Reliability-Based Calibration of Strength-Reduction Factors for Flexural Design of FRP-RC Beams Under Various Load Combinations

Abstract

1. Introduction

- In particular, the reliability-based evaluation of CSA provisions is conducted not only for the basic load combination of dead and live loads, but also for the other load combinations such as wind and snow loads. To our knowledge, there has not yet been any report on reliability analysis of load combinations containing wind and snow, whereas publications in this field have dealt so far with the basic load combination of dead and live loads. Given the essential differences existing in the probabilistic nature of various load types, further study on this topic would be in high demand. Moreover, the load factors are not the same in different codes; thus, CSA possesses its own factored load combinations.

- In the next stage, the flexural strength equations for different failure modes are calibrated to achieve the target reliability indexes. This is carried out in the context of CSA code, in which partial strength-reduction factors exist for concrete, steel, and FRP materials. More importantly, three target reliability indexes of 3.5, 3.8, and 4 are considered herein, as opposed to the other works with a fixed-value target reliability index. Finally, the flexural strength equations are calibrated by introducing proper reduction factors to achieve the target reliability indexes. The whole procedure is carried out for several load combinations including dead, live, snow, and wind loads.

- In this study, a large experimental database on the concrete beams reinforced longitudinally with glass, carbon, or aramid FRP bars, and failed in the flexural mode, is collated from the wider literature. The experimental data contain 81, 211, and 11 tested FRP-RC beams that failed in FRP rupture, concrete crushing, and the balanced state, respectively. The collected set of test data, which is the largest one reported so far, is used to evaluate the model uncertainty associated with the existing design equations. In addition, a design space consisting of 8192 beams is built to evaluate the reliability index for the current provisions. Then, a parametric study is conducted to evaluate the effects of the FRP reinforcement ratio on the reliability index.

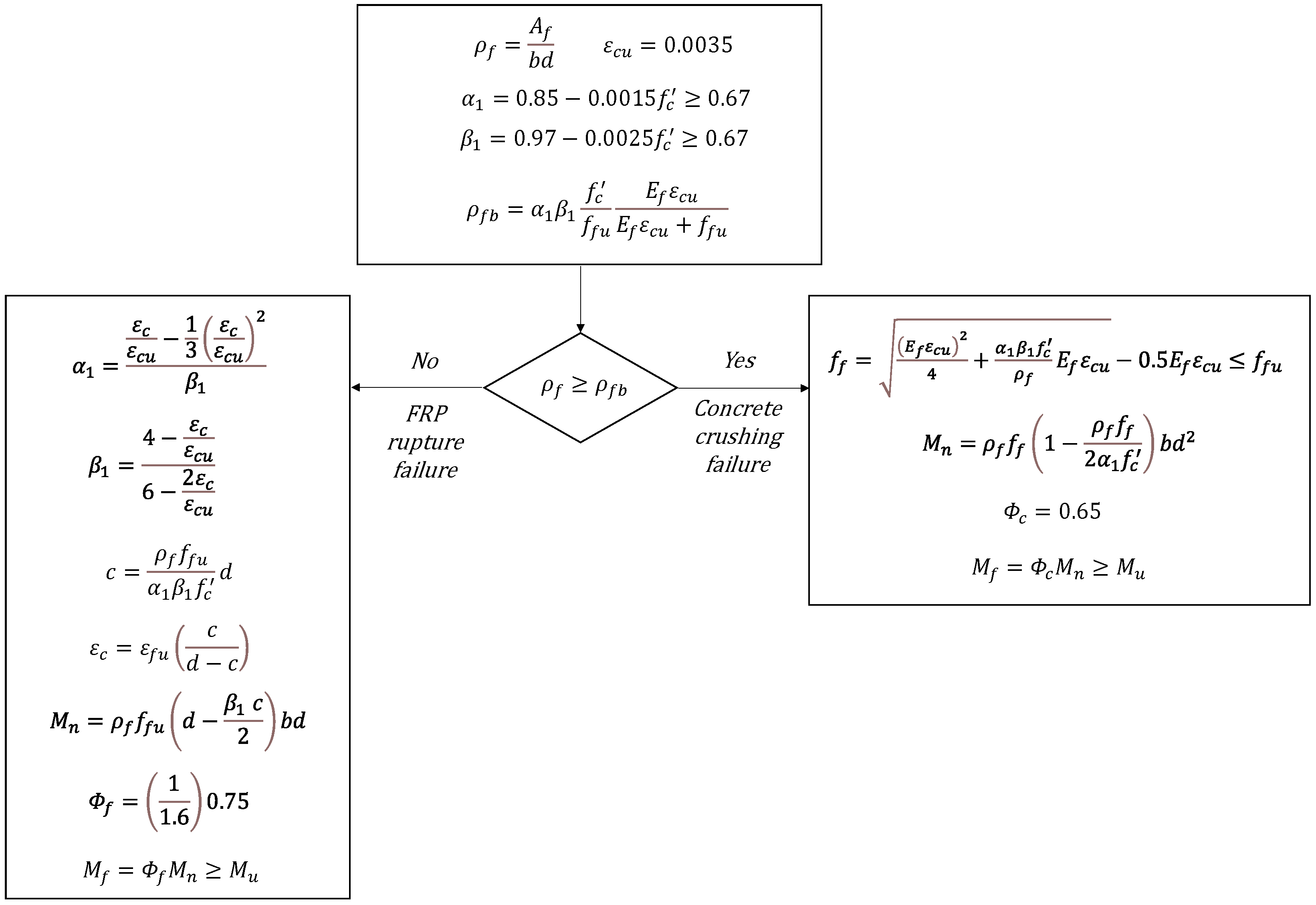

2. Provisions of CSA for Flexural Design of FRP-RC Beams

3. Methodology of Reliability-Based Evaluation

3.1. Statistical Characteristics of Uncertain Variables

3.2. Limit State Function

3.3. Method of Reliability Analysis

- Problem statement: The design point is to be determined in the standard normal space by minimizing subject to the limit state equation . In a mathematical form, we have the following:Thereby, the reliability index is computed as .

- Transformation to standard normal space: Each uncertain parameter is mapped to a standard normal random variable through a Jacobian J, such that and . Later on, all computations are performed in the standard normal space, while the limit space function is expressed in terms of x.

- Initialization: An initial guess for the design point, , is chosen, for instance, (i.e., the mean in standard normal space), or the Rosenblatt transform of the mean . Then, , which leads us to evaluate the limit state function and its gradient in the original space .

- Gradient transformation: At iteration , the gradient is calculated and transformed to the space using the following formula:where is the Jacobian of the transformation.

- Compute search direction: The gradient in space is normalized as follows:Let . Then, the classical HLRF update direction is as follows:

- Improved step via line search: A line search (or step size reduction) is conducted to ensure stable convergence. First, let . Then, a merit function (e.g., or the norm of its gradient) at the trial point is evaluated:If convergence improves (e.g., the absolute value of decreases), is accepted. Otherwise, is decreased (e.g., by halving), and this step is repeated. Once a suitable is found, the update is performed as follows:

- Map back to the original space: The updated values, , are computed. Furthermore, and are evaluated.

- Convergence check: It is checked whether any of the following termination criteria are met:

- ◦

- is below a threshold (i.e., the limit state is nearly zero).

- ◦

- is sufficiently small.

- ◦

- The change in the reliability index or is very little between successive iterations.

If it is not converged, then set and repeat from step 4. - Final results: Once convergence is achieved, is the approximate design point in the standard normal space. Thereby, the reliability index is determined as . Transforming back to the original space yields , which is the design point in the space.

3.4. Design Space

4. Target Reliability Index

5. Results and Discussion

5.1. The Safety Level of the Existing Code

5.2. Sensitivity Analysis

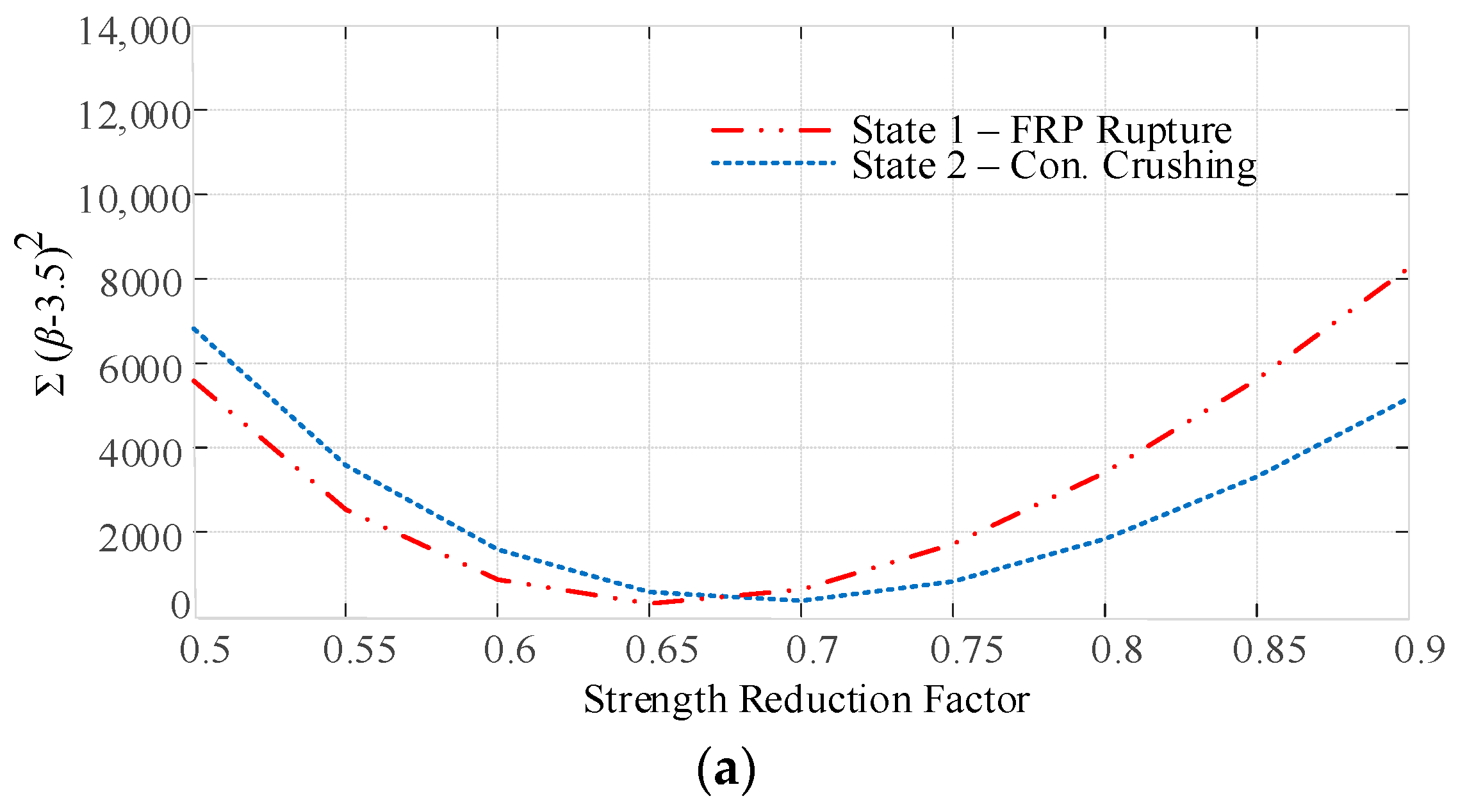

5.3. Reliability-Based Calibration of Strength-Reduction Factors

| State No. | Failure Mode | m | β | ||

|---|---|---|---|---|---|

| Mean | |||||

| 11 | FRP Rupture | 0.65 | 0.75 | 0.8 | 3.872 |

| 12 | Concrete Crushing | 0.65 | 0.75 | 1.0 | 3.726 |

5.4. The Probabilistic Assessment of

5.5. Evaluation of Reliability of Existing Code Under Different Load Combinations

- The reliability index for the existing equations of CSA S806-12 for FRP rupture varies from 5.07 to 4.4 at L/(L + D) = 0.3 and 0.9, respectively. For concrete crushing, changes from 3.8 to 3.56 at L/(L + D) = 0.4 and 0.9, respectively. For snow loads, in the case of FRP rupture alters from 5.2 to 4.6 at S/(S + D) = 0.3 and 0.9, respectively, while for concrete crushing, the changes are in the range of 4–3.8 for S/(S + D) = 0.4–0.9. As for wind loads, the reliability index shows a large decrease from 5 to 3.73 when the load ratio, W/(W + D), increases from 0.2 to 0.9 in the case of FRP rupture, whereas for concrete crushing, = 3.7–3.1 corresponds to the load ratios of 0.3–0.9.

- When considering the two failure modes, it is evident (Figure 7) that the variation in with respect to varying values of load ratios is larger (in order of 2–3 times) for FRP rupture compared to that for concrete crushing. In other words, the reliability of FRP rupture mode of failure is more sensitive to the load ratios in all load combinations considered herein, as compared to the case of concrete crushing.

- When looking at different load combinations, it is observed that change in due to varying values of load ratios is largest for wind loads as compared to live or snow loads. This is true for each of the failure modes.

5.6. Relaibility-Based Calibration of Design Provisions for Different Load Combinations

6. Conclusions

- (1)

- Reliability analysis of the flexural strength provisions for FRP-RC beams based on the current version of CSA S806 revealed that there is a remarkable difference in the reliability indices between the two common failure modes, namely β = 4.895 for FRP rupture versus β = 3.726 for concrete crushing. This difference is observed in the combinations of dead plus live, wind, and snow loads, with the corresponding load factors provided as per CSA and over a wide range of load ratios. The main source of conservatism accompanied by the FRP rupture mode of flexural failure is related to the incorporation of a smaller strength-reduction factor in the current CSA code when considering the FRP rupture mode of failure.

- (2)

- The uncertainty associated with the parameters involved in the formula for revealed that when 0.6 < < 1.4, the occurrence of both failure modes (namely, concrete crushing and FRP rupture) are possible but with different levels of probability, such that at = 1, almost half of the total number of failed beams is the FRP rupture type, and the other half is the concrete crushing mode. This highlights the need to provide similar reliability indexes for the two failure modes, particularly in the transition range of 0.6 < < 1.4 so as to achieve the target reliability index regardless of which failure type may take place.

- (3)

- Reliability-based calibration is conducted to provide a consistent reliability index for both failure modes and for various target reliability indices of 3.5, 3.8, and 4. As a result, and in order to arrive at = 3.8, it is proposed to modify the current provisions by introducing an additional reduction factor equal to 0.8, which is multiplied by the nominal flexural capacity in the case of the FRP rupture mode of failure, while the strength-reduction factors (i.e., = 0.65 and = 0.75) currently existing in the CSA code are kept unchanged. The nominal flexural strength provision of the current CSA code for the concrete crushing mode of failure is deemed to be sufficient. A similar approach can be taken for any other desired value of the target reliability index.

- (4)

- The reliability assessment of the current provisions of CSA under three load combinations considered herein revealed that the variation in with respect to varying values of load ratios is larger (in order of 2 or 3 times) for FRP rupture compared to that for concrete crushing. Furthermore, it is concluded that changes in due to varying values of load ratios are largest for wind loads compared to live or snow loads.

- (5)

- The reliability of the flexural strength provisions with the modifications proposed in the current paper is evaluated for three load combinations of dead plus live, snow, and wind, which contain the load increment factors given in accordance with CSA. It is concluded that the target reliability index could be achieved with a reasonable accuracy for both failure modes within a feasible range of load ratios, endorsing a successful reliability-based calibration procedure especially for load combinations related to live and snow loads, and, to a lesser extent, for wind loads.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Cross-sectional area of FRP bars | |

| Width of beam cross-section | |

| Effective depth of beam cross-section | |

| Depth of the neutral axis from the uttermost compression side of cross-section | |

| Depth of neutral axis corresponding to the balance state | |

| D | Dead load |

| Young’s modulus of FRP bars | |

| Compressive strength of concrete | |

| Tensile stress in the FRP bars | |

| Ultimate tensile strength of FRP bars | |

| Limit state function | |

| L | Live load |

| m | Modification factor multiplied by the nominal flexural strength |

| Unfactored moment due to dead load | |

| Mexp | Experimental value for the flexural strength of tested beam |

| Factored design value of flexural strength | |

| Unfactored moment due to live load | |

| Unfactored moment due to the total load | |

| Nominal flexural strength | |

| Prediction based on the code equation for flexural strength of tested beam | |

| Factored moment due to the total load | |

| Total number of virtual beams in the design space | |

| Pf | Model uncertainty variable (i.e., the so-called professional factor) |

| Load variable in the limit state function | |

| Resistance variable in the limit state function | |

| S | Snow load |

| W | Wind load |

| β | The reliability index |

| Target reliability index | |

| Coefficient of variation (COV) | |

| Ultimate compressive strain in concrete | |

| Ultimate tensile strain in FRP bar | |

| Bias | |

| Mean value | |

| The ratio of FRP reinforcement existing in the cross-section | |

| The balanced ratio of FRP reinforcement | |

| Standard deviation (SD) | |

| Strength-reduction factor for concrete crushing mode of failure | |

| Strength-reduction factor for FRP rupture mode of failure |

References

- ACI 440.1 R-03; Guide for the Design and Construction of Concrete Reinforced with FRP Bars. American Concrete Institute: Detroit, MI, USA, 2003.

- ACI 440.1R-06; Guide for the Design and Construction of Structural Concrete Reinforced with FRP Bars. American Concrete Institute: Farmington Hills, MI, USA, 2006.

- CAN/CSA S806-02; Design and Construction of Building Components with Fiber Reinforced Polymers. Canadian Standards Association (CSA): Rexdale, ON, Canada, 2002.

- CAN/CSA S806-12; Design and Construction of Building Components with Fiber Reinforced Polymers. Canadian Standards Association (CSA): Rexdale, ON, Canada, 2012.

- Wahrhaftig, A.D.; Rodrigues, R.B.; Carvalho, R.F.; Fortes, A.S. Strengthening reinforced concrete beams with carbon fiber laminate mounted in a u-shape for static and vibration purposes. Int. J. Civ. Eng. 2022, 20, 27–40. [Google Scholar] [CrossRef]

- Zeng, J.J.; Ye, Y.Y.; Liu, W.T.; Zhuge, Y.; Liu, Y.; Yue, Q.R. Behaviour of FRP spiral-confined concrete and contribution of FRP longitudinal bars in FRP-RC columns under axial compression. Eng. Struct. 2023, 281, 115747. [Google Scholar]

- Zeng, J.J.; Zeng, W.B.; Ye, Y.Y.; Liao, J.; Zhuge, Y.; Fan, T.H. Flexural behavior of FRP grid reinforced ultra-high-performance concrete composite plates with different types of fibers. Eng. Struct. 2022, 272, 115020. [Google Scholar]

- Zeng, J.J.; Hao, Z.H.; Sun, H.Q.; Zeng, W.B.; Fan, T.H.; Zhuge, Y. Durability assessment of ultra-high-performance concrete (UHPC) and FRP grid-reinforced UHPC plates under marine environments. Eng. Struct. 2025, 323, 119313. [Google Scholar]

- He, Z.; Qiu, F. Probabilistic assessment on flexural capacity of GFRP-reinforced concrete beams designed by guideline ACI 440.1 R-06. J. Constr. Build. Mater. 2011, 25, 1663–1670. [Google Scholar]

- Shield, C.K.; Galambos, T.V.; Gulbrandsen, P. On the History and Reliability of the Flexural Strength of FRP Reinforced Concrete Members in ACI 440.1 R; American Concrete Institute: Farmington Hills, MI, USA, 2011; p. 275. [Google Scholar]

- Ribeiro, S.E.C.; Diniz, S.M.C. Reliability-based design recommendations for FRP reinforced concrete beams. Eng. Struct. 2013, 52, 273–283. [Google Scholar]

- Zadeh, H.J.; Nanni, A. Reliability analysis of concrete beams internally reinforced with fiber-reinforced polymer bars. ACI Struct. J. 2013, 110, 1023–1032. [Google Scholar]

- Nasrollahzadeh, K.; Aghamohammadi, R. Reliability analysis of shear strength provisions for FRP-reinforced concrete beams. Eng. Struct. 2018, 176, 785–800. [Google Scholar]

- Shamass, R.; Abarkan, I.; Ferreira, F.P. FRP RC beams by collected test data: Comparison with design standard, parameter sensitivity, and reliability analyses. Eng. Struct. 2023, 297, 116933. [Google Scholar]

- Hassanzadeh, A.M.; Dehestani, M.; Nazarpour, H. Reliability analysis of flexural provisions of FRP-RC beams and sensitivity analysis based on FORM. Eng. Struct. 2023, 285, 116037. [Google Scholar]

- Tarawneh, A.; Alajarmeh, O.; Alawadi, R.; Amirah, H.; Alramadeen, R. Database evaluation and reliability calibration for flexural strength of hybrid FRP/steel-RC Beams. Compos. Struct. 2024, 329, 117758. [Google Scholar] [CrossRef]

- Sang, B.; Song, S.; Wang, A.; Liu, X. Reliability analysis and calibration for flexural design provisions of GFRP-RC beams. Structures 2024, 69, 107435. [Google Scholar]

- Mirza, S.A.; MacGregor, J.G. Probabilistic study of strength of reinforced concrete members. Can. J. Civ. Eng. 1982, 9, 431–448. [Google Scholar]

- Nowak, A.S.; Szerzsen, M.M. Calibration of design code for buildings (ACI 318): Part 1—Statistical models for resistance. ACI Struct. J. 2003, 100, 377–382. [Google Scholar]

- El-Sayed, A.; El-Salakawy, E.; Benmokrane, B. Shear strength of one-way concrete slabs reinforced with fiber-reinforced polymer composite bars. J. Compos. Constr. 2005, 9, 147–157. [Google Scholar]

- El-Sayed, A.K.; El-Salakawy, E.F.; Benmokrane, B. Shear strength of FRP reinforced concrete beams without transverse reinforcement. ACI Struct. J. 2006, 103, 235–243. [Google Scholar]

- Michaluk, R.; Rizkalla, S.; Tadros, G.; Benmokrane, B. Flexural behavior of one-way concrete slabs reinforced by fiber reinforced plastic reinforcement. ACI Struct. J. 1998, 95, 353–365. [Google Scholar]

- El-Sayed, A.K.; El-Salakawy, E.F.; Benmokrane, B. Shear capacity of high-strength concrete beams reinforced with FRP bars. ACI Struct. J. 2006, 103, 383–389. [Google Scholar]

- Kocaoz, S.; Samaranayake, V.A.; Nanni, A. Tensile characterization of glass FRP bars. Compos. Part B Eng. 2005, 36, 127–134. [Google Scholar]

- ACI 440.1R-15; Guide for the Design and Construction of Structural Concrete Reinforced with FRP Bars. American Concrete Institute: Farmington Hills, MI, USA, 2015.

- Nowak, A.S.; Collins, K.R. Reliability of Structures; McGraw-Hill: Boston, MA, USA, 2000. [Google Scholar]

- Nawy, E.G.; Neuwerth, G.E.; Phillips, C.J. Behavior of fiber glass reinforced concrete beams. J. Struct. Div. 1971, 97, 2203–2215. [Google Scholar] [CrossRef]

- Nawy, E.G.; Neuwerth, G.E. Fiberglass reinforced concrete slabs and beams. J. Struct. Div. 1977, 103, 421–440. [Google Scholar]

- Faza, S.S.; GangaRao, H.V. Bending and Bond Behavior of Concrete Beams Reinforced with Plastic Rebars. In Proceedings of the Third Bridge Engineering Conference: Papers Presented at the Third Bridge Engineering Conference, Denver, CO, USA, 10–13 March 1991. [Google Scholar]

- Faza, S.S. Bending and Bond Behavior and Design of Concrete Beams Reinforced with Fiber Reinforced Plastic Rebars. Diss. Abstr. Int. 1992, 53, 213. [Google Scholar]

- Brown, V.L.; Bartholomew, C.L. FRP reinforcing bars in reinforced concrete members. ACI Mater. J. 1993, 90, 34–39. [Google Scholar]

- Benmokrane, B.; Chaallal, O.; Masmoudi, R. Flexural response of concrete beams reinforced with FRP reinforcing bars. ACI Struct. J. 1996, 93, 46–55. [Google Scholar]

- Benmokrane, B.; Masmoudi, R. FRP C-bar as reinforcing rod for concrete structures. In Proceedings of the 2nd International Conference on Advanced Composite Materials in Bridges and Structures, ACMBS-II, Montreal, QC, Canada, 11–14 August 1996. [Google Scholar]

- Brown, V.L.; Bartholomew, C.L. Long-term deflections of GFRP-reinforced concrete beams. In Proceedings of the First International Conference on Composites in Infrastructure, Tucson, AZ, USA, 15–17 January 1996. [Google Scholar]

- Al-Salloum, Y.A.; Alsayed, S.H.; Almusallam, T.H.; Amjad, M.A. Some Design Consideration for Concrete Beams Reinforced by Glass Fiber Reinforced Plastics (GFRP) Bars. In Proceedings of the First International Conference on Composites in Infrastructure, Tucson, AZ, USA, 15–17 January 1996. [Google Scholar]

- Alsayed, S.H.; Al-Salloum, Y.A.; Almusallam, T.H. Performance of glass fiber reinforced plastic bars as a reinforcing material for concrete structures. Compos. Part B Eng. 2000, 31, 555–567. [Google Scholar]

- Vijay, P.V.; GangaRao, H.V.S. A unified limit state approach using deformability factors in concrete beams reinforced with GFRP bars. In Materials for the New Millennium; ASCE: Reston, VA, USA, 1996; pp. 657–665. [Google Scholar]

- Almusallam, T.H.; Al-Salloum, Y.A.; Alsayed, S.H.; Amjad, M.A. Behavior of concrete beams doubly reinforced by FRP bars. In Proceedings of the Third International Symposium on Nonmetallic (FRP) Reinforcement for Concrete Structures (FRPRCS-3); Japan Concrete In-Stitute: Sapporo, Japan, 1997; Volume 2, pp. 471–478. [Google Scholar]

- Cosenza, E.; Manfredi, G.; Realfonzo, R. Behavior and modeling of bond of FRP rebars to concrete. J. Compos. Constr. 1997, 1, 40–51. [Google Scholar]

- Sonobe, Y.; Fukuyama, H.; Okamoto, T.; Kani, N.; Kimura, K.; Kobayashi, K.; Teshigawara, M. Design guidelines of FRP reinforced concrete building structures. J. Compos. Constr. 1997, 1, 90–115. [Google Scholar]

- Benmokrane, B.; Theriault, M.; Masmoudi, R.; Rizkalla, S. Effect of reinforcement ratio on concrete members reinforced with FRP bars. Evol. Technol. Compet. Edge 1997, 42, 87–98. [Google Scholar]

- Nawy, E.G.; Neuwerth, G.E. Fiber glass as main reinforcement for concrete two-way slabs, plates and beams. In Engineering Research Bulletin; Rutgers University: New Brunswick, NJ, USA, 1976. [Google Scholar]

- Swamy, N.; Aburawi, M. Structural implications of using GFRP bars as concrete reinforcement. In Proceedings of the Third International Symposium on Nonmetallic (FRP) Reinforcement for Concrete Structures (FRPRCS-3), Sapporo, Japan, 14–16 October 1997; Volume 3, pp. 503–510. [Google Scholar]

- Duranovic, N.; Pilakoutas, K.; Waldron, P. Tests on concrete beams reinforced with glass fiber reinforced plastic bars. In Proceedings of the Third International Symposium on Nonmetallic (FRP) Reinforcement for Concrete Structures (FRPRCS-3), Sapporo, Japan, 14–16 October 1997; pp. 479–486. [Google Scholar]

- Gao, D.; Benmokrane, B.; Masmoudi, R. A calculating method of flexural properties of FRP-reinforced concrete beam: Part I: Crack width and deflection. In Technical Report, Department of Civil Engineering; University of Sherbrooke: Sherbrooke, QC, Canada, 1998. [Google Scholar]

- Grace, N.F.; Soliman, A.K.; Abdel-Sayed, G.; Saleh, K.R. Behavior and ductility of simple and continuous FRP reinforced beams. J. Compos. Constr. 1998, 2, 186–194. [Google Scholar]

- Theriault, M.; Benmokrane, B. Effects of FRP reinforcement ratio and concrete strength on flexural behavior of concrete beams. J. Compos. Constr. 1998, 2, 7–16. [Google Scholar]

- Alsayed, S.H. Flexural behavior of concrete beams reinforced with GFRP bars. Cem. Concr. Compos. 1998, 20, 1–11. [Google Scholar] [CrossRef]

- Pecce, M.; Manfredi, G.; Cosenza, E. Experimental Response and Code Models of GFRP RC Beams in Bending. J. Compos. Constr. 2000, 4, 182–190. [Google Scholar]

- Toutanji, H.A.; Saafi, M. Flexural behavior of concrete beams reinforced with glass fiber-reinforced polymer (GFRP) bars. Struct. J. 2000, 97, 712–719. [Google Scholar]

- Aiello, M.A.; Ombres, L. Load-deflection analysis of FRP reinforced concrete flexural members. J. Compos. Constr. 2000, 4, 164–171. [Google Scholar]

- Yost, J.R.; Goodspeed, C.H.; Schmeckpeper, E.R. Flexural performance of concrete beams reinforced with FRP grids. J. Compos. Constr. 2001, 5, 18–25. [Google Scholar]

- Thiagarajan, G. Experimental and analytical behavior of carbon fiber-based rods as flexural reinforcement. J. Compos. Constr. 2003, 7, 64–72. [Google Scholar]

- Rashid, M.A.; Mansur, M.A.; Paramasivam, P. Behavior of aramid fiber-reinforced polymer reinforced high strength concrete beams under bending. J. Compos. Constr. 2005, 9, 117–127. [Google Scholar]

- Al-Sunna, R.; Pilakoutas, K.; Waldron, P.; Al-Hadeed, T. Deflection of FRP reinforced concrete beams. In Proceedings of the 2nd FIB congress, Naples, Italy, 5 June 2006; pp. 5–8. [Google Scholar]

- Wang, H.; Belarbi, A. Flexural behavior of fiber-reinforced-concrete beams reinforced with FRP rebars. ACI Struct. J. 2005, 51, 895–914. [Google Scholar]

- Ashour, A.F. Flexural and shear capacities of concrete beams reinforced with GFRP bars. Constr. Build. Mater. 2006, 20, 1005–1015. [Google Scholar]

- Ashour, A.F.; Family, M. Tests of concrete flanged beams reinforced with CFRP bars. Mag. Concr. Res. 2006, 58, 627–639. [Google Scholar]

- Rafi, M.M.; Nadjai, A.; Ali, F.; Talamona, D. Aspects of behavior of CFRP reinforced concrete beams in bending. Constr. Build. Mater. 2008, 22, 277–285. [Google Scholar] [CrossRef]

- Ashour, A.F.; Habeeb, M.N. Continuous concrete beams reinforced with CFRP bars. Proc. Inst. Civ. Eng. Struct. Build. 2008, 161, 349–357. [Google Scholar] [CrossRef]

- Barris, C.; Torres, L.; Turon, A.; Baena, M.; Catalan, A. An experimental study of the flexural behaviour of GFRP RC beams and comparison with prediction models. Compos. Struct. 2009, 91, 286–295. [Google Scholar] [CrossRef]

- Shin, S.; Seo, D.; Han, B. Performance of concrete beams reinforced with GFRP bars. J. Asian Archit. Build. Eng. 2009, 8, 197–204. [Google Scholar] [CrossRef]

- Chitsazan, I.; Kobraei, M.; Jumaat, M.Z.; Shafigh, P. An experimental study on the flexural behaviour of FRP RC bemas and comparison of the ultimate moment capacity with ACI. J. Civ. Eng. Constr. Technol. 2010, 1, 27–42. [Google Scholar]

- Kalpana, V.G.; Subramanian, K. Behavior of concrete beams reinforced with GFRP bars. J. Reinf. Plast. Compos. 2011, 30, 1915–1922. [Google Scholar] [CrossRef]

- Issa, M.S.; Metwally, I.M.; Elzeiny, S.M. Influence of fibers on flexural behavior and ductility of concrete beams reinforced with GFRP rebars. Eng. Struct. 2011, 33, 1754–1763. [Google Scholar] [CrossRef]

- Getzlaf, D.D. An Investigation into the Flexural Behavior of GFRP Reinforced Concrete Beams. Ph.D. Thesis, University of Toronto, Toronto, ON, Canada, 2012. [Google Scholar]

- Adam, M.A.; Said, M.; Mahmoud, A.A.; Shanour, A.S. Analytical and experimental flexural behavior of concrete beams reinforced with glass fiber reinforced polymers bars. Constr. Build. Mater. 2015, 84, 354–366. [Google Scholar] [CrossRef]

- Lau, D.; Pam, H.J. Experimental study of hybrid FRP reinforced concrete beams. Eng. Struct. 2010, 32, 3857–3865. [Google Scholar] [CrossRef]

- Ascione, L.; Mancusi, G.; Spadea, S. Flexural behaviour of concrete beams reinforced with GFRP bars. Strain 2010, 46, 460–469. [Google Scholar] [CrossRef]

- Kassem, C.; Farghaly, A.S.; Benmokrane, B. Evaluation of flexural behavior and serviceability performance of concrete beams reinforced with FRP bars. J. Compos. Constr. 2011, 15, 682–695. [Google Scholar] [CrossRef]

- El-Nemr, A.; Ahmed, E.A.; Benmokrane, B. Flexural behavior and serviceability of normal and high-strength concrete beams reinforced with glass fiber-reinforced polymer bars. ACI Struct. J. 2013, 110, 1077. [Google Scholar]

- Goldston, M.W. Behavior of Concrete Beams Reinforced with GFRP Bars Under Static & Impact Loading. Ph.D. Thesis, University of Wollongong, Wollongong, Australia, 2016. [Google Scholar]

- Berry, M.; Johnson, J.; McDevitt, K. Effect of cold temperatures on the behavior and ultimate capacity of GFRP-reinforced concrete beams. Cold Reg. Sci. Technol. 2017, 136, 9–16. [Google Scholar] [CrossRef]

- Mohtaj Khorasani, A.M.; Esfahani, M.R.; Sabzi, J. The effect of transverse and flexural reinforcement on deflection and cracking of GFRP bar reinforced concrete beams. Compos. Part B Eng. 2019, 161, 530–546. [Google Scholar] [CrossRef]

- Rackwitz, R.; Fiessler, B. Structural reliability under combined random load sequences. Comput. Struct. 1978, 9, 489–494. [Google Scholar] [CrossRef]

- Der Kiureghian, A. First-and second-order reliability methods. In Engineering Design Reliability Handbook; Nikolaidis, E., Ghiocel, D.M., Singhal, S., Eds.; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Okeil, A.; Belarbi, A.; Kuchma, D. Reliability assessment of FRP-strengthened concrete bridge girders in shear. J. Compos. Constr. ASCE 2013, 17, 91–100. [Google Scholar]

- Szerszen, M.M.; Nowak, A.S. Calibration of Design Code for Buildings (ACI 318): Part 2: Reliability Analysis and Resistance Factors. ACI Struct. J. 2003, 100, 383–391. [Google Scholar]

- Aghamohammadi, R.; Nasrollahzadeh, K.; Mofidi, A.; Gosling, P. Reliability-based assessment of bond strength models for near-surface mounted FRP bars and strips to concrete. Compos. Struct. 2021, 272, 114132. [Google Scholar] [CrossRef]

- ACI 318–11; Building Code Requirements for Structural Concrete and Commentary. American Concrete Institute: Farmington Hills, MI, USA, 2011.

- Eurocode EN 1990; Fundamentals of Structural Design. CEN: Brussels, Belgium, 2001.

- ISO 2394; International Organization for Standardization. General Principles on Reliability of Structures: Geneva, Switzerland, 2015.

| Source of Uncertainty | Name (Unit) | Nominal Value | Mean | Bias | SD | COV | Distribution (PDF) | Ref. |

|---|---|---|---|---|---|---|---|---|

| Fabrication | (mm) | b + 2.286 | - | 4.826 | - | Normal | [18] | |

| (mm) | d − 4.826 | - | 12.70 | - | Normal | |||

| (mm2) | - | 1 | - | 0.003 | Lognormal | [12] | ||

| Material | (MPa) | - | - | 0.101 | Normal | [19] | ||

| (MPa) () (GPa) | () | 597 (40) | - | 36 (1) | - | Normal [25] (Normal) [24] | [20] | |

| 608 a (39) | - | 28 (1) | - | [21] | ||||

| 692 a (41.3) | - | 19.4 (1.25) | - | [22] | ||||

| 754 a (420) | - | 19 (1) | - | [21] | ||||

| 769 (135) | - | 7 (5) | - | [23] | ||||

| 986 (134) | - | 50 (9) | - | |||||

| 1536 a (128) | - | 31 (5) | - | [20] | ||||

| Load b | Dead (kN) | D | - | 1.05 | - | 0.10 | Normal | [26] |

| Live (kN) | L | - | 1.00 | - | 0.18 | Extreme Value Type I (Gumbel) | ||

| Snow (kN) | S | - | 0.82 | - | 0.26 | Lognormal | ||

| Wind (kN) | W | - | 0.78 | - | 0.37 | Extreme Value Type I (Gumbel) |

| Parameter | Concrete Crushing (211 Specimens) | FRP Rupture (81 Specimens) | Balanced Failure (11 Specimens) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Min. | Max. | Median | Min. | Max. | Median | Min. | Max. | Median | |

| (mm) | 90 | 500 | 180 | 100 | 500 | 152 | 100 | 200 | 152 |

| (mm) | 101 | 404 | 215 | 122 | 504 | 253 | 127 | 269 | 245 |

| (%) | 0.195 | 3.910 | 1.146 | 0.119 | 1.225 | 0.499 | 0.280 | 1.260 | 0.772 |

| (MPa) | 16.30 | 100.50 | 39.60 | 19.60 | 85.60 | 43.00 | 28.00 | 76.49 | 29.42 |

| (MPa) | 504 | 2069 | 776 | 586 | 2250 | 732 | 539 | 1506 | 1000 |

| (GPa) | 26 | 200 | 45 | 30 | 200 | 44 | 29 | 122 | 64 |

| (kN) | 4.00 | 238 | 50.80 | 3.16 | 200.46 | 36.80 | 4.60 | 82.52 | 50.84 |

| State No. | Code | Failure Mode | Number of Test Data | |||

|---|---|---|---|---|---|---|

| Mean | COV | Mean | ||||

| 1 | CSA S806-12 | FRP Rupture | 92 | 0.954 | 18.241 | 4.895 |

| 2 | Concrete Crushing | 222 | 1.070 | 19.297 | 3.726 | |

| 3 | CSA S806-02 | FRP Rupture | 92 | 0.954 | 18.241 | 2.917 |

| 4 | Concrete Crushing | 222 | 1.070 | 19.297 | 4.040 | |

| State No. | Failure Mode | βt | β | |

|---|---|---|---|---|

| Mean | ||||

| 5 | FRP Rupture | 3.5 | 0.65 | 3.533 |

| 6 | Concrete Crushing | 0.70 | 3.433 | |

| 7 | FRP Rupture | 3.8 | 0.60 | 3.872 |

| 8 | Concrete Crushing | 0.65 | 3.726 | |

| 9 | FRP Rupture | 4.0 | 0.60 | 3.872 |

| 10 | Concrete Crushing | 0.60 | 4.041 |

| Parameter | Concrete Crushing (211 Specimens) | FRP Rupture (81 Specimens) | Balanced Failure (11 Specimens) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Min. | Max. | Mean | Min. | Max. | Mean | Min. | Max. | Mean | |

| 0.612 | 13.959 | 2.886 | 0.269 | 3.084 | 0.818 | 0.781 | 1.698 | 1.335 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Attarchian, N.; Aghamohammadi, R.; Nasrollahzadeh, K. Reliability-Based Calibration of Strength-Reduction Factors for Flexural Design of FRP-RC Beams Under Various Load Combinations. J. Compos. Sci. 2025, 9, 154. https://doi.org/10.3390/jcs9040154

Attarchian N, Aghamohammadi R, Nasrollahzadeh K. Reliability-Based Calibration of Strength-Reduction Factors for Flexural Design of FRP-RC Beams Under Various Load Combinations. Journal of Composites Science. 2025; 9(4):154. https://doi.org/10.3390/jcs9040154

Chicago/Turabian StyleAttarchian, Nahid, Reza Aghamohammadi, and Kourosh Nasrollahzadeh. 2025. "Reliability-Based Calibration of Strength-Reduction Factors for Flexural Design of FRP-RC Beams Under Various Load Combinations" Journal of Composites Science 9, no. 4: 154. https://doi.org/10.3390/jcs9040154

APA StyleAttarchian, N., Aghamohammadi, R., & Nasrollahzadeh, K. (2025). Reliability-Based Calibration of Strength-Reduction Factors for Flexural Design of FRP-RC Beams Under Various Load Combinations. Journal of Composites Science, 9(4), 154. https://doi.org/10.3390/jcs9040154