Abstract

As the volume of polymer waste continues to grow, the development of methods for their processing and the creation of composites is an urgent task. In this work, the characteristics of sand–polymer composites based on reclaimed thermoplastics (1:3 mixture of polyolefins) are investigated. It was found that composites containing up to 75 wt% silica sand (100–300 μm) retained acceptable compressive strength (at least 25 MPa) at a strain of no more than 5%. Sand surface treatment improved the interaction between polymer and filler, increasing compressive strength by 10–15% and impact strength by 10% at 70–75 wt% of filler. The deformation and strength parameters of composites modified with carbon nanocomponents were investigated. The dependencies of compressive and bending strength on technological parameters of formation were obtained. The role of modifying components in appretization and reinforcement was shown. The introduction of technological lubricants improved homogeneity but reduced strength. The strengthening effect was related to the increase in the proportion of polymer interacting with the filler surface when the thickness of the polymer matrix reached the nanostate. The introduction of silica nanoparticles (up to 0.1 wt%) increased the compressive strength by 15%. However, the decrease in melt fluidity limited the degree of filling. The obtained composites are promising for application as structural materials in hull products used in limited climatic conditions.

1. Introduction

Currently, the development of composite materials on the basis of thermoplastic binders takes into account the required level of technical and economic characteristics and the operating conditions of products based on them: the nature and magnitude of the applied load, the presence of aggressive factors of the working environment, tribocontacting, electrical and thermal conductive characteristics of the material and so on [1,2,3,4,5]. Numerous scientific works are devoted to the study of properties of polymer composites with various fillers. Researchers have investigated the influence of the filler particle size on the strength characteristics of composites [6,7,8]. Other works have studied the effect of filler surface modification on adhesion to the polymer matrix [9,10,11]. These and other studies have made a significant contribution to the understanding of the behavior of filled polymer systems.

The developed compositions of polymer composite materials on a thermoplastic or thermosetting base containing sandy-clay dispersed components in amounts up to 95 wt% are widely and successfully used in foundry production when creating casting molds [12,13,14,15]. Sand–polymer composites are also used in the production of building structures for the finishing of buildings and structures, and the production of various small architectural forms [16,17,18]. The specified composites compositions are characterized by low requirements to the purity of the applied polymer components and fillers, the dimensional accuracy and surface roughness of the obtained products, and the ability to be subjected to machining by cutting to achieve the required quality of working surfaces [12,19,20]. At the same time, the level of deformation and strength parameters of the formed highly filled polymer composites is determined by the fractional composition of the applied fillers [21,22].

It should be noted that the chemical composition of the filler, its particle shape and its physical characteristics, determined by its origin, have a significant influence on the level of mechanical parameters of the obtained products [23,24]. It should be noted that the fractional composition, the shape of single particles and the surface activity of the filler have a determining influence on the mechanical properties of the obtained sand–polymer composites (SPCs) [25]. Particles of quartz-containing filler with a fraction size within 10–500 μm [26], with its limiting content in the composite up to 90–92 wt%, have the highest efficiency of polymer matrix structure formation. At the same time, the maximum strengthening effects (up to 30%) in tension and compression are demonstrated by composites based on polyolefins with quartz-containing filler, with filler particle size within 10–50 μm and a content up to 25 wt%. In [27], it is shown that the introduction of a compatibilizer—copolymer of polypropylene with maleic anhydride—into the composition of a sand–polymer composite on the basis of polypropylene provides an increase in the compatibility of the components of the polypropylene–quartz composite system, and the use of technological lubricants and plasticizers improves the ability of the composite for thermoforming by increasing the fluidity of the melt. At the same time, an increase in the content of functional additives allows the quartz content to be increased without loss of processability of the composition processing; however, along with this, there is a proportional decrease in the strength parameters of the composite [28].

The strengthening of polymeric thermoplastic materials is achieved by the introduction of active or activated nanocomponents into the binder, which ensure the formation of supramolecular ordering due to the interaction of active centers of polymer macromolecules with nanoparticles exhibiting a charge mosaic [29,30].

It should also be noted that a decrease in the share of thermoplastic binder in the composition of SPCs causes technological difficulties in processing and accelerates the processes of the thermomechanical degradation of the polymers [31]. To reduce the intensity of polymer matrix degradation and the subsequent loss of strength during the processing of composites into products, antioxidants that contribute to the inhibition of thermo-oxidative reactions are introduced into their composition [32].

However, despite the achieved successes, there are still a number of unresolved issues related to the optimization of compositions and technologies for obtaining highly filled SPCs based on regenerated thermoplastics. In particular, it is necessary to investigate the influence of filler content, filler surface modification and the introduction of nanomodifiers on the deformation and strength characteristics of composites.

Thus, the purpose of this work was to determine the influence of the content of the components of SPCs on the deformation and strength characteristics of composites obtained by the thermomechanical combination of binder, filler and modifiers.

2. Materials and Methods

2.1. Preparation of Materials

As the object of research, we used composite compositions based on a binder, which is a mixture of polyolefins of the composition “high-pressure polyethylene (HPPE) + polypropylene (PP)” produced by JSC “Belvtorpolymer” (Grodno, Belarus) in the ratio of components 1:3. The specified ratio of the binder was chosen taking into account the high strain–strength characteristics (σv no less than 35 MPa) and low melt viscosity (PTR = 18 ± 1 g/10 min) of PP, as well as the need to increase the frost resistance and impact toughness of PP by modifying it with LDPE additives (σv no less than 22 MPa; PTR = 2.6 ± 0.3 g/10 min; Charpy impact toughness—not destroyed), ensuring the resistance of the composite to dynamic loads [16]. The components were mixed in a single-screw extruder Z-7M (ITC-Pro, Shchyolkovo, Russia) with a constant pitch of turns, with a screw diameter of 25 mm, a material cylinder length of 400 mm, a compression ratio of 1.8 and a power consumption of 2.8 kW (Figure 1).

Figure 1.

Extruder.

Quartz sand of 180–260 μm fraction, dedusted by washing with water jet, followed by drying at 95 ± 5 °C to a moisture content of no more than 0.1 wt% in a drying cabinet SHS-80-01 SPU, was used for the formation of SPCs. Dusted silica sand in order to increase the adhesive interaction between the surface of the filler and the binder was treated by mechanically stirring the filler in a 50% solution of stearic acid in ethyl alcohol heated to 55 ± 3 °C until the solvent evaporated. The mass of the solution for the treatment of silica sand was selected so that after the evaporation of the alcohol, the content of stearic acid was 3–4 wt%.

2.2. Properties of Materials

The initial and stearic acid-modified sand was mixed with the polymer component in the form of flakes in specified ratios (Table 1).

Table 1.

Compositions of sand–polymer materials based on polyolefins.

The density values of the sand–polymer composite samples are summarized in Table 2.

Table 2.

Density values of sand–polymer composite samples.

It should also be noted that an increase in the quartz filler content leads to a decrease in the deformation properties of the SPC.

To increase the melt fluidity, SEWA113—Sevilen (ethylene-vinyl acetate copolymer) (OOO «MNTP», Novopolotsk, Belarus) in an amount not exceeding 5 wt% was forced into composites containing more than 50 wt% of silica sand.

In order to increase the deformation and strength characteristics of the polymer matrix, highly dispersed particles of pyrogenic silicon dioxide, which is a white powder with an average monoparticle size of 5 nm and a specific surface area of 380 m2/g (trade name “Aerosil-380”), were introduced into the composition of the polymer binder by powdering the granules of the initial raw material before extrusion.

The obtained SPC mass was subjected to thermo-pressing in a closed mold and heated to a temperature of 150 ± 5 °C using a hydraulic press, leading to the formation of flat block samples with a thickness of about 30 mm, in the mode of pre-pressing the mass to a pressure of 10 MPa, with the subsequent movement of the press beam at a rate of 10 mm/min to an ultimate compression pressure of no more than 50 MPa (Figure 2).

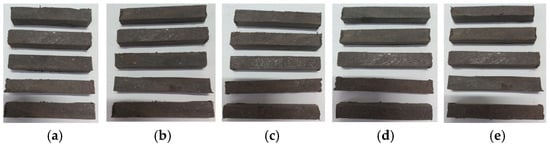

Figure 2.

Samples of composite materials: (a) SPC60; (b) SPC 65; (c) SPC 70; (d) SPC 75; (e) SPC 80.

2.3. Mechanical Testing

The obtained SPC samples were kept for 5–7 min before curing under conditions of mold cooling in air to a temperature below 60 °C (below the heat resistance level). From the pressed mass, block composite samples in the form of bars of 15 × 15 mm cross-section and 30 mm in length were obtained after 24 h on an SQ-60 abrasive cutting machine in an amount of at least 5 samples of each SPC composition. To cut the pressed semi-finished products into samples of the specified sizes, an abrasive cutting wheel 230 × 2.0 × 32 mm 14A63H39 BU (JSC “LugaAbrasiv”, Luga, Russia) 80 m/s2 cl GOST 21963-82 (ISO 603-15) was used at a cutting speed of 7.5 m/s and a feed rate of 0.5 mm/s.

To ensure the homogeneity of the SPC composition, the modes of thermo-mixing of the components were as follows: material cylinder heating temperature—190 ± 3 °C; ejection head heating temperature—210 ± 3 °C. The most effective mixing of the components visually occurred at a screw speed approximately 20 rpm during 3 min of the composite in the melt state. At higher mixing speeds and by increasing the mixing time, an increase in the intensity of gas formation was observed, which indicated the occurrence of thermal and mechanical destruction of the highly filled polymer binder.

To evaluate the compressive strength of samples containing quartz filler in the range of 50–80 wt%, bars of square cross-section were subjected to compression on the long side with the fixation of force parameters on a tensile machine R-1500 in compression mode using the fixture “type 2” according to the methodology presented in GOST 33519—2015 (ISO 1183-1). The durability of the obtained SPC samples under dynamic loading conditions was investigated by the Charpy impact toughness index on samples in the form of uncut bars of 5 pieces of each SPC composition according to GOST 4647-2015 (ISO 179:2010). To evaluate the efficiency of the distribution of the components of SPC, the density of the obtained compositions was investigated according to GOST 15139-69 (ISO 1183-1), item 2, by measuring and weighing the samples.

3. Results and Discussion

Thermoplastic binders are used in the production of SPCs, mainly in the form of reclaimed raw materials. Reclaimed raw materials are used in the production of non-critical products, most often for construction purposes. Such products do not have high deformation–strength characteristics (compressive strength no more than 37 MPa and bending strength no more than 5 MPa) and are not products with a long service life [33,34]. The use of mixtures of polymer materials leads to the production of composites with low dynamic strength, which is explained by the mutual thermodynamic incompatibility of most polymer materials.

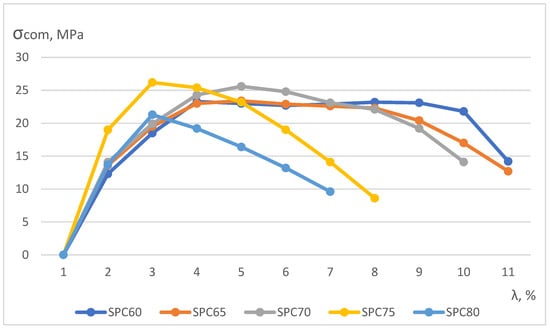

As a result of testing SPC samples for uniaxial compression, data on the fracture toughness limit of the studied composites were obtained. The results of the study are presented in Figure 3.

Figure 3.

Deformation–strength dependencies under the uniaxial compression of SPC samples filled with quartz filler in the range of 60–80 wt%.

It should be noted that the minimum content of the matrix binder in highly filled polymer composites (up to 5 wt%) is determined by the viscosity characteristics of the polymer material and the size of the filler particles [35,36]. In this case, under the specified conditions of the preparation of composite samples, when the filler content reaches 75 wt%, the maximum strength of the samples under compression is achieved. A further increase in the quartz filler content leads to the weakening of the composite.

The specified behavior of the filler is explained by the insufficient content of the binder and the homogeneity of its distribution. At the same time, the density of the samples with a decrease in the concentration of the polymer binder increases to a value of 1.52 g/cm3 with a quartz sand content of 75 wt%, and exceeding this value causes a decrease in the density of the composite. This can be explained by the difficulty of mixing the components (Table 2).

It should also be noted that an increase in the quartz filler content leads to a decrease in the deformation properties of the SPC. Thus, in the case of SPC60, at 10% deformation of the test sample, a reduction in the level of compressive stresses by 40% is observed, while for SPC75, with the highest value of the compressive strength, a decrease in strength by 40% occurs at 5.5% deformation of the sample. A decrease in the proportion of the polymer binder leads to a reduction in the deformation parameters of the composite, and a subsequent increase in the quartz filler by more than 75 wt% (Figure 3, SPC80) causes a decrease in the deformation and strength characteristics of sand–polymer materials.

To reduce the negative effect of the low-molecular component on the deformation and strength characteristics of the composite in the composition of the high-molecular binder, it is necessary to provide a monolayer coating of the surface of quartz sand particles with stearic acid molecules. This approach can be achieved by treating the sand with an alcohol solution of stearic acid. To increase the dissolution rate, stearic acid powder was added to the solvent preheated to 55 °C in a 1:1 ratio. Complete dissolution was monitored by the absence of sediment. Quartz sand was treated with the prepared solution by mechanically mixing the components in the presence of a surfactant solution containing 5 wt% stearic acid in each composite formulation. The solvent was removed from the composition by drying the treated quartz filler in air under exhaust ventilation.

Presumably, the surface treatment of the filler by coating the particles with a surfactant will lead to the modification of the surface of the quartz filler and reduce its “polymerophobicity”.

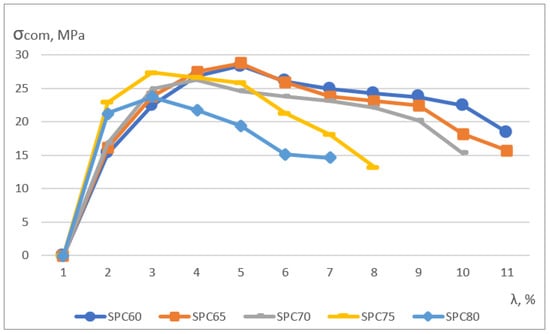

The deformation–strength dependencies under the uniaxial compression of SPC samples filled within 60–80 wt% with quartz filler coated with stearic acid are shown in Figure 4.

Figure 4.

Deformation–strength dependencies under the uniaxial compression of SPC samples filled within 60–80 wt% with quartz filler, coated with stearic acid.

The SPC60 specimen shows relatively low compressive strength compared to other specimens. The peak strength is reached at a strain of about 3–4%.

The compressive strength of sample SPC65 is significantly higher than that of SPC60. The peak strength is also reached at a strain of about 4–5%. The compressive strength of the SPC70 specimen is slightly lower than that of SPC65, but still higher than that of SPC60. The peak strength is reached at a strain of about 5%.

After reaching the peak strength, a decrease in strength is observed for all specimens with a further increase in strain. This indicates the failure of the composite structure.

The obtained dependencies of the ultimate strength under the uniaxial compression of SPCs filled with finished quartz sand indicate an increase in the intensity of interaction between the filler and the polymer binder. Thus, in the case of SPC65 filled with a modified filler, an increase in the ultimate value of the strength under compression by 25% is noted in comparison with the unmodified filler. At the same time, the nature of deformation dependencies under the compression of samples with a modified quartz filler does not change significantly. This fact probably indicates the primary dependence of the deformation behavior of sand–polymer composites on the type of binder used, in particular its deformation capacity during destruction.

Polyolefins used in obtaining SPC compositions are characterized by low impact strength values [19]. At the same time, the authors noted an increase in the dynamic strength of composite compositions based on polypropylene modified with polyethylene and dispersed fillers under impact conditions.

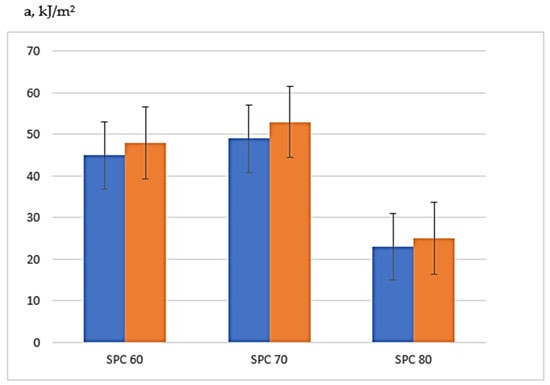

The introduction of dressed quartz sand into the SPC composition somewhat increases the ability of the structural components of the highly filled composites studied to absorb the energy of dynamic impact when testing impact strength according to Charpy on uncut samples (Figure 5).

Figure 5.

Charpy impact strength values of unnotched SPC samples filled with 60–80 wt% quartz filler in the original and modified state.

It should be noted that an insignificant increase in the dynamic strength indicator does not exceed 10% regardless of the content of quartz filler, but it is consistently manifested in samples filled with both original and modified quartz sand.

In all samples (SPC 60, SPC 70, and SPC 80), the impact toughness is higher for the samples with modified sand (red bars) compared to the samples with original sand. It can also be seen that the more silica sand in the SPC, the lower the impact strength. The modification of silica sand leads to an improvement in the ability of the SPC to absorb energy during impact. This improvement, although small, is stable and is observed at different concentrations of silica filler. The silica sand content is inversely proportional to the impact toughness.

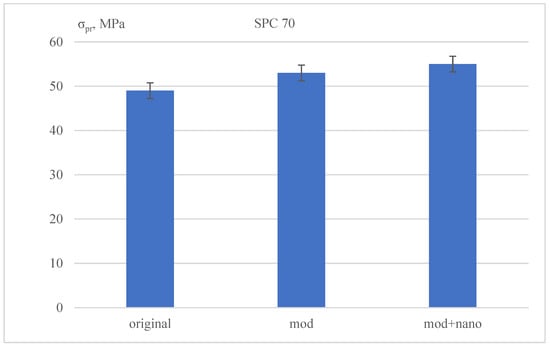

The finishing of quartz filler particles not only ensures the good adhesion of the filler surface to the polymer binder but also helps to reduce the interaction between filler particles and prevents their agglomeration, which causes a decrease in the physical, mechanical and technological characteristics of the resulting composites. It is known that highly dispersed particles of cluster-structured materials with a developed surface (high specific surface area) exhibit high modifying capacity in the composition of thermoplastic polymer matrices due to the charge state [37,38]. First of all, the strengthening of the polymer matrix occurs due to the formation of supramolecular formations in the amorphous phase of the polymer structure. This fact suggests that the modification of the polymer binder with highly dispersed particles exhibiting a charge state will improve the deformation and strength characteristics of the SPC. For this purpose, silicon dioxide was introduced into the composition of SPC75. This is a white powder with an average particle size of 5 nm (trade name “Aerosil-380” (Evonik, Germany) and a specific surface area of 380 m2/g, possessing excellent adsorption properties. The choice of the SPC70 composition is due to the acceptable level of deformation and strength characteristics of the composite. The silicon dioxide content was 0.1 wt% of the content of the thermoplastic matrix of the mixed composition. The test results are shown in Figure 6.

Figure 6.

Histograms of the uniaxial compression strength of SPC70 samples filled with the original quartz filler (original), coated with stearic acid (mod) and also containing a nanomodifier of the binder and filled with coated quartz sand (mod + nano).

The obtained results indicate a slight increase in the strength of the sand–polymer composite material modified with highly dispersed silicon dioxide. However, in our opinion, it is not possible to achieve a significant effect with the used method of introducing the modifier into the composite (dusting the polymer component before mixing and melting) due to the deposition of nanoparticles on the surface of all the components of the SPC. To achieve the effect of modifying the composite system with nanoparticles, it is necessary to preliminarily introduce nanomodifiers into the polymer binder. However, such an approach will lead to a loss of melt fluidity due to the active interaction of cluster particles with the macromolecules of the thermoplastic matrix and the manifestation of a thickening effect [39], which, in turn, will lead to a decrease in the wetting ability of the melt with respect to the quartz filler. Attempts to obtain block samples of SPCs with a quartz sand content of more than 70 wt% by the proposed method were unsuccessful due to an insufficiently uniform distribution of the thermoplastic binder in the composite system. The solution to this problem requires additional research and a search for technological methods for creating SPCs on thermoplastic matrices modified with highly dispersed particles that exhibit the effects of the nanostate of the substance. Evidently, the increase in melt viscosity can be associated with the activity of quartz particles, mechanically activated under conditions of critical filler content [40].

4. Conclusions

The following main results were obtained in this study:

(1) During the experiments, it was found that the composite polymer composite based on a mixture of polyolefins filled with quartz sand with a filler particle dispersion within 100–300 μm maintains an acceptable level of uniaxial compression strength (at least 25 MPa) if the filler content does not exceed 75 wt% when deforming composite samples by no more than 5%.

(2) Finishing the surface of quartz particles somewhat improves the interaction of the polymer binder with the filler, which is manifested in an increase in the tensile strength of compressed samples by 10–15% and in impact toughness by 10% within 70–75 wt% of the quartz filler content.

(3) A positive effect was noted when introducing silicon dioxide nanoparticles into the polymer composite. In particular, with a nanomodifier content of no more than 0.1 wt% (the so-called “doping additive”), an increase in the compressive strength limit of SPC70 samples with coated filler particles by 15% was observed in comparison with the original composition.

(4) A more significant effect of the nanocomponents in the SPC composition on the strength indicators should be expected if the active highly dispersed particles fully modify the polymer binder before mixing with the quartz filler. However, the existing decrease in the melt flow index of the binder when modified with nanocomponents will lead to a limitation of the maximum content of the dispersed filler.

(5) Further research will be conducted in the direction of finding and optimizing methods for homogenizing the components of composite systems with abnormally low binder content to improve performance characteristics.

Author Contributions

Conceptualization, A.S. (Alexandr Skaskevich) and V.Y.; methodology, A.S. (Alexandr Skaskevich), O.Z. and V.H.; formal analysis, A.S. (Altay Smagulov), O.R. and O.Z.; investigation, V.H. and G.Z.; resources, O.R.; writing—original draft preparation, V.H. and A.S. (Alexandr Skaskevich); writing—review and editing, O.Z. and G.Z.; supervision, M.M.; funding acquisition, V.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research is financed by the Committee of Science of the Ministry of Science and Higher Education of the Republic of Kazakhstan (grant under the theme AP19680121 “Development of compositions of sand–polymer composite materials and technological support of their processing in products of machine-building purposes”).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| HPPE | High-pressure polyethylene |

| PP | Polypropylene |

| SPC | Sand–polymer composite |

| GOST | Interstate standard |

| ISO | International Organization for Standardization |

References

- Laeth, H.; Praveen Sreerench, R.; Shilpa, P.; Alok, J.; Anandhi, R.J.; Praveena, K. The Development of Composites Materials: From Conventional to Innovative Uses. E3S Web Conf. 2024, 529, 01050. [Google Scholar]

- Huang, X.; Su, S.; Xu, Z.; Miao, Q.; Li, W.; Wang, L. Advanced Composite Materials for Structure Strengthening and Resilience Improvement. Buildings 2023, 13, 2406. [Google Scholar] [CrossRef]

- Lebedev, M.P.; Startsev, O.V.; Kychkin, A.K. The effects of aggressive environments on the mechanical properties of basalt plastics. Hellion 2020, 6, e03481. [Google Scholar] [CrossRef]

- Yi, H.; Oh, K.; Kou, R.; Qiao, Y. Sand-filler structural material with low content of polyethylene binder. Sustain. Mater. Technol. 2020, 25, e00194. [Google Scholar] [CrossRef]

- Terekhov, I.V.; Chistyakov, E.M. Binders Used for the Manufacturing of Composite Materials by Liquid Composite Molding. Polymers 2022, 14, 87. [Google Scholar] [CrossRef]

- Siraj, S.; Al-Marzouqi, A.H.; Iqbal, M.Z.; Ahmed, W. Impact of Micro Silica Filler Particle Size on Mechanical Properties of Polmeric Based Composite Material. Polymers 2022, 14, 4830. [Google Scholar] [CrossRef] [PubMed]

- Vinayagamoorthy, R. Effect of particle sizes on the mechanical behavior of limestone-reinforced hybrid plastics. Polym. Polym. Compos. 2020, 28, 410–420. [Google Scholar] [CrossRef]

- Poyraz, B.; Eren, S.; Subaşı, S. Filler Type and Particle Distribution Effect on Some Properties of Polymer Composites. Celal Bayar Univ. J. Sci. 2021, 17, 79–89. [Google Scholar] [CrossRef]

- Rao, P.V.C. Effects of matrix modification on mechanical and durability characteristics of polymer composites through variations in micro fillers, macro fillers and fibers. Constr. Build. Mater. 2020, 235, 117505. [Google Scholar] [CrossRef]

- Jesionowski, T.; Bula, K.; Janiszewski, J.; Jurga, J. The influence of filler modification on its aggregation and dispersion behaviour in silica/PBT composite January. Instrum. Sci. Technol. 2003, 10, 225–242. [Google Scholar] [CrossRef]

- Slieptsova, I.; Savchenko, B.; Sova, N.; Slieptsov, A. Polymer sand composites based on the mixed and heavily contaminated thermoplastic waste. IOP Conf. Ser. Mater. Sci. Eng. 2016, 111, 012027. [Google Scholar] [CrossRef]

- Sharshin, V.; Sukhorukov, D.; Sukhorukova, E. Polymer composite material for the manufacture of molds in the production of evaporative patterns. IOP Conf. Ser. Mater. Sci. Eng. 2020, 896, 012106. [Google Scholar] [CrossRef]

- Retnam, B.S.J.; Benin, M.A.; Dhas, J.E.R.; Samuel, G.D.; Prasad, A.; Veeranjaneyulu, K. Comparative analysis of tensile properties on thermoplastic & thermosetting polymer composites. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Uygunoglua, T.; Gunes, I.; Brostow, W. Physical and Mechanical Properties of Polymer Composites with High Content of Wastes Including Boron. Mater. Res. 2015, 18, 1188–1196. [Google Scholar] [CrossRef]

- Xie, F. Sustainable polymer composites: Functionality and applications. Funct. Compos. Mater 2021, 2, 15. [Google Scholar] [CrossRef]

- Shmoilov, E.; Fedotov, M.; Sharutin, I.; Ilyukhin, R.; Stepanov, S.; Panina, N.; Gurenchuk, L.; Kapyrin, P.; Kabantsev, O.; Kornev, O. Polymer composites for external reinforcement of building structures. Int. J. Comput. Civ. Struct. Eng. 2024, 20, 21–34. [Google Scholar] [CrossRef]

- Yusuf, M.; Salami, O.; Amusat, W.O. Advances in carbon-fiber reinforced polymers and composites for sustainable concrete structures. World J. Adv. Res. Rev. 2024, 23, 2308–2330. [Google Scholar] [CrossRef]

- Aguiar, J.B.; Ozkul, M.H.; Cunha, S. Report from 13th ICPIC and 7th ASPIC: New Trends on Concrete-Polymer Composites. Adv. Mater. Res. 2013, 687, 45–56. [Google Scholar] [CrossRef]

- Saikaew, C.; Weingwiset, S. Optimization of molding sand composition for quality improvement of iron castings. Appl. Clay Sci. 2012, 67–68, 26–31. [Google Scholar] [CrossRef]

- Geier, N.; Pereszlai, C. Analysis of Characteristics of Surface Roughness of Machined CFRP Composites. Period. Polytech. Mech. Eng. 2019, 64, 67–80. [Google Scholar] [CrossRef]

- Onyango, W.A.; Czel, G. Strength evaluation and melt rheology of highly mineral filled polymer composites. Conf. MultiSci. XXXVII. Microcad Int. Multidiscip. Sci. Conf. 2024, 14, 149–166. [Google Scholar] [CrossRef]

- Zhang, T.; Ping, S.; Mei, Z.; Cheng, Z. Microstructure Deformation and Fracture Mechanism of Highly Filled Polymer Composites under Large Tensile Deformation. J. Phys. Conf. Ser. 2013, 419, 012014. [Google Scholar] [CrossRef]

- Mazitova, A.K.; Zaripov, I.I.; Aminova, G.K.; Ovod, M.V.; Suntsova, N.L. Fillers for polymer composite materials. Nanotechnol. Constr. A Sci. Internet-J. 2022, 14, 294–299. [Google Scholar] [CrossRef]

- Mukherjee, G.S.; Jain, A.; Banerjee, M. Engineering Matrix Materials for Composites: Their Variety, Scope and Applications. Fine Chem. Eng. 2023, 4, 13. [Google Scholar] [CrossRef]

- Semakina, O.K.; Phomenko, A.N.; Leonteva, A.A.; Rymanova, I.E. Research of surface properties of fillers for polymers. Procedia Chem. 2015, 15, 79–83. [Google Scholar] [CrossRef]

- Stepashkin, A.A.; Chukov, D.I.; Olifirov, L.K.; Salimon, A.I.; Tcherdyntsev, V.V. Quasicrystalline Powders as the Fillers for Polymer-Based Composites: Production, Introduction to Polymer Matrix Properties. In Proceedings of the Scientific-Practical Conference “Research and Development—2016”; Springer: Berlin/Heidelberg, Germany, 2016; pp. 429–437. [Google Scholar]

- Pérez, E.; Berna, C.; Piacquadio, M. Multifractal analysis of tensile toughness and filler dispersion for polypropylene–CaCO3 composites. Appl. Surf. Sci. 2012, 258, 8940–8945. [Google Scholar] [CrossRef]

- Onoprienko, N.N.; Rahimbaev, S.M. Influence of composition of functional additives and deformation modes on flow behavior of polymer composite materials. IOP Conf. Ser. Mater. Sci. Eng. 2018, 327, 32043. [Google Scholar] [CrossRef]

- Akulova, M.V.; Koksharov, S.A.; Meteleva, O.V.; Fedosov, S.V. On Some Features of Nanostructural Modification of Polymer-Inorganic Composite Materials for Light Industry and for Building Industry. In Proceedings of the Scientific-Practical Conference “Research and Development—2016”; Springer: Berlin/Heidelberg, Germany, 2017; pp. 491–500. [Google Scholar]

- Wang, Y.; Desroches, G.J.; Macfarlane, R.J. Ordered polymer composite materials: Challenges and opportunities. Nanoscale 2021, 13, 426–443. [Google Scholar] [CrossRef]

- Sorokin, A.E.; Sagomonova, V.A.; Petrova, A.P.; Solov’yanchik, L.V. Thermoplastic-Based Binders for Polymer-Composite Materials (Literature Review). Polym. Sci. Ser. D Glues Seal. Mater. 2022, 15, 359–365. [Google Scholar] [CrossRef]

- Zhukova, I.; Flik, E.; Shubina, E.; Mishurov, V.; Kashparov, I. Synergism of the action of some stabilisers against the destruction of polymer materials. E3S Web Conf. 2021, 273, 04014. [Google Scholar] [CrossRef]

- Bai, Y.; Liu, J.; Song, Z.; Chen, Z.; Jiang, C.; Lan, X.; Shi, X.; Bu, F.; Kanungo, D.P. Unconfined Compressive Properties of Composite Sand Stabilized with Organic Polymers and Natural Fibers. Polymers 2019, 11, 1576. [Google Scholar] [CrossRef] [PubMed]

- Badache, A.; Benosman, A.S.; Senhadji, Y.; Mouli, M. Thermo-physical and mechanical characteristics of sand-based lightweight composite mortars with recycled high-density polyethylene (HDPE). Constr. Build. Mater. 2018, 163, 40–52. [Google Scholar] [CrossRef]

- Shalygina, T.A.; Rudenko, M.S.; Nemtsev, I.V.; Parfenov, V.A.; Voronina, S.Y.; Simonov-Emelyanov, I.D.; Borisova, P.E. Influence of the Filler Particles’ Surface Morphology on the Polyurethane Matrix’s Structure Formation in the Composite. Polymers 2021, 13, 3864. [Google Scholar] [CrossRef]

- Riazati, A.; Ghafoori, M. Investigating the effect of the amount of solid particles on the rheological behavior of highly filled composites. J. Chem. Lett. 2024, 5, 144–151. [Google Scholar] [CrossRef]

- Alias, A.H.; Norizan, M.N.; Sabaruddin, F.A.; Asyraf, M.R.M.; Norrrahim, M.N.F.; Ilyas, A.R.; Kuzmin, A.M.; Rayung, M.; Shazleen, S.S.; Nazrin, A. Hybridization of MMT/Lignocellulosic Fiber Reinforced Polymer Nanocomposites for Structural Applications: A Review. Coatings 2021, 11, 1355. [Google Scholar] [CrossRef]

- Auchynnikau, Y.; Avdeychik, S.; Antonov, A.; Skaskevich, A.A.; Kravchenko, V. Mechanisms for the formation of anti-based coatings fluorinated polymeroligomeric compositions. In Proceedings of the Mechanika 2015: 20th International Scientific Conference, Kaunas, Lithuania, 23–24 April 2015. [Google Scholar]

- Šupová, M.; Martynková, G.S.; Barabaszová, K. Effect of Nanofillers Dispersion in Polymer Matrices: A Review. Sci. Adv. Mater. 2011, 3, 1–25. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Madhu, P.; Gowda, Y.T.G.; Sanjay, M.R.; Siengchin, S. A comprehensive review on the effect of synthetic filler materials on fiber-reinforced hybrid polymer composites. J. Text. Inst. 2021, 113, 1231–1239. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).