The Fossil, the Green, and the In-Between: Life Cycle Assessment of Manufacturing Composites with Varying Bio-Based Content

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Selection

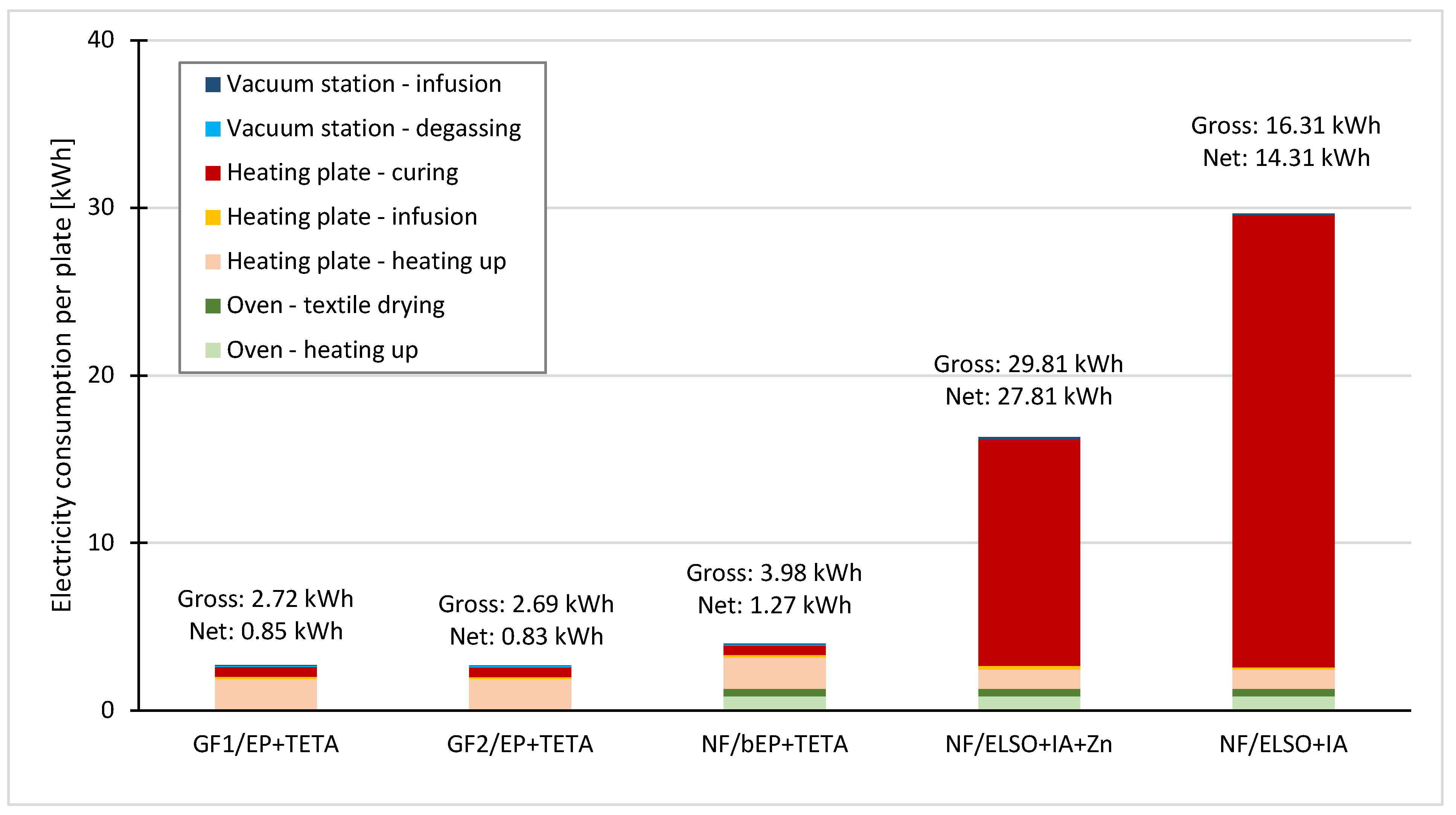

2.2. Composite Manufacturing

2.3. Life Cycle Assessment

2.3.1. Functional Units

2.3.2. Life Cycle Inventory

2.3.3. Allocation and Biogenic Carbon

2.3.4. Life Cycle Impact Assessment

3. Results

3.1. Functional Equivalence of the Composites

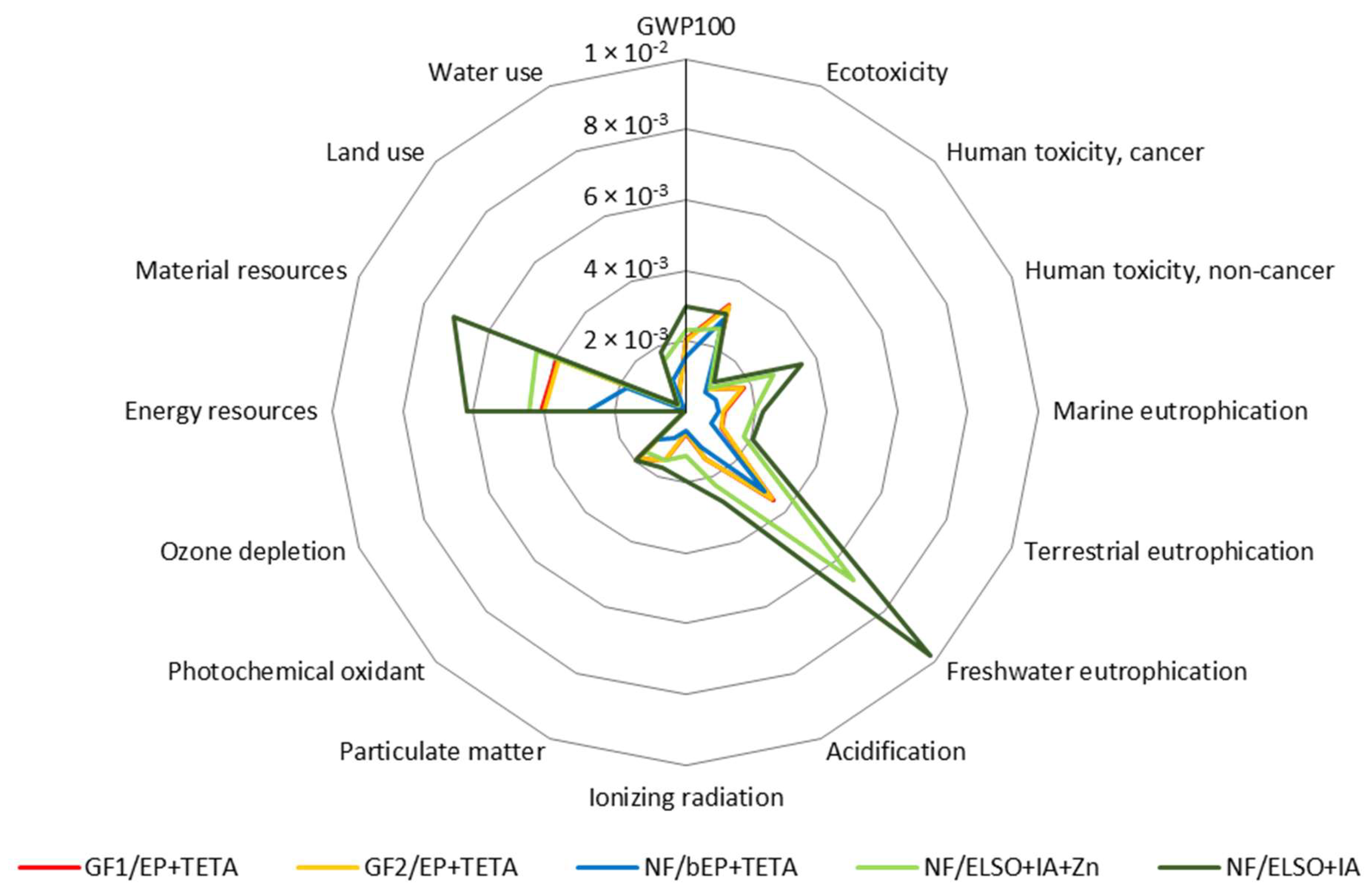

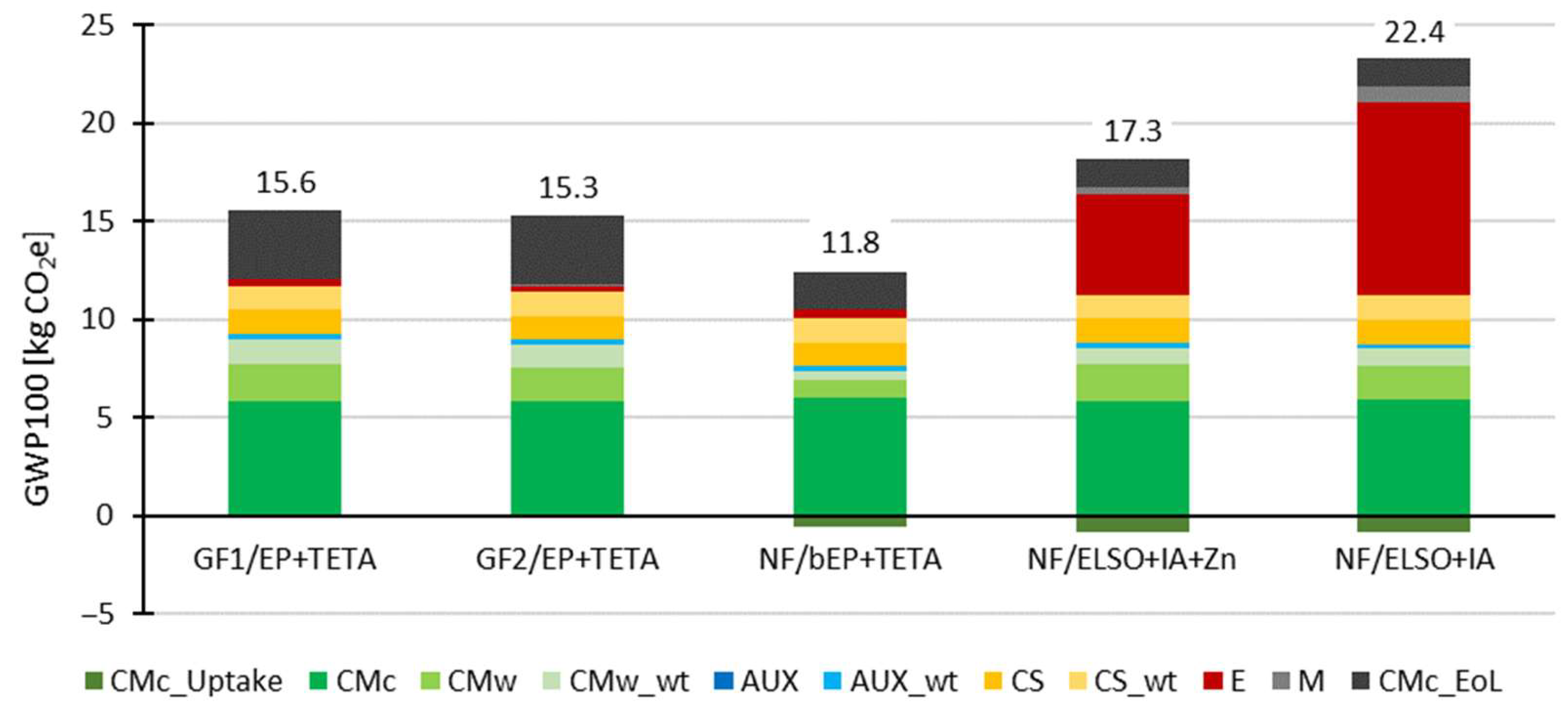

3.2. Environmental Impacts per Composite Plate

- The relatively small amounts of biogenic materials needed per plate require a limited extent of agricultural activity;

- The magnitude of land use impacts is also a consequence of choices undertaken in the background database, where the land requirement is divided by the crop cultivation period.

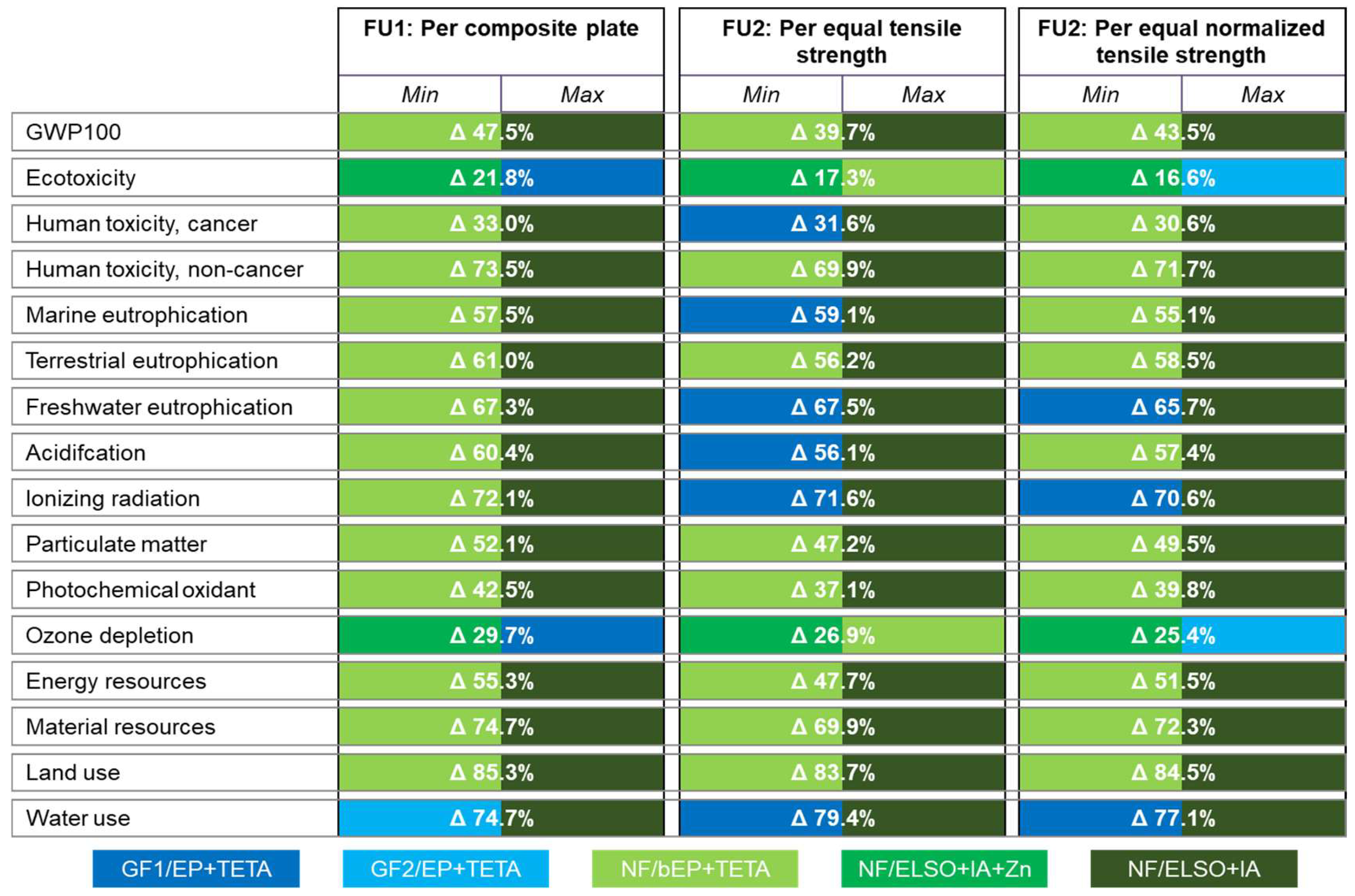

3.3. Environmental Impacts per Equal Level of Functionality

- The consideration of tensile strength as a functionality parameter gives the GF1/EP+TETA composite the competitive edge in environmental performance in six impact categories compared to the other options, especially NF/bEP+TETA. FU2 using normalized tensile strength values for Ashby equivalence provides the middle ground, where NF/bEP+TETA still exhibits the lowest scores in 11 impact categories;

- NF/ELSO+IA remains the least advantageous composite for all three functional units regarding environmental impacts in most categories. Nevertheless, in the two distinctions of FU2 the differences between the best and least performant option are less pronounced than in FU1. The only three impact categories where FU2 can lead to potentially more pronounced differences among the composite types are water use and marine and freshwater eutrophication;

- In FU1, the GF2 composite exhibits marginally lower environmental impacts (of maximum 2.8% difference) than the composite using GF1. In FU2, the opposite is the case. Additionally, the percentage variance between GF1 and GF2 is more pronounced, with GF1 outperforming GF2 by up to 9.5%.

4. Discussion

4.1. Limitations and Uncertainties

4.2. Benchmarking with Previous LCA Studies

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Commission: Directorate-General for Research and Innovation. A Sustainable Bioeconomy for Europe—Strengthening the Connection Between Economy, Society and the Environment—Updated Bioeconomy Strategy; Publications Office of the European Union: Luxembourg, 2018; Available online: https://data.europa.eu/doi/10.2777/792130 (accessed on 2 December 2024).

- Andrew, J.J.; Dhakal, H.N. Sustainable biobased composites for advanced applications: Recent trends and future opportunities—A critical review. Compos. Part. C Open Access 2022, 7, 100220. [Google Scholar] [CrossRef]

- Singh, M.K.; Tewari, R.; Zafar, S.; Rangappa, S.M.; Siengchin, S. A comprehensive review of various factors for application feasibility of natural fiber-reinforced polymer composites. Results Mater. 2023, 17, 100355. [Google Scholar] [CrossRef]

- Fadlallah, S.; Sinha Roy, P.; Garnier, G.; Saito, K.; Allais, F. Are lignin-derived monomers and polymers truly sustainable? An in-depth green metrics calculations approach. Green. Chem. 2021, 23, 1495–1535. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management-Life Cycle Assessment-Principles and Framework (14040). International Organization for Standardization: Geneva, Switzerland, 2006.

- Hesser, F. Environmental advantage by choice: Ex-ante LCA for a new Kraft pulp fibre reinforced polypropylene composite in comparison to reference materials. Compos. Part. B Eng. 2015, 79, 197–203. [Google Scholar] [CrossRef]

- La Rosa, A.D.; Recca, G.; Summerscales, J.; Latteri, A.; Cozzo, G.; Cicala, G. Bio-based versus traditional polymer composites. A life cycle assessment perspective. J. Clean. Prod. 2014, 74, 135–144. [Google Scholar] [CrossRef]

- Deng, Y.; Paraskevas, D.; Tian, Y.; van Acker, K.; Dewulf, W.; Duflou, J.R. Life cycle assessment of flax-fibre reinforced epoxidized linseed oil composite with a flame retardant for electronic applications. J. Clean. Prod. 2016, 133, 427–438. [Google Scholar] [CrossRef]

- Witthayolankowit, K.; Rakkijakan, T.; Ayub, R.; Kumaniaev, I.; Pourchet, S.; Boni, G.; Watjanatepin, P.; Zarafshani, H.; Gabrion, X.; Chevallier, A.; et al. Use of a fully biobased and non-reprotoxic epoxy polymer and woven hemp fabric to prepare environmentally friendly composite materials with excellent physical properties. Compos. Part. B Eng. 2023, 258, 110692. [Google Scholar] [CrossRef]

- Jayamani, E.; Jie, T.J.; Bin Bakri, M.K. Life cycle assessment of sustainable composites. In Advances in Sustainable Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2021; pp. 245–265. ISBN 9780128203385. [Google Scholar]

- Beigbeder, J.; Soccalingame, L.; Perrin, D.; Bénézet, J.-C.; Bergeret, A. How to manage biocomposites wastes end of life? A life cycle assessment approach (LCA) focused on polypropylene (PP)/wood flour and polylactic acid (PLA)/flax fibres biocomposites. Waste Manag. 2019, 83, 184–193. [Google Scholar] [CrossRef]

- Corbière-Nicollier, T.; Gfeller Laban, B.; Lundquist, L.; Leterrier, Y.; Månson, J.-A.; Jolliet, O. Life cycle assessment of biofibres replacing glass fibres as reinforcement in plastics. Resour. Conserv. Recycl. 2001, 33, 267–287. [Google Scholar] [CrossRef]

- Batouli, S.M.; Zhu, Y.; Nar, M.; D’Souza, N.A. Environmental performance of kenaf-fiber reinforced polyurethane: A life cycle assessment approach. J. Clean. Prod. 2014, 66, 164–173. [Google Scholar] [CrossRef]

- Duflou, J.R.; Yelin, D.; van Acker, K.; Dewulf, W. Comparative impact assessment for flax fibre versus conventional glass fibre reinforced composites: Are bio-based reinforcement materials the way to go? CIRP Ann. 2014, 63, 45–48. [Google Scholar] [CrossRef]

- Roy, P.; Defersha, F.; Rodriguez-Uribe, A.; Misra, M.; Mohanty, A.K. Evaluation of the life cycle of an automotive component produced from biocomposite. J. Clean. Prod. 2020, 273, 123051. [Google Scholar] [CrossRef]

- Ramachandran, K.; Gnanasagaran, C.L.; Vekariya, A. Life cycle assessment of carbon fiber and bio-fiber composites prepared via vacuum bagging technique. J. Manuf. Process. 2023, 89, 124–131. [Google Scholar] [CrossRef]

- Hervy, M.; Evangelisti, S.; Lettieri, P.; Lee, K.-Y. Life cycle assessment of nanocellulose-reinforced advanced fibre composites. Compos. Sci. Technol. 2015, 118, 154–162. [Google Scholar] [CrossRef]

- Le Duigou, A.; Deux, J.-M.; Davies, P.; Baley, C. PLLA/Flax Mat/Balsa Bio-Sandwich—Environmental Impact and Simplified Life Cycle Analysis. Appl. Compos. Mater. 2012, 19, 363–378. [Google Scholar] [CrossRef]

- Ashby, M.F.; Jones, D.R.H. Engineering Materials: An Introduction to Properties, Applications and Design: 1, 5th ed.; Butterworth-Heinemann: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Zhou, C.; Shi, S.Q.; Chen, Z.; Cai, L.; Smith, L. Comparative environmental life cycle assessment of fiber reinforced cement panel between kenaf and glass fibers. J. Clean. Prod. 2018, 200, 196–204. [Google Scholar] [CrossRef]

- Kirschnick, U.; Feuchter, M.; Ravindran, B.; Salzmann, M.; Duretek, I.; Fauster, E.; Schledjewski, R. Manufacturing bio-based fiber-reinforced polymer composites: Process performance in RTM and VARI processes. Adv. Manuf. Polym. Compos. Sci. 2024, 10, 2379205. [Google Scholar] [CrossRef]

- Lau, K.; Hung, P.; Zhu, M.-H.; Hui, D. Properties of natural fibre composites for structural engineering applications. Compos. Part B Eng. 2018, 136, 222–233. [Google Scholar] [CrossRef]

- Tapper, R.J.; Longana, M.L.; Norton, A.; Potter, K.D.; Hamerton, I. An evaluation of life cycle assessment and its application to the closed-loop recycling of carbon fibre reinforced polymers. Compos. Part B Eng. 2020, 184, 107665. [Google Scholar] [CrossRef]

- Campbell, F.C. Thermoset Resins: The Glue That Holds the Strings Together. In Manufacturing Processes for Advanced Composites; Elsevier: Amsterdam, The Netherlands, 2004; pp. 63–101. ISBN 9781856174152. [Google Scholar]

- Rwahwire, S.; Tomkova, B.; Periyasamy, A.P.; Kale, B.M. Green thermoset reinforced biocomposites. In Green Composites for Automotive Applications; Elsevier: Amsterdam, The Netherlands, 2019; pp. 61–80. ISBN 9780081021774. [Google Scholar]

- Zhang, Y.; Liu, X.; Wan, M.; Zhu, Y.; Zhang, K. From renewable biomass to bio-based epoxy monomers and bio-based epoxy curing agents: Synthesis and performance. Polym. Degrad. Stab. 2024, 229, 110988. [Google Scholar] [CrossRef]

- Kim, J.R.; Sharma, S. The development and comparison of bio-thermoset plastics from epoxidized plant oils. Ind. Crops Prod. 2012, 36, 485–499. [Google Scholar] [CrossRef]

- Cullis, C.A.; Cullis, M.A. Comparison Between the Genomes of a Fiber and an Oil-Seed Variety of Flax. In Genetics and Genomics of Linum; Cullis, C.A., Ed.; Springer International Publishing: Cham, Siwtzerland, 2019; pp. 89–96. ISBN 978-3-030-23963-3. [Google Scholar]

- Lotfy, W.A.; Ghanem, K.M.; El-Helow, E.R. Citric acid production by a novel Aspergillus niger isolate: II. Optimization of process parameters through statistical experimental designs. Bioresour. Technol. 2007, 98, 3470–3477. [Google Scholar] [CrossRef] [PubMed]

- Blößl, Y.; Schledjewski, R. A robust empirical model equation for the compaction response of textile reinforcements. Polym. Compos. 2021, 42, 297–308. [Google Scholar] [CrossRef]

- Schillfahrt, C.; Fauster, E.; Schledjewski, R. Influence of process pressures on filling behavior of tubular fabrics in bladder-assisted resin transfer molding. Adv. Manuf. Polym. Compos. Sci. 2017, 3, 148–158. [Google Scholar] [CrossRef]

- Van Oosterom, S.; Allen, T.; Battley, M.; Bickerton, S. An objective comparison of common vacuum assisted resin infusion processes. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105528. [Google Scholar] [CrossRef]

- Lunetto, V.; Galati, M.; Settineri, L.; Iuliano, L. Sustainability in the manufacturing of composite materials: A literature review and directions for future research. J. Manuf. Process. 2023, 85, 858–874. [Google Scholar] [CrossRef]

- Hermansson, F.; Ekvall, T.; Janssen, M.; Svanström, M. Allocation in recycling of composites—The case of life cycle assessment of products from carbon fiber composites. Int. J. Life Cycle Assess. 2022, 27, 419–432. [Google Scholar] [CrossRef]

- Hischier, R.; Hellweg, S.; Capello, C.; Primas, A. Establishing Life Cycle Inventories of Chemicals Based on Differing Data Availability (9 pp). Int. J. Life Cycle Assess. 2005, 10, 59–67. [Google Scholar] [CrossRef]

- Holzapfel, P.; Bach, V.; Finkbeiner, M. Electricity accounting in life cycle assessment: The challenge of double counting. Int. J. Life Cycle Assess. 2023, 28, 771–787. [Google Scholar] [CrossRef]

- Ashby, M.F. Materials Selection in Mechanical Design, 4th ed.; Butterworth-Heinemann: Oxford, UK, 2011; ISBN 9781856176637. [Google Scholar]

- Meng, F.; McKechnie, J.; Turner, T.A.; Pickering, S.J. Energy and environmental assessment and reuse of fluidised bed recycled carbon fibres. Compos. Part A Appl. Sci. Manuf. 2017, 100, 206–214. [Google Scholar] [CrossRef]

- Ecoinvent. Ecoinvent Database; Ecoinvent Associatio: Zürich, Switzerland, 2023. [Google Scholar]

- Karimzadeh, R.; Godini, H.R.; Ghashghaee, M. Flowsheeting of steam cracking furnaces. Chem. Eng. Res. Des. 2009, 87, 36–46. [Google Scholar] [CrossRef]

- European Commission—Joint Research Centre—Institute for Environment and Sustainability. International Reference Life Cycle Data System (ILCD) Handbook—General Guide for Life Cycle Assessment—Detailed Guidance; EUR 24708 EN; Publications Office of the European Union: Luxembourg, 2010. [Google Scholar]

- Gomez-Campos, A.; Vialle, C.; Rouilly, A.; Sablayrolles, C.; Hamelin, L. Flax fiber for technical textile: A life cycle inventory. J. Clean. Prod. 2021, 281, 125177. [Google Scholar] [CrossRef]

- Kikuchi, Y.; Oshita, Y.; Mayumi, K.; Hirao, M. Greenhouse gas emissions and socioeconomic effects of biomass-derived products based on structural path and life cycle analyses: A case study of polyethylene and polypropylene in Japan. J. Clean. Prod. 2017, 167, 289–305. [Google Scholar] [CrossRef]

- Mayumi, K.; Kikuchi, Y.; Hirao, M. Life Cycle Assessment of Biomass-Derived Resin for Sustainable Chemical Industry. Chem. Eng. Trans. 2010, 19, 19–25. [Google Scholar] [CrossRef]

- Moretti, C.; Junginger, M.; Shen, L. Environmental life cycle assessment of polypropylene made from used cooking oil. Resour. Conserv. Recycl. 2020, 157, 104750. [Google Scholar] [CrossRef]

- Lefeuvre, A.; Yerro, X.; Jean-Marie, A.; Vo Dong, P.A.; Azzaro-Pantel, C. Modelling pyrolysis process for CFRP recycling in a closed-loop supply chain approach. In 27th European Symposium on Computer Aided Process Engineering; Elsevier: Amsterdam, The Netherlands, 2017; pp. 2029–2034. ISBN 9780444639653. [Google Scholar]

- Wernet, G.; Hellweg, S.; Hungerbühler, K. A tiered approach to estimate inventory data and impacts of chemical products and mixtures. Int. J. Life Cycle Assess. 2012, 17, 720–728. [Google Scholar] [CrossRef][Green Version]

- Nunes, A.O.; Viana, L.R.; Guineheuc, P.-M.; Da Silva Moris, V.A.; Paiva, J.M.F.d.; Barna, R.; Soudais, Y. Life cycle assessment of a steam thermolysis process to recover carbon fibers from carbon fiber-reinforced polymer waste. Int. J. Life Cycle Assess. 2018, 23, 1825–1838. [Google Scholar] [CrossRef]

- Wien Energie GmbH. Spittelau Waste Incineration Plant. Available online: https://positionen.wienenergie.at/en/projects/spittelau-waste-incineration-plant/ (accessed on 2 August 2023).

- Dominguez Aldama, D.; Grassauer, F.; Zhu, Y.; Ardestani-Jaafari, A.; Pelletier, N. Allocation methods in life cycle assessments (LCAs) of agri-food co-products and food waste valorization systems: Systematic review and recommendations. J. Clean. Prod. 2023, 421, 138488. [Google Scholar] [CrossRef]

- Garcia, R.; Alvarenga, R.A.; Huysveld, S.; Dewulf, J.; Allacker, K. Accounting for biogenic carbon and end-of-life allocation in life cycle assessment of multi-output wood cascade systems. J. Clean. Prod. 2020, 275, 122795. [Google Scholar] [CrossRef]

- Wiloso, E.I.; Heijungs, R.; Huppes, G.; Fang, K. Effect of biogenic carbon inventory on the life cycle assessment of bioenergy: Challenges to the neutrality assumption. J. Clean. Prod. 2016, 125, 78–85. [Google Scholar] [CrossRef]

- Hansen, R.N.; Eliassen, J.L.; Schmidt, J.; Andersen, C.E.; Weidema, B.P.; Birgisdóttir, H.; Hoxha, E. Environmental consequences of shifting to timber construction: The case of Denmark. Sustain. Prod. Consum. 2024, 46, 54–67. [Google Scholar] [CrossRef]

- Sazdovski, I.; Hauschild, M.Z.; Arfelis, S.; Bala, A.; Fullana-i-Palmer, P. Short Communication: Biogenic carbon in fast-moving products: A deception or real contribution to circularity? Environ. Adv. 2024, 15, 100461. [Google Scholar] [CrossRef]

- Zampori, L.; Pant, R. Suggestions for Updating the Organisation Environmental Footprint (OEF) Method; EUR 29682 EN; Publications Office of the European Union: Luxembourg, 2019; ISBN 978-92-76-00654-1. [Google Scholar]

- Bishop, G.; Styles, D.; Lens, P.N. Environmental performance comparison of bioplastics and petrochemical plastics: A review of life cycle assessment (LCA) methodological decisions. Resour. Conserv. Recycl. 2021, 168, 105451. [Google Scholar] [CrossRef]

- Andreasi Bassi, S.; Biganzoli, F.; Ferrara, N.; Amadei, A.; Valente, A.; Sala, S.; Ardente, F. Updated Characterisation and Normalisation Factors for the Environmental Footprint 3.1 Method; Publications Office of the European Union: Luxembourg, 2023; ISBN 978-92-76-99069-7. [Google Scholar]

- Ciroth, A. OpenLCA; GreenDelta: Berlin, Germany, 2022. [Google Scholar]

- Patti, A.; Acierno, D. Materials, Weaving Parameters, and Tensile Responses of Woven Textiles. Macromol 2023, 3, 665–680. [Google Scholar] [CrossRef]

- Yenilmez, B.; Senan, M.; Murat Sozer, E. Variation of part thickness and compaction pressure in vacuum infusion process. Compos. Sci. Technol. 2009, 69, 1710–1719. [Google Scholar] [CrossRef]

- Resch-Fauster, K.; Džalto, J.; Anusic, A.; Mitschang, P. Effect of the water absorptive capacity of reinforcing fibers on the process ability, morphology, and performance characteristics of composites produced from polyfurfuryl alcohol. Adv. Manuf. Polym. Compos. Sci. 2018, 4, 13–23. [Google Scholar] [CrossRef]

- Matuštík, J.; Paulu, A.; Kočí, V. Is normalization in Life Cycle Assessment sustainable? Alternative approach based on natural constraints. J. Clean. Prod. 2024, 444, 141234. [Google Scholar] [CrossRef]

- Allacker, K.; Mathieux, F.; Manfredi, S.; Pelletier, N.; Camillis, C.d.; Ardente, F.; Pant, R. Allocation solutions for secondary material production and end of life recovery: Proposals for product policy initiatives. Resour. Conserv. Recycl. 2014, 88, 1–12. [Google Scholar] [CrossRef]

- Kusenberg, M.; Eschenbacher, A.; Djokic, M.R.; Zayoud, A.; Ragaert, K.; Meester, S.d.; van Geem, K.M. Opportunities and challenges for the application of post-consumer plastic waste pyrolysis oils as steam cracker feedstocks: To decontaminate or not to decontaminate? Waste Manag. 2022, 138, 83–115. [Google Scholar] [CrossRef]

- Orjuela, A.; Clark, J. Green chemicals from used cooking oils: Trends, challenges, and opportunities. Curr. Opin. Green. Sustain. Chem. 2020, 26, 100369. [Google Scholar] [CrossRef]

- Kim, H.C.; Wallington, T.J. Life Cycle Assessment of Vehicle Lightweighting: A Physics-Based Model To Estimate Use-Phase Fuel Consumption of Electrified Vehicles. Environ. Sci. Technol. 2016, 50, 11226–11233. [Google Scholar] [CrossRef] [PubMed]

- Furberg, A.; Arvidsson, R.; Molander, S. A practice-based framework for defining functional units in comparative life cycle assessments of materials. J. Ind. Ecol. 2022, 26, 718–730. [Google Scholar] [CrossRef]

- Ravindran, B.; Agathocleous, T.; Oswald-Tranta, B.; Fauster, E.; Feuchter, M. Impact Characteristics and Repair Approaches of Distinct Bio-Based Matrix Composites: A Comparative Analysis. J. Compos. Sci. 2024, 8, 126. [Google Scholar] [CrossRef]

- Ravindran, B.; Feuchter, M.; Schledjewski, R. Investigation of the Mechanical Properties of Sandwich Composite Panels Made with Recyclates and Flax Fiber/Bio-Based Epoxy Processed by Liquid Composite Molding. J. Compos. Sci. 2023, 7, 122. [Google Scholar] [CrossRef]

- Deng, Y.; van Acker, K.; Dewulf, W.; Duflou, J.R. Environmental Assessment of Printed Circuit Boards from Biobased Materials. In Glocalized Solutions for Sustainability in Manufacturing; Hesselbach, J., Herrmann, C., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 605–610. ISBN 978-3-642-19691-1. [Google Scholar]

- Rajendran, S.; Scelsi, L.; Hodzic, A.; Soutis, C.; Al-Maadeed, M.A. Environmental impact assessment of composites containing recycled plastics. Resour. Conserv. Recycl. 2012, 60, 131–139. [Google Scholar] [CrossRef]

- Wang, Y.; Gan, H.-L.; Liang, C.-X.; Zhang, Z.-Y.; Xie, M.; Xing, J.-Y.; Xue, Y.-H.; Liu, H. Network structure and properties of crosslinked bio-based epoxy resin composite: An in-silico multiscale strategy with dynamic curing reaction process. Giant 2021, 7, 100063. [Google Scholar] [CrossRef]

- Bruhn, S.; Sacchi, R.; Cimpan, C.; Birkved, M. Ten questions concerning prospective LCA for decision support for the built environment. Build. Environ. 2023, 242, 110535. [Google Scholar] [CrossRef]

| GF1 | GF2 | NF | |

|---|---|---|---|

| Fiber type | Glass | Glass | Flax |

| Textile name | WRS | Interglas 92130 FK144 | ampliTexTM 5042 |

| Company | Glasscom, Spain | Porcher Industries, Germany | Bcomp, Switzerland |

| Textile architecture | 2 × 2 twill weave | Plain weave | 4 × 4 twill weave |

| Areal weight [g/m2] | 580 | 395 | 500 |

| Materials | GF1/EP+TETA | GF2/EP+TETA | NF/bEP+TETA | NF/ELSO+IA+Zn | NF/ ELSO+IA |

|---|---|---|---|---|---|

| Layers [no] | 9 | 13 | 6 | 6 | 6 |

| Textile 1 [g] | 376 | 366 | 204 | 204 | 204 |

| Matrix 2 [g] | 320 | 320 | 320 | 264 | 264 |

| Hardener 2 [g] | 80 | 80 | 80 | 136 | 136 |

| Catalyst 2 [g] | - | - | - | 4 | - |

| Materials | GF1/EP+TETA | GF2/EP+TETA | NF/bEP+TETA | NF/ELSO+IA+Zn | NF/ ELSO+IA |

|---|---|---|---|---|---|

| Resin pre-heating | - | - | - | 30 min at 80 °C | 30 min at 80 °C |

| Matrix mixing | 2 min at ambient air | 2 min at ambient air | 2 min at ambient air | 30 min at 80 °C | 30 min at 80 °C |

| Matrix degassing | 6 min at ambient air | 6 min at ambient air | 4 min at ambient air | - | - |

| Infusion | 240 s at 100 °C | 200 s at 100 °C | 230 s at 100 °C | 680 s at 100 °C | 360 s at 100 °C |

| Curing | 30 min at 100 °C | 30 min at 100 °C | 30 min at 100 °C | 600 min at 120 °C | 1200 min at 120 °C |

| Tensile Strength [MPa] | Young’s Modulus [GPa] | Flexural Strength [MPa] | Flexural Modulus [GPa] | ILSS [MPa] | |

|---|---|---|---|---|---|

| GF1/EP+TETA FVC: 58% | 659 ± 17 | 30.0 ± 1.7 | 694 ± 35 | 29.2 ± 0.7 | 46.3 ± 1.0 |

| GF2/EP+TETA FVC: 53% | 441 ± 13 | 27.8 ± 1.0 | 486 ± 11 | 26.8 ± 0.3 | 41.6 ± 1.4 |

| NF/bEP+TETA FVC: 40% | 114 ± 9 | 15.1 ± 0.9 | 183 ± 10 | 12.4 ± 0.8 | 27.3 ± 1.3 |

| NF/ELSO+IA+Zn FVC: 42% | 92 ± 3 | 11.1 ± 0.6 | 99 ± 4 | 8.0 ± 0.5 | 10.0 ± 0.2 |

| NF/ELSO+IA FVC: 40% | 100 ± 8 | 9.2 ± 1.2 | 113 ± 7 | 5.1 ± 1.5 | 14.1 ± 0.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kirschnick, U.; Ravindran, B.; Sieberer, M.; Fauster, E.; Feuchter, M. The Fossil, the Green, and the In-Between: Life Cycle Assessment of Manufacturing Composites with Varying Bio-Based Content. J. Compos. Sci. 2025, 9, 93. https://doi.org/10.3390/jcs9030093

Kirschnick U, Ravindran B, Sieberer M, Fauster E, Feuchter M. The Fossil, the Green, and the In-Between: Life Cycle Assessment of Manufacturing Composites with Varying Bio-Based Content. Journal of Composites Science. 2025; 9(3):93. https://doi.org/10.3390/jcs9030093

Chicago/Turabian StyleKirschnick, Ulrike, Bharath Ravindran, Manfred Sieberer, Ewald Fauster, and Michael Feuchter. 2025. "The Fossil, the Green, and the In-Between: Life Cycle Assessment of Manufacturing Composites with Varying Bio-Based Content" Journal of Composites Science 9, no. 3: 93. https://doi.org/10.3390/jcs9030093

APA StyleKirschnick, U., Ravindran, B., Sieberer, M., Fauster, E., & Feuchter, M. (2025). The Fossil, the Green, and the In-Between: Life Cycle Assessment of Manufacturing Composites with Varying Bio-Based Content. Journal of Composites Science, 9(3), 93. https://doi.org/10.3390/jcs9030093