Optimization of Innovative Hybrid Polylactic Acid+ and Glass Fiber Composites: Mechanical, Physical, and Thermal Evaluation of Woven Glass Fiber Reinforcement in Fused Filament Fabrication 3D Printing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Specimen Manufacturing Procedure

- (a)

- Initial Layer:

- (b)

- Glass Fiber Addition:

- (c)

- Next Layer:

- (d)

- Layer Variation:

- 0 layers: PLA+ only. (t = 3 mm)

- 1 layer: Glass fiber added at 50% of the printing process (t = 3.15 mm).

- 2 layers: Glass fiber added at 33% and 66% (t = 3.3 mm).

- 3 layers: Glass fiber added at 25%, 50%, and 75% (t = 3.45 mm).

- 4 layers: Glass fiber added at 20%, 40%, 60%, and 80% (t = 3.6 mm).

2.2.2. Mechanical Testing

- (a)

- Tensile Test

- (b)

- Flexural Test

- (c)

- Impact Charpy Test

- (d)

- Durometer Hardness Test

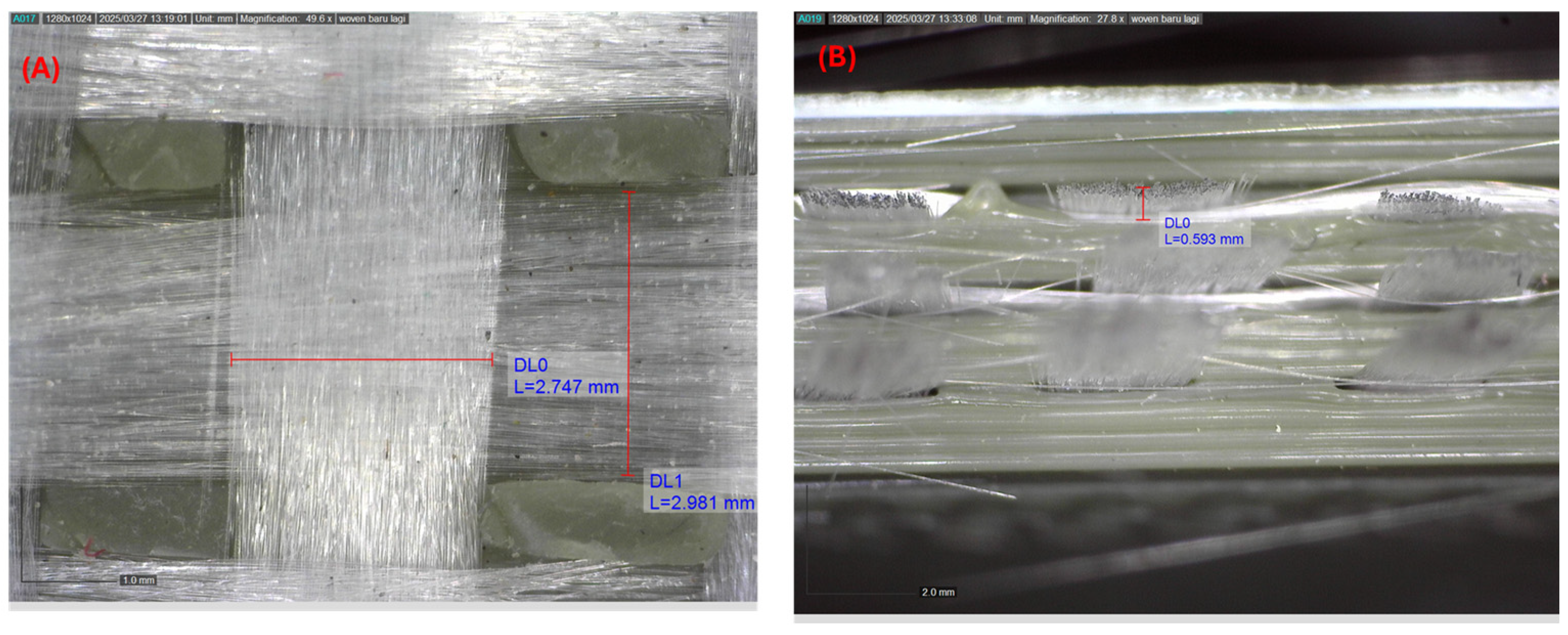

2.2.3. Characterization

3. Results

3.1. Tensile Test

3.2. Flexural Test

3.3. Impact Test

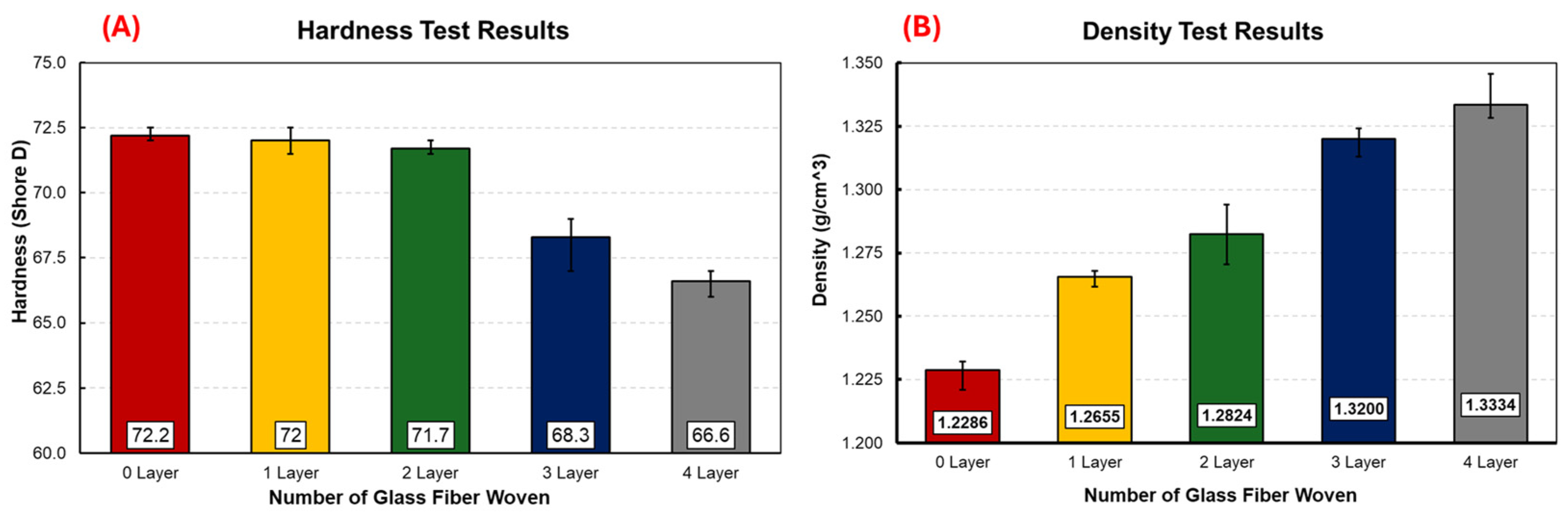

3.4. Hardness Test

3.5. Density Test

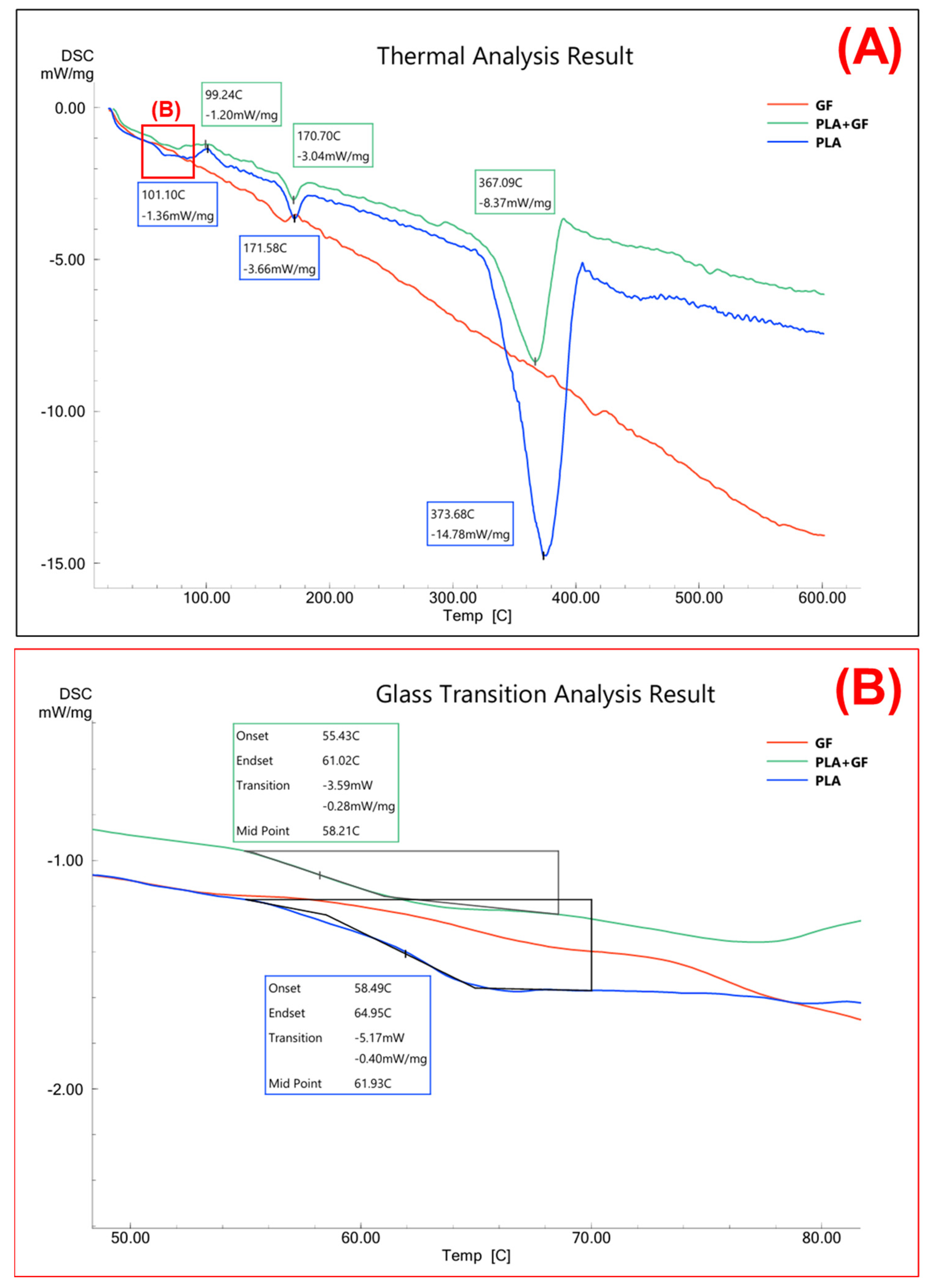

3.6. Thermal Analysis

4. Discussion

4.1. The Effect of Adding Woven Glass Fiber on Material Properties

4.2. The Effect of Orientation and the Number of Woven Glass Fiber Layers

4.3. Application and Implications

5. Conclusions

- From the results of the tensile test combined with DIC analysis, the addition of woven glass fiber during the manufacturing process made the material stronger in withstanding tensile loads. PLA+ composites with the addition of four layers of glass fiber were 85% stronger compared to standard PLA+. DIC analysis showed that the glass fiber helped distribute the load, preventing stress concentration in one area.

- From the results of the bending tests, the addition of woven glass fiber during the manufacturing process made the material stronger in withstanding bending loads. PLA+ composites with the addition of four layers of glass fiber were 13% stronger compared to standard PLA+. The addition of glass fiber also caused a change in the failure mode experienced by the specimens.

- From the impact test results, the addition of woven glass fiber during the manufacturing process made the material tougher when absorbing energy from impact loads. PLA+ composites with the addition of four layers of glass fiber were 450% tougher compared to standard PLA+. Glass fiber facilitated load distribution, enhancing energy absorption, making the material suitable for shin pads and vehicle bumpers

- The hardness test results indicate that the incorporation of woven glass fiber during production diminished the material’s resistance to indentation in hardness testing. PLA+ composites with four layers of glass fiber had an indentation resistance of just 66.6 ShD, which is inferior to the typical PLA+ measurement of 72.2 ShD.

- The DSC thermal study revealed that the addition of woven glass fiber during production increases the material’s likelihood of breaking down at high temperatures due to the chemical reaction between the glass fiber and PLA+. PLA+ exhibited −14.78 mW/mg during material decomposition, whereas PLA+ reinforced with woven glass fiber demonstrated −8.37 mW/mg, indicating a 40% reduction.

- The addition of woven glass fiber during the 3D printing FFF process using PLA+ filament improved the mechanical properties of PLA+ in resisting static loads. This was proven by the results of tensile, bending, and impact tests. However, PLA+ composites reinforced with glass fiber had a drawback in resisting indentation, as evidenced by the decreased hardness values during hardness testing. The DSC thermal study reveals that the addition of woven glass fiber to the manufacturing process increased the material’s likelihood of breaking down at high temperatures due to a chemical reaction between the glass fiber and PLA+. PLA+ exhibited −14.78 mW/mg during material decomposition, whereas PLA+ reinforced with woven glass fiber demonstrated −8.37 mW/mg, indicating a 40% reduction.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alami, A.H.; Ghani Olabi, A.; Alashkar, A.; Alasad, S.; Aljaghoub, H.; Rezk, H.; Abdelkareem, M.A. Additive Manufacturing in the Aerospace and Automotive Industries: Recent Trends and Role in Achieving Sustainable Development Goals. Ain Shams Eng. J. 2023, 14, 102516. [Google Scholar] [CrossRef]

- Kharat, V.J.; Singh, P.; Sharath Raju, G.; Kumar Yadav, D.; Satyanarayana; Gupta, M.; Arun, V.; Hussein Majeed, A.; Singh, N. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Khan, F.; Hossain, N.; Mim, J.J.; Rahman, S.M.; Iqbal, M.J.; Billah, M.; Chowdhury, M.A. Advances of Composite Materials in Automobile Applications—A Review. J. Eng. Res. 2024, in press. [Google Scholar] [CrossRef]

- Fredi, G.; Dorigato, A. Compatibilization of Biopolymer Blends: A Review. Adv. Ind. Eng. Polym. Res. 2024, 7, 373–404. [Google Scholar] [CrossRef]

- Praveena, B.A.; Lokesh, N.; Buradi, A.; Santhosh, N.; Praveena, B.L.; Vignesh, R. A Comprehensive Review of Emerging Additive Manufacturing (3D Printing Technology): Methods, Materials, Applications, Challenges, Trends and Future Potential. Mater. Today Proc. 2022, 52, 1309–1313. [Google Scholar] [CrossRef]

- Zhang, J.; Lin, G.; Vaidya, U.; Wang, H. Past, Present and Future Prospective of Global Carbon Fibre Composite Developments and Applications. Compos. B Eng. 2023, 250, 110463. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Siengchin, S. A Review on Lightweight Materials for Defence Applications: Present and Future Developments. Def. Technol. 2023, 24, 1–17. [Google Scholar] [CrossRef]

- Penumakala, P.K.; Santo, J.; Thomas, A. A Critical Review on the Fused Deposition Modeling of Thermoplastic Polymer Composites. Compos. B Eng. 2020, 201, 108336. [Google Scholar] [CrossRef]

- Alandro, D.; Nugraha, A.D.; Maulana, I.A.; Nugroho, A.D.; Erlangga, W.; Muflikhun, M.A. Comprehensive Assessment of Hybrid GFRP-Graphite Filler Using Modified Complex Arcan Fixture: Experimental and Simulation Approach. Compos. Part A Appl. Sci. Manuf. 2024, 180, 108094. [Google Scholar] [CrossRef]

- Erlangga, W.; Alandro, D.; Yudha, N.K.; Utomo, R.S.B.; Putro, A.J.N.; Rochardjo, H.S.B.; Muflikhun, M.A. Enhanced Mechanical Properties of the Hybrid CFRP-SLA Laminates through Laminate Modifications. Mater. Lett. 2024, 365, 136461. [Google Scholar] [CrossRef]

- Cao, L.; Xiao, J.; Kim, J.K.; Zhang, X. Effect of Post-Process Treatments on Mechanical Properties and Surface Characteristics of 3D Printed Short Glass Fiber Reinforced PLA/TPU Using the FDM Process. CIRP J. Manuf. Sci. Technol. 2023, 41, 135–143. [Google Scholar] [CrossRef]

- Muflikhun, M.A.; Syahril, M.; Mamba’udin, A.; Santos, G.N.C. A Novel of Hybrid Laminates Additively Manufactured via Material Extrusion—Vat Photopolymerization. J. Eng. Res. 2023, 11, 498–508. [Google Scholar] [CrossRef]

- Nugraha, A.D.; Kumar, V.V.; Gautama, J.P.; Wiranata, A.; Mangunkusumo, K.G.H.; Rasyid, M.I.; Dzanzani, R.; Muflikhun, M.A. Investigating the Characteristics of Nano-Graphite Composites Additively Manufactured Using Stereolithography. Polymers 2024, 16, 1021. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Zhang, D.; Wan, G.; Li, B.; Zhao, G. Glass Fiber Reinforced PLA Composite with Enhanced Mechanical Properties, Thermal Behavior, and Foaming Ability. Polymer 2019, 181, 121803. [Google Scholar] [CrossRef]

- Wang, X.; Huang, L.; Li, Y.; Wang, Y.; Lu, X.; Wei, Z.; Mo, Q.; Zhang, S.; Sheng, Y.; Huang, C.; et al. Research Progress in Polylactic Acid Processing for 3D Printing. J. Manuf. Process. 2024, 112, 161–178. [Google Scholar] [CrossRef]

- Nugroho, A.D.; Herianto; Alandro, D.; Muflikhun, M.A. Additively Manufactured Lattice and Sandwich Structure Consists of Hybrid GFRP–PLA PU–Graphite-Foam for Lightweight Structure Applications. Prog. Addit. Manuf. 2024, 10, 1201–1216. [Google Scholar] [CrossRef]

- Kadhum, A.H.; Al-Zubaidi, S.; Alkareem, S.S.A. Optimization of Mechanical Properties and Surface Characteristics of PLA+ 3D Printing Materials. Int. J. Chem. Eng. 2023, 2023, 8887905. [Google Scholar] [CrossRef]

- Kühnert, I.; Spörer, Y.; Brünig, H.; Tran, N.H.A.; Rudolph, N. Processing of Poly(Lactic Acid); Springer: Berlin/Heidelberg, Germany, 2017; pp. 1–33. [Google Scholar]

- Trivedi, A.K.; Gupta, M.K.; Singh, H. PLA Based Biocomposites for Sustainable Products: A Review. Adv. Ind. Eng. Polym. Res. 2023, 6, 382–395. [Google Scholar] [CrossRef]

- Nugraha, A.D.; Syahril, M.; Muflikhun, M.A. Excellent Performance of Hybrid Model Manufactured via Additive Manufacturing Process Reinforced with GFRP for Sport Climbing Equipment. Heliyon 2023, 9, e14706. [Google Scholar] [CrossRef]

- Rao, H.J.; Singh, S.; Singh, N.; Ramulu, P.J.; Santos, T.F.; Santos, C.M.; Senthamaraikannan, P.; Suyambulingam, I.; Gapsari, F.; Raharjo, R.; et al. Enhancing Mechanical Performance and Water Resistance of Careya-Banana Fiber Epoxy Hybrid Composites through PLA Coating and Alkali Treatment. J. Mater. Res. Technol. 2024, 32, 4304–4315. [Google Scholar] [CrossRef]

- Wu, J.; Li, A.; Lyu, Y.; Yang, B.; Fu, K.; Yang, D. Dual-Composite Additive Manufacturing of Glass Fibre and Recycled Carbon Fibre Reinforced Thermoplastic Composites with Customised Fibre Layout. Compos. Struct. 2025, 354, 118815. [Google Scholar] [CrossRef]

- Aryaswara, L.G.; Kusni, M.; Wijanarko, D.; Muflikhun, M.A. Advanced Properties and Failure Characteristics of Hybrid GFRP-Matrix Thin Laminates Modified by Micro Glass Powder Filler for Hard Structure Applications. J. Eng. Res. 2024, 13, 142–155. [Google Scholar] [CrossRef]

- Nugraha, A.D.; Adi, R.K.; Kumar, V.V.; Kusumawanto, A.; Prawara, B.; Junianto, E.; Hikmawan, M.F.; Muflikhun, M.A. Investigating the Mechanical Properties and Crashworthiness of Hybrid PLA/GFRP Composites Fabricated Using FDM-Filament Winding. Heliyon 2024, 10, e39062. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Ma, M.; Duongthipthewa, A.; Zhang, W.; Lang, Y.; Luo, G.; Su, Y.; Liu, M.; Zhou, L.; Su, Z. “Totally-Additive-Manufacturing”-Functionalized Carbon Fiber-Reinforced Polymer Composites with an Ultrasensitive Self-Sensing Network. Compos. Part A Appl. Sci. Manuf. 2025, 189, 108596. [Google Scholar] [CrossRef]

- Ali, W.; Mehboob, A.; Han, M.G.; Chang, S.H. Novel Biodegradable Hybrid Composite of Polylactic Acid (PLA) Matrix Reinforced by Bioactive Glass (BG) Fibres and Magnesium (Mg) Wires for Orthopaedic Application. Compos. Struct. 2020, 245, 112322. [Google Scholar] [CrossRef]

- Maqsood, N.; Rimašauskas, M. Characterization of Carbon Fiber Reinforced PLA Composites Manufactured by Fused Deposition Modeling. Compos. Part C Open Access 2021, 4, 100112. [Google Scholar] [CrossRef]

- Kumar, K.R.; Mohanavel, V.; Kiran, K. Mechanical Properties and Characterization of Polylactic Acid/Carbon Fiber Composite Fabricated by Fused Deposition Modeling. J. Mater. Eng. Perform. 2022, 31, 4877–4886. [Google Scholar] [CrossRef]

- Wang, A.; Tang, X.; Zeng, Y.; Zou, L.; Bai, F.; Chen, C. Carbon Fiber-Reinforced PLA Composite for Fused Deposition Modeling 3D Printing. Polymers 2024, 16, 2135. [Google Scholar] [CrossRef]

- Ismail, K.I.; Pang, R.; Ahmed, R.; Yap, T.C. Tensile Properties of In Situ 3D Printed Glass Fiber-Reinforced PLA. Polymers 2023, 15, 3436. [Google Scholar] [CrossRef]

- Chicos, L.A.; Pop, M.A.; Zaharia, S.M.; Lancea, C.; Buican, G.R.; Pascariu, I.S.; Stamate, V.M. Fused Filament Fabrication of Short Glass Fiber-Reinforced Polylactic Acid Composites: Infill Density Influence on Mechanical and Thermal Properties. Polymers 2022, 14, 4988. [Google Scholar] [CrossRef]

- Chaudhary, V.; Radhakrishnan, S.; Das, P.P.; Dwivedi, S.P.; Mishra, S.; Gupta, P. Development and Mechanical Characterization of PLA Composites Reinforced with Jute and Nettle Bio Fibers. Biomass Convers. Biorefin. 2023, 15, 3443–3455. [Google Scholar] [CrossRef]

- Sethu, S.; Kalimuthu, M.; Nagarajan, R.; Krishnan, K.; Mohammad, F.; Arul Kumar, M. Hybrid Fabrication and Characterization of Biocompatible Bamboo/PLA Composites. J. Mater. Res. Technol. 2024, 29, 2656–2666. [Google Scholar] [CrossRef]

- Fathima, S.; Deeraj, B.D.S.; Appukuttan, S.; Joseph, K. 12—Carbon Fiber and Glass Fiber Reinforced Elastomeric Composites. In Fiber Reinforced Composites; Joseph, K., Oksman, K., George, G., Wilson, R., Appukuttan, S., Eds.; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Cambridge, UK, 2021; pp. 307–340. ISBN 978-0-12-821090-1. [Google Scholar]

- ASTM Standard D3039/D3039M-08; American Society for Testing and Materials. Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2008.

- ASTM D790-17; American Society for Testing and Materials. Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM E23; American Society for Testing and Materials. Standard Test Methods for Notched Bar Impact Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D2240; American Society for Testing and Materials. Standard Test Method for Rubber Property—Durometer Hardness. ASTM International: West Conshohocken, PA, USA, 2015.

- Yang, H.; Pan, B. Measuring Large Tensile Deformation of Polymers Using Fluorescent 3D-Digital Image Correlation with Adaptive Incremental Calculation Strategy. Polym. Test. 2024, 132, 108377. [Google Scholar] [CrossRef]

- Harilal, R.; Ramji, M. Adaptation of Open Source 2D DIC Software Ncorr for Solid Mechanics Applications. In Proceedings of the 9th International Symposium on Advanced Science and Technology in Experimental Mechanics, New Delhi, India, 1–6 November 2014; pp. 1–6. [Google Scholar]

- Blaber, J.; Adair, B.; Antoniou, A. Ncorr: Open-Source 2D Digital Image Correlation Matlab Software. Exp. Mech. 2015, 55, 1105–1122. [Google Scholar]

- Ilyas, R.A.; Zuhri, M.Y.M.; Aisyah, H.A.; Asyraf, M.R.M.; Hassan, S.A.; Zainudin, E.S.; Sapuan, S.M.; Sharma, S.; Bangar, S.P.; Jumaidin, R.; et al. Natural Fiber-Reinforced Polylactic Acid, Polylactic Acid Blends and Their Composites for Advanced Applications. Polymers 2022, 14, 202. [Google Scholar] [CrossRef]

- Akhyar; Gani, A.; Ibrahim, M.; Ulmi, F.; Farhan, A. The Influence of Different Fiber Sizes on the Flexural Strength of Natural Fiber-Reinforced Polymer Composites. Results Mater. 2024, 21, 100534. [Google Scholar] [CrossRef]

- Russo, P.; Acierno, D.; Simeoli, G.; Iannace, S.; Sorrentino, L. Flexural and Impact Response of Woven Glass Fiber Fabric/Polypropylene Composites. Compos. B Eng. 2013, 54, 415–421. [Google Scholar] [CrossRef]

- Sadaq, S.I.; Kumar, V.S.; Ahmed, G.M.S.; Irfan, M. Experimental Investigation and Impact Analysis of GFRP Composite Laminates. Mater. Today Proc. 2015, 2, 2808–2816. [Google Scholar] [CrossRef]

- Simeoli, G.; Sorrentino, L.; Touchard, F.; Mellier, D.; Oliviero, M.; Russo, P. Comparison of Falling Dart and Charpy Impacts Performances of Compatibilized and Not Compatibilized Polypropylene/Woven Glass Fibres Composites. Compos. B Eng. 2019, 165, 102–108. [Google Scholar] [CrossRef]

- Alarifi, M.I.; Alarifi, I.M. Comprehensive Structural Evaluation of Composite Materials in 3D-Printed Shin Guards. J. Mater. Res. Technol. 2023, 27, 6912–6923. [Google Scholar] [CrossRef]

- Ultimaker PETG Technical Data Sheet 2022. Available online: https://um-support-files.ultimaker.com/materials/2.85mm/tds/PETG/Ultimaker-PETG-TDS-v1.00.pdf (accessed on 20 March 2025).

- Murat, B.I.S.; Rahman, A.A.A. Study of Impact Damage Behavior in Woven Carbon Fiber Plates. Procedia Eng. 2017, 170, 47–54. [Google Scholar]

- Park, S.-J.; Seo, M.-K. Composite Characterization. In Interface Science and Technology; Elsevier: Amsterdam, The Netherlands, 2011; Volume 18, pp. 631–738. [Google Scholar] [CrossRef]

- Hassan, A.; Salleh, N.M.; Yahya, R.; Sheikh, M.R.K. Fiber Length, Thermal, Mechanical, and Dynamic Mechanical Properties of Injection-Molded Glass-Fiber/Polyamide 6,6: Plasticization Effect. J. Reinf. Plast. Compos. 2011, 30, 488–498. [Google Scholar] [CrossRef]

- Angin, N.; Caylak, S.; Ertas, M.; Donmez Cavdar, A. Effect of Alkyl Ketene Dimer on Chemical and Thermal Properties of Polylactic Acid (PLA) Hybrid Composites. Sustain. Mater. Technol. 2022, 32, e00386. [Google Scholar] [CrossRef]

- Nugraha, A.D.; Alandro, D.; Nugroho, A.D.; Supriyanto, E.; Tanbar, F.; Muflikhun, M.A. Load-Displacement Experimental Data from Shear Loading of Hybrid GFRP-Graphite Filler Using a Complex Arcan Fixture. Data Brief. 2024, 53, 110139. [Google Scholar] [CrossRef]

- Çelik, Y.H.; Türkan, C. Investigation of Mechanical Characteristics of GFRP Composites Produced from Chopped Glass Fiber and Application of Taguchi Methods to Turning Operations. SN Appl. Sci. 2020, 2, 849. [Google Scholar] [CrossRef]

- Hashemi, M.; Hatami, O.; Tajbakhsh, M.R. Investigation of the Performance of the Structure and Energy Absorption in Sandwich Panels of PLA/TPU Manufactured by the FFF Technique. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2023, 238, 416–429. [Google Scholar] [CrossRef]

- Osa-uwagboe, N.; Silberschimdt, V.V.; Aremi, A.; Demirci, E. Mechanical Behaviour of Fabric-Reinforced Plastic Sandwich Structures: A State-of-the-Art Review. J. Sandw. Struct. Mater. 2023, 25, 591–622. [Google Scholar]

- Wang, P.; Yang, J.; Hu, Y.; Huo, J.; Feng, X. Innovative Design of a Helmet Based on Reverse Engineering and 3D Printing. Alex. Eng. J. 2021, 60, 3445–3453. [Google Scholar] [CrossRef]

- Anirudh, K.; Yeole, S.N. Development of a 3D Printed Knee Protective Pad Prototype. Mater. Today Proc. 2021, 44, 2442–2446. [Google Scholar]

- Cazón-Martín, A.; Iturrizaga-Campelo, M.; Matey-Muñoz, L.; Rodríguez-Ferradas, M.I.; Morer-Camo, P.; Ausejo-Muñoz, S. Design and Manufacturing of Shin Pads with Multi-Material Additive Manufactured Features for Football Players: A Comparison with Commercial Shin Pads. Proc. Inst. Mech. Eng. P. J. Sport. Eng. Technol. 2018, 233, 160–169. [Google Scholar] [CrossRef]

- Giammaria, V.; Capretti, M.; Del Bianco, G.; Boria, S.; Santulli, C. Application of Poly(Lactic Acid) Composites in the Automotive Sector: A Critical Review. Polymers 2024, 16, 3059. [Google Scholar] [CrossRef] [PubMed]

- Tuli, N.T.; Khatun, S.; Rashid, A. Bin Unlocking the Future of Precision Manufacturing: A Comprehensive Exploration of 3D Printing with Fiber-Reinforced Composites in Aerospace, Automotive, Medical, and Consumer Industries. Heliyon 2024, 10, e27328. [Google Scholar] [CrossRef] [PubMed]

| Variable | Value | Unit |

|---|---|---|

| Layer Height | 0.2 | mm |

| Layer Width | 0.4 | mm |

| Wall Thickness | 1.2 | mm |

| Nozzle Temperature | 208 | °C |

| Bed Temperature | 60 | °C |

| Print Speed | 60 | mm/s |

| Infill | 100 | % |

| Top/Bottom Line Direction | 45/−45 | ° |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Putro, A.J.N.; Bagaskara, G.; Prasetya, I.A.; Jamasri; Wiranata, A.; Wu, Y.-C.; Muflikhun, M.A. Optimization of Innovative Hybrid Polylactic Acid+ and Glass Fiber Composites: Mechanical, Physical, and Thermal Evaluation of Woven Glass Fiber Reinforcement in Fused Filament Fabrication 3D Printing. J. Compos. Sci. 2025, 9, 164. https://doi.org/10.3390/jcs9040164

Putro AJN, Bagaskara G, Prasetya IA, Jamasri, Wiranata A, Wu Y-C, Muflikhun MA. Optimization of Innovative Hybrid Polylactic Acid+ and Glass Fiber Composites: Mechanical, Physical, and Thermal Evaluation of Woven Glass Fiber Reinforcement in Fused Filament Fabrication 3D Printing. Journal of Composites Science. 2025; 9(4):164. https://doi.org/10.3390/jcs9040164

Chicago/Turabian StylePutro, Ardi Jati Nugroho, Galang Bagaskara, Ibnu Adnan Prasetya, Jamasri, Ardi Wiranata, Yi-Chieh Wu, and Muhammad Akhsin Muflikhun. 2025. "Optimization of Innovative Hybrid Polylactic Acid+ and Glass Fiber Composites: Mechanical, Physical, and Thermal Evaluation of Woven Glass Fiber Reinforcement in Fused Filament Fabrication 3D Printing" Journal of Composites Science 9, no. 4: 164. https://doi.org/10.3390/jcs9040164

APA StylePutro, A. J. N., Bagaskara, G., Prasetya, I. A., Jamasri, Wiranata, A., Wu, Y.-C., & Muflikhun, M. A. (2025). Optimization of Innovative Hybrid Polylactic Acid+ and Glass Fiber Composites: Mechanical, Physical, and Thermal Evaluation of Woven Glass Fiber Reinforcement in Fused Filament Fabrication 3D Printing. Journal of Composites Science, 9(4), 164. https://doi.org/10.3390/jcs9040164