Effects of Matrix Properties on the Interfacial Shear Strength Between Carbon Fiber and Various Thermoplastic Polymers, and Their Influence on the Mechanical Properties of Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

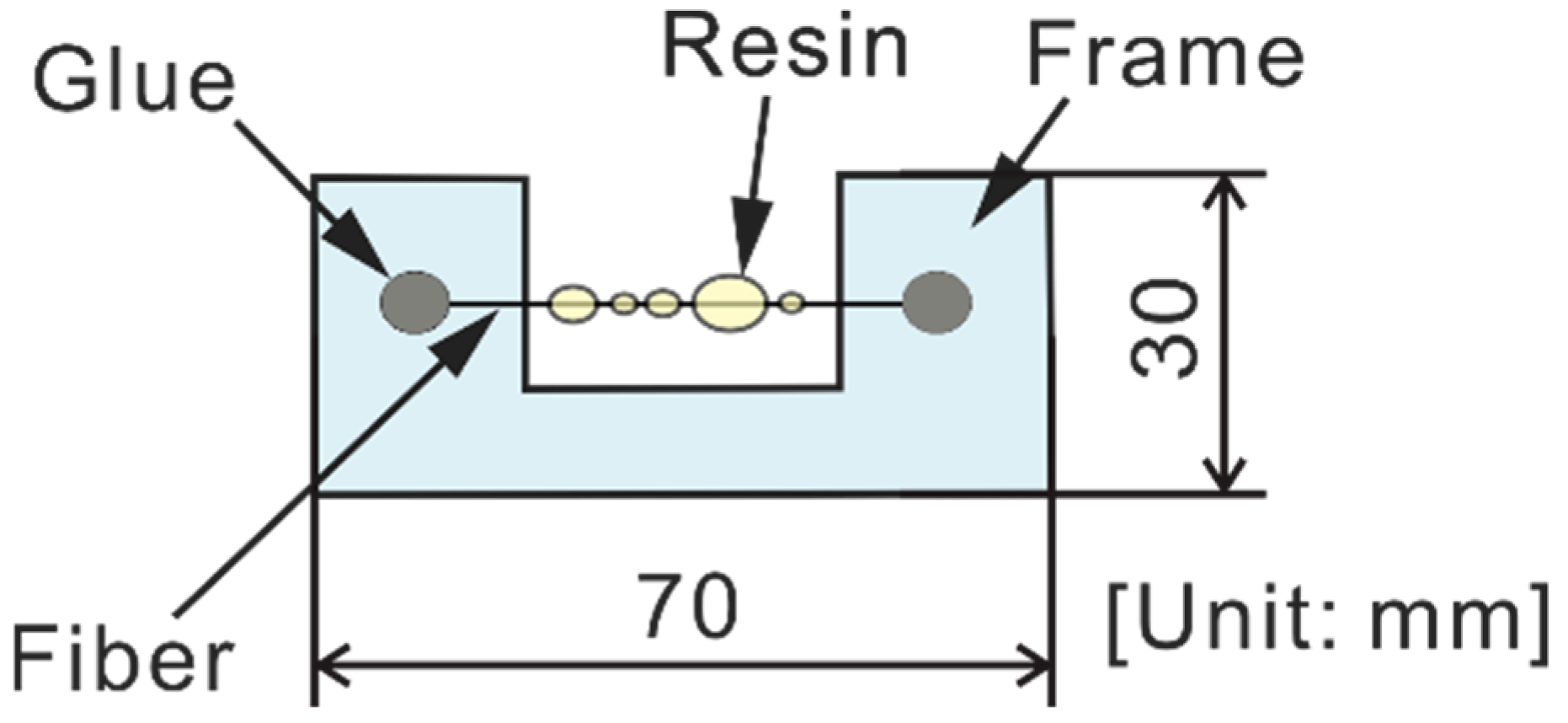

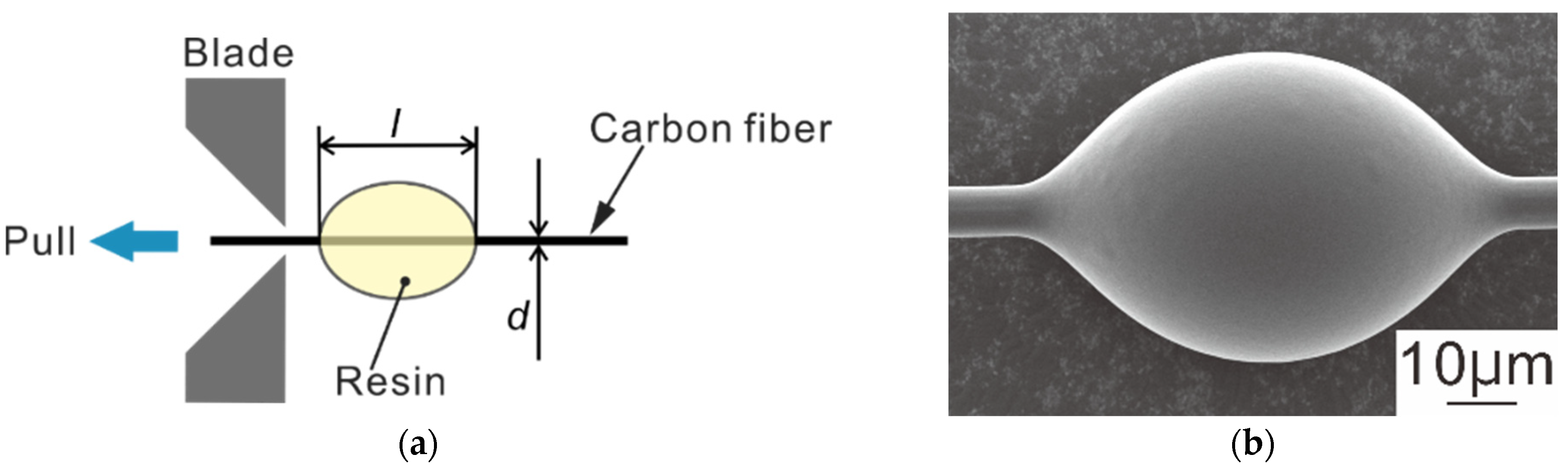

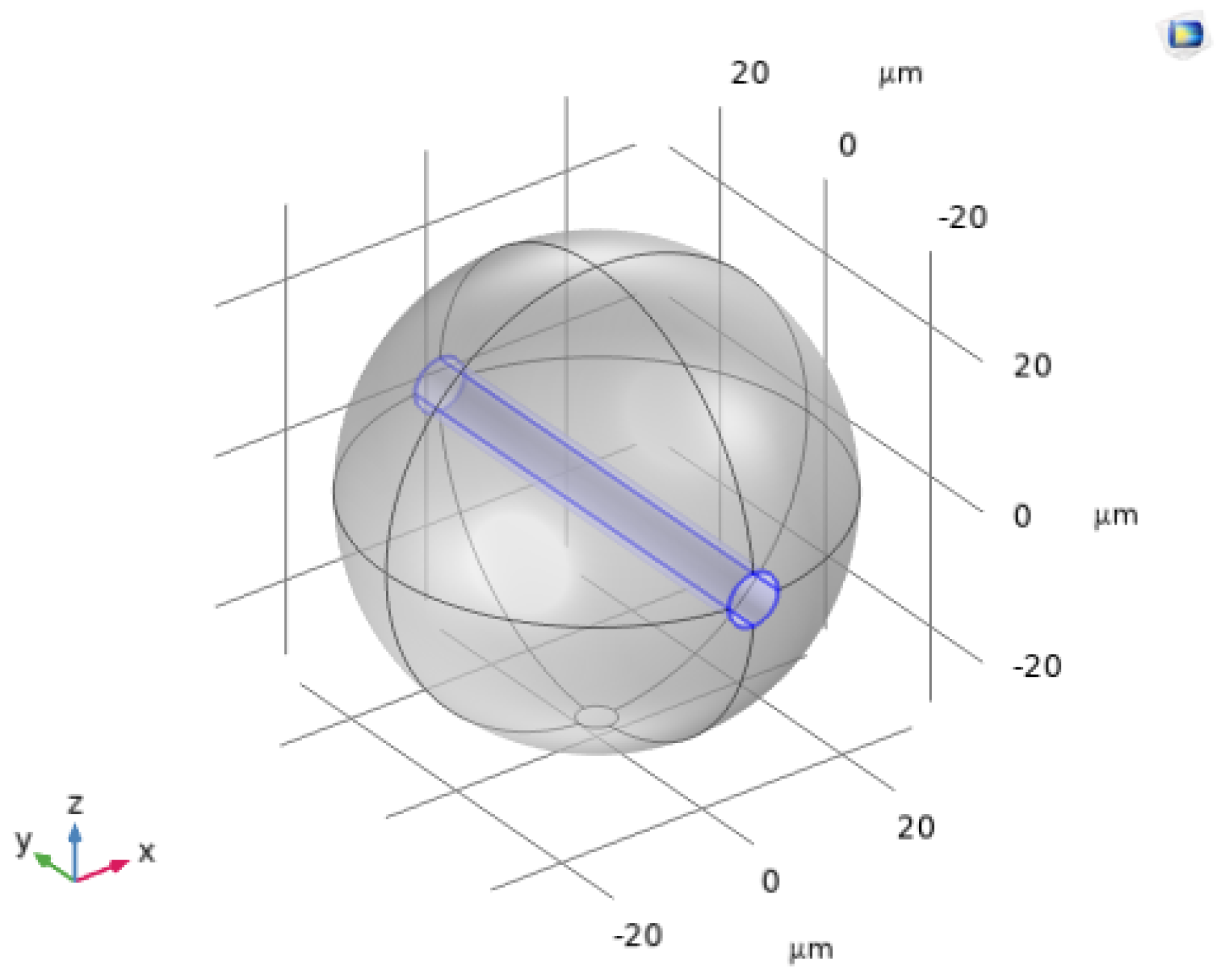

2.2. Microdroplet Test

2.3. Evaluation of Matrix Properties

2.3.1. Tensile Test

2.3.2. Thermal Analysis

2.3.3. Measurement of Matrix Density

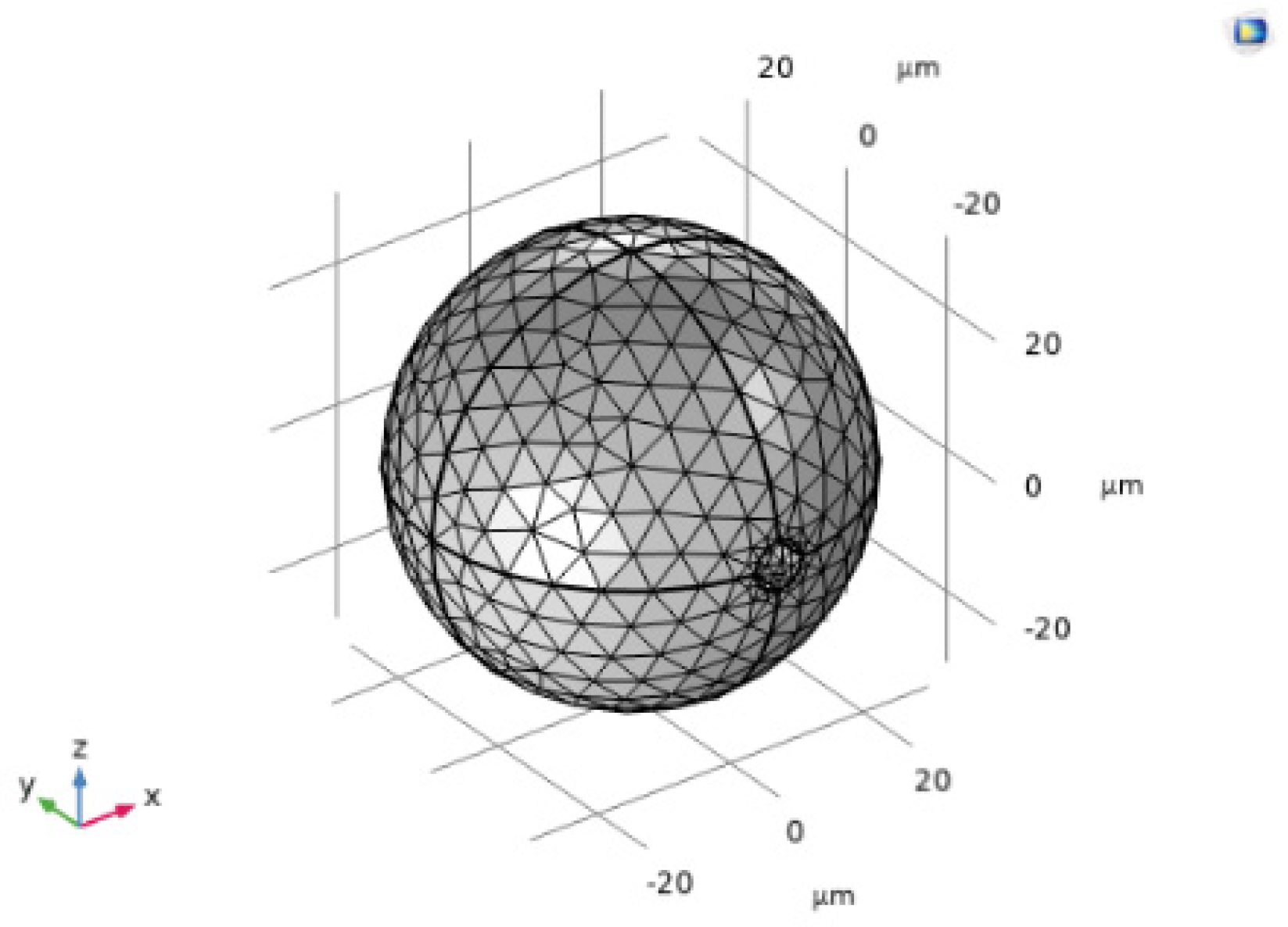

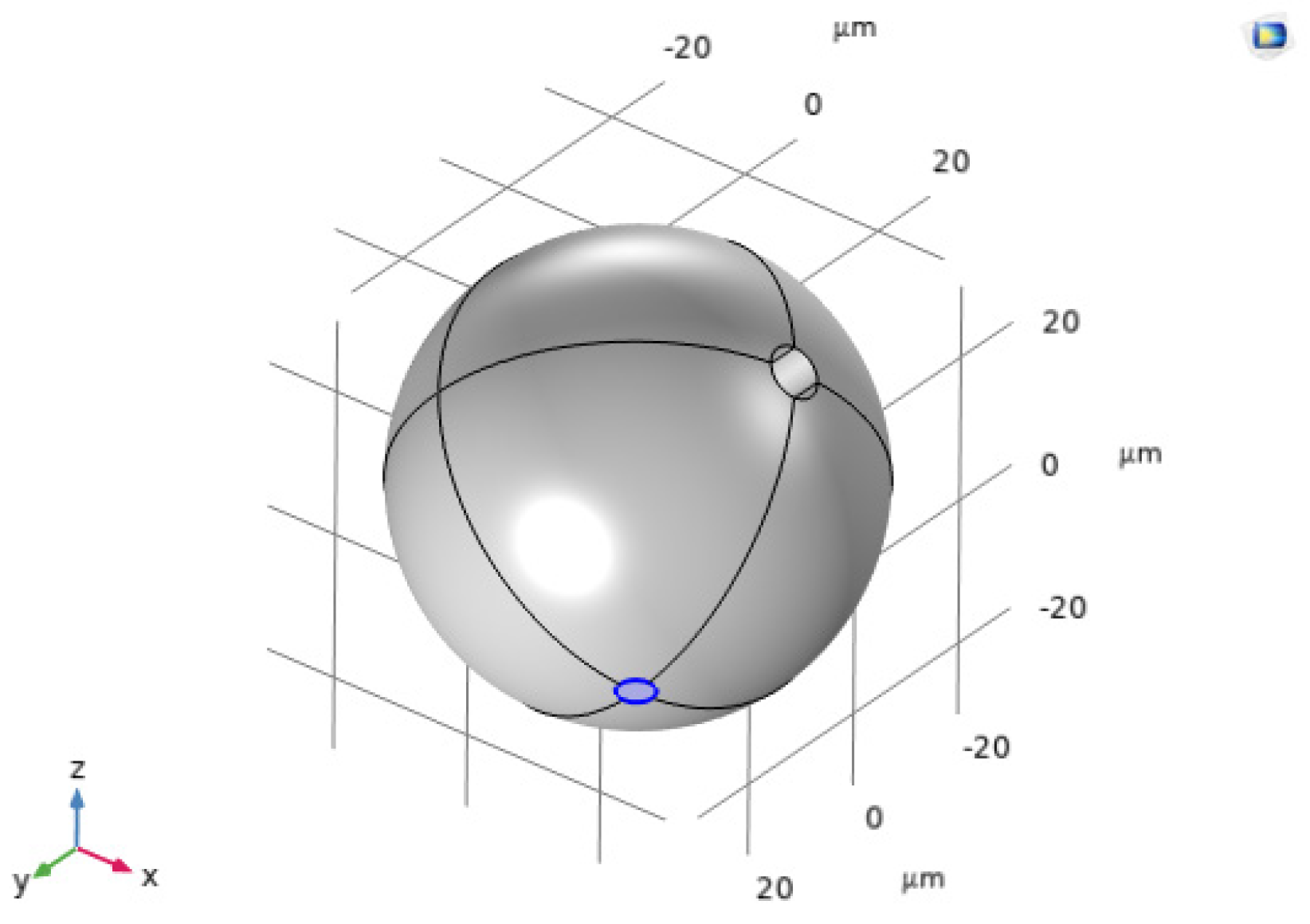

2.3.4. FEM Analysis of Matrix Tightening Stress

2.4. Molding of CFRTP Laminates

2.5. Evaluation of the Mechanical Properties of CFRTP Laminates

3. Results and Discussion of Interfacial Shear Strength

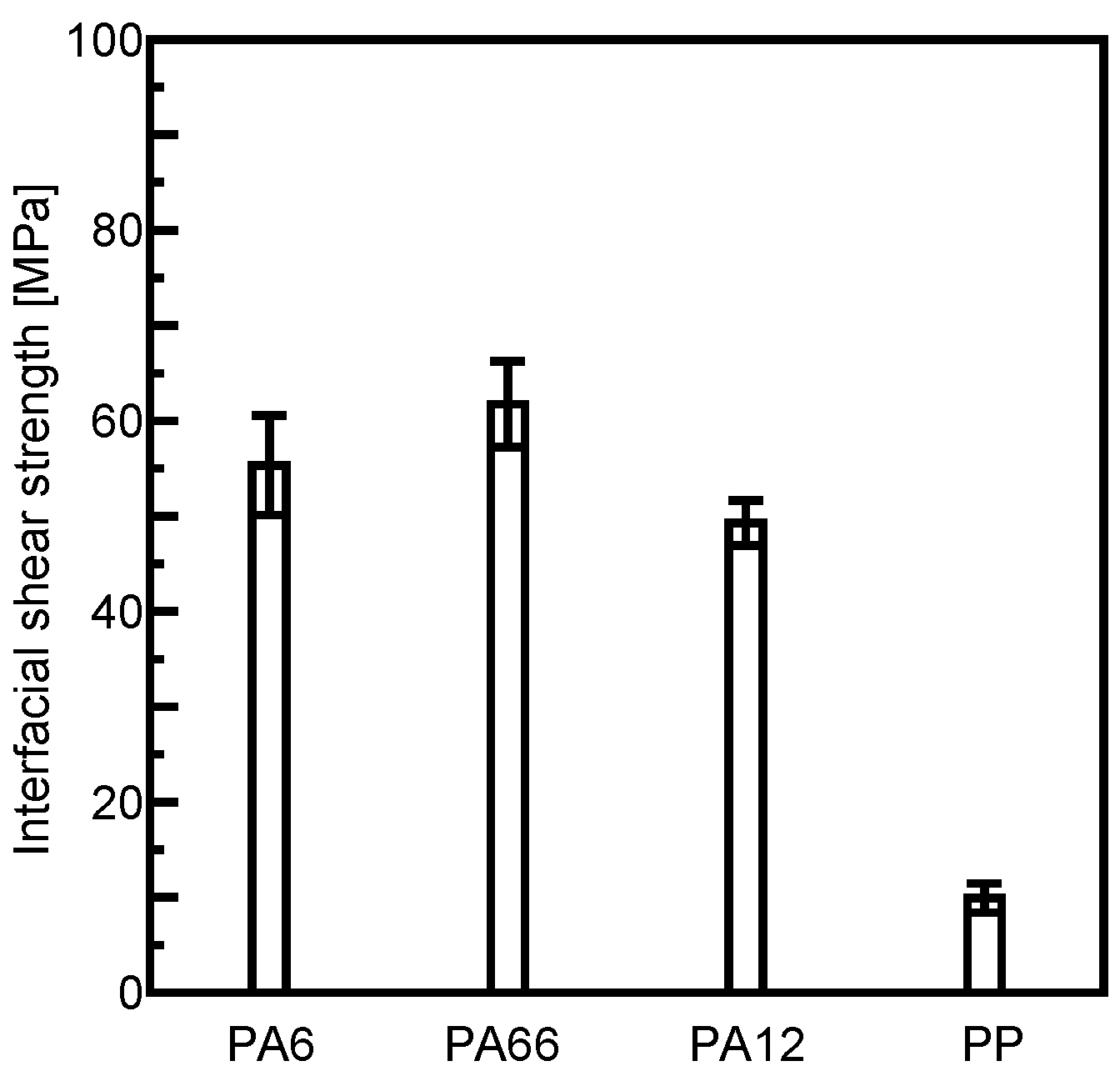

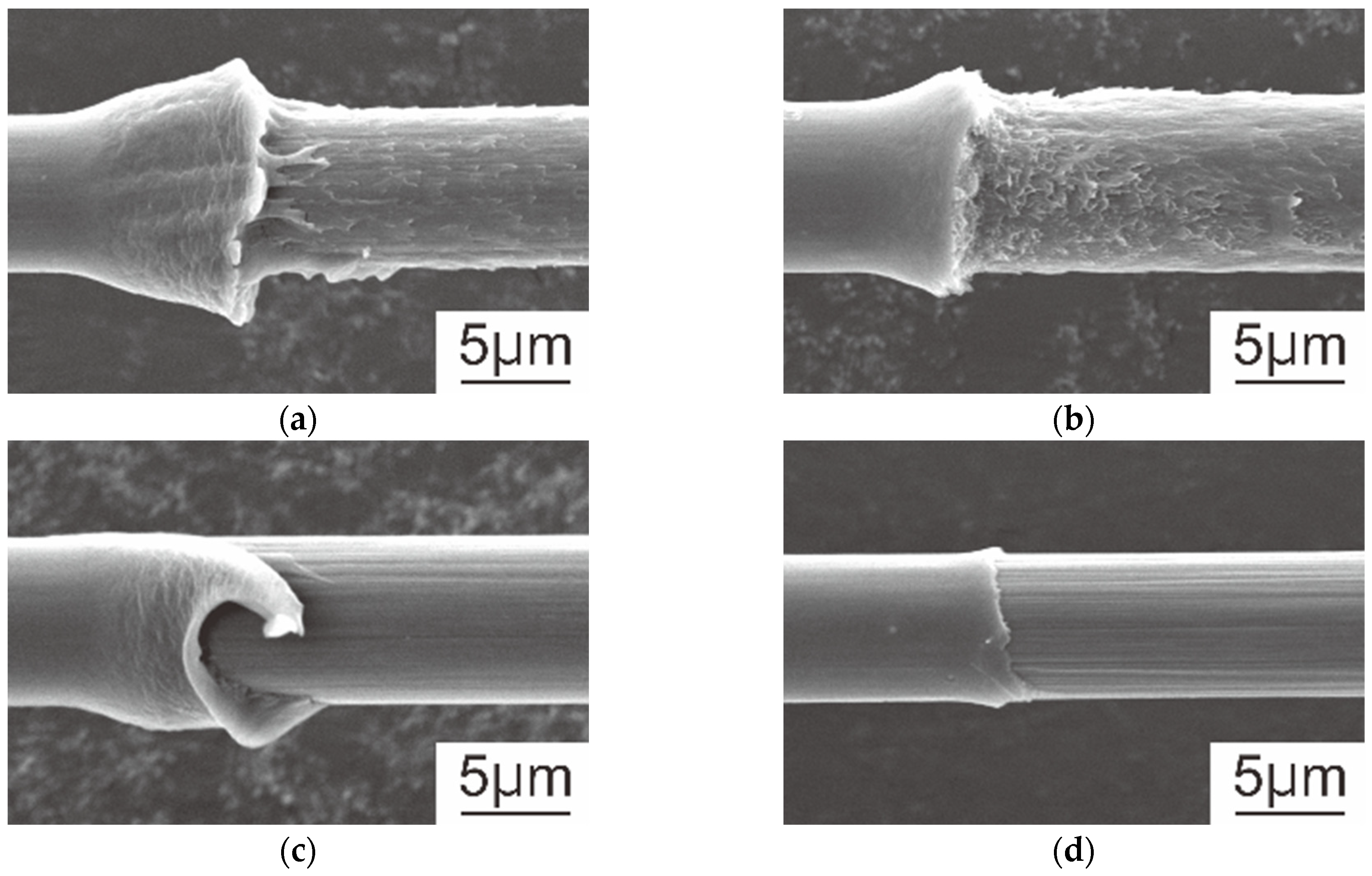

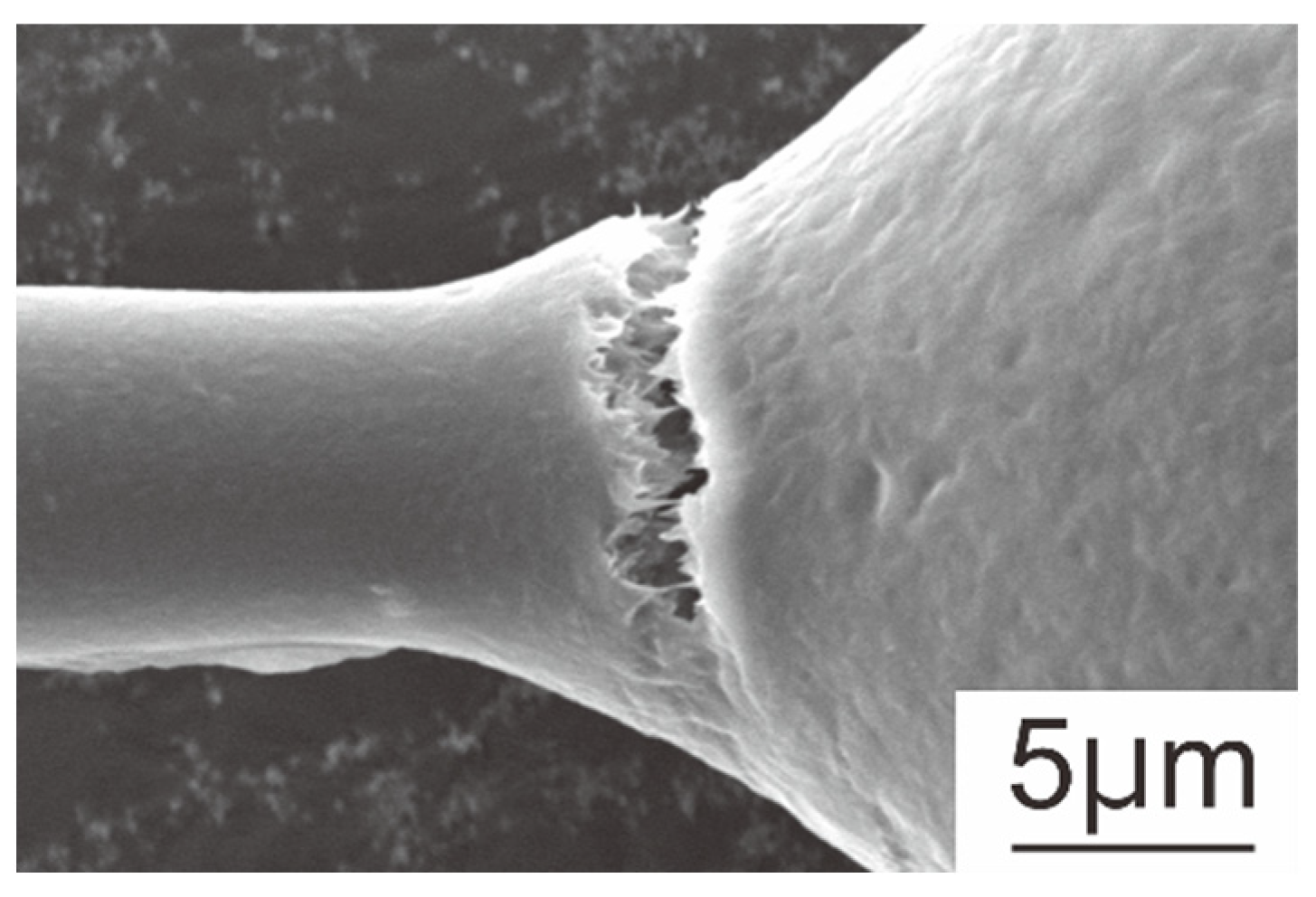

3.1. Microdroplet Test

3.2. Evaluation of Matrix Properties

3.3. Relationship Between Fiber–Matrix Interfacial Shear Strength and Matrix Properties

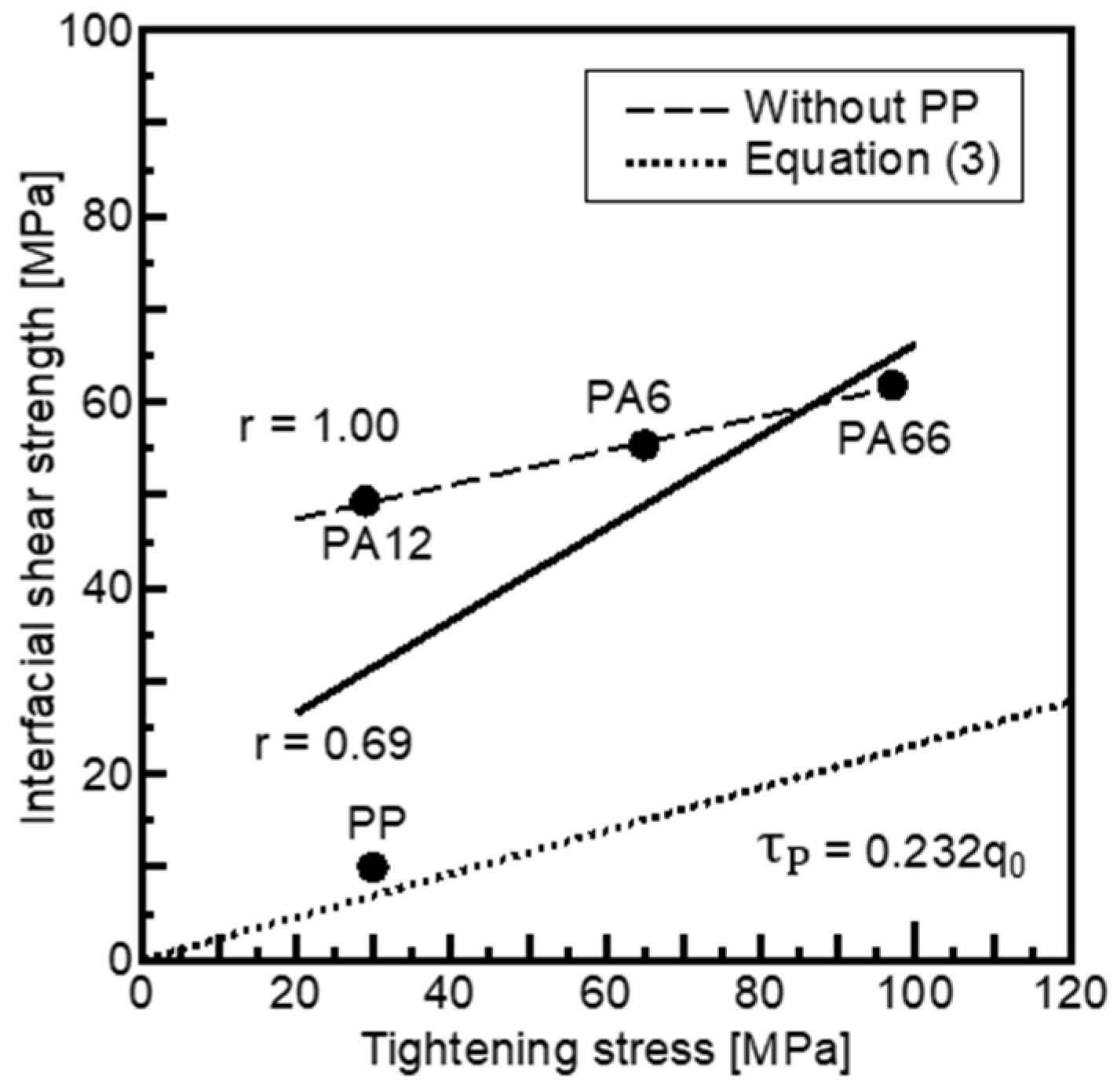

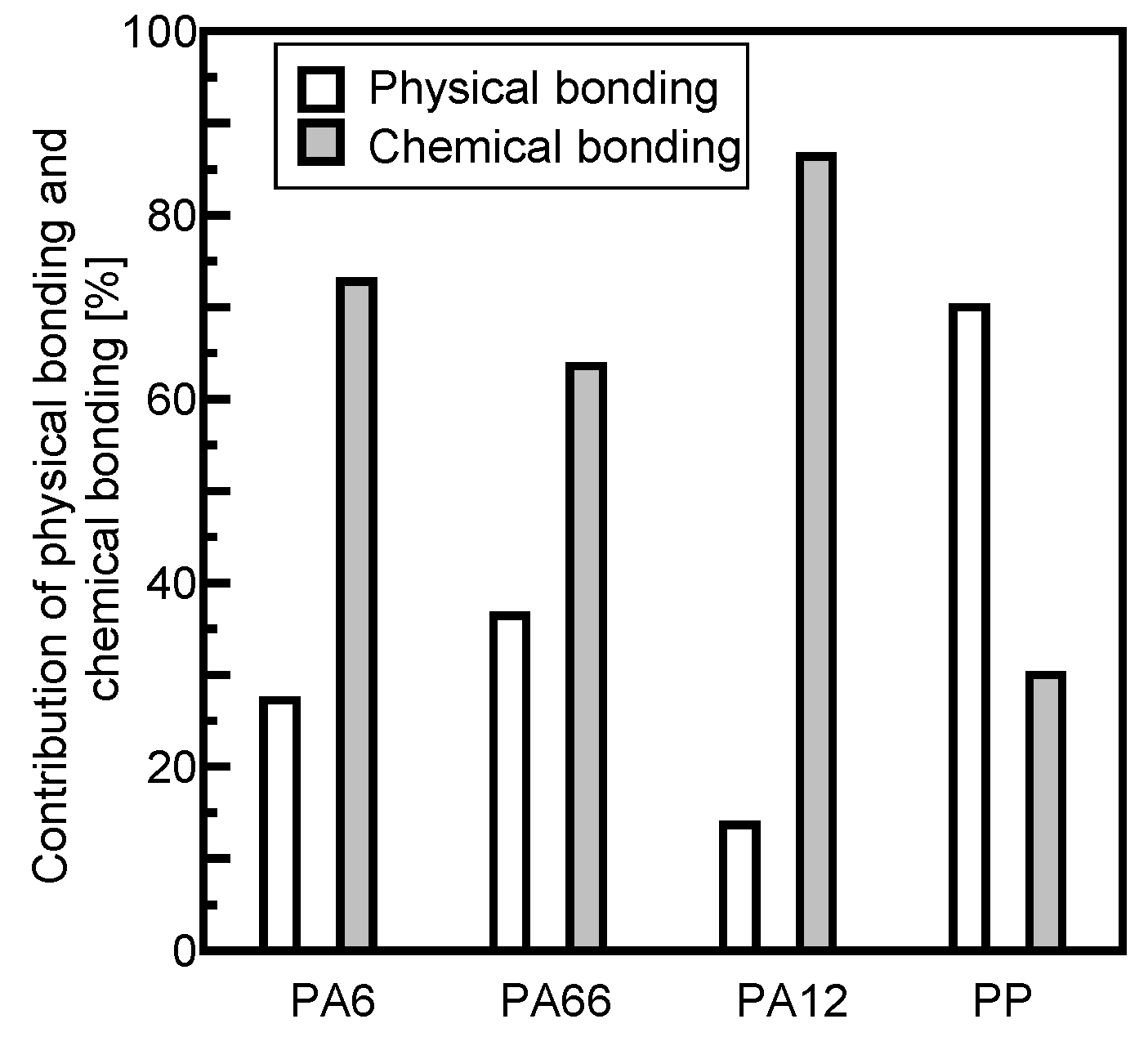

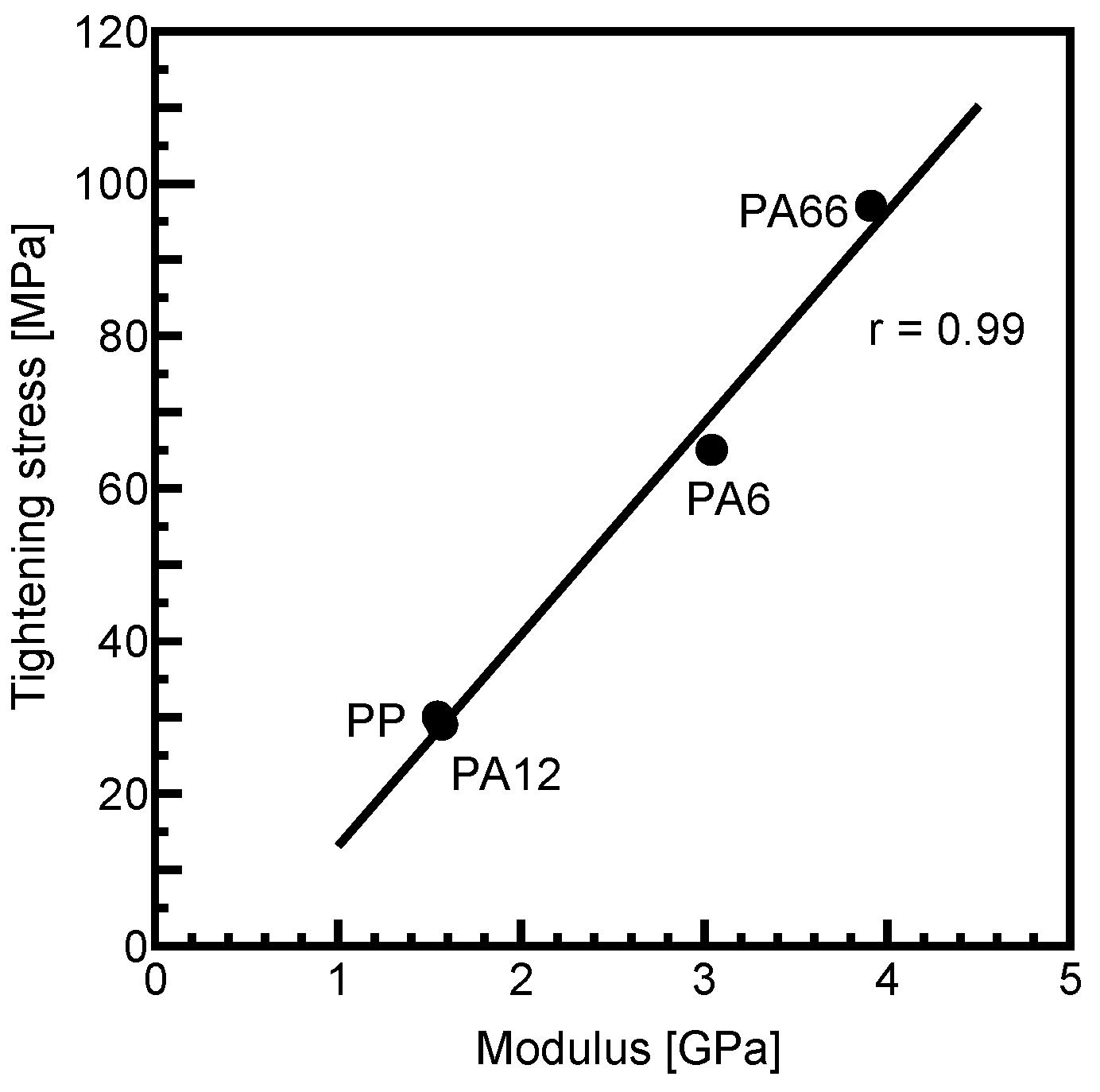

3.3.1. Relationship Between Fiber–Matrix Interfacial Shear Strength and Matrix Tightening Stress

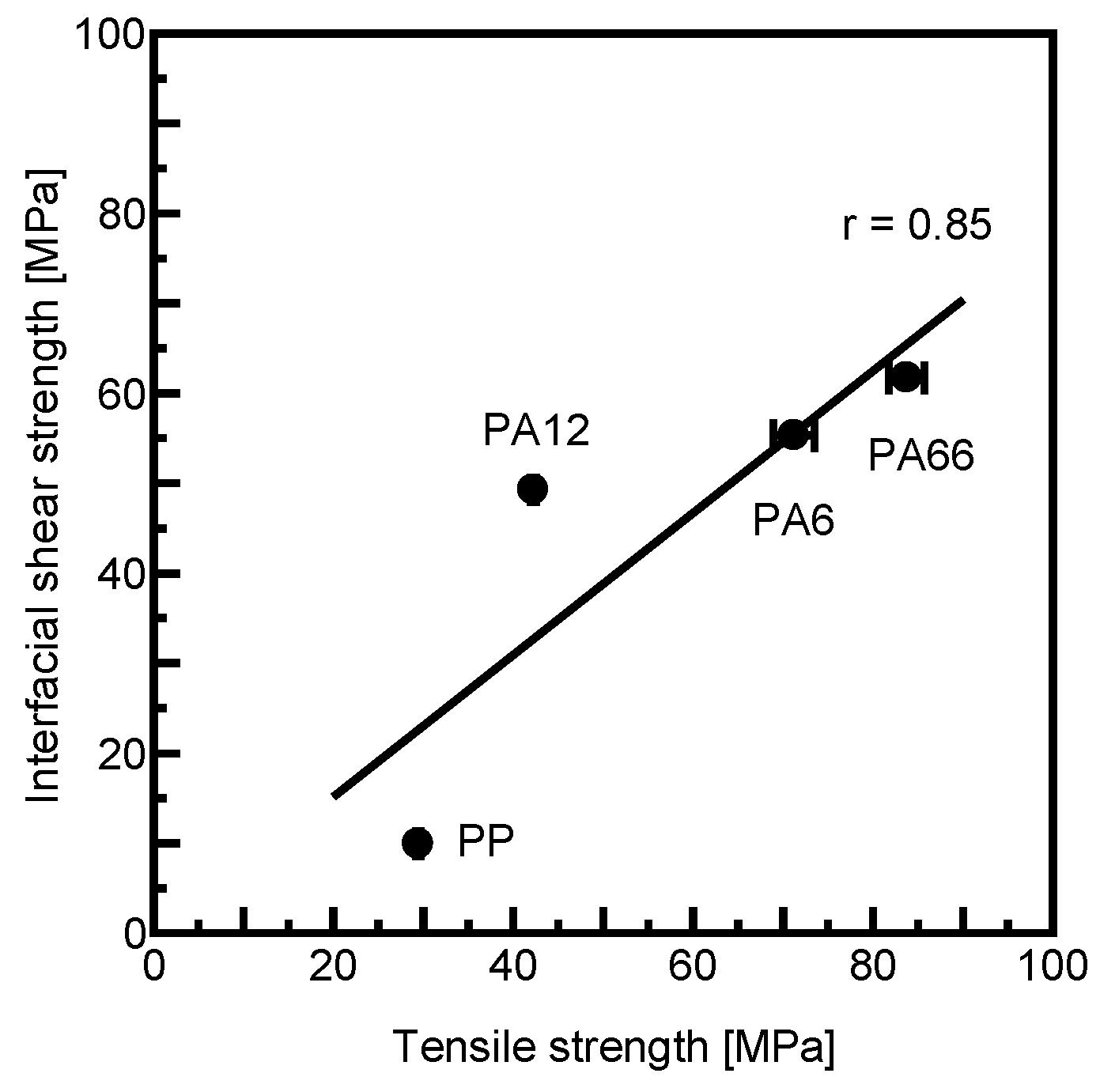

3.3.2. Relationship Between Fiber–Matrix Interfacial Shear Strength and Tensile Strength of Matrix

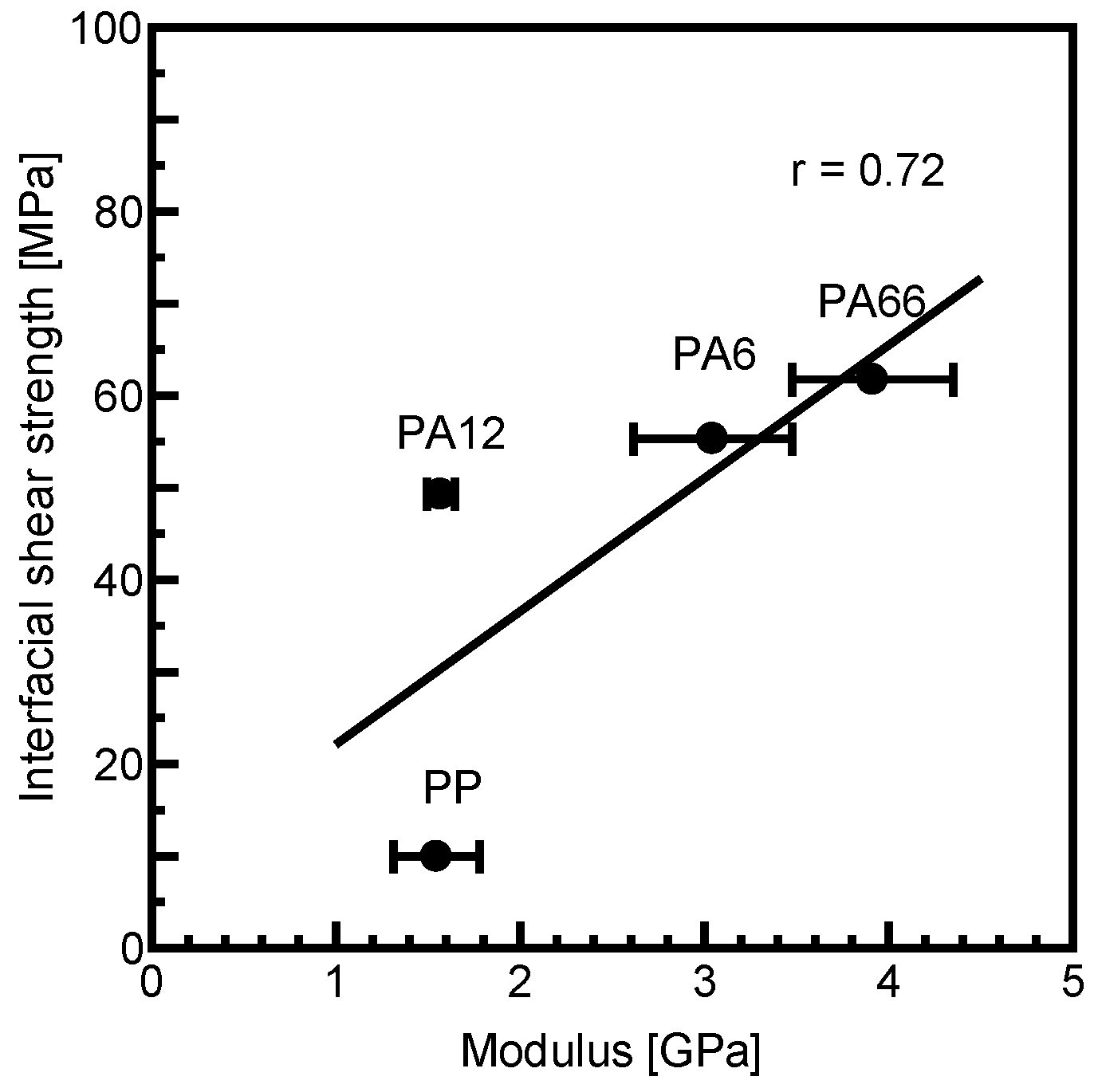

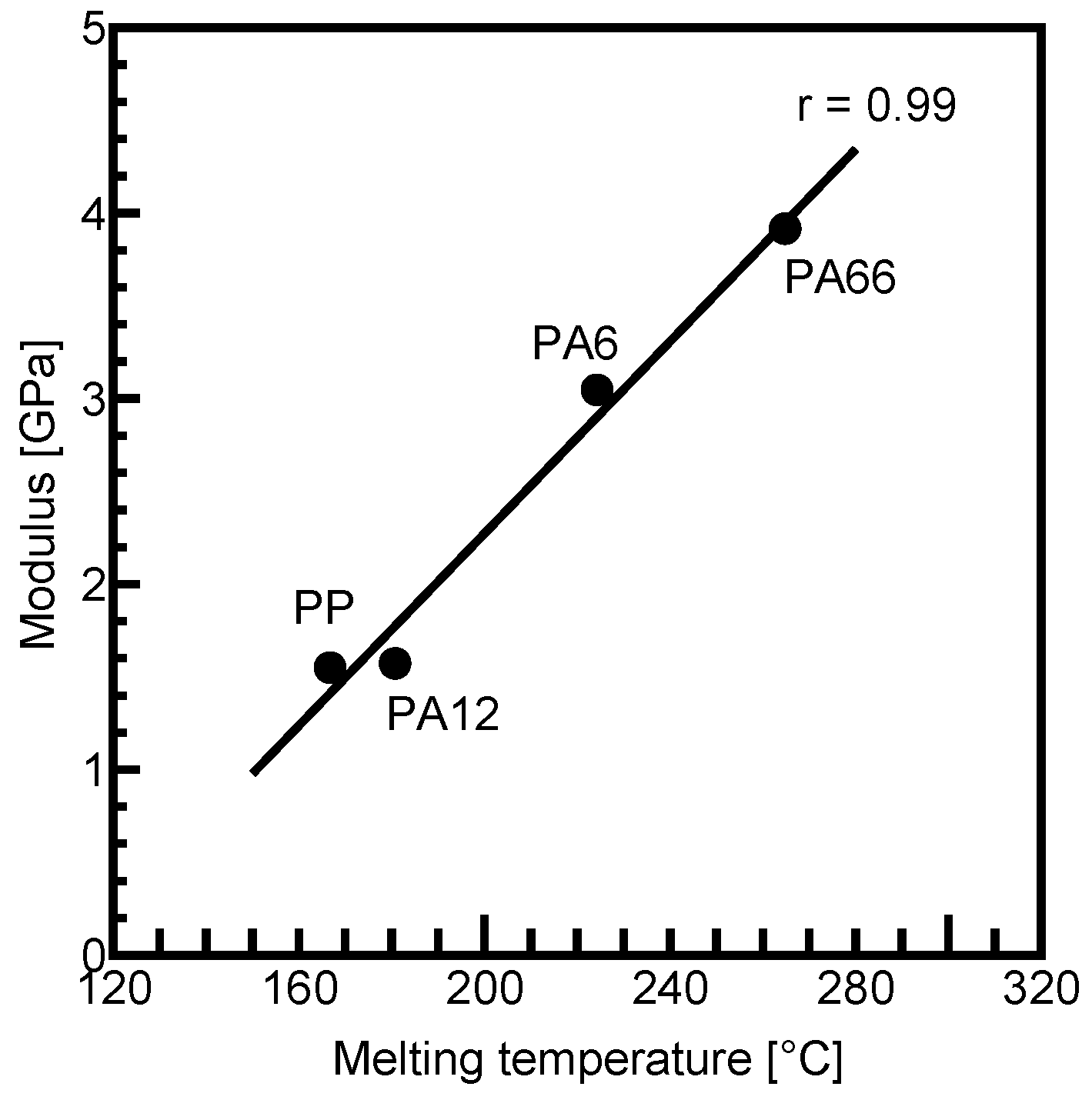

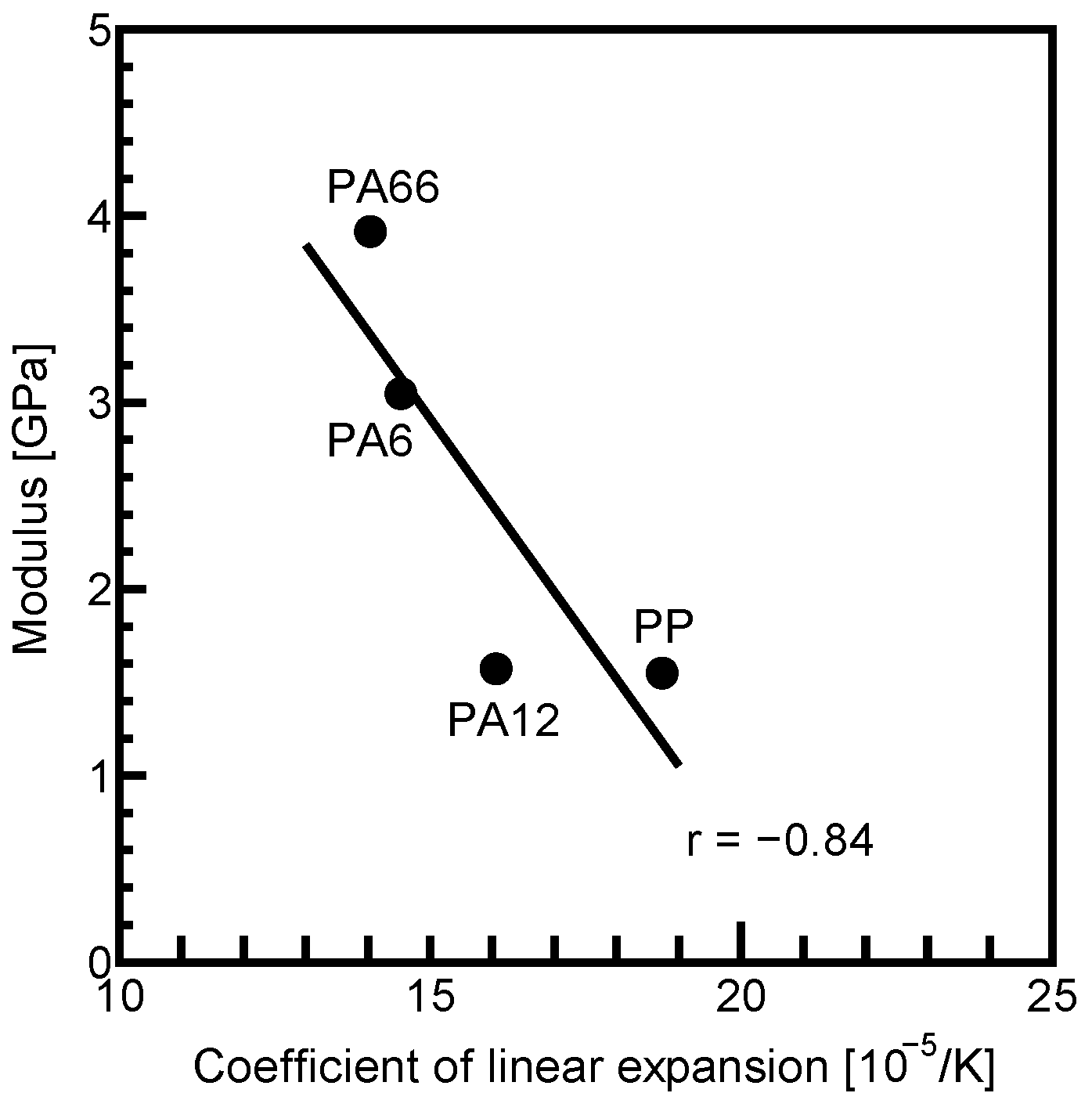

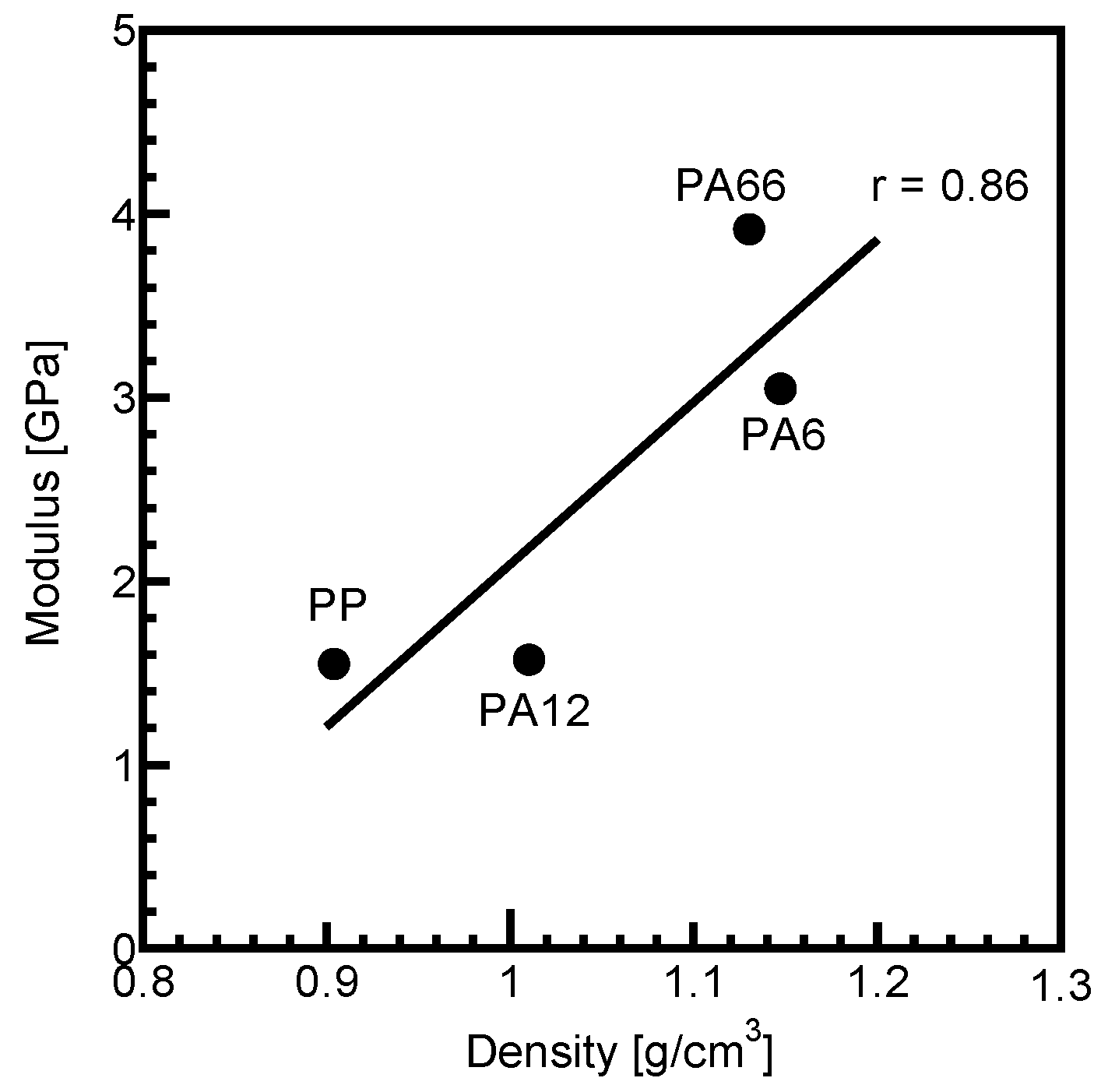

3.3.3. Relationship Between Fiber–Matrix Interfacial Shear Strength and Matrix Modulus

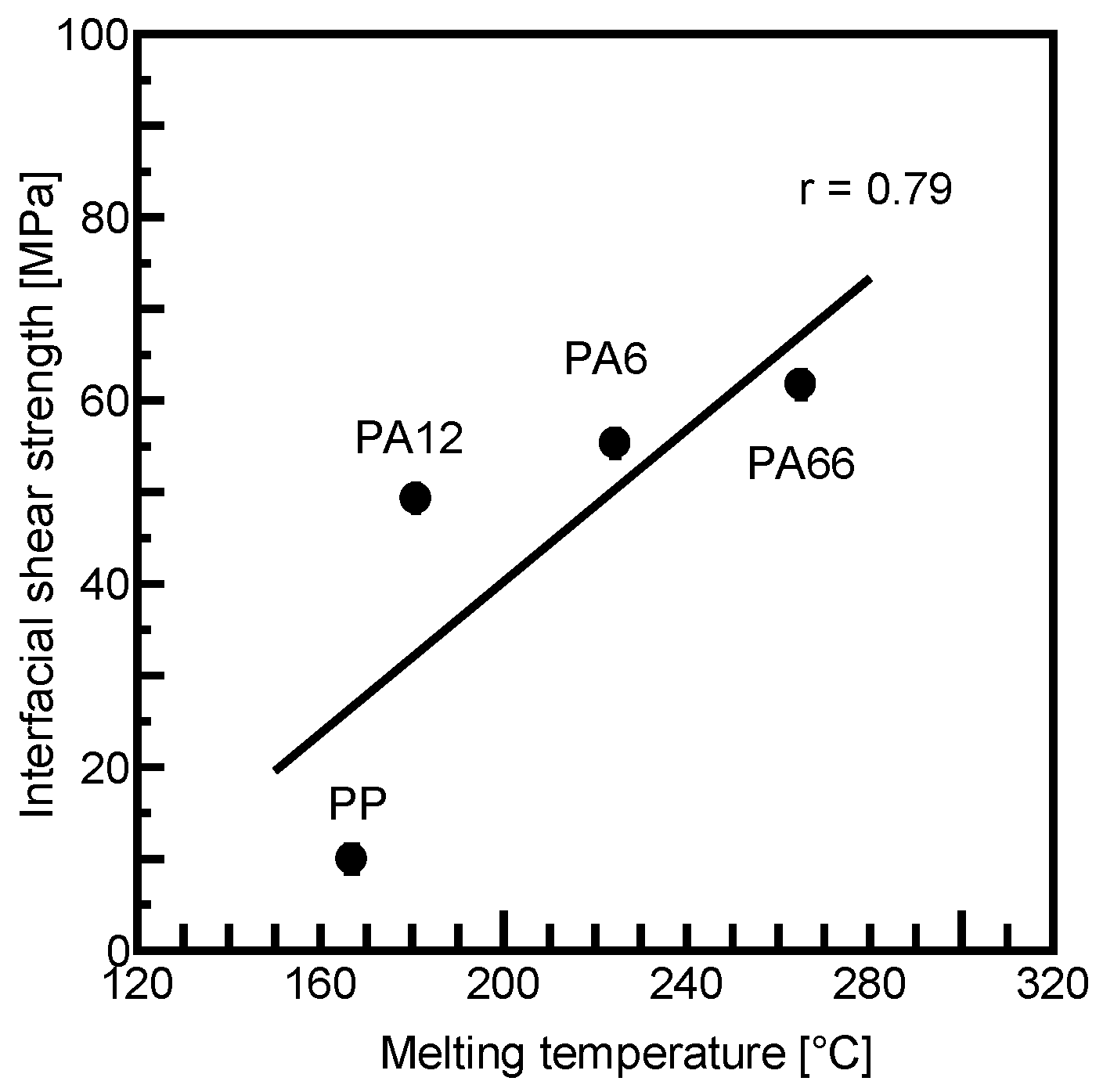

3.3.4. Relationship Between Fiber–Matrix Interfacial Shear Strength and Melting Temperature of Matrix

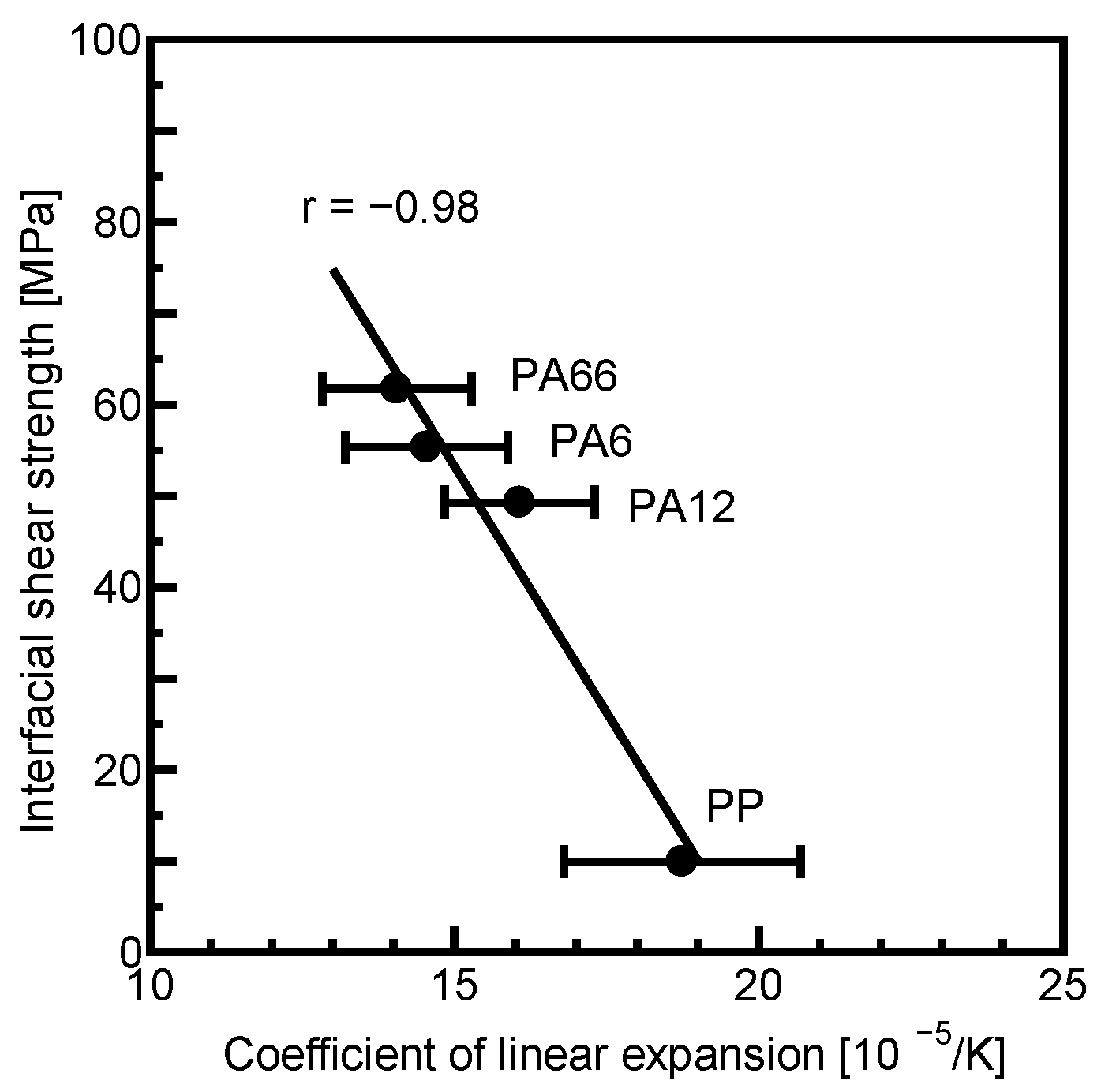

3.3.5. Relationship Between Fiber–Matrix Interfacial Shear Strength and Coefficient of Linear Expansion of Matrix

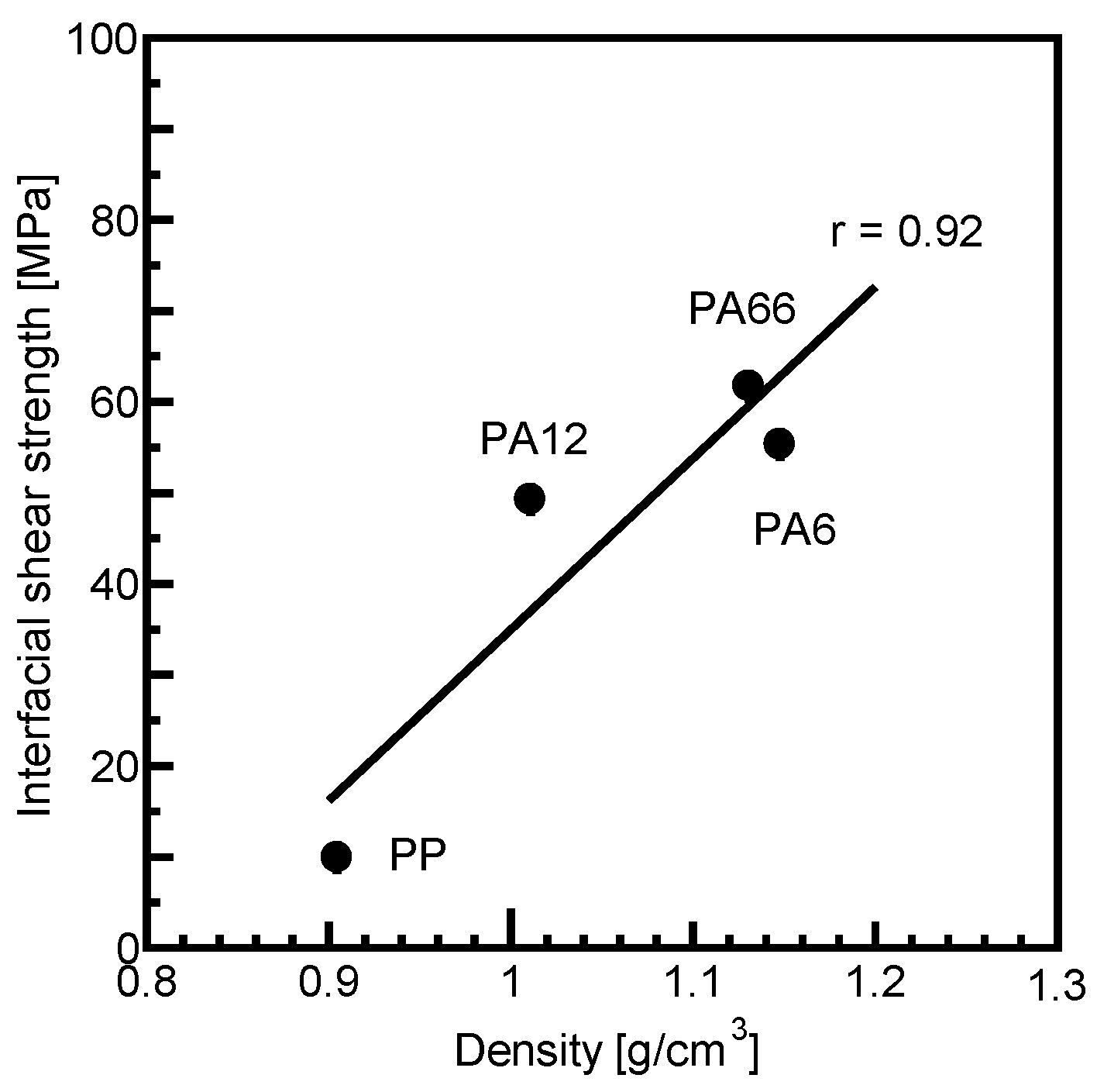

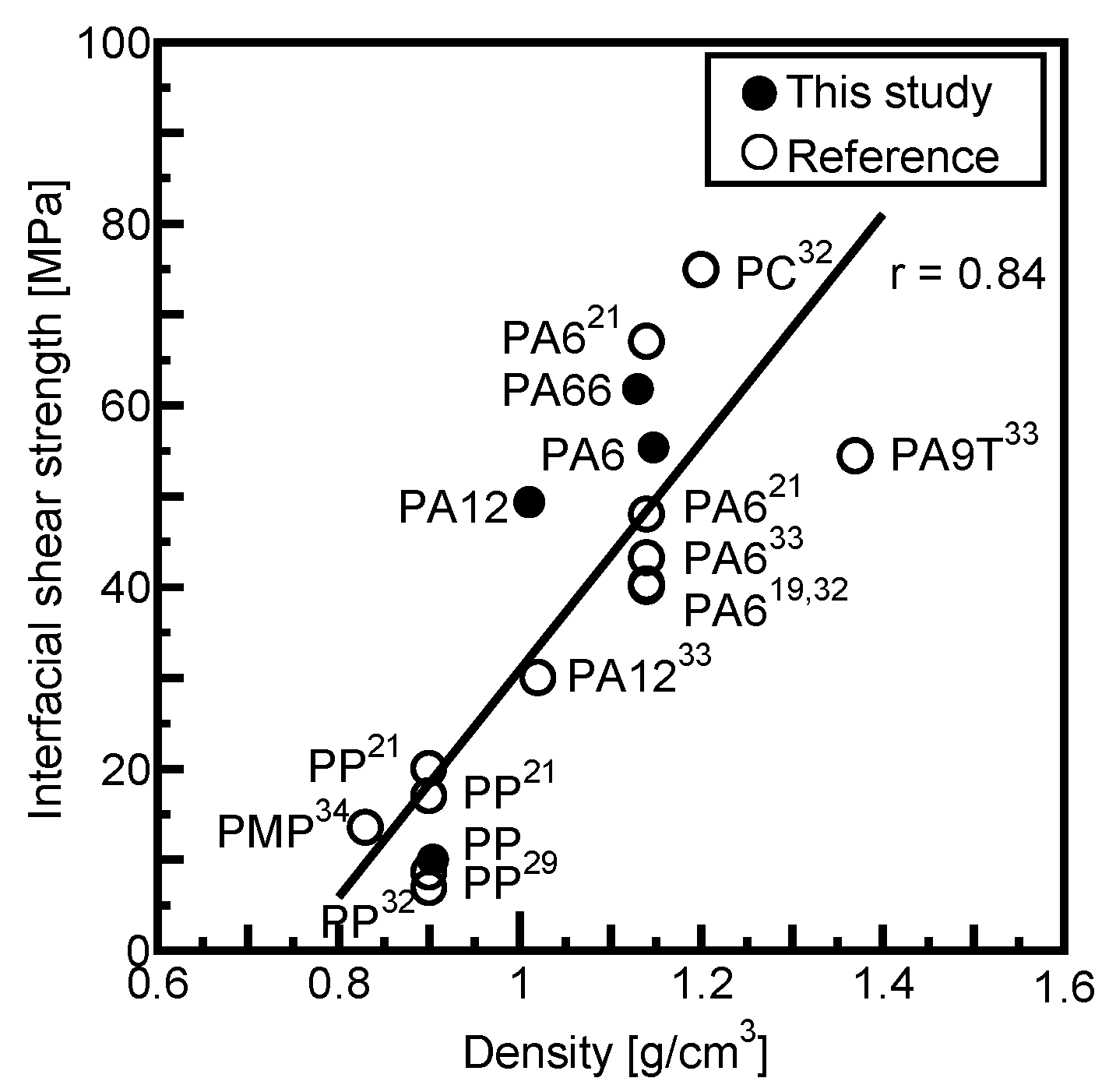

3.3.6. Relationship Between Fiber–Matrix Interfacial Shear Strength and Matrix Density

4. Results and Discussion of Mechanical Properties of CFRTP

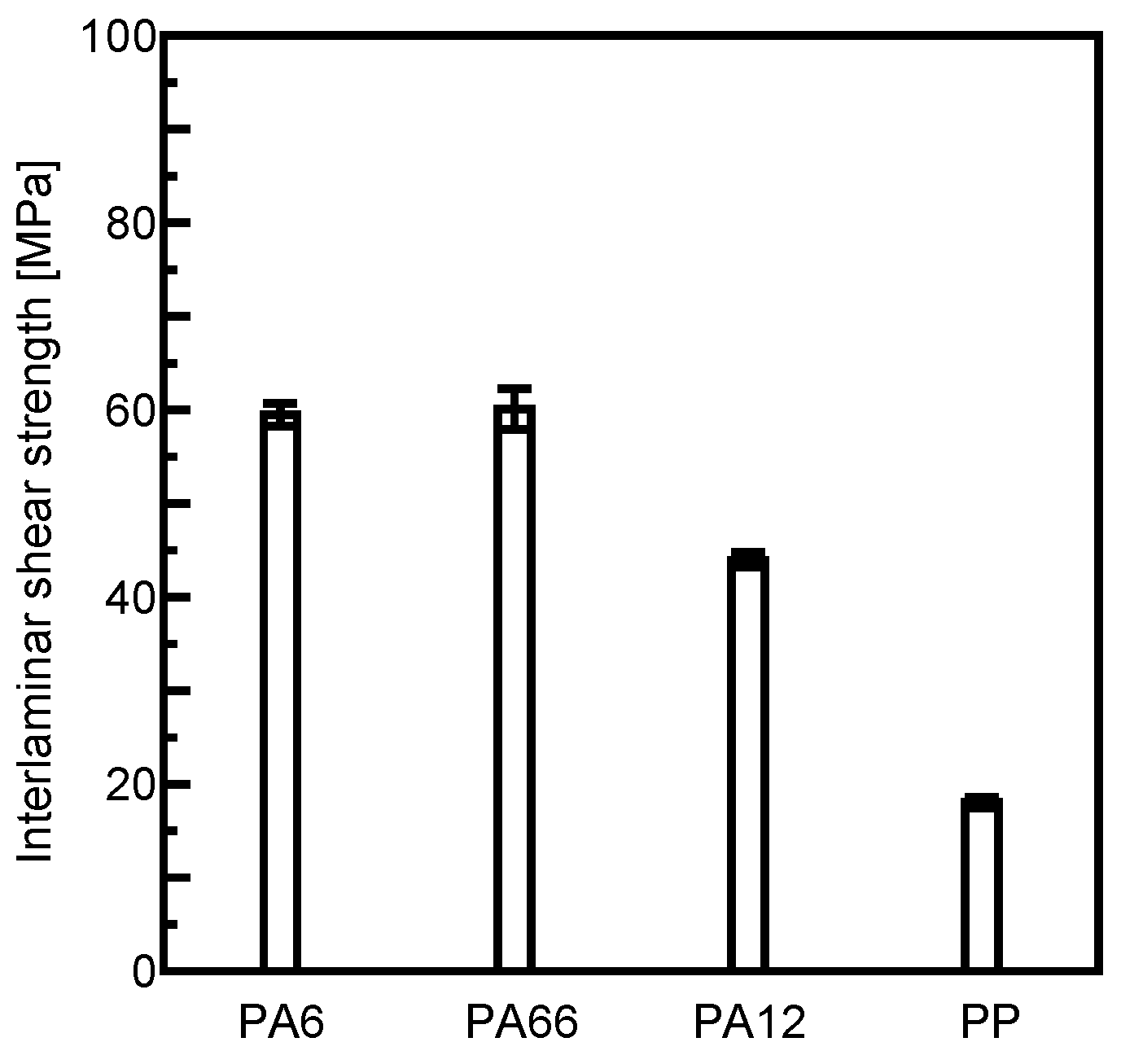

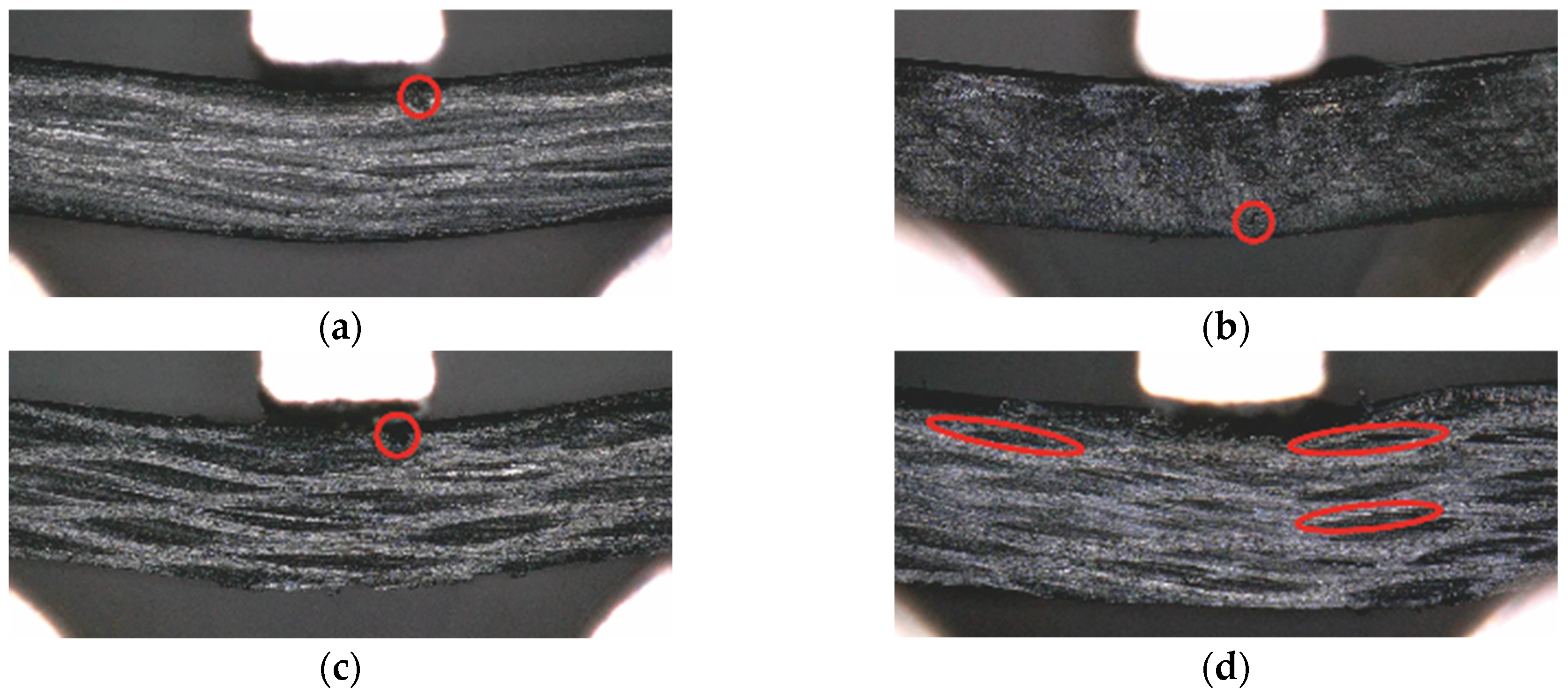

4.1. Short-Beam Three-Point Bending Test

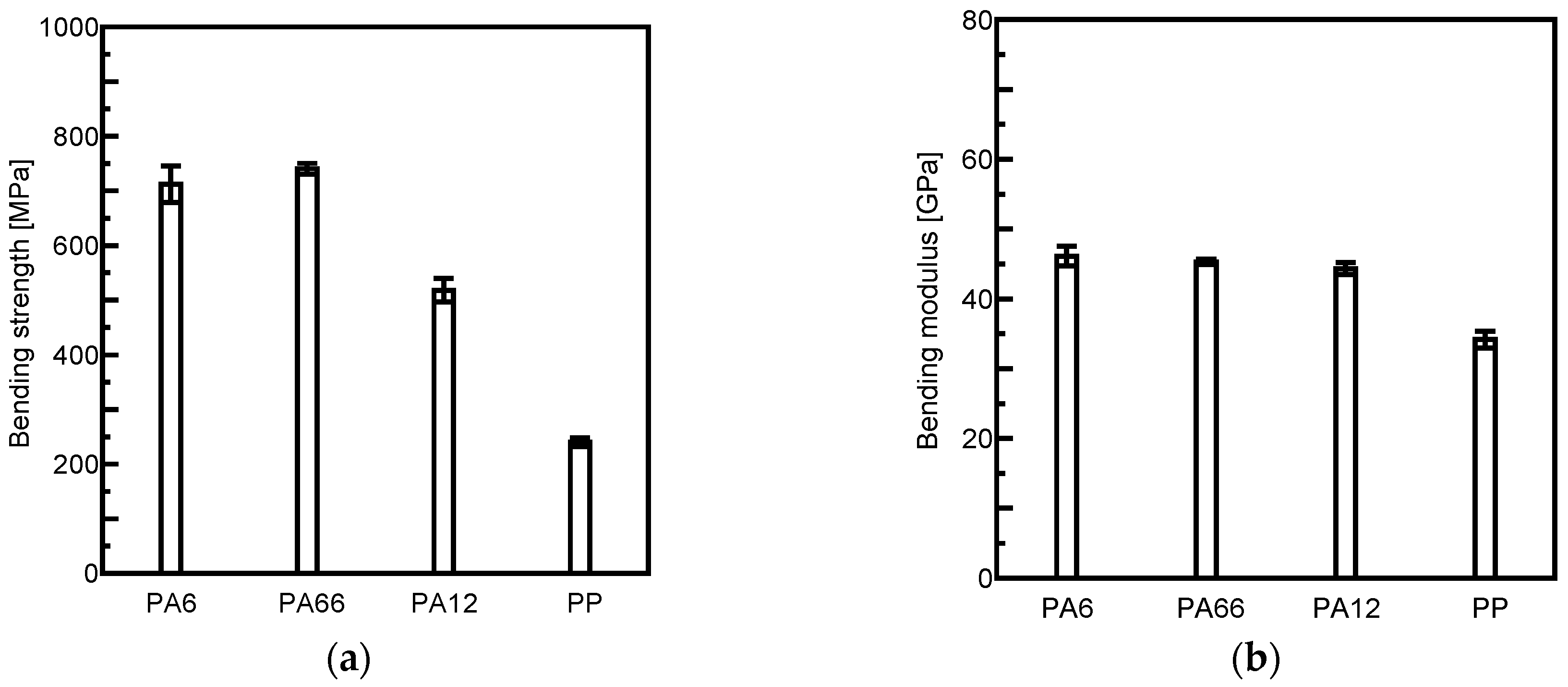

4.2. Three-Point Bending Test

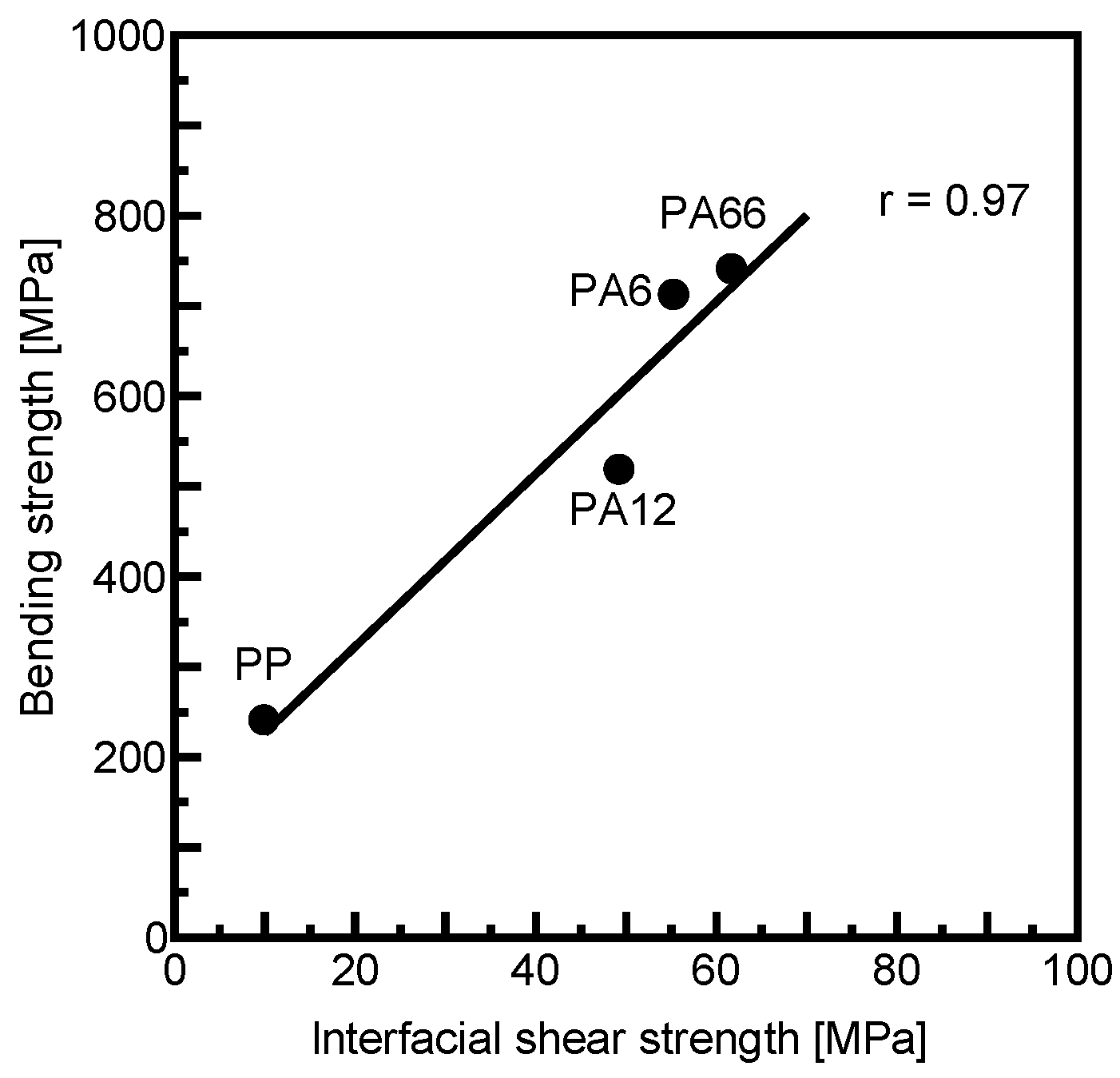

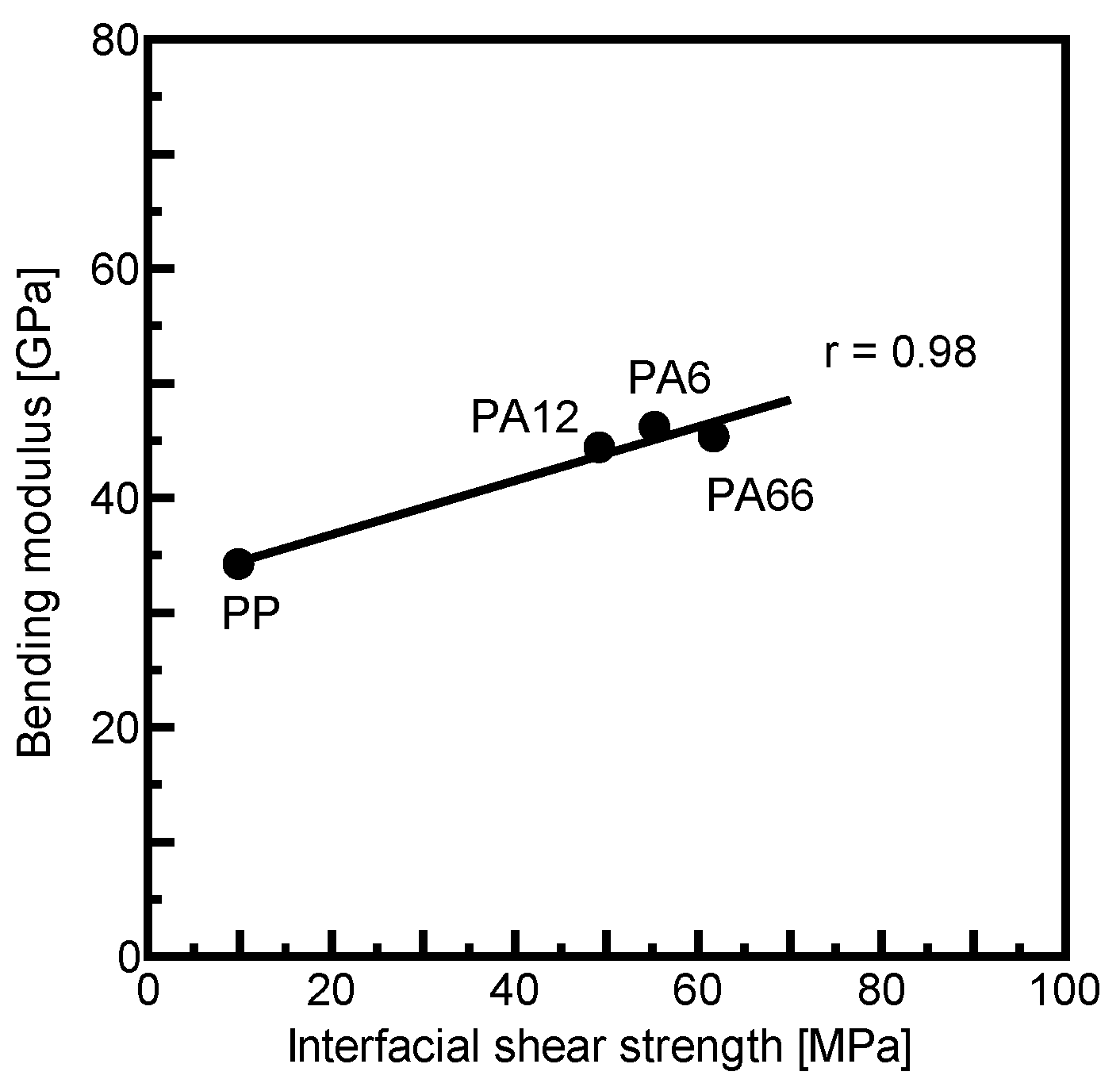

4.3. Relationship Between Mechanical Properties of CFRTP Laminates and Fiber–Matrix Interfacial Strength

5. Conclusions

- Fiber–matrix interfacial shear strength exhibited a positive correlation with matrix tightening stress, which constricts the fiber in the radial direction, as well as with matrix density, tensile strength, modulus, and melting temperature of each matrix. In contrast, it showed a negative correlation with the coefficient of linear expansion of the matrices.

- Higher fiber–matrix interfacial shear strength can be achieved by using a matrix with a higher density, even without direct evaluation of fiber–matrix interfacial strength, as fiber–matrix interfacial shear strength showed a strong positive correlation with matrix density.

- The mechanical properties of CFRTP laminates were enhanced when matrices with higher fiber–matrix interfacial shear strength were used.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mcauley, W.J. Global Sustainability and Key Needs in Future Automotive Design. Environ. Sci. Technol. 2003, 37, 5414–5416. [Google Scholar] [CrossRef]

- Warsen, J.; Krinke, S. The Life Cycle Approach at Volkswagen. ATZ Worldw. 2012, 114, 4–9. [Google Scholar] [CrossRef]

- Ishikawa, T.; Amaoka, K.; Masubuchi, Y.; Yamamoto, T.; Yamanaka, A.; Arai, M.; Takahashi, J. Overview of Automotive Structural Composites Technology Developments in Japan. Compos. Sci. Technol. 2018, 155, 221–246. [Google Scholar] [CrossRef]

- Sugawara, Z.; Togami, K.; Okabe, R. Approach to Advanced Composite Material Technology to Realize Weight Reduction of Future Aircraft toward Decarbonization of Air Transportation. Mitsubishi Heavy Ind. Tech. Rev. 2022, 59, 4. Available online: https://www.mhi.co.jp/technology/review/en/abstracte-59-4-170.html (accessed on 5 February 2025).

- Wazeer, A.; Das, A.; Abeykoon, C.; Sinha, A.; Karmakar, A. Composites for electric vehicles and automotive sector: A review. Green Energy Intell. Transp. 2023, 2, 100043. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, J. Advanced lightweight materials for Automobiles: A review. Mater. Des. 2022, 221, 110994. [Google Scholar] [CrossRef]

- Siengchin, S. A Review on Lightweight Materials for Defence Applications: Present and Future Developments. Def. Technol. 2023, 24, 1–17. [Google Scholar] [CrossRef]

- Verpoest, I. History of Composites Volume 2: The Last 50 Years and the Future. Available online: https://reader.jeccomposites.com/reader/cbe5360b-ec87-405c-92af-a828560cf720?origin=%2Fcatalog%2F50-years-of-composites%2F50-years-of-composites%2Fn2-2023 (accessed on 14 January 2025).

- Marsh, G. Reinforced thermoplastics, the next wave? Reinf. Plast. 2014, 58, 24–28. [Google Scholar] [CrossRef]

- Mohammadi, H.; Ahmad, Z.; Mazlan, A.S.; Johari, F.A.M.; Siebert, G.; Petrů, M.; Koloor, R.S.S. Lightweight Glass Fiber-Reinforced Polymer Composite for Automotive Bumper Applications: A Review. Polymers 2023, 15, 193. [Google Scholar] [CrossRef]

- Kim, J.K.; Mai, Y.W. Engineered Interfaces in Fiber Reinforced Composites; Elsevier Science: Amsterdam, The Netherlands, 1998. [Google Scholar]

- Mahboubizadeh, S.; Sadeq, A.; Arzaqi, Z.; Ashkani, O.; Samadoghli, M. Advancements in fiber-reinforced polymer (FRP) composites: An extensive review. Discov. Mater. 2024, 4, 22. [Google Scholar] [CrossRef]

- Jesson, A.D.; Watts, F.J. The Interface and Interphase in Polymer Matrix Composites: Effect on Mechanical Properties and Methods for Identification. Polym. Rev. 2012, 52, 321–354. [Google Scholar] [CrossRef]

- Li, J. Effect of carbon fiber surface treatment with HNO3 and KOH on the interfacial bonding of PMMA resin composite. Mater. Sci. Pol. 2023, 41, 301–310. [Google Scholar] [CrossRef]

- Pawlak, M.A.; Górny, T.; Dopierała, Ł.; Paczos, P. The Use of CFRP for Structural Reinforcement-Literature Review. Metals 2022, 12, 1470. [Google Scholar] [CrossRef]

- Ji, X.; Dai, Y.; Zheng, B.L.; Ye, L.; Mai, Y.W. Interface end theory and re-evaluation in interfacial strength test methods. Compos. Interfaces 2003, 10, 567–580. [Google Scholar] [CrossRef]

- Nishida, H.; Okubo, K.; Fujii, T.; Carvelli, V. Improvement of Bending Strength of Carbon Fiber/Thermoplastic Epoxy Composites-Effects of Molecular Weight of Epoxy on Carbon Fiber/Matrix Interfacial Strength and Connection of Cracks in Matrix. Open J. Compos. Mater. 2017, 7, 207–217. [Google Scholar] [CrossRef]

- Wang, X.; Xu, D.; Liu, H.Y.; Zhou, H.; Mai, Y.W.; Yang, J.; Li, E. Effects of thermal residual stress on interfacial properties of polyphenylene sulphide/carbon fibre (PPS/CF) composite by microbond test. J. Mater. Sci. 2015, 51, 334–343. [Google Scholar] [CrossRef]

- Tanaka, K.; Morioka, N.; Kawaguchi, M.; Watanabe, K. Effect of Silica Addition to Resin on Fiber Matrix Interfacial Shear Strength of Carbon Fiber Reinforced Polyamide Resin at High Temperature. J. Soc. Mater. Sci. Jpn. 2022, 71, 501–507. [Google Scholar] [CrossRef]

- Aratani, Y.; Kobori, H.; Tanaka, K. Effect of Interfacial Chemical and Physical Bonding on The Interfacial Shear Strength of Glass Fiber/Polyamide Resin and Mechanical Properties of The Composites. J. Soc. Mater. Sci. Jpn. 2023, 72, 697–704. [Google Scholar] [CrossRef]

- Tanaka, K.; Okuda, S.; Katayama, T. Effect of Air Oxidation of Carbon Fiber on Interfacial Shear Strength of Carbon Fiber Reinforced Thermoplastics. J. Soc. Mater. Sci. Jpn. 2020, 69, 358–364. [Google Scholar] [CrossRef]

- Weng, P.; Prasad, V.; Rao, S.P.; O’Dowd, N.; Murphy, N.; Ivankovic, A.; Scarselli, G. Interfacial properties of carbon fiber-reinforced biobased resin composites by single fiber fragmentation, fiber push-out, and interlaminar shear strength. Polym. Compos. 2024, 45, 3355–3369. [Google Scholar] [CrossRef]

- Irisawa, T.; Inagaki, R.; Iida, J.; Iwamura, R.; Ujihara, K.; Kobayashi, S.; Tanabe, Y. The influence of oxygen containing functional groups on carbon fibers for mechanical properties and recyclability of CFRTPs made with in-situ polymerizable polyamide 6. Compos. Part A 2018, 112, 91–99. [Google Scholar] [CrossRef]

- Zhao, G.L.; Warrior, A.N.; Long, C.A. A micromechanical study of residual stress and its effect on transverse failure in polymer-matrix composites. Int. J. Solids Struct. 2006, 43, 5449–5467. [Google Scholar] [CrossRef]

- Liu, W.B.; Zhang, S.; Hao, L.F.; Jiao, W.C.; Yang, F.; Li, X.F.; Wang, R.G. Interfacial Shear Strength in Carbon Fiber-Reinforced Poly (phthalazinone ether ketone) Composites. Polym. Compos. 2013, 34, 1921–1926. [Google Scholar] [CrossRef]

- Thomason, L.J.; Yang, L. Temperature dependence of the interfacial shear strength in glass-fibre polypropylene composites. Compos. Sci. Technol. 2011, 71, 1600–1605. [Google Scholar] [CrossRef]

- Herrera-Franco, J.P.; Valadez-González, A. A study of the mechanical properties of short natural-fiber reinforced composites. Compos. Part B 2005, 36, 597–608. [Google Scholar] [CrossRef]

- Fu, S.Y.; Feng, X.Q.; Lauke, B.; Mai, Y.W. Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate-polymer composites. Compos. Part B 2008, 39, 933–961. [Google Scholar] [CrossRef]

- Arao, Y.; Yumitori, S.; Suzuki, H.; Tanaka, T.; Tanaka, K.; Katayama, T. Mechanical properties of injection-molded carbon fiber/polypropylene composites hybridized with nanofillers. Compos. Part A 2013, 55, 19–26. [Google Scholar] [CrossRef]

- Ashby, F.M. Materials Selection in Mechanical Design, 5th ed.; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Aratani, Y.; Okuda, S.; Tanaka, K. Effects of Cooling Speed of Specimen at Preparation, Temperature during Test and Sizing agent on Glass Fiber / Polyamide Resin Interfacial Shear Strength. J. Soc. Mater. Sci. Jpn. 2021, 70, 684–689. [Google Scholar] [CrossRef]

- Tanaka, K.; Kashihara, H.; Katayama, T. Vacuum Assisted High Speed Compression Molding and Evaluation of Mechanical Properties of Continuous Carbon Fiber Reinforced Polycarbonate Composite. J. Soc. Mater. Sci. Jpn. 2011, 60, 251–258. [Google Scholar] [CrossRef]

- Tanaka, K.; Hosoo, N.; Katayama, T. Effects of Temperature on the Fiber Matrix Interfacial Properties of Carbon Fiber Reinforced Highly Heat Resistant Polyamide Resin. J. Soc. Mater. Sci. Jpn. 2017, 66, 746–751. [Google Scholar] [CrossRef]

- Yokozeki, T.; Kobayashi, Y.; Arai, H.; Otani, A.; Nakai, A.; Goto, K. Characterization of Mechanical Properties of CFRP Using Thermoplastic Matrix without Moisture Absorption. J. Jpn. Soc. Compos. Mater. 2016, 42, 163–168. [Google Scholar] [CrossRef]

- Hirai, M.; Nishijima, S.; Toda, Y. Study on Interlaminar Shear Strength Test Method of Fiber Reinforced Organic Composite Materials. Cryog. Supercond. Soc. Jpn. 2022, 57, 155–159. [Google Scholar] [CrossRef]

- Dong, Y.; Zhu, Y.; Zhao, Y.; Liu, F.; Wang, E.; Fu, Y. Enhance interfacial properties of glass fiber/epoxy composites with environment-friendly water-based hybrid sizing agent. Compos. Part A 2017, 102, 357–367. [Google Scholar] [CrossRef]

| PA6 | PA66 | PA12 | PP | |

|---|---|---|---|---|

| Environment | Under atmospheric conditions | |||

| Heating rate | 10 °C/min | |||

| Initial load | 50 gf (490 mN) | |||

| Temperature range | 30 °C to 190 °C | 30 °C to 230 °C | 30 °C to 150 °C | 30 °C to 130 °C |

| Dimensional change from 180 °C to 190 °C | Dimensional change from 220 °C to 230 °C | Dimensional change from 140 °C to 150 °C | Dimensional change from 120 °C to 130 °C | |

| Dimension at 180 °C | Dimension at 220 °C | Dimension at 140 °C | Dimension at 120 °C | |

| 10 °C | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tanaka, K.; Sakakibara, R. Effects of Matrix Properties on the Interfacial Shear Strength Between Carbon Fiber and Various Thermoplastic Polymers, and Their Influence on the Mechanical Properties of Composites. J. Compos. Sci. 2025, 9, 174. https://doi.org/10.3390/jcs9040174

Tanaka K, Sakakibara R. Effects of Matrix Properties on the Interfacial Shear Strength Between Carbon Fiber and Various Thermoplastic Polymers, and Their Influence on the Mechanical Properties of Composites. Journal of Composites Science. 2025; 9(4):174. https://doi.org/10.3390/jcs9040174

Chicago/Turabian StyleTanaka, Kazuto, and Ryota Sakakibara. 2025. "Effects of Matrix Properties on the Interfacial Shear Strength Between Carbon Fiber and Various Thermoplastic Polymers, and Their Influence on the Mechanical Properties of Composites" Journal of Composites Science 9, no. 4: 174. https://doi.org/10.3390/jcs9040174

APA StyleTanaka, K., & Sakakibara, R. (2025). Effects of Matrix Properties on the Interfacial Shear Strength Between Carbon Fiber and Various Thermoplastic Polymers, and Their Influence on the Mechanical Properties of Composites. Journal of Composites Science, 9(4), 174. https://doi.org/10.3390/jcs9040174