Rheological and Mechanical Properties of Self-Compacting Geopolymer Concrete Reinforced with Short Basalt Fibres

Abstract

1. Introduction

2. Experimental Investigation

2.1. Selection of Materials

- Fly ash;

- Micro fly ash;

- Slag;

- Fine aggregate (FA);

- Coarse aggregate (CA);

- Alkali activator (sodium metasilicate);

- Water.

2.2. Mix Preparation

3. Results and Discussion

3.1. Rheological Properties

3.1.1. Slump Flow Test

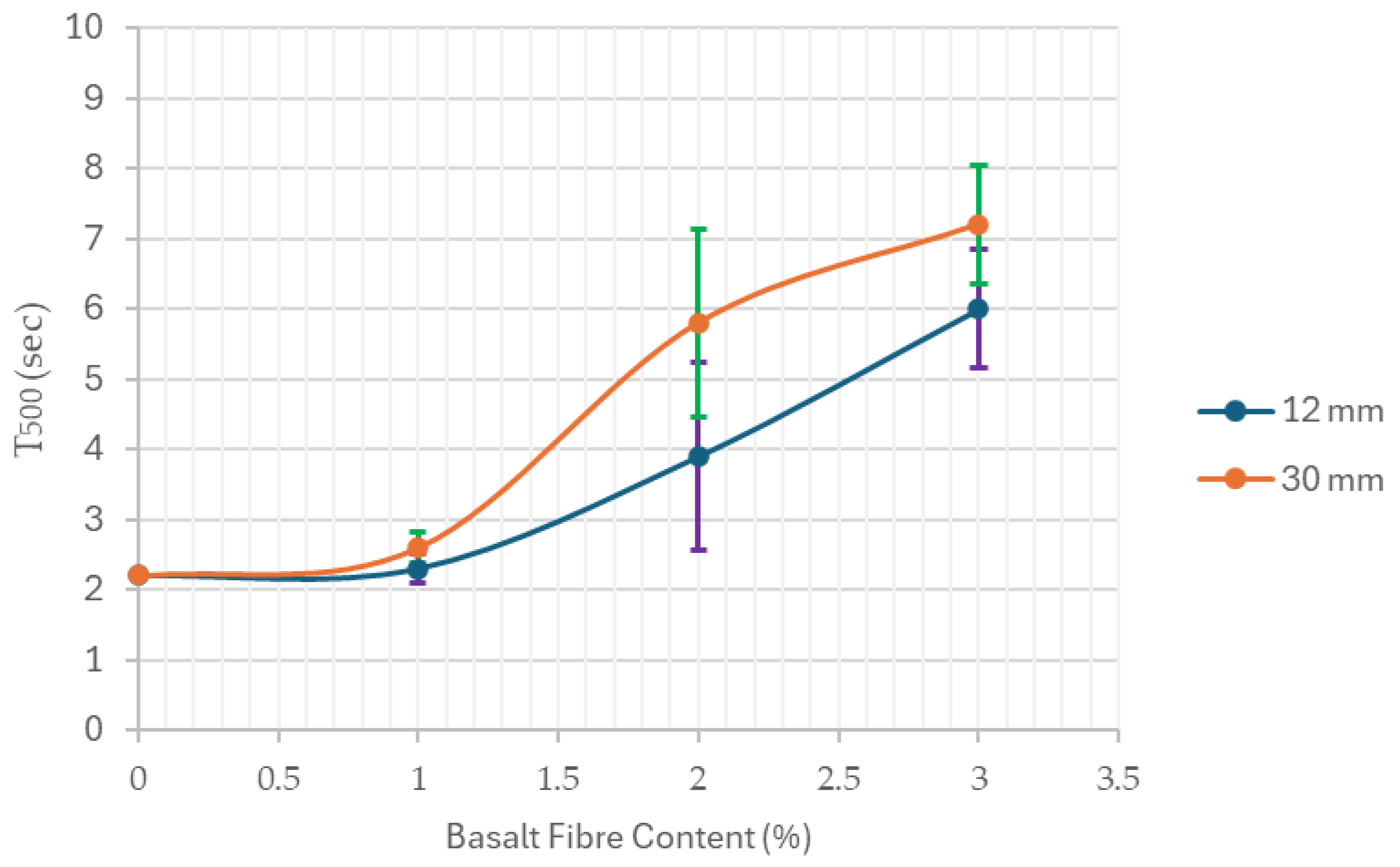

3.1.2. T500 Test

3.1.3. J-Ring Test

3.2. Mechanical Properties

3.2.1. Compressive Strength

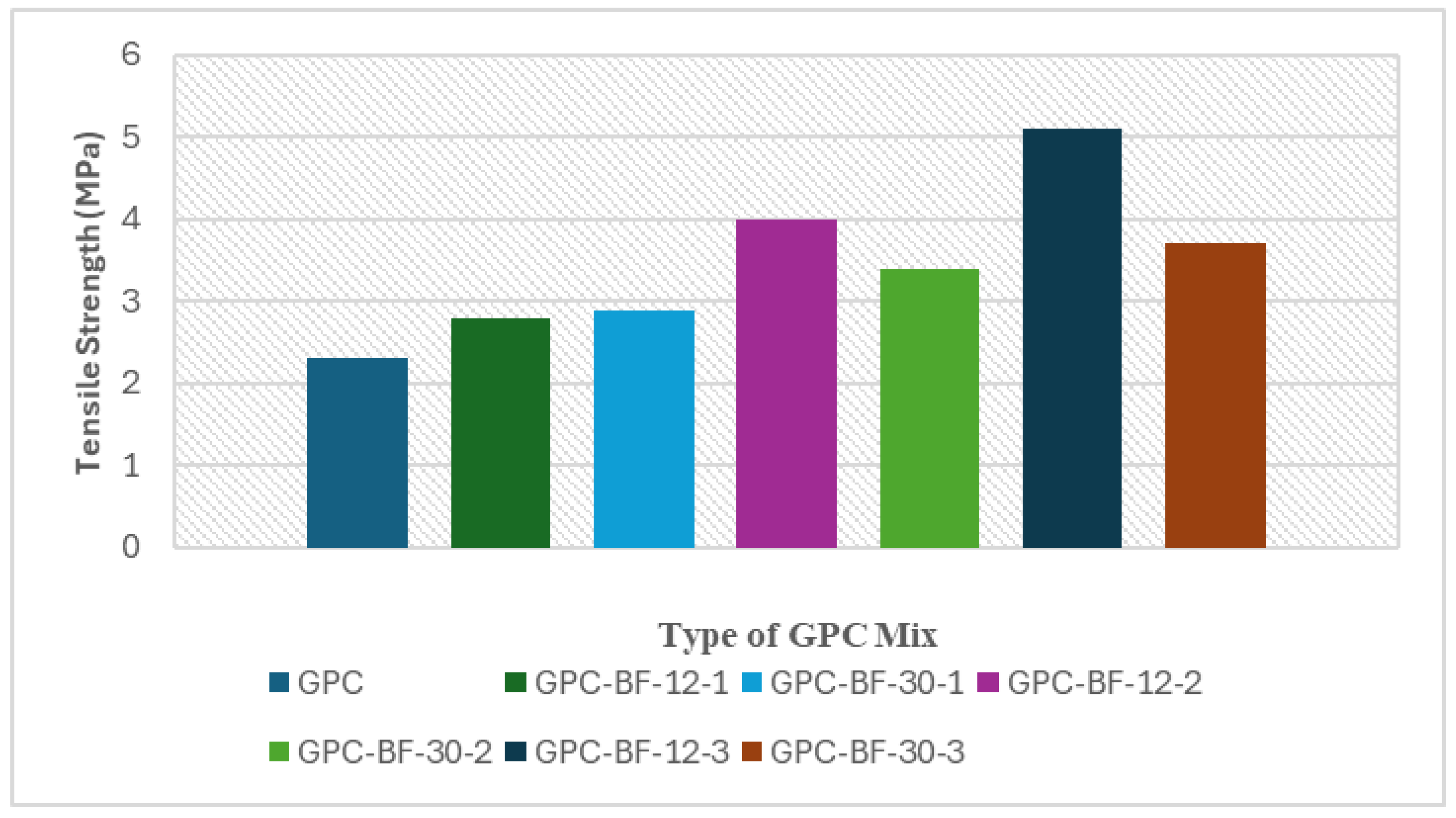

3.2.2. Split Tensile Strength

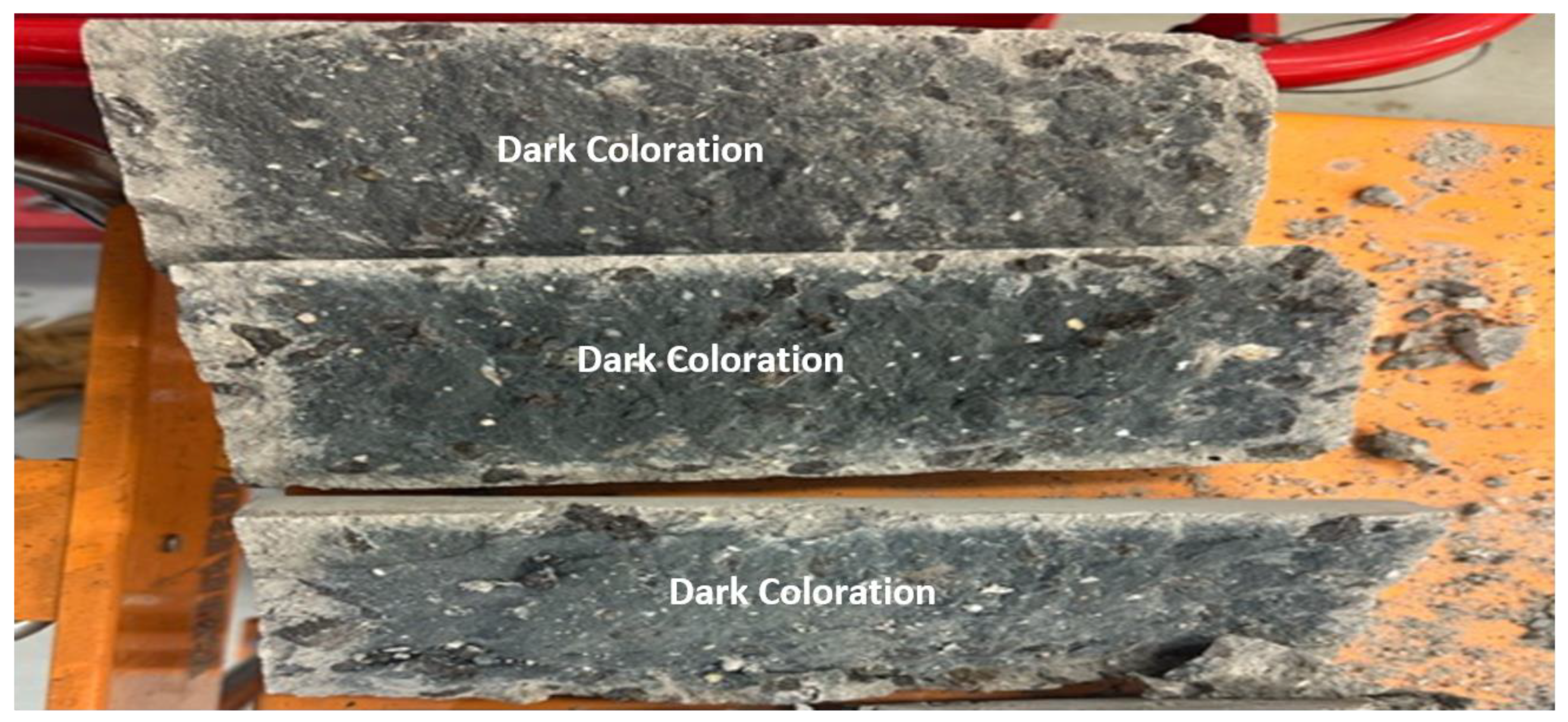

4. Results and Discussion: Optical Microscopic Analysis

5. Tensile Strength Prediction Using Analytical Method

6. Conclusions

- A self-compacting geopolymer concrete (GPC) mix incorporating basalt fibres was successfully developed to meet self-compacting standards.

- The workability of the fibre-reinforced GPC mixes decreased with an increase in the basalt fibre content. Using a higher amount of fibre was found to have detrimental effects on the T500 results of the GPC-BF mixes. Concrete with the selected fibre lengths and fibre contents met the slump flow and J-ring requirements.

- The compressive strength for the 12 mm length basalt fibre-incorporated GPC mixes showed an insignificant initial drop in compressive strength. However, a significant increase in compressive strength was found for the GPC-BF mix with a higher content (up to 3%) compared to the control specimen.

- On the other hand, the compressive strength of the 30 mm fibre-incorporated geopolymer concretes decreased with increasing basalt fibre content. The highest reduction in compressive strength was found to be around 28% for the GPC-BF mix with a 3% fibre content compared to the control GPC mix. The short fibres (12 mm) were more effective compared to the long fibres (30 mm) in terms of increasing the compressive strength.

- The changes in compressive strength between 28 days and 56 days of curing time were insignificant for all the GPC-BF mixes.

- The enhancement in tensile strength was more significant for the GPC-BF-12 mixes (12 mm fibres) than the GPC-BF-30 mixes (30 mm fibres). The short (12 mm) basalt fibre-incorporated GPC showed a significant increase in tensile strength of around 26%, 74%, and 121% for fibre contents of 1%, 2%, and 3%, respectively, compared to the control GPC.

- The microscopic images of the GPC-BF specimens showed cracking around the basalt fibres in all the specimens. Microcracks radiating from the boundary of the basalt fibres indicated a weak bond strength between the geopolymer binder and the basalt fibres. For both selected lengths of basalt fibres, a higher fibre content led to fibre clustering, causing localised stress concentrations and a reduced compressive strength.

- The microscopic images also showed the presence of more voids in the geopolymer concrete mix as the basalt fibre content increased. The presence of these voids might have been caused by excess water at the surface of the basalt fibres, which could not react with the binder and, in turn, evaporated, leaving behind voids. Thus, the compressive strength decreased with increasing basalt fibre content.

- Considering the workability and mechanical properties, the optimal fibre content for self-compacting geopolymer concrete was 1% for the 30 mm length basalt fibres. In contrast, up to 3% can be recommended for the 12 mm long basalt fibres. These mixes provided balanced performance, maintaining good workability characteristics and a satisfactory mechanical strength.

- The proposed analytical method was found to be able to predict the tensile strength of the basalt fibre-reinforced geopolymer concrete specimens.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Timakul, P.; Rattanaprasit, W.; Aungkavattana, P. Improving compressive strength of fly ash-based geopolymer composites by basalt fibre addition. Ceram. Int. 2016, 42, 6288–6295. [Google Scholar] [CrossRef]

- Rahman, S.K.; Al-Ameri, R. A newly developed self-compacting geopolymer concrete under ambient conditions. Constr. Build. Mater. 2021, 267, 121822. [Google Scholar] [CrossRef]

- Lee, N.K.; Jang, J.G.; Lee, H. Shrinkage characteristics of alkali-activated fly ash/slag paste and mortar at early ages. Cem. Concr. Compos. 2014, 53, 239–248. [Google Scholar] [CrossRef]

- Heweidak, M.; Kafle, B.; Al-Ameri, R. Influence of Hybrid Basalt Fibres’ Length on Fresh and Mechanical Properties of Self-Compacted Ambient-Cured Geopolymer Concrete. J. Compos. Sci. 2022, 6, 292. [Google Scholar] [CrossRef]

- McDonald, L. Toward Market Acceptance: Understanding Wear Characteristics of Basalt Fibre Reinforced Polymers. The American Ceramic Society. 12 March 2021. Available online: https://ceramics.org/ceramic-tech-today/understanding-wear-characteristics-of-basalt-fiber-reinforced-polymers/ (accessed on 4 May 2025).

- Arivalagan, S. Study on the compressive and split tensile strength properties of basalt fibre concrete members. Glob. J. Res. Civ. Struct. Eng. 2012, 12, 23–28. [Google Scholar]

- Cao, H.; Lang, H.; Meng, S. Experimental research on the basic structure and properties of the continuous basalt fibre. Hi-Tech Fibre Appl. 2007, 32, 1–8. [Google Scholar]

- Zhou, H.; Jia, B.; Huang, H.; Mou, Y. Experimental study on basic mechanical properties of basalt fibre reinforced concrete. Materials 2020, 13, 1362. [Google Scholar] [CrossRef]

- Lee, J.; Song, J.; Kim, H. Chemical stability of basalt fibre in alkaline solution. Fibres Polym. 2014, 15, 2329–2334. [Google Scholar] [CrossRef]

- Jalasutram, S.; Sahoo, D.; Matsagar, V. Experimental investigation of the mechanical properties of basalt fibre-reinforced concrete. Struct. Concr. 2017, 18, 292–302. [Google Scholar] [CrossRef]

- Jiang, C.; Fan, K.; Wu, F.; Chen, D. Experimental study on the mechanical properties and microstructure of chopped basalt fibre reinforced concrete. Mater. Des. 2014, 58, 187–193. [Google Scholar] [CrossRef]

- Kizilkanat, A.; Kabay, N.; Akyüncü, V.; Chowdhury, S.; Akça, A. Mechanical properties and fracture behaviour of basalt and glass fibre reinforced concrete: An experimental study. Constr. Build. Mater. 2015, 100, 218–224. [Google Scholar] [CrossRef]

- Bheel, N. Basalt fibre-reinforced concrete: Review of fresh and mechanical properties. J. Build. Pathol. Rehabil. 2021, 6, 12. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Ali, M. Effect of basalt fibres on mechanical properties of calcium carbonate whisker-steel fibre reinforced concrete. Constr. Build. Mater. 2018, 192, 742–753. [Google Scholar] [CrossRef]

- Zeng, Y.; Tan, A. Comparison of effects of basalt and polyacrylonitrile fibres on toughness behaviours of lightweight aggregate concrete. Constr. Build. Mater. 2021, 282, 122572. [Google Scholar] [CrossRef]

- Yan, P.; Chen, B.; Afga, S.; Haque, M.; Wu, M.; Han, J. Experimental research on ductility enhancement of ultra-high performance concrete incorporation with basalt fibre, polypropylene fibre and glass fibre. Constr. Build. Mater. 2021, 279, 122489. [Google Scholar] [CrossRef]

- Ayub, T.; Shafiq, N.; Nuruddin, M. Effect of chopped basalt fibres on the mechanical properties and microstructure of high-performance fibre reinforced concrete. Adv. Mater. Sci. Eng. 2014, 2014, 587686. [Google Scholar] [CrossRef]

- Annadurai, S.; Baskar, P.; Elango, K. Geopolymer concrete reinforced with basalt fibres: An experimental investigation. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Pham, T. Enhanced properties of high-silica rice husk ash-based geopolymer paste by incorporating basalt fibres. Constr. Build. Mater. 2020, 245, 118422. [Google Scholar]

- Amuthakkannan, P.; Manikandan, V.; Jappes, J.; Uthayakumar, M. Effect of fibre length and fibre content on mechanical properties of short basalt fibre reinforced polymer matrix composites. Mater. Phys. Mech. 2013, 16, 107–117. [Google Scholar]

- Ali, N.; Canpolat, O.; Aygörmez, Y.; Al-Mashhadani, M. Evaluation of the 12–24 mm basalt fibers and boron waste on reinforced metakaolin-based geopolymer. Constr. Buil. Mat. 2020, 251, 118976. [Google Scholar] [CrossRef]

- Ma, J.; Qiu, X.; Cheng, L.; Wang, Y. Experimental research on the fundamental mechanical properties of presoaked basalt fibre concrete. In Proceedings of the Advances in FRP Composites in Civil Engineering: Proceedings of the 5th International Conference on FRP Composites in Civil Engineering (CICE 2010), Beijing, China, 27–29 September 2010; Springer: Berlin/Heidelberg, Germany, 2010; pp. 85–88. [Google Scholar]

- AS1012.2:2014; Methods of Testing Concrete—Preparing Concrete Mixes in the Laboratory. Standards Australia: Sydney, Australia, 2014.

- AS1012.8.1:2014; Methods of Testing Concrete—Compressive Strength Tests—Concrete, Mortar, and Grout Specimens. Standards Australia: Sydney, Australia, 2014.

- AS3600:2018; Concrete Structures. Standards Australia: Sydney, Australia, 2018.

- EFNARC. Guidelines for Self-Compacting Concrete; Association House: London, UK, 2002; pp. 32–34. [Google Scholar]

- AS1012.3.5; Methods of Testing Concrete—Determination of Properties Related to the Consistency of Concrete—Slump Flow, T500 and J-Ring Test. Standards Australia: Sydney, Australia, 2015.

- Borhan, T. Thermal and mechanical properties of basalt fibre reinforced concrete. Proc. World Acad. Sci. Eng. Technol. 2013, 76, 313. [Google Scholar]

- Islam, G.; Akter, S.; Reza, T. Sustainable high-performance, self-compacting concrete using ladle slag. Clean. Eng. Technol. 2022, 7, 100439. [Google Scholar] [CrossRef]

- Al-Rousan, E.; Khalid, H.; Rahman, M. Fresh, mechanical, and durability properties of basalt fibre-reinforced concrete (BFRC): A review. Dev. Built Environ. 2023, 14, 100155. [Google Scholar] [CrossRef]

- Vedhasakthi, K.; Chithra, R. Strength attributes and microstructural characterisation of basalt fibre incorporated self-compacting concrete. J. Build. Eng. 2023, 78, 107592. [Google Scholar] [CrossRef]

- Dias, D.; Thaumaturg, C. Fracture toughness of geopolymer concrete reinforced with basalt fibres. Cem. Concr. Compos. 2005, 27, 49–54. [Google Scholar] [CrossRef]

- Sivanantham, P.A.; Prabhu, G.G.; Vimal Arokiaraj, G.G.; Sunil, K. Effect of Fibre Aspect-Ratio on the Fresh and Strength Properties of Steel Fibre Reinforced Self-Compacting Concrete. Adv. Mater. Sci. Eng. 2022, 2022, 1207273. [Google Scholar] [CrossRef]

- Ahmad, J.; Yu, T.; Hadi, M. Basalt Fibre-Reinforced Polymer-Confined Geopolymer Concrete. ACI Struct. J. 2021, 118, 289–300. [Google Scholar]

- Revade, A. Compressive and split tensile strength of chopped basalt fibre concrete. Int. Res. J. Eng. Technol. 2017, 4, 347–351. [Google Scholar]

- Wang, Y.; Hu, S.; He, Z. Mechanical and fracture properties of geopolymer concrete with basalt fibre using digital image correlation. Theor. Appl. Fract. Mech. 2021, 112, 102909. [Google Scholar] [CrossRef]

- Shaikh, F.; Haque, S. The behaviour of carbon and basalt fibres reinforced fly ash geopolymer at elevated temperatures. Int. J. Concr. Struct. Mater. 2018, 12, 35. [Google Scholar] [CrossRef]

- Fang, S.; Hong, H.; Zhang, P. Mechanical property tests and strength formulas of basalt fiber reinforced recycled aggregate concrete. Materials 2018, 11, 1851. [Google Scholar] [CrossRef]

- ACI 318-11: Building Code Requirements for Structural Concrete and Commentary; American Concrete Institute (ACI): Farmington Hills, MI, USA, 2011; ISBN 9780870317446.

| Material | Control (GPC) | GPC-BF12-1/GPC-BF30-1 | GPC-BF12-2/GPC-BF30-2 | GPC-BF12-3/GPC-BF30-3 | % in Total Mix |

|---|---|---|---|---|---|

| Fly Ash (kg) | 8.14 | 8.14 | 8.14 | 8.14 | 16 |

| Micro Fly Ash (kg) | 2.04 | 2.04 | 2.04 | 2.04 | 4 |

| Slag (kg) | 6.1 | 6.1 | 6.1 | 6.1 | 12 |

| Sodium Metasilicate (kg) | 1.6 | 1.6 | 1.6 | 1.6 | 32 |

| CA (kg) | 11.5 | 11.5 | 11.5 | 11.5 | 22 |

| FA (kg) | 12.9 | 12.9 | 12.9 | 12.9 | 25 |

| Water (kg) | 8.1 | 8.1 | 8.1 | 8.1 | 16 |

| BFs (kg) | 0 | - | - | - | 0 |

| BFs (kg) | - | 0.5 | - | - | 1 |

| BFs (kg) | - | - | 1 | - | 2 |

| BFs (kg) | - | - | - | 1.5 | 3 |

| Designation | Length (mm) | Diameter (µm) | Density (g/cm3) | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|---|---|

| BF 12 | 12 | 13 | 2.6–2.8 | 1000 | 2.4–3.15 |

| BF 30 | 30 | 13 | 2.6–2.8 | 1000 | 2.4–3.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, S.; Khanna, P.; Stewart, J.; Kafle, B.; Al-Ameri, R. Rheological and Mechanical Properties of Self-Compacting Geopolymer Concrete Reinforced with Short Basalt Fibres. J. Compos. Sci. 2025, 9, 264. https://doi.org/10.3390/jcs9060264

Ali S, Khanna P, Stewart J, Kafle B, Al-Ameri R. Rheological and Mechanical Properties of Self-Compacting Geopolymer Concrete Reinforced with Short Basalt Fibres. Journal of Composites Science. 2025; 9(6):264. https://doi.org/10.3390/jcs9060264

Chicago/Turabian StyleAli, Saima, Pulkit Khanna, James Stewart, Bidur Kafle, and Riyadh Al-Ameri. 2025. "Rheological and Mechanical Properties of Self-Compacting Geopolymer Concrete Reinforced with Short Basalt Fibres" Journal of Composites Science 9, no. 6: 264. https://doi.org/10.3390/jcs9060264

APA StyleAli, S., Khanna, P., Stewart, J., Kafle, B., & Al-Ameri, R. (2025). Rheological and Mechanical Properties of Self-Compacting Geopolymer Concrete Reinforced with Short Basalt Fibres. Journal of Composites Science, 9(6), 264. https://doi.org/10.3390/jcs9060264