3.1. Tensile Behaviour

The mean output for the tensile test results is presented in

Figure 4, with each structure’s calculated properties listed in

Table 3 (blue is used for nylon, red for NCCF and black for NSCF).

The comparison of tensile properties for both CF and SF composites revealed that the longitudinal orientation had significantly higher levels of strength and stiffness, followed by quasi-isotropic structures and, finally, the transverse orientation (CL/SL > CQ/SQ > CT/ST) as the orientation of the filaments, where fibres are aligned along the loading direction, provided better performance. CF composites had higher levels of tensile modulus and strength when compared to corresponding SF structures except for the transverse orientation because thanks to continuous fibres take the most applied load and, therefore, provide the best performance: CL had twice the strength and stiffness compared to SL. Generally, longitudinal specimens outperformed transversal ones in terms of stiffness and strength. Also, short fibres have a scatter in their orientation inside the filaments. However, the elongation at break demonstrated an opposite trend: the transverse orientation had the highest fracture strain and the longitudinal one the lowest, with quasi-isotropic structures in between. Also, the SF structures had higher elongation at break, almost three times, compared to CF composites, except for the transverse structures due to low elongation at break of continuous carbon fibres.

The results confirmed the high axial load-bearing capacity of the CFs compared to the SFs, although having half the fibre content. The tensile stress–strain curves for SFs show non-linearity, with the tensile moduli decreasing with increasing strain because of progressive structure damage as SF had porosity acting as locations of stress concentrations [

24] together with ends of fibres. The pure nylon sample had a low yield strength (28.25 MPa) and the lowest stiffness (0.46 GPa) but the highest elongation at break (554.03%) compared to the composite structures.

The post-experiment tensile specimens of the MEAM composites are presented in

Figure 5. The pure nylon underwent large deformation, thanks to the pronounced plasticity of the polymer, explaining the high elongation at break. The slightly uneven porosity distribution and higher springback in parts with more material after rupture led to significant curvature of the post-fractured nylon samples due to the considerably reduced thickness of the gauge part. However, the composites, in general, demonstrated an elastic–brittle fracture, indicated by the sharp drop in tensile stress after fracture with a nearly flat fractured surface after the tests. Additionally, a fractography analysis was performed on these tension-loaded specimens in our previous study [

24], where the fibre pull-outs indicated weak bonding between the nylon matrix and the carbon fibres in the microstructure. CT showed the most complex response with brittle fracture of fibre layers followed by a ductile fracture of the polymer matrix, which resulted in the high elongation at break due to debonding and delamination between the matrix and the fibre layers. The FDM process inherently results in the formation of small pores between the printed layers, even when optimised printing parameters are employed. To mitigate this issue, post-processing techniques such as annealing could be explored to enhance the layer bonding. Annealing facilitates improved fibre–matrix adhesion by promoting interlayer diffusion and reducing the void content. Consequently, this could lead to an increase in inter-laminar strength, thereby enhancing the overall mechanical properties of the composites [

45].

3.2. Compressive Behaviour

The mean compressive test results and the calculated properties of each MEAM structure are presented in

Figure 6 and

Table 4, respectively. The initial compressive modulus was calculated between 0 and 0.5% strain, and the compressive yield strength was selected right before the rapid change in compressive stress to plateau. The 0.2% offset rule could not be applied as the stress curves were not linear in the elastic deformation. Large load-induced changes in the specimen shape produced the assessment of the levels of strength and strain-at-failure for compressive loading.

Adding SF and CF increased the compressive yield strength and the initial modulus of the MEAM composites. For CF composites, the compressive modulus followed the same pattern as the tensile ones for the structural orientations, with the longitudinal samples having the highest stiffness, followed by quasi-isotropic configuration and then the transverse direction. This indicated that continuous fibres oriented in the loading direction increased the overall stiffness of the structure. However, CQ had a slightly higher level of yield strength (69.85 MPa) than CL (62.34 MPa), which could be attributed to the lower porosity of the quasi-isotropic structure compared to the unidirectional one [

24,

33]. The compressive response of SF composites was more complex: the longitudinal orientation had the highest yield strength (121.28 MPa), but the quasi-isotropic structure showed a higher compressive modulus (2.30 GPa). This suggests that short fibres oriented in the loading direction can increase the strength of the composite, but the higher porosity of the unidirectional structure (compared to the quasi-isotropic orientation) reduces the stiffness of the structure, thus leading to the unpredictable behaviour of SF composites [

24]. When comparing corresponding composite orientations, the unidirectional CF structures exhibited higher stiffness but lower strength than the unidirectional SF structures, and the opposite was true for the quasi-isotropic orientation.

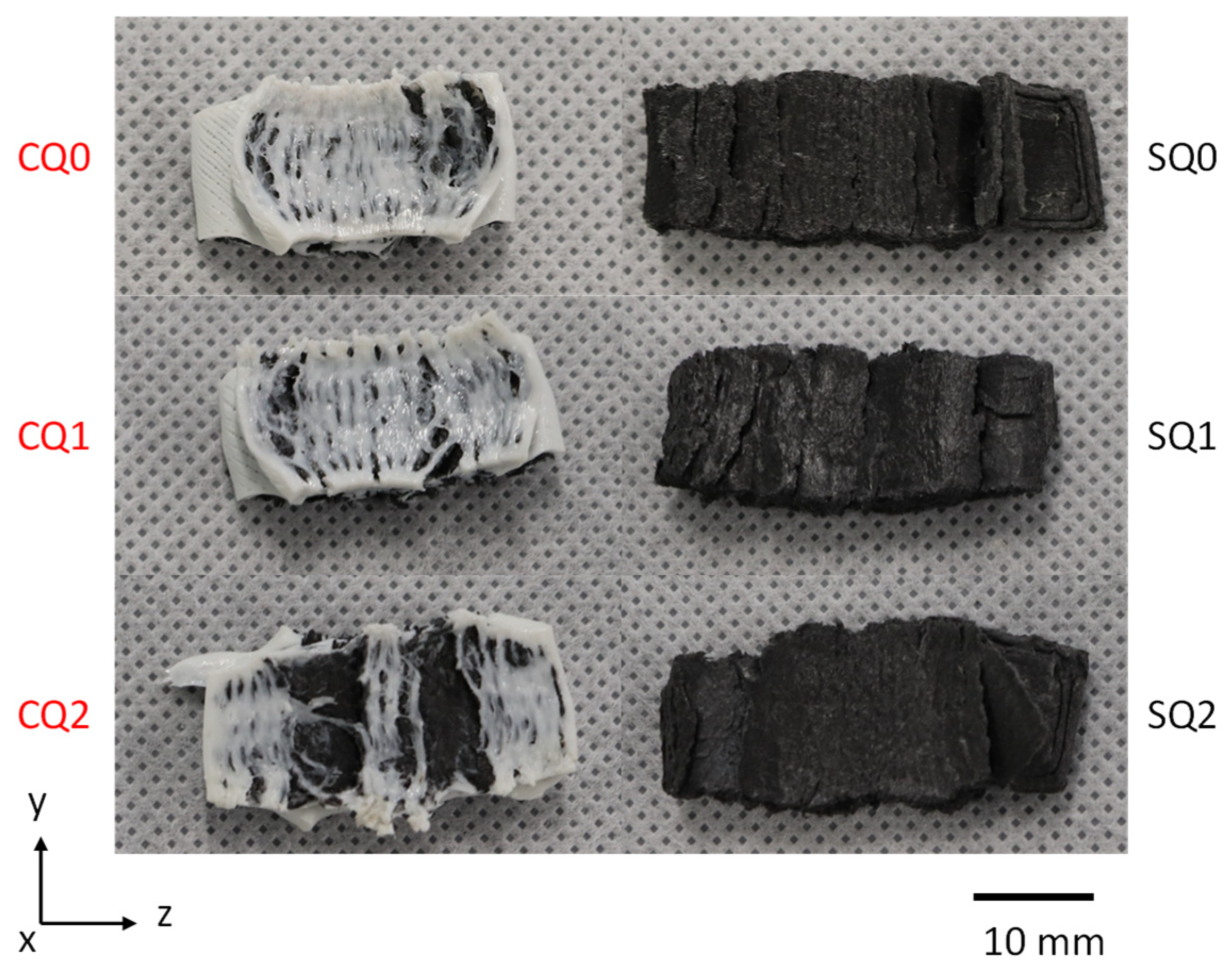

The post-experiment compression samples for different MEAM structures are presented in

Figure 7. All the structures underwent elastic–plastic deformation where the structure’s response plateaued after yielding, followed by the material’s densification. The pure nylon sample flattened equally in all directions, indicating considerable isotropy for this AM polymer with good bonding between the filaments. However, the composites generally flattened more in the z-direction under compression, with SF structures demonstrating more layer separation compared to CF structures. Exposed fibres indicated weaker bonding between the adjacent printed layers, showing the influence of fibres on the deformation direction. Some studies [

38,

39] presented higher levels of strength and stiffness for pure nylon compared to its composites, but the post-experimental images showed buckled samples that led to premature failure and inconclusive results for the properties. To improve the predictability of compression behaviour, microstructural features such as fibre waviness, interfacial bonding and matrix deformation could be investigated to provide insights into non-linear densification and flattening mechanisms, thereby improving the accuracy of predictions. Additionally, numerical simulations based on the concept of the representative volume element (RVE) could be employed to enhance the design and optimisation of these materials. By incorporating realistic microstructural characteristics, RVE models could capture local distributions of stresses and deformation mechanisms more accurately, leading to improved predictions of constitutive behaviour under compression.

3.3. Tensile vs. Compressive Behaviour

The comparison of tension–compression performance and post-experimental images revealed that pure nylon underwent elastic–plastic deformation for both loading directions. However, the composites showed an elastic–brittle fracture under tension and elastic–plastic deformation under compression, indicating that the loading direction influenced the damage and failure behaviours of the AM composites. To determine the variation in the mechanical performance based on the loading regime, the ratios of the strengths and moduli obtained from the tension–compression tests were calculated and listed in

Table 5.

The MEAM nylon showed similar yield strength for both tension and compression; however, the low modulus ratio indicates that the nylon structure was twice as stiffer under compressive load. For the NCCF composites, CL performed significantly better under a tensile load, whereas CT performed better under compression. CQ demonstrated the least strength anisotropy of the CF composites, although the structure still exhibited higher levels of strength and stiffness under tension. The SF composites demonstrated a more complex pattern, with both unidirectional orientations, SL and ST, revealing considerably higher stiffness under tensile load but higher strength under compression. SQ also had the least anisotropy for the strength ratio among NSCF composites while still having higher strength and stiffness under tension like CQ. As most MEAM composite properties were significantly better under tension, it can be concluded that the orientation of these structures should be tailored for applications to withstand loads under tension (except for CT, which should be modified for bearing compressive loads).

The quasi-isotropic specimens (a hybrid of unidirectional, 0°/90° and cross-ply +45°/−45° layers) demonstrated the lowest extent of anisotropy. This indicates that further hybridisation using additional orientation angles of fibres (such as +30°/−30° and +60°/−60°) may further lower the anisotropy. Thus, a balance between stiffness and strength across different loading directions could be achieved for such MEAM composites. Additionally, since CL showed higher tensile strength while SL showed higher compressive strength, a combination of both CF and SF layers could be fabricated to produce a hybrid composite structure. This could reduce the tension–compression asymmetry by balancing the strength for different orientations and improve the capacity of these structures for applications with complex loading regimes. The strength and stiffness ratios of these MEAM structures could also be used in advanced numerical models in future studies and reproduce the varying performance by accounting for both filament and loading directions.

3.4. Tensile Strain Rate Sensitivity

The quasi-isotropic orientations (CQ and SQ) demonstrated lower anisotropy in the mechanical tests, and a previous study [

24] showed lower porosity of these structures compared to the unidirectional orientations. Therefore, these structures were further tested with increased loading speed to determine the strain rate sensitivity of these composites. The mean tensile stress–strain results for the quasi-isotropic specimens under different strain rates are presented in

Figure 8. The properties calculated for each case are listed in

Table 6 and compared to those for the original (lowest) strain rate, followed by

Figure 9 with the post-experimental specimens.

The quasi-isotropic composites showed an overall decrease in both the tensile strength and modulus of the structures but an increase in the elongation at break with an increased strain rate. For CQ, increasing the strain rate by two orders of magnitude reduced the strength by about 14% and the stiffness by only 2.4%, with a significant increase in the elongation at break (nearly 24%). Although no pattern was found for the decrease in tensile strength of SQ with increased strain rate, the stiffness was significantly reduced (by approximately 60%), while the elongation at break was considerably increased (almost 42%) for SQ when the strain rate was increased. The strain rate affected the mechanical properties of SQ significantly more than those of CQ. Therefore, the MEAM composites, especially the SQ, were considerably more sensitive to higher strain rates under tensile load: the 100-fold increase in the strain rate resulted in a change of up to 60% in their mechanical properties. The post-experiment samples again showed an elastic–brittle fracture, indicating that the damage and failure mechanisms remained consistent with the tensile loading direction even under an increased strain rate.

Fisher et al. [

38] and Vanei et al. [

40] conducted strain rate sensitivity analyses for SF nylon composites with fibres oriented in the loading direction. In contrast, this study also investigated transverse and quasi-isotropic cases of fibre orientations. In these specimens, fibres were aligned in other major directions beyond the longitudinal axis, along with continuous-fibre composites, for a comprehensive assessment of strain rate-dependent behaviour across different fibre types and configurations. Both studies reported an increase in stiffness with strain rate; however, Fisher et al. [

38] observed the increased strength, whereas Vanei et al. [

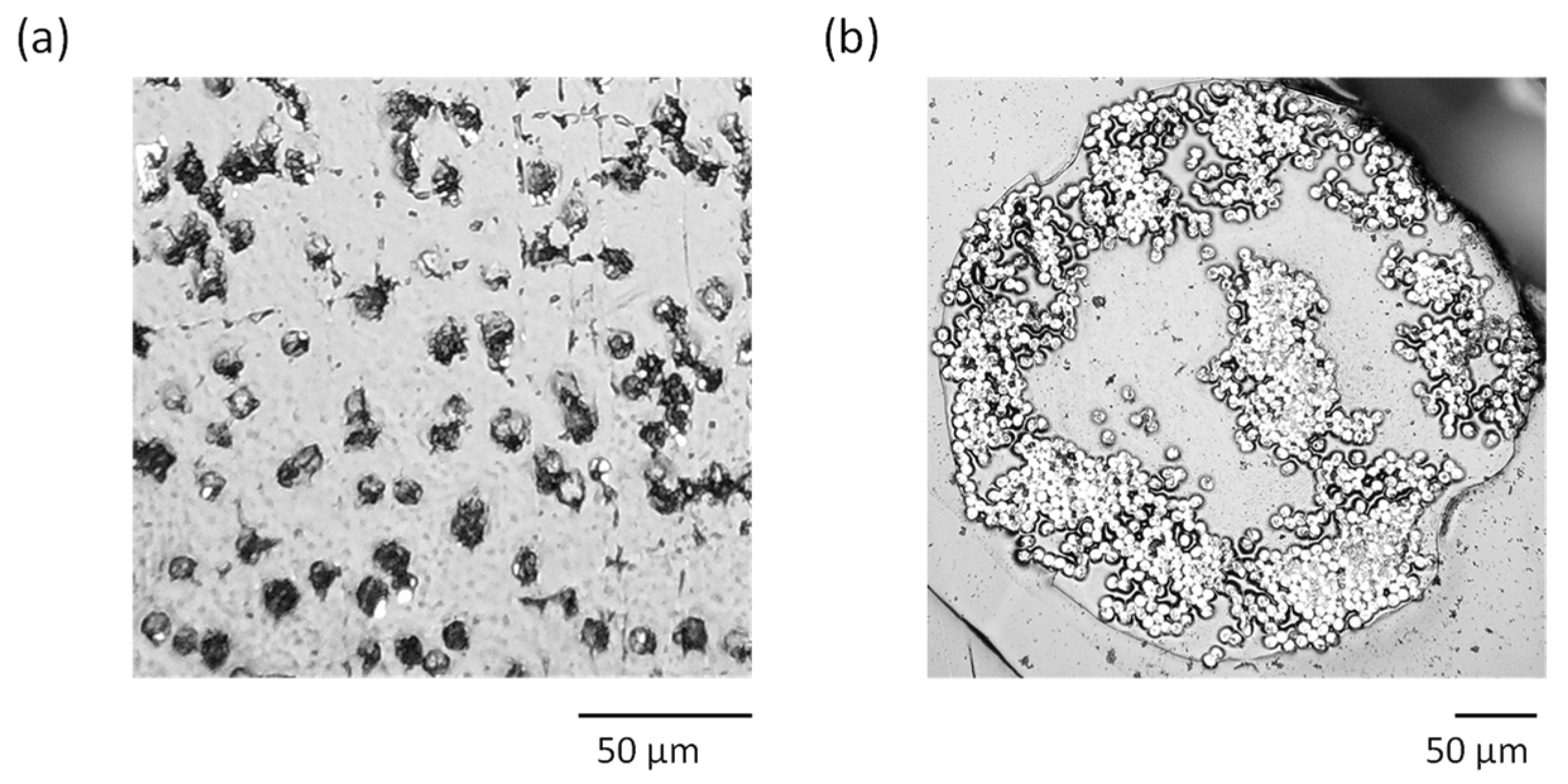

40] reported the opposite trend without providing significant explanations for these phenomena. The microstructural analysis of MEAM composites studied here showed up to 20% porosity [

24]. At higher strain rates, the time for the stress to redistribute across these weak porous interfaces decreases significantly. This leads to higher local stress (and strain) concentration and an early onset of damage, thus reducing the strength and stiffness. The high energy of deformation increased the elongation at the break of the composites. Since SQ had higher porosity, the change in mechanical properties of SQ was also larger [

24]. The decreased mechanical performance with strain rate suggests these MEAM composites are unsuitable for pure tensile-load applications under high strain rates.

3.5. Compressive Strain Rate Sensitivity

The mean compressive stress vs. strain result of the quasi-isotropic orientations under different strain rates and the calculated properties are presented in

Figure 10 and

Table 7, respectively, while

Figure 11 shows the post-compression specimens, similar to the analysis of tensile strain rate sensitivity.

Both MEAM composites demonstrated increased compressive strength with strain rate: CQ with marginally increased strength (up to 4% at two orders magnitude of higher strain rate) while SQ had a considerably higher strength increased by nearly 50% compared to the original strain rate. Although CQ similarly showed some increase in stiffness (by around 5% for the same increase in strain rate), SQ showed a significantly lower compressive stiffness (about 63%). The compressive strain rate affected the mechanical properties of SQ significantly more than those of CQ, similar to the case of tensile strain rate sensitivity analysis.

Fisher et al. [

38] did not provide an explanation for the increased compressive modulus with strain rate for SF composite with a concentric pattern. In our study, the rapid compression of the structures led to earlier densification, increasing the strength of the composites with the strain rate. For CQ, this also increased the stiffness of the structures, but the high porosity in SQ [

24] allowed easier and quicker compression of the structures, leading to an overall decrease in their stiffness. Similarly to the tensile strain rate sensitivity analysis, the SQ composites were also sensitive to compressive loads under high strain rates as the mechanical properties decreased by 63% for the strain rate increase by a factor of 100. The post-experiment samples again showed elastic–plastic deformation with directional flattening for all strain rate cases, further indicating the consistent damage and failure of the composites under compressive load. Unlike the tensile sensitivity analysis, CQ demonstrated increased strength and stiffness at high strain rates, making it suitable for energy-absorbing applications where compressive forces dominate, such as impact-resistant panels and helmets. On the other hand, SQ exhibited high strength but low stiffness, which could influence its deformation behaviour under impact loading. While the increased strength is beneficial, the lower stiffness may lead to excessive deformation, potentially affecting its ability to dissipate energy effectively.