Leveraging Delayed Strength Gains in Supplementary Cementitious Material Concretes: Rethinking Mix Design for Enhanced Cost Efficiency and Sustainability

Abstract

1. Introduction

2. Materials and Methods

2.1. Features of Starting Materials

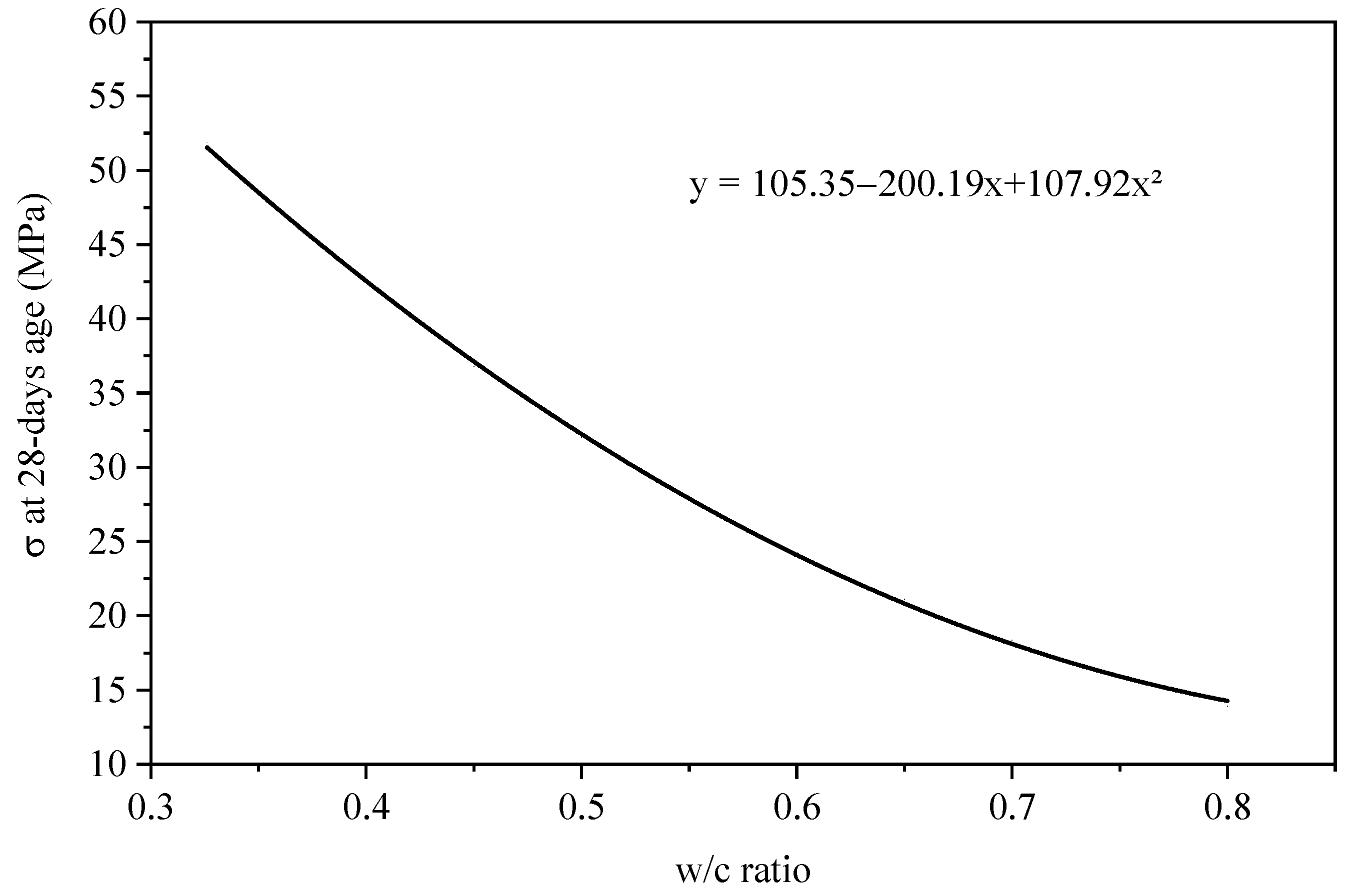

2.2. Mix Design of Concretes

2.3. Characterization of the Manufactured Concretes

2.3.1. Compressive Strength Test

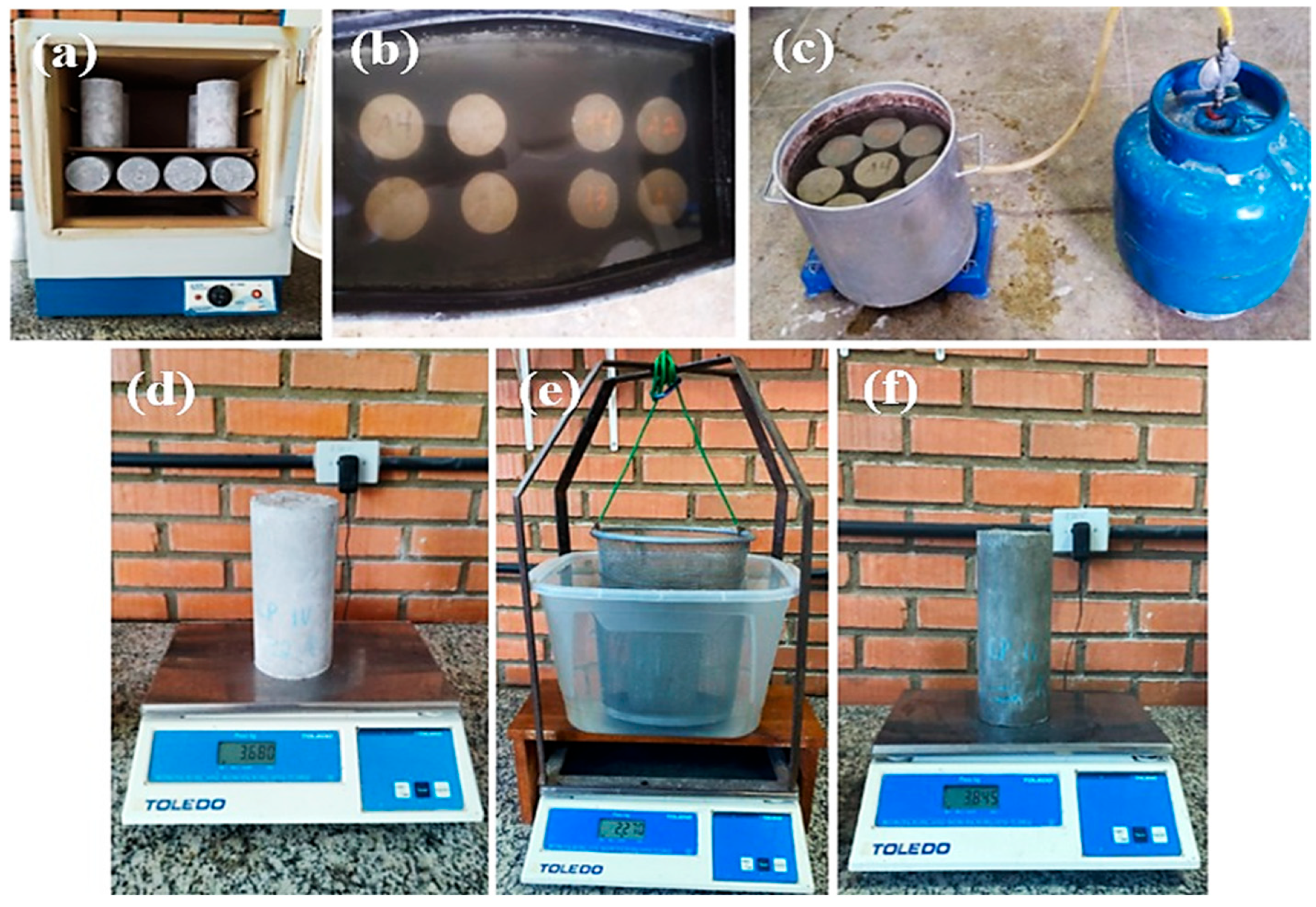

2.3.2. Water Absorption Test, Void Content, and Specific Mass Determination

2.4. Comparative Cost Analysis

2.5. Statistical Analysis

3. Results

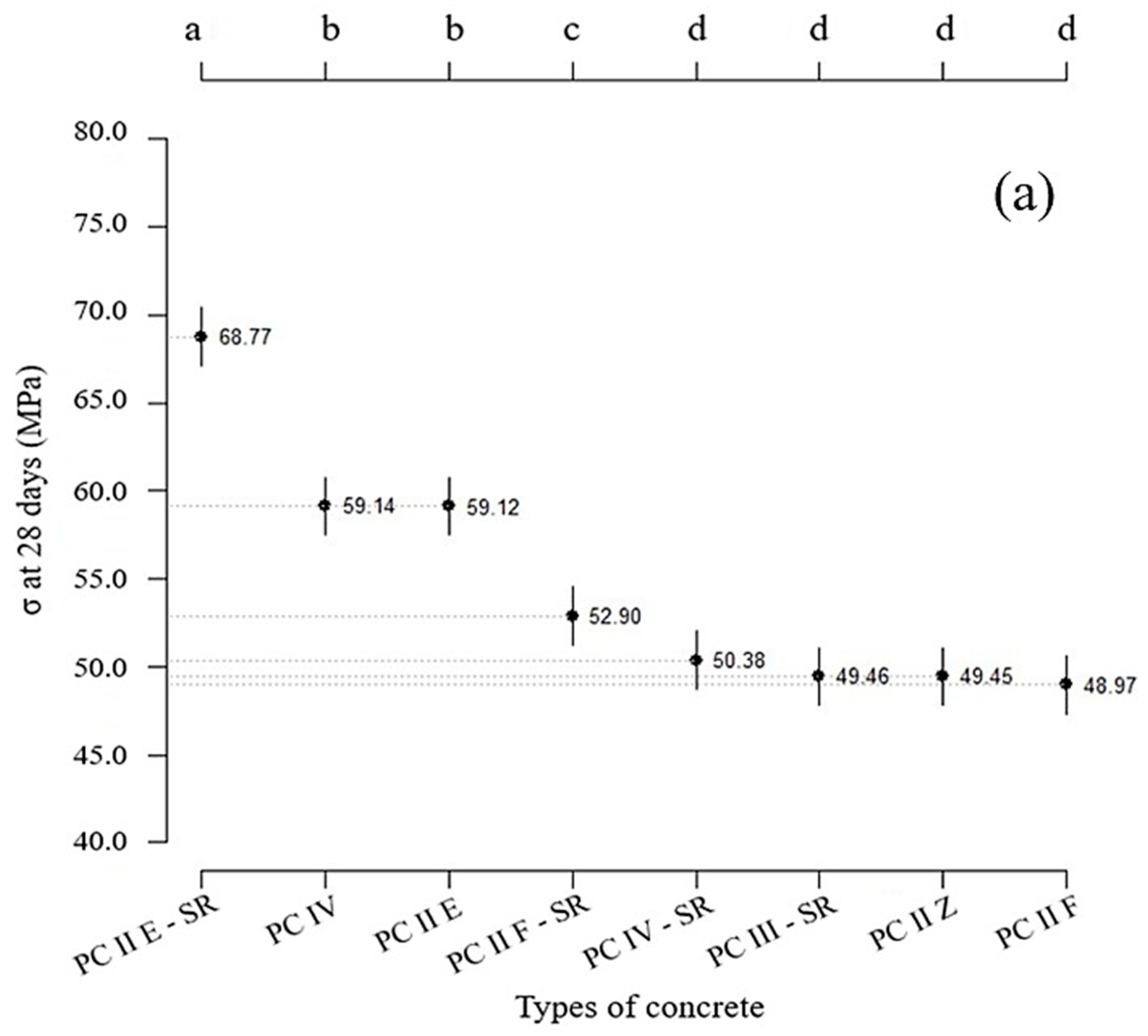

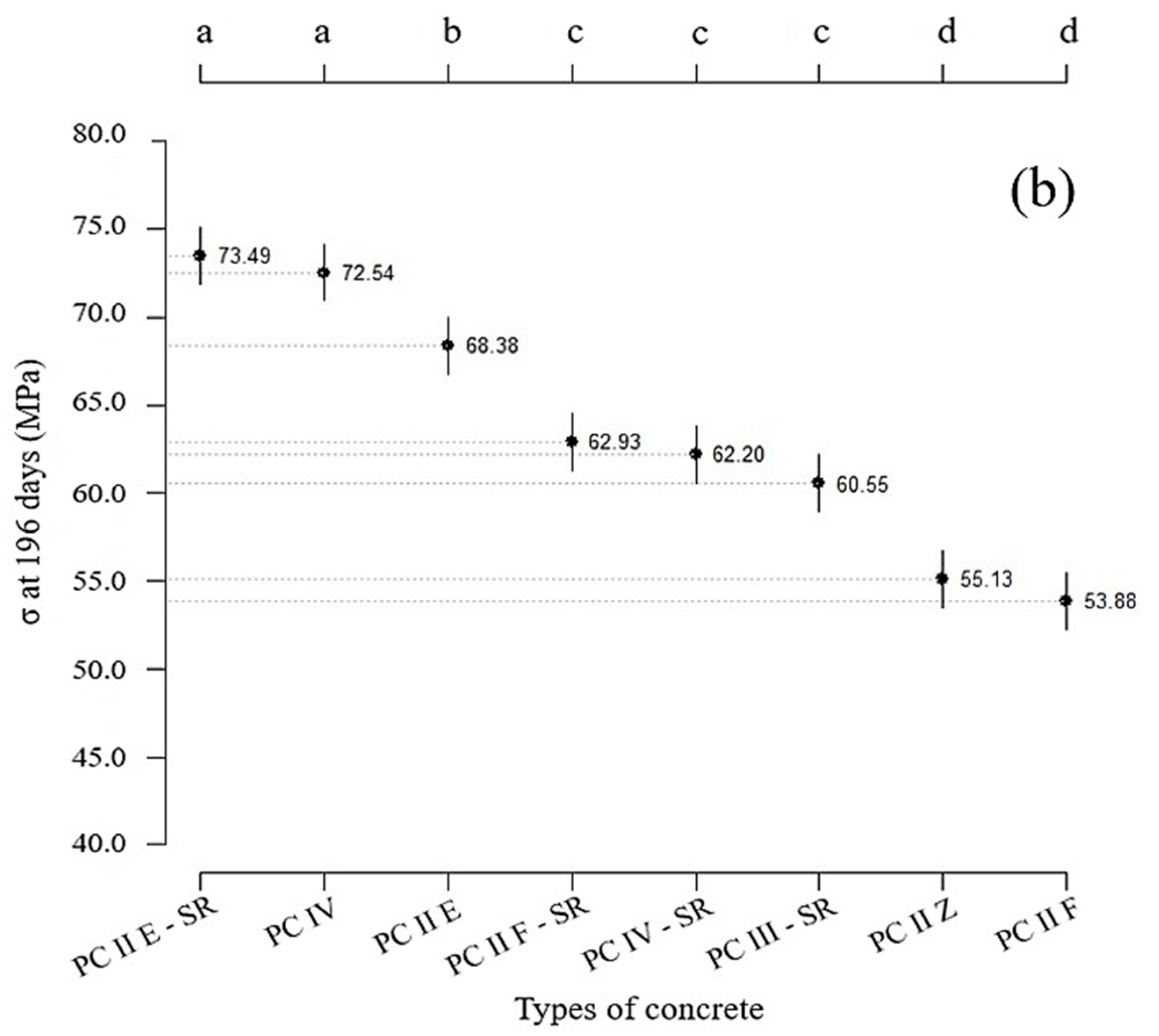

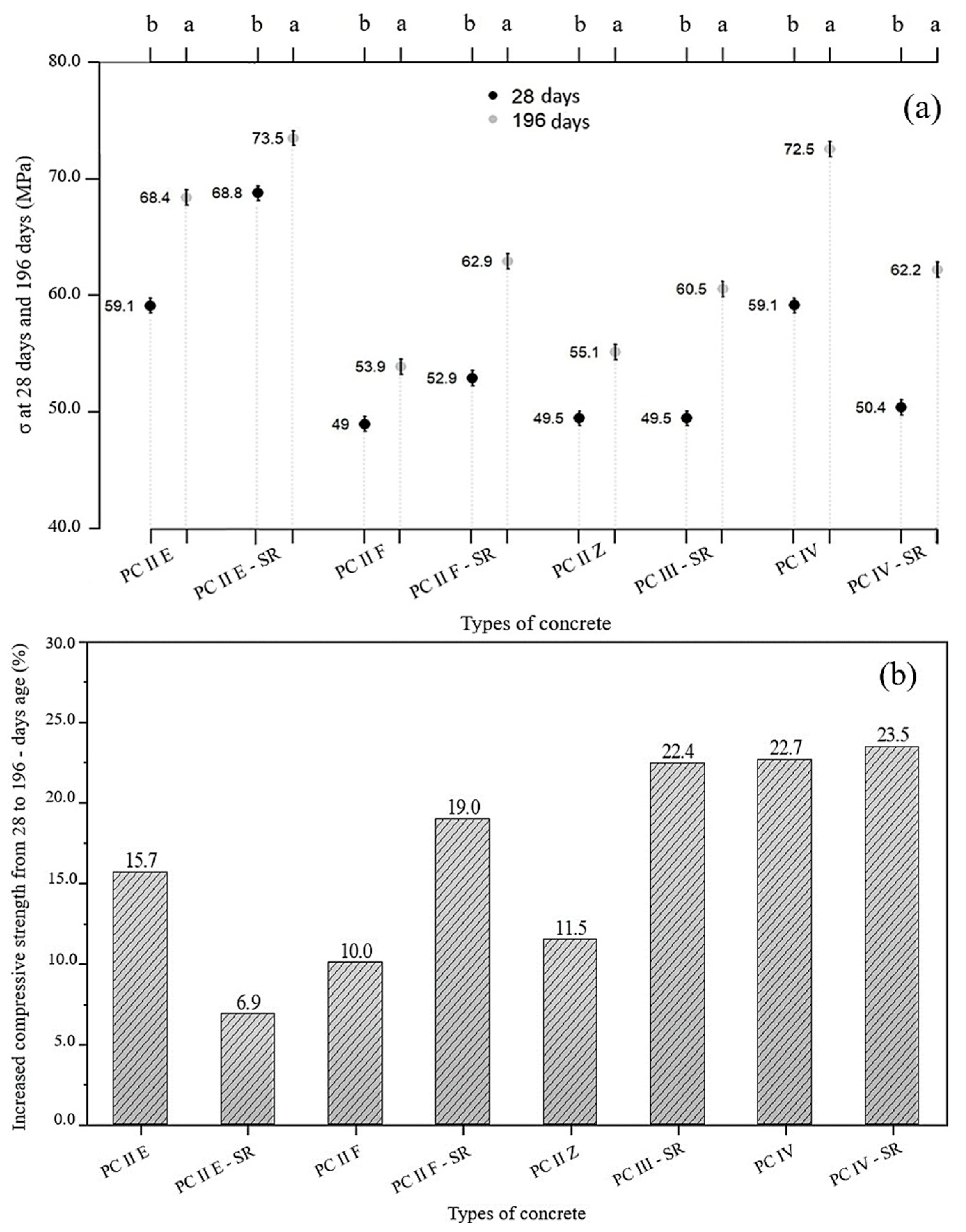

3.1. Resistance to Axial Compression

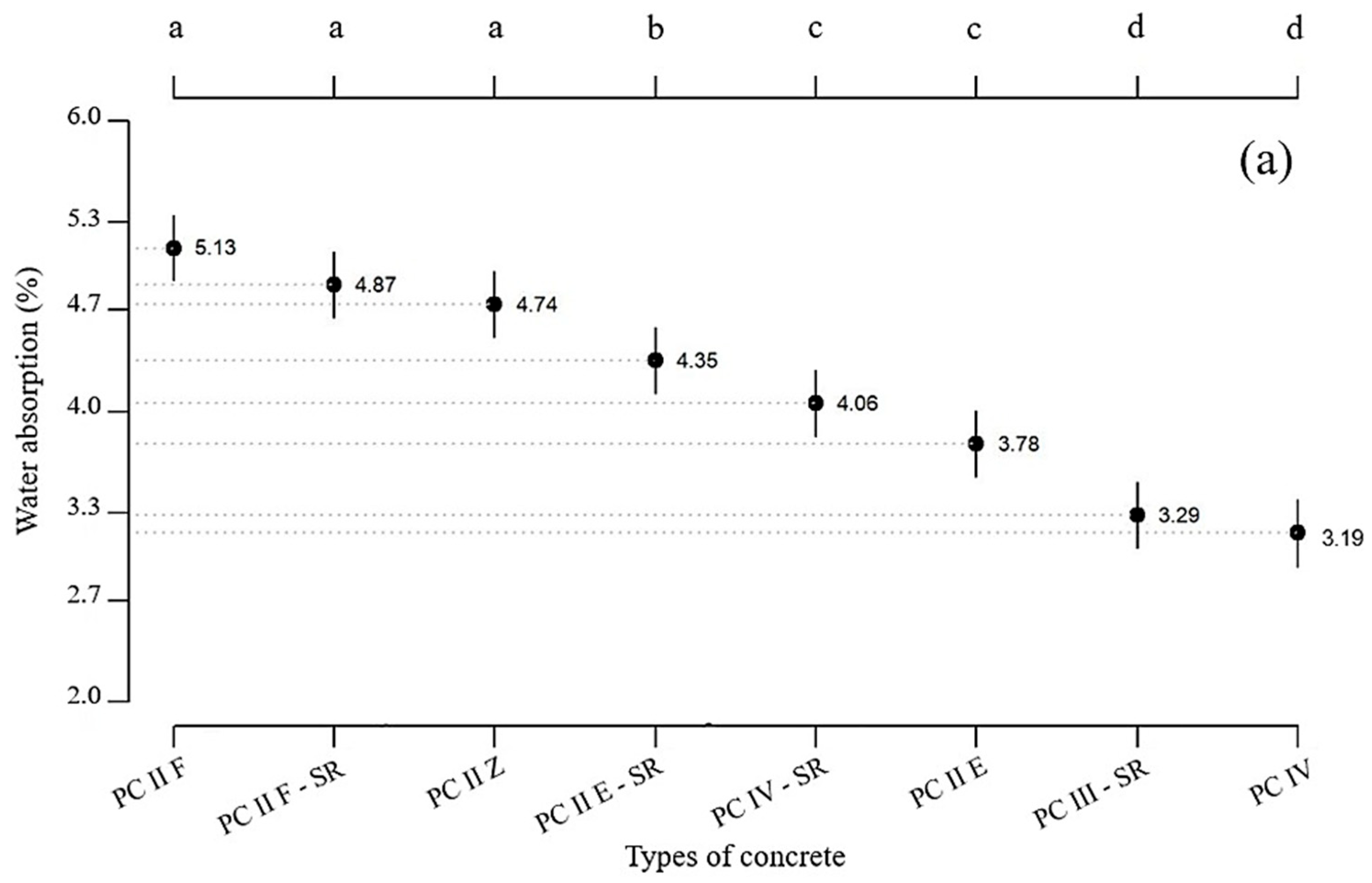

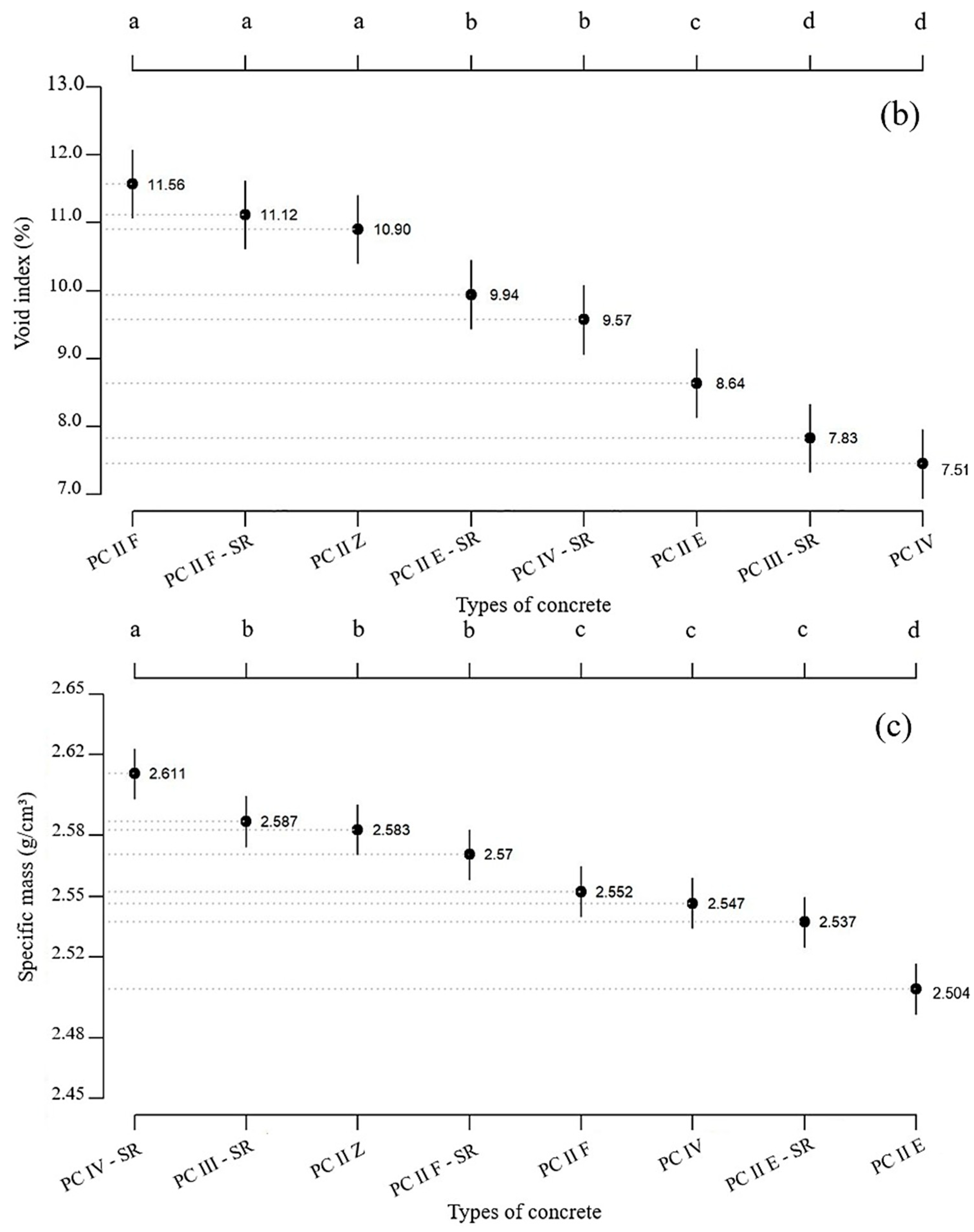

3.2. Water Absorption, Void Index, and Specific Mass

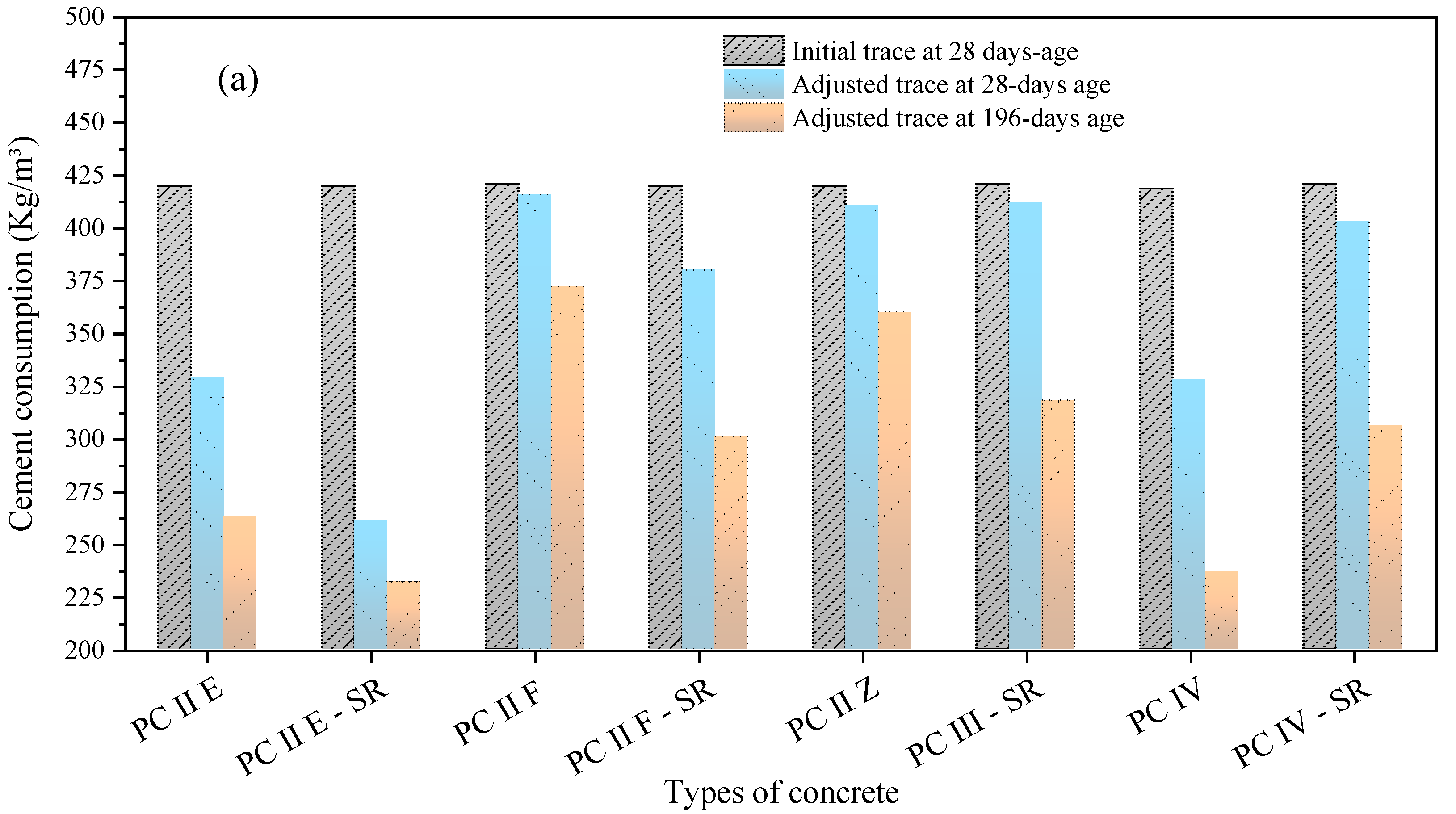

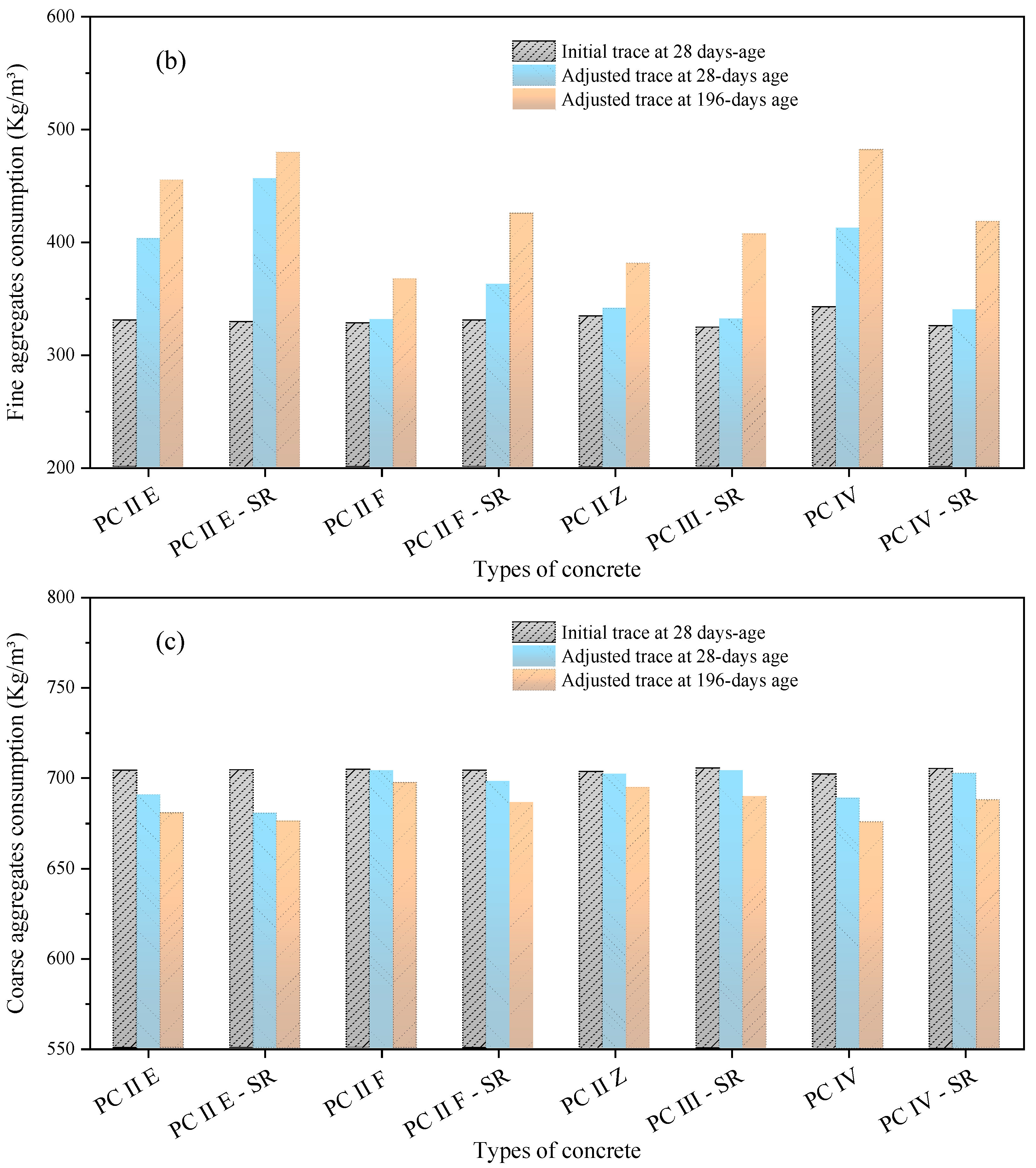

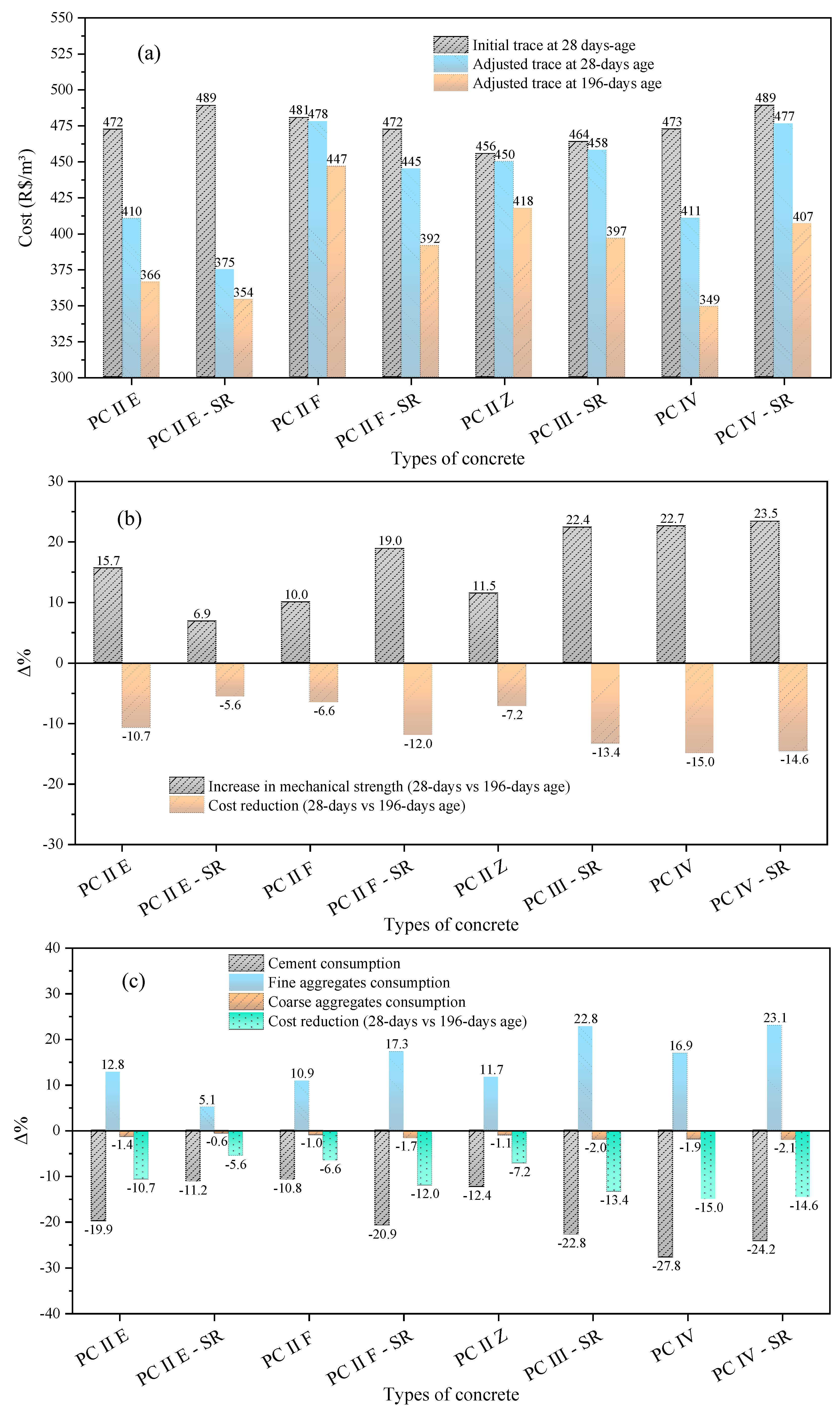

3.3. Cost Analysis of Concretes

4. Discussion

5. Conclusions

- ✓

- The results showed significant differences in axial compressive strength based on the type of cement used. Concretes with PC IV, PC III-SR, and PC IV-SR cements exhibited the greatest strength gains at long-term ages. This is attributed to the slower and progressive pozzolanic reactions associated with these cements. On the other hand, concretes with filler additions (PC II F and PC II F-SR) showed lower initial strength and inferior strength gain over time. This can be attributed to the finely ground filler material, which increases porosity and reduces compressive strength.

- ✓

- Concretes with higher pozzolan content, such as those with PC IV cement, exhibited lower water absorption and void index due to the efficient filling of capillary pores, known as the “pore refinement” effect. This property is crucial for improving the durability and longevity of concrete structures.

- ✓

- The cost analysis revealed that adjusting the cement mix to achieve a targeted strength can significantly impact production costs. Optimizing the mix design based on mechanical performance and financial viability can lead to significant cost savings in construction projects. Considering the characteristic strength at long-term ages instead of the usual 28 days had a significant impact on samples with high SCM content, especially PC III and PC IV, resulting in savings near 14%. The impact was lower for other concretes. In conclusion, this study highlights the importance of selecting appropriate cement types and optimizing mix designs to enhance both mechanical properties and cost-effectiveness in concrete construction projects. These findings provide valuable insights for engineers and construction professionals, enabling them to make informed decisions about cement selection and mix design to achieve desired performance and economic efficiency.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pierrehumbert, R. There is no plan b for dealing with the climate crisis. Bull. At. Sci. 2019, 75, 215–221. [Google Scholar] [CrossRef]

- Chatham House. Making Concrete Change: Innovation in Low-Carbon Cement and Concrete; Chatham House: London, UK, 2018; Available online: https://www.chathamhouse.org/2018/06/making-concrete-change-innovation-low-carbon-cement-and-concrete (accessed on 11 February 2025).

- Global Cement and Concrete Association (GCCA). Global Cement and Concrete Industry Announces Roadmap to Achieve Groundbreaking Net Zero CO2 Emissions by 2050; GCCA. 2021. Available online: https://gccassociation.org/news/global-cement-and-concrete-industry-announces-roadmap-to-achieve-groundbreaking-net-zero-co2-emissions-by-2050 (accessed on 11 February 2025).

- Sindicato Nacional da Indústria do Cimento (SNIC). Resultados Preliminares 2023; SNIC. 2023. Available online: http://snic.org.br/assets/pdf/resultados-preliminares/1731334457.pdf (accessed on 11 February 2025).

- World Business Council for Sustainable Development Guidelines for Emissions Monitoring and Reporting. WBCSD: Geneva, Switzerland, 2012. Available online: https://docs.wbcsd.org/2012/03/GuidelinesEmissionsMonitoringandReporting.pdf (accessed on 11 February 2025).

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 4th ed.; McGraw-Hill Education: New York, NY, USA, 2014. [Google Scholar]

- Lopes, J.P.; Rudnick, T.; Martins, C.H. Utilização de resíduos industriais para produção de concreto sustentável. REEC Rev. Eletrônica Eng. Civ. 2018, 14, 216–228. [Google Scholar] [CrossRef]

- Sun, J.; Shen, X.; Tan, G.; Tanner, J.E. Compressive strength and hydration characteristics of high-volume fly ash concrete prepared from fly ash. J. Therm. Anal. Calorim. 2019, 136, 565–580. [Google Scholar] [CrossRef]

- Neville, A.M.; Brooks, J.J. Concrete Technology, 2nd ed.; Pearson Education Ltd.: London, UK, 2010. [Google Scholar]

- NBR 16697; Cimento Portland—Requisitos. ABNT: Rio de Janeiro, Brazil, 2018.

- NBR 5739; Concreto—Ensaio de Compressão de Corpos de Prova Cilíndricos. ABNT: Rio de Janeiro, Brazil, 2018.

- NBR 9778; Argamassa e Concreto Endurecidos—Determinação da Absorção de Água por Imersão—Índice de Vazios e Massa Específica. ABNT: Rio de Janeiro, Brazil, 2009.

- NBR 16916; Agregado Miúdo—Determinação da Densidade e da Absorção de Água. ABNT: Rio de Janeiro, Brazil, 2021.

- NBR 16917; Agregado Graúdo—Determinação da Densidade e da Absorção de Água. ABNT: Rio de Janeiro, Brazil, 2021.

- de Jesus, W.S.; da Silva, M.F.S.; de Almeida, S.M.T.; Souza, T.M.; Leal, E.S.; Souza, R.S.; Sacramento, L.A.; Allaman, I.B.; de Castro Pessôa, J.R. Comparative study of ASTM C1202 and IBRACON/NT Build 492 testing methods for assessing chloride ion penetration in concretes using different types of cement. Buildings 2025, 15, 302. [Google Scholar] [CrossRef]

- NBR 6118; Projeto de Estruturas de Concreto. ABNT: Rio de Janeiro, Brazil, 2023.

- NBR 16889; Concreto—Determinação da Consistência Pelo Abatimento do Tronco de Cone. ABNT: Rio de Janeiro, Brazil, 2020.

- Abrams, D.A. Design of Concrete Mixtures; Structural Materials Research Laboratory, Lewis Institute: Chicago, IL, USA, 1919; Volume 1. [Google Scholar]

- R Core Team. R: A Language and Environment for Statistical Computing. R Foundation for Statistical Computing: Vienna, Austria, 2023. Available online: http://www.R-project.org/ (accessed on 21 December 2022).

- Jelihovschi, E.G.; Faria, J.C.; Allaman, I.B. ScottKnott: A package for performing the Scott-Knott clustering algorithm in R. TEMA 2014, 15, 3–17. [Google Scholar] [CrossRef]

- NBR 8953; Concreto Para Fins Estruturais—Classificação Pela Massa Específica, por Grupos de Resistência e Consistência. ABNT: Rio de Janeiro, 2015.

- Ram, K.; Londono-Zuluaga, D.; Serdar, M.; Scrivener, K. The effect of cement reduction and substitution on the mechanical and durability properties of concrete. In Proceedings of the International Conference on Concrete Repair, Rehabilitation and Retrofitting (ICCRRR 2022), Cape Town, South Africa, 3–5 October 2022; MATEC Web of Conferences 364. p. 02008. [Google Scholar]

- Medeiros, M.H.F.; Rocha, F.C.; Medeiros-júnior, R.A.; Helene, P. Potencial de corrosão: Influência da umidade, relação água/cimento, teor de cloretos e cobrimento. IBRACON Struct. Mater. J. 2017, 10, 864–885. [Google Scholar]

- Esteves, I.C.A.; Hino, J.R., Jr.; Réus, G.C.; Medeiros, M.H.F. Influência do consumo de cimento na dosagem do concreto sobre a formação da película passivadora do aço. Tech. Sci. J. CREA PR 2018, 1, 143–155. [Google Scholar]

- Medeiros, R.A., Jr.; Lima, M.G.; Medeiros, M.H.F.; Real, L.V. Investigação da resistência à compressão e da resistividade elétrica de concretos com diferentes tipos de cimento. ALCONPAT J. 2014, 4, 116–132. [Google Scholar]

- Muhammad, A.; Usman, N.; Gambo, N. Effect of binary blended pozzolanic materials on properties of self-compacting concrete. Int. J. Constr. Manag. 2022, 22, 1323–1332. [Google Scholar] [CrossRef]

- Huynh, T.P.; Ho, L.S.; Van Ho, Q. Experimental investigation on the performance of concrete incorporating fine dune sand and ground granulated blast-furnace slag. Constr. Build. Mater. 2022, 347, 128512. [Google Scholar] [CrossRef]

- Prasanna, P.K.; Srinivasu, K.; Murthy, A.R. Strength and durability of fiber reinforced concrete with partial replacement of cement by ground granulated blast furnace slag. Mater. Today Proc. 2021, 47, 5416–5425. [Google Scholar] [CrossRef]

- Magalhães, T.A. Análise da Penetração de Íons Cloreto Em Compósitos Cimentícios Contendo Diferentes Teores de Escória De Alto Forno. Master’s Thesis, Postgraduate Program in Civil Construction at the Federal University of Minas Gerais, Belo Horizonte, Minas Gerais, Brazil, 2019. [Google Scholar]

- Ogirigbo, O.; Black, L. Chloride binding and diffusion in slag blends: Influence of slag composition and temperature. Constr. Build. Mater. 2017, 149, 816–825. [Google Scholar] [CrossRef]

- Ramezanianpour, A.; Ghiasvand, E.; Nickseresht, I.; Mahdikhani, M.; Moodi, F. Influence of various amounts of limestone powder on performance of Portland limestone cement concretes. Cem. Concr. Compos. 2009, 31, 715–720. [Google Scholar] [CrossRef]

- Ananyachandran, P.; Vasugi, V. Development of a sustainable high early strength concrete incorporated with pozzolans, calcium nitrate and triethanolamine: An experimental study. Sustain. Energy Technol. Assess. 2022, 54, 102857. [Google Scholar] [CrossRef]

- Liu, J.C.; Hossain, M.U.; NG, T.S.; Ye, H. High-performance green concrete with high-volume natural pozzolan: Mechanical, carbon emission and cost analysis. J. Build. Eng. 2023, 68, 106087. [Google Scholar] [CrossRef]

- Ahmad, S.; Baghabra Al-Amoudi, O.S.; Khan, S.M.S.; Maslehuddin, M. Effect of silica fume inclusion on the strength, shrinkage and durability characteristics of natural pozzolan-based cement concrete. Case Stud. Constr. Mater. 2022, 17, e01255. [Google Scholar] [CrossRef]

- Baghabra Al-Amoudi, O.S.; Ahmad, S.; Maslehuddin, M.; Khan, S.M.S. Lime-activation of natural pozzolan for use as supplementary cementitious material in concrete. Ain. Shams. Eng. J. 2022, 13, 101602. [Google Scholar] [CrossRef]

- Rahman, S.A.; Dodd, A.; Khair, S.; Shaikh, F.U.A.; Sarker, P.K.; Hosan, A. Assessment of lithium slag as a supplementary cementitious material: Pozzolanic activity and microstructure development. Cem. Concr. Compos. 2023, 143, 105262. [Google Scholar] [CrossRef]

- Wang, Y.; Shui, Z.; Wang, L.; Gao, X.; Huang, Y.; Song, Q.; Liu, K. Alumina-rich pozzolan modification on Portland-limestone cement concrete: Hydration kinetics, formation of hydrates and long-term performance evolution. Constr. Build. Mater. 2020, 258, 119712. [Google Scholar] [CrossRef]

- Bediako, M.; Valentini, L. Strength performance and life cycle assessment of high-volume low-grade kaolin clay pozzolan concrete: A Ghanaian scenario. Case Stud. Constr. Mater. 2022, 17, e01679. [Google Scholar] [CrossRef]

- Adegoke, H.A.; Ikumapayi, C.M. Effects of induction furnace slag on the durability properties of concrete. Constr. Build. Mater. 2024, 419, 135263. [Google Scholar] [CrossRef]

- Rahman, S.A.; Shaikh, F.U.A.; Sarker, P.K. Fresh, mechanical, and microstructural properties of lithium slag concretes. Cem. Concr. Compos. 2024, 148, 105469. [Google Scholar] [CrossRef]

- Bhagath Singh, G.V.P.; Durga Prasad, V. Environmental impact of concrete containing high volume fly ash and ground granulated blast furnace slag. J. Clean. Prod. 2024, 448, 141729. [Google Scholar] [CrossRef]

- AS 3972:2010; General Purpose and Blended Cements. Standards Australia: Sydney, Australia, 2010.

- BS EN 197-1:2011; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. British Standards Institution: London, UK, 2011.

- ASTM C150/C150M-22; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2022.

- GS 1118:16; General Specification for Cement. Development Bureau, Hong Kong Government: Hong Kong, 2016.

| Type of Cement | Abbreviation | Clinker + Gypsum | Granulated Blast-Furnace Slag | Pozzolan | Carbonates (Filler) |

|---|---|---|---|---|---|

| Portland cement blended with granulated blast-furnace slag | PC II E | 51–94 | 6–34 | 0 | 0–15 |

| Portland cement blended with pozzolanic material | PC II Z | 71–94 | 0 | 6–14 | 0–15 |

| Portland cement blended with carbonate material | PC II F | 75–89 | 0 | 0 | 11–25 |

| Blast-furnace Portland cement | PC III | 25–65 | 35–75 | 0 | 0–10 |

| Pozzolanic Portland cement | PC IV | 45–85 | 0 | 15–50 | 0–10 |

| Cement Type | Specific Mass (kg/m3) | Loose Unit Mass (kg/m3) | Compacted Unit Mass (kg/m3) | Fineness Modulus | Maximum Diameter (mm) | Moisture |

|---|---|---|---|---|---|---|

| PC II E | 3000 a | |||||

| PC II E-SR | 2990 b | |||||

| PC II F | 2980 b | |||||

| PC II F-SR | 3000 c | |||||

| PC II Z | 3030 d | |||||

| PC III-SR | 2950 e | |||||

| PC IV | 3100 f | |||||

| PC IV-SR | 2960 a | |||||

| Fine aggregate | 2845 | 1639 | 1769 | 1.71 | 1.18 | 2.94 |

| Coarse aggregate | 2719 | 1367 | 1553 | 2.46 | 12.5 | 0.32 |

| Superplasticizer | 1090 * |

| Type of Concrete | Cement (kg/m3) | Fine Aggregate (kg/m3) | Coarse Aggregate (kg/m3) | Water (L/m3) | w/c Ratio | SP (L/m3) |

|---|---|---|---|---|---|---|

| PC II E | 420.30 | 330.44 | 704.20 | 137.12 | 0.33 | 0.77 |

| PC II E-SR | 420.44 | 329.21 | 704.43 | 137.21 | 0.33 | 0.96 |

| PC II F | 420.58 | 327.98 | 704.66 | 137.29 | 0.33 | 1.16 |

| PC II F-SR | 420.30 | 330.44 | 704.20 | 137.12 | 0.33 | 0.58 |

| PC II Z | 419.89 | 334.06 | 703.51 | 136.87 | 0.33 | 0.39 |

| PC III-SR | 421.00 | 324.22 | 705.37 | 137.55 | 0.33 | 0.48 |

| PC IV | 418.97 | 342.21 | 701.98 | 136.30 | 0.33 | 0.77 |

| PC IV-SR | 420.86 | 325.48 | 705.13 | 137.47 | 0.33 | 0.58 |

| Type of Concrete | w/c at 28 Days | w/c at 196 Days |

|---|---|---|

| PC II E | 0.279 | 0.227 |

| PC II E-SR | 0.225 | 0.201 |

| PC II F | 0.347 | 0.313 |

| PC II F-SR | 0.319 | 0.257 |

| PC II Z | 0.343 | 0.304 |

| PC III-SR | 0.343 | 0.271 |

| PC IV | 0.279 | 0.206 |

| PC IV-SR | 0.337 | 0.261 |

| Type of Concrete | Dosage at 28 Days | Dosage at 196 Days | ||

|---|---|---|---|---|

| w/c at 28 Days | Increase (%) | w/c at 196 Days | Increase (%) | |

| PC II E | 0.439 | 25.37 | 0.540 | 54.34 |

| PC II E-SR | 0.545 | 55.74 | 0.610 | 74.28 |

| PC II F | 0.353 | 0.86 | 0.392 | 11.97 |

| PC II F-SR | 0.384 | 9.65 | 0.477 | 36.35 |

| PC II Z | 0.357 | 1.89 | 0.403 | 15.00 |

| PC III-SR | 0.357 | 1.92 | 0.453 | 29.36 |

| PC IV | 0.439 | 25.42 | 0.596 | 70.31 |

| PC IV-SR | 0.364 | 3.92 | 0.470 | 34.16 |

| Type of Concrete | Consumption at 28 Days | Consumption at 196 Days | ||||||

|---|---|---|---|---|---|---|---|---|

| Cement (kg/m3) | Fine Aggregate (kg/m3) | Coarse Aggregate (kg/m3) | Water (L/m3) | Cement (kg/m3) | Fine Aggregate (kg/m3) | Coarse Aggregate (kg/m3) | Water (L/m3) | |

| PC II E | 328.56 | 403.21 | 690.46 | 132.05 | 263.33 | 454.96 | 680.70 | 128.45 |

| PC II E-SR | 260.82 | 456.26 | 680.45 | 128.36 | 231.52 | 479.58 | 676.05 | 126.74 |

| PC II F | 416.65 | 331.11 | 704.07 | 137.08 | 371.58 | 367.11 | 697.28 | 134.57 |

| PC II F-SR | 379.79 | 362.58 | 698.13 | 134.88 | 300.55 | 425.43 | 686.27 | 130.51 |

| PC II Z | 410.88 | 341.14 | 702.18 | 136.38 | 360.07 | 381.04 | 694.65 | 133.60 |

| PC III-SR | 411.94 | 331.53 | 703.99 | 137.05 | 318.05 | 407.27 | 689.70 | 131.77 |

| PC IV | 327.75 | 412.24 | 688.76 | 131.43 | 236.79 | 482.07 | 675.58 | 126.56 |

| PC IV-SR | 403.13 | 339.74 | 702.44 | 136.47 | 305.63 | 418.12 | 687.65 | 131.02 |

| Author | SCM | Optimal Content (%) | w/b | Compressive Strength (MPa) | Findings | ||||

|---|---|---|---|---|---|---|---|---|---|

| 28 Days | 56 Days | 90 Days | 180 Days | 270 Days | |||||

| (Adegoke, Ikumapayi [39]) | Control | - | - | 6.8 | 7.1 (+4.4%) | 9.4 (+38.2%) | - | - | The authors used Portland limestone cement (CEM II) with a strength class of 42.5. The highest compressive strength, reaching 14.4 MPa, was achieved with a 25% substitution of induced blast-furnace slag (FS) at 90 days. Due to its predominantly crystalline nature, the slag showed low reactivity, resulting in only a modest 12.5% increase in strength compared to the 28-days age. However, a significant increase was observed in the control sample from 28 to 90 days. |

| FS | 25 | - | 11.5 | 12.8 (+11.3%) | 14.4 (+12.5%) | - | - | ||

| (Rahman, Shaikh, Sarker [40]) | Control | - | 0.43 | 40.4 | - | 49.9 (+23.5%) | - | - | Authors utilized OPC without SCMs, conforming to AS 3972:2010 [42], for general purpose. The highest compressive strength at 28 days was attained with 20% lithium slag (LS), while at 90 days, it was achieved with 40% *. LS content ranging from 20% to 40% accelerated pozzolanic activity during the early stages. LS comprises 31.6% amorphous aluminosilicate, initiating pozzolanic activity within 3 to 7 days. Concretes containing 60% fly ash (FA) exhibited the highest strengths among those containing fly ash. The low solubility of fly ash in an alkaline environment did not expedite strength gain, indicating its slower pozzolanic nature compared to LS. |

| LS | 20 | 49.8 | 52.5 (+5.4%) | ||||||

| LS | 40 | 47 | - | 58.6 (+24.7%) | - | - | |||

| FA | 60 | 38.8 | - | 45 (+16%) | - | - | |||

| (Liu et al. [33]) | Control | - | 0.33 | 75 | 82 (+9.3%) | - | - | - | The authors utilized OPC without SCMs, conforming to the BS EN 197-1 [43] standard with a strength class of 52.5. The authors asserted that 1 g of volcanic ash (VA) consumes 321 milligrams of Portlandite, indicating its low reactivity compared to other pozzolans. Although not explicitly stated, this could explain why the strength at 28 days was lower than that of the control concrete. However, both the control and VA-based concretes demonstrated a reasonably significant increase in strength by 56 days compared to 28 days of age. |

| VA | 30 | 72.1 | 79.9 (+10.8%) | - | - | - | |||

| (Ananyachandran, Vasugi [32]) | Control | - | 0.35 | 50 | - | - | 51.8 (+3.6) | 52 (+0.38%) | Three different types of cementitious materials were employed in this study: (1) 53-grade Ordinary Portland Cement (OPC) as the control, (2) Portland Slag Cement (PSC), and (3) Ordinary Portland Cement with 15% Metakaolin substitution. Both Metakaolin (MK) and Furnace Slag (FS) contributed to enhanced resistance compared to the standard sample, with MK standing out for its high reactivity and fine particle size. However, the difference in long-term strength development compared to the 28-day hydration period was not significant for either SCM, remaining below 10%. |

| FS | 21–35 | 54.9 | 56.0 (+2%) | 56.8 (+3.5%) | 58.1 (+5.8%) | 59.2 (+7.8%) | |||

| MK | 15 | 63.1 | 64.8 (+2.7%) | 65.9 (+4.4%) | 67.2 (+6.5%) | 68.3 (+8.2%) | |||

| (Ahmad et al. [34]) | Control | - | 0.4 | 53.2 | - | 57 (+7.1%) | 63 (+18.4%) | - | In this study, OPC Type I, conforming to ASTM C150 [44], was used. The concrete incorporating 20% natural pozzolan (NP) and 5% silica fume (SF) exhibited a greater increase in strength over time compared to the reference concrete after 28 days of curing. Additionally, both samples showed a significant strength gain of 17–18% from 180 to 28 days. |

| NP + SF * | 20–5 * | 63.9 | - | 69.5 (+8.7%) | 74.9 (+17.2%) | - | |||

| (Baghabra Al-Amoudi et al. [35]) | Control | - | 0.4 | 53 | - | 58 (+9.4%) | 64 (+20.7%) | - | Author used OPC Type I, conforming to ASTM C 150 [44]. The activation of natural pozzolan (NP) by hydrated lime (HL) enhanced both the initial and final strength and compensated for the loss of strength due to the substitution of OPC with NP. Not only did it improve the initial strength by approximately 10 to 15% across all ages, but the HL-treated concrete also exhibited superior strength compared to the OPC concrete. Finally, the strength gain reached up to approximately 25% at 180 days compared to the standard sample. |

| NP + HL * | 20–7 * | 58.5 | - | 65.2 (+11.5%) | 73.2 (+25.2%) | - | |||

| (Bediako, Valentini [38]) | Control | - | 0.48 | 34 | 40 (+17.6%) | - | - | - | Portland cement class 42.5 R without SCMs (likely CEM I), conforming to GS 1118:16 [45], was used. The 10% clay pozzolan (CP) sample showed a gain in strength compared to the standard sample, particularly at the 28-day hydration mark. This suggests a pozzolanic reaction occurred, where products formed and filled spaces, enhancing strength. Comparing the samples, later ages slightly favor the CP sample, but there is a significant gain for the standard sample. |

| CP | 10 | 42.1 | 45.4 (+7.8%) | - | - | - | |||

| (Wang et al. [37]) | Control | 0.35 | 52.6 | 58.3 (+10.8%) | - | - | - | The authors used Portland limestone cement (PLC) as a reference, adhering to BS EN 197-1 [43] standards. The increase in strength is attributed to the formation of carboaluminates, which fills voids in the matrix, resulting in a denser structure. The addition of Metakaolin (MK) accelerates the hydration of PLC paste, and at low MK replacement levels, this effect can be enhanced further by ultra-fine fly ash (UFA). | |

| MK | 11 | 66.3 | 71.4 (+7.7%) | - | - | - | |||

| MK + UFA * | 10 + 10 * | 72.9 | 75.8 (+4%) | - | - | - | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Jesus, W.S.; de Almeida, T.M.S.; da Silva, S.F.M.; Souza, M.T.; Leal, E.S.; Souza, R.S.; Sacramento, L.A.; Allaman, I.B.; Pessôa, J.R.d.C. Leveraging Delayed Strength Gains in Supplementary Cementitious Material Concretes: Rethinking Mix Design for Enhanced Cost Efficiency and Sustainability. J. Compos. Sci. 2025, 9, 110. https://doi.org/10.3390/jcs9030110

de Jesus WS, de Almeida TMS, da Silva SFM, Souza MT, Leal ES, Souza RS, Sacramento LA, Allaman IB, Pessôa JRdC. Leveraging Delayed Strength Gains in Supplementary Cementitious Material Concretes: Rethinking Mix Design for Enhanced Cost Efficiency and Sustainability. Journal of Composites Science. 2025; 9(3):110. https://doi.org/10.3390/jcs9030110

Chicago/Turabian Stylede Jesus, Wanderson Santos, Thalles Murilo Santos de Almeida, Suânia Fabiele Moitinho da Silva, Marcelo Tramontin Souza, Eduarda Silva Leal, Ramon Santos Souza, Laio Andrade Sacramento, Ivan Bezerra Allaman, and José Renato de Castro Pessôa. 2025. "Leveraging Delayed Strength Gains in Supplementary Cementitious Material Concretes: Rethinking Mix Design for Enhanced Cost Efficiency and Sustainability" Journal of Composites Science 9, no. 3: 110. https://doi.org/10.3390/jcs9030110

APA Stylede Jesus, W. S., de Almeida, T. M. S., da Silva, S. F. M., Souza, M. T., Leal, E. S., Souza, R. S., Sacramento, L. A., Allaman, I. B., & Pessôa, J. R. d. C. (2025). Leveraging Delayed Strength Gains in Supplementary Cementitious Material Concretes: Rethinking Mix Design for Enhanced Cost Efficiency and Sustainability. Journal of Composites Science, 9(3), 110. https://doi.org/10.3390/jcs9030110