1. Introduction

Natural fiber-reinforced composites (NFRCs) have gained significant attention in various industries, such as automotive, building and construction, and biomedical, due to their advantageous mechanical properties, including availability, high strength-to-weight ratio, sustainability, and recyclability [

1]. NFRC materials reduce carbon emissions, support a circular economy, and provide sustainable solutions for a better environment for future generations. Since the beginning of the Industrial Revolution, numerous conventional and advanced manufacturing techniques have been developed. Among these, three-dimensional printing (3DP), also known as additive manufacturing (AM), has gained significant attention in modern manufacturing industries [

2]. However, when it comes to mechanical properties, traditionally fabricated composites or parts typically demonstrate better performance, especially in terms of mechanical strength, than those produced using 3DP [

3]. Based on the type of reinforcement material, composite materials are classified as natural fiber-reinforced composites, polymeric composites, and so on. However, based on the fabrication process, composite materials are categorized into various types, including unidirectional composites, particulate composites, woven composites, bidirectional composites, and hybrid composites [

4,

5]. In woven composites, the structures can be complex in terms of dimensions and weaving patterns. They are typically classified as plain or twill weaves. Plain weaves are structured with a 1 × 1 thread ratio, while twill weaves follow a 2 × 2 pattern in both the warp and weft directions [

6].

To calculate the mechanical properties of woven composite RVEs without conducting solid experiments, several methods have been developed, including theoretical approaches and finite element methods (FEMs). Compared to solid experiments, finite element methods and theoretical approaches are sufficient to predict the mechanical properties of composite materials [

5]. Using the finite element method, the generation of a representative volume element (RVE) is one of the most straightforward techniques for estimating mechanical properties, particularly the elastic moduli, including Young’s modulus (longitudinal and transverse), shear modulus (in-plane and out-of-plane), and Poisson’s ratio (major and minor) [

7]. In both recent and earlier studies, significant research has been conducted on the RVE of woven composites. For example, earlier investigations employed the finite element method (FEM) to generate woven composite RVEs, considering the RVE size and its effects on local and global strain. These studies highlighted the significant role of RVE size in influencing the response of both local and global strains [

8]. Apart from RVE size, several factors can significantly influence the elastic moduli of woven composites, including fiber volume fraction, yarn fiber volume fraction, fabric thickness, yarn spacing, and shear angle [

6]. Fiber volume fraction refers to the proportion of fibers used to reinforce composite materials. It plays a crucial role in determining the mechanical behavior of these composites, affecting characteristics such as ductility and brittleness after fabrication. A recent study examined the effects of fiber volume fraction on the ballistic performance of woven composite representative volume elements (RVEs). The findings indicated that higher fiber volume fractions generally resulted in better energy absorption and performance outcomes [

9]. However, this trend does not apply in all situations. For instance, the present study revealed that excessively high fiber volume fractions can make composites too stiff, leading to premature failure. This suggests that lower fiber volume fractions, ranging from 0.1 to 0.5, may be more favorable for achieving optimal performance [

10]. Similarly to fiber volume fraction, yarn fiber volume fraction can significantly affect the elastic moduli of materials. The key distinction between the two is that the yarn fiber volume fraction refers specifically to the proportion of fiber contained within the yarn, whereas the fiber volume fraction encompasses the total fiber amount throughout the entire woven composite [

11]. Although the yarn fiber volume fraction typically ranges from 0.45 to 0.65, optimal outcomes are generally achieved at higher fractions [

12]. Yarn spacing is also a crucial factor to consider in woven composites, as it can significantly impact the elastic moduli. Yarn spacing refers to the distance between two yarns in the representative volume element (RVE) of woven composites. A recent study comparing different yarn spacings in woven composite RVEs found that the elastic moduli decreased as yarn spacing increased from 1 mm to 3 mm. However, this trend does not hold for every increment. Specifically, while the elastic moduli decreased when yarn spacing increased from 1 mm to 2.5 mm, there was a noticeable increase in elastic moduli at a spacing of 3 mm [

13]. In woven composites, whether they are plain or have more complex structures, the shear angle plays a crucial role in influencing the elastic moduli. The shear angle reflects the angle formed between the two yarns—warp and weft—during the manufacturing process of the woven composites [

13,

14]. This angle can range from −45 degrees to 45 degrees. However, optimal elastic moduli in woven composites RVE are typically achieved within the lower angle range [

11,

13,

14]. The fabric thickness in the RVE refers to the thickness of the woven composites, which can also have a significant influence on their properties [

6]. However, this parameter has not been extensively discussed in recent studies.

Apart from the aforementioned numerical analyses, several recent and earlier studies have developed theoretical methods, which were later compared with numerical and experimental results to predict the elastic properties [

15,

16,

17,

18,

19]. This earlier study most likely first predicted the elastic modulus of E-glass woven composites by designing a new analytical model, which was later compared with Hashin’s concentric cylinder and Halpin–Tsai models. Both models accurately predicted all outcomes without any significant discrepancies [

15]. Later, the Mori–Tanaka model and the finite element method were employed, and experimental outcomes were compared in this research. This investigation also revealed that the finite element method, the theoretical method, and experiments can be rigorous tools to predict the outcomes in the RVEs of woven composites [

16]. Similarly to the aforementioned studies, some newly developed theoretical models, namely the stochastic fracture model [

17], data-driven reduced-order models [

18], and the continuum model [

19], have been developed in recent years, which have also been validated against the numerical and experimental outcomes in woven composites RVE.

Numerous recent studies have employed various statistical methods to optimize material properties or identify the best combinations of influencing factors. These methods are beneficial because they allow for the design of experiments based on input parameters while simultaneously considering multiple variables and outcomes within a unified framework. Furthermore, they enable the prediction of optimal results by comparing the effects of the selected parameters [

5,

20,

21,

22]. To enhance the outcomes of RVE simulations, a recent study incorporated artificial intelligence-based statistical analysis on random RVEs by employing geometric descriptors and statistical functions [

23]. Similarly, an earlier study adopted a statistical approach by considering the density of the RVE as a key variable to improve prediction efficiency [

24]. One of the main advantages of using statistical analysis to predict the elastic moduli of an RVE is its ability to generate multiple variables, which can be optimized to enhance predictive accuracy. For instance, previous research explored different RVE sizes and achieved precise estimations of thermal and mechanical properties by applying the integral range approach [

25]. However, a key limitation remains in establishing robust correlations among RVE variables, and accurately estimating optimal parameters in the optimization process continues to pose challenges, particularly in the context of woven composites.

It is undoubtedly true that, in recent years, significant research has focused on the development of woven composites by investigating their elastic moduli through numerical and theoretical methods, particularly finite element analysis, often using various types of polymer fibers. Although these studies have provided valuable insights, they have primarily focused on parametric analyses without incorporating a comprehensive statistical approach. This represents a notable gap in the existing body of research. To address this limitation, the present study examines the effects of three key parameters—yarn spacing, shear angle, and fabric thickness—on the mechanical behavior of woven composites. These parameters are analyzed while maintaining other influential factors, such as fiber volume fraction and yarn fiber volume fraction, at constant levels. By employing a statistical framework, this study aims to offer a more holistic understanding of how these parameters interact and contribute to the overall performance of woven composites (plain and twill structures), which are numerically embedded by jute fiber and epoxy matrix.

2. Finite Element Modeling Setup, Material Properties, and Design of Experiment

All numerical investigations were conducted using ANSYS version 19 FEM software, specifically within the Material Designer tool. First, the material properties of both the fiber and the matrix were defined and added to the material library. These properties were then assigned to the Material Designer to initiate the simulation setup. The fiber volume fraction and yarn fiber volume fraction were kept constant at 0.325 and 0.65, respectively, based on values reported in the literature. Other parameters—yarn spacing, shear angle, and fabric thickness—were varied and defined within the Material Designer interface. The weave structure was also specified at this stage. Following the geometry definition, the repeat count and algorithm were selected. The lenticular algorithm was chosen for this investigation as it produces more accurate and reliable results for woven composite modeling.

Mesh generation in finite element method (FEM) analysis, particularly for representative volume elements (RVEs), is a complex and critical task. Different FEM approaches employ various mesh generation techniques. For instance, in one study, a high-resolution mesh was generated in ABAQUS to achieve more accurate results for the RVE [

26]. Considering this complexity, the present research utilized conformal and periodic meshing for all RVEs using the Material Designer tool. Although Material Designer also provides a block meshing option, periodic meshing offers a more refined structure and facilitates property estimation with fewer complications. Moreover, a significant limitation of block meshing is that the Material Designer is unable to properly mesh all the edges of the RVE using this technique. For these reasons, periodic and conformal meshing techniques were adopted in all RVE simulations. The mesh size is set to 0.2 mm, and it was observed that varying the mesh size does not significantly impact the outcomes, especially in the microscale virtual domain. In addition, the cell type is triangular by default. Subsequently, boundary conditions, which are provided by default in Material Designer, were applied. Finally, simulations were run with the constant material output option selected to compute the effective material properties.

Figure 1a illustrates the shear angle to provide insights into the deformation characteristics of woven jute composite RVEs.

Figure 1b presents the multiscale approach of the composites, describing the transition from the microscale to the actual plain weave structure. In

Figure 1c, yarn spacing is shown in a plain-weave-structure RVE with a spacing of 1.5 mm; here, the repeat count is set to 2 for improved visualization.

Figure 1d displays the woven jute composites’ twill-weave RVE structure.

Figure 1e,f provide a microscale representation of the twill composite captured through scanning electron microscopy. Following this, the difference in fabric thickness in NFRC-woven composites is depicted in

Figure 1g,h, showing real structural variations. However, in

Figure 1i, a meshed twill RVE was presented, subjected to both conformal and block meshing. Finally, the material properties of the jute fiber and epoxy matrix are listed in

Table 1. The material properties are taken as isotropic from the literature [

5].

The design of the experiments (DOEs) is conducted using Design Expert software version 13. After defining the input variables in the software, the response surface methodology has been selected. Later, the chosen design type was a central composite with a quadratic model. The runs mean the number of experiments is determined as 30 by selecting no blocks. The design of the experiment is given in

Table 2.

Although periodic boundary conditions are a default feature in ANSYS Material Designer, they are explicitly presented and discussed in this research [

13]. These boundary conditions are primarily applied along the three principal directions or planes of the woven composites: a, b, and c, and discussed in Equations (1)–(7).

The boundary conditions used to predict the longitudinal elastic moduli of woven composites are as follows:

Similarly, in the c plane, the boundary conditions are as follows:

For the in-plane and out-of-plane shear moduli (G

12, G

23, and G

13), the periodic boundary conditions are provided below.

However, for both major and minor Poisson’s ratios, the following equations are used:

6. Future Research Scope

This study aims to investigate the elastic moduli of natural fiber-reinforced jute composites using statistical and numerical methods, considering key manufacturing parameters such as shear angle, fabric thickness, and yarn spacing. The authors also recognize several promising directions for future research, particularly relevant to microscale investigations. The potential areas for future research are outlined below:

This research only investigated the plain- and twill-type-woven composite RVE using the ANSYS-19 material designer. Future research could involve solid experimentations and compare them with numerical and theoretical approaches to improve the elastic properties of woven or braided composites embedded in natural fibers.

This investigation analyzed only the interactions between the considered variables and responses. However, the interfacial bonding between fibers and the matrix could be further explored by examining different volume fractions through solid experimentations.

Environmental factors, such as humidity, temperature, and moisture, can significantly affect the mechanical performance of jute composites. Although this study focused on the mechanical properties of jute-woven composites, future research could explore the impact of these environmental factors through real experiments.

The study only considered two regular types of woven composite, namely plain and twill. However, a future comparative analysis can be generated numerically and experimentally with other types of woven structures, namely satin, multiaxial, hybrid, and so on, which would be embedded with natural fibers.

7. Conclusions

Natural fiber-reinforced composite materials have attracted significant attention in both the contemporary composite industry and academic research due to their potential to promote sustainability, renewability, and a reduced carbon footprint, along with offering low fabrication costs. Accordingly, plain- and twill-woven jute composites represent promising alternatives to conventional synthetic or polymeric composites, particularly for real-life applications where environmental sustainability is a primary concern. In this study, a series of numerical simulations were conducted to optimize key processing parameters and achieve the most favorable performance outcomes. These optimized parameters provide valuable insights for future researchers and manufacturers, helping to elucidate the significance and effects of the variables considered and guiding their application during the fabrication process. The main findings of the study are summarized below:

ANSYS Material Designer effectively predicted the elastic moduli of both plain- and twill-woven jute composites RVEs without complications and with minimal computational time. Therefore, this robust tool can be reliably used to determine key parameters for jute woven composites RVEs prior to the manufacturing process.

The plain-woven jute composite yielded superior outcomes across all DOE cases compared to the twill-woven composite. Interestingly, the highest and lowest outcomes for both composites were observed within the same DOE cases, indicating strong correlations among the considered responses. Despite their structural differences, both composites exhibited their maximum and minimum values in DOE-1 and DOE-10, respectively.

ANOVA for the plain-woven composite, yarn spacing, and fabric thickness was found to significantly influence the elastic moduli, while the shear angle showed minimal impact. Conversely, in the twill-woven composite, all three parameters—shear angle, yarn spacing, and fabric thickness—played critical roles in affecting the elastic properties.

Based on the percentage contribution (PC%) analysis of the variables to the responses, it was observed that, in the plain-woven jute composite, the considered variables contributed approximately 0–24% to the overall responses. In contrast, the twill-woven jute composite exhibited significantly higher contributions, ranging from 0 to 53%.

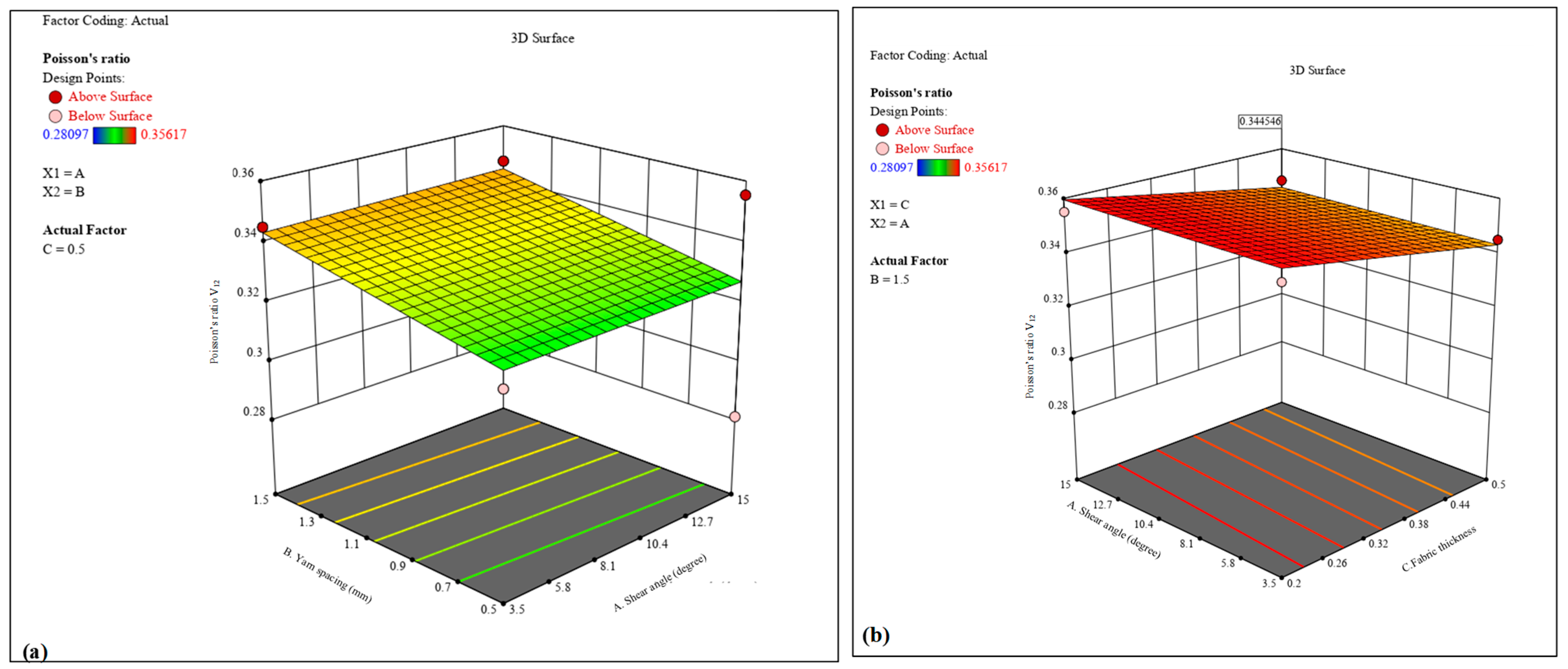

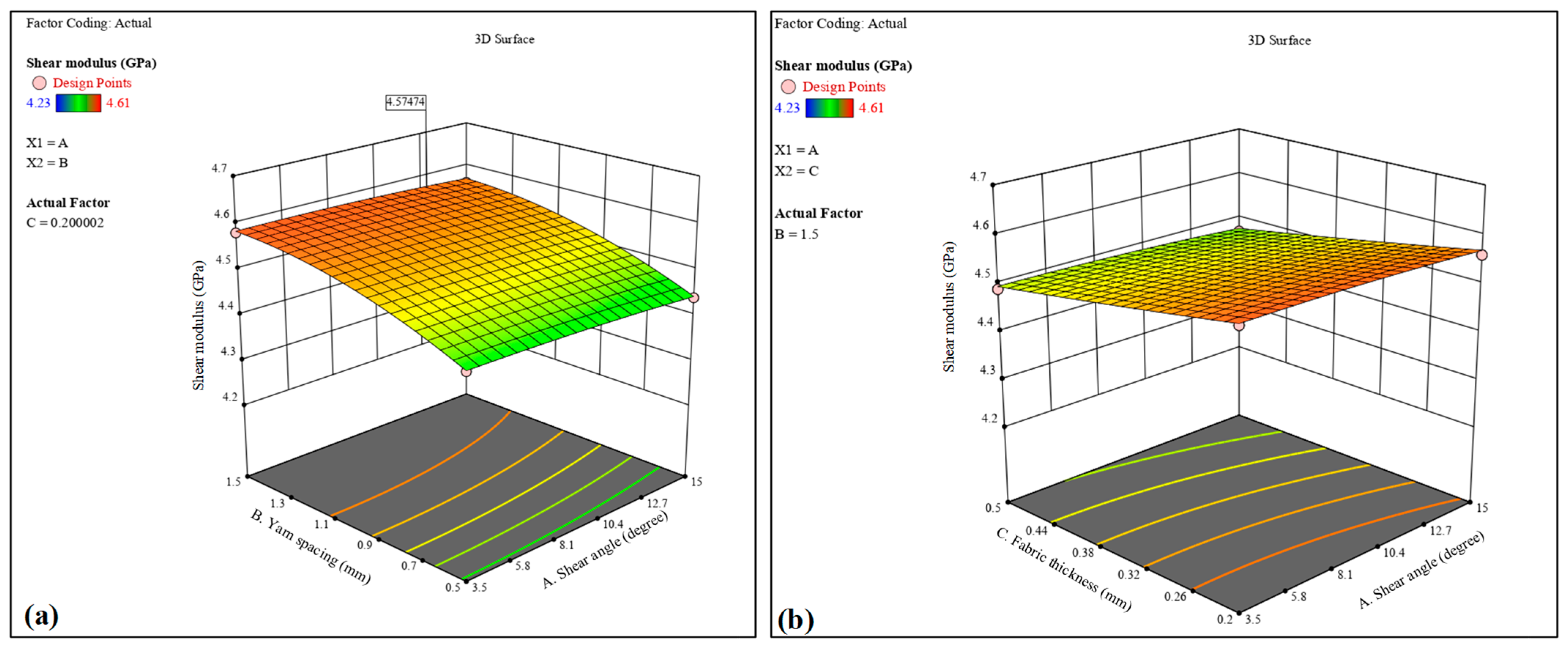

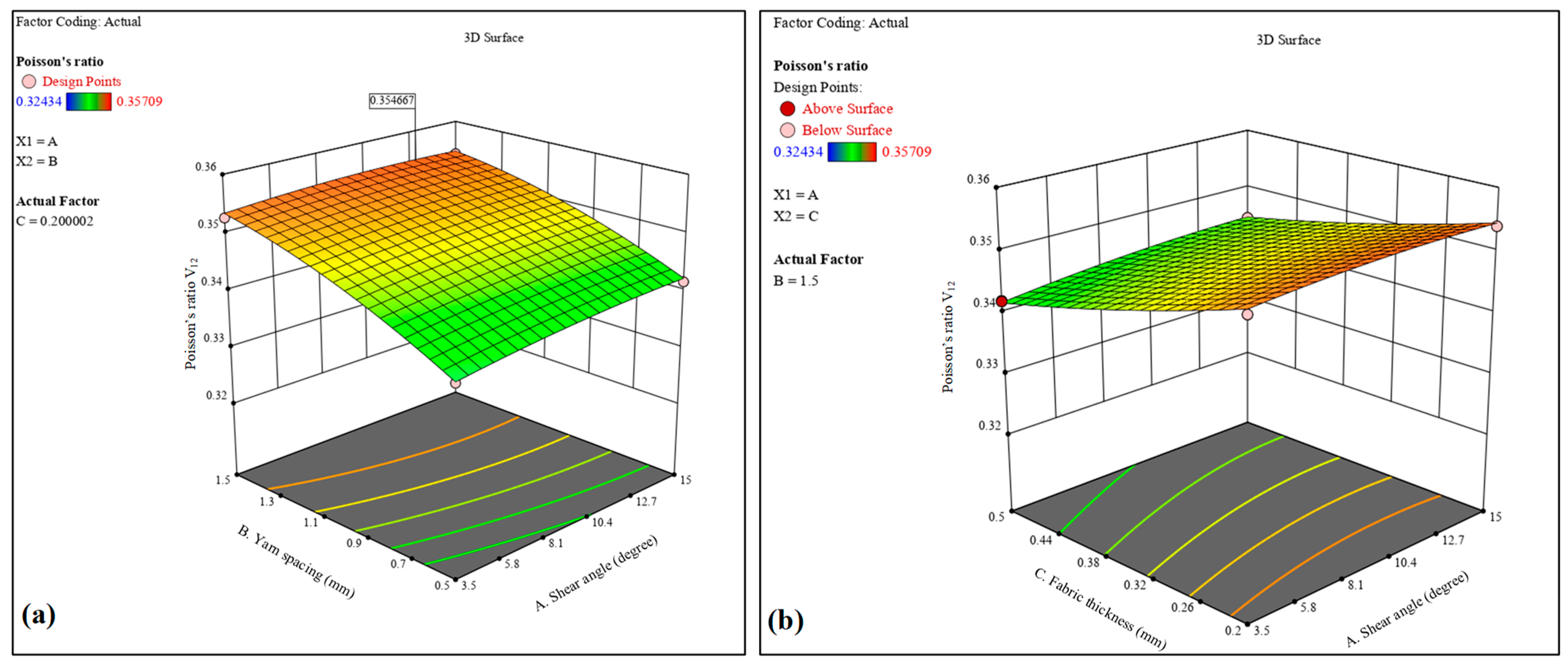

The 3D contour analysis further supports the ANOVA results by illustrating the relationships between each response and the corresponding variables. Consistent and logical trends were validated through this analysis. Overall, it was observed that yarn spacing and fabric thickness exhibit significant surface interactions with all elastic moduli in both plain- and twill-woven composites. In contrast, the shear angle demonstrated negligible interaction effects across all responses.

The optimized outcomes for both plain- and twill-woven jute composites were obtained at a shear angle of 9.25 degrees, yarn spacing of 1.0 mm, and fabric thickness of 0.35 mm. For the plain-woven composite, the optimized properties were E11—11.10 GPa, G12—4.4 GPa, and V12—0.34. In the case of the twill-woven composite, the optimized results were E11—11.54 GPa, G12—4.47 GPa, and V12—0.34. The differences between the software predictions and numerical confirmations were minimal in both cases, indicating the high accuracy of the prediction method.