Fabrication of SiC–Aluminum Composites via Binder Jetting 3D Printing and Infiltration: A Feasibility Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

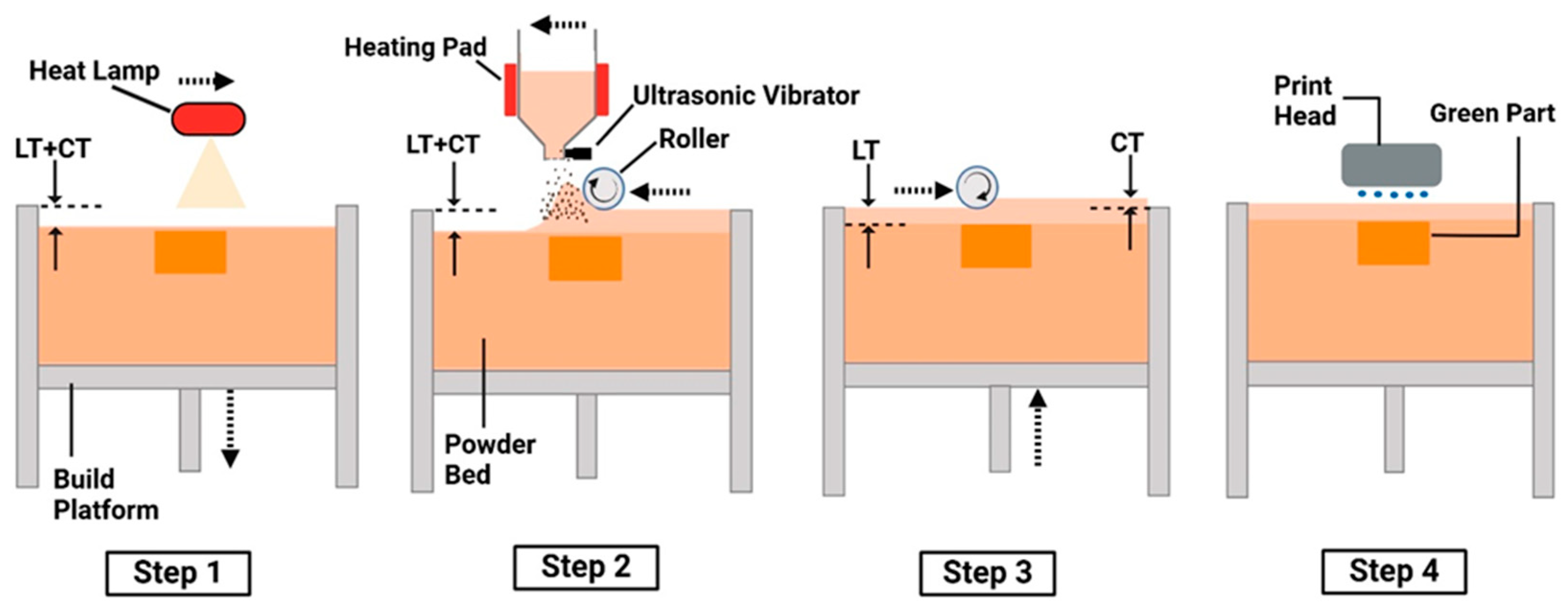

2.2. Binder Jetting 3D Printing of SiC Preforms

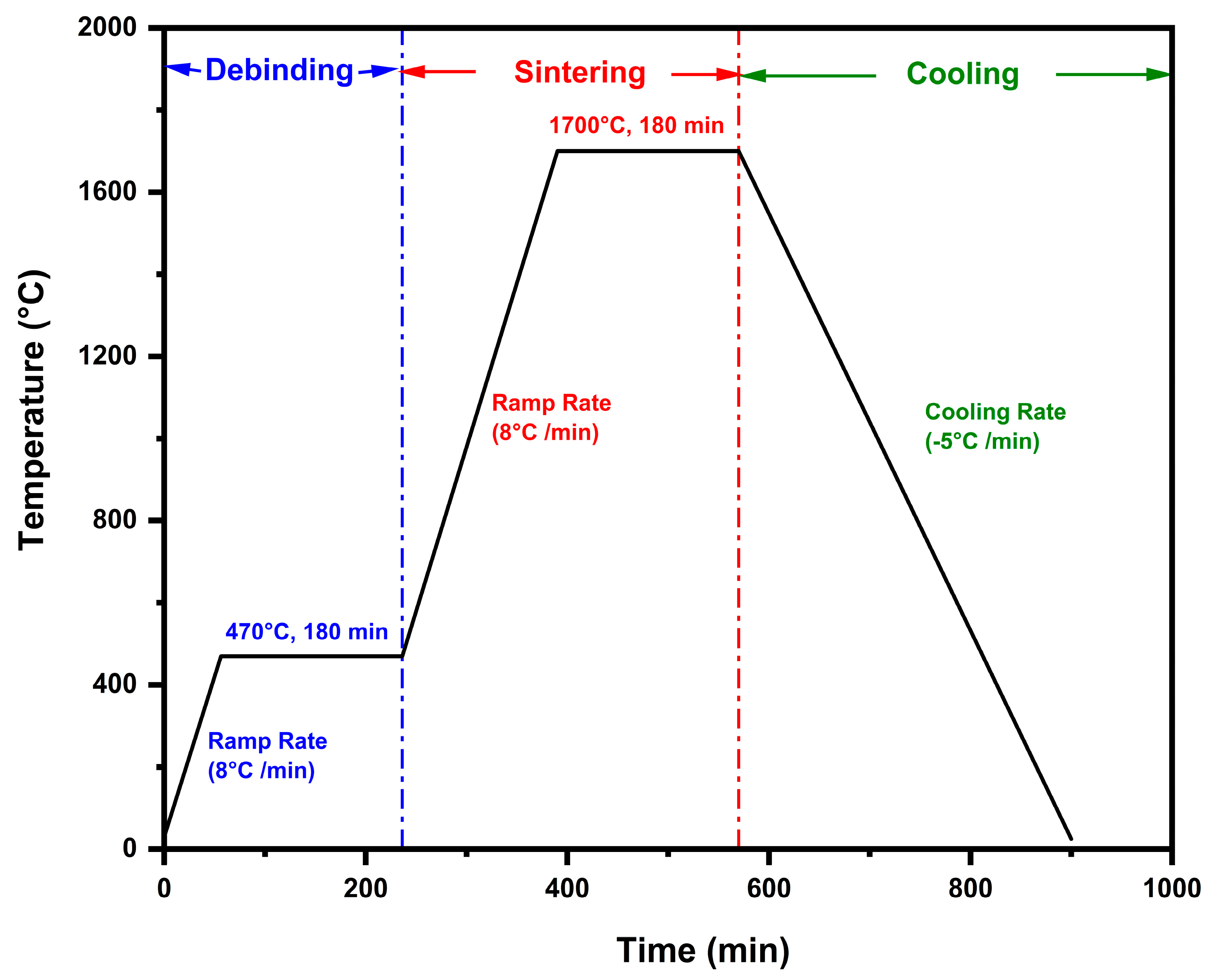

2.3. Post-Printing Steps (Curing, Depowdering, Debinding, and Sintering) Prior to Infiltration

2.4. Infiltration of SiC Preforms with Aluminum

2.5. Characterization Techniques

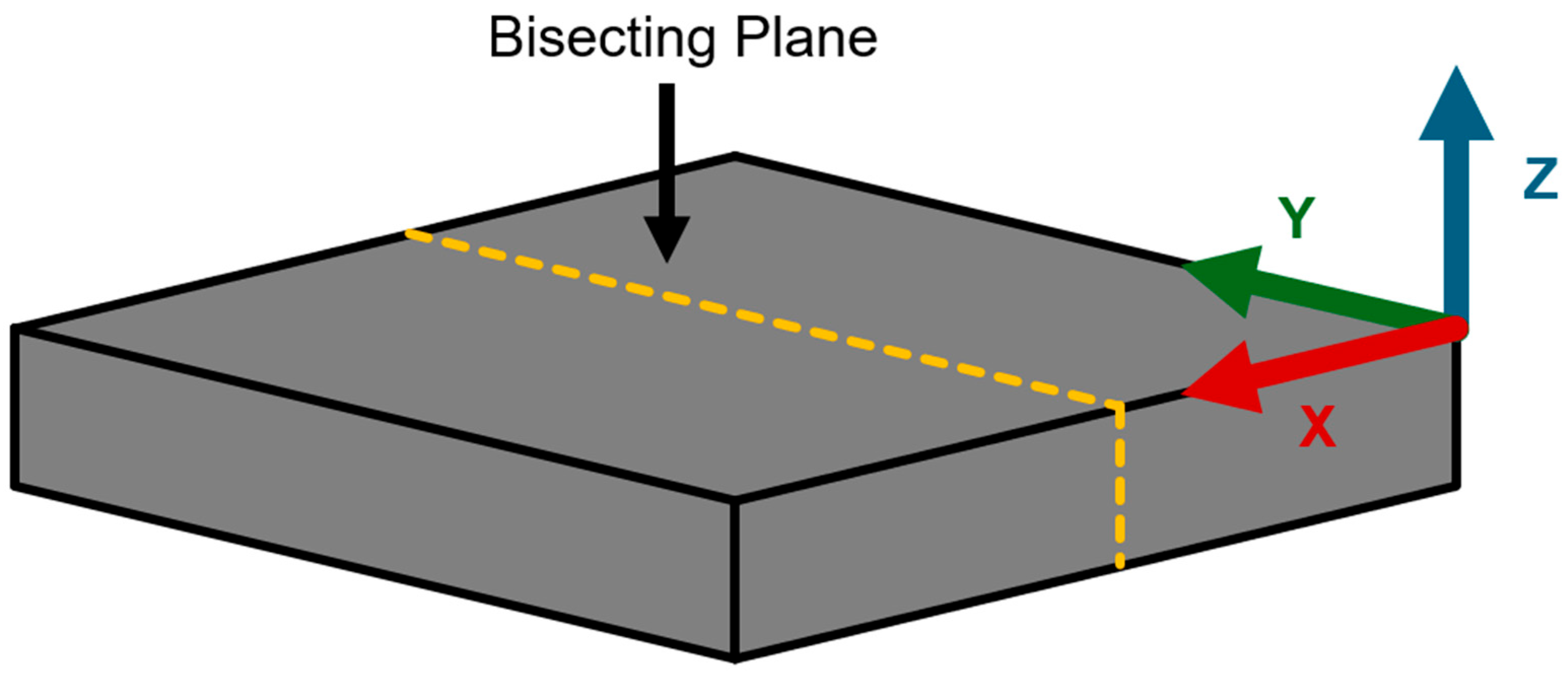

2.5.1. Cross-Sectional Imaging of SiC Preform After Infiltration

2.5.2. Density Measurement

2.5.3. Detection of Presence of Aluminum in SiC Preforms Using X-Ray Diffraction

2.5.4. Composition Analysis Using Energy-Dispersive X-Ray Spectroscopy (EDS)

3. Results and Discussion

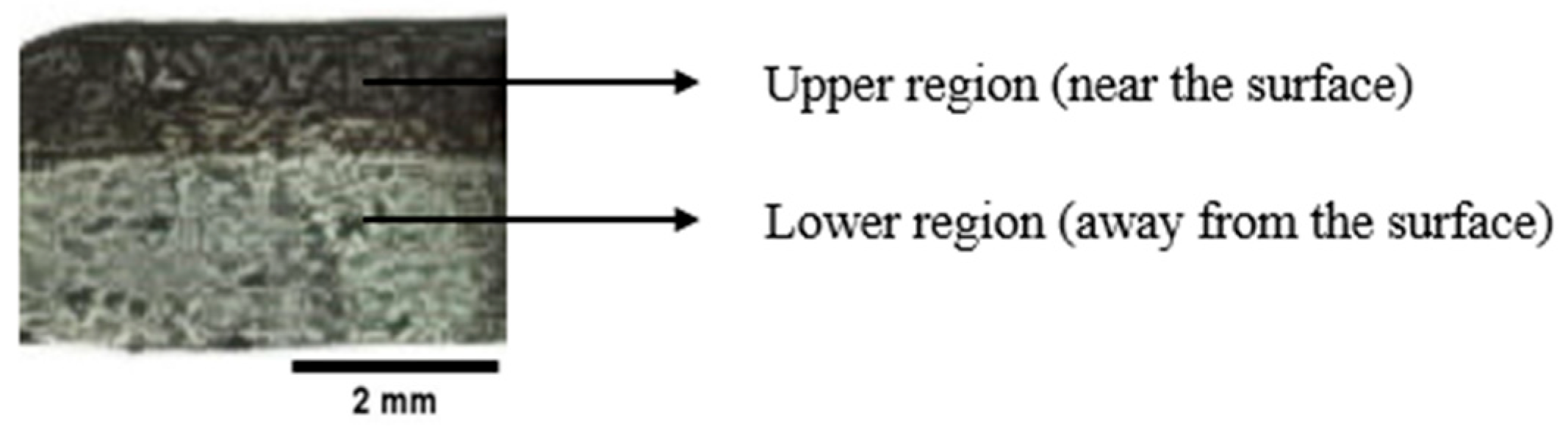

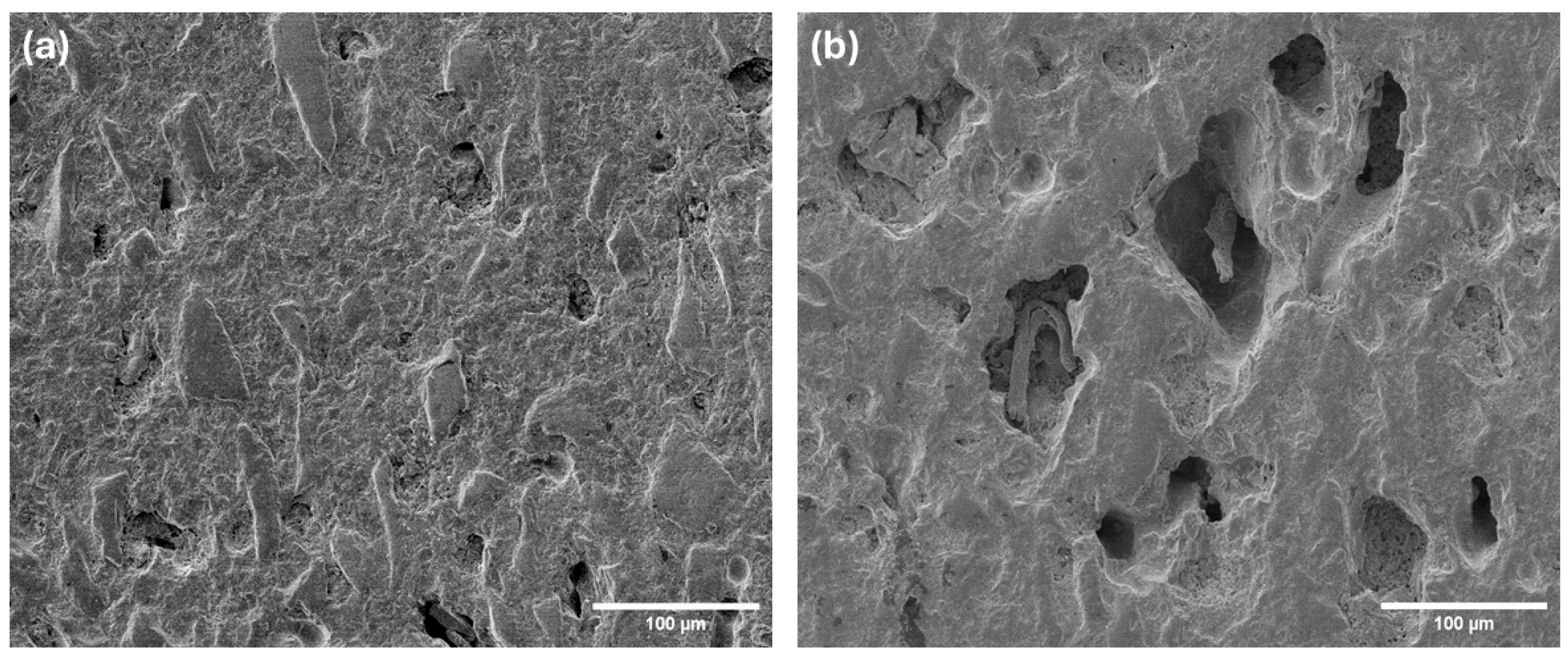

3.1. Cross-Sectional Image of Infiltrated SiC Preform

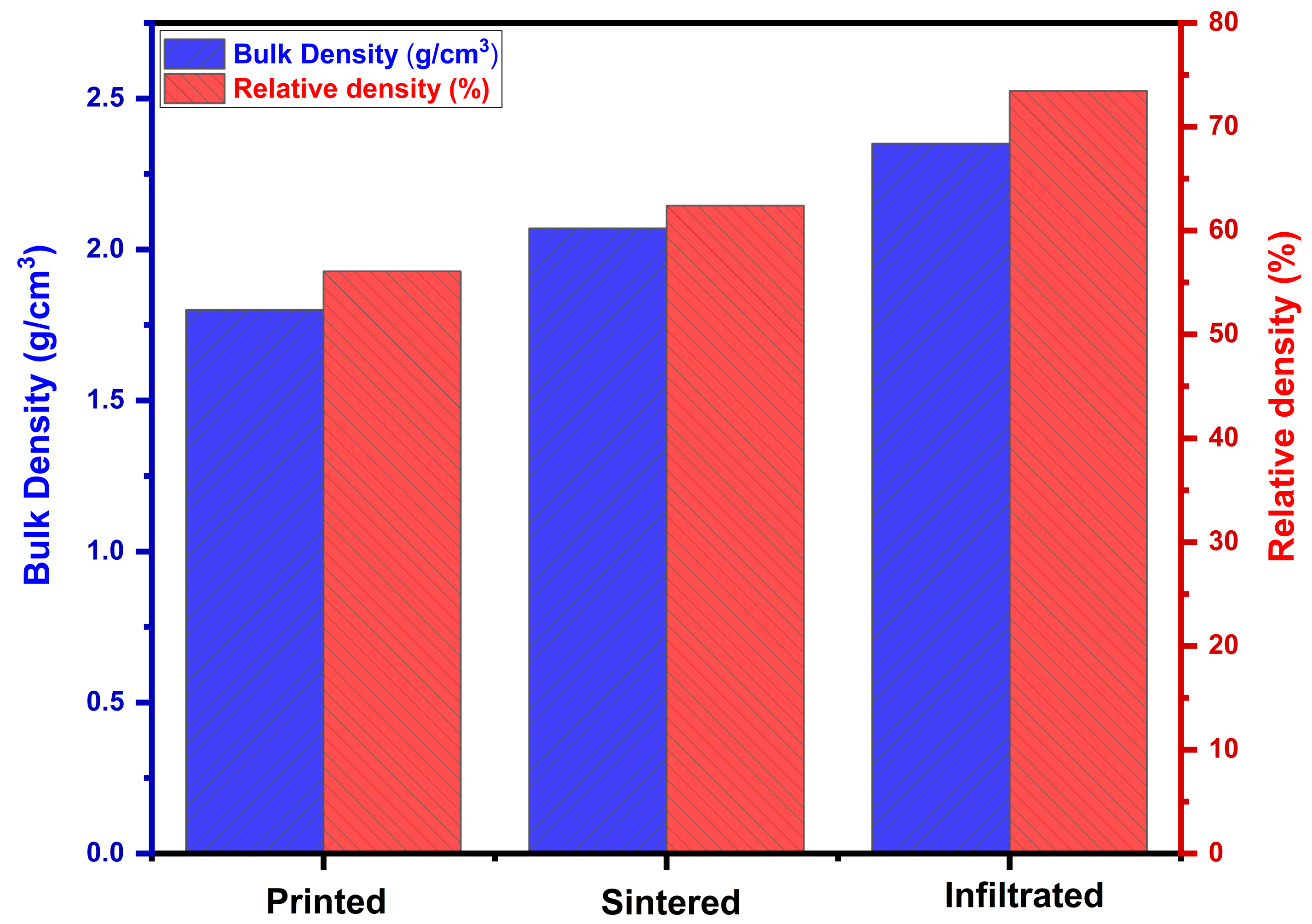

3.2. Density

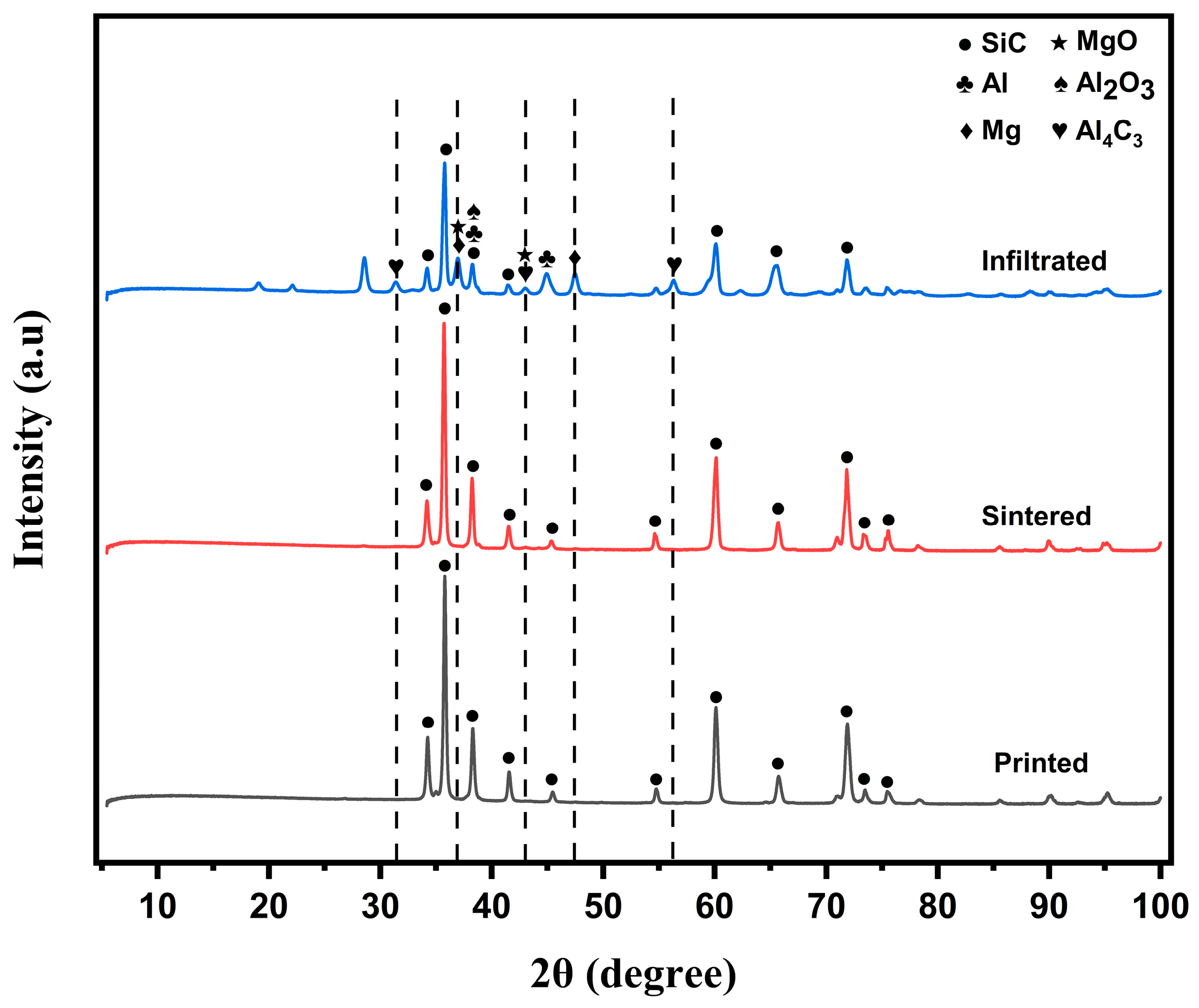

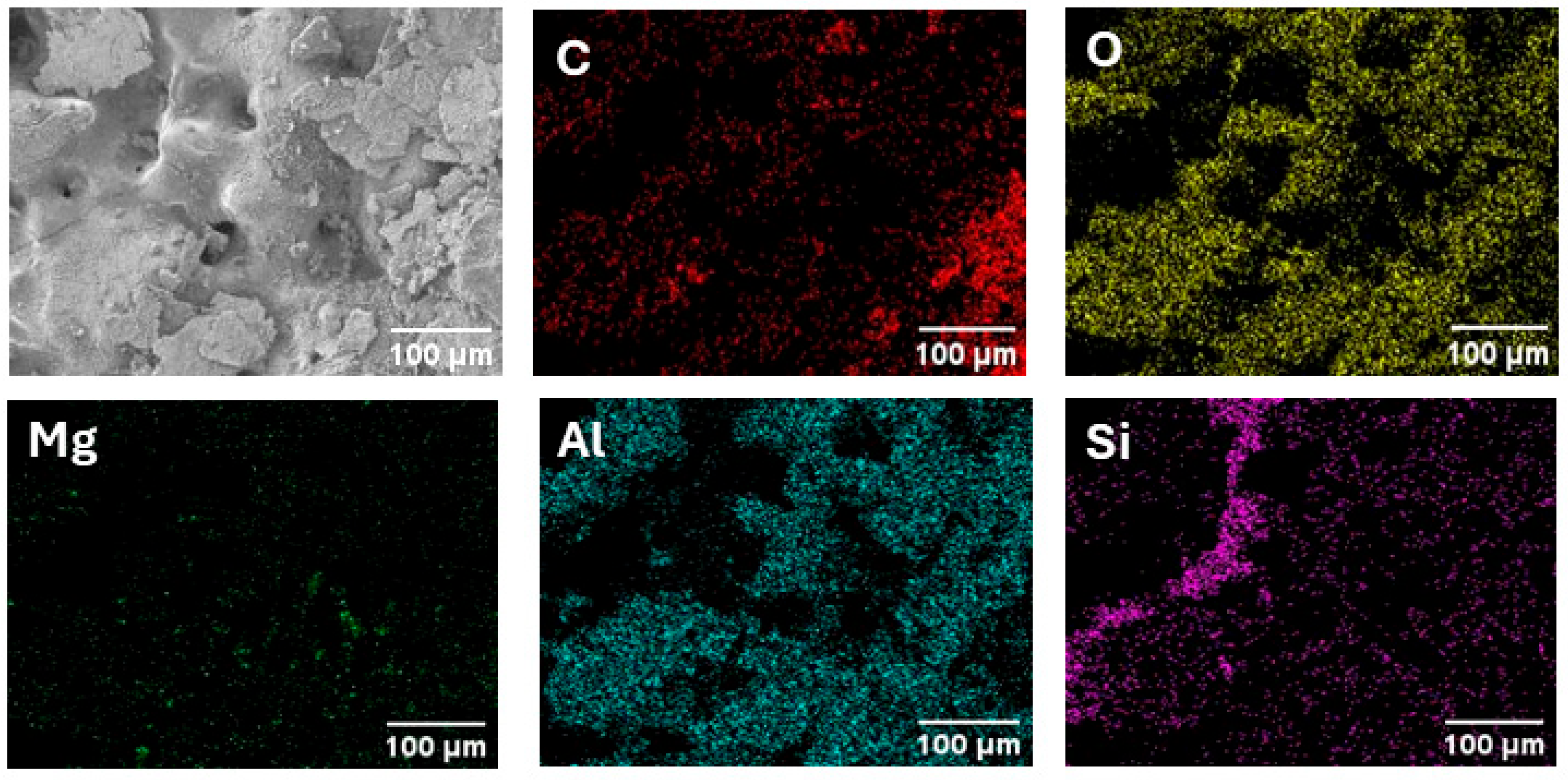

3.3. Composition

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, L.-Y.; Qin, P.; Zhang, L.; Zhang, L.-C. An overview of additively manufactured metal matrix composites: Preparation, performance, and challenge. Int. J. Extrem. Manuf. 2024, 6, 052006. [Google Scholar] [CrossRef]

- Ghinatti, E.; Bertolini, R.; Sorgato, M.; Ghiotti, A.; Bruschi, S. Tool wear and surface finish analysis after drilling Al-SiC metal matrix composite with DLC-coated tools at varying feed. Procedia CIRP 2024, 123, 53–58. [Google Scholar] [CrossRef]

- Monazzah, A.H.; Pouraliakbar, H.; Bagheri, R.; Reihani, S.M.S. Al-Mg-Si/SiC laminated composites: Fabrication, architectural characteristics, toughness, damage tolerance, fracture mechanisms. Compos. Part B Eng. 2017, 125, 49–70. [Google Scholar] [CrossRef]

- An, Q.; Cong, X.S.; Shen, P.; Jiang, Q.C. Roles of alloying elements in wetting of SiC by Al. J. Alloys Compd. 2019, 784, 1212–1220. [Google Scholar] [CrossRef]

- Gutema, E.M.; Lemu, H.G. Conventional Machining of Metal Matrix Composites towards Sustainable Manufacturing—Present Scenario and Future Prospects. J. Compos. Sci. 2024, 8, 356. [Google Scholar] [CrossRef]

- Hashim, J.; Looney, L.; Hashmi, M.S.J. The enhancement of wettability of SiC particles in cast aluminium matrix composites. J. Mater. Process. Technol. 2001, 119, 329–335. [Google Scholar] [CrossRef]

- Song, X.-Y.; Shu, S.-L.; Zhang, S.; Yang, H.-Y.; Qiu, F.; Jiang, Q.-C. Microstructure, solidification defects and mechanical properties of high-modulus and high-strength SiC/AlSi10Mg composites fabricated by selective laser melting. Ceram. Int. 2024, 50, 26607–26623. [Google Scholar] [CrossRef]

- Shetty, A.; Bhat, T.; Sharma, S.; Hegde, A.K.N.; Prabhu, R.; Anne, G. Effects of Magnesium Content and Age Hardening Parameters on the Hardness and Ultimate Tensile Strength of SiC-Reinforced Al-Si-Mg Composites. J. Compos. Sci. 2024, 9, 5. [Google Scholar] [CrossRef]

- Jayashree, P.; Sharma, S.; Kumar, S.; Bangera, M.; Bhat, R. Tension and Impact Analysis of Tungsten Inert Gas Welded Al6061-SiC Composite. J. Compos. Sci. 2023, 7, 78. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, R.; Hu, X.; Wang, C.-A.; Huang, Y. Characterization of a powder metallurgy SiC/Cu–Al composite. J. Mater. Process. Technol. 2008, 197, 43–48. [Google Scholar] [CrossRef]

- Sadhu, K.K.; Mandal, N.; Sahoo, R.R. SiC/graphene reinforced aluminum metal matrix composites prepared by powder metallurgy: A review. J. Manuf. Process. 2023, 91, 10–43. [Google Scholar] [CrossRef]

- Ghinatti, E. Ultrasonic Vibration Assisted Turning for Reducing Tool Wear in Metal Matrix Composite Machining; University of Padua: Padua, Italy, 2021. [Google Scholar]

- Liu, J.; Zheng, Z.; Wang, J.; Wu, Y.; Tang, W.; Lü, J. Pressureless infiltration of liquid aluminum alloy into SiC preforms to form near-net-shape SiC/Al composites. J. Alloys Compd. 2008, 465, 239–243. [Google Scholar] [CrossRef]

- Polozov, I.; Razumov, N.; Masaylo, D.; Silin, A.; Lebedeva, Y.; Popovich, A. Fabrication of silicon carbide fiber-reinforced silicon carbide matrix composites using binder jetting additive manufacturing from irregularly-shaped and spherical powders. Materials 2020, 13, 1766. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhao, Y.F. Investigation of sintering shrinkage in binder jetting additive manufacturing process. Procedia Manuf. 2017, 10, 779–790. [Google Scholar] [CrossRef]

- Bai, Y.; Wagner, G.; Williams, C.B. Effect of particle size distribution on powder packing and sintering in binder jetting additive manufacturing of metals. J. Manuf. Sci. Eng. 2017, 139, 081019. [Google Scholar] [CrossRef]

- Yu, T.; Zhao, Z.; Li, J. Effect of sintering temperature and sintering additives on the properties of alumina ceramics fabricated by binder jetting. Ceram. Int. 2023, 49, 9948–9955. [Google Scholar] [CrossRef]

- Do, T.; Kwon, P.; Shin, C.S. Process development toward full-density stainless steel parts with binder jetting printing. Int. J. Mach. Tools Manuf. 2017, 121, 50–60. [Google Scholar] [CrossRef]

- Snelling, D.A.; Williams, C.B.; Suchicital, C.T.; Druschitz, A.P. Binder jetting advanced ceramics for metal-ceramic composite structures. Int. J. Adv. Manuf. Technol. 2017, 92, 531–545. [Google Scholar] [CrossRef]

- Zulfia, A.; Hand, R. The production of Al-Mg alloy/SiC metal matrix composites by pressureless infiltration. J. Mater. Sci. 2002, 37, 955–961. [Google Scholar] [CrossRef]

- Kunchala, P.; Kappagantula, K. 3D printing high density ceramics using binder jetting with nanoparticle densifiers. Mater. Des. 2018, 155, 443–450. [Google Scholar] [CrossRef]

- Pasha, M.M.; Arman, M.S.; Khan, F.; Pei, Z.; Kachur, S. Effects of Layer Thickness and Compaction Thickness on Green Part Density in Binder Jetting Additive Manufacturing of Silicon Carbide: Designed Experiments. J. Manuf. Mater. Process. 2024, 8, 148. [Google Scholar] [CrossRef]

- Mostafaei, A.; Elliott, A.M.; Barnes, J.E.; Li, F.; Tan, W.; Cramer, C.L.; Nandwana, P.; Chmielus, M. Binder jet 3D printing—Process parameters, materials, properties, modeling, and challenges. Prog. Mater. Sci. 2021, 119, 100707. [Google Scholar] [CrossRef]

- Gonzalez, J.; Mireles, J.; Lin, Y.; Wicker, R.B. Characterization of ceramic components fabricated using binder jetting additive manufacturing technology. Ceram. Int. 2016, 42, 10559–10564. [Google Scholar] [CrossRef]

- Khan, F.; Arman, M.S.; Sanders, J.; Pasha, M.M.; Rahman, A.M.; Pei, Z.; Dong, T. Binder Jetting 3D Printing Utilizing Waste Algae Powder: A Feasibility Study. Intell. Sustain. Manuf. 2024, 1, 10016. [Google Scholar] [CrossRef]

- Porter, Q.; Moghadasi, M.; Pei, Z.; Ma, C. Dense and strong ceramic composites via binder jetting and spontaneous infiltration. Ceram. Int. 2023, 49, 17363–17370. [Google Scholar] [CrossRef]

- Aguilar-Martinez, J.; Hernandez, M.; Castillo-Torres, J.; Pech-Canul, M. Effect of particle size and Mg content on the processing parameters of Al-Si-Mg/SiCp composites processed by pressureless infiltration. Rev. Mex. Física 2007, 53, 198–204. [Google Scholar]

- Täffner, U.; Carle, V.; Schäfer, U.; Hoffmann, M.J. Preparation and Microstructural Analysis of High-Performance Ceramics. In Metallography and Microstructures; ASM International: Almere, The Netherlands, 2004; pp. 1057–1066. [Google Scholar]

- Spierings, A.B.; Schneider, M.U.; Eggenberger, R. Comparison of density measurement techniques for additive manufactured metallic parts. Rapid Prototyp. J. 2011, 17, 380–386. [Google Scholar] [CrossRef]

- Paudel, B.J.; To, A.C. Spatial green density variation and its effect on distortion prediction in binder jet additive manufacturing. Addit. Manuf. 2025, 98, 104640. [Google Scholar] [CrossRef]

- ISO 18754:2013; Fine ceramics (Advanced Ceramics, Advanced Technical Ceramics)-Determination of Density and Apparent Porosity. ISO: Geneva, Switzerland, 2013.

- Vaßen, R.; Kaiser, A.; Förster, J.; Buchkremer, H.; Stöver, D. Densification of ultrafine SiC powders. J. Mater. Sci. 1996, 31, 3623–3637. [Google Scholar] [CrossRef]

- ICSD. Inorganic Crystal Structure Database. 1913. Available online: https://icsd.products.fiz-karlsruhe.de/en/about/about-icsd (accessed on 24 January 2025).

- Miyanaji, H.; Rahman, K.M.; Da, M.; Williams, C.B. Effect of fine powder particles on quality of binder jetting parts. Addit. Manuf. 2020, 36, 101587. [Google Scholar] [CrossRef]

| Printing Parameter | Value |

|---|---|

| Layer thickness (µm) | 45 |

| Compaction thickness (µm) | 35 |

| Ultrasonic intensity (%) | 100 |

| Roller traverse speed (mm/s) | 15 |

| Roller rotation speed (rpm) | 300 |

| Roughening roller rotation speed (rpm) | 50 |

| Binder saturation (%) | 60 |

| Binder set time (s) | 30 |

| Bed temperature (°C) | 50 |

| Drying time (s) | 15 |

| Packing rate (%) | 50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, F.; Sanders, J.; Arman, M.S.; Pasha, M.M.; Kachur, S.; Pei, Z. Fabrication of SiC–Aluminum Composites via Binder Jetting 3D Printing and Infiltration: A Feasibility Study. J. Compos. Sci. 2025, 9, 111. https://doi.org/10.3390/jcs9030111

Khan F, Sanders J, Arman MS, Pasha MM, Kachur S, Pei Z. Fabrication of SiC–Aluminum Composites via Binder Jetting 3D Printing and Infiltration: A Feasibility Study. Journal of Composites Science. 2025; 9(3):111. https://doi.org/10.3390/jcs9030111

Chicago/Turabian StyleKhan, Fahim, Jackson Sanders, Md Shakil Arman, Mostafa Meraj Pasha, Stephen Kachur, and Zhijian Pei. 2025. "Fabrication of SiC–Aluminum Composites via Binder Jetting 3D Printing and Infiltration: A Feasibility Study" Journal of Composites Science 9, no. 3: 111. https://doi.org/10.3390/jcs9030111

APA StyleKhan, F., Sanders, J., Arman, M. S., Pasha, M. M., Kachur, S., & Pei, Z. (2025). Fabrication of SiC–Aluminum Composites via Binder Jetting 3D Printing and Infiltration: A Feasibility Study. Journal of Composites Science, 9(3), 111. https://doi.org/10.3390/jcs9030111