. Sci. 2023, 58, 14997–15020. [Google Scholar] [CrossRef]

- Elgohary, D.H. Technological aspects of body armour textiles for ballistic protection application. J. Text. Inst. 2024, 116, 535–549. [Google Scholar] [CrossRef]

- Finckenor, M.M.; Marshall, G.C. Comparison of High-Performance Fiber Materials Properties in Simulated and Actual Space Environments, NASA Technical Reports Server. NASA/TM-2017-219634. 2017. Available online: https://ntrs.nasa.gov/citations/20170006996 (accessed on 5 May 2025).

- Cunniff, P.M. The Performance of Poly(Para-Phenylene Benzobizoxazole) (Pbo) Fabric for Fragmentation Protective Body Armor. In Proceedings of the 18th International Symposium on Ballistics, San Antonio, TX, USA, 15–19 November 1999; pp. 837–844. [Google Scholar]

- Ashok, B. Lightweight Ballistic Composites: Military and Law-Enforcement Applications, 2nd ed.; Woodhead Publishing: Sawston, UK, 2016. [Google Scholar]

- Frederick, W.; Paul, B. Fiberglass and Glass Technology Energy-Friendly Compositions and Applications; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Donnet, J.-B.; Bansal, R.C. Carbon Fibers; CRC Press: Boca Raton, FL, USA, 1998. [Google Scholar] [CrossRef]

- Buckley, J.D.; Edie, D.D. Carbon-Carbon Materials and Composites; Noyes Publications: Park Ridge, NJ, USA, 1993. [Google Scholar]

- Li, M.; Abtew, M.A.; Chen, X.; Boussu, F. Stabbing and ballistic resistances of the predeformed multiply three-dimensional interlock fabrics. In Advanced Structural Textile Composites Forming; Elsevier: Amsterdam, The Netherlands, 2025; pp. 495–526. [Google Scholar] [CrossRef]

- Abtew, M.A. A comprehensive review on advancements, innovations and applications of 3D warp interlock fabrics and its composite materials. Compos. Part B Eng. 2024, 278, 111395. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Bruniaux, P. 3D Woven Fabrics-A Promising Structure for Women Soft Body Armor Development. In Advanced Weaving Technology; Springer International Publishing: Cham, Switzerland, 2022; pp. 607–631. [Google Scholar] [CrossRef]

- Shah, S.H.; Megat-Yusoff, P.S.M.; Karuppanan, S.; Choudhry, R.S.; Din, I.U.; Othman, A.R.; Sharp, K.; Gerard, P. Compression and buckling after impact response of resin-infused thermoplastic and thermoset 3D woven composites. Compos. Part B Eng. 2021, 207, 108592. [Google Scholar] [CrossRef]

- Carrillo, J.G.; Gamboa, R.A.; Flores-Johnson, E.A.; Gonzalez-Chi, P.I. Ballistic performance of thermoplastic composite laminates made from aramid woven fabric and polypropylene matrix. Polym. Test. 2012, 31, 512–519. [Google Scholar] [CrossRef]

- Gohel, G.; Bhudolia, S.K.; Leong, K.F.; Gerard, P. Understanding the impact properties and damage phenomenon of ultra-lightweight all-thermoplastic composite structures. Int. J. Impact Eng. 2023, 172, 104405. [Google Scholar] [CrossRef]

- Xie, W.; Lee, J.H. Intrinsic Dynamics and Toughening Mechanism of Multilayer Graphene upon Microbullet Impact. ACS Appl. Nano Mater. 2020, 3, 9185–9191. [Google Scholar] [CrossRef]

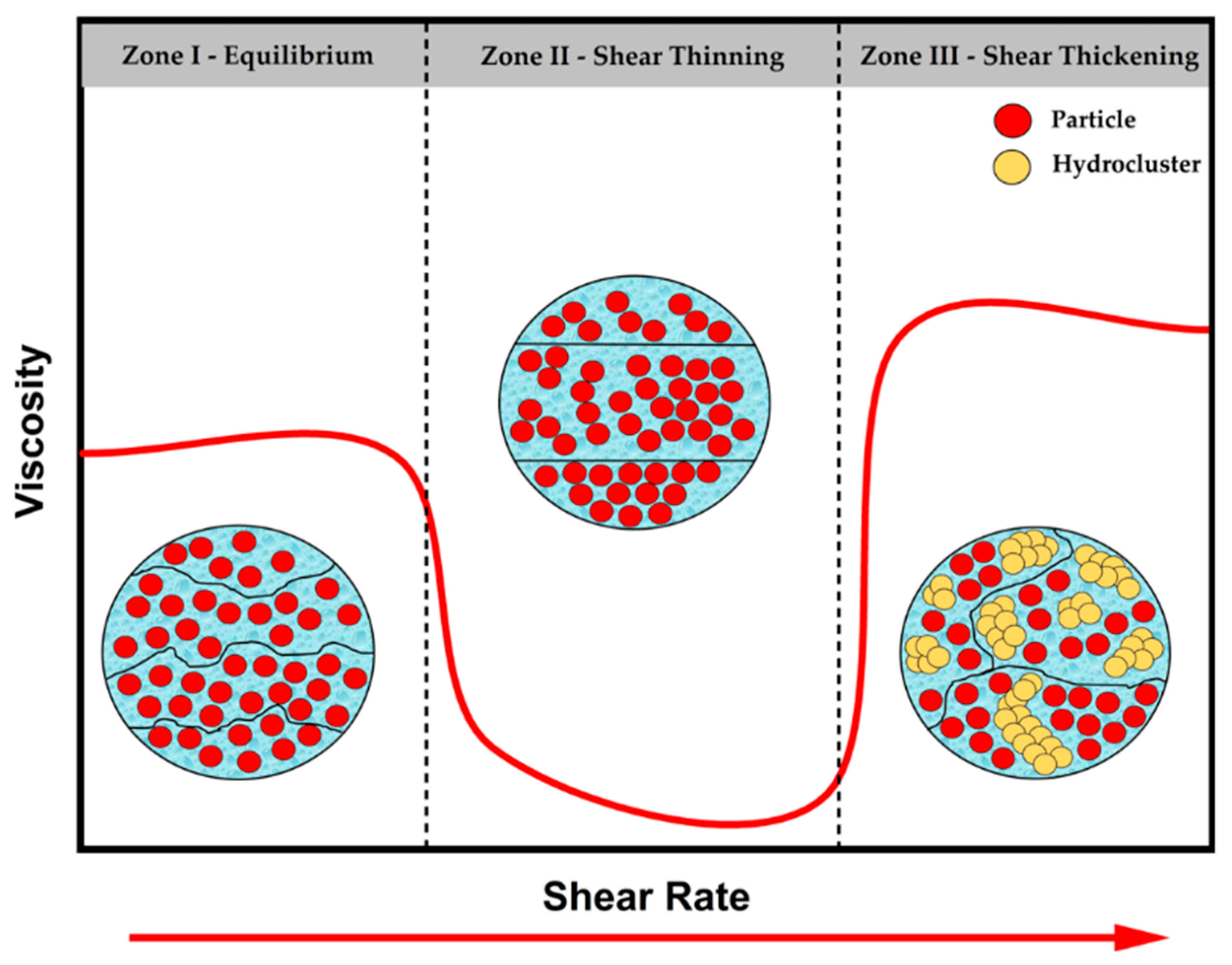

- Kawaguchi, G.; Cam, E.; Baur, J.; Lopez, B. Application of Shear Thickening Fluids on Soft Body Armour; Research Project; California State Polytechnic University: Pomona, CA, USA, 2023. [Google Scholar]

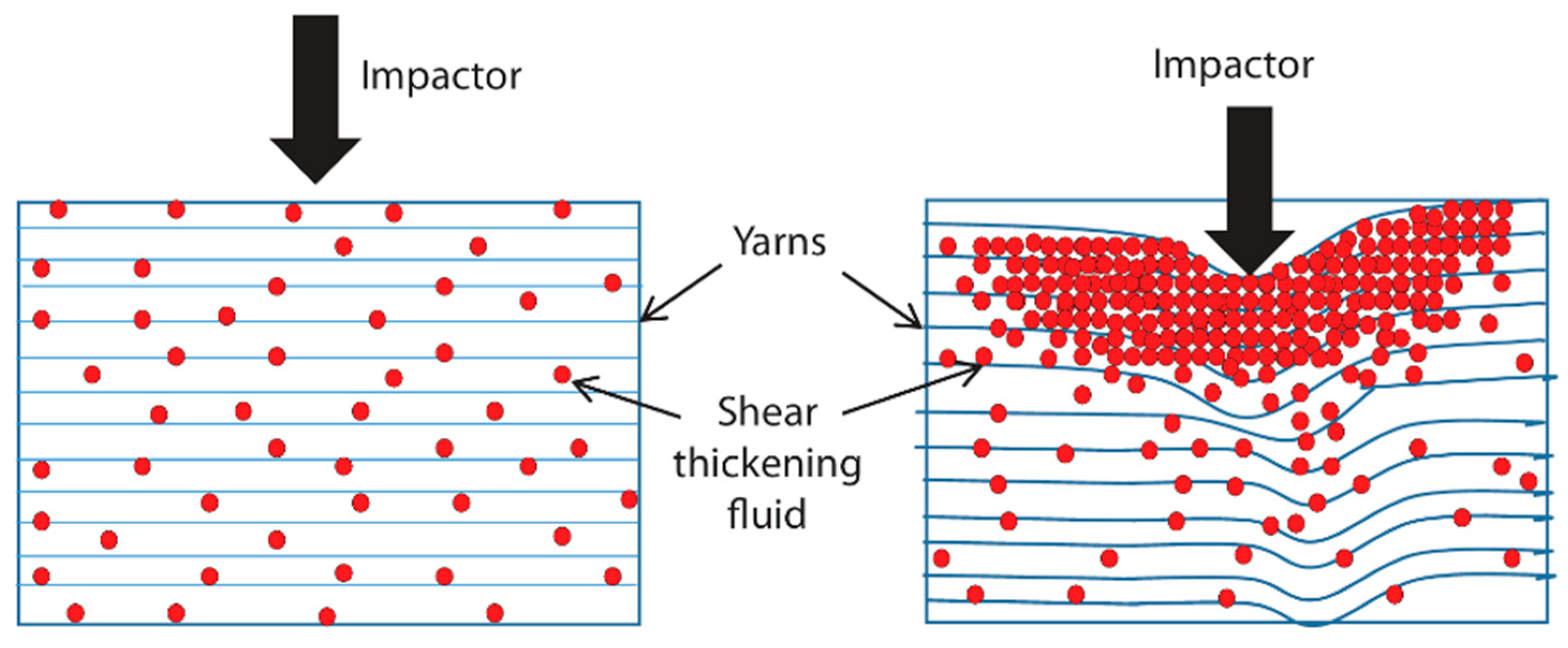

- Lee, Y.S.; Wetzel, E.D.; Wagner, N.J. The ballistic impact characteristics of Kevlar® woven fabrics impregnated with a colloidal shear thickening fluid. J. Mater. Sci. 2003, 38, 2825–2833. [Google Scholar] [CrossRef]

- Ribeiro, M.P.; da Silveira, P.H.P.M.; de Oliveira Braga, F.; Monteiro, S.N. Fabric Impregnation with Shear Thickening Fluid for Ballistic Armor Polymer Composites: An Updated Overview. Polymers 2022, 14, 4357. [Google Scholar] [CrossRef]

- Grigoryan, V.A.; Kobylkin, I.F.F.; Marinin, V.M.; Bespalov, I.A. Ballistic Performance of Textile Armor Treated with Shear Thickening Fluid. Tech. Wyr. Włókiennicze 2009, 17, 12–15. Available online: http://yadda.icm.edu.pl/baztech/element/bwmeta1.element.baztech-article-LOD7-0021-0016 (accessed on 13 May 2025).

- Barnes, H.A. Shear-Thickening (‘Dilatancy’) in Suspensions of Nonaggregating Solid Particles Dispersed in Newtonian Liquids. J. Rheol. 1989, 33, 329–366. [Google Scholar] [CrossRef]

- Wagner, N.J.; Brady, J.F. Shear thickening in colloidal dispersions. Phys. Today 2009, 62, 27–32. [Google Scholar] [CrossRef]

- Ding, J.; Tracey, P.; Li, W.; Peng, G.; Whitten, P.G.; Wallace, G.G. Review on Shear Thickening Fluids and Applications. Text. Light Ind. Sci. Technol. 2013, 2, 161–173. Available online: www.tlist-journal.org (accessed on 6 March 2025).

- Maranzano, B.J.; Wagner, N.J. Flow-small angle neutron scattering measurements of colloidal dispersion microstructure evolution through the shear thickening transition. J. Chem. Phys. 2002, 117, 10291–10302. [Google Scholar] [CrossRef]

- Hoffman, R.L. Discontinuous and dilatant viscosity behavior in concentrated suspensions. II. Theory and experimental tests. J. Colloid Interface Sci. 1974, 46, 491–506. [Google Scholar] [CrossRef]

- Brown, E.; Forman, N.A.; Orellana, C.S.; Zhang, H.; Maynor, B.W.; Betts, D.E.; DeSimone, J.M.; Jaeger, H.M. Generality of shear thickening in dense suspensions. Nat. Mater. 2010, 9, 220–224. [Google Scholar] [CrossRef]

- Seto, R.; Mari, R.; Morris, J.F.; Denn, M.M. Discontinuous Shear Thickening of Frictional Hard-Sphere Suspensions. Phys. Rev. Lett. 2013, 111, 218301. [Google Scholar] [CrossRef]

- Mahfuz, H.; Clements, F.; Rangari, V.; Dhanak, V.; Beamson, G. Enhanced stab resistance of armor composites with functionalized silica nanoparticles. J. Appl. Phys. 2009, 105, 064307. [Google Scholar] [CrossRef]

- Kalman, D.P.; Merrill, R.L.; Wagner, N.J.; Wetzel, E.D. Effect of particle hardness on the penetration behavior of fabrics intercalated with dry particles and concentrated particle-fluid suspensions. ACS Appl. Mater. Interfaces 2009, 1, 2602–2612. [Google Scholar] [CrossRef]

- Tan, V.B.C.; Tay, T.E.; Teo, W.K. Strengthening fabric armour with silica colloidal suspensions. Int. J. Solids Struct. 2005, 42, 1561–1576. [Google Scholar] [CrossRef]

- Pan, Y.; Sang, M.; Zhang, J.; Sun, Y.; Liu, S.; Hu, Y.; Gong, X. Flexible and lightweight Kevlar composites towards flame retardant and impact resistance with excellent thermal stability. Chem. Eng. J. 2023, 452, 139565. [Google Scholar] [CrossRef]

- Kang, T.J.; Hong, K.H.; Yoo, M.R. Preparation and properties of fumed silica/Kevlar composite fabrics for application of stab resistant material. Fibers Polym. 2010, 11, 719–724. [Google Scholar] [CrossRef]

- Decker, M.J.; Halbach, C.J.; Nam, C.H.; Wagner, N.J.; Wetzel, E.D. Stab resistance of shear thickening fluid (STF)-treated fabrics. Compos. Sci. Technol. 2007, 67, 565–578. [Google Scholar] [CrossRef]

- Alexe, F.; Sau, C.; Iorga, O.; Toader, G.; Diacon, A.; Rusen, E.; Lazaroaie, C.; Ginghina, R.E.; Tiganescu, T.V.; Teodorescu, M.; et al. Experimental Investigations on Shear Thickening Fluids as ‘Liquid Body Armors’: Non-Conventional Formulations for Ballistic Protection. Polymers 2024, 16, 2305. [Google Scholar] [CrossRef]

- Gong, X.; Xu, Y.; Zhu, W.; Xuan, S.; Jiang, W.; Jiang, W. Study of the knife stab and puncture-resistant performance for shear thickening fluid enhanced fabric. J. Compos. Mater. 2014, 48, 641–657. [Google Scholar] [CrossRef]

- Qin, J.; Guo, B.; Zhang, L.; Wang, T.; Zhang, G.; Shi, X. Soft armor materials constructed with Kevlar fabric and a novel shear thickening fluid. Compos. Part B Eng. 2020, 183, 107686. [Google Scholar] [CrossRef]

- Feng, X.; Li, S.; Wang, Y.; Wang, Y.; Liu, J. Effects of different silica particles on quasi-static stab resistant properties of fabrics impregnated with shear thickening fluids. Mater. Des. 2014, 64, 456–461. [Google Scholar] [CrossRef]

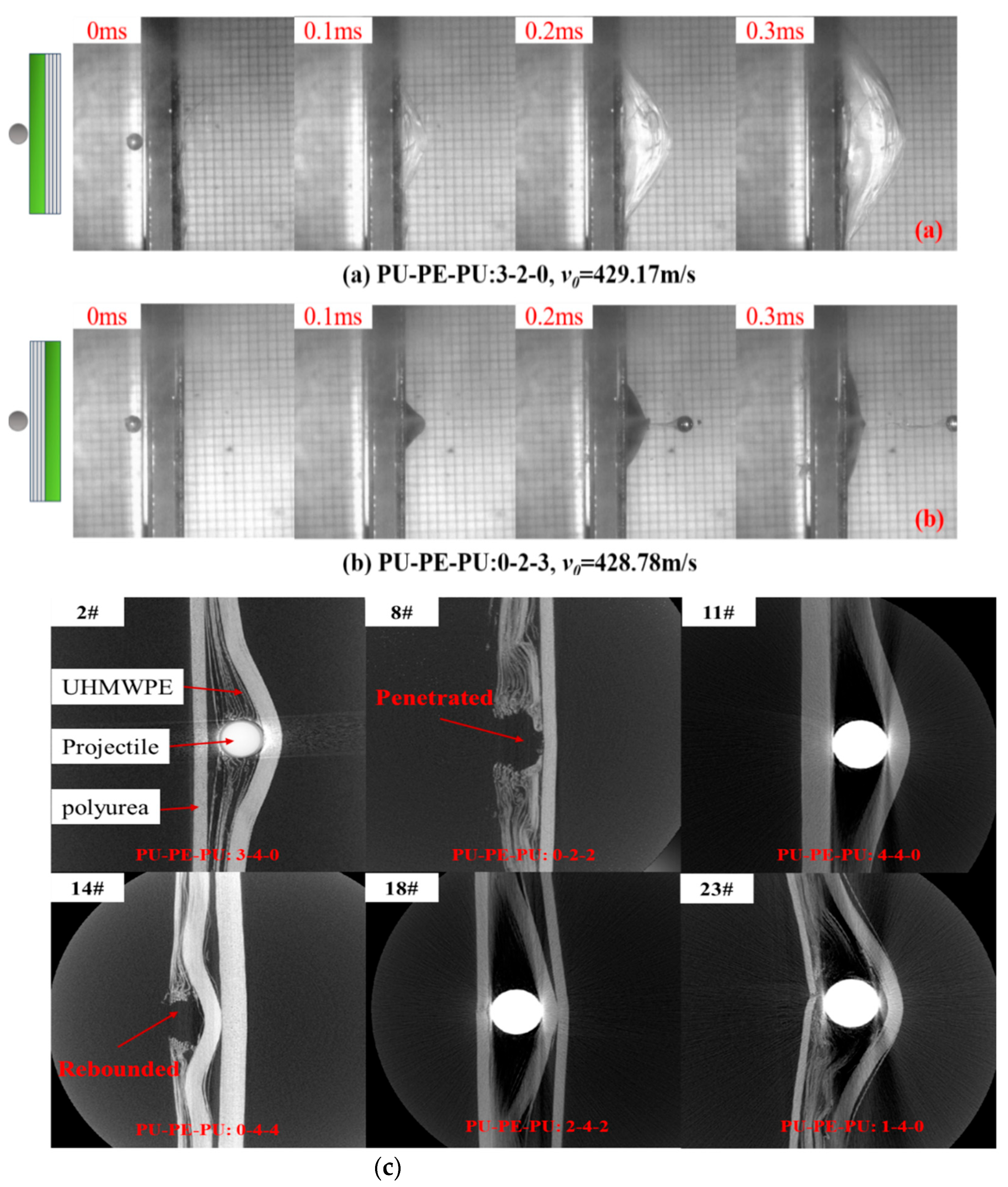

- Tan, Z.H.; Zuo, L.; Li, W.H.; Liu, L.S.; Zhai, P.C. Dynamic response of symmetrical and asymmetrical sandwich plates with shear thickening fluid core subjected to penetration loading. Mater. Des. 2016, 94, 105–110. [Google Scholar] [CrossRef]

- Wei, R.; Dong, B.; Zhai, W.; Li, H. Stab-Resistant Performance of the Well-Engineered Soft Body Armor Materials Using Shear Thickening Fluid. Molecules 2022, 27, 6799. [Google Scholar] [CrossRef]

- Bajya, M.; Majumdar, A.; Butola, B.S.; Verma, S.K.; Bhattacharjee, D. Design strategy for optimising weight and ballistic performance of soft body armour reinforced with shear thickening fluid. Compos. Part B Eng. 2020, 183, 2019. [Google Scholar] [CrossRef]

- Mawkhlieng, U.; Majumdar, A. Designing of hybrid soft body armour using high-performance unidirectional and woven fabrics impregnated with shear thickening fluid. Compos. Struct. 2020, 253, 112776. [Google Scholar] [CrossRef]

- Hassan, T.A.; Rangari, V.K.; Jeelani, S. Synthesis, processing and characterization of shear thickening fluid (STF) impregnated fabric composites. Mater. Sci. Eng. A 2010, 527, 2892–2899. [Google Scholar] [CrossRef]

- Manukonda, B.H.; Chatterjee, V.A.; Verma, S.K.; Bhattacharjee, D.; Biswas, I.; Neogi, S. Rheology based design of shear thickening fluid for soft body armor applications. Period. Polytech. Chem. Eng. 2020, 64, 75–84. [Google Scholar] [CrossRef]

- Srivastava, A.; Butola, B.S.; Majumdar, A. Improving the impact resistance performance of STF treated Kevlar fabric structures. Mater. Today Proc. 2019, 16, 1538–1541. [Google Scholar] [CrossRef]

- Chen, F.; Tang, Z.-H.; Zhu, Y.; Deng, J.-Q.; Li, Y.-Q.; Fu, Y.-Q.; Fu, S.-Y. Gradient shear thickening gel/Kevlar fabric multi-layer armor with enhanced impact attenuation property. Compos. Struct. 2024, 330, 117829. [Google Scholar] [CrossRef]

- He, Q.; Cao, S.; Wang, Y.; Xuan, S.; Wang, P.; Gong, X. Impact resistance of shear thickening fluid/Kevlar composite treated with shear-stiffening gel. Compos. Part A Appl. Sci. Manuf. 2018, 106, 82–90. [Google Scholar] [CrossRef]

- Cao, S.; Chen, Q.; Wang, Y.; Xuan, S.; Jiang, W.; Gong, X. High strain-rate dynamic mechanical properties of Kevlar fabrics impregnated with shear thickening fluid. Compos. Part A Appl. Sci. Manuf. 2017, 100, 161–169. [Google Scholar] [CrossRef]

- Zhao, C.; Wang, Y.; Cao, S.; Xuan, S.; Jiang, W.; Gong, X. Conductive shear thickening gel/Kevlar wearable fabrics: A flexible body armor with mechano-electric coupling ballistic performance. Compos. Sci. Technol. 2019, 182, 107782. [Google Scholar] [CrossRef]

- Zeka, M.B.; Aytaç, A. Investigation of Impact Performance of STF Impregnated Composites. Mechanika 2023, 29, 88–96. [Google Scholar] [CrossRef]

- Khodadadi, A.; Liaghat, G.; Sabet, A.; Hadavinia, H.; Aboutorabi, A.; Razmkhah, O.; Akbari, M.; Tahmasebi, M. Experimental and numerical analysis of penetration into Kevlar fabric impregnated with shear thickening fluid. J. Thermoplast. Compos. Mater. 2018, 31, 392–407. [Google Scholar] [CrossRef]

- Qin, J.; Zhang, G.; Zhou, L.; Li, J.; Shi, X. Dynamic/quasi-static stab-resistance and mechanical properties of soft body armour composites constructed from Kevlar fabrics and shear thickening fluids. RSC Adv. 2017, 7, 39803–39813. [Google Scholar] [CrossRef]

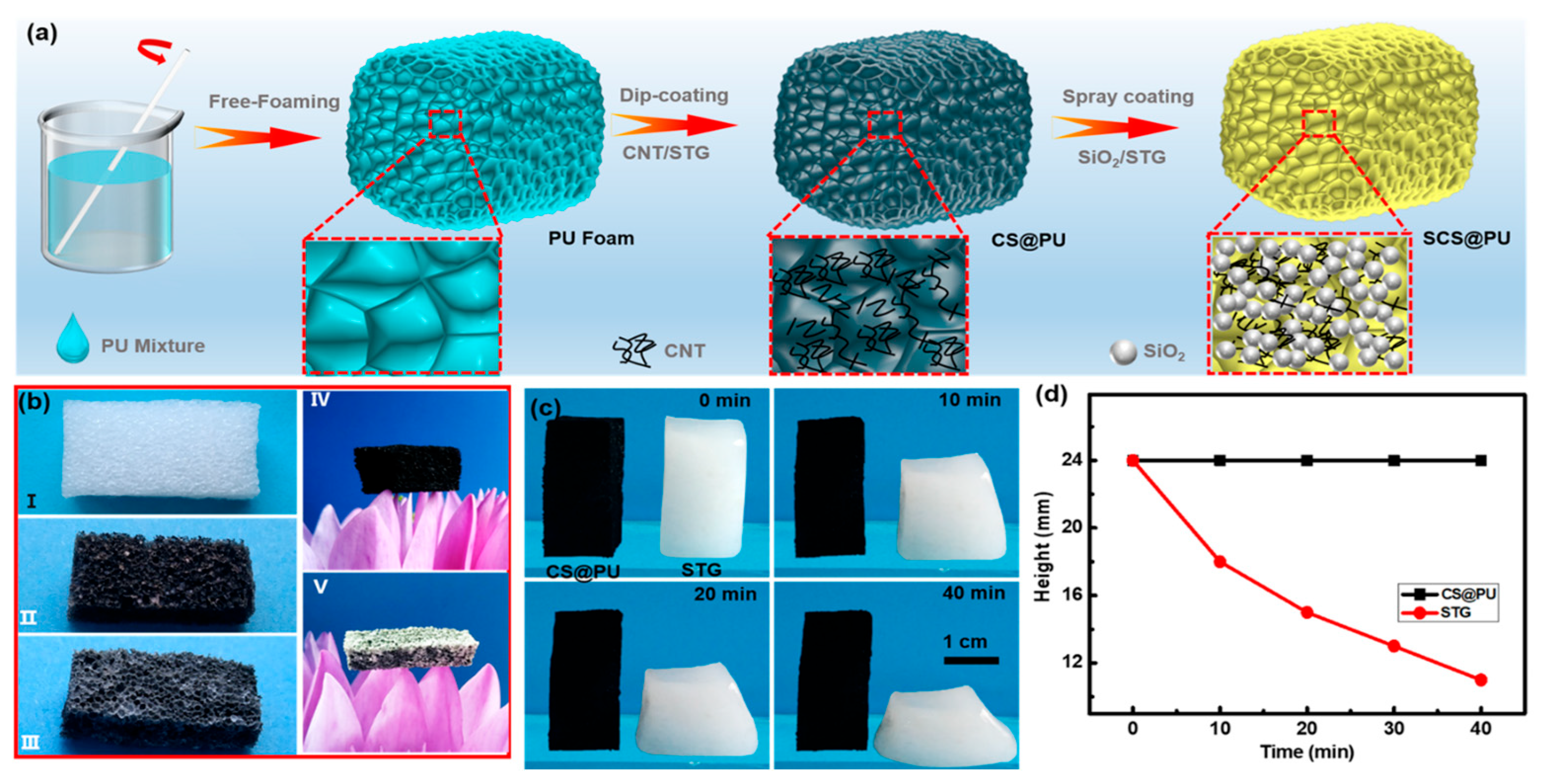

- Fan, T.; Xue, S.-S.; Zhu, W.-B.; Zhang, Y.-Y.; Li, Y.-Q.; Chen, Z.-K.; Huang, P.; Fu, S.-Y. Multifunctional Polyurethane Composite Foam with Outstanding Anti-impact Capacity for Soft Body Armors. ACS Appl. Mater. Interfaces 2022, 14, 13778–13789. [Google Scholar] [CrossRef] [PubMed]

- Fan, T.; Sun, Z.; Zhang, Y.; Li, Y.; Chen, Z.; Huang, P.; Fu, S. Novel Kevlar fabric composite for multifunctional soft body armor. Compos. Part B Eng. 2022, 242, 110106. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, S.; Wang, Y.; Fan, X.; Ding, L.; Xuan, S.; Gong, X. Conductive shear thickening gel/polyurethane sponge: A flexible human motion detection sensor with excellent safeguarding performance. Compos. Part A Appl. Sci. Manuf. 2018, 112, 197–206. [Google Scholar] [CrossRef]

- Fan, Z.; Zhao, C.; Wu, J.; Cai, Y.; Zhou, J.; Zhang, J.; Gong, X.; Xuan, S. Intelligent safeguarding Leather with excellent energy absorption via the toughness-flexibility coupling designation. Compos. Part A Appl. Sci. Manuf. 2022, 161, 107078. [Google Scholar] [CrossRef]

- Cao, S.; Pang, H.; Zhao, C.; Xuan, S.; Gong, X. The CNT/PSt-EA/Kevlar composite with excellent ballistic performance. Compos. Part B Eng. 2020, 185, 107793. [Google Scholar] [CrossRef]

- Tu, H.; Yang, H.; Xu, P.; Yang, Z.; Tang, F.; Dong, C.; Chen, Y.; Ren, L.; Cao, W.; Huang, C.; et al. Protective performance of shear stiffening gel-modified foam against ballistic impact: Experimental and numerical study. Def. Technol. 2024, 32, 510–520. [Google Scholar] [CrossRef]

- Lu, Z.; Li, D.; Yuan, Z. Polypyrrole coating on aramid fabrics for improved stab resistance and multifunction. J. Eng. Fiber. Fabr. 2022, 17, 15589250221081856. [Google Scholar] [CrossRef]

- Protyai, M.I.H.; Adib, F.M.; Taher, T.I.; Karim, M.R.; Rashid, A.B. Performance evaluation of kevlar fiber reinforced epoxy composite by depositing graphene/SiC/Al2O3 nanoparticles. Hybrid Adv. 2024, 6, 100245. [Google Scholar] [CrossRef]

- Liu, P.; Wang, Z.; Zhang, H.; Huang, G. Investigation of ballistic performance of aramid fabrics modified by polyethylene and graphene in high temperature and humidity environments. J. Phys. Conf. Ser. 2024, 2892, 012014. [Google Scholar] [CrossRef]

- Kukle, S.; Valisevskis, A.; Briedis, U.; Balgale, I.; Bake, I. Hybrid Soft Ballistic Panel Packages with Integrated Graphene-Modified Para-Aramid Fabric Layers in Combinations with the Different Ballistic Kevlar Textiles. Polymers 2024, 16, 2106. [Google Scholar] [CrossRef]

- Mohammed, M.T. Graphene-Based Multilayer Polymer Nanocomposite Systems for Force Protection Applications. Doctoral’s Dissertation, The University of Mississipi, Oxford, MS, USA, 2024. Available online: https://www.proquest.com/docview/3158980460?pq-origsite=gscholar&fromopenview=true&sourcetype=Dissertations&Theses (accessed on 9 March 2025).

- Zunino, M.O.H.; Pereira, I.M.; Dias, R.R.; Lavoratti, A.; Beltrami, L.V.R.; Poletto, M.; Zattera, A.J. Graphene Nanoplatelets on Multi-Scale Polymer Composites for Potential Ballistic Shielding. Mater. Res. 2023, 26, e20220062. [Google Scholar] [CrossRef]

- Goswami, M.R.; Singh, P.; Chamoli, P.; Bhardwaj, S.; Raina, K.K.; Shukla, R.K. Tuning of shear thickening behavior and elastic strength of polyvinylidene fluoride via doping of ZnO-graphene. J. Appl. Polym. Sci. 2021, 138, 51260. [Google Scholar] [CrossRef]

- Vignesh, S.; Surendran, R.; Sekar, T.; Rajeswari, B. Ballistic impact analysis of graphene nanosheets reinforced kevlar-29. Mater. Today Proc. 2021, 45, 788–793. [Google Scholar] [CrossRef]

- Nitin, M.S.; Kumar, S.S. Ballistic performance of synergistically toughened Kevlar/epoxy composite targets reinforced with multiwalled carbon nanotubes/graphene nanofillers. Polym. Compos. 2022, 43, 782–797. [Google Scholar] [CrossRef]

- Qiu, Y.; Wu, L.; Liu, S.; Yu, W. Impact-Protective Bicontinuous Hydrogel/Ultrahigh-Molecular Weight Polyethylene Fabric Composite with Multiscale Energy Dissipation Structures for Soft Body Armor. ACS Appl. Mater. Interfaces 2022, 15, 10053–10063. [Google Scholar] [CrossRef]

- Zhang, X.; Li, T.-T.; Wang, Y.; Shiu, B.-C.; Peng, H.-K.; Lou, C.-W.; Lin, J.-. H Hydrogel with high toughness and strength for fabricating high performance stab-resistant aramid composite fabric. J. Mater. Res. Technol. 2021, 15, 1630–1641. [Google Scholar] [CrossRef]

- Wang, S.; Wang, Q.; Zhang, X.; Liu, T.; Cui, Z.; Chen, M.; Fan, X.; Sun, R. Low-Temperature-Tolerant Strain-Sensing Flexible Composite for Soft Body Armor. ACS Appl. Mater. Interfaces 2023, 15, 30880–30890. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, S.; Chen, M.; Wei, L.; Dong, J.; Sun, R. Anti-puncture, frigostable, and flexible hydrogel-based composites for soft armor. J. Mater. Res. Technol. 2022, 21, 2915–2925. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, S.; Chen, X.; Cui, Z.; Li, X.; Zhou, Y.; Wang, H.; Sun, R.; Wang, Q. Bioinspired Flexible Kevlar/Hydrogel Composites with Antipuncture and Strain-Sensing Properties for Personal Protective Equipment. ACS Appl. Mater. Interfaces 2024, 16, 45473–45486. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, Y.; Song, X.; Li, Y.; Zhang, L.; Meng, Y.; Zhang, X.; Qiu, X.; Huang, J. Starfish-Inspired Cut-Resistant Hydrogel with Self-Growing Armor: Where Softness Meets Toughness. Adv. Funct. Mater. 2023, 33, 202304439. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, W.; Cai, J.; Huang, J.; Qiu, X. Equip the hydrogel with armor: Strong and super tough biomass reinforced hydrogels with excellent conductivity and anti-bacterial performance. J. Mater. Chem. A 2019, 7, 26917–26926. [Google Scholar] [CrossRef]

- Pan, M.; Nguyen, K.-C.T.; Yang, W.; Liu, X.; Chen, X.-Z.; Major, P.W.; Le, L.H.; Zeng, H. Soft armour-like layer-protected hydrogels for wet tissue adhesion and biological imaging. Chem. Eng. J. 2022, 434, 134418. [Google Scholar] [CrossRef]

- Zhu, T.; Jiang, C.; Wang, M.; Zhu, C.; Zhao, N.; Xu, J. Skin-Inspired Double-Hydrophobic-Coating Encapsulated Hydrogels with Enhanced Water Retention Capacity. Adv. Funct. Mater. 2021, 31, 2102433. [Google Scholar] [CrossRef]

- Wang, X.; Zhan, S.; Lu, Z.; Li, J.; Yang, X.; Qiao, Y.; Men, Y.; Sun, J. Healable, Recyclable, and Mechanically Tough Polyurethane Elastomers with Exceptional Damage Tolerance. Adv. Mater. 2020, 32, e2005759. [Google Scholar] [CrossRef]

- Li, Z.; Zhu, Y.; Niu, W.; Yang, X.; Jiang, Z.; Lu, Z.; Liu, X.; Sun, J. Healable and Recyclable Elastomers with Record-High Mechanical Robustness, Unprecedented Crack Tolerance, and Superhigh Elastic Restorability. Adv. Mater. 2021, 33, 2101498. [Google Scholar] [CrossRef]

- Veysset, D.; Hsieh, A.J.; Kooi, S.E.; Nelson, K.A. Molecular influence in high-strain-rate microparticle impact response of poly(urethane urea) elastomers. Polymer 2017, 123, 30–38. [Google Scholar] [CrossRef]

- Zhang, Q.; He, H.; Xi, K.; Huang, X.; Yu, X.; Jia, X. Synthesis of N -Phenylaminomethyl POSS and Its Utilization in Polyurethane. Macromolecules 2011, 44, 550–557. [Google Scholar] [CrossRef]

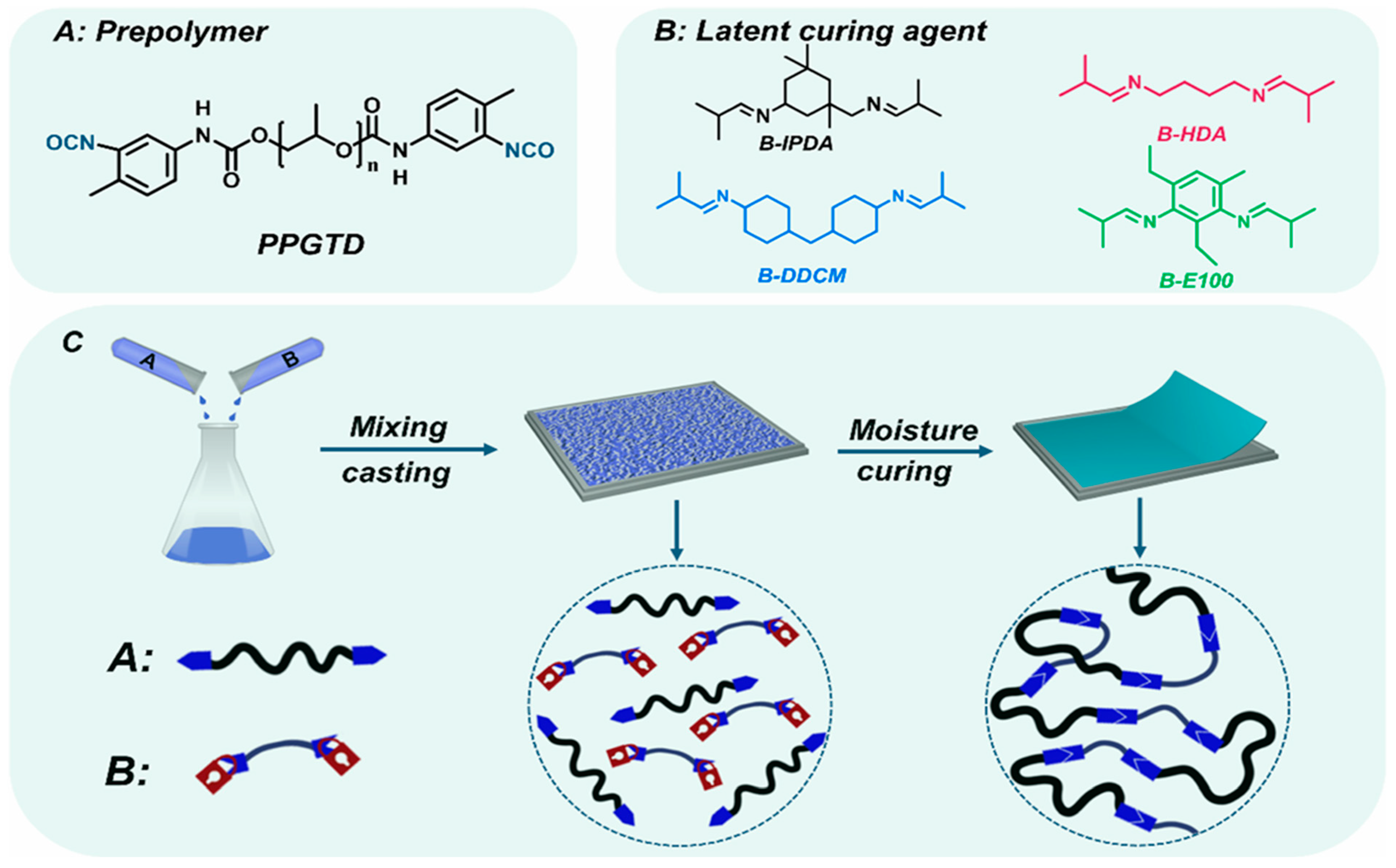

- Zhang, Z.; Qian, L.; Cheng, J.; Xie, Q.; Ma, C.; Zhang, G. Room-Temperature Self-Healing Polyurea with High Puncture and Impact Resistances. Chem. Mater. 2023, 35, 1806–1817. [Google Scholar] [CrossRef]

- Programs, J. Ballistic Resistance of Body Armor NIJ Standard 0101.07. In National Institute of Justice Guide: Body Armor; U.S. Department of Justice: Washington, DC, USA, 2024. [Google Scholar]

- Veeturi, U.; Pramanick, R.; Jadhav, R.; Verma, S.K.; Kumar, P.D.; Neogi, S. Degradation and failure mechanisms in kevlar armor: A study on ultraviolet exposure and multi-impact loading. J. Text. Inst. 2025, 1–16. [Google Scholar] [CrossRef]

- Fayed, A.I.H.; Elgohary, D.H. Improving the efficiency of old aramids soft body armor panels using polyaspartic polyurea. J. Text. Inst. 2025, 1–9. [Google Scholar] [CrossRef]

- Wang, L.; Kong, J.; Chu, D.; Wang, Y.; Wang, T.; Liu, Z. Enhancing ballistic performance: Effect of polyurea coating on backface deformation of UHMWPE laminates. Compos. Struct. 2025, 355, 118846. [Google Scholar] [CrossRef]

- Chang, C.; Shih, C.; You, J.; Youh, M.; Liu, Y. Preparation and Ballistic Performance of a Multi-Layer Armor System Composed of Kevlar/Polyurea Composites and Shear Thickening Fluid (STF)-Filled Paper Honeycomb Panels. Polymers 2021, 13, 3080. [Google Scholar] [CrossRef] [PubMed]

- Higgins, K.M.; Lord, C.K.; Lightsey, S.L.; Malley, K.; Waters, N.E. Ballistic Resistance of Personal Body Armor, Washington, DC, USA. 2001. Available online: https://www.nij.gov/topics/corrections/recidivism/Pages/welcome.aspx (accessed on 26 March 2025).

- Sabol, W.J.; Tillery, C.; Stoe, D.; O’Shea, M. Selection Application Guide 0101.06 to Ballistic-Resistance Body Armor, Washington, DC, USA. 2014. Available online: https://www.ncjrs.gov/pdffiles1/nij/247281.pdf (accessed on 27 March 2025).

- Hernon, J. NIJ’s Bullet-Resistant Vest Standard Reaches Milestone. NIJ J. 2003, 24–27. Available online: https://www.ojp.gov/ncjrs/virtual-library/abstracts/nijs-bullet-resistant-vest-standard-reaches-milestone (accessed on 27 March 2025).

- Payne, T.; Malbon, C.; O’Rourke, S. HOSDB Body Armour Standards for UK Police (2007): Part 3—Knife and Spike Resistance Standard for Body Armour, St. Albans, UK. 2017. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/634517/Home_Office_Body_Armour_Standard.pdf (accessed on 27 March 2025).

- Hepper, A.; Longhurst, D.; Cooper, G.; Gotts, P. Ballistic Protection. In Ryan’s Ballistic Trauma; Springer: London, UK, 2011; pp. 125–147. [Google Scholar] [CrossRef]

- Forster, A.L.; Rice, K.D.; Riley, M.A.; Chan-ou-Teung, A.; Guigues, E.; Forster, A.M. Specifying and testing idealized bust surrogates for testing of female stab-resistant body armor. Text. Res. J. 2015, 85, 2108–2124. [Google Scholar] [CrossRef]

- ISO 11402; International Standard ITEH Standard ITEH Standard Preview. ISO: Geneva, Switzerland, 2004; 10406, pp. 3–6.

- Carr, D.J.; Wilson, C.A.; Laing, R.M. Anthropometric methods for the successful design of military clothing and equipment. In Advances in Military Textiles and Personal Equipment; Woodhead Publishing: Sawston, UK, 2012; pp. 49–63. [Google Scholar] [CrossRef]

- Zakaria, N.; Gupta, D. Apparel sizing: Existing sizing systems and the development of new sizing systems. In Anthropometry, Apparel Sizing and Design; Elsevier: Amsterdam, The Netherlands, 2014; pp. 3–33. [Google Scholar] [CrossRef]

- Ashdown, S. Sizing in Clothing: Developing Effective Sizing Systems for Ready-to-Wear Clothing; Woodhead Publishing: Sawston, UK, 2007. [Google Scholar] [CrossRef]

- Fuster, V.; Jerez, A.; Ortega, A. Anthropometry and strength relationship: Male-female differences. Anthropol. Anz. 1998, 56, 49–56. [Google Scholar] [CrossRef]

- Meyer, J.P.; Allen, N.J. A three-component conceptualization of organizational commitment. Hum. Resour. Manag. Rev. 1991, 1, 61–89. [Google Scholar] [CrossRef]

- Li, P.; Choi-Rokas, H.; Mitchell, B.; Tashjian, A.; Hurley, M. An iterative and anthropometrically driven approach to body armor plate design for females. In Digital Human Modeling and Applied Optimization; Scataglini, S., Rajulu, S., Eds.; AHFE International: New York, NY, USA, 2023; Volume 76. [Google Scholar] [CrossRef]

- Abtew, M.A.; Bruniaux, P.; Boussu, F. Customizations of women bullet-proof jacket through 3d design process. Text. Leather Rev. 2019, 2, 23–31. [Google Scholar] [CrossRef]

- Foust, C.; Jenson, C. Industry Analysis for Body Armor Procurement; MBA Professional Reportl Naval Postgraduate School: Monterey, CA, USA, 2023. [Google Scholar]

- Klemic, G. Ballistic-Resistant Body Armor for Women, Varick Street, NY, USA. 2020. Available online: www.dhs.gov/science-and-technology/SAVER (accessed on 26 March 2025).

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Loghin, C.; Cristian, I. Ballistic impact mechanisms—A review on textiles and fibre-reinforced composites impact responses. Compos. Struct. 2019, 223, 110966. [Google Scholar] [CrossRef]

- Abtew, M.A.; Sitotaw, D.B.; Bajya, M. Comprehensive Review of Endogenous and Exogenous Parameters Influencing Dynamic Stab Impact Performance in Protective Textiles and Fibrous Composite Materials. J. Compos. Sci. 2025, 9, 138. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Cristian, I.; Dejene, B.K. Experimental investigation on dynamic stab resistance of high-performance multi-layer textile materials. Def. Technol. 2025, 47, 1–14. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Cristian, I. Exploring the effects of angle of incidence on stabbing resistance in advanced protective textiles: Novel experimental framework and analysis. Def. Technol. 2025, 44, 67–82. [Google Scholar] [CrossRef]

- Santos, T.; Santos, C.; Aquino, M.; Rangappa, S.M.; Siengchin, S.; Nascimento, J.; Medeiros, I. Effects of UV sensitivity and accelerated photo-aging on stab resistance of ρ-aramid fabrics impregnated with shear thickening fluids (STFs). Heliyon 2023, 9, e15020. [Google Scholar] [CrossRef] [PubMed]

- Hani, A.R.A.; Roslan, A.; Mariatti, J.; Maziah, M. Body armor technology: A review of materials, construction techniques and enhancement of ballistic energy absorption. Adv. Mater. Res. 2012, 488–489, 806–812. [Google Scholar] [CrossRef]

- Hymas, C.; Lacey, S.; Rohrbach, K.; Gillard, S.; Berkey, C. Novel PBA-Grafted Carbon Nanotube Soft Body Armor, University of Maryland. Available online: https://mse.umd.edu/sites/mse.umd.edu/files/documents/undergrad/enma490/PBA Grafted CNT Soft Body Armor Final Report.pdf (accessed on 5 March 2025).

- Peoples, G.; Silk, A.; Notley, S.; Holland, L.; Collier, B.; Lee, D. The Effect of a Tiered Body Armour System on Soldier Physical Mobility; University of Wollongong: Wollongong, NSW, Australia, 2010. [Google Scholar]

- Shah, M.A.; Pirzada, B.M.; Price, G.; Shibiru, A.L.; Qurashi, A. Applications of nanotechnology in smart textile industry: A critical review. J. Adv. Res. 2022, 38, 55–75. [Google Scholar] [CrossRef]

- Merkle, A.C.; Ward, E.E.; O’Connor, J.V.; Roberts, J.C. Assessing behind Armor Blunt Trauma (BABT) under NIJ standard-0101.04 conditions using human torso models. J. Trauma-Inj. Infect. Crit. Care 2008, 64, 1555–1561. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Loghin, C.; Cristian, I.; Chen, Y.; Wang, L. Yarn degradation during weaving process and its effect on the mechanical behaviours of 3D warp interlock p-aramid fabric for industrial applications. J. Ind. Text. 2022, 51, 9047S–9070S. [Google Scholar] [CrossRef]

| Size | Chest Breadth (mm) | Chest Circumference (mm) | Waist Breadth (mm) | Waist Circumference (mm) | Waist Front Length, Sitting | Weight (kg) | BMI | Stature (mm) |

|---|---|---|---|---|---|---|---|---|

| XZ | 296 | 910 | 245 | 300 | 805 | 360 | 64.0 | 24.9 |

| S | 317 | 971 | 263 | 330 | 902 | 371 | 73.2 | 25.9 |

| M | 336 | 1058 | 285 | 339 | 944 | 376 | 78.0 | 30.4 |

| R | 355 | 1082 | 305 | 355 | 1017 | 392 | 91.7 | 30.8 |

| L(S) | 366 | 1139 | 322 | 284 | 1065 | 366 | 96.7 | 35.3 |

| L(l) | 367 | 1173 | 336 | 402 | 1121 | 410 | 97.9 | 35.4 |

| XL | 402 | 1232 | 355 | 436 | 1234 | 403 | 117.7 | 37.4 |

| XXL | 434 | 1316 | 374 | 465 | 1297 | 432 | 117.3 | 44.6 |

| Material/Composite | Manufacturing Method | Advantages | Challenges | Approximate Cost Implications | Ref. |

|---|---|---|---|---|---|

| Para-Aramid (Kevlar®, Twaron®) | 2D/3D weaving, Lamination | High ballistic resistance, lightweight | UV degradation, limited multi-threat resistance, moderate flexibility | Moderate to High | [66,67]. |

| UHMWPE (Dyneema®, Spectra®) | UD Laminate, Hot pressing | Excellent ballistic resistance, lightweight | Thermal instability, difficult recycling | High | [66,67]. |

| Thermoplastic 3D-FRC (Elium®) | Resin infusion, Compression molding | High impact tolerance, less damage sensitivity, recyclability | Higher resin cost, process adaptation required | Moderate to High | [76] |

| Thermoset 3D-FRC (Epoxy) | Resin infusion, Compression molding | High strength, established processes | Brittle failure, sensitive to impact damage, less recyclable | Moderate | [76] |

| STF-treated Fabrics (Kevlar + Silica/PEG) | Dip coating, Sandwich Laminate | Improved energy absorption, lightweight | Fluid leakage, breathability issues | Moderate to High | [74] |

| Graphene/Carbon Nanotube Composites | Infusion, Coating, Hybrid laminate | High strength, multifunctional (conductivity, sensing) | High material cost, limited scalability | High | [79]. |

| 3D Warp Interlock Fabrics | 3D weaving | Seamless shaping, reduced weak points | Complex weaving, limited scalability | Moderate | [54,55,56]. |

| Shear Thickening Gels (STG) + Foams | Infusion into foam matrix | Enhanced shock absorption | Process development, material stability | High | [80] |

| Silica Concentrations (wt.%) | Impacts on STF Behavior | Effect on Ballistic Protection |

|---|---|---|

| <20% | Very fluid, weak thickening effect | Minimal improvement in energy absorption |

| 20–30% | Moderate thickening, good balance | Improved protection while keeping flexibility |

| 40% (Most common) | Strong thickening, ideal viscosity | Best balance of impact resistance and flexibility |

| 50–60% | Very thick STF, higher resistance | Better impact resistance but reduced flexibility |

| Sample Code | Polymer Matrix | Fumed Silica (0.2–0.3 µm) [wt.%] | Pyrogenic Silica (>40 µm) [wt.%] |

|---|---|---|---|

| P1 | PEG 400 | 20 | - |

| P2 | PEG 400 | 30 | - |

| P3 | PEG 400 | - | 20 |

| P4 | PEG 400 | - | 30 |

| P5 | PPG 400 | 20 | - |

| P6 | PPG 400 | - | 20 |

| P7 | PEG 200 1 | - | 40 |

| P8 | PEG 400 1 | - | 40 |

| P9 | PPG 400 1 | - | 40 |

| P10 | PEG 400 | - | 27 |

| P-bk | PEG 400 | - | - |

| Threat Level | Caliber | Bullet | Mass (g) |

|---|---|---|---|

| I | 0.22 long rifle; 0.380 ACP | Lead round nose; FMJ round nose | 2.6; 6.2 |

| IIA | 9 mm; 0.40 S&W | FMJ round nose; FMJ | 8.0; 11.7 |

| II | 9 mm; 0.357 Magnum | FMJ round nose; jacketed soft point | 8.0; 10.2 |

| IIIA | High velocity 9 mm; 0.44 Magnum | FMJ round nose; jacketed hollow point | 8.0; 15.6 |

| III | 7.62 mm rifle | Full metal jacket | 9.6 |

| IV | 0.30 caliber rifle | Armor-piercing | 10.8 |

| Threat Level | Designation | Caliber | Bullet | Mass (g) | Velocity (m/s) |

|---|---|---|---|---|---|

| Handgun Level 1 | HG1 | 9 mm; 0.40 S&W | FMJ round node: FMJ | 8.0; 11.7 | 332; 312 |

| Handgun Level 2 | HG2 | 0.357 Magnum; 0.44 Magnum | Jacketed soft point: SJHP | 10.2; 15.6 | 427 |

| Rifle Level 1 | RF1 | 7.62 mm NATO | Full metal jacket (M80) | 9.6 | 838 |

| Rifle Level 2 | RF2 | Intermediate rifle calibers | Steel core or enhanced FMJ | -- | -- |

| Rifle Level 3 | RF3 | 0.30-06 caliber rifle | Armor-piercing (M2 AP) | 10.8 | 878 |

| Level of Protection | Ammunition Type | Bullet Mass (Grams/Grains) | Test Velocity (m/s) | Test Distance | Maximum Allowed BFS (Indentation) | Intended Threat Level |

|---|---|---|---|---|---|---|

| HO1 | 9 mm FMJ (Full Metal Jacket) 9 mm JHP (Hollow Point) | 8.0 g (124 grain) | 365 ± 10 | 5 m | Mean: 44 mm | Low-velocity handgun threats (standard pistols) |

| HO2 | 9 mm FMJ 9 mm JHP | 8.0 g (124 grain) | 430 ± 10 | 5 m | Single shot: 44 mm | Higher-velocity handgun threats |

| HO3 | 7.62 mm NATO Ball (Radway Green L44A1/L2A2) 7.62 × 39 mm surrogate (e.g., AK-47) | 9.3 g (144 grain) NATO | NATO: 830 ± 15 | 10 m | Mean: 44 mm | Intermediate rifle threats (military-grade rifles) |

| HO4 | SAKO 0.308 Winchester (Barnes TSX BT or similar) | 7.9 g (122 grain) Surrogate | Surrogate: 705 ± 15 | 10 m | Single shot: 44 mm | High-threat rifle ammunition (sniper rounds) must also meet HO3 criteria |

| SG1 | 12-Gauge Shotgun Slug (Winchester 1 oz. Rifled) | 10.7 g (165 grain) | 820 ± 15 | 10 m | Mean: 25 mm | Heavy shotgun projectile threats |

| Special Levels | Examples: 0.357 Magnum (Soft Point) 5.56 × 45 mm NATO SS109 Federal Tactical Bonded 5.56 mm | 28.4 g (1 oz.) | 435 ± 25 | Specific per ammunition type | Single shot: 30 mm | Customized or unique operational threats |

| Threat Class | Energy | Energy Density | Common Calibers |

|---|---|---|---|

| I up to 250 J or up to 5 J/mm2 | 22 short 22 long 22 L.R. common calibers 32 S.&W. 32 S.&W. long 6.35 Browning 7.65 Browning 9 mm Brown. short | 22 short 22 long 32 S.&W. 32 S.&W. long 44 S.&W. Spl. 6.35 Browning 7.65 Browning 9 mm Brown. short | 22 short 22 long 32 S.&W. 32 S.&W. long 6.35 Browning 7.65 Browning 9 mm Brown. short |

| II up to 500 J or up to 8 J/mm2 | 22 Win. Mag. 38 Spl. 44 S.&W. Spl. 45 Auto 7.65 Parabellum 9 mm Brown. long 9 mm Luger 9 mm Makarov | 22 L.R. 38 Spl. 40 S&W 45 Auto 45 Colt 9 mm Brown. long 9 mm Luger 9 mm Makarov | 38 Spl. 45 Auto 9 mm Brown. long 9 mm Luger 9 mm Makarov |

| III up to 750 J or up to 11 J/mm2 | 10 mm Auto 357 SIG 38 Super Auto 40 S &W 45 Colt 7.62 × 25 Tokarev 9 × 21 | 10 mm Auto 357 SIG 38 Super Auto 7.65 Parabellum 9 × 21 | 10 mm Auto 357 SIG 38 Super Auto 9 × 21 |

| IV higher than 750 J or higher than 11 J/mm2 | 357 Magnum 41 Rem. Mag. 44 Rem. Mag. | 357 Magnum 41 Rem. Mag. 44 Rem. 7.62 × 25 Tokarev 22 Win. Mag. | 357 Magnum 41 Rem. Mag. 44 Rem. Mag. |

| Standard | Origin | Year Introduced | Protection Levels | Key Features | Backing Material |

|---|---|---|---|---|---|

| NIJ 0101.04 | USA | 2000 | Level I to IV | Six levels, V50 test, BFS < 44 mm, widely used | Roma Plastilina No. 1 clay |

| NIJ 0101.06 | USA | 2008 | Type IIA to IV + Special Type | Pre-conditioning, Special Type, refined threat levels | Roma Plastilina No. 1 clay |

| NIJ 0101.07 | USA | 2023 | HG1, HG2, RF1 to RF3 | Oblique shots, new level system (HG/RF), gender-specific testing | Molded clay appliques |

| HOSDB/CAST | UK | 1993 (latest 2017) | HO1 to HO4, SG1, Special Levels | Covers ballistic, knife, and spike threats; shaped panels; BFS < 44 or 25 mm | Roma Plastilina No. 1 clay |

| VPAM | Germany | 1999 | Class I to IV (based on energy and energy density) | Energy density-based classification; protection probability modeling | Custom setup depending on the threat |

| ISO/FDIS 14876-1 | International (ISO/CEN) | 2002 | Bullet, knife, and spike resistance are defined | General requirements; ergonomic design; realistic testing methods | Flexible (realistic simulation) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tamjid, M.I.; Abtew, M.A.; Kopot, C. Lightweight Textile and Fiber-Reinforced Composites for Soft Body Armor (SBA): Advances in Panel Design, Materials, and Testing Standards. J. Compos. Sci. 2025, 9, 337. https://doi.org/10.3390/jcs9070337

Tamjid MI, Abtew MA, Kopot C. Lightweight Textile and Fiber-Reinforced Composites for Soft Body Armor (SBA): Advances in Panel Design, Materials, and Testing Standards. Journal of Composites Science. 2025; 9(7):337. https://doi.org/10.3390/jcs9070337

Chicago/Turabian StyleTamjid, Mohammed Islam, Mulat Alubel Abtew, and Caroline Kopot. 2025. "Lightweight Textile and Fiber-Reinforced Composites for Soft Body Armor (SBA): Advances in Panel Design, Materials, and Testing Standards" Journal of Composites Science 9, no. 7: 337. https://doi.org/10.3390/jcs9070337

APA StyleTamjid, M. I., Abtew, M. A., & Kopot, C. (2025). Lightweight Textile and Fiber-Reinforced Composites for Soft Body Armor (SBA): Advances in Panel Design, Materials, and Testing Standards. Journal of Composites Science, 9(7), 337. https://doi.org/10.3390/jcs9070337