Comparison Study on Flat and Curved Glass-Fiber-Reinforced Polymer Panels Subjected to High-Velocity Impacts with Spherical and Conical Projectiles: An Experimental and Numerical Study

Abstract

1. Introduction

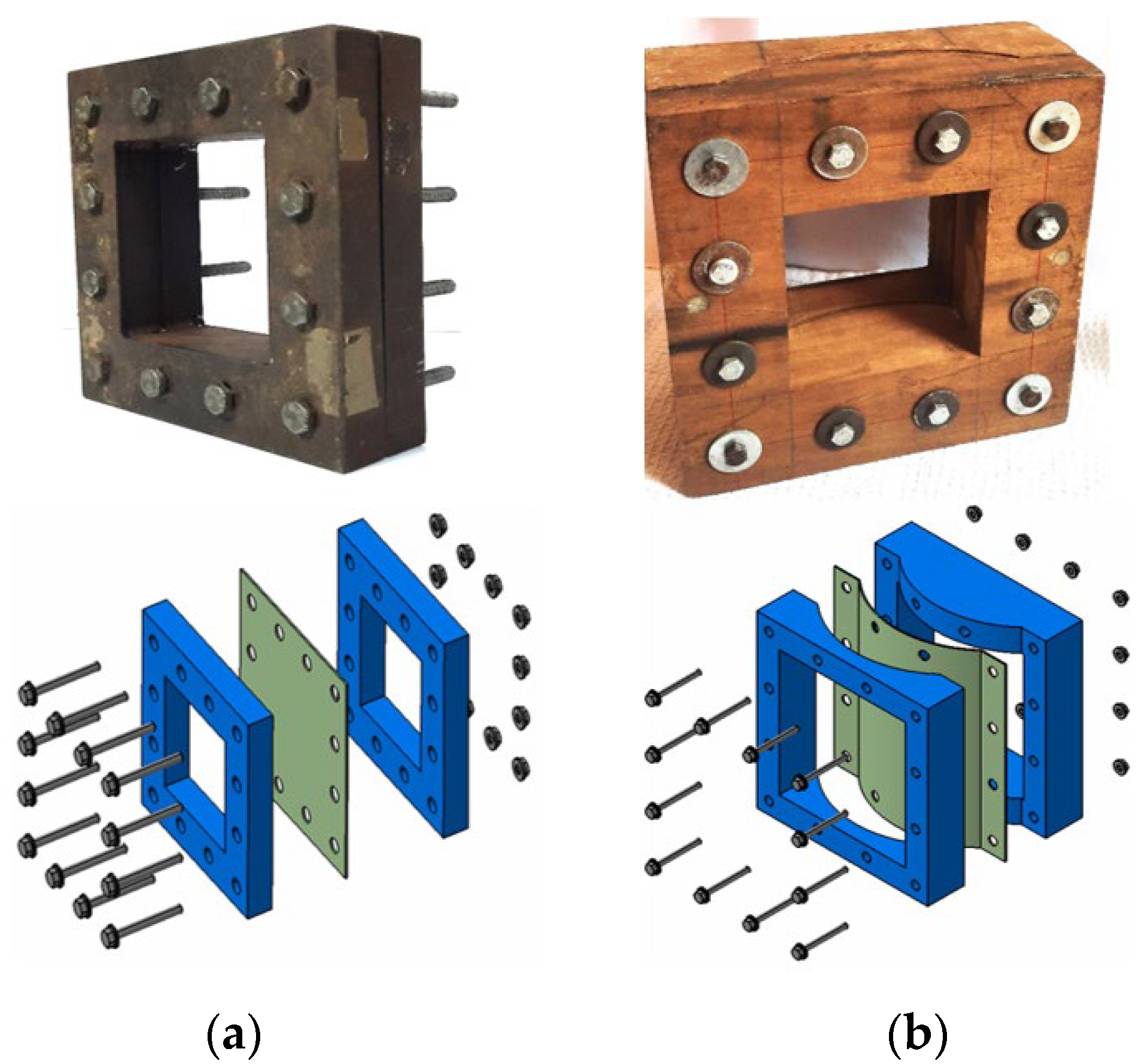

2. Experiment

2.1. Materials and Fabrication

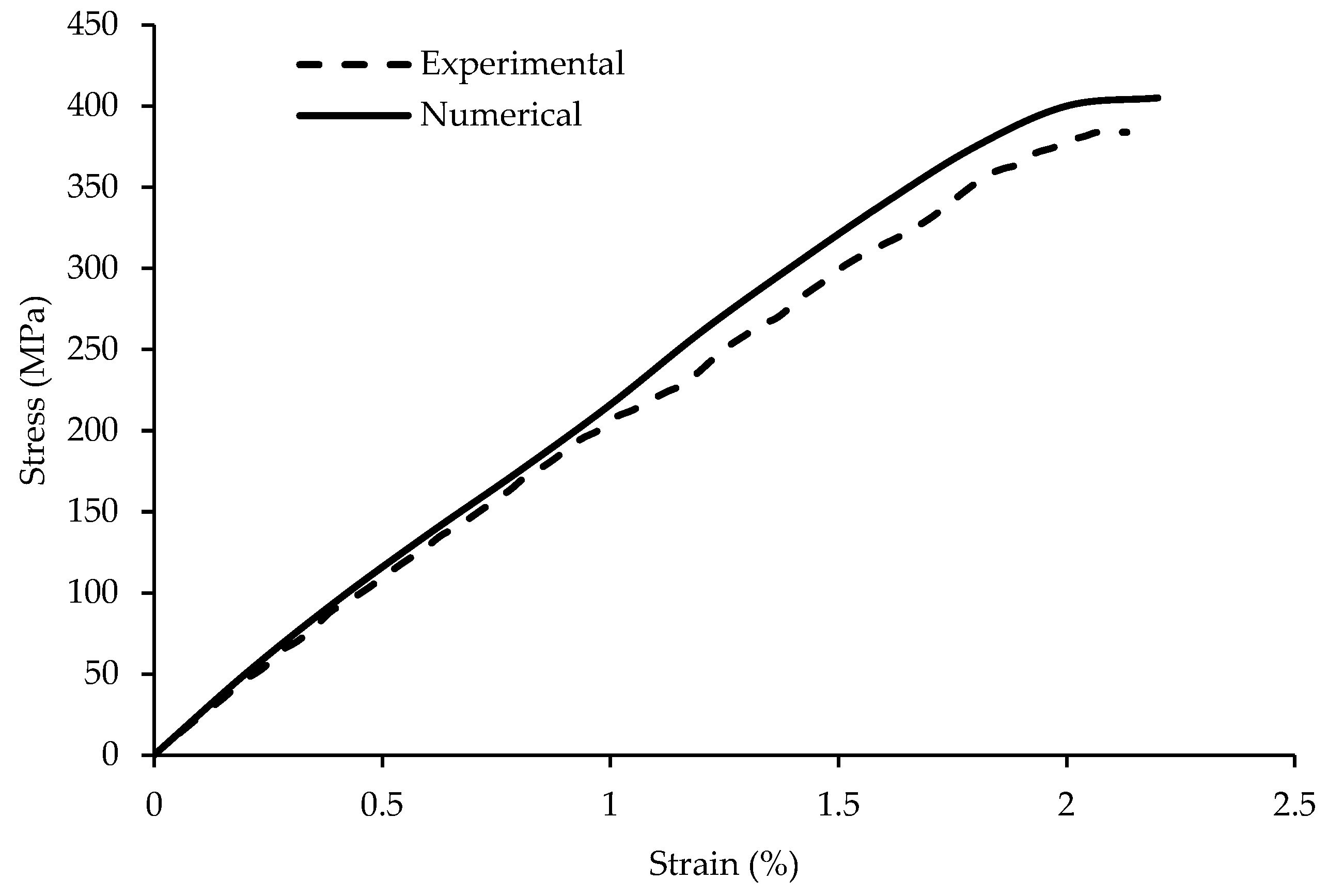

2.2. Material Tests

2.3. Impact Tests

3. Numerical Analysis

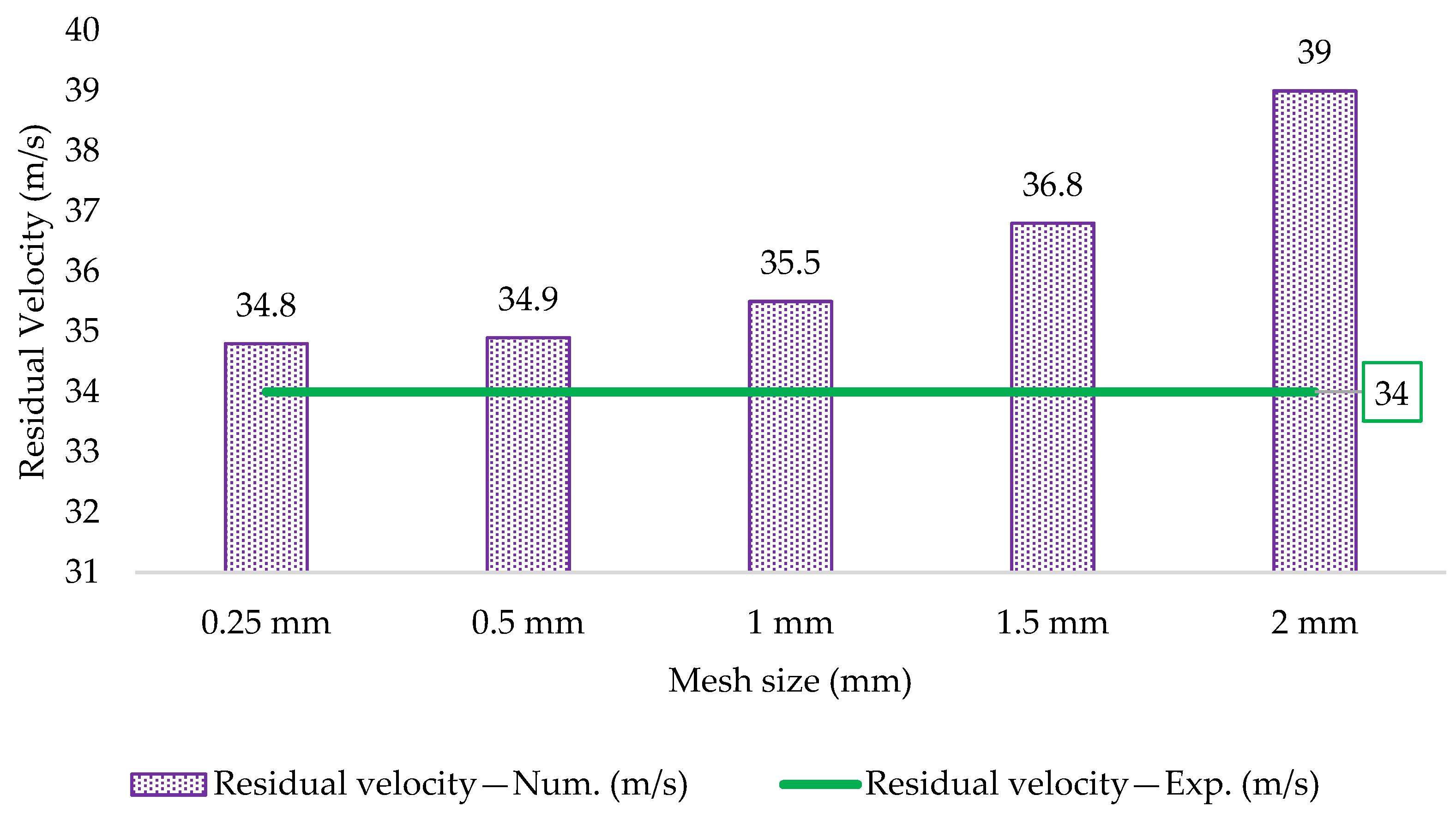

3.1. Finite Element Model

3.2. Material Model

3.3. Influence of Strain Rate

3.4. Contact Modeling

3.5. Boundary Conditions

4. Results and Discussion

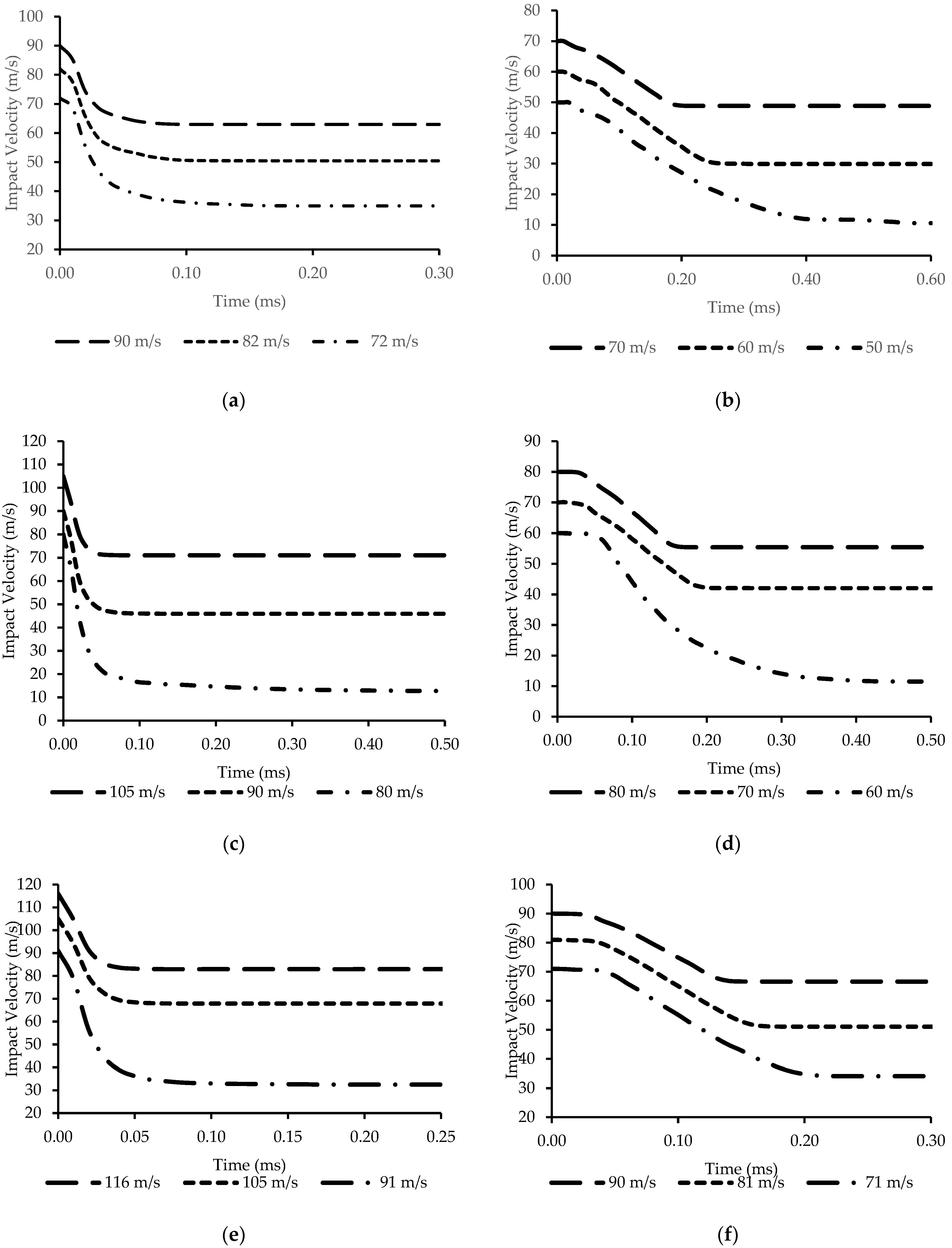

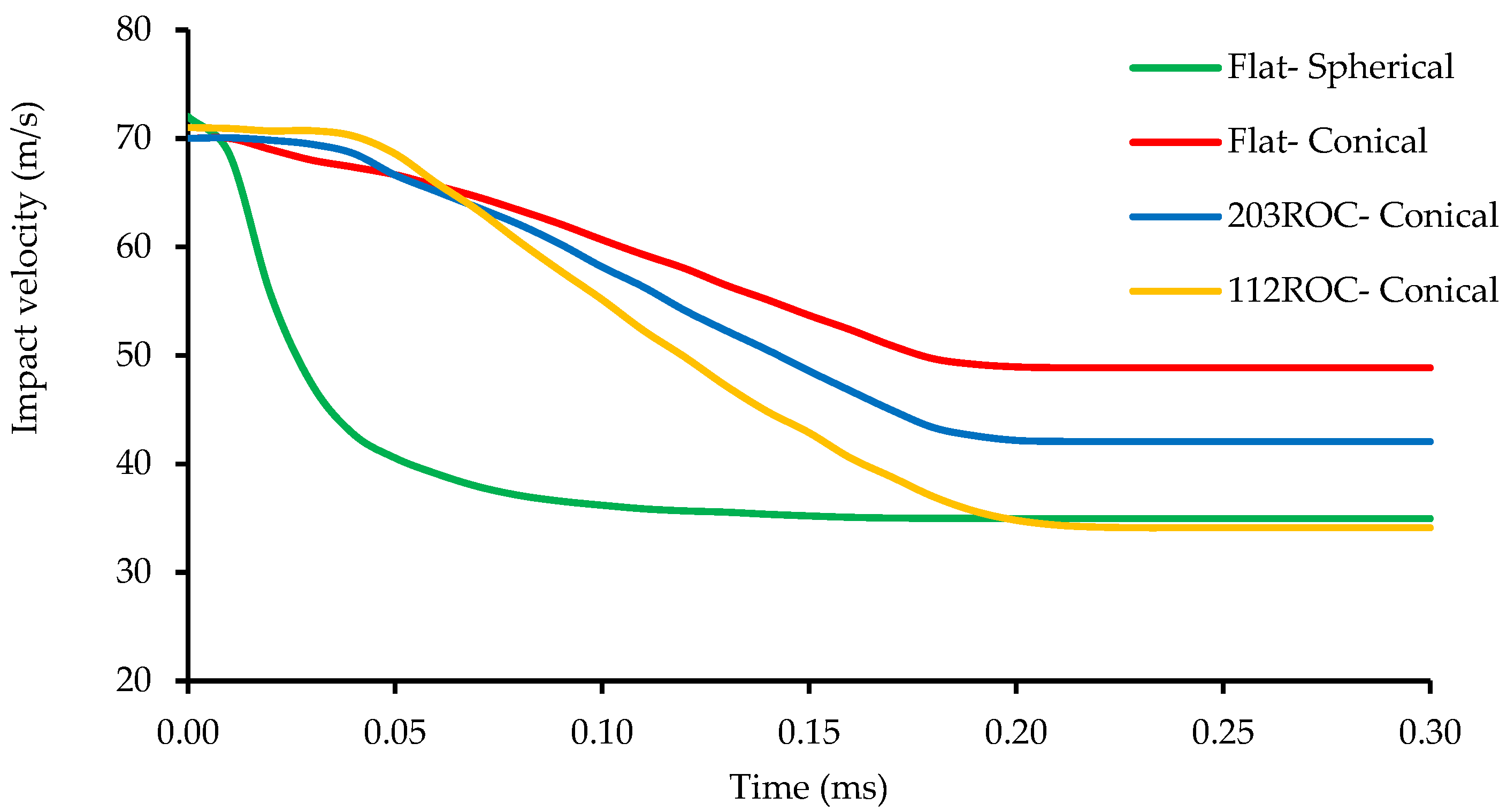

4.1. Residual Velocity Analysis

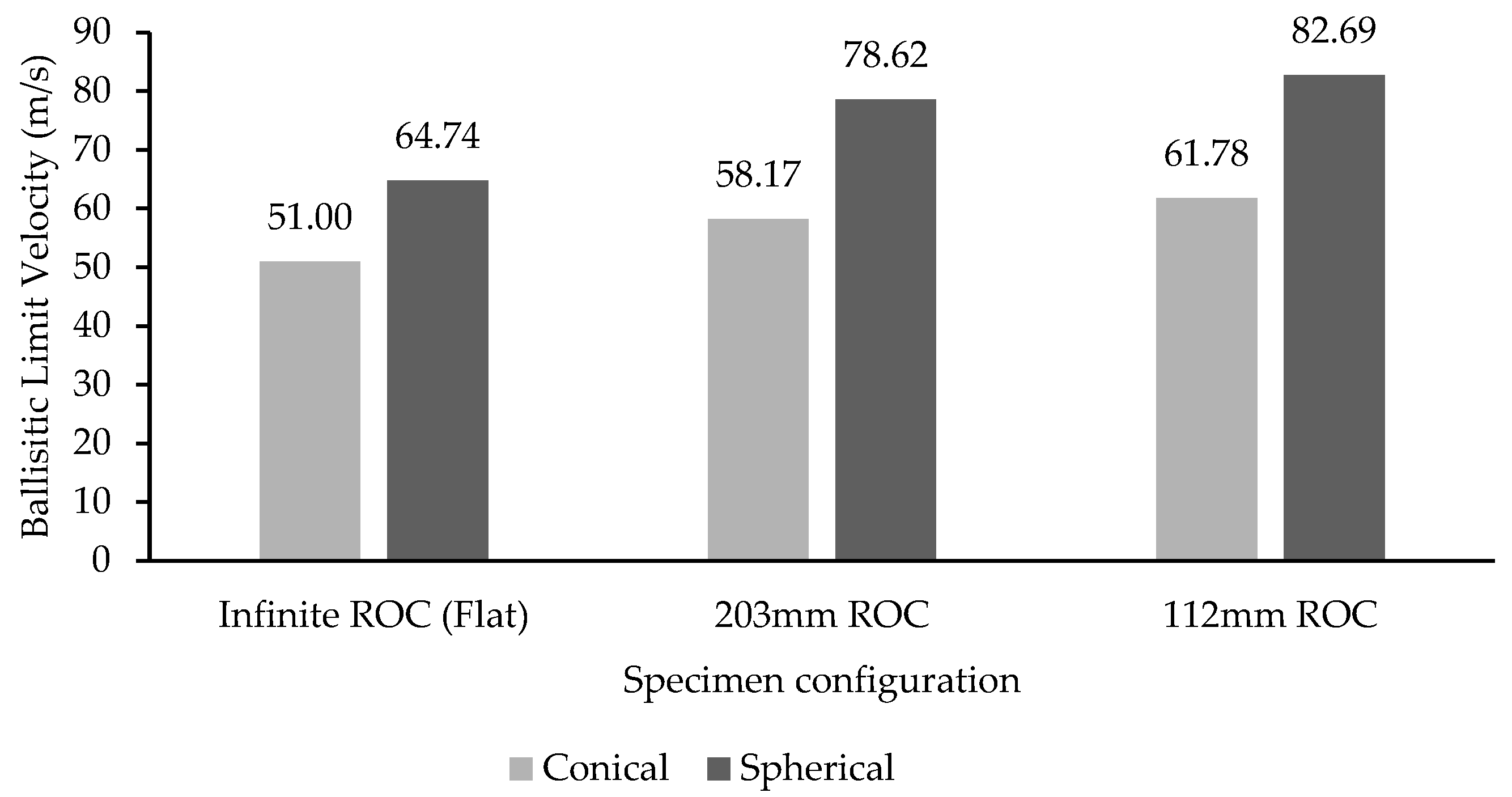

4.2. Ballistic Limit Analysis

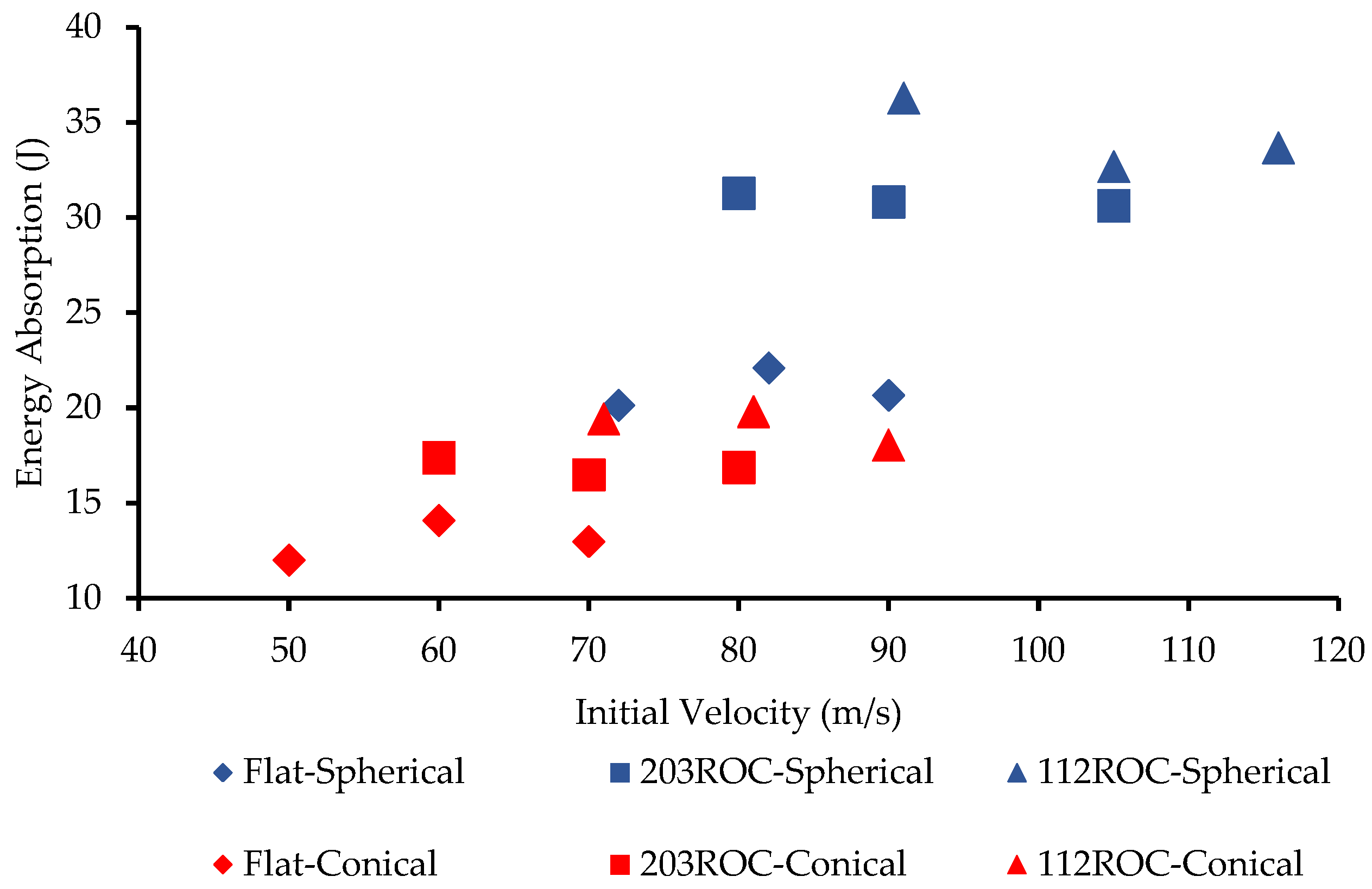

4.3. Energy Absorption Capability

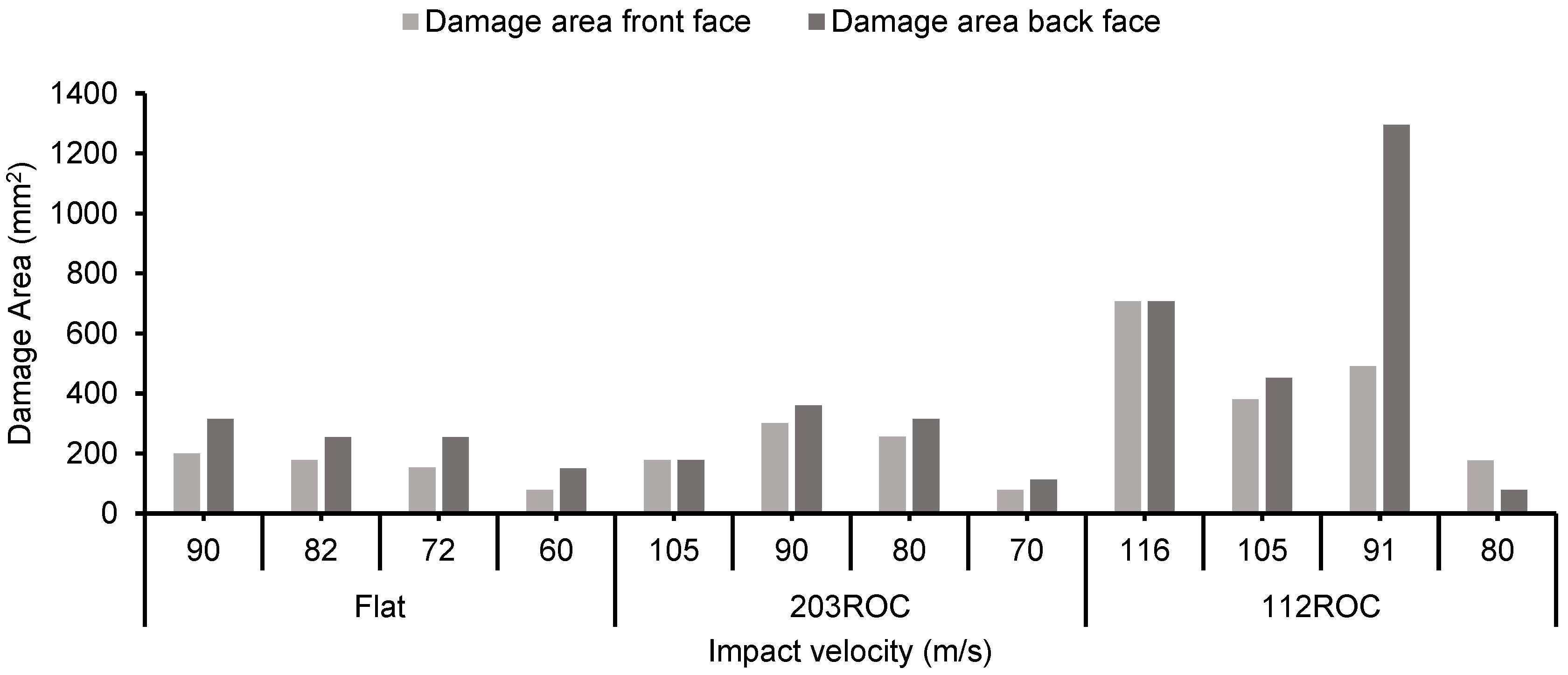

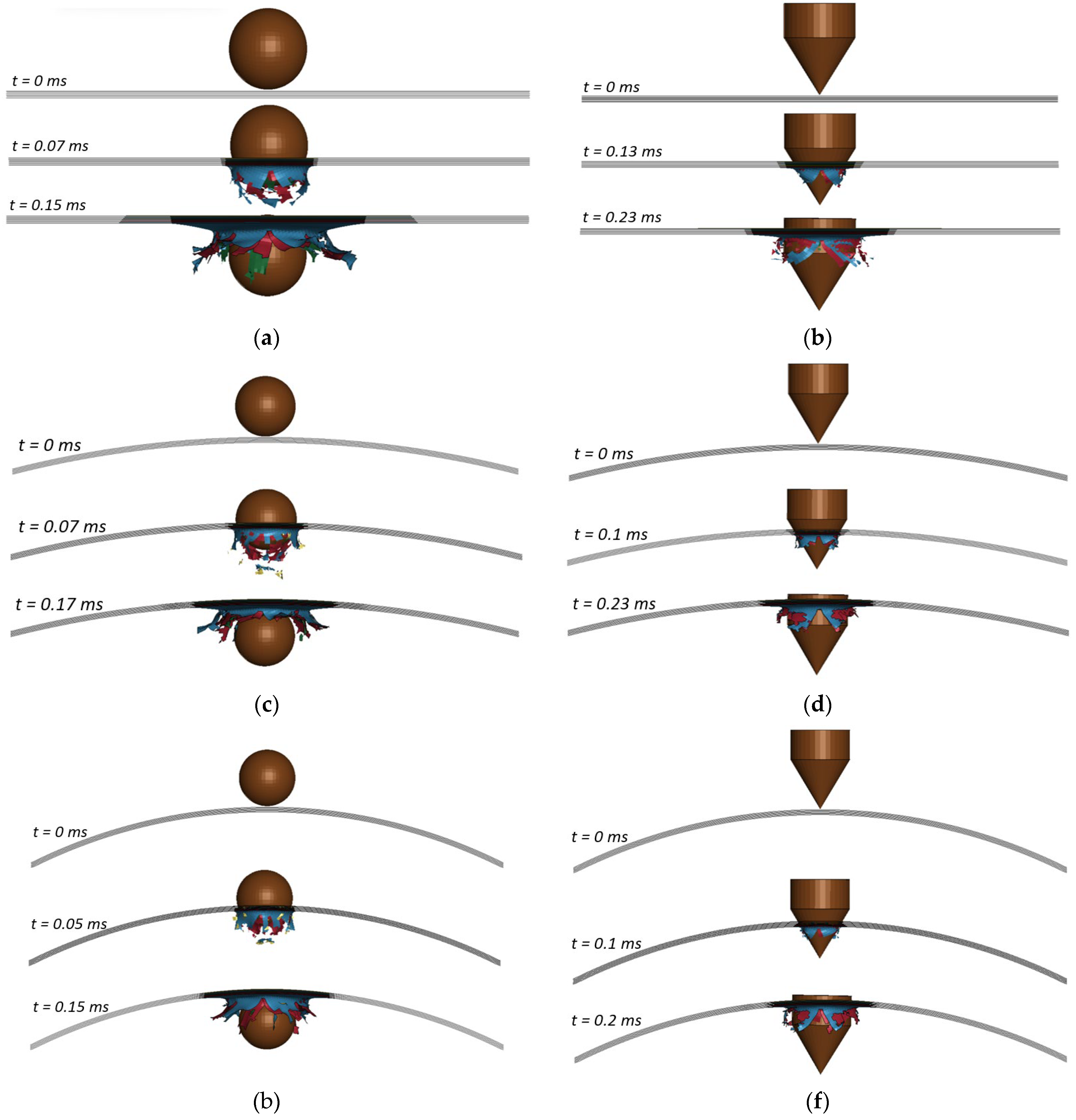

4.4. Damage Analysis

5. Conclusions

- (1)

- The findings from the material tests reveal that the mechanical properties of GFRP laminates are quantified as follows: a tensile modulus of 20 GPa, a tensile strength of 386 MPa, a compressive strength of 72.6 MPa, a shear strength of 105 MPa, and an interlaminar shear stress of 10.3 MPa.

- (2)

- This research indicates that the panel with a 112 mm radius of curvature (ROC) exhibited superior ballistic limit velocity and energy absorption capabilities when compared to both the 203 mm ROC and flat panels. A decrease in the panel’s radius of curvature correlates with an increase in its energy absorption. Specifically, the ballistic limit velocity of the 112 mm ROC panel surpassed that of the flat panels by 22% for spherical impactors and by 17% for conical projectiles. The recorded ballistic limit velocities for the flat, 203 mm ROC, and 112 mm ROC panels were 64.74 m/s, 78.62 m/s, and 82.69 m/s for spherical impactors, and 51 m/s, 58 m/s, and 61.78 m/s for conical impactors, respectively.

- (3)

- The maximum energy absorption of the 112ROC panel is 36.3 J when subjected to a 91 m/s spherical impact, resulting in the largest damage area of 1296 mm2 on its backside. The spherical projectile causes more damage to the panel than the conical projectile due to its larger contact area with the panel.

- (4)

- The primary failure mechanisms identified in the 112ROC panel subjected to a spherical impact at 91 m/s include delamination, fiber pullout, and matrix debonding. Additionally, the 112ROC panel demonstrated a greater extent of fiber and matrix area that was compromised by the impactor.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Petron. Glass Fiber Reinforced Polymer (GFRP). Available online: https://petronthermoplast.com/glass-fiber-reinforced-polymer/ (accessed on 5 August 2024).

- Morampudi, P.; Namala, K.K.; Gajjela, Y.K.; Barath, M.; Prudhvi, G. Review on glass fiber reinforced polymer composites. Mater. Today Proc. 2020, 43, 314–319. [Google Scholar] [CrossRef]

- Sawada, T.; Kusaka, T. Strength predictions by applied effective volume theory in short-glass-fiber-reinforced plastics. Polym. Test 2017, 62, 143–153. [Google Scholar] [CrossRef]

- Carvalho, D.; Ferreira, N.; França, B.; Marques, R.; Silva, M.; Silva, S.; Silva, E.; Macário, D.; Barroso, L.; Silva, C.J.; et al. Advancing sustainability in the automotive industry: Bioprepregs and fully bio-based composites. Compos. Part C Open Access 2024, 14, 100459. [Google Scholar] [CrossRef]

- Feito, N.; Loya, J.A.; Muñoz-Sánchez, A.; Das, R. Numerical modelling of ballistic impact response at low velocity in aramid fabrics. Materials 2019, 12, 2087. [Google Scholar] [CrossRef]

- Alam, S.; Aboagye, P. Numerical Modeling on Ballistic Impact Analysis of the Segmented Sandwich Composite Armor System. Appl. Mech. 2024, 5, 340–361. [Google Scholar] [CrossRef]

- Chen, F.; Peng, Y.; Chen, X.; Wang, K.; Liu, Z.; Chen, C. Investigation of the Ballistic Performance of GFRP Laminate under 150 m/s High-Velocity Impact: Simulation and Experiment. Polymers 2021, 13, 604. [Google Scholar] [CrossRef]

- Shyamsunder, L.; Maurya, A.; Rajan, S.D.; Cordasco, D.; Revilock, D.; Blankenhorn, G. Impact simulation of composite panels for aerospace applications. Compos. B Eng. 2022, 247, 110320. [Google Scholar] [CrossRef]

- Yang, C.; Gao, Y.; Guo, W.; Yang, Y.; Xu, P.; Alqahtani, M.S. High-velocity impact behavior of curved GFRP composites for rail vehicles: Experimental and numerical study. Polym. Test 2022, 116, 107774. [Google Scholar] [CrossRef]

- Coelho, C.A.C.P.; Navalho, F.V.P.; Reis, P.N.B. Impact response of laminate cylindrical shells. Frat. Integrita Strutt. 2019, 13, 411–418. [Google Scholar] [CrossRef]

- Menna, C.; Asprone, D.; Caprino, G.; Lopresto, V.; Prota, A. Numerical simulation of impact tests on GFRP composite laminates. Int. J. Impact Eng. 2011, 38, 677–685. [Google Scholar] [CrossRef]

- Donadon, M.V.; Iannucci, L.; Falzon, B.G.; Hodgkinson, J.M.; de Almeida, S.F.M. A progressive failure model for composite laminates subjected to low velocity impact damage. Comput. Struct. 2008, 86, 1232–1252. [Google Scholar] [CrossRef]

- Yang, C.; Chen, Z.; Yao, S.; Xu, P.; Li, S.; Alqahtani, M.S. Parametric study on the crushing performance of a polyurethane foam-filled CFRP/Al composite sandwich structure. Polym. Test 2022, 108, 107515. [Google Scholar] [CrossRef]

- Castellano, A.; Fraddosio, A.; Piccioni, M.D. Quantitative analysis of QSI and LVI damage in GFRP unidirectional composite laminates by a new ultrasonic approach. Compos. B Eng. 2018, 151, 106–117. [Google Scholar] [CrossRef]

- Muhi, R.J.; Najim, F.; de Moura, M.F.S.F. The effect of hybridization on the GFRP behavior under high velocity impact. Compos. B Eng. 2009, 40, 798–803. [Google Scholar] [CrossRef]

- Seifoori, S.; Izadi, R.; Yazdinezhad, A.R. Impact damage detection for small- and large-mass impact on CFRP and GFRP composite laminate with different striker geometry using experimental, analytical and FE methods. Acta Mech. 2019, 230, 4417–4433. [Google Scholar] [CrossRef]

- Mishra, Y.; Kumar, N.H.; Priya, I.I.M. Simulation of high velocity impact test on GFRP. IOP Conf. Ser. Mater. Sci. Eng. 2020, 912, 052004. [Google Scholar] [CrossRef]

- Seifoori, S.; Parrany, A.M.; Mirzarahmani, S. Impact damage detection in CFRP and GFRP curved composite laminates subjected to low-velocity impacts. Compos. Struct. 2021, 261, 113278. [Google Scholar] [CrossRef]

- Zhao, D.; Liu, T.; Lu, X.; Meng, X. Experimental and numerical analysis of a novel curved sandwich panel with pultruded GFRP strip core. Compos. Struct. 2022, 288, 115404. [Google Scholar] [CrossRef]

- Saghafi, H.; Minak, G.; Zucchelli, A. Effect of preload on the impact response of curved composite panels. Compos. B Eng. 2014, 60, 74–81. [Google Scholar] [CrossRef]

- Song, Z.; Le, J.; Whisler, D.; Kim, H. Skin-stringer interface failure investigation of stringer-stiffened curved composite panels under hail ice impact. Int. J. Impact Eng. 2018, 122, 439–450. [Google Scholar] [CrossRef]

- Serhat, G.; Basdogan, I. Design of curved composite panels for optimal dynamic response using lamination parameters. Compos. B Eng. 2018, 147, 135–146. [Google Scholar] [CrossRef]

- Haque, B.Z.; Gillespie, J.W. A new penetration equation for ballistic limit analysis. J. Thermoplast. Compos. Mater. 2015, 28, 950–972. [Google Scholar] [CrossRef]

- Bidi, A.; Liaghat, G.; Rahimi, G.; Hadavinia, H. Experimental and numerical analysis of impact on curved nanocomposite panels. Mech. Adv. Mater. Struct. 2019, 26, 1365–1375. [Google Scholar] [CrossRef]

- Chinnarasu, A.; Ramajeyathilagam, K. Low velocity impact behavior of curved nano composite Panel- A Numerical study. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Razali, N.; Sultan, M.T.H.; Safri, S.N.A.; Basri, S.; Yidris, N.; Mustapha, F. High Velocity Impact Test on Glass Fiber Reinforced Polymer (GFRP) Using a Single Stage Gas Gun (SSGG)-An Experimental Based Approach. Appl. Mech. Mater. 2014, 564, 376–381. [Google Scholar] [CrossRef]

- Jordan, J.B.; Naito, C.J. An experimental investigation of the effect of nose shape on fragments penetrating GFRP. Int. J. Impact Eng. 2014, 63, 63–71. [Google Scholar] [CrossRef]

- Dey, S.; Børvik, T.; Hopperstad, O.S.; Leinum, J.R.; Langseth, M. The effect of target strength on the perforation of steel plates using three different projectile nose shapes. Int. J. Impact Eng. 2004, 30, 1005–1038. [Google Scholar] [CrossRef]

- Bendarma, A.; Jankowiak, T.; Rusinetk, A.; Lodygowski, T.; Czarnota, C.; Bernier, R.; Khalfaoui, M. Experimental and Numerical Analysis of Aluminum-Polyethylene Composite Structure Subjected to Tension and Perforation Under Dynamic Loading for a Wide Range of Temperatures. J. Dyn. Behav. Mater. 2024, 10, 51–74. [Google Scholar] [CrossRef]

- Gladman, B. Ls-Dyna® Keyword User’s Manual. Available online: https://www.dynasupport.com/manuals/ls-dyna-manuals/ls-dyna_manual_volume_ii_r11.pdf. (accessed on 13 September 2024.).

- Ghasemnejad, H.; Furquan, A.S.M.; Mason, P.J. Charpy impact damage behavior of single and multi-delaminated hybrid composite beam structures. Mater. Des. 2010, 31, 3653–3660. [Google Scholar] [CrossRef]

- Naresh, K.; Shankar, K.; Velmurugan, R.; Gupta, N.K. High strain rate studies for different laminate configurations of bi-directional glass/epoxy and carbon/epoxy composites using DIC. Structures 2020, 27, 2451–2465. [Google Scholar] [CrossRef]

- Karthick, P.; Ramajeyathilagam, K. Numerical study of influence of target thickness and projectile incidence angle on ballistic resistance of the GFRP composites. Mater. Today Proc. 2021, 47, 992–999. [Google Scholar] [CrossRef]

- Dogan, F.; Hadavinia, H.; Donchev, T.; Bhonge, P.S. Delamination of impacted composite structures by cohesive zone interface elements and tiebreak contact. Cent. Eur. J. Eng. 2012, 2, 612–626. [Google Scholar] [CrossRef]

- Sy, B.L.; Fawaz, Z.; Bougherara, H. Numerical simulation correlating the low velocity impact behavior of flax/epoxy laminates. Compos. Part A Appl. Sci. Manuf. 2019, 126, 105582. [Google Scholar] [CrossRef]

- Chinnarasu, A.; Ramajeyathilagam, K. Numerical study on influence of target thickness on impact response of GFRP composites. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Memic, F.; Catovic, A. The influence of projectile impact velocity and target characteristics on the terminal ballistics parameters of small-caliber projectile. Def. Secur. Stud. 2024, 5, 46–64. [Google Scholar] [CrossRef]

- Ansari, M.M.; Chakrabarti, A. Ballistic Performance of Unidirectional Glass Fiber Laminated Composite Plate under Normal and Oblique Impact. Procedia. Eng. 2017, 173, 161–168. [Google Scholar] [CrossRef]

- Mohammadi, B.; Pourhosseinshahi, M.; Bakhtiari, M.Y. Simulation of energy dissipation mechanisms in evaluating the critical interlaminar strain energy release rate of cross-ply carbon/epoxy laminated composites. Theor. Appl. Fract. Mech. 2021, 114, 103003. [Google Scholar] [CrossRef]

| No | Length × Width(mm) | Thickness (mm) | Elongation Break (%) | Tensile Strength (MPa) |

|---|---|---|---|---|

| 1 | 250 × 25 | 1.18 | 2.011 | 396.7 |

| 2 | 250 × 25 | 1.23 | 2.087 | 384.1 |

| 3 | 250 × 25 | 1.17 | 2.023 | 378 |

| 4 | 250 × 25 | 1.24 | 2.048 | 387.2 |

| 5 | 250 × 25 | 1.19 | 2.069 | 383.8 |

| Average | 250 × 25 | 1.20 | 2.0476 | 386 |

| Youngs modulus E1 (GPa) | 20 |

| Youngs modulus E2 (GPa) | 20 |

| Poisson’s ratio 12 | 0.25 |

| Shear modulus G12 (GPa) | 2.5 |

| Longitudinal tensile strength (MPa) | 386 |

| Transverse tensile strength (MPa) | 386 |

| Longitudinal compressive strength (MPa) | 72.6 |

| Transverse compressive strength (MPa) | 72.6 |

| Shear strength (MPa) | 38 |

| Interlaminar shear strength (MPa) | 10.3 |

| Part | Nodes Count | Elements Count | Element Type |

|---|---|---|---|

| Flat laminate | 155,526 | 153,600 | Shell |

| 203ROC laminates | 244,818 | 242,400 | Shell |

| 112ROC laminates | 252,054 | 249,600 | Shell |

| Spherical Projectile | 24,376 | 23,625 | Solid |

| Conical Projectile | 10,081 | 9216 | Solid |

| Properties | Value | Unit |

|---|---|---|

| Mass m | 10 | g |

| Youngs modulus E | 210 | GPa |

| Density of conical Impactor ρ | 9.516 × 10−6 | Kg/mm3 |

| Density of spherical Impactor ρ | 1.112 × 10−5 | Kg/mm3 |

| Poisson’s ratio | 0.3 | - |

| Projectile | Panel Configuration | Initial Velocity (m/s) | Residual Velocity (m/s) | Velocity Drop (m/s) | Exp. vs. Num. Variation % | ||

|---|---|---|---|---|---|---|---|

| Experimental | Numerical | Experimental | Numerical | ||||

| Spherical | Flat Plate (Infinite ROC) | 90 | 63 | 62.9 | 27 | 27.1 | −0.1 |

| 82 | 48 | 50.4 | 34 | 31.6 | 4.7 | ||

| 72 | 34 | 34.9 | 38 | 37.1 | 2.5 | ||

| 60 | Rebounded | - | - | - | |||

| 203 mm ROC Panel | 105 | 70 | 71 | 35 | 34 | 1.4 | |

| 90 | 44 | 45.9 | 46 | 44.1 | 4.1 | ||

| 80 | 12 | 12.7 | 68 | 67.3 | 5.5 | ||

| 70 | Rebounded | - | - | - | |||

| 112 mm ROC Panel | 116 | 82 | 82.9 | 34 | 33.1 | 1 | |

| 105 | 67 | 67.8 | 38 | 37.2 | 1.1 | ||

| 91 | 32 | 32.5 | 59 | 58.5 | 1.5 | ||

| 80 | Rebounded | - | - | - | |||

| Conical | Flat Plate (Infinite ROC) | 70 | 48 | 48.8 | 22 | 21.2 | 1.6 |

| 60 | 28 | 29.8 | 32 | 30.2 | 6 | ||

| 50 | 10 | 10.6 | 40 | 39.4 | 5.6 | ||

| 40 | Rebounded | - | - | - | - | ||

| 203 mm ROC Panel | 80 | 55 | 55.4 | 25 | 24.6 | 0.7 | |

| 70 | 40 | 42 | 30 | 28 | 4.7 | ||

| 60 | 11 | 11.5 | 49 | 48.5 | 4.3 | ||

| 50 | Rebounded | - | - | - | - | ||

| 112 mm ROC Panel | 90 | 67 | 66.6 | 23 | 23.4 | −0.6 | |

| 81 | 51 | 51 | 30 | 30 | 0 | ||

| 71 | 34 | 34.1 | 37 | 36.9 | 0.3 | ||

| 60 | Rebounded | - | - | - | - | ||

| Projectile Shape | Specimen Configuration | Ballistic Limit Velocity (m/s) | Error % | |

|---|---|---|---|---|

| Exp. | Num. | |||

| Spherical | Flat | 64.7 | 64 | −1.08 |

| 203 mm ROC | 78.6 | 77.9 | −0.9 | |

| 112 mm ROC | 82.7 | 82 | −0.8 | |

| Conical | Flat | 51 | 50.3 | −1.37 |

| 203 mm ROC | 58.1 | 57.5 | −1.03 | |

| 112 mm ROC | 61.8 | 62 | 0.3 | |

| Projectile | Panel Configuration | Initial Velocity (m/s) | Initial Energy (J) | Residual Velocity (m/s) | Energy Absorbed (J) | Energy Absorption % |

|---|---|---|---|---|---|---|

| Spherical | Flat Plate-1 | 90 | 40.5 | 63 | 20.7 | 51.00 |

| Flat Plate-2 | 82 | 33.6 | 48 | 22.1 | 65.73 | |

| Flat Plate-3 | 72 | 25.9 | 34 | 20.1 | 77.70 | |

| Flat Plate-4 | 60 | 18 | 0 | 18.0 | 100.00 | |

| 203 mm ROC-1 | 105 | 55.1 | 70 | 30.6 | 55.56 | |

| 203 mm ROC-2 | 90 | 40.5 | 44 | 30.8 | 76.10 | |

| 203 mm ROC-3 | 80 | 32 | 12 | 31.3 | 97.75 | |

| 203 mm ROC-4 | 70 | 24.5 | 0 | 24.5 | 100.00 | |

| 112 mm ROC-1 | 116 | 67.3 | 82 | 33.7 | 50.03 | |

| 112 mm ROC-2 | 105 | 55.1 | 67 | 32.7 | 59.28 | |

| 112 mm ROC-3 | 91 | 41.4 | 32 | 36.3 | 87.63 | |

| 112 mm ROC-4 | 80 | 32 | 0 | 32.0 | 100.00 | |

| Conical | Flat Plate-1 | 70 | 24.5 | 48 | 13.0 | 52.98 |

| Flat Plate-2 | 60 | 18.0 | 28 | 14.1 | 78.22 | |

| Flat Plate-3 | 50 | 12.5 | 10 | 12.0 | 96.00 | |

| Flat Plate-4 | 40 | 8.0 | 0 | 8.0 | 100.00 | |

| 203 mm ROC-1 | 80 | 32.0 | 55 | 16.9 | 52.73 | |

| 203 mm ROC-2 | 70 | 24.5 | 40 | 16.5 | 67.35 | |

| 203 mm ROC-3 | 60 | 18.0 | 11 | 17.4 | 96.64 | |

| 203 mm ROC-4 | 50 | 12.5 | 0 | 12.5 | 100.00 | |

| 112 mm ROC-1 | 90 | 40.5 | 67 | 18.1 | 44.58 | |

| 112 mm ROC-2 | 81 | 32.8 | 51 | 19.8 | 60.36 | |

| 112 mm ROC-3 | 71 | 25.2 | 34 | 19.4 | 77.07 | |

| 112 mm ROC-4 | 60 | 18.0 | 0 | 18.0 | 100.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arivoli, C.; Ramajeyathilagam, K. Comparison Study on Flat and Curved Glass-Fiber-Reinforced Polymer Panels Subjected to High-Velocity Impacts with Spherical and Conical Projectiles: An Experimental and Numerical Study. J. Compos. Sci. 2025, 9, 147. https://doi.org/10.3390/jcs9040147

Arivoli C, Ramajeyathilagam K. Comparison Study on Flat and Curved Glass-Fiber-Reinforced Polymer Panels Subjected to High-Velocity Impacts with Spherical and Conical Projectiles: An Experimental and Numerical Study. Journal of Composites Science. 2025; 9(4):147. https://doi.org/10.3390/jcs9040147

Chicago/Turabian StyleArivoli, Chinnarasu, and Kashi Ramajeyathilagam. 2025. "Comparison Study on Flat and Curved Glass-Fiber-Reinforced Polymer Panels Subjected to High-Velocity Impacts with Spherical and Conical Projectiles: An Experimental and Numerical Study" Journal of Composites Science 9, no. 4: 147. https://doi.org/10.3390/jcs9040147

APA StyleArivoli, C., & Ramajeyathilagam, K. (2025). Comparison Study on Flat and Curved Glass-Fiber-Reinforced Polymer Panels Subjected to High-Velocity Impacts with Spherical and Conical Projectiles: An Experimental and Numerical Study. Journal of Composites Science, 9(4), 147. https://doi.org/10.3390/jcs9040147