Potential Use of Residual Powder Generated in Cork Stopper Industry as Valuable Additive to Develop Biomass-Based Composites for Injection Molding

Abstract

1. Introduction

2. Materials and Method

2.1. Materials

2.2. Sieving and Screening of Cork Powder

2.3. Moisture Content Determination of Microparticulated Cork

2.4. Fabrication of CPCs

2.5. Fabrication of Tensile Specimens

2.6. Characterization Methods

2.6.1. Characterization by Scanning Electron Microscopy (SEM)

2.6.2. Fourier Transform Infrared Spectroscopy (FTIR)

2.6.3. Methodology for Density Analysis

2.6.4. X-Ray Computerized Tomography (CT) Characterization of CPCs

2.6.5. Characterization of Thermal Properties

2.6.6. Tensile Testing

2.6.7. Statistical Analysis ANOVA

3. Results and Discussion

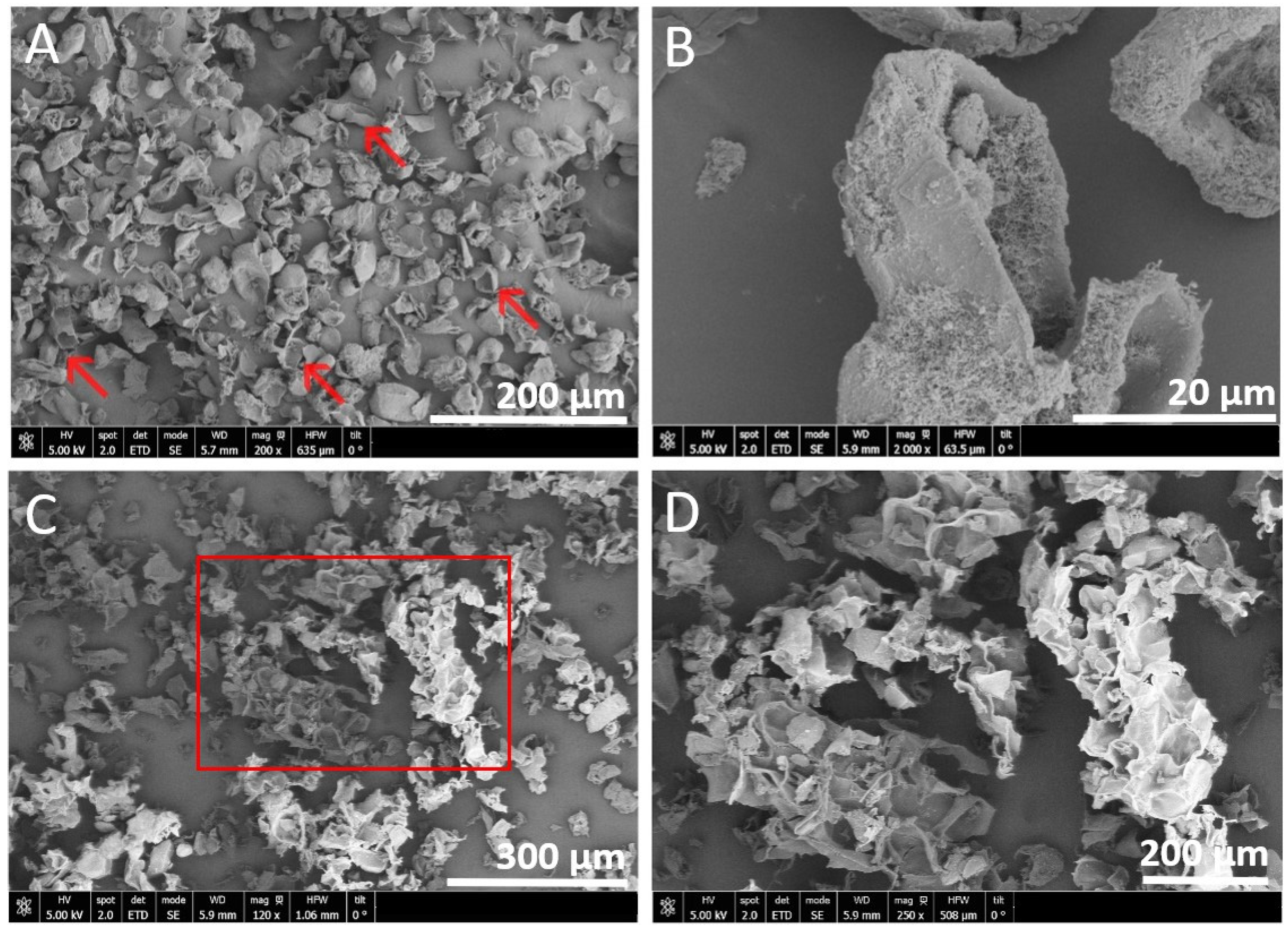

3.1. Morphology of the Cork Particles Analyzed by SEM

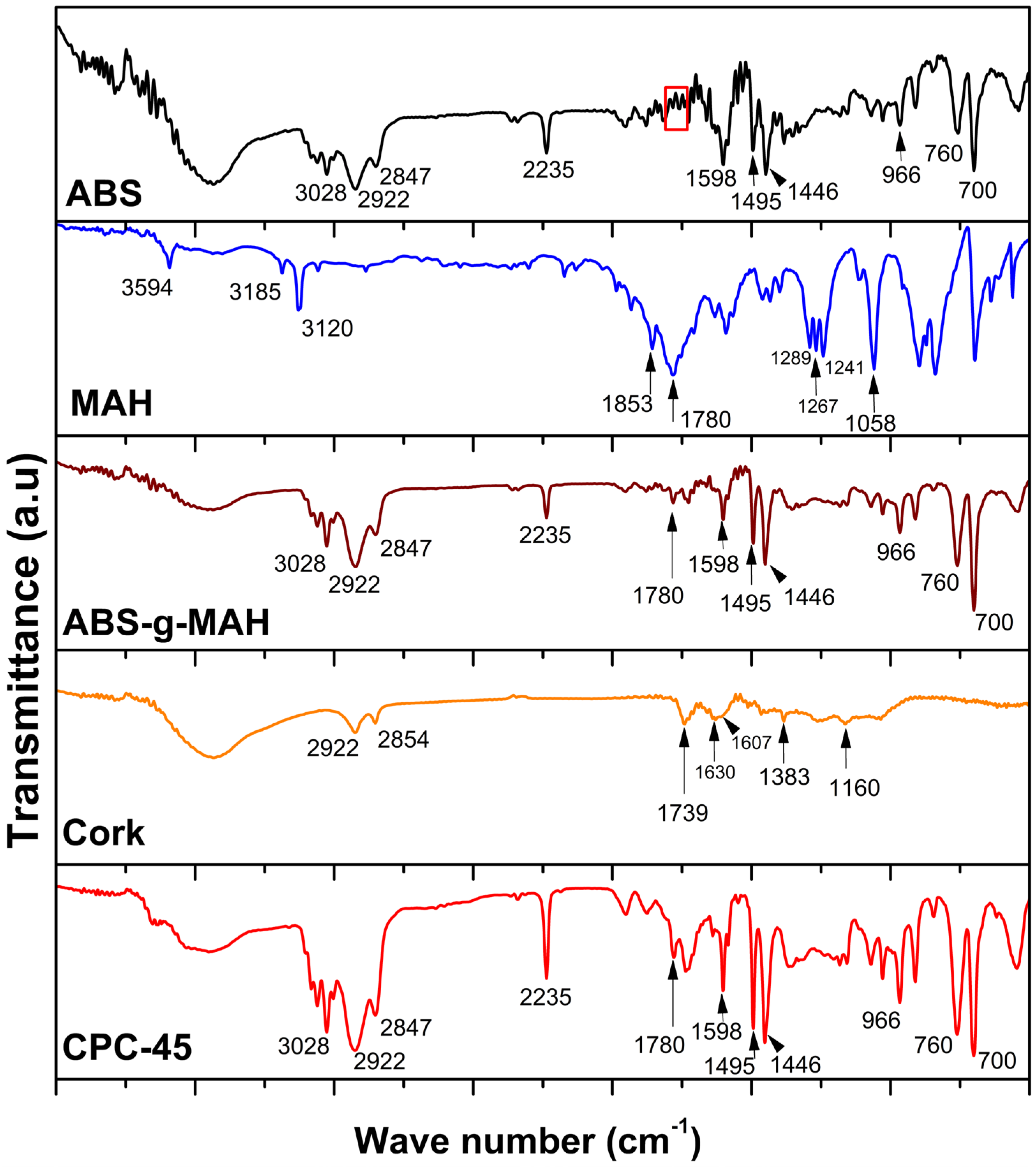

3.2. Fourier-Transform Infrared Spectroscopy Analysis

3.3. Density

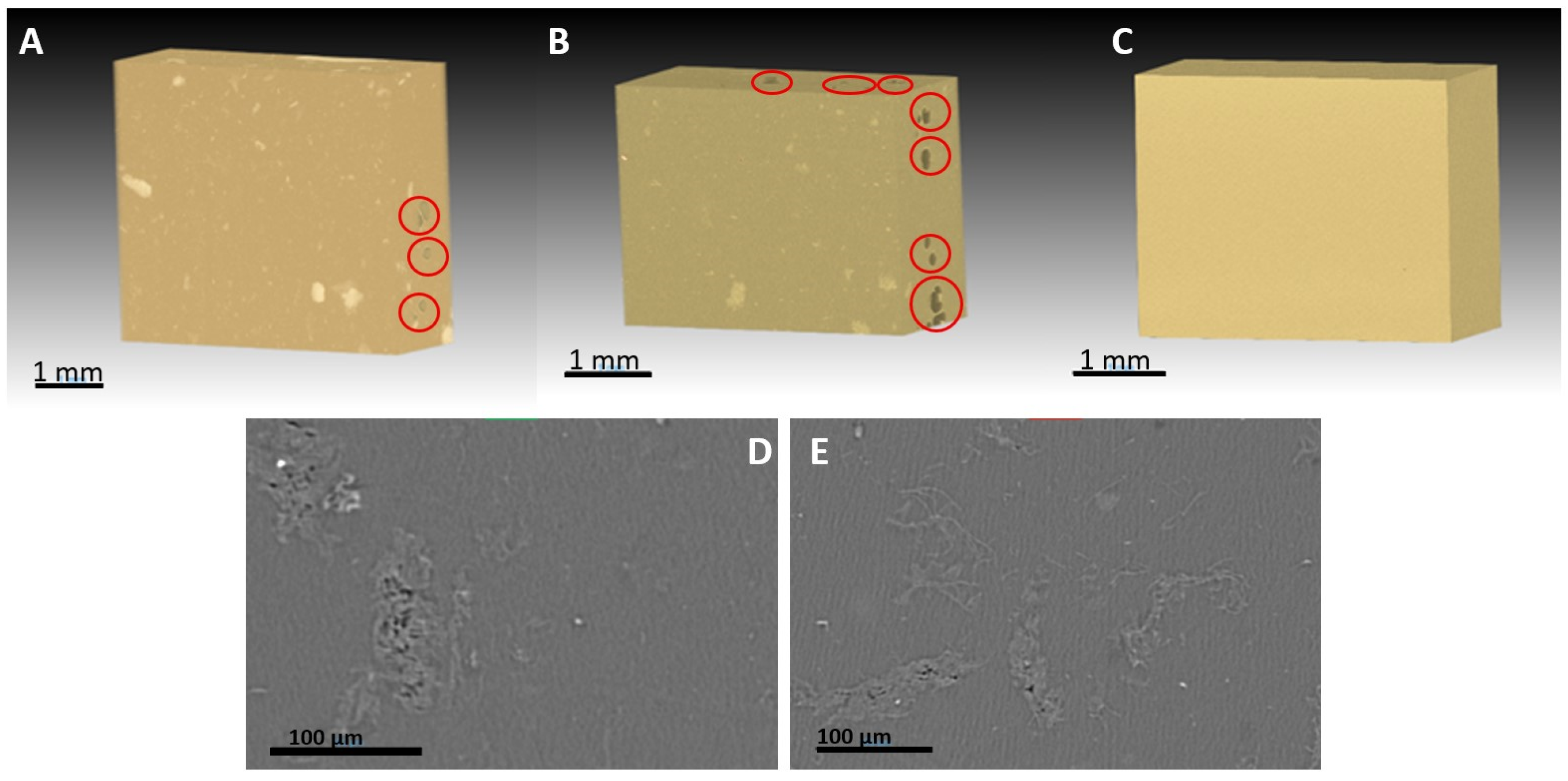

3.4. CT Analysis of CPCs

3.5. Thermal Stability Analysis

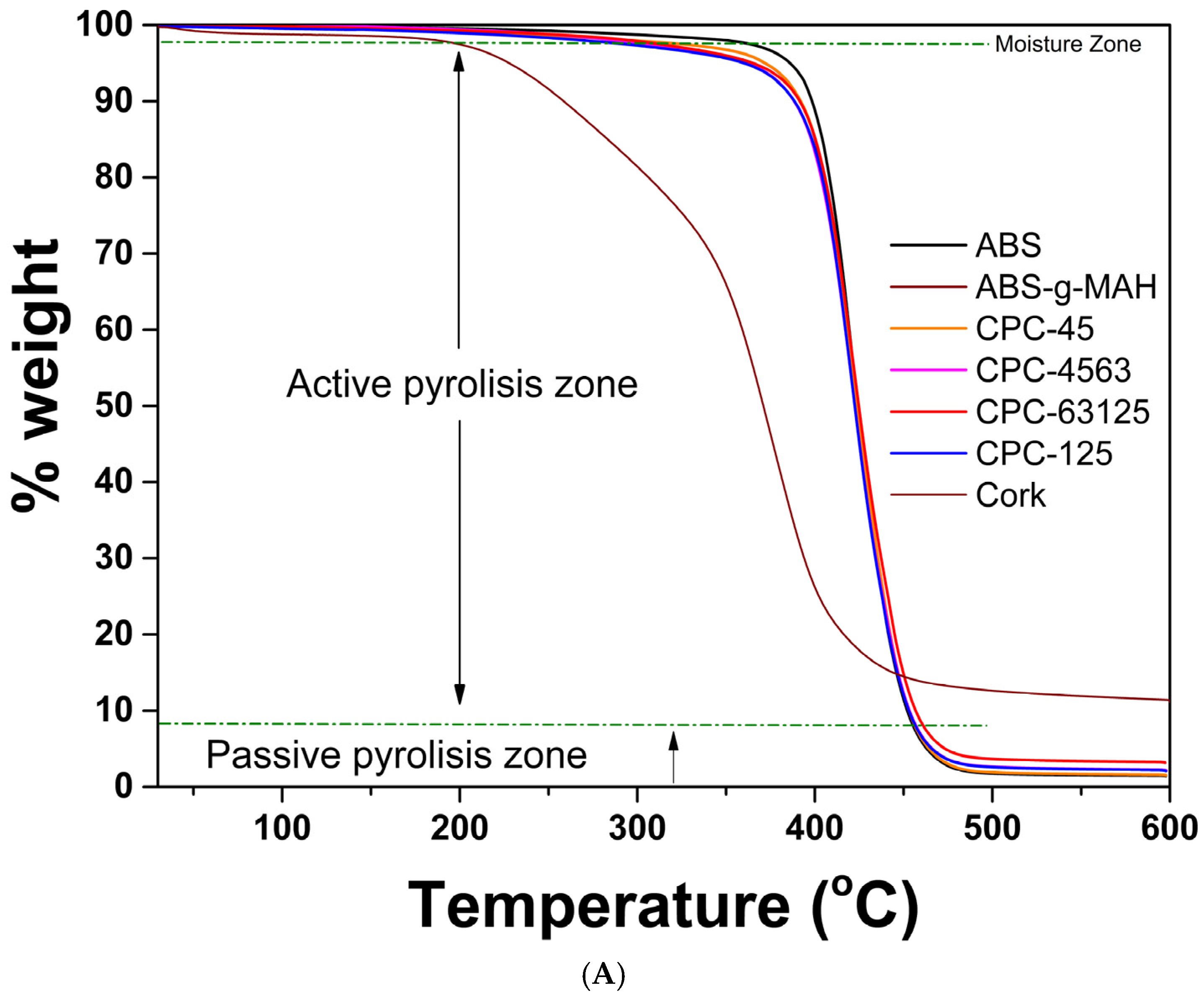

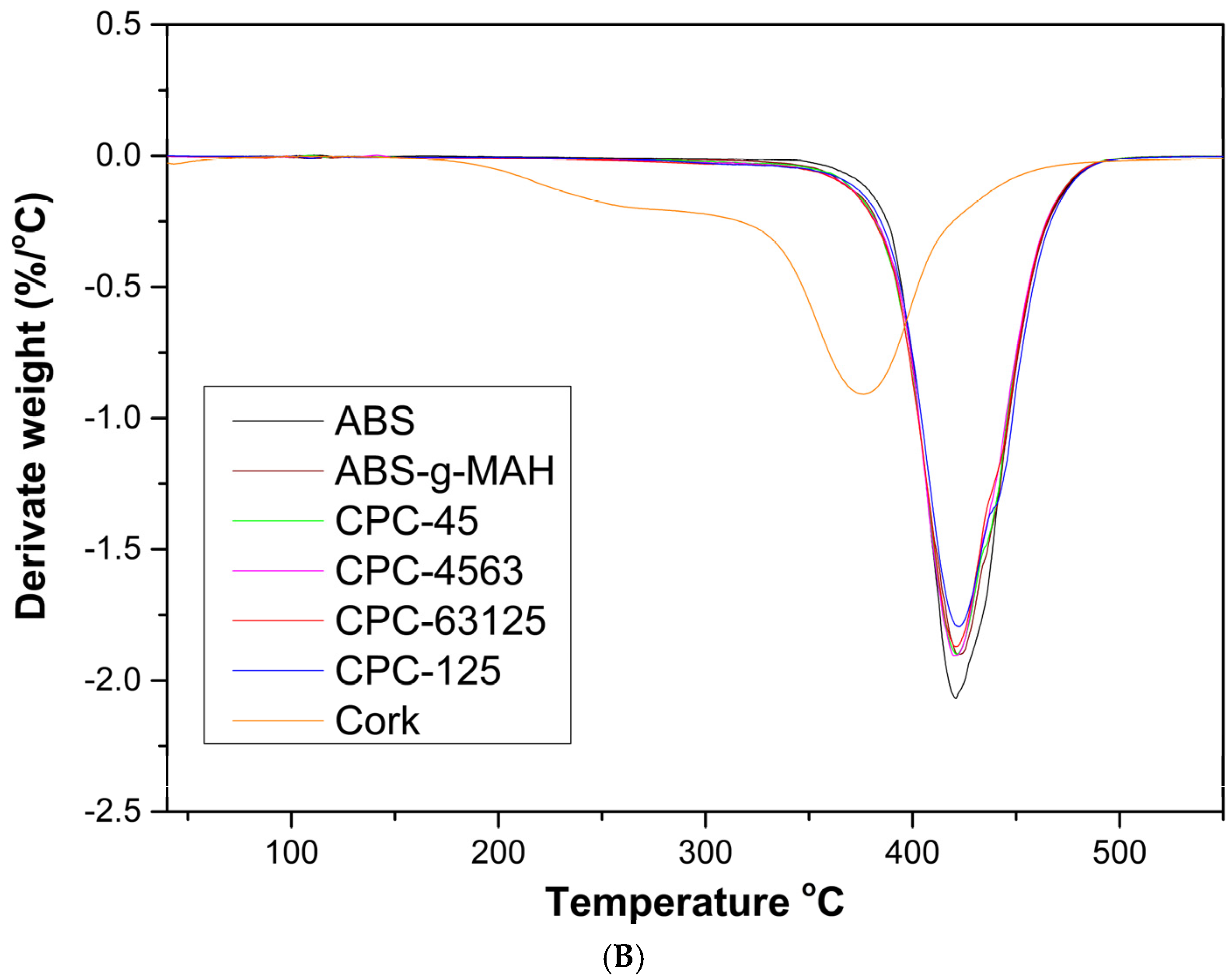

3.5.1. Thermogravimetric Analysis and Derivative Thermograms (DTG)

3.5.2. Differential Scanning Calorimetry

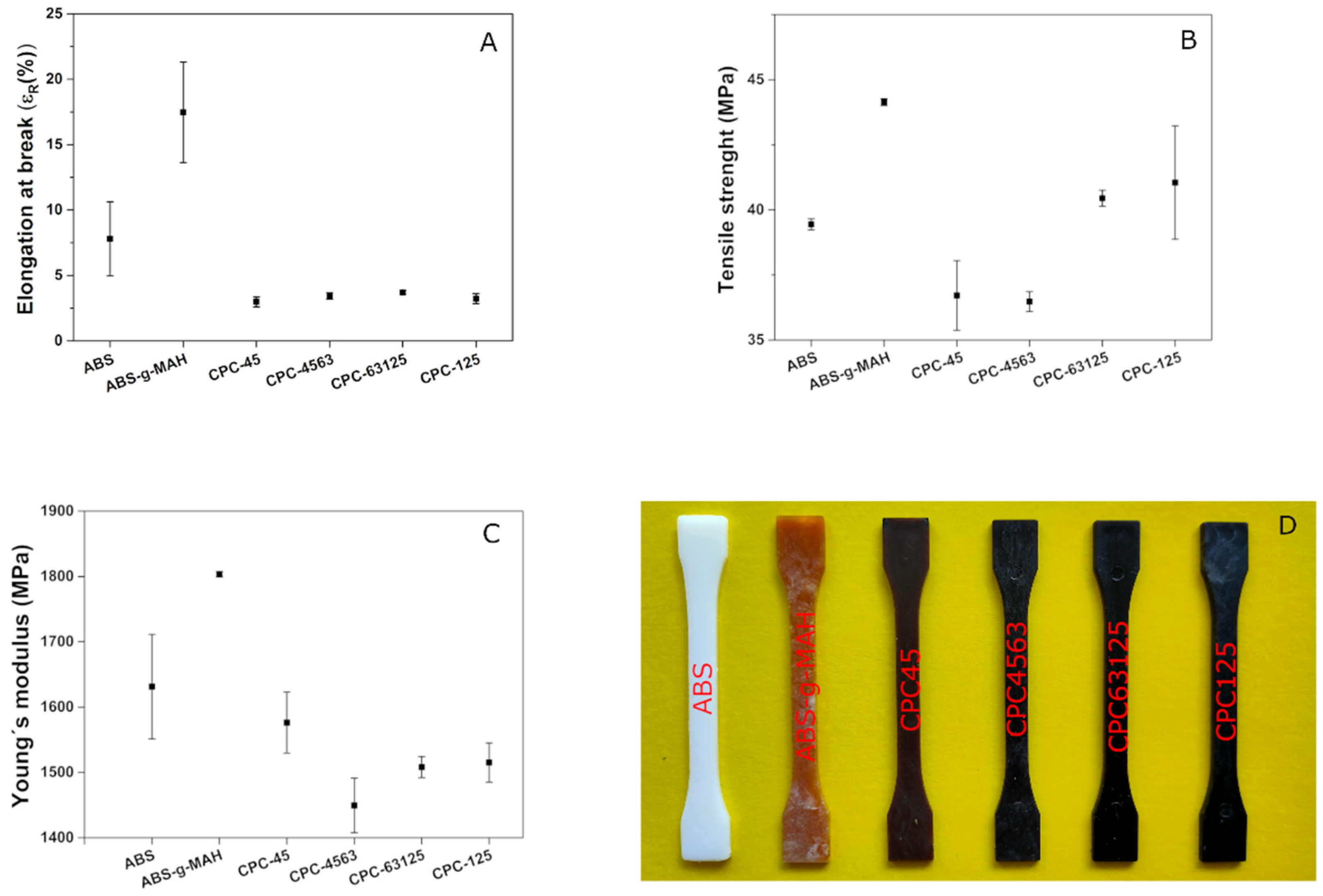

3.6. Mechanical Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- van Oosterhout, L.; Dijkstra, H.; Borst, D.; Duijndam, S.; Rehdanz, K.; van Beukering, P. Triggering sustainable plastics consumption behavior: Identifying consumer profiles across Europe and designing strategies to engage them. Sustain. Prod. Consum. 2023, 36, 148–160. [Google Scholar] [CrossRef]

- Mielinger, E.; Weinrich, R. A review on consumer sorting behaviour: Spotlight on food and Fast Moving Consumer Goods plastic packaging. Environ. Dev. 2023, 47, 100890. [Google Scholar] [CrossRef]

- Kibria, G. Impacts of microplastic on fisheries and seafood security—Global analysis and synthesis. Sci. Total Environ. 2023, 904, 166652. [Google Scholar] [CrossRef]

- Heidbreder, L.M.; Bablok, I.; Drews, S.; Menzel, C. Tackling the plastic problem: A review on perceptions, behaviors, and interventions. Sci. Total Environ. 2019, 668, 1077–1093. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Wang, X.; Su, M.; Zou, X.; Duan, L.; Zhang, H. Characteristics of Plastic Pollution in the Environment: A Review. Bull. Environ. Contam. Toxicol. 2021, 107, 577–584. [Google Scholar] [CrossRef]

- MacLeod, M.; Arp, H.P.H.; Tekman, M.B.; Jahnke, A. The global threat from plastic pollution. Science 2021, 373, 61–65. [Google Scholar] [CrossRef]

- Hsissou, R.; Seghiri, R.; Benzekri, Z.; Hilali, M.; Rafik, M.; Elharfi, A. Polymer composite materials: A comprehensive review. Compos. Struct. 2021, 262, 113640. [Google Scholar] [CrossRef]

- Ghosh, A.K.; Dwivedi, M. (Eds.) Advantages and Applications of Polymeric Composites. In Processability of Polymeric Composites; Springer: New Delhi, India, 2020; pp. 29–57. [Google Scholar] [CrossRef]

- Ozturk, F.; Cobanoglu, M.; Ece, R.E. Recent advancements in thermoplastic composite materials in aerospace industry. J. Thermoplast. Compos. Mater. 2023, 37, 3084–3116. [Google Scholar] [CrossRef]

- Spini, F.; Bettini, P. End-of-Life wind turbine blades: Review on recycling strategies. Compos. B Eng. 2024, 275, 111290. [Google Scholar] [CrossRef]

- Zhang, J.; Lin, G.; Vaidya, U.; Wang, H. Past, present and future prospective of global carbon fibre composite developments and applications. Compos. B Eng. 2023, 250, 110463. [Google Scholar] [CrossRef]

- Rani, M.; Choudhary, P.; Krishnan, V.; Zafar, S. A review on recycling and reuse methods for carbon fiber/glass fiber composites waste from wind turbine blades. Compos. B Eng. 2021, 215, 108768. [Google Scholar] [CrossRef]

- Abdur Rahman, M.; Haque, S.; Athikesavan, M.M.; Kamaludeen, M.B. A review of environmental friendly green composites: Production methods, current progresses, and challenges. Environ. Sci. Pollut. Res. 2023, 30, 16905–16929. [Google Scholar] [CrossRef] [PubMed]

- Mishra, B.; Mohanta, Y.K.; Reddy, C.N.; Reddy, S.D.M.; Mandal, S.K.; Yadavalli, R.; Sarma, H. Valorization of agro-industrial biowaste to biomaterials: An innovative circular bioeconomy approach. Circ. Econ. 2023, 2, 100050. [Google Scholar] [CrossRef]

- Yang, Y.; Guan, Y.; Li, C.; Xu, T.; Dai, L.; Xu, J.; Si, C. Application and carbon footprint evaluation of lignin-based composite materials. Adv. Compos. Hybrid Mater. 2024, 7, 61. [Google Scholar] [CrossRef]

- Gil, L. Cork composites: A review. Materials 2009, 2, 776–789. [Google Scholar] [CrossRef]

- Pinto, J.R.A.; Sanches, N.B.; Diniz, M.F.; Santos, R.S.; De Oliveira, J.I.; Dutra, R.D.C.L. Expanded perlite/cork fillers applied to aerospace insulation material. An. Acad. Bras. Cienc. 2018, 90, 3197–3206. [Google Scholar] [CrossRef]

- Silva, J.M.; Gamboa, P.V.; Nunes, C.; Paulo, L.; Franco, N. Cork: Is it a good material for aerospace structures? In Proceedings of the 52nd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Denver, CO, USA, 4–7 April 2011; pp. 1–11. [Google Scholar] [CrossRef]

- Luna, C.B.B.; Siqueira, D.D.; Araújo, E.M.; Wellen, R.M.R.; de Mélo, T.J.A. Approaches on the acrylonitrile-butadiene-styrene functionalization through maleic anhydride and dicumyl peroxide. J. Vinyl Addit. Technol. 2021, 27, 308–318. [Google Scholar] [CrossRef]

- Nourbakhsh, A.; Ashori, A. Wood plastic composites from agro-waste materials: Analysis of mechanical properties. Bioresour. Technol. 2010, 101, 2525–2528. [Google Scholar] [CrossRef]

- Serra-Parareda, F.; Espinach, F.X.; Pelach, M.À.; Méndez, J.A.; Vilaseca, F.; Tarrés, Q. Effect of NaOH Treatment on the Flexural Modulus of Hemp Core Reinforced Composites and on the Intrinsic Flexural Moduli of the Fibers. Polymers 2020, 12, 1428. [Google Scholar] [CrossRef]

- Fernandes, E.M.; Pires, R.A.; Reis, R.L. Cork Biomass Biocomposites: Lightweight and Sustainable Materials; Elsevier Ltd.: Amsterdam, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Gil, L. Cork powder waste: An overview. Biomass Bioenergy 1997, 13, 59–61. [Google Scholar] [CrossRef]

- Duarte, A.P.; Bordado, J.C. Cork—A renewable raw material: Forecast of industrial potential and development priorities. Front. Mater. 2015, 2, 2. [Google Scholar] [CrossRef]

- Zhai, W.; Zhong, Y.; Xu, M.; Wei, X.; Cai, L.; Xia, C. Transforming wastes into functional materials: Natural cork-based physical structural components and polymers. Green Chem. 2024, 26, 8615–8641. [Google Scholar] [CrossRef]

- Brites, F.; Malça, C.; Gaspar, F.; Horta, J.F.; Franco, M.C.; Biscaia, S.; Mateus, A. The Use of Polypropylene and High-Density Polyethylene on Cork Plastic Composites for Large Scale 3D Printing. Appl. Mech. Mater. 2019, 890, 205–225. [Google Scholar] [CrossRef]

- Magalhães da Silva, S.P.; Antunes, T.; Costa, M.E.V.; Oliveira, J.M. Cork-like filaments for Additive Manufacturing. Addit. Manuf. 2020, 34, 101229. [Google Scholar] [CrossRef]

- Brites, F.; Malça, C.; Gaspar, F.; Horta, J.F.; Franco, M.C.; Biscaia, S.; Mateus, A. Cork Plastic Composite Optimization for 3D Printing Applications. Procedia Manuf. 2017, 12, 156–165. [Google Scholar] [CrossRef]

- Gama, N.; Ferreira, A.; Barros-Timmons, A. 3D printed cork/polyurethane composite foams. Mater. Des. 2019, 179, 107905. [Google Scholar] [CrossRef]

- Magalhães da Silva, S.P.; Silva, M.A.; Oliveira, J.M. Non-isothermal cold crystallization kinetics of cork–polymer biocomposites based on polylactic acid for fused filament fabrication. J. Therm. Anal. Calorim. 2020, 146, 1667–1678. [Google Scholar] [CrossRef]

- Magalhães da Silva, S.P.; Oliveira, J.M. Cork-polylactide composites reinforced with polyhydroxyalkanoates for additive manufacturing. In Proceedings of the ECCM 2018—18th European Conference on Composite Materials, Athens, Greece, 25–28 June 2018; pp. 24–28. [Google Scholar]

- Menager, C.; Guigo, N.; Wu, X.; Vincent, L.; Sbirrazzuoli, N. “Green” composites prepared from polyfurfuryl alcohol and cork residues: Thermal and mechanical properties. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105473. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Szostak, M.; Barczewski, M.; Łuczak, P. Cork-wood hybrid filler system for polypropylene and poly(lactic acid) based injection molded composites. Structure evaluation and mechanical performance. Compos. B Eng. 2019, 163, 655–668. [Google Scholar] [CrossRef]

- Fernandes, E.M.; Correlo, V.M.; Mano, J.F.; Reis, R.L. Cork-polymer biocomposites: Mechanical, structural and thermal properties. Mater. Des. 2015, 82, 282–289. [Google Scholar] [CrossRef]

- Lakreb, N.; Bezzazi, B.; Pereira, H. Mechanical behavior of multilayered sandwich panels of wood veneer and a core of cork agglomerates. Mater. Des. 2015, 65, 627–636. [Google Scholar] [CrossRef]

- Castro, O.; Silva, J.M.; Devezas, T.; Silva, A.; Gil, L. Cork agglomerates as an ideal core material in lightweight structures. Mater. Des. 2010, 31, 425–432. [Google Scholar] [CrossRef]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos. B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef]

- Pupure, L.; Varna, J.; Joffe, R.; Berthold, F.; Miettinen, A. Mechanical properties of natural fiber composites produced using dynamic sheet former. Wood Mater. Sci. Eng. 2020, 15, 76–86. [Google Scholar] [CrossRef]

- Li, M.; Pu, Y.; Thomas, V.M.; Yoo, C.G.; Ozcan, S.; Deng, Y.; Nelson, K.; Ragauskas, A.J. Recent advancements of plant-based natural fiber–reinforced composites and their applications. Compos. B Eng. 2020, 200, 108254. [Google Scholar] [CrossRef]

- Fernandes, E.M.; Correlo, V.M.; Mano, J.F.; Reis, R.L. Polypropylene-based cork-polymer composites: Processing parameters and properties. Compos. B Eng. 2014, 66, 210–223. [Google Scholar] [CrossRef]

- Fernandes, E.M.; Aroso, I.M.; Mano, J.F.; Covas, J.A.; Reis, R.L. Functionalized cork-polymer composites (CPC) by reactive extrusion using suberin and lignin from cork as coupling agents. Compos. B Eng. 2014, 67, 371–380. [Google Scholar] [CrossRef]

- Magalhães Da Silva, S.P.; Lima, P.S.; Oliveira, J.M. Rheological behaviour of cork-polymer composites for injection moulding. Compos. B Eng. 2016, 90, 172–178. [Google Scholar] [CrossRef]

- Nyambo, C.; Mohanty, A.K.; Misra, M. Effect of maleated compatibilizer on performance of PLA/wheat straw-based green composites. Macromol. Mater. Eng. 2011, 296, 710–718. [Google Scholar] [CrossRef]

- Manaf, O.; Sheeja Jowhar, A.; Sujith, A. Effect of unsaturation on physicochemical properties of maleic anhydride–grafted acrylonitrile butadiene styrene terpolymer. J. Elastomers Plast. 2017, 50, 520–536. [Google Scholar] [CrossRef]

- Silva, S.P.; Sabino, M.A.; Fernandas, E.M.; Correlo, V.M.; Boesel, L.F.; Reis, R.L. Cork: Properties, capabilities and applications. Int. Mater. Rev. 2005, 50, 345–365. [Google Scholar] [CrossRef]

- Smith, B.C. The C=O Bond Part IV: Acid Anhydrides. Spectroscopy 2018, 33, 16–20. [Google Scholar]

- Garcia, A.R.; Lopes, L.F.; de Barros, R.B.; Ilharco, L.M. The Problem of 2,4,6-Trichloroanisole in Cork Planks Studied by Attenuated Total Reflection Infrared Spectroscopy: Proof of Concept. J. Agric. Food Chem. 2015, 63, 128–135. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, E.M.; Correlo, V.M.; Chagas, J.A.M.; Mano, J.F.; Reis, R.L. Properties of new cork–polymer composites: Advantages and drawbacks as compared with commercially available fibreboard materials. Compos. Struct. 2011, 93, 3120–3129. [Google Scholar] [CrossRef]

- Olongal, M.; Mohamed Nainar, M.A.; Marakkattupurathe, M.; Muslim Veettil Asharaf, S.; Athiyanathil, S. Effect of poly(ethylene-co-vinyl acetate) additive on mechanical properties of maleic anhydride-grafted acrylonitrile butadiene styrene for coating applications. J. Vinyl Addit. Technol. 2019, 25, 287–295. [Google Scholar] [CrossRef]

- Ihamouchen, C.; Djidjelli, H.; Boukerrou, A. Development and characterization of a new cork-based material. Mater. Today Proc. 2020, 36, 34–40. [Google Scholar] [CrossRef]

- Daver, F.; Lee, K.P.M.; Brandt, M.; Shanks, R. Cork-PLA composite filaments for fused deposition modelling. Compos. Sci. Technol. 2018, 168, 230–237. [Google Scholar] [CrossRef]

- Khieng, T.K.; Debnath, S.; Ting Chaw Liang, E.; Anwar, M.; Pramanik, A.; Basak, A.K. A review on mechanical properties of natural fibre reinforced polymer composites under various strain rates. J. Compos. Sci. 2021, 5, 130. [Google Scholar] [CrossRef]

- Antunes, T.; da Silva, S.P.M.; Costa, M.E.V.; Oliveira, J.M. Cork-based filaments for Additive Manufacturing. In Proceedings of the 7th International Conference on Additve Manufacturing, Maribor, Slovenia, 10–11 October 2018; pp. 173–176. Available online: https://www.icat.si/18_index.php (accessed on 23 June 2025).

- Chansoda, K.; Suwanjamrat, C.; Chookaew, W. Study on processability and mechanical properties of parawood-powder filled PLA for 3D printing material. IOP Conf. Ser. Mater. Sci. Eng. 2020, 773, 012053. [Google Scholar] [CrossRef]

| Cork Particle Size (µm) | % Moisture |

|---|---|

| <45 | 3.6% |

| ≥45 ≤63 | 3.7% |

| ≥63 ≤125 | 5.1% |

| ≥125 | 3.8% |

| Formulations | Cork Particle Size (μm) | %w/w Cork Powder |

|---|---|---|

| ABS | Without cork | Without cork |

| ABS-g-MAH | Without cork | Without cork |

| CPC-45 | <45 | 10 |

| CPC-4563 | ≥45 ≤63 | 10 |

| CPC-63125 | ≥63 ≤125 | 10 |

| CPC-125 | ≥125 | 10 |

| Babyplast 6/12 | |

|---|---|

| Material Load (mm) | 7.5 |

| Cooling time (s) | 20 |

| Temperature profile (Plasticizer/Chamber/Nozzle) | 230/240/240 °C |

| Injection speed | 100% |

| 1st Holding pressure (Bar) | 70 |

| 1st Holding pressure time (s) | 1.5 |

| 2nd Holding pressure (Bar) | 50 |

| 2nd Holding pressure time (s) | 1 |

| Suction (mm) | 0 |

| 2nd injection speed | 100% |

| Material | Density (g/cm3) |

|---|---|

| ABS | 1.05 ± 0.06 |

| ABS-g-MAH | 0.84 ± 0.04 |

| CPC-45 | 1.09 ± 0.05 |

| CPC-4563 | 1.16 ± 0.06 |

| CPC-63125 | 1.19 ± 0.06 |

| CPC-125 | 1.11 ± 0.06 |

| Samples | T0.1 (°C) | Tdm (°C) |

|---|---|---|

| ABS | 398 | 421 |

| Cork | 258 | 376 |

| ABS-g-MAH | 392 | 420 |

| CPC-45 | 392 | 421 |

| CPC-4563 | 388 | 421 |

| CPC-63125 | 392 | 421 |

| CPC-125 | 388 | 422 |

| Sample | Tg (°C) | Tm (°C) | ΔHm (J/g) | Td (°C) | ΔHd (J/g) |

|---|---|---|---|---|---|

| ABS | 107.72 | 196.20 | 2.99 | 425.22 | 50.47 |

| ABS-g-MAH | 106.05 | 195.69 | 3.41 | 426.12 | 49.22 |

| ABS45 | 105.03 | 197.12 | 4.75 | 425.27 | 49.36 |

| ABS4563 | 105.34 | 196.52 | 6.06 | 424.51 | 47.35 |

| ABS63125 | 107.38 | 196.57 | 4.33 | 424.60 | 51.84 |

| ABS125 | 104.55 | 196.50 | 2.23 | 426.65 | 53.31 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Romero-Ocaña, I.; Herrera, M.; Fernández-Delgado, N.; Molina, S.I. Potential Use of Residual Powder Generated in Cork Stopper Industry as Valuable Additive to Develop Biomass-Based Composites for Injection Molding. J. Compos. Sci. 2025, 9, 330. https://doi.org/10.3390/jcs9070330

Romero-Ocaña I, Herrera M, Fernández-Delgado N, Molina SI. Potential Use of Residual Powder Generated in Cork Stopper Industry as Valuable Additive to Develop Biomass-Based Composites for Injection Molding. Journal of Composites Science. 2025; 9(7):330. https://doi.org/10.3390/jcs9070330

Chicago/Turabian StyleRomero-Ocaña, Ismael, Miriam Herrera, Natalia Fernández-Delgado, and Sergio I. Molina. 2025. "Potential Use of Residual Powder Generated in Cork Stopper Industry as Valuable Additive to Develop Biomass-Based Composites for Injection Molding" Journal of Composites Science 9, no. 7: 330. https://doi.org/10.3390/jcs9070330

APA StyleRomero-Ocaña, I., Herrera, M., Fernández-Delgado, N., & Molina, S. I. (2025). Potential Use of Residual Powder Generated in Cork Stopper Industry as Valuable Additive to Develop Biomass-Based Composites for Injection Molding. Journal of Composites Science, 9(7), 330. https://doi.org/10.3390/jcs9070330