Biocomposites for Marine Applications: A Review of Friction, Wear, and Environmental Degradation

Abstract

1. Introduction

2. Effect of Marine Environment on Composites

2.1. The Marine Environment: Relevance and Engineering Challenges

2.2. Background on Marine Tribology

2.3. Importance of Friction and Wear in Marine Applications

2.4. Salinity and Ionic Interactions with Polymer Matrices

- Ion exchange and release of functional components: in polymer systems containing quaternary salts or antifouling materials, salinity accelerates the ion exchange between the matrix and seawater, facilitating the release of components such as biocides or functional additives. In this sense, a low salinity can be considered a safety requirement against the development of biofouling [48]. This phenomenon has been observed in PMMA matrices containing saline polymers, where the release of active cations significantly increased in saline solutions (up to 2 M NaCl) [49].

- Ion-activated cross-linking: Some composites are designed to trigger ionic cross-linking in the presence of salt water. In an innovative system with inorganic fillers, ion diffusion activated bonds with matrix functional groups, improving structural strength and paving the way for self-healing materials in saline environments [50].

- Effects of single ions on enzymatic degradation: Different cations and anions influence the enzymatic degradation of anti-biofouling matrices. Chaotropic ions (e.g., I−) reduce the enzymatic activity by “salting-in”, while cosmotropic ones (e.g., SO42−) increase it by “salting-out”, thus modulating the stability and longevity of polymeric materials in the sea [51].

2.5. Moisture Absorption, Swelling, and Fiber–Matrix Debonding

- Moisture absorption and diffusion: moisture enters the polymer matrix mainly through diffusion according to Fick’s law, driven by the polarity of the material and the ambient temperature. Natural fibers, being hygroscopic, accelerate absorption, leading to matrix plasticization, reduction of Tg (glass transition temperature) and maximum service temperature, and loss of structural stiffness [52].

- Swelling and microfractures: once absorbed, moisture causes uneven swelling of the fibers, exerting pressure on the matrix that can trigger internal cracks, interlaminar stresses, and cyclic hydrolysis fatigue. Some longtime aging studies exist that confirm this evidence; for example, in flax/poly(lactic acid) (PLA) biocomposites exposed to marine immersion for 2 years, a mechanical decline directly proportional to water absorption (~12%) and a progressive loss of cohesion between fibers and matrix are observed [53]. The selection of PLA in the specific investigation is justified by the widespread use of this polymer as the matrix for biocomposites in different sectors [54]. This suggested a potential penetration also into the marine field, which has remained more limited than previously expected, despite the considerable interest in additively manufactured parts made with PLA [55].

- Fiber–matrix debonding by tribological effects, due to the combined effect of swelling of the fibers and hydration of the matrix, impedes the interfacial adhesion. This phenomenon has been largely documented: in composites reinforced with glass microspheres, the water absorption increases with volume fraction, inducing a 9–13% drop in tensile strength and over 20% in flexural strength [56]; in z-direction stitched glass–epoxy laminates, a 55% loss in fracture toughness was observed after 35 days in seawater, with debonding visible under SEM microscopy [57]. In three-dimensional woven (3D6D) materials, interstitial swelling and water transport along the microchannels led to up to a 47% decrease in compressive strength, confirming that moisture delamination is the main driver of mechanical degradation [58]. Even though all cases are related to the synthetic composites, there is no reason to assume that the phenomenon would be absent in biocomposites, where wettability issues are inherently severe and need specific studies every time a less-used lignocellulosic fiber is introduced in the composites [59].

2.6. Thermal Cycling and Hygrothermal Aging

- Hygrothermal absorption and microstructural damage: A study on ultrahigh molecular weight poly(ethylene) (UHMWPE) biocomposites loaded with different weight fractions of mollusk shell powder shows that hygrothermal aging accelerated by exposure at 80 °C in a Ringer’s physiological solution reduces wear resistance and modifies tribological behavior. This results in the generation of microcracks and localized swelling that favor delamination [63]. On biocomposites, an issue that is of significant importance is the need to have adequate fire-resistant behavior through the addition of adapted additives, such as 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) or aluminum diethyl phosphinate (AlPi). An analysis carried out in [64] on flax/epoxy composites demonstrated that though DOPO approximately doubled the amount of water absorbed, the fire-retardant effect was maintained, except for the highest level of humidity at 70 °C temperature.

- Plasticization and loss of mechanical properties: In glass fiber (GF)–thermoplastic composites immersed at 35 °C and 70 °C, mechanical loss reaches up to 50%, especially for flexural and compressive properties. Matrix cracking and fiber–matrix debonding are observed as the main failure mechanisms [65]. Early studies involving bio resins, such as poly (butyl succinate) (PBS), with silk and henequen fibers at 60 °C and 85% relative humidity (RH) indicated a decrease in storage modulus in the region of 20 and 505, respectively [66].

- Changes in glass transition (Tg): Contrary to expectations, some studies on fiberglass show that hygrothermal aging can also increase Tg due to secondary cross-linking reactions, affecting stiffness and tribological response under repeated loading, which extends the temperature range of glassy polymer [67]. However, the presence of lignocellulosic fibers, such as in the case of hemp, indicates a reduction in Tg, both using a partially bio-based epoxy and a poly(methyl methacrylate) (PMMA) matrix, though slightly more severe for immersion at 60 °C than is the case at 21 °C [68].

2.7. Biofouling and Microbiological Impacts on Material Surfaces

- Microbial colonization and release of degrading metabolites: Immersed composite surfaces are attacked by bacterial communities that produce organic acids, biosurfactants, and hydrolytic enzymes. These compounds degrade polymer bonds, promoting interlaminar detachment and surface embrittlement. Studies on graphite/epoxy composites have shown that biofouling accelerates the decline in tensile strength and induces microfracture signals detectable by acoustic emission [74]. Other long-term studies based on jute and sawdust epoxy composites exposed to drain water showed a significant loss due to the microbial damage, in particular a reduction in the tensile strength of 57% for the jute composite and of 40% for the sawdust composite, after their exposure to drain water for 1 year. Regarding the flexural strength, a decrease in the flexural strength of 43% and 34% for the jute and the sawdust composite, respectively, during the same period was observed. In this case, the biological action of some microorganisms producing enzymes like lipases and proteases led to the deterioration of the composite matrix, worsening the structural and mechanical properties of the composite material [75].

- Biofilm–matrix interaction and tribology: Biofilm acts as a viscoelastic intermediate layer between the material and the surrounding medium, altering friction, adhesion, and wear rate. In biodegradable polyurethane composites modified with clay and the biocide dichloro octylisothiazolinone (DCOIT), colonization by bacteria and diatoms was significantly reduced, confirming the role of chemical design in biofouling management [76]. As a whole, it can be suggested that biocides commonly used in biocomposites, such as tannic acid, might have an effect in considerably delaying the formation of biofilm [77]. In a more general way, tannins form a multifunctional category of chemicals widely used in the development of bioplastics and biocomposites, according to a recent review [78].

- Role of plasticizers in the formation of fouling biofilms: The chemical formulation of the matrix influences the selection and density of microbial communities. It is no surprise that the use of bioplasticizers for the formulation of plastics might promote biological action in them [79]. This will likely lead to a larger and faster formation of biofilms, since also on conventional plastics, such as poly(vinyl chloride) (PVC), bioplasticizers are well known to promote some biodegradation [80]. Conversely, in polystyrene (PS), microplastics from plastics and resins produced using bisphenol A (BPA) or diethylhexyl phthalate (DEHP) showed greater biofilm-induced biodegradation than those in the absence of plasticizers. This occurred in a specific context that aimed at reproducing the Australian coral reef environment [81].

- Accelerated degradation in the presence of natural fillers: In polyhydroxybutyrate co-valerate (PHBV)-based biocomposites with olive pomace flours, microbiological degradation is more marked, with crack formation and erosion visible already after 6 months at 40 °C in seawater, confirming that the biocompatibility of the matrix accelerates environmental decomposition [82]. Natural fillers—like rice husk, peanut and groundnut shell powder, and wood sawdust—are, in fact, hydrophilic species and consequently favor water absorption in the composite matrix [83]. In marine environments, water absorption in the polymeric matrix favors its biodegradability and the colonization of microorganisms with consequent biofouling. A review by Brebu [84] reports the effect of natural fillers blending on different polymeric matrices: Polyethylene (PE) and polypropylene (PP) composites do not show great biodegradability, while polyhydroxyalkanoate (PHA)-based composites showed better biodegradability performances; wood plastic composites (WPC) were shown to be subjected to attack by fungi in case of warm temperature and high moisture environments, thus not making them useful for outdoor applications; poly lactic acid (PLA), a hydrophobic polymer obtained from natural sources, can be modified to be more hydrophilic if blended with chitosan, favoring microbial colonization. This, together with an increase in the crystallinity of the polymer in the composite material, leads to an enhancement of the biodegradability of the material. The biodegradability of poly butylene succinate (PBS) was also reported to increase when used with hemp fillers up to 70%.

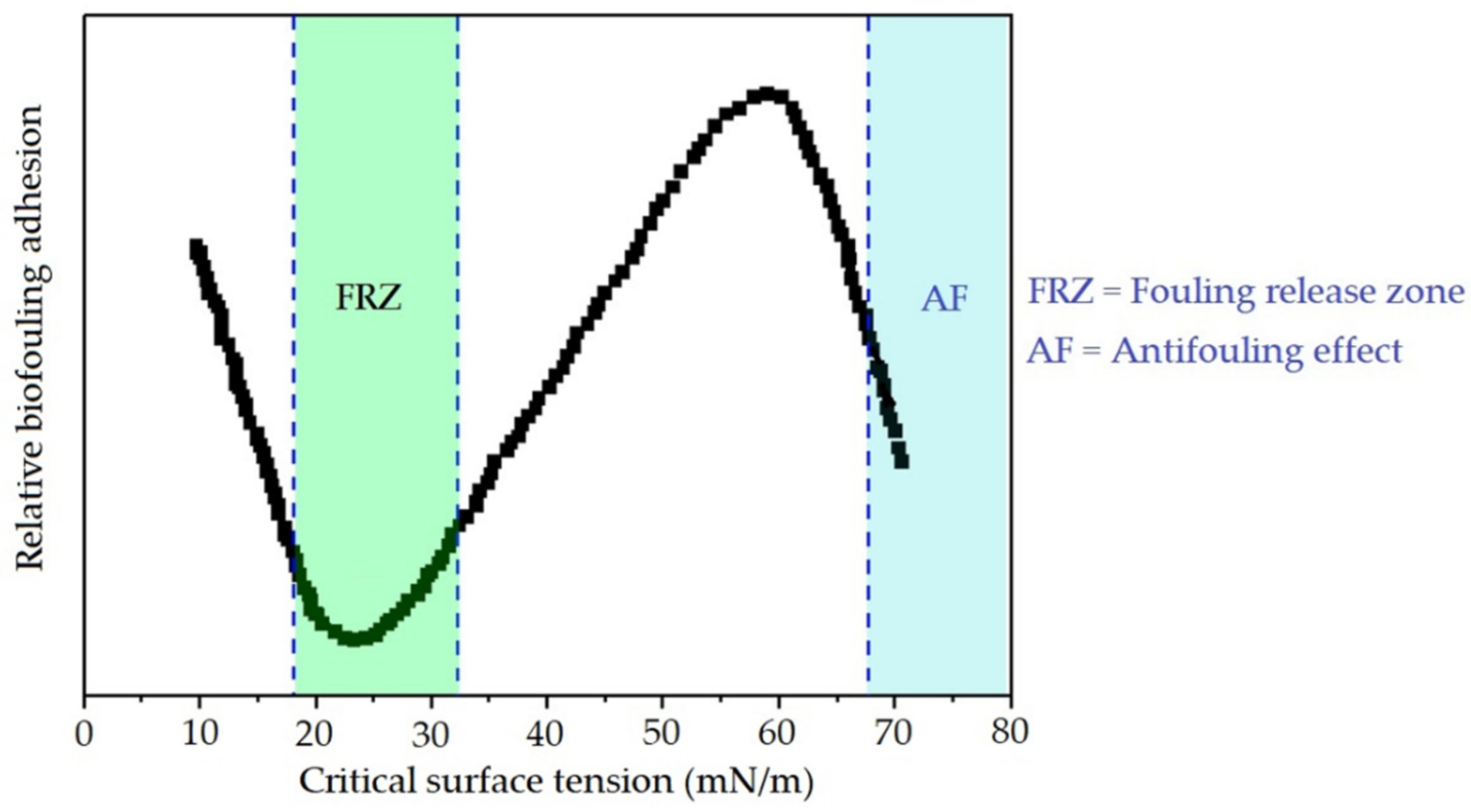

- Correlations with surface energy and hardness: Polymers with high surface energy (e.g., GFRP) are more susceptible to biofouling than flexible ones (e.g., silicone), since they provide an easier gripping surface. The surface free energy is defined as the energy needed to create a new surface from a bulk solid. The relationship between surface energy and bacterial adhesion, due to critical surface tension depending on contact angle, can be described by the Baier curve (Figure 2), which reaches its minimum around 22–24 mN/m. This experimental data allows the design for fouling release and anti-fouling materials and coatings [85]. Hydrophobic materials having low surface energy avoid initial fouling and facilitate the detachment of already present organisms on the ship hulls [86]. Furthermore, tribological properties worsen in proportion to biological accumulation, with a loss of mechanical resistance up to 7.5% in poly(ethylene terephthalate) (PET) and polyurethane (PU) [87].

3. Biocomposites in Marine Applications

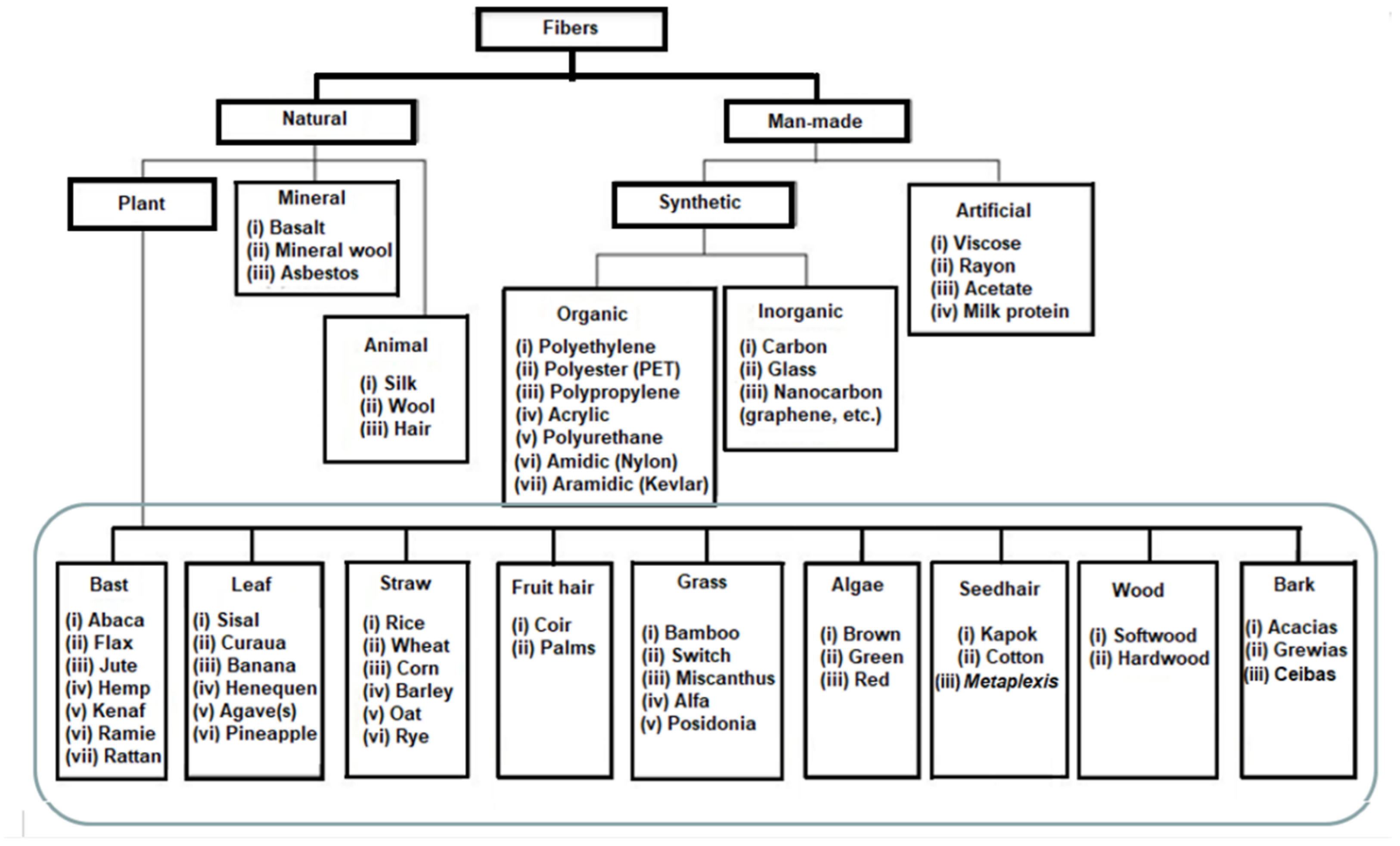

3.1. Natural Fibers: Types, Properties, and Marine Performance

3.2. Matrix Systems: Bio-Based vs. Synthetic Resins

3.3. Filler and Coupling Agents: Role in Durability and Wear

3.4. Fabrication Techniques and Effects on Tribological Behavior

- Compression Molding: This generates compact and homogeneous structures with low porosity, contributing to better wear resistance. However, it is less suitable for complex geometries.

- Injection Molding: This allows high productivity and complex shapes but can introduce internal defects such as microvoids, which increase susceptibility to fatigue wear.

- Resin Transfer Molding (RTM): This is used for structural components; it offers a good compromise between dimensional control and quality of the fiber–matrix interface.

- Electrospinning and 3D Printing: This allows customizable microstructures and potential friction reduction, thanks to controlled surface geometries, but is still limited by industrial scalability [176].

- Studies on food biocomposites for aquaculture show that technique and formulation influence stability in water, a parameter useful as an indirect indicator of tribological resistance [177].

- FEM analyses on marine biocomposite panels reveal that manufacturing defects influence flexural behavior and delamination resistance, aspects that can be correlated to contact wear [178].

- Work on metallic nanoporous structures highlights how microstructural modifications in manufacturing influence friction and surface adhesive strength, principles applicable to composite matrices [179].

| Technique | Advantages | Disadvantages | Marine Suitability |

|---|---|---|---|

| Compression (or vacuum) molding | High fiber content, low porosity, good mechanical strength | Limited shape complexity, longer cycle times | Excellent for panels and structural parts with water resistance. Applied for flax–epoxy in [180]. |

| Injection molding | Suitable for complex geometries, high production rate | Possible void formation, lower mechanical integrity in moist environments | Moderate; careful design needed to minimize water ingress. Potential offered as far as tensile performance is involved is explored in [181], as opposed to vacuum infusion (Figure 6). |

| Resin Transfer Molding (RTM) | Good control over fiber orientation, uniform resin distribution | Higher cost, complex tooling, limited to low-medium volume | High; ideal for load-bearing marine components. Flax–cork sandwich panels were proposed in [182]. |

| Extrusion | Continuous process, scalable, good for thermoplastics | Poor control over fiber distribution, limited to simple shapes | Moderate; applicable with proper material selection, interesting when constant-thickness components are needed [183]. |

| Electrospinning | Nanostructured fibers, tunable properties, high surface area | Scalability issues, high cost, slow throughput | Experimental; potential for coatings or specialty layers with antibacterial properties—an application concept adapted from biomedical industry [184] |

| 3D printing | Custom geometries, minimal waste, rapid prototyping | Material limitations, anisotropy, mechanical weakness in some directions | Low to moderate; promising for non-structural components, yet resistant to seawater, depending on the matrix material [185]. |

4. Advances in Seawater Protection of Biocomposites

4.1. Interfacial Engineering for Moisture and Wear Resistance

4.2. Surface Treatments and Barrier Coatings

4.3. Functional Fillers for Enhanced Tribological Stability

4.4. Anti-Biofouling Strategies and Their Impact on Friction

4.5. Integrated Material Designs for Marine Tribological Durability

5. Discussion

5.1. Summary of the Main Degradation Mechanisms

5.2. Effects of Structure and Materials on Tribological Phenomena

5.3. Comparison of Mitigation Strategies: Benefits and Limitations

5.4. Gaps in the Literature and Research Perspectives

- The development of multi-agent testing protocols (combining mechanical, chemical, and biological stress).

- Full-scale validation through exposure to controlled or natural marine environments.

- Multiscale optimization of materials, integrating molecular modifications, microstructural reinforcements, and surface functionalizations.

- Eco-friendly design, considering the complete life cycle of the material and its interaction with marine ecosystems.

5.5. Practical Implications for the Design of Marine Biocomposites

5.6. Final Considerations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AlPi | Aluminum diethyl phosphinate |

| BPA | Bisphenol A |

| COF | Coefficient of friction |

| DCOIT | Dichloro octylisothiazolinone |

| DEHP | Diethylhexyl phthalate |

| DOPO | 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide |

| FDCA | 2,5-furandicarboxylic acid |

| GF | Glass fibers |

| LBCs | Laminated bamboo composites |

| MA | Maleic anhydride |

| PALF | Pineapple leaf fibers |

| PBS | Poly(butyl succinate) |

| PE-g-MA | Maleic anhydride-grafted-polyethylene |

| PHA | Poly(hydroxyalkanoate) |

| PHBV | Poly(hydroxybutirate-co-valerate) |

| PLA | Poly(lactic acid) |

| PMMA | Poly(methyl methacrylate) |

| PPS | Polyphenylene sulfide |

| PU | Polyurethane |

| PVC | Polyvinylchloride |

| RTM | Resin transfer molding |

| SEBS-g-MA | Styrene–ethylene–butylene–styrene block copolymer maleic anhydride grafted |

| UHMWPE | Ultra-high molecular weight poly(ethylene) |

References

- John, M.J. Environmental degradation in biocomposites. In Biocomposites for High-Performance Applications; Ray, D., Ed.; Woodhead Publishing: Cambridge, UK, 2017; pp. 181–194. [Google Scholar] [CrossRef]

- Hao, Z.; Zhang, Z.; Zhou, W.; Zhang, S.; Ma, T.; Wei, H.; Wang, G.; Wang, Q.; Wang, L.; Li, R. Progress of material degradation: Metals and polymers in deep-sea environments. Corros. Rev. 2024. online first. [Google Scholar] [CrossRef]

- Sen, R. Durability of advanced composites in a marine environment. Int. J. Mater. Prod. Technol. 2003, 19, 118–129. [Google Scholar] [CrossRef]

- Merah, N.; Ashraf, F.; Shaukat, M.M. Mechanical and moisture barrier properties of epoxy–nanoclay and hybrid epoxy–nanoclay glass fibre composites: A review. Polymers 2022, 14, 1620. [Google Scholar] [CrossRef]

- Bengtsson, S. The sails of the Wasa: Unfolding, identification and preservation. Int. J. Naut. Archaeol. 1975, 4, 27–41. [Google Scholar] [CrossRef]

- Dickinson, H.W. A condensed history of rope-making. Trans. Newcom. Soc. 1942, 23, 71–91. [Google Scholar] [CrossRef]

- Nan, J.; Zhi, C.; Meng, J.; Miao, M.; Yu, L. Seawater aging effect on fiber-reinforced polymer composites: Mechanical properties, aging mechanism, and life prediction. Text. Res. J. 2023, 93, 3393–3413. [Google Scholar] [CrossRef]

- Zhu, Z.; Xiao, P.; Kang, A.; Kou, C.; Chen, J. Preparation of biomass composites with high performance and carbon sequestration from waste wood fibers. Constr. Build. Mater. 2023, 404, 133295. [Google Scholar] [CrossRef]

- Edyvean, R. Consequences of fouling on shipping. In Biofouling; Dürr, S., Thomason, J.C., Eds.; Wiley and Sons: Hoboken, NJ, USA, 2010; pp. 217–225. [Google Scholar] [CrossRef]

- Wood, R.J. Marine wear and tribocorrosion. Wear 2017, 376, 893–910. [Google Scholar] [CrossRef]

- Brailo, M.; Buketov, A.; Yakushchenko, S.; Sapronov, O.; Vynar, V.; Kobelnik, O. The investigation of tribological properties of epoxy-polyether composite materials for using in the friction units of means of sea transport. Mater. Perform. Character. 2018, 7, 275–299. [Google Scholar] [CrossRef]

- Herbert-Read, J.E.; Thornton, A.; Amon, D.J.; Birchenough, S.N.R.; Côté, I.M.; Dias, M.P.; Godley, B.J.; Keith, S.A.; McKinley, E.; Peck, L.S.; et al. A global horizon scan of issues impacting marine and coastal biodiversity conservation. Nat. Ecol. Evol. 2022, 6, 1262–1270. [Google Scholar] [CrossRef]

- Elliott, M.; Borja, Á.; Cormier, R. Managing marine resources sustainably–ecological, societal and governance connectivity, coherence and equivalence in complex marine transboundary regions. Ocean Coast. Manag. 2023, 245, 106875. [Google Scholar] [CrossRef]

- Huang, Y.; Sultan, M.T.H.; Shahar, F.S.; Grzejda, R.; Łukaszewicz, A. Hybrid fiber-reinforced biocomposites for marine applications: A review. J. Compos. Sci. 2024, 8, 430. [Google Scholar] [CrossRef]

- Li, C.; Feng, C.; Zhang, L.; Shan, J.; Shi, M. A review of the effect of hydrothermal aging on the mechanical properties of 2D fiber-reinforced resin matrix composites. Polym. Adv. Technol. 2024, 35, e6239. [Google Scholar] [CrossRef]

- Shifler, D.A.; Aylor, D.M. Factors Affecting Corrosion Performance and Testing of Materials and Components in Sea Water. In NACE CORROSION; NACE: Houston, TX, USA, 2005; p. NACE-05224. [Google Scholar]

- Beura, S.; Chakraverty, A.P.; Pati, S.N.; Pradhan, D.D.; Thatoi, D.N.; Mohanty, U.K. Effect of salinity and strain rate on sea water aged GFRP composite for marine applications. Mater. Today Commun. 2023, 34, 105056. [Google Scholar] [CrossRef]

- Ansell, M.P. Natural fibre composites in a marine environment. In Natural Fibre Composites; Elsevier: Amsterdam, The Netherlands, 2014; pp. 365–374. [Google Scholar] [CrossRef]

- Gupta, B.R. Friction and wear mechanism of polymers, their composites and nanocomposites. In Tribology of Polymers, Polymer Composites, and Polymer Nanocomposites; Elsevier: Amsterdam, The Netherlands, 2023; pp. 51–117. [Google Scholar] [CrossRef]

- Zhang, Z.; Ouyang, W.; Liang, X.; Yan, X.; Yuan, C.; Zhou, X.; Guo, Z.; Dong, C.; Liu, Z.; Jin, Y.; et al. Review of the evolution and prevention of friction, wear, and noise for water-lubricated bearings used in ships. Friction 2024, 12, 1–38. [Google Scholar] [CrossRef]

- Wang, D.; Li, Z.; Zhu, Y. Lubrication and tribology in seawater hydraulic piston pump. J. Mar. Sci. Appl. 2003, 2, 35–40. [Google Scholar] [CrossRef]

- Haq, M.I.U.; Raina, A.; Vohra, K.; Kumar, R.; Anand, A. An assessment of tribological characteristics of different materials under sea water environment. Mater. Today Proc. 2018, 5, 3602–3609. [Google Scholar] [CrossRef]

- Yuan, W.; Yao, X.; Guo, Q.; Li, C.; Chi, B.; Yu, J. Tribological Behavior of Shaft-Surface Pairs with PPS and Its Composites in Seawater Media Under Cyclic Loadings. Tribol. Lett. 2024. preprint. [Google Scholar] [CrossRef]

- Shan, L.; Wang, Y.; Li, J.; Li, H.; Wu, X.; Chen, J. Tribological behaviours of PVD TiN and TiCN coatings in artificial seawater. Surf. Coat. Technol. 2013, 226, 40–50. [Google Scholar] [CrossRef]

- Liang, Y.; Zhang, F.; Xing, H.; Wang, C.; Chen, N.; Wang, W.; Zhang, Z. Lubrication and wear characteristics of bionic composite texture on friction pair under seawater condition. Surf. Topogr. Metrol. Prop. 2025, 13, 015023. [Google Scholar] [CrossRef]

- Chamley, A.; Baley, C.; Gayet, N.; Sarrazin, J.; Fuchs, S.; Freyermouth, F.; Davies, P. (Bio)degradation of biopolymer and biocomposite in deep-sea environments. Mar. Pollut. Bull. 2024, 209, 117230. [Google Scholar] [CrossRef] [PubMed]

- Monikandan, V.V.; Pratheesh, K.; Santulli, C.; Digra, S.; Prasanth, P.V.; Dhas, E.R. History of tribology: Assessing the prehistoric impacts, progress on industrial and scientific revolution eras, and contemporary interdisciplinary research trends. Tribologia 2024, 41, 4–15. [Google Scholar] [CrossRef]

- Prabhakar, K.; Debnath, S.; Ganesan, R.; Palanikumar, K. A review of mechanical and tribological behaviour of polymer composite materials. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 3rd International Conference on Science, Technology, and Interdisciplinary Research (IC-STAR), 18–20 September 2017, Bandar Lampung, Indonesia; IOP Publishing: Bristol, UK, 2018; Volume 344, p. 012015. [Google Scholar] [CrossRef]

- Ravi, S.; Mohanavel, V.; Ayyar, M.; Kathiresan, S.; Kannan, S.; Munimathan, A.; Kaliappan, S. Effect of continuous fiber reinforcement on mechanical and tribological characteristics of cellulose and human hair fiber polymer composites. Results Eng. 2025, 25, 104480.S. [Google Scholar]

- Sultan, M.; Jamir, M.; Majid, M.; Azmi, A.; Saba, N. (Eds.) Tribological Applications of Composite Materials; Springer: Singapore, 2021. [Google Scholar] [CrossRef]

- Milosevic, M.; Valášek, P.; Ruggiero, A. Tribology of natural fibers composite materials: An overview. Lubricants 2020, 8, 42. [Google Scholar] [CrossRef]

- Tran, L.Q.N.; Yuan, X.W.; Bhattacharyya, D.; Fuentes, C.; Van Vuure, A.W.; Verpoest, I. Fiber-matrix interfacial adhesion in natural fiber composites. Int. J. Mod. Phys. B 2015, 29, 1540018. [Google Scholar] [CrossRef]

- Bakry, M.; Mousa, M.O.; Ali, W.Y. Friction and wear of friction composites reinforced by natural fibres. Mater. Werkst. 2013, 44, 21–28. [Google Scholar] [CrossRef]

- Muthu Samy, M.; Lenin Singaravelu, D. Green friction: Exploring the evolution and potential of natural fibers and other brake pad ingredients in sustainable automotive engineering—A review. Polym. Compos. 2025, 46, 5882–5909. [Google Scholar] [CrossRef]

- Ammar, Z.; Ibrahim, H.; Adly, M.; Sarris, I.; Mehanny, S. Influence of natural fiber content on the frictional material of brake pads—A review. J. Compos. Sci. 2023, 7, 72. [Google Scholar] [CrossRef]

- Saindane, U.V.; Soni, S.; Menghani, J.V. Recent research status on synthesis and characterization of natural fibers reinforced polymer composites and modern friction materials—An overview. Mater. Today Proc. 2020, 26, 1616–1620. [Google Scholar] [CrossRef]

- Shuhimi, F.F.; Abdollah, M.F.B.; Kalam, M.A.; Masjuki, H.H.; Mustafa, A.E.; Mat Kamal, S.E.; Amiruddin, H. Effect of operating parameters and chemical treatment on the tribological performance of natural fiber composites: A review. Part. Sci. Technol. 2017, 35, 512–524. [Google Scholar] [CrossRef]

- Chaudhary, V.; Bajpai, P.K.; Maheshwari, S. An investigation on wear and dynamic mechanical behavior of jute/hemp/flax reinforced composites and its hybrids for tribological applications. Fibers Polym. 2018, 19, 403–415. [Google Scholar] [CrossRef]

- Pani, P.R.; Nayak, R.K.; Routara, B.C.; Sekhar, P.C. Flexural and specific wear rate of seawater aged bamboo, jute and glass fiber reinforced polymer hybrid composites. Mater. Today Proc. 2019, 18, 3409–3414. [Google Scholar] [CrossRef]

- Velasco-Parra, J.A.; Valencia, F.R.; Lopez-Arraiza, A.; Ramón-Valencia, B.; Castillo-López, G. Jute fibre reinforced biocomposite: Seawater immersion effects on tensile properties and its application in a ship hull design by finite-element analysis. Ocean Eng. 2023, 290, 116301. [Google Scholar] [CrossRef]

- Castegnaro, S.; Gomiero, C.; Battisti, C.; Poli, M.; Basile, M.; Barucco, P.; Pizzarello, U.; Quaresimin, M.; Lazzaretto, A. A bio-composite racing sailboat: Materials selection, design, manufacturing and sailing. Ocean Eng. 2017, 133, 142–150. [Google Scholar] [CrossRef]

- Sarkar, P.K.; Kandasubramanian, B. Metals to polymer composites for submerged hull: A paradigm shift. Polym. Plast. Technol. Mater. 2021, 60, 1785–1819. [Google Scholar] [CrossRef]

- Rubino, F.; Nisticò, A.; Tucci, F.; Carlone, P. Marine application of fiber reinforced composites: A review. J. Mar. Sci. Eng. 2020, 8, 26. [Google Scholar] [CrossRef]

- Santulli, C. Evolution and recent advancements of composite materials in marine applications. In Applications of Composite Materials in Engineering; Puttegowda, M., Yashas Gowda, T.G., Binoj, J.S., Rangappa, S.M., Siengchin, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2025; pp. 195–218. [Google Scholar] [CrossRef]

- El Hawary, O.; Boccarusso, L.; Ansell, M.P.; Durante, M.; Pinto, F. An overview of natural fiber composites for marine applications. J. Mar. Sci. Eng. 2023, 11, 1076. [Google Scholar] [CrossRef]

- Chengpeng, W.; Shenghui, W.; Haizeng, W.; Guoling, R.; Yexiang, X.; Jiang, Z.; Xiupeng, L.I. Research status and prospects of tribological behaviors of key friction pairs of materials in marine equipment. Mater. Sci. 2021, 27, 148–154. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, D. Comparative investigation on the tribological behavior of reinforced plastic composite under natural seawater lubrication. Mater. Des. 2013, 51, 983–988. [Google Scholar] [CrossRef]

- de Castro, M.C.T.; Vance, T.; Yunnie, A.L.; Fileman, T.W.; Hall-Spencer, J.M. Low salinity as a biosecurity tool for minimizing biofouling on ship sea chests. Ocean Sci. 2018, 14, 661–667. [Google Scholar] [CrossRef]

- Bekiari, V.; Nikolaou, K.; Koromilas, N.; Lainioti, G.C.; Avramidis, P.; Hotos, G.N.; Kallitsis, J.K.; Bokias, G. Release of Polymeric Biocides from Synthetic Matrices for Marine Biofouling Applications. Agric. Agric. Sci. Procedia 2015, 4, 445–450. [Google Scholar] [CrossRef]

- Mosby, B.M.; Shah, S.; Braun, P.V. Salt Water-Triggered Ionic Cross-Linking of Polymer Composites by Controlled Release of Functional Ions. ACS Omega 2018, 3, 16127–16133. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Pan, J.; Ma, C.; Zhang, G.; Liu, G. Specific Ion Effects on the Enzymatic Degradation of Polymeric Marine Antibiofouling Materials. Langmuir 2019, 35, 11157–11166. [Google Scholar] [CrossRef]

- Sathyanarayanan, S. Investigation of the Moisture Diffusion Process in Fibre-Reinforced Composites by Studying the Diffusivities in Hot-wet Temperature Resin-matrix. SSRG Int. J. Mech. Eng. 2014, 1, 7–12. [Google Scholar] [CrossRef]

- Le Duigou, A.; Bourmaud, A.; Davies, P.; Baley, C. Long Term Immersion in Natural Seawater of Flax/PLA Biocomposite. Ocean Eng. 2014, 90, 140–148. [Google Scholar] [CrossRef]

- Giammaria, V.; Capretti, M.; Del Bianco, G.; Boria, S.; Santulli, C. Application of poly(lactic acid) composites in the automotive sector: A critical review. Polymers 2024, 16, 3059. [Google Scholar] [CrossRef]

- Menezes, O.; Roberts, T.; Motta, G.; Patrenos, M.H.; McCurdy, W.; Alotaibi, A.; Vanderpool, M.; Vaseghi, M.; Beheshti, A.; Davami, K. Performance of additively manufactured polylactic acid (PLA) in prolonged marine environments. Polym. Degrad. Stabil. 2022, 199, 109903. [Google Scholar] [CrossRef]

- Anandakumar, P.; Kanny, K.; Mohan, T.P.; Velmurugan, R. Mechanical Behavior of Glass Fiber–Reinforced Hollow Glass Particles Filled Epoxy Composites under Moisture Environment. Polym. Compos. 2024, 45, 8613–8630. [Google Scholar] [CrossRef]

- Hassan, A.; Khan, R.; Khan, N.; Aamir, M.; Pimenov, D.Y.; Giasin, K. Effect of Seawater Ageing on Fracture Toughness of Stitched Glass Fiber/Epoxy Laminates for Marine Applications. J. Mar. Sci. Eng. 2021, 9, 196. [Google Scholar] [CrossRef]

- Wang, X.; Liu, X.; Liu, D.; Wang, Z.; Zhu, Y.; Qian, K.; Zhang, D. Influence of Moisture Absorption on Mechanical Properties and Damage Mechanisms of Three-Dimensional Six-Directional Braided Composites under Hydrostatic Pressure. Polym. Test. 2022, 114, 107693. [Google Scholar] [CrossRef]

- Khaldi, M.; Vivet, A.; Bourmaud, A.; Sereir, Z.; Kada, B. Damage analysis of composites reinforced with Alfa fibers: Viscoelastic behavior and debonding at the fiber/matrix interface. J. Appl. Polym. Sci. 2016, 133, 43760. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.Y.; Richardson, M.O.W. Effect of water absorption on the mechanical properties of hemp fibre reinforced unsaturated polyester composites. Compos. Sci. Technol. 2007, 67, 1674–1683. [Google Scholar] [CrossRef]

- Chow, C.P.L.; Xing, X.S.; Li, R.K.Y. Moisture absorption studies of sisal fibre reinforced polypropylene composites. Compos. Sci. Technol. 2007, 67, 306–313. [Google Scholar] [CrossRef]

- Le Duigou, A.; Davies, P.; Baley, C. Seawater ageing of flax/poly(lactic acid) biocomposites. Polym. Degrad. Stab. 2009, 94, 1151–1162. [Google Scholar] [CrossRef]

- Sidia, B.; Bensalah, W. Hygrothermal Aging Effects on Tribological and Mechanical Behaviors of Mollusc Shell-Reinforcement UHMWPE Biocomposites. J. Thermoplast. Compos. Mater. 2022, 36, 3021–3040. [Google Scholar] [CrossRef]

- Campana, C.; Léger, R.; Sonnier, R.; Ienny, P.; Ferry, L. Effect of hygrothermal ageing on the mechanical and fire properties of a flame retardant flax fiber/epoxy composite. Polymers 2022, 14, 3962. [Google Scholar] [CrossRef]

- Hussnain, S.M.; Shah, S.Z.H.; Megat-Yusoff, P.S.M.; Choudhry, R.S.; Hussain, M. Hygrothermal Effects on the Durability of Resin-Infused Thermoplastic E-Glass Fiber-Reinforced Composites in Marine Environment. Polym. Compos. 2024, 45, 13901–13923. [Google Scholar] [CrossRef]

- Han, S.O.; Ahn, H.J.; Cho, D. Hygrothermal effect on henequen or silk fiber reinforced poly(butylene succinate) biocomposites. Compos. Part B Eng. 2010, 41, 491–497. [Google Scholar] [CrossRef]

- Rajkumar, K.; Elen, M.; Sushmita, K.; Overman, N.; Nickerson, E.K.; Murdy, P.; Presuel-Moreno, F.; Fifield, L.S. Hygrothermal Aging and Recycling Effects on Mechanical and Thermal Properties of Recyclable Thermoplastic Glass Fiber Composites. Polym. Compos. 2024, 46, 4332–4349. [Google Scholar] [CrossRef]

- Drouhet, Q.; Touchard, F.; Chocinski-Arnault, L. Influence of hygrothermal aging on mechanical properties and damage mechanisms of hemp-reinforced biocomposites. J. Nat. Fibers 2022, 19, 15404–15421. [Google Scholar] [CrossRef]

- Lu, J.; Zheng, C.; Wang, L.; Dai, Y.; Wang, Z.; Song, Z. T700 Carbon Fiber/Epoxy Resin Composite Material Hygrothermal Aging Model. Materials 2025, 18, 369. [Google Scholar] [CrossRef] [PubMed]

- Qiu, H.; Feng, K.; Gapeeva, A.; Meurisch, K.; Kaps, S.; Li, X.; Yu, L.; Mishra, Y.K.; Adelung, R.; Baum, M. Functional polymer materials for modern marine biofouling control. Prog. Polym. Sci. 2022, 127, 101516. [Google Scholar] [CrossRef]

- Fragassa, C.; Mattiello, S.; Fronduti, M.; Del Gobbo, J.; Gagic, R.; Santulli, C. Prevention of Biofouling Due to Water Absorption of Natural Fiber Composites in the Aquatic Environment: A Critical Review. J. Compos. Sci. 2024, 8, 532. [Google Scholar] [CrossRef]

- Lindholdt, A.; Dam-Johansen, K.; Olsen, S.M.; Yebra, D.M.; Kiil, S. Effects of biofouling development on drag forces of hull coatings for ocean-going ships: A review. J. Coat. Technol. Res. 2015, 12, 415–444. [Google Scholar] [CrossRef]

- Fruleux, T.; Sauleau, P.; Caudal, F.; Champion, M.; Chauvin, L.; Castro, M.; Le Duigou, A. Marine biofilm formation on flax fibre reinforced biocomposites. Biofouling 2024, 40, 415–430. [Google Scholar] [CrossRef]

- Puh, J.S.; Wagner, P.A.; Little, B.J.; Bradley, W.L. The Effect of Biofouling on Graphite/Epoxy Composites. J. Compos. Technol. Res. 1998, 20, 59–67. [Google Scholar] [CrossRef]

- Haque, M.S.; Islam, M.A. Microbial degradation of the waste jute fiber and sawdust fiber-based epoxy composites in drainage system. Heliyon 2024, 10, e39397. [Google Scholar] [CrossRef]

- Ali, A.; Xiao, Y.; Song, L.; Hu, J.; Rao, Q.; Shoaib, M.; Amin, B.U.; Zhan, X.; Zhang, Q. Biodegradable Polyurethane-Based Clay Composite and Their Anti-Biofouling Properties. Colloids Surf. A Physicochem. Eng. Asp. 2021, 625, 126946. [Google Scholar] [CrossRef]

- Stepczyńska, M.; Rytlewski, P.; Moraczewski, K.; Pawłowska, A.; Karasiewicz, T. Novel biocomposite of starch and flax fiber modified with tannic acid with biocidal properties. Polymers 2024, 16, 1108. [Google Scholar] [CrossRef]

- Santulli, C.; Gabrielli, S.; Roselli, G. Use and Roles of Tannins in Polysaccharide-Based Bioplastics and Biocomposites. Organics 2025, 6, 19. [Google Scholar] [CrossRef]

- Muobom, S.S.; Umar, A.M.S.; Soongseok, Y.; Brolin, A.P. A review on plasticizers and eco-friendly bioplasticizers: Biomass sources and market. Int. J. Eng. Res. 2020, 9, 1138–1144. [Google Scholar]

- Visakh, P.M.; Darie-Nita, R.N. Polyvinylchloride (PVC)-Based Blends: State of Art, New Challenges. In Polyvinylchloride-Based Blends: Preparation, Characterization and Applications; Visakh, P.M., Darie-Nita, R.N., Eds.; Springer Nature: London, UK, 2021. [Google Scholar] [CrossRef]

- Gulizia, A.M.; Bell, S.C.; Kuek, F.; Santana, M.; Edmunds, R.C.; Yeoh, Y.K.; Sato, Y.; Haikola, P.; van Herwerden, L.; Motti, C.A.; et al. Biofilm Development as a Factor Driving the Degradation of Plasticised Marine Microplastics. J. Hazard. Mater. 2024, 460, 136975. [Google Scholar] [CrossRef] [PubMed]

- Hassaini, L.; Kaci, M.; Dehouche, N.; Bruzaud, S. A Degradation Study of Poly(3-Hydroxybutyrate-co-3-Hydroxyvalerate) and Olive Husk Flour Biocomposites under Marine Environment. Macromol. Symp. 2022, 404, 2200026. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Puttegowda, M.; Thyavihalli Girijappa, Y.G.; Rangappa, S.M.; Siengchin, S. Effect of natural filler materials on fiber reinforced hybrid polymer composites: An Overview. J. Nat. Fibers 2020, 19, 4132–4147. [Google Scholar] [CrossRef]

- Brebu, M. Environmental Degradation of Plastic Composites with Natural Fillers—A Review. Polymers 2020, 12, 166. [Google Scholar] [CrossRef] [PubMed]

- Baier, R.E.; Meyer, A.E. Surface analysis of fouling-resistant marine coatings. Biofouling 1992, 6, 165–180. [Google Scholar] [CrossRef]

- Cao, Z.; Cao, P. Research Progress on Low-Surface-Energy Antifouling Coatings for Ship Hulls: A Review. Biomimetics 2023, 8, 502. [Google Scholar] [CrossRef]

- Muthukumar, T.; Aravinthan, A.; Lakshmi, K.; Venkatesan, R.; Vedaprakash, L.; Doble, M. Fouling and Stability of Polymers and Composites in Marine Environment. Int. Biodeterior. Biodegrad. 2011, 65, 276–284. [Google Scholar] [CrossRef]

- Palanisamy, S.; Kalimuthu, M.; Nagarajan, R.; Fernandes Marlet, J.M.; Santulli, C. Physical, chemical, and mechanical characterization of natural bark fibers (NBFs) reinforced polymer composites: A bibliographic review. Fibers 2023, 11, 13. [Google Scholar] [CrossRef]

- More, A.P. Flax fiber–based polymer composites: A review. Adv. Compos. Hybrid Mater. 2022, 5, 1–20. [Google Scholar] [CrossRef]

- Deshmukh, G.S. Advancement in hemp fibre polymer composites: A comprehensive review. J. Polym. Eng. 2022, 42, 575–598. [Google Scholar] [CrossRef]

- Gogna, E.; Kumar, R.; Anurag; Sahoo, A.K.; Panda, A. A comprehensive review on jute fiber reinforced composites. In Advances in Industrial and Production Engineering: Select Proceedings of FLAME; Shanker, K., Shankar, R., Sindhwani, R., Eds.; Springer Nature: London, UK, 2019; pp. 459–467. [Google Scholar] [CrossRef]

- Sumi, S.; Unnikrishnan, N.; Mathew, L. Experimental investigations on biological resistance of surface modified coir geotextiles. Int. J. Geosynth. Ground Eng. 2016, 2, 31. [Google Scholar] [CrossRef]

- Elfaleh, I.; Abbassi, F.; Habibi, M.; Ahmad, F.; Guedri, M.; Nasri, M.; Garnier, C. A comprehensive review of natural fibers and their composites: An eco-friendly alternative to conventional materials. Results Eng. 2023, 19, 101271. [Google Scholar] [CrossRef]

- Chandramohan, D.; Murali, B.; Vasantha-Srinivasan, P.; Dinesh Kumar, S. Mechanical, moisture absorption, and abrasion resistance properties of bamboo–jute–glass fiber composites. J. Bio-Tribo-Corros. 2019, 5, 66. [Google Scholar] [CrossRef]

- Teixidó, H.; Staal, J.; Caglar, B.; Michaud, V. Capillary effects in fiber reinforced polymer composite processing: A review. Front. Mater. 2022, 9, 809226. [Google Scholar] [CrossRef]

- Rangappa, S.M.; Siengchin, S.; Parameswaranpillai, J.; Jawaid, M.; Ozbakkaloglu, T. Lignocellulosic fiber reinforced composites: Progress, performance, properties, applications, and future perspectives. Polym. Compos. 2022, 43, 645–691. [Google Scholar] [CrossRef]

- Feng, Y.; Hao, H.; Lu, H.; Chow, C.L.; Lau, D. Exploring the development and applications of sustainable natural fiber composites: A review from a nanoscale perspective. Compos. Part B Eng. 2024, 276, 111369. [Google Scholar] [CrossRef]

- Fragassa, C. Marine applications of natural fibre-reinforced composites: A manufacturing case study. In Advances in Applications of Industrial Biomaterials; Pellicer, E., Nikolic, D., Sort, J., Baró, M., Zivic, F., Grujovic, N., Grujic, R., Pelemis, S., Eds.; Springer: Cham, Switzerland, 2017; pp. 21–47. [Google Scholar] [CrossRef]

- Narayana, V.L.; Rao, L.B. A brief review on the effect of alkali treatment on mechanical properties of various natural fiber reinforced polymer composites. Mater. Today Proc. 2021, 44, 1988–1994. [Google Scholar] [CrossRef]

- Fang, X.; Xu, J.; Guo, H.; Liu, Y. The effect of alkali treatment on the crystallinity, thermal stability, and surface roughness of bamboo fibers. Fibers Polym. 2023, 24, 505–514. [Google Scholar] [CrossRef]

- Mohammed, M.; Mohammed, A.M.M.; Oleiwi, J.K.; Adam, T.; Betar, B.O.; Gopinath, S.C.; Ihmedee, F.H.; Anton, K. Influence of Fiber Treatments on Water Absorption Behavior in Natural Fiber-Reinforced Polymer Composites: A Review. Al-Rafidain J. Eng. Sci. 2025, 3, 410–430. [Google Scholar] [CrossRef]

- Tserki, V.; Zafeiropoulos, N.E.; Simon, F.; Panayiotou, C. A study of the effect of acetylation and propionylation surface treatments on natural fibres. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1110–1118. [Google Scholar] [CrossRef]

- Zaman, H.U.; Khan, R.A. Acetylation used for natural fiber/polymer composites. J. Thermoplast. Compos. Mater. 2021, 34, 3–23. [Google Scholar] [CrossRef]

- Abd Halip, J.; Hua, L.S.; Ashaari, Z.; Tahir, P.M.; Chen, L.W.; Uyup, M.K.A. Effect of treatment on water absorption behavior of natural fiber–reinforced polymer composites. In Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Jawaid, M., Thariq, M., Saba, N., Eds.; Woodhead Publishing: Cambridge, UK, 2019; pp. 141–156. [Google Scholar] [CrossRef]

- Fragassa, C.; Pesic, A.; Mattiello, S.; Pavlovic, A.; Santulli, C. Exploring the Potential of Posidonia oceanica Fibers in Eco-Friendly Composite Materials: A Review. J. Mar. Sci. Eng. 2025, 13, 177. [Google Scholar] [CrossRef]

- Garcia-Garcia, D.; Quiles-Carrillo, L.; Montanes, N.; Fombuena, V.; Balart, R. Manufacturing and characterization of composite fibreboards with Posidonia oceanica wastes with an environmentally-friendly binder from epoxy resin. Materials 2017, 11, 35. [Google Scholar] [CrossRef] [PubMed]

- Seggiani, M.; Cinelli, P.; Mallegni, N.; Balestri, E.; Puccini, M.; Vitolo, S.; Lardicci, C.; Lazzeri, A. New bio-composites based on polyhydroxyalkanoates and posidonia oceanica fibres for applications in a marine environment. Materials 2017, 10, 326. [Google Scholar] [CrossRef]

- Chauhan, V.; Kärki, T.; Varis, J. Review of natural fiber-reinforced engineering plastic composites, their applications in the transportation sector and processing techniques. J. Thermoplast. Compos. Mater. 2022, 35, 1169–1209. [Google Scholar] [CrossRef]

- Wataniyakun, W.; Le Gall, M.; El Rakwe, M.; Karl, C.W.; Larsen, R.B. Biodegradable fishing gears: A potential solution to ghost fishing and marine plastic pollution. Mar. Pollut. Bull. 2025, 212, 117607. [Google Scholar] [CrossRef] [PubMed]

- Jagadeesh, P.; Puttegowda, M.; Mavinkere Rangappa, S.; Siengchin, S. A review on extraction, chemical treatment, characterization of natural fibers and its composites for potential applications. Polym. Compos. 2021, 42, 6239–6264. [Google Scholar] [CrossRef]

- Miller, S.A.; Srubar III, W.V.; Billington, S.L.; Lepech, M.D. Integrating durability-based service-life predictions with environmental impact assessments of natural fiber–reinforced composite materials. Resour. Conserv. Recycl. 2015, 99, 72–83. [Google Scholar] [CrossRef]

- Summerscales, J. Durability of composites in the marine environment. In Durability of Composites in a Marine Environment; Davies, P., Rajapakse, Y., Eds.; Springer: Dordrecht, The Netherlands, 2014; pp. 1–13. [Google Scholar]

- Santulli, C. Fabrication and characterization of a filament for 3D printing from polylactic acid with Cryptostegia grandiflora fiber. Mater. Sci. 2024, 42, 1–10. [Google Scholar] [CrossRef]

- Chandrasekar, M.; Ishak, M.R.; Sapuan, S.M.; Leman, Z.; Jawaid, M. A review on the characterisation of natural fibres and their composites after alkali treatment and water absorption. Plast. Rubber Compos. 2017, 46, 119–136. [Google Scholar] [CrossRef]

- Sahu, P.; Gupta, M.K. A review on the properties of natural fibres and its bio-composites: Effect of alkali treatment. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2020, 234, 198–217. [Google Scholar] [CrossRef]

- Punyamurthy, R.; Sampathkumar, D.; Srinivasa, C.V.; Bennehalli, B. Effect of alkali treatment on water absorption of single cellulosic abaca fiber. BioResources 2012, 7, 3515–3524. [Google Scholar]

- Chen, Y.; Su, N.; Zhang, K.; Zhu, S.; Zhu, Z.; Qin, W.; Yang, Y.; Shi, Y.; Fan, S.; Wang, Z.; et al. Effect of fiber surface treatment on structure, moisture absorption and mechanical properties of luffa sponge fiber bundles. Ind. Crops Prod. 2018, 123, 341–352. [Google Scholar] [CrossRef]

- Kamali Moghaddam, M.; Karimi, E. The effect of oxidative bleaching treatment on Yucca fiber for potential composite application. Cellulose 2020, 27, 9383–9396. [Google Scholar] [CrossRef]

- Palaniappan, M.; Palanisamy, S.; Murugesan, T.; Tadepalli, S.; Khan, R.; Ataya, S.; Santulli, C. Influence of washing with sodium lauryl sulphate (SLS) surfactant on different properties of ramie fibres. BioResources 2024, 19, 2609–2625. [Google Scholar] [CrossRef]

- Sayeb, S.; Marzoug, I.; Hassen, M.B.; Sakli, F.; Rodesli, S. Study of water sorption properties for esparto grass ultimate fibre (ALFA fibre). J. Text. Inst. 2010, 101, 19–27. [Google Scholar] [CrossRef]

- Hu, W.; Wang, X.; Cai, M.; Zhang, C.; Zhong, D.; Wang, X.; Zhou, Y.; Xia, L.; Zhou, S.; Xu, W. Environmentally friendly salt-free and low-alkaline coloration of lyocell fibers in an ethanol–water mixture with excellent exhaustion. Green Chem. 2025, 27, 3751–3763. [Google Scholar] [CrossRef]

- Varma, V.K.; Sarangi, S.K. Characterization of Bauhinia variegata natural fiber treated with bleaching, benzoylation, and alkalization. Eng. Res. Expr. 2024, 6, 025528. [Google Scholar] [CrossRef]

- Ladaci, N.; Saadia, A.; Belaadi, A.; Boumaaza, M.; Chai, B.X.; Abdullah, M.M.; Al-Khawlani, A.; Ghernaout, D. ANN and RSM prediction of water uptake of recycled HDPE biocomposite reinforced with treated palm waste W. filifera. J. Nat. Fibers 2024, 21, 2356697. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Valenza, A. Effect of sodium bicarbonate treatment on mechanical properties of flax-reinforced epoxy composite materials. J. Compos. Mater. 2018, 52, 1061–1072. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Nicoletti, F.; Vitale, G.; Prestipino, M.; Valenza, A. A new eco-friendly chemical treatment of natural fibres: Effect of sodium bicarbonate on properties of sisal fibre and its epoxy composites. Compos. Part B Eng. 2016, 85, 150–160. [Google Scholar] [CrossRef]

- Lee, Y.J.; Chung, C.H. Study on the mechanical properties of marine FRP laminates. J. Compos. Mater. 2003, 37, 967–983. [Google Scholar] [CrossRef]

- Oladele, I.O.; Adelani, S.O.; Makinde-Isola, B.A.; Omotosho, T.F. Coconut/coir fibers, their composites and applications. In Plant Fibers, Their Composites, and Applications; Sanjay, M.R., Siengchin, S., Parameswaranpillai, J., Ozbakkaloglu, T., Wang, H., Eds.; Woodhead Publishing: Cambridge, UK, 2022; pp. 181–208. [Google Scholar] [CrossRef]

- Nguyen, D.T.; Le, H.C. Potential of jute fiber-reinforced composites in the manufacture of components and equipment used on ships and hulls. J. Emerg. Sci. Eng. 2023, 1, 14–21. [Google Scholar] [CrossRef]

- Blier, T.; Troalen, W.; Baley, C.; Baral, N. Flax Fiber Reinforced Composites in Boat Building: A Comprehensive Review and Application-Oriented Testing. In SNAME Chesapeake Sailing Yacht Symposium, Proceedings of the SNAME 25th Chesapeake Sailing Yacht Symposium, Annapolis, MD, USA, 14–15 March 2025; SNAME: Annapolis, MD, USA, 2025; p. D021S006R001. [Google Scholar] [CrossRef]

- Jasti, A.; Biswas, S. Effect of ocean water absorption on flexural properties of Cannabis sativa L. hemp fibre reinforced polymer composites for marine applications. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2023, 237, 3894–3907. [Google Scholar] [CrossRef]

- Yu, C. Sisal. In Bast and Other Plant Fibres; Franck, R.E., Ed.; Woodhead Publishing: Cambridge, UK, 2005; pp. 228–273. [Google Scholar] [CrossRef]

- Salazar, V.L.P.; Leão, A.L.; Rosa, D.S.; Gomez, J.G.C.; Alli, R.C.P. Biodegradation of coir and sisal applied in the automotive industry. J. Polym. Environ. 2011, 19, 677–688. [Google Scholar] [CrossRef]

- Rajan, R.K.; Zulkifli, R.; Tahir, M.F.M.; Ude, A.U. Tensile properties and water absorption of Gigantochloa Scortechinii bamboo strip with epoxy layer coating under sea water conditions. Results Eng. 2024, 24, 102969. [Google Scholar] [CrossRef]

- Huang, P.; Chang, W.S.; Ansell, M.P.; John, C.Y.; Shea, A. Porosity estimation of Phyllostachys edulis (Moso bamboo) by computed tomography and backscattered electron imaging. Wood Sci. Technol. 2017, 51, 11–27. [Google Scholar] [CrossRef]

- Hamidon, M.H.; Sultan, M.T.; Ariffin, A.H.; Shah, A.U. Effects of fibre treatment on mechanical properties of kenaf fibre reinforced composites: A review. J. Mater. Res. Technol. 2019, 8, 3327–3337. [Google Scholar] [CrossRef]

- Yusof, Y.; Yahya, S.A.B. Pineapple leaf fiber as a new potential natural fiber in rope making. Adv. Mater. Res. 2013, 785, 628–633. [Google Scholar] [CrossRef]

- Dhanenderan, N.; Uvaraja, V.C.; Bensam Raj, J.; Malarkodi, P. Physical, chemical and thermal analysis of banana flower pistil fiber for the potential application of composite manufacturing. Proc. Inst. Mech. Eng. Part E 2023, 237, 1344–1353. [Google Scholar] [CrossRef]

- Peng, B.Y.; Su, Y.; Chen, Z.; Chen, J.; Zhou, X.; Benbow, M.E.; Criddle, C.S.; Wu, W.-M.; Zhang, Y. Biodegradation of polystyrene by dark (Tenebrio obscurus) and yellow (Tenebrio molitor) mealworms (Coleoptera: Tenebrionidae). Environ. Sci. Technol. 2019, 53, 5256–5265. [Google Scholar] [CrossRef]

- Klose, L.; Meyer-Heydecke, N.; Wongwattanarat, S.; Chow, J.; Pérez García, P.; Carré, C.; Streit, W.; Antranikian, G.; Romero, A.M.; Liese, A. Towards sustainable recycling of epoxy-based polymers: Approaches and challenges of epoxy biodegradation. Polymers 2023, 15, 2653. [Google Scholar] [CrossRef] [PubMed]

- Haramina, T.; Hadžić, N.; Keran, Z. Epoxy resin biocomposites reinforced with flax and hemp fibers for marine applications. J. Mar. Sci. Eng. 2023, 11, 382. [Google Scholar] [CrossRef]

- Nash, N.H.; Egan, L.; Bachour, C.; Manolakis, I.; Comer, A.J. Bio-Based Epoxy Resin Systems as Potential Alternatives to Petroleum Based Epoxy Matrices in Marine Fibre-Reinforced Polymer Composites. SciSpace 2019, 296534488. Available online: https://www.scipedia.com/public/Nash_et_al_2019a (accessed on 24 June 2025).

- Ramon, E.; Sguazzo, C.; Moreira, P.M. A review of recent research on bio-based epoxy systems for engineering applications and potentialities in the aviation sector. Aerospace 2018, 5, 110. [Google Scholar] [CrossRef]

- Capretti, M.; Giammaria, V.; Santulli, C.; Boria, S.; Del Bianco, G. Use of bio-epoxies and their effect on the performance of polymer composites: A critical review. Polymers 2023, 15, 4733. [Google Scholar] [CrossRef]

- Gopalakrishna, K.G.; Reddy, N.; Zhao, Y. Biocomposites from Biofibers and Biopolymers. In Biopolymer Composites in Electronics; Khan, A., Mavinkere Rangappa, S., Siengchin, S., Asiri, A., Eds.; Springer: Cham, Switzerland, 2020; pp. 95–123. [Google Scholar] [CrossRef]

- Raffaele, M.; Corigliano, P.; Cucinotta, F.; Palomba, G.; Salmeri, F. Life Cycle Assessment and Experimental Mechanical Investigation of Test Samples for High-Performance Racing Boats. J. Mar. Sci. Eng. 2024, 12, 2028. [Google Scholar] [CrossRef]

- Lopez-Arraiza, A.; Essamari, L.; Iturrondobeitia, M.; Boullosa-Falces, D.; Justel, D. Life cycle assessment of glass fibre versus flax fibre reinforced composite ship hulls. Sci. Rep. 2025, 15, 16283. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, L.; Shun, W.; Dai, J.; Peng, Y.; Liu, X. Recent development on bio-based thermosetting resins. J. Polym. Sci. 2021, 59, 1474–1490. [Google Scholar] [CrossRef]

- Čuk, N.; Štular, D.; Ocepek, M.; Langerholc, J.; Venturini, P. Development of Renewable Polyester Resins for Coil Coatings Based on 2, 5-Furandicarboxylic Acid. Coatings 2025, 15, 350. [Google Scholar] [CrossRef]

- Meng, J.; Li, Z.; Bai, X.; Gao, X.; Dong, Y.; Sheng, L.; Sun, J.; Guo, K. Design evolution towards sustainability: From dual furan and eugenol biomass to functional epoxy resin and its upgrading. Chem. Eng. J. 2025, 506, 159604. [Google Scholar] [CrossRef]

- Medina, R.; Haupert, F.; Schlarb, A.K. Improvement of tensile properties and toughness of an epoxy resin by nanozirconium-dioxide reinforcement. J. Mater. Sci. 2008, 43, 3245–3252. [Google Scholar] [CrossRef]

- Zhang, X.; Bitaraf, V.; Wei, S.; Guo, Z.; Zhang, X.; Wei, S.; Colorado, H.A. Vinyl ester resin: Rheological behaviors, curing kinetics, thermomechanical, and tensile properties. AIChE J. 2014, 60, 266–274. [Google Scholar] [CrossRef]

- Misumi, J.; Ganesh, R.; Sockalingam, S.; Gillespie, J.W., Jr. Experimental characterization of tensile properties of epoxy resin by using micro-fiber specimens. J. Reinf. Plast. Compos. 2016, 35, 1792–1801. [Google Scholar] [CrossRef]

- Hanon, M.M.; Marczis, R.; Zsidai, L. Influence of the 3D printing process settings on tensile strength of PLA and HT-PLA. Period. Polytech. Mech. Eng. 2021, 65, 38–46. [Google Scholar] [CrossRef]

- Kainulainen, T.P.; Hukka, T.I.; Ozeren, H.D.; Sirviö, J.A.; Hedenqvist, M.S.; Heiskanen, J.P. Utilizing furfural-based bifuran diester as monomer and comonomer for high-performance bioplastics: Properties of poly(butylene furanoate), poly(butylene bifuranoate), and their copolyesters. Biomacromolecules 2019, 21, 743–752. [Google Scholar] [CrossRef]

- Najah, M.I.; Aisyah, R.; Adzila, S.; Haq, R.H.A. Mechanical properties of calcium phosphate reinforced polyhydroxyalkanoate (PHA) biocomposite. J. Thermoplast. Compos. Mater. 2023, 36, 3294–3311. [Google Scholar] [CrossRef]

- Xiao, G.Z.; Shanahan, M.E.R. Water absorption and desorption in an epoxy resin with degradation. J. Polym. Sci. B Polym. Phys. 1997, 35, 2659–2670. [Google Scholar] [CrossRef]

- Kalenda, P. Chemical-resistance values of epoxy resins hardened with polyamines. Pigment Resin Technol. 2001, 30, 150–158. [Google Scholar] [CrossRef]

- Feng, L.; Li, R.; Yang, H.; Chen, S.; Yang, W. The hyperbranched polyester reinforced unsaturated polyester resin. Polymers 2022, 14, 1127. [Google Scholar] [CrossRef]

- Ching, Y.C.; Gunathilake, T.U.; Ching, K.Y.; Chuah, C.H.; Sandu, V.; Singh, R.; Liou, N.S. Effects of high temperature and ultraviolet radiation on polymer composites. In Durability and Life Prediction in Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Jawaid, M., Sultan, M.T.H., Saba, N., Eds.; Woodhead Publishing: Cambridge, UK, 2018; pp. 407–426. [Google Scholar]

- Rahman, M.I.A.M.; Ariffin, A.H. The Development of Pineapple Leaves Fibre Composite Material for Marine Application Using Hand Lay-Up Method. Res. Progr. Mech. Manufact. Eng. 2024, 5, 70–78. [Google Scholar]

- Biswas, S. Mechanical properties of bamboo-epoxy composites a structural application. Adv. Mater. Res. 2012, 1, 221–231. [Google Scholar] [CrossRef]

- Fitriadi, N.; Rizal, M.; Fonna, S. Physical and Thermal Characteristics of Coco Peat Fibre Reinforced Polyurethane Composite for Insulation Box in Marine Application. J. Eng. Sci. Technol. 2022, 17, 3787–3799. [Google Scholar]

- Dhanenderan, N.; Rajasekaran, P.; Pauldoss, S.P.; Arumuganainar, K. Innovative development of sustainable epoxy toughened through banana flower pistil: Mechanical along with water absorption performance evaluation. Phys. Scr. 2025, 100, 035980. [Google Scholar] [CrossRef]

- Huang, Y.; Sultan, M.T.H.; Shahar, F.S.; Łukaszewicz, A.; Oksiuta, Z.; Grzejda, R. Kenaf Fiber-Reinforced Biocomposites for Marine Applications: A Review. Materials 2025, 18, 999. [Google Scholar] [CrossRef]

- Taj, A.; Swamy, R.P.; Naik, K.; Bharat, K.N. Physical effects of nanoaluminum oxide and nanographene on kenaf epoxy composite; vacuum bagging process. J. Appl. Polym. Sci. 2023, 140, e53374. [Google Scholar] [CrossRef]

- Raj, R.R.; Sathish, S.; Mansadevi, T.L.D.; Supriya, R.; Sekar, S.; Patil, P.P.; Tonmoy, M.M. Effect of Graphene Fillers on the Water Absorption and Mechanical Properties of NaOH-Treated Kenaf Fiber-Reinforced Epoxy Composites. J. Nanomater. 2022, 2022, 1748121. [Google Scholar] [CrossRef]

- Palmiyanto, M.H.; Surojo, E.; Ariawan, D.; Imaduddin, F. E-glass/kenaf fibre reinforced thermoset composites filled with MCC and immersion in a different fluid. Sci. Rep. 2022, 12, 20332. [Google Scholar] [CrossRef]

- Manik, P.; Samuel, S.; Tuswan, T.; Jokosisworo, S.; Nadapdap, R.K. Mechanical properties of laminated bamboo composite as a sustainable green material for fishing vessel: Correlation of layer configuration in various mechanical tests. J. Mech. Behav. Mater. 2022, 31, 673–690. [Google Scholar] [CrossRef]

- Corradi, S.; Isidori, T.; Corradi, M.; Soleri, F.; Olivari, L. Composite boat hulls with bamboo natural fibres. Int. J. Mater. Prod. Technol. 2009, 36, 73–89. [Google Scholar] [CrossRef]

- Mentari, P.R.A.; Suharti, S.; Andreansyah, I.; Pratama, A.W.; Agustina, S.; Suhartana, S.; Syamani, F.A. Characterization of High-Density Polyethylene (HDPE)-based Biocomposite with Green Seaweed Caulerpa lentillifera as Filler and Polyethylene-grafted-Maleic Anhydride (PE-g-MA) as Coupling Agent. Biointerface Res. Appl. Chem. 2024, 14, 136. [Google Scholar] [CrossRef]

- Fragassa, C.; Mattiello, S.; Latini, M.; Pesic, A.; Santulli, C. Saltwater immersion effects on bio-composites reinforced with seashell powders. Appl. Compos. Mater. 2025, 32, 123–138. [Google Scholar] [CrossRef]

- Li, L.; Yu, H.; Gui, C.; Hu, L.; Zou, M.; Ren, S.; Huan, W.; Yu, X.; Wang, X. Bio-marine shell powder-filled jute fabric/epoxy composites: Chemical, combustion, and mechanical properties. Polym. Compos. 2025, 46, 4853–4862. [Google Scholar] [CrossRef]

- Echeverria, C.A.; Pahlevani, F.; Gaikwad, V.; Sahajwalla, V. The effect of microstructure, filler load and surface adhesion of marine bio-fillers, in the performance of Hybrid Wood-Polypropylene Particulate Bio-composite. J. Clean. Prod. 2017, 154, 284–294. [Google Scholar] [CrossRef]

- Essabir, H.; Bensalah, M.O.; Rodrigue, D.; Bouhfid, R.; Qaiss, A.E.K. Biocomposites based on argan nut shell and a polymer matrix: Effect of filler content and coupling agent. Carbohydr. Polym. 2016, 143, 70–83. [Google Scholar] [CrossRef]

- Cardon, L.; Ragaert, K.; Koster, R. Design and fabrication of biocomposites. In Biopolymers—Processing and Products; Niaounakis, M., Ed.; Elsevier: Amsterdam, The Netherlands, 2010; Chapter 2; pp. 25–43. [Google Scholar] [CrossRef]

- Siraj, M.T.; Alshybani, I.; Payel, S.B.; Shahadat, M.R.B.; Rahman, M.Z. Advances in biocomposite fabrication: Emerging technologies and their potential applications. In Sustainable Composites for Aerospace Applications; Jawaid, M., Sultan, M.T.H., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; Chapter 76. [Google Scholar] [CrossRef]

- Paolucci, M.; Fasulo, G.; Volpe, M.G. Employment of marine polysaccharides to manufacture functional biocomposites for aquaculture feeding applications. Mar. Drugs 2015, 13, 2680–2693. [Google Scholar] [CrossRef] [PubMed]

- Roy, H.; Pahlevani, F.; Cholake, S.T.; Echeverria, C.A.; Banerjee, A.; Sahajwalla, V. Simulation of marine bio-composite using empirical data combined with finite element technique. J. Compos. Sci. 2018, 2, 48. [Google Scholar] [CrossRef]

- Kim, S.; Lee, S.; Choi, D.; Lee, K.H.; Park, H.; Hwang, W. Fabrication of metal nanohoneycomb structures and their tribological behavior. Adv. Compos. Mater. 2008, 17, 101–110. [Google Scholar] [CrossRef]

- Popineau, V.; Célino, A.; Le Gall, M.; Martineau, L.; Baley, C.; Le Duigou, A. Vacuum-bag-only (VBO) molding of flax fiber-reinforced thermoplastic composites for naval shipyards. Appl. Compos. Mater. 2021, 28, 791–808. [Google Scholar] [CrossRef]

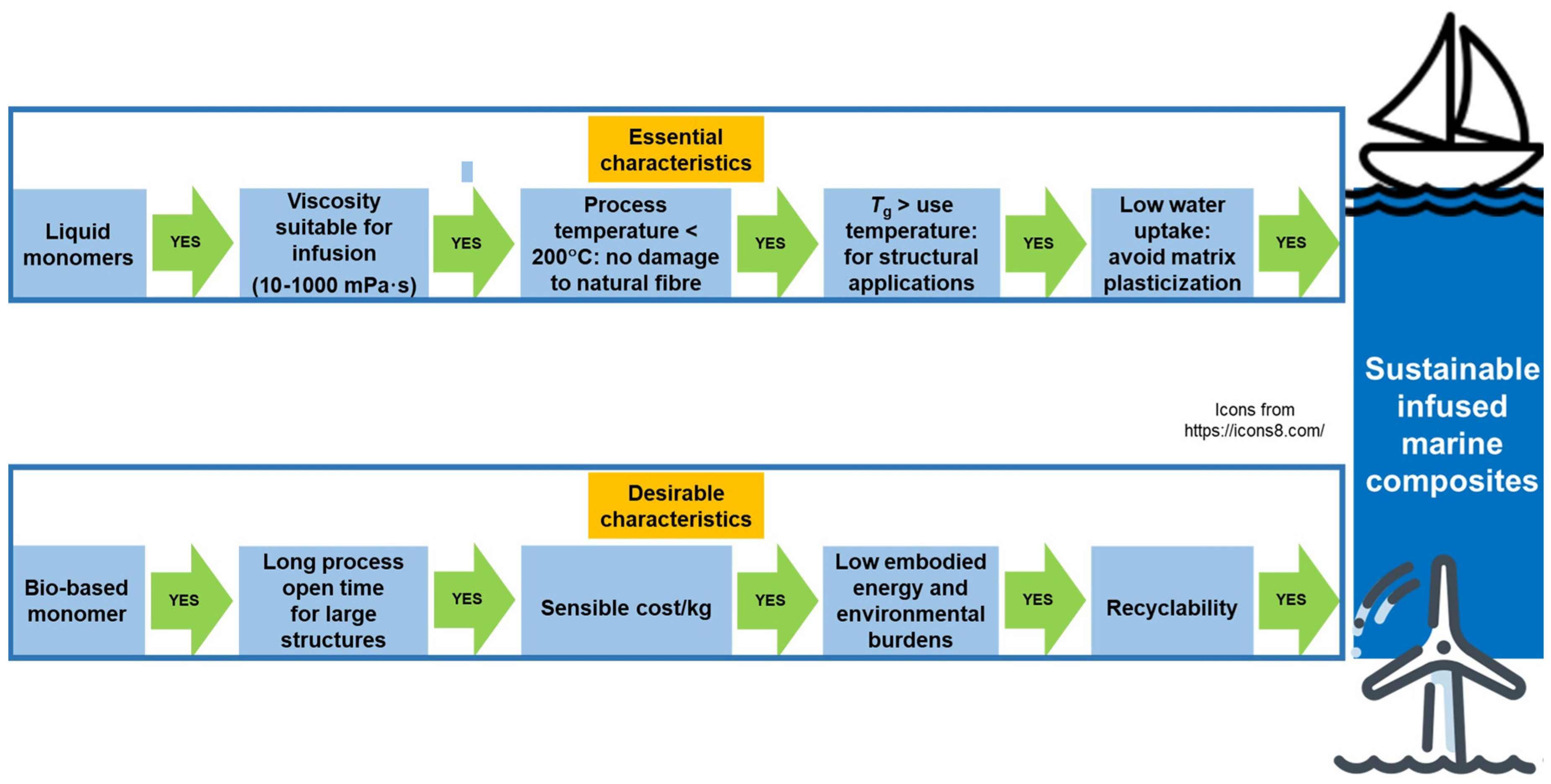

- Qin, Y.; Summerscales, J.; Graham-Jones, J.; Meng, M.; Pemberton, R. Monomer selection for in situ polymerization infusion manufacture of natural-fiber reinforced thermoplastic-matrix marine composites. Polymers 2020, 12, 2928. [Google Scholar] [CrossRef] [PubMed]

- Ait Talaoul, A.; Assarar, M.; Zouari, W.; Ayad, R.; Mazian, B.; Behlouli, K. Investigation of the Flexural Behavior and Damage Mechanisms of Flax/Cork Sandwich Panels Manufactured by Liquid Thermoplastic Resin. J. Compos. Sci. 2024, 8, 539. [Google Scholar] [CrossRef]

- Summerscales, J. Composites manufacturing for marine structures. In Marine Applications of Advanced Fibre-Reinforced Composites; Graham-Jones, J., Summerscales, J., Eds.; Woodhead Publishing: Cambridge, UK, 2016; pp. 19–55. ISBN 0081002009. [Google Scholar]

- Cesur, S.; Oktar, F.N.; Ekren, N.; Kilic, O.; Alkaya, D.B.; Seyhan, S.A.; Ege, Z.R.; Lin, C.-C.; Kuruca, S.E.; Erdemir, G.; et al. Preparation and characterization of electrospun polylactic acid/sodium alginate/orange oyster shell composite nanofiber for biomedical application. J. Aust. Ceram. Soc. 2020, 56, 533–543. [Google Scholar] [CrossRef]

- Chaudhary, B.; Li, H.; Matos, H. Long-term mechanical performance of 3D printed thermoplastics in seawater environments. Results Mater. 2023, 17, 100381. [Google Scholar] [CrossRef]

- Varghese, A.M.; Mittal, V. Surface modification of natural fibers. In Biodegradable and Biocompatible Polymer Composites: Processing, Properties and Applications; Shimpi, N.G., Ed.; Woodhead Publishing: Cambridge, UK, 2017; p. 115. [Google Scholar]

- Cheng, X.Q.; Baig, Y.; Li, Z.N. Effects of stitching parameters on tensile strength of FRPs under hygrothermal conditions. Adv. Mater. Res. 2012, 570, 63–77. [Google Scholar] [CrossRef]

- Gupta, U.S.; Dhamarikar, M.; Dharkar, A.; Chaturvedi, S.; Kumrawat, A.; Giri, N.; Tiwari, S.; Namdeo, R. Plasma modification of natural fiber: A review. Mater. Today Proc. 2021, 43, 451–457. [Google Scholar] [CrossRef]

- Fan, H.; Wang, J.; Tao, Z.; Huang, J.; Rao, P.; Kurokawa, T.; Gong, J.P. Adjacent Cationic–Aromatic Sequences Yield Strong Electrostatic Adhesion of Hydrogels in Seawater. Nat. Commun. 2019, 10, 5127. [Google Scholar] [CrossRef] [PubMed]

- Hu, H.; Bai, Z.; Sun, Y.; Gao, Y.; Zhang, K.; Wang, H. Solvent-free preparation of bio-based composite coating with improved crystallinity and unique corrosion resistance. Prog. Org. Coat. 2023, 179, 107520. [Google Scholar] [CrossRef]

- Şükür, E.F.; Önal, G. Long-term salt-water durability of GNPs reinforced basalt-epoxy multiscale composites for marine applications. Tribol. Int. 2021, 158, 106910. [Google Scholar] [CrossRef]

- Tian, H.; Zhan, Y.; Tian, L.; Sun, J. Corrosion resistance self-healing coating with bioinspired interfacial structure. Prog. Org. Coat. 2023, 174, 107303. [Google Scholar] [CrossRef]

- Hudda, A.; Singh, S.; Tiwari, S.; Kumar, H.V.; Vesh, A.; Imamuddin, M.; Roy, D.; Prasad, N.E. Unravelling the Role of Nanofillers Towards the Stability of Polymer Matrix Composite in Marine Environment. Adv. Compos. Mater. 2022, 32, 268–282. [Google Scholar] [CrossRef]

- Seo, E.; Seong, M.R.; Lee, J.W.; Lim, H.; Park, J.W.; Kim, H.; Hwang, H.; Lee, D.; Kim, J.; Kim, G.H.; et al. Anti-Biofouling Features of Eco-Friendly Oleamide-PDMS Copolymers. ACS Omega 2020, 5, 11515–11521. [Google Scholar] [CrossRef]

- Sankaran, S.; Palani, G.; Yang, Y.L.; Trilaksana, H. Enhancing natural fiber-based polymeric composites with biochar filler particles derived from groundnut shell biomass waste. Biomass Convers. Biorefin. 2025, 15, 14399–14410. [Google Scholar] [CrossRef]

- Post, W.; Kuijpers, L.J.; Zijlstra, M.; Van Der Zee, M.; Molenveld, K. Effect of mineral fillers on the mechanical properties of commercially available biodegradable polymers. Polymers 2021, 13, 394. [Google Scholar] [CrossRef]

- Wang, D.; Liu, Y.; Zhou, F. Anti-Biofouling Friction Power Generation Coating Material and Application Thereof. Korean Patent n. KR101489640B1, 4 February 2015. [Google Scholar]

- Sharma, M.; Sharma, H.; Shannigrahi, S. Tribology of Advanced Composites/Biocomposites Materials. In Green Tribology; Bhushan, B., Ed.; Woodhead Publishing: Cambridge, UK, 2017; Chapter 18. [Google Scholar] [CrossRef]

- Lee, B.P.; Messersmith, P.B.; Israelachvili, J.N.; Waite, J.H. Mussel-inspired adhesives and coatings. Annu. Rev. Mater. Res. 2011, 41, 99–132. [Google Scholar] [CrossRef] [PubMed]

- Pulikkalparambil, H.; Babu, A.; Thilak, A.; Vighnesh, N.P.; Rangappa, S.M.; Siengchin, S. A review on sliding wear properties of sustainable biocomposites: Classifications, fabrication and discussions. Heliyon 2023, 9, e14381. [Google Scholar] [CrossRef]

- Seshadhri, V.; Alagarsamy, S.V.; Rajagopal, M. Tribological behaviour of AZ31 Mg hybrid bio-composite reinforced with zirconium dioxide and seashell bio-ceramics. Phys. Scr. 2024, 100, 015043. [Google Scholar] [CrossRef]

- Curto, M.; Le Gall, M.; Catarino, A.I.; Niu, Z.; Davies, P.; Everaert, G.; Dhakal, H.N. Long-term durability and ecotoxicity of biocomposites in marine environments: A review. RSC Adv. 2021, 11, 32917–32941. [Google Scholar] [CrossRef]

- Chang, B.P.; Mohanty, A.K.; Misra, M. Studies on durability of sustainable biobased composites: A review. RSC Adv. 2020, 10, 17955–17999. [Google Scholar] [CrossRef]

- Santulli, C.; Fiore, V. Seawater aging and its degradation effects on the mechanical properties of biocomposites. In Handbook of Bioplastics and Biocomposites Engineering Applications; Elsevier: Amsterdam, The Netherlands, 2024; pp. 423–440. [Google Scholar] [CrossRef]

- Sekaran, J.J.G.; Thirumurugan, P.; Kandavalli, S.R.; Swarnalatha, K. Dynamic mechanical, tensile fatigue and water absorption behaviour of polyester composites comprises of Amaranthus dubius stem natural fiber and its root waste crystalline cellulose. Biomass Convers. Biorefin. 2024, 14, 32499–32507. [Google Scholar] [CrossRef]

- Strangis, G.; Rossi, D.; Cinelli, P.; Seggiani, M. Seawater biodegradable poly (butylene succinate-co-adipate)—Wheat bran biocomposites. Materials 2023, 16, 2593. [Google Scholar] [CrossRef] [PubMed]

- Snowdon, A.A.; Dennington, S.P.; Longyear, J.E.; Wharton, J.A.; Stoodley, P. Surface properties influence marine biofilm rheology, with implications for ship drag. Soft Matter 2023, 19, 3675–3687. [Google Scholar] [CrossRef]

- Gandini, A.; Lacerda, T.M. Furan polymers: State of the art and perspectives. Macromol. Mater. Eng. 2022, 307, 2100902. [Google Scholar] [CrossRef]

- Paul, R.; Zindani, D.; Bhowmik, S. Investigation on physicomechanical, tribological and optimality condition for coir filler-reinforced polymeric composites. Arab. J. Sci. Eng. 2023, 48, 3615–3630. [Google Scholar] [CrossRef]

- Woolnough, C.A.; Yee, L.H.; Charlton, T.; Foster, L.J.R. Environmental degradation and biofouling of ‘green’ plastics including short and medium chain length polyhydroxyalkanoates. Polym. Int. 2010, 59, 658–667. [Google Scholar] [CrossRef]

- Piras, S.; Salathia, S.; Guzzini, A.; Zovi, A.; Jackson, S.; Smirnov, A.; Fragassa, C.; Santulli, C. Biomimetic use of food-waste sources of calcium carbonate and phosphate for sustainable materials—A review. Materials 2024, 17, 843. [Google Scholar] [CrossRef] [PubMed]

- Taghaddosi, S.; Akbari, A.; Yegani, R. Preparation, characterization and anti-fouling properties of nanoclays embedded polypropylene mixed matrix membranes. Chem. Eng. Res. Des. 2017, 125, 35–45. [Google Scholar] [CrossRef]

- Kumar, S.V.; Singh, H. Wear, morphological and thermal behavior of flax fibre reinforced epoxy composites. Indian J. Fibre. Text. Res. 2023, 48, 326–335. [Google Scholar] [CrossRef]

- Sumesh, K.R.; Ajithram, A.; Anjumol, K.S.; Sai Krishnan, G. Influence of natural fiber addition and fiber length in determining the wear resistance of epoxy-based composites. Polym. Compos. 2024, 45, 3029–3042. [Google Scholar] [CrossRef]

- Taha, I. Investigation of flax fibre reinforced epoxy friction composites. Mater. Werkst. 2012, 43, 1059–1066. [Google Scholar] [CrossRef]

- Afshar, A.; Alkhader, M.; Korach, C.S.; Chiang, F.P. Effect of long-term exposure to marine environments on the flexural properties of carbon fiber vinylester composites. Compos. Struct. 2015, 126, 72–77. [Google Scholar] [CrossRef]

- Oluwoye, I.; Machuca, L.L.; Higgins, S.; Suh, S.; Galloway, T.S.; Halley, P.; Tanaka, S.; Iannuzzi, M. Degradation and lifetime prediction of plastics in subsea and offshore infrastructures. Sci. Total Environ. 2023, 904, 166719. [Google Scholar] [CrossRef] [PubMed]

- Weber, F.; Esmaeili, N. Marine biofouling and the role of biocidal coatings in balancing environmental impacts. Biofouling 2023, 39, 661–681. [Google Scholar] [CrossRef] [PubMed]

- Sathish, T.; Mohanavel, V.; Raja, T.; Djearamane, S.; Velmurugan, P.; Nasif, O.; Alfarraj, S.; Wong, L.S.; Manikandan, V.; Ravichandran, M. Influence of compression molding process parameters in mechanical and tribological behavior of hybrid polymer matrix composites. Polymers 2021, 13, 4195. [Google Scholar] [CrossRef]

- Huang, X.; Ye, R.; Zhao, L. Research progresses of composites with natural fibers recycled from textiles waste. J. Eng. Fibers Fabr. 2025, 20, 15589250251338265. [Google Scholar] [CrossRef]

- Otoni, C.G.; Azeredo, H.M.; Mattos, B.D.; Beaumont, M.; Correa, D.S.; Rojas, O.J. The food–materials nexus: Next generation bioplastics and advanced materials from agri-food residues. Adv. Mater. 2021, 33, 2102520. [Google Scholar] [CrossRef]

| Natural Fiber | Sea-Related Properties | Some Applications |

|---|---|---|

| Coir [127] | High resistance to saltwater and microbial attack | Ropes, mats, and fenders |

| Jute [128] | Moderate resistance to water; non-Fickian behavior | Non-structural components, paneling, and linings |

| Flax [129] | Low water absorption when treated | Composites for boat hulls, decks, and other structural components |

| Hemp [130] | Resistant to UV light, durable, and strong; Fickian behavior | Ropes and sails, composites for boat hulls |

| Sisal [131] | Resistant to salt water yet not to microbial degradation (risk of fungal growth) [132] | Ropes and twines |

| Bamboo [133] | High strength-to-weight ratio, high anisotropy owing to variable porosity structure [134] | Materials for flooring, decking, and structural components in boat hulls |

| Kenaf [135] | High tensile strength, light yet stiff, biodegradable | Interior panels and in structural applications after treatment |

| Pineapple leaf (PALF) [136] | Abundant waste, good torque properties for thinner filaments | Ropes (as the competitor with sisal) |

| Banana fronds (flower pistils) [137] | Quasi-constant flexural properties at all orientations, not very resistant to saltwater | Ship components above water |

| Property | Synthetic Resins | Bio-Based Resins |

|---|---|---|

| Origin | Petrochemical | Renewable sources (biomass, vegetable oils) |

| Typical Examples | Epoxy, Unsaturated polyesters, Vinyl esters | PLA, PHA, Bio-epoxies, Furano–epoxies |

| Tensile Strength | Normally around 80–100 MPa Over 60 MPa for epoxy [150]; 63 MPa for vinyl esters cured at 40 °C [151]; A value of 114 MPa was measured in [152]. | 50–70 MPa for PLA (up to 58 MPa was measured in [153] for different raster angles); 70–90 MPa for furans (over 65 MPa was measured in [154]) |

| Young’s Modulus | Over 3 GPa for epoxy [150], less for other resins | 1–2.5 GPa, yet often much lower for PHA (even limited to 300–400 MPa) [155] |

| Water Absorption | Very low and rapidly desorbed (may produce critical effects only at temperatures such as 90 °C) [156] | High–moderate (depending on the type of bio resin) |

| Chemical Resistance | Very good (problems with acids, improving with polyamine concentration in epoxy) [157] | Good, but lower in saline environments for PLA/PHA |

| Thermal Stability | High (>100 °C) | Limited (~60–80 °C for PLA; >100 °C for furan-based resins) |

| Glass Transition Temperature (Tg) | 90–130 °C (~100 °C for unsaturated polyester) [158] | 60–120 °C (depending on the bio resin type) |

| UV Resistance | Variable (may require additives, such as UV stabilizers) (organic polymer coatings) [159] | Generally low, requires surface treatments |

| Biodegradability | None in non-prepared environment | High (especially for PLA, PHA) |

| Durability in Marine Environments | Excellent (with protective coatings) | Variable, can be improved with surface treatments |

| Environmental Compatibility | Low (end-of-life issues) | Higher (possible compostability) |

| Commercial Availability | Wide | Limited but growing |

| Raw Material Cost | Medium (relatively inexpensive) | Variable (currently higher than synthetic resins) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fragassa, C.; Conticelli, F.; Francucci, B.; Seccacini, G.; Santulli, C. Biocomposites for Marine Applications: A Review of Friction, Wear, and Environmental Degradation. J. Compos. Sci. 2025, 9, 331. https://doi.org/10.3390/jcs9070331

Fragassa C, Conticelli F, Francucci B, Seccacini G, Santulli C. Biocomposites for Marine Applications: A Review of Friction, Wear, and Environmental Degradation. Journal of Composites Science. 2025; 9(7):331. https://doi.org/10.3390/jcs9070331

Chicago/Turabian StyleFragassa, Cristiano, Francesca Conticelli, Beatrice Francucci, Giacomo Seccacini, and Carlo Santulli. 2025. "Biocomposites for Marine Applications: A Review of Friction, Wear, and Environmental Degradation" Journal of Composites Science 9, no. 7: 331. https://doi.org/10.3390/jcs9070331

APA StyleFragassa, C., Conticelli, F., Francucci, B., Seccacini, G., & Santulli, C. (2025). Biocomposites for Marine Applications: A Review of Friction, Wear, and Environmental Degradation. Journal of Composites Science, 9(7), 331. https://doi.org/10.3390/jcs9070331