The Silylation Effect of C/SiC Nanofillers on Mechanical Properties of Cellulose Nanocomposite: Insights from Molecular Dynamics Simulations

Abstract

1. Introduction

2. Materials and Methods

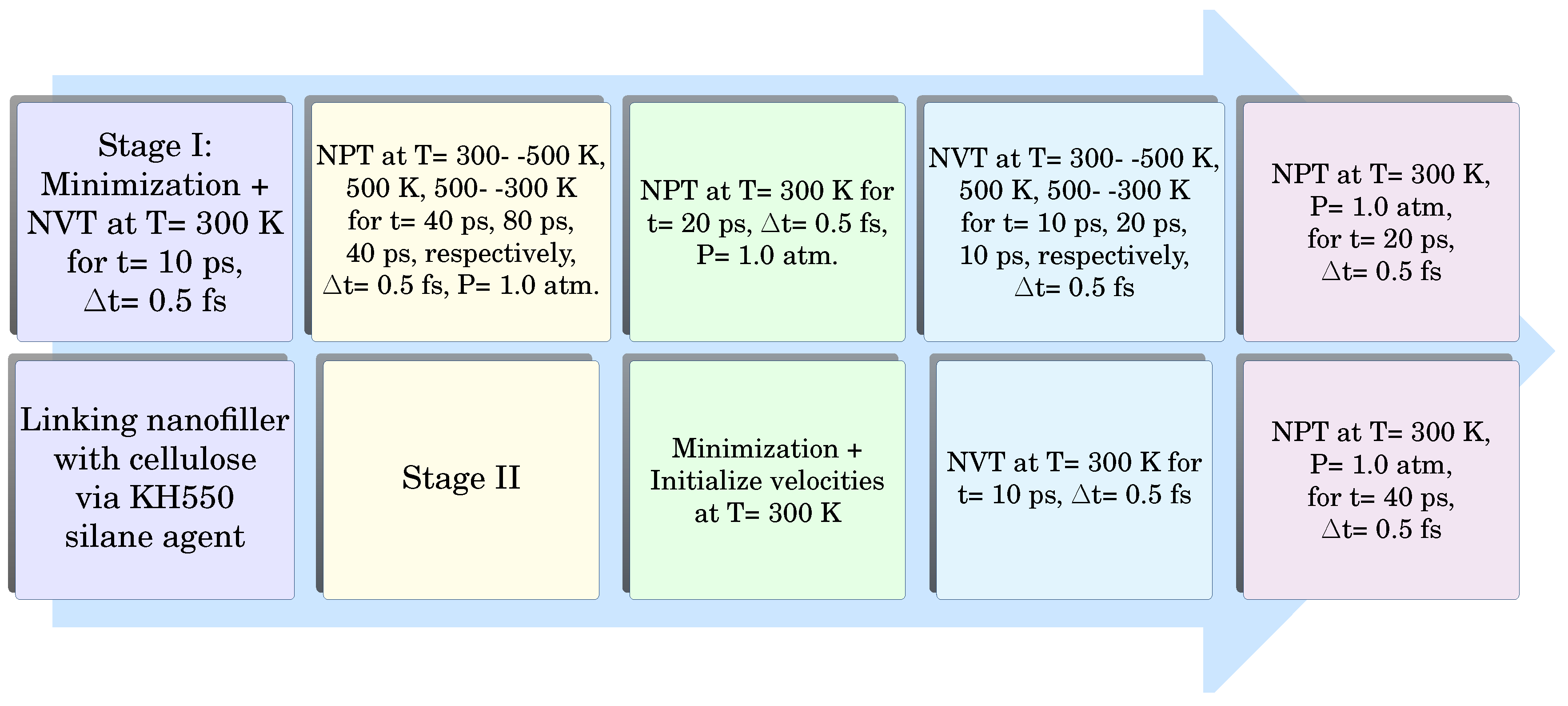

2.1. Molecular Dynamics Simulation

2.2. Reinforcing Cellulose with Silylated C/SiC Nanofillers

3. Results and Discussion

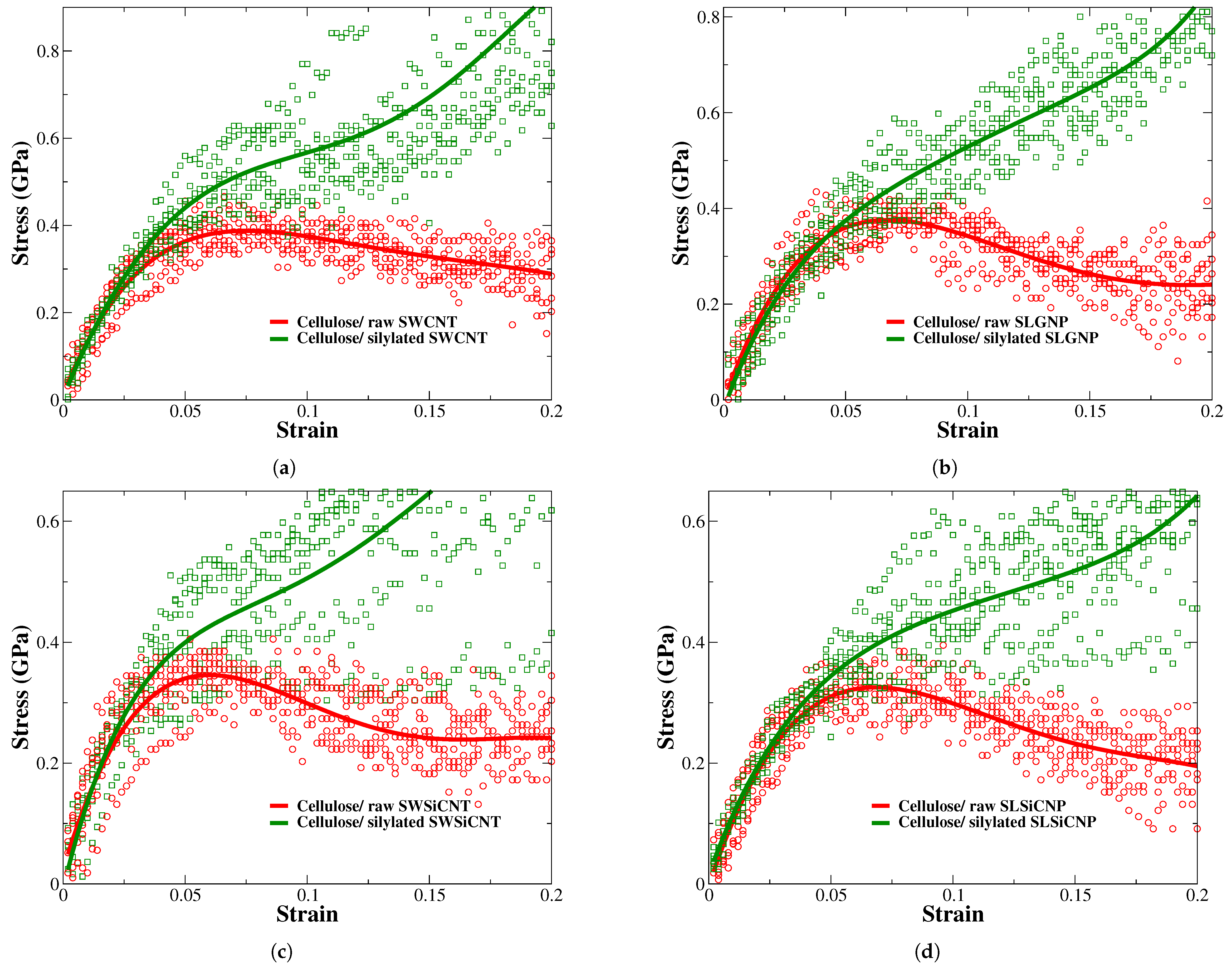

The Structural Reinforcing Effect of Silylated C/SiC Nanofillers

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Balla, V.K.; Kate, K.H.; Satyavolu, J.; Singh, P.; Tadimeti, J.G.D. Additive manufacturing of natural fiber reinforced polymer composites: Processing and prospects. Compos. Part Eng. 2019, 174, 106956. [Google Scholar] [CrossRef]

- Nissilä, T.; Karhula, S.S.; Saarakkala, S.; Oksman, K. Cellulose nanofiber aerogels impregnated with bio-based epoxy using vacuum infusion: Structure, orientation and mechanical properties. Compos. Sci. Technol. 2018, 155, 64–71. [Google Scholar] [CrossRef]

- Zhang, D.; Huang, Y. Dispersion characterizations and adhesion properties of epoxy composites reinforced by carboxymethyl cellulose surface treated carbon nanotubes. Powder Technol. 2022, 404, 117505. [Google Scholar] [CrossRef]

- Kabir, M.; Wang, H.; Lau, K.; Cardona, F. Tensile properties of chemically treated hemp fibres as reinforcement for composites. Compos. Part Eng. 2013, 53, 362–368. [Google Scholar] [CrossRef]

- Fujisawa, S.; Saito, T.; Kimura, S.; Iwata, T.; Isogai, A. Comparison of mechanical reinforcement effects of surface-modified cellulose nanofibrils and carbon nanotubes in PLLA composites. Compos. Sci. Technol. 2014, 90, 96–101. [Google Scholar] [CrossRef]

- Zhu, B.; Wang, K.; Sun, W.; Fu, Z.; Ahmad, H.; Fan, M.; Gao, H. Revealing the adsorption energy and interface characteristic of cellulose-graphene oxide composites by first-principles calculations. Compos. Sci. Technol. 2022, 218, 109209. [Google Scholar] [CrossRef]

- Morgan, J.; Craciun, M.; Eichhorn, S. Quantification of stress transfer in a model cellulose nanocrystal/graphene bilayer using Raman spectroscopy. Compos. Sci. Technol. 2019, 177, 34–40. [Google Scholar] [CrossRef]

- Wu, Y.; Li, W.; Zhang, X.; Li, B.; Luo, X.; Liu, S. Clarification of GO acted as a barrier against the crack propagation of the cellulose composite films. Compos. Sci. Technol. 2014, 104, 52–58. [Google Scholar] [CrossRef]

- Li, K.; Qi, D. Molecular dynamics simulation of mechanical properties of carbon nanotube reinforced cellulose. J. Mol. Model. 2023, 29, 127. [Google Scholar] [CrossRef]

- Lee, T.W.; Lee, S.E.; Jeong, Y.G. Carbon nanotube/cellulose papers with high performance in electric heating and electromagnetic interference shielding. Compos. Sci. Technol. 2016, 131, 77–87. [Google Scholar] [CrossRef]

- Fitzka, M.; Schönbauer, B.M.; Stojanovic, V.; Rennhofer, H.; Lichtenegger, H.; Carroll, J.W.; Sanaei, N.; Mapkar, J.; Mayer, H. Ultrasonic fatigue of unfilled and carbon nanotube (CNT) reinforced polyetheretherketone (PEEK). Ultrasonics 2024, 138, 107236. [Google Scholar] [CrossRef] [PubMed]

- Tan, X.; Jiang, Y.; Peng, Q.; Subrova, T.; Saskova, J.; Wiener, J.; Venkataraman, M.; Militky, J.; Kejzlar, P.; Mahendran, A.R.; et al. Development and characterization of silane crosslinked cellulose/graphene oxide conductive hydrophobic membrane. Cellulose 2023, 30, 4561–4574. [Google Scholar] [CrossRef]

- Xu, M.; Girish, Y.R.; Rakesh, K.P.; Wu, P.; Manukumar, H.M.; Byrappa, S.M.; Udayabhanu; Byrappa, K. Recent advances and challenges in silicon carbide (SiC) ceramic nanoarchitectures and their applications. Mater. Today Commun. 2021, 28, 102533. [Google Scholar] [CrossRef]

- Eghbalian, M.; Ansari, R.; Haghighi, S. Molecular dynamics investigation of the mechanical properties and fracture behaviour of hydroxyl-functionalised carbon and silicon carbide nanotubes-reinforced polymer nanocomposites. Mol. Simul. 2023, 49, 415–426. [Google Scholar] [CrossRef]

- Nor Arman, N.S.; Chen, R.S.; Ahmad, S. Review of state-of-the-art studies on the water absorption capacity of agricultural fiber-reinforced polymer composites for sustainable construction. Constr. Build. Mater. 2021, 302, 124174. [Google Scholar] [CrossRef]

- Jayaraman, T.; Murthy, A.P.; Elakkiya, V.; Chandrasekaran, S.; Nithyadharseni, P.; Khan, Z.; Senthil, R.A.; Shanker, R.; Raghavender, M.; Kuppusami, P.; et al. Recent development on carbon based heterostructures for their applications in energy and environment: A review. J. Ind. Eng. Chem. 2018, 64, 16–59. [Google Scholar] [CrossRef]

- Worajittiphon, P.; Santiwongsathit, N.; Bai, S.L.; Daranarong, D.; Punyodom, W.; Sriyai, M.; Jantanasakulwong, K.; Rachtanapun, P.; Ross, S.; Tipduangta, P.; et al. Carboxymethyl cellulose/poly(vinyl alcohol) blended films reinforced by buckypapers of carbon nanotubes and 2D material (MoS2): Enhancing mechanical strength, toughness, and barrier properties. Int. J. Biol. Macromol. 2023, 242, 124726. [Google Scholar] [CrossRef]

- Plimpton, S. Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Design, M. Material Exploration Design Analysis (MedeA) Release 3.6, 2023. Angel Fire, New Mexico, USA. 2023. Available online: https://www.materialsdesign.com (accessed on 20 August 2023).

- Zhao, H.; Chang, A.; Wang, Y. Structural, elastic, and electronic properties of cubic perovskite BaHfO3 obtained from first principles. Phys. Condens. Matter 2009, 404, 2192–2196. [Google Scholar] [CrossRef]

- Anderson, O.L. A simplified method for calculating the debye temperature from elastic constants. J. Phys. Chem. Solids 1963, 24, 909–917. [Google Scholar] [CrossRef]

- Yu, M.F.; Lourie, O.; Dyer, M.J.; Moloni, K.; Kelly, T.F.; Ruoff, R.S. Strength and Breaking Mechanism of Multiwalled Carbon Nanotubes Under Tensile Load. Science 2000, 287, 637–640. [Google Scholar] [CrossRef] [PubMed]

- Drieux, P.; Chollon, G.; Jacques, S.; Couégnat, G.; Jouannigot, S.; Weisbecker, P. Synthesis and characterization of monolithic CVD-SiC tubes. J. Eur. Ceram. Soc. 2016, 36, 1873–1883. [Google Scholar] [CrossRef]

- Raum, K.; Cleveland, R.O.; Peyrin, F.; Laugier, P. Derivation of elastic stiffness from site-matched mineral density and acoustic impedance maps. Phys. Med. Biol. 2006, 51, 747. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Chandra, R.; Kumar, P.; Kumar, N. Molecular dynamics simulation of carbon nanotubes. Nanosci. Technol. Int. J. 2013, 4, 1–27. [Google Scholar] [CrossRef]

- Choi, J.; Shin, H.; Yang, S.; Cho, M. The influence of nanoparticle size on the mechanical properties of polymer nanocomposites and the associated interphase region: A multiscale approach. Compos. Struct. 2015, 119, 365–376. [Google Scholar] [CrossRef]

- Lu, J.; Qiu, Y.; Baron, R.; Molinero, V. Coarse-Graining of TIP4P/2005, TIP4P-Ew, SPC/E, and TIP3P to Monatomic Anisotropic Water Models Using Relative Entropy Minimization. J. Chem. Theory Comput. 2014, 10, 4104–4120. [Google Scholar] [CrossRef]

- Research, D.E.S. Schrödinger Release 2021-2: Desmond Molecular Dynamics System. New York, NY, USA. 2021. Available online: https://www.schrodinger.com (accessed on 15 April 2023).

- Watowich, S.J.; Meyer, E.S.; Hagstrom, R.; Josephs, R. A stable, rapidly converging conjugate gradient method for energy minimization. J. Comput. Chem. 1988, 9, 650–661. [Google Scholar] [CrossRef]

- Gindl, W.; Martinschitz, K.J.; Boesecke, P.; Keckes, J. Structural changes during tensile testing of an all-cellulose composite by in situ synchrotron X-ray diffraction. Compos. Sci. Technol. 2006, 66, 2639–2647. [Google Scholar] [CrossRef]

- Rahman, R.; Foster, J.T.; Haque, A. Molecular Dynamics Simulation and Characterization of Graphene–Cellulose Nanocomposites. J. Phys. Chem. A 2013, 117, 5344–5353. [Google Scholar] [CrossRef]

- Moradian, R.; Behzad, S.; Chegel, R. Ab initio density functional theory investigation of structural and electronic properties of double-walled silicon carbide nanotubes. Phys. E Low-Dimens. Syst. Nanostruct. 2009, 42, 172–175. [Google Scholar] [CrossRef]

- Wang, L.; Tang, C.; Wang, X.; Zheng, W. Molecular dynamics simulation on the thermodynamic properties of insulating paper cellulose modified by silane coupling agent grafted nano-SiO2. AIP Adv. 2019, 9, 125134. [Google Scholar] [CrossRef]

- Jiang, K.; Yan, Z.; Fang, W.; Zhang, Y. Molecular Dynamics Simulation on Tensile Behavior of Cellulose at Different Strain Rates. Adv. Mater. Sci. Eng. 2023, 2023, 7890912. [Google Scholar] [CrossRef]

- Khanjanzadeh, H.; Behrooz, R.; Bahramifar, N.; Gindl-Altmutter, W.; Bacher, M.; Edler, M.; Griesser, T. Surface chemical functionalization of cellulose nanocrystals by 3-aminopropyltriethoxysilane. Int. J. Biol. Macromol. 2018, 106, 1288–1296. [Google Scholar] [CrossRef]

- Rajan, R.; Rainosalo, E.; Ramamoorthy, S.K.; Thomas, S.P.; Zavašnik, J.; Vuorinen, J.; Skrifvars, M. Mechanical, thermal, and burning properties of viscose fabric composites: Influence of epoxy resin modification. J. Appl. Polym. Sci. 2018, 135, 46673. [Google Scholar] [CrossRef]

- Sayadi, S.; Brouillette, F. Silylation of phosphorylated cellulosic fibers with an aminosilane. Carbohydr. Polym. 2024, 343, 122500. [Google Scholar] [CrossRef]

- Shishehbor, M.; Pouranian, M.R. Tuning the Mechanical and Adhesion Properties of Carbon Nanotubes Using Aligned Cellulose Wrap (Cellulose Nanotube): A Molecular Dynamics Study. Nanomaterials 2020, 10, 154. [Google Scholar] [CrossRef]

- Du, D.; Tang, C.; Tang, Y.; Yang, L.; Hao, J. Molecular simulation on the mechanical and thermal properties of carbon nanowire modified cellulose insulating paper. Compos. Struct. 2021, 261, 113283. [Google Scholar] [CrossRef]

- Meng, Q.; Manas-Zloczower, I. Carbon nanotubes enhanced cellulose nanocrystals films with tailorable electrical conductivity. Compos. Sci. Technol. 2015, 120, 1–8. [Google Scholar] [CrossRef]

- Hamedi, M.M.; Hajian, A.; Fall, A.B.; Håkansson, K.; Salajkova, M.; Lundell, F.; Wågberg, L.; Berglund, L.A. Highly Conducting, Strong Nanocomposites Based on Nanocellulose-Assisted Aqueous Dispersions of Single-Wall Carbon Nanotubes. ACS Nano 2014, 8, 2467–2476. [Google Scholar] [CrossRef]

| Material | PCFF | Reference |

|---|---|---|

| CNTs (12,12) | 535.47 | 270–950 [22] |

| SiCNTs (12,12) | 399.42 | 400 [23] |

| Chiral Index (n, m) | Elastic Constant C33 (GPa) | Poisson’s Ratio, | Elastic Modulus, E33 (GPa) | Error % | |

|---|---|---|---|---|---|

| PCFF | Reference [25] | ||||

| 10, 10 | 561.71 | 0.1608 | 527.10 | 519 | 1.56 |

| 12, 12 | 513.04 | 0.2276 | 444.22 | 440 | 0.96 |

| 16, 16 | 420.68 | 0.2371 | 358.68 | 360 | 0.37 |

| 20, 20 | 363.70 | 0.2714 | 290.16 | 317 | 8.47 |

| Nanofiller | Molecular Formula | Dimensions (Å) |

|---|---|---|

| Raw SWCNT (3,3) | C246H12 | l = 50.93 |

| Silylated SWCNT (3,3) | Si24C318N24O72H252 | d = 5.02 |

| Raw SLGNP | C264H58 | l = 51.84 |

| Silylated SLGNP | Si24C336N24O72H298 | w = 14.19 |

| Raw SWSiCNT (3,3) | Si123C123H12 | l = 64.09 |

| Silylated SWSiCNT (3,3) | Si147C195N24O72H252 | d = 6.10 |

| Raw SLSiCNP | Si132C132H58 | l = 65.13 |

| Silylated SLSiCNP | Si156C204N24O72H298 | w = 17.48 |

| Material | Molecular Formula | Matrix Composition | Loading of Nanofiller (wt.%) |

|---|---|---|---|

| Raw cellulose | C1200O1000H2040 | - | |

| Raw cellulose/SWCNT | C1446O1000H2052 | 8.40 | |

| Raw cellulose/S-SWCNT | Si22C1512N22O1044H2228 | 16.10 (7.70 1) | |

| Raw cellulose/SLGNP | C1464O1000H2098 | 9.00 | |

| Raw cellulose/S-SLGNP | Si22C1530N22O1044H2274 | Cellulose: 20 | 16.70 (8.30 1) |

| Raw cellulose/SWSiCNT | Si123C1323O1000H2052 | 13.20 | |

| Raw cellulose/S-SWSiCNT | Si145C1389N22O1044H2228 | 20.20 (12.20 1) | |

| Raw cellulose/SLSiCNP | Si132C1332O1000H2098 | 14.10 | |

| Raw cellulose/S-SLSiCNP | Si154C1398N22O1044H2274 | 21.00 (13.10 1) |

| Material | Elasticity (GPa) | Shear Modulus (GPa) | Poisson’s Ratio | Density (g/mL) |

|---|---|---|---|---|

| Raw cellulose | 10.1167 | 4.0050 | 0.2636 | 1.3781 |

| Raw cellulose/SWCNT | 12.1183 | 4.7667 | 0.2706 | 1.4192 |

| Raw cellulose/SLGNP | 11.8017 | 4.6150 | 0.2786 | 1.4221 |

| Raw cellulose/SWSiCNT | 11.5917 | 4.5383 | 0.2772 | 1.4144 |

| Raw cellulose/SLSiCNP | 11.3083 | 4.4483 | 0.2715 | 1.4168 |

| Raw cellulose/S-SWCNT | 15.0967 | 6.0233 | 0.2530 | 1.4257 |

| Raw cellulose/S-SLGNP | 14.0367 | 5.6133 | 0.2510 | 1.3933 |

| Raw cellulose/S-SWSiCNT | 13.6817 | 5.4883 | 0.2472 | 1.3974 |

| Raw cellulose/S-SLSiCNP | 13.0150 | 5.2117 | 0.2486 | 1.3882 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Maharma, A.Y.; Markert, B.; Bamer, F. The Silylation Effect of C/SiC Nanofillers on Mechanical Properties of Cellulose Nanocomposite: Insights from Molecular Dynamics Simulations. J. Compos. Sci. 2025, 9, 284. https://doi.org/10.3390/jcs9060284

Al-Maharma AY, Markert B, Bamer F. The Silylation Effect of C/SiC Nanofillers on Mechanical Properties of Cellulose Nanocomposite: Insights from Molecular Dynamics Simulations. Journal of Composites Science. 2025; 9(6):284. https://doi.org/10.3390/jcs9060284

Chicago/Turabian StyleAl-Maharma, Ahmad Y., Bernd Markert, and Franz Bamer. 2025. "The Silylation Effect of C/SiC Nanofillers on Mechanical Properties of Cellulose Nanocomposite: Insights from Molecular Dynamics Simulations" Journal of Composites Science 9, no. 6: 284. https://doi.org/10.3390/jcs9060284

APA StyleAl-Maharma, A. Y., Markert, B., & Bamer, F. (2025). The Silylation Effect of C/SiC Nanofillers on Mechanical Properties of Cellulose Nanocomposite: Insights from Molecular Dynamics Simulations. Journal of Composites Science, 9(6), 284. https://doi.org/10.3390/jcs9060284