1. Introduction

The single shot drilling of Aramid Fiber Reinforced Plastic (AFRP) and Al7075-T6 materials highlights the challenges of drilling dissimilar materials, where the hardness disparity and adhesive bonding characteristics require precise parameter optimization to maintain tool life and hole quality. Drilling holes poses significant challenges due to the wear experienced by cutting tools, which must be managed to prevent damage to both the tools and the workpieces. The heterogeneous [

1] and anisotropic [

2] nature of fiber-reinforced composites further aggravate tool wear, making the drilling process more complex and often leading to delamination issues [

3]. Therefore, an in-depth examination of tool wear is essential to evaluate factors such as tool lifespan, robustness, and cutting efficiency.

An in-depth assessment of tool wear behavior under different drilling conditions provides valuable insights into tool lifespan, robustness, and cutting efficiency. The four key tool geometry variables that affect the cutting mechanism are the point angle, helix angle, primary clearance angle, and chisel edge angle. SenthilKumar et al. [

4] reported that wear concentrated at the chisel edge notably increases thrust force, thereby reducing tool robustness and accelerating wear progression. Fernández-Pérez et al. [

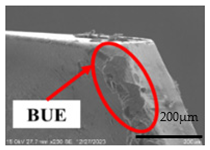

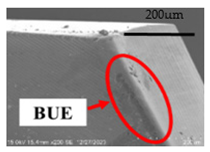

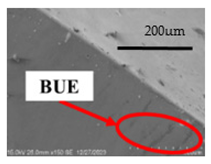

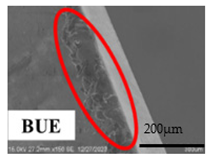

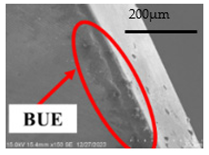

5], in their investigation of Ti/CFRP/Ti stack drilling, used SEM analysis to observe brittle fractures extending from the cutting edge toward the tool tip. Their findings indicated that delamination and subsequent loss of the diamond coating shortened the effective cutting-edge length, inducing thermal stresses due to mismatched thermal expansion coefficients between the diamond layer and carbide substrate. Such thermal–mechanical interactions were found to degrade the cutting efficiency and shorten the tool lifespan. Furthermore, the reduction in built-up edge (BUE) formation with increasing cutting speed, as noted by previous studies [

6], enhances cutting stability by minimizing material adhesion. At elevated temperatures, the softened BUE weakens and detaches from the cutting edge, reducing cutting resistance but simultaneously exposing the tool to abrasive wear and micro-fracturing [

7]. These wear mechanisms directly influence surface integrity and hole quality, which are critical parameters defining drilling efficiency. Additionally, Bakkal et al. [

8] analyzed chip morphology during the drilling of bulk metallic glass and identified six distinct chip forms, linking long ribbon-like chips to tool failure due to chip entanglement and poor evacuation. Such findings highlight that tool wear mechanisms, combined with drill geometry and chip evacuation behavior, collectively determine tool robustness, operational lifespan, and overall cutting performance [

4,

5,

6,

7,

8].

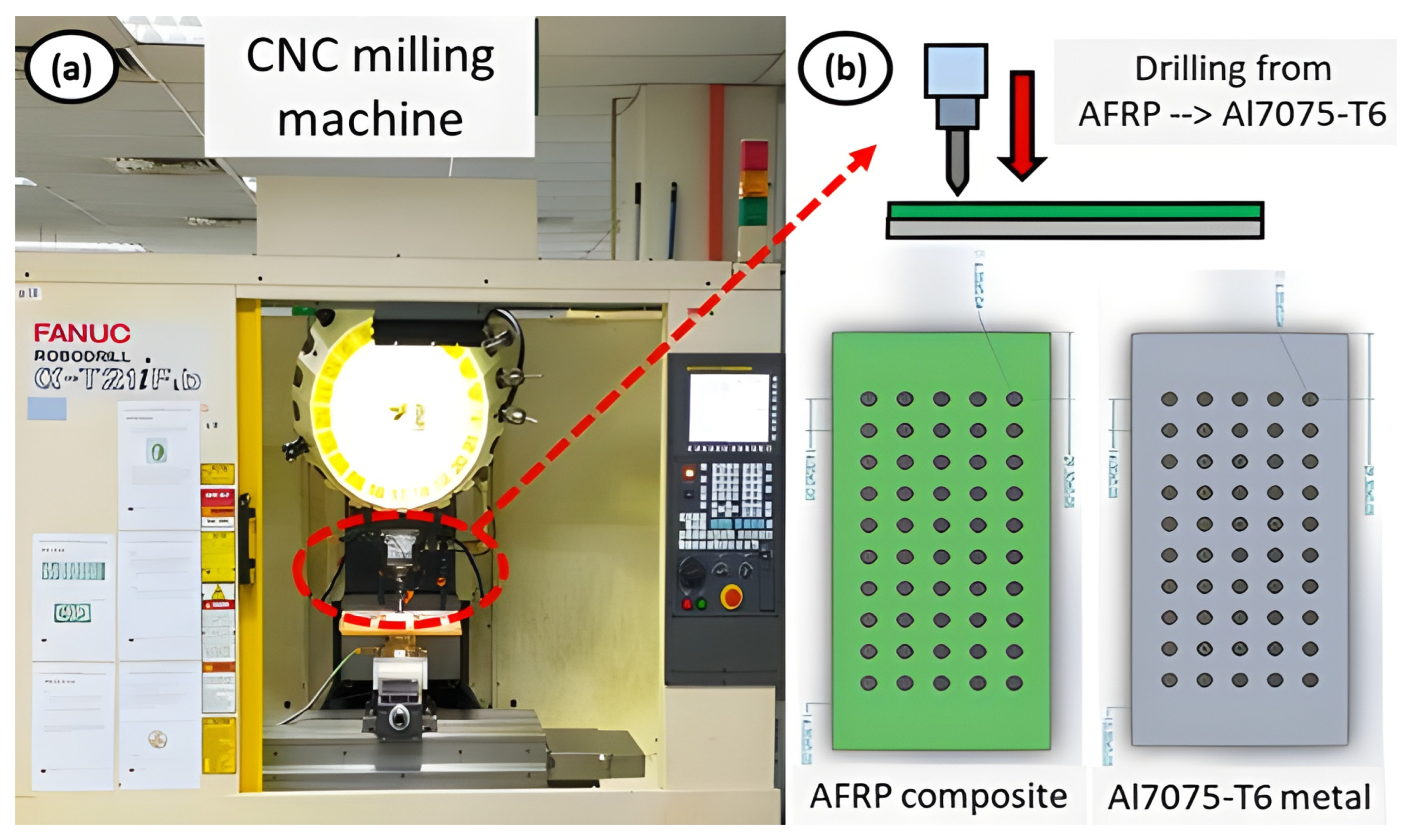

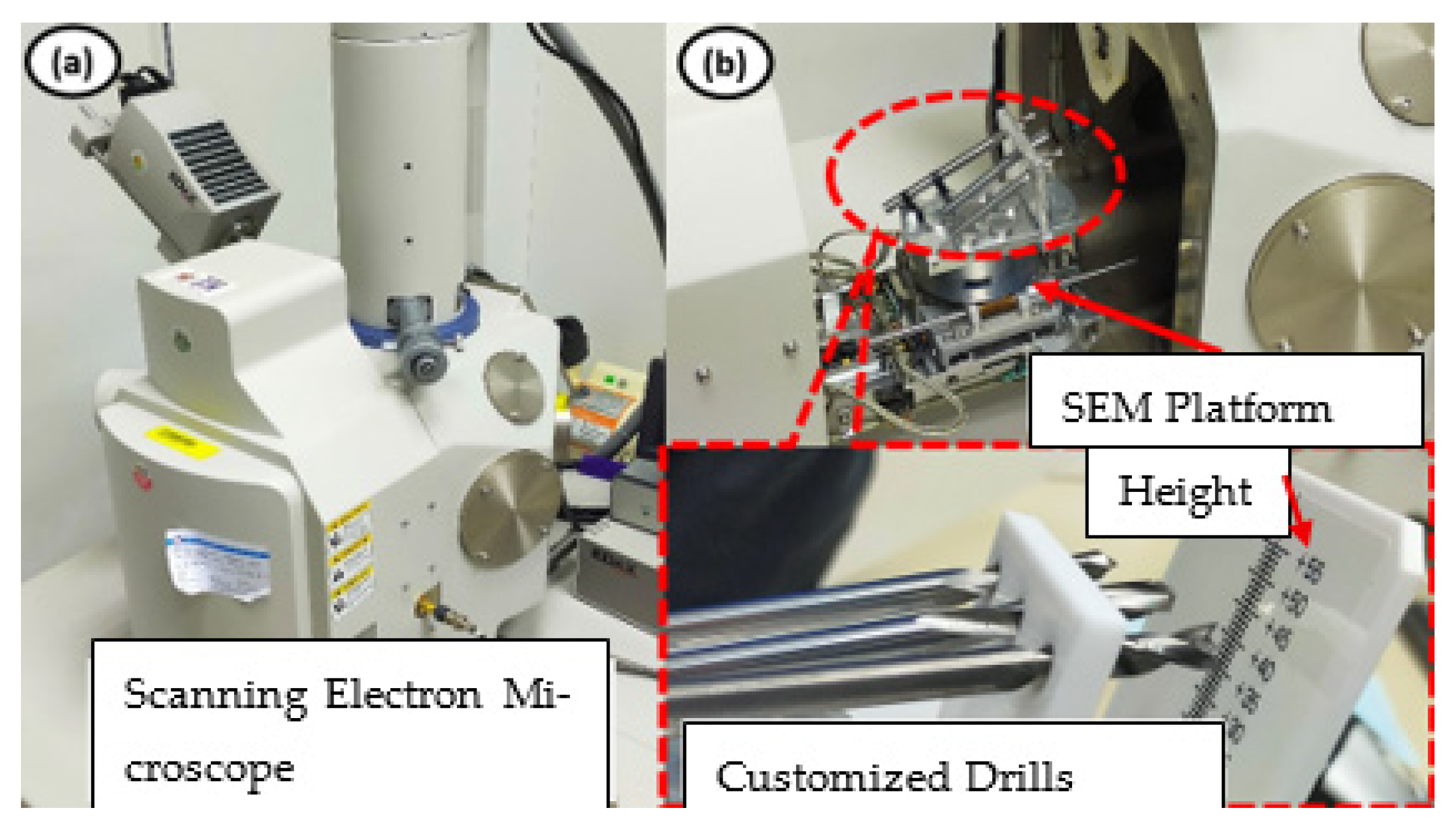

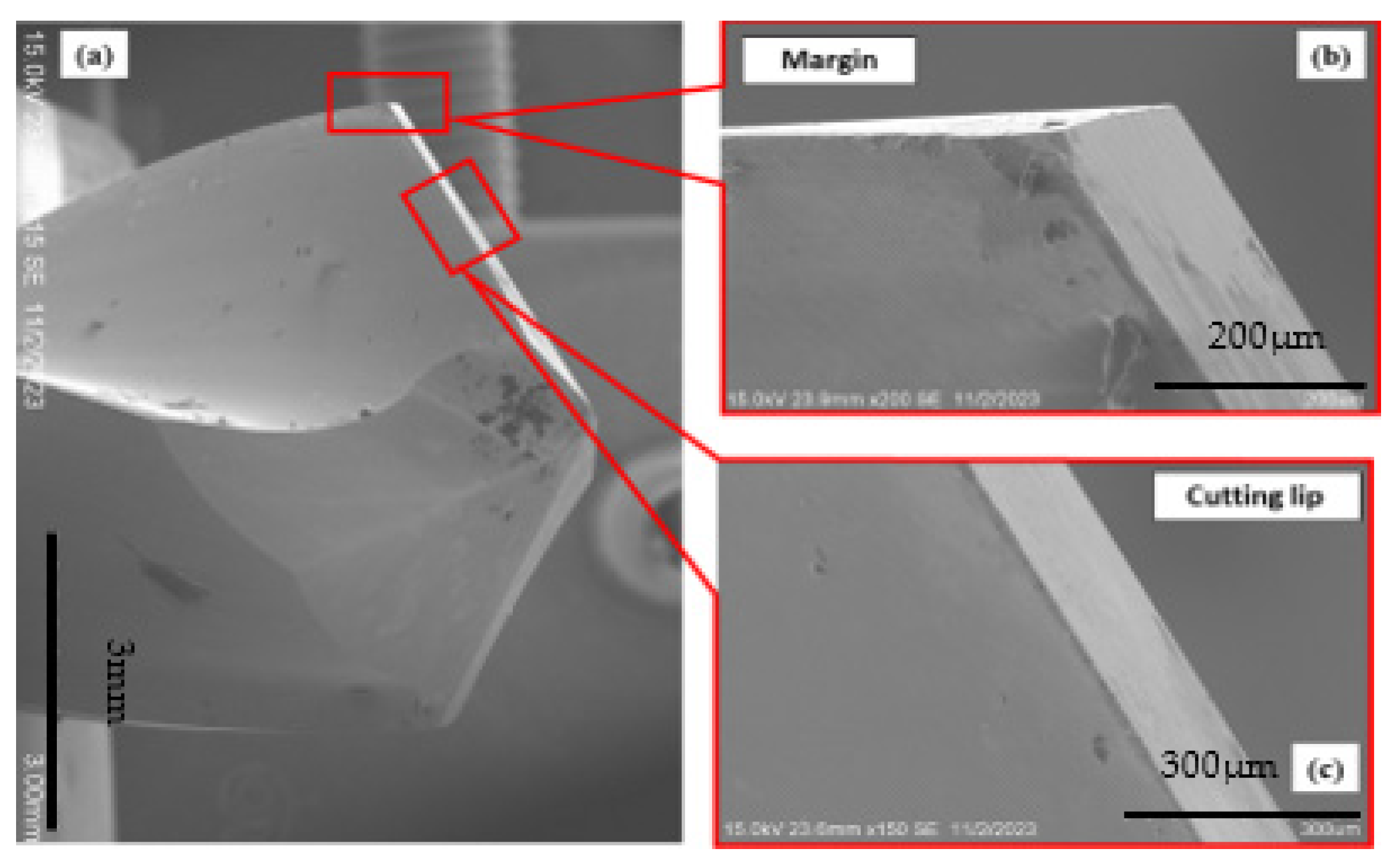

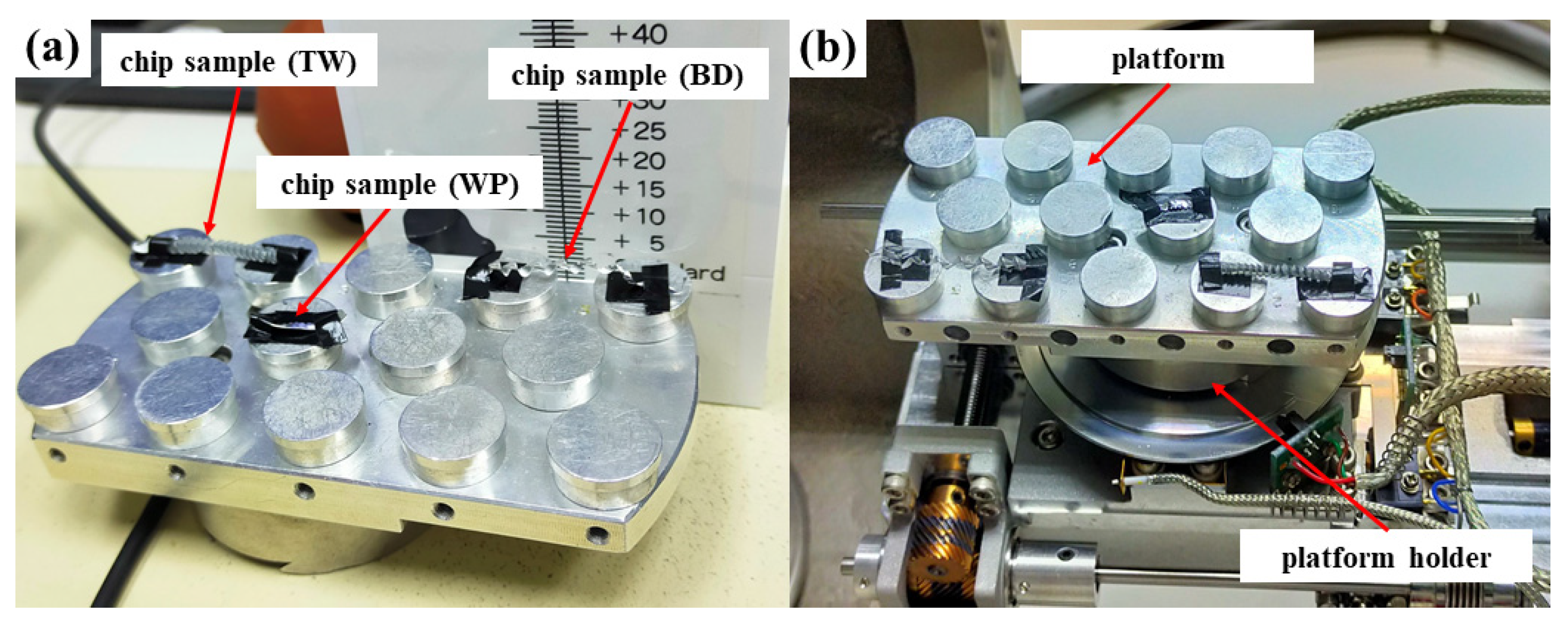

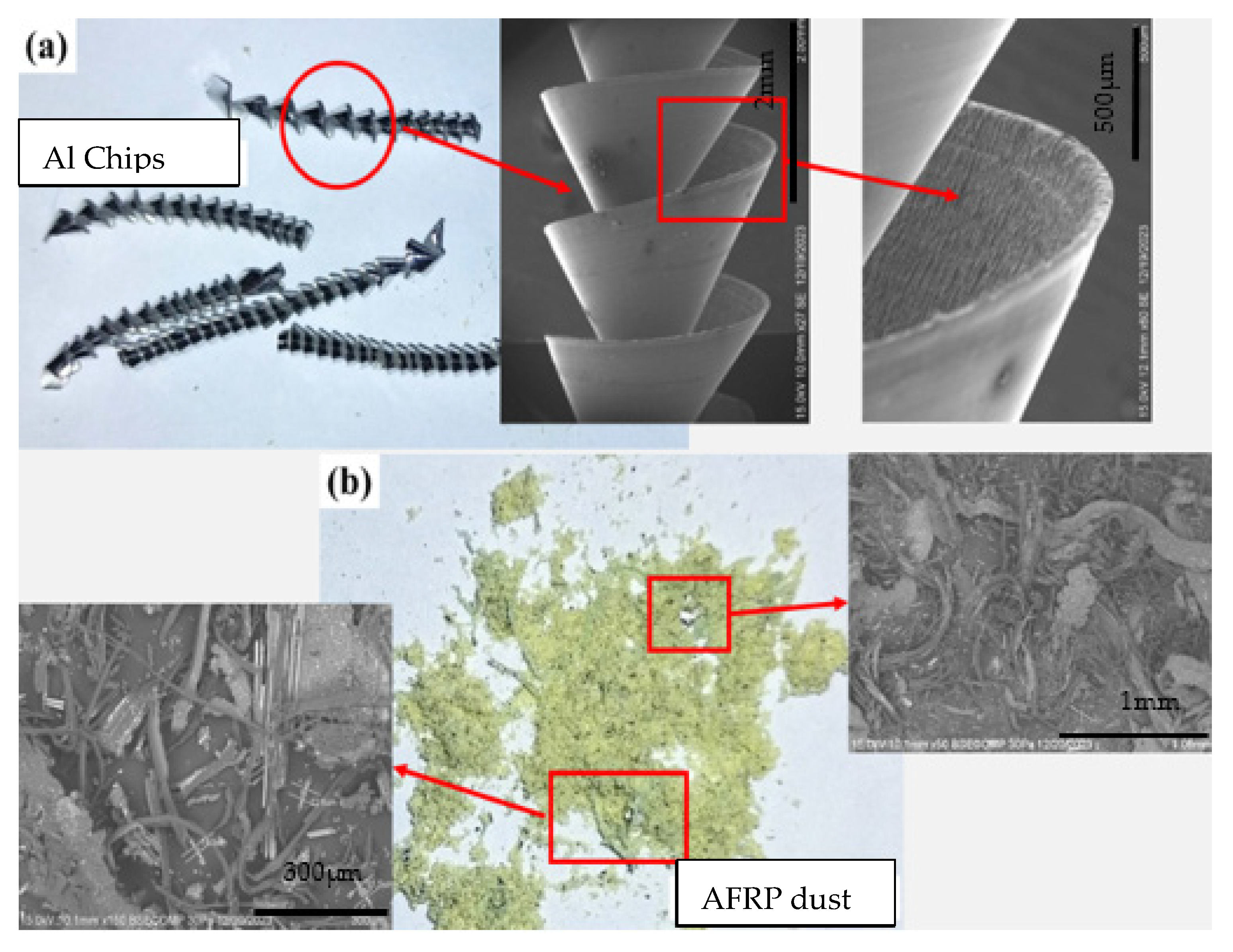

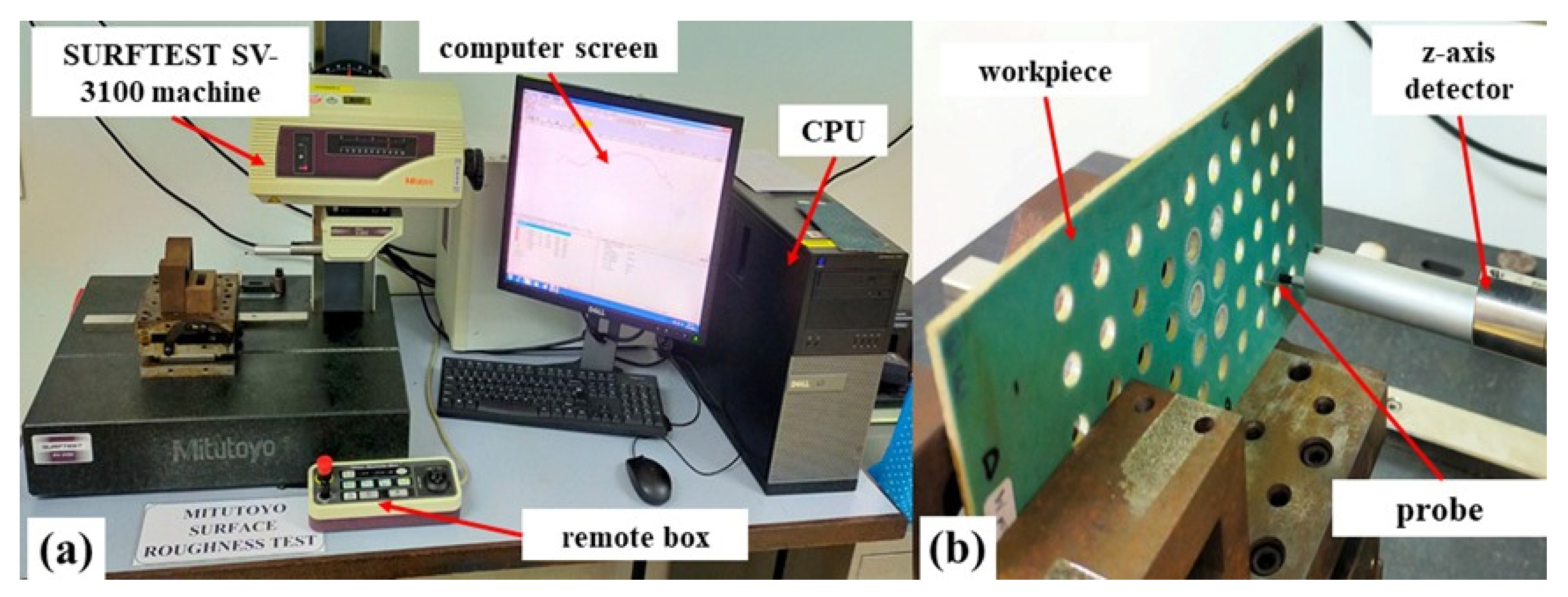

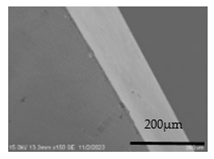

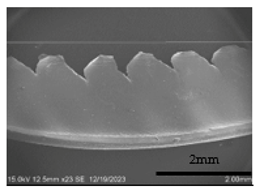

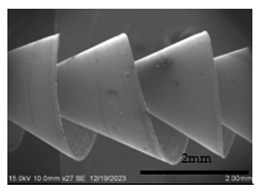

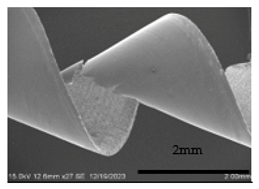

This paper presents an experimental investigation aimed at identifying the most suitable drill bit design that delivers the best performance among three customized geometries developed for drilling AFRP/Al7075-T6 stacked materials. The variations in drill geometry were intended to improve chip evacuation efficiency, minimize the adhesion layer formation on the cutting edges, and enhance overall hole quality. To evaluate the performance of each drill bit, Scanning Electron Microscopy (SEM) was used to examine the tool tips, while chip and dust morphology analyses were conducted to assess material removal characteristics. The percentage of adhesion layer (PAL) was calculated to quantitatively assess tool wear and identify the drill bit exhibiting the highest wear resistance and most stable drilling performance, characterized by consistent hole quality and reduced risk of edge chipping.

Although extensive work has explored single shot drilling of CFRP/Al7075-T6 and CFRP/Ti6Al4V stack ups, especially in relation to machining parameters, tool geometry, and coatings, research on single shot drilling of AFRP/Al7075-T6 remains limited within the aerospace sector. This gap is significant given the growing adoption of aramid fibre composites in lightweight structural applications. Accordingly, this study aims to address this deficiency by proposing and evaluating a customized tool geometry specifically designed for efficiency, and damage controlled single shot drilling of AFRP/Al7075-T6 aerospace stack ups. In addition, this study investigates the wear mechanisms associated with adhesion layer formation during drilling and evaluates the influence of different drill geometries on chip formation, which in turn affects the resulting surface roughness. The combined effects of tool wear, chip behaviour, and drill design are comprehensively examined in this paper.

4. Conclusions

Based on the experimental investigation conducted on the drilling of AFRP/Al7075-T6 stacked materials using three customized drill geometries, the following conclusions can be drawn:

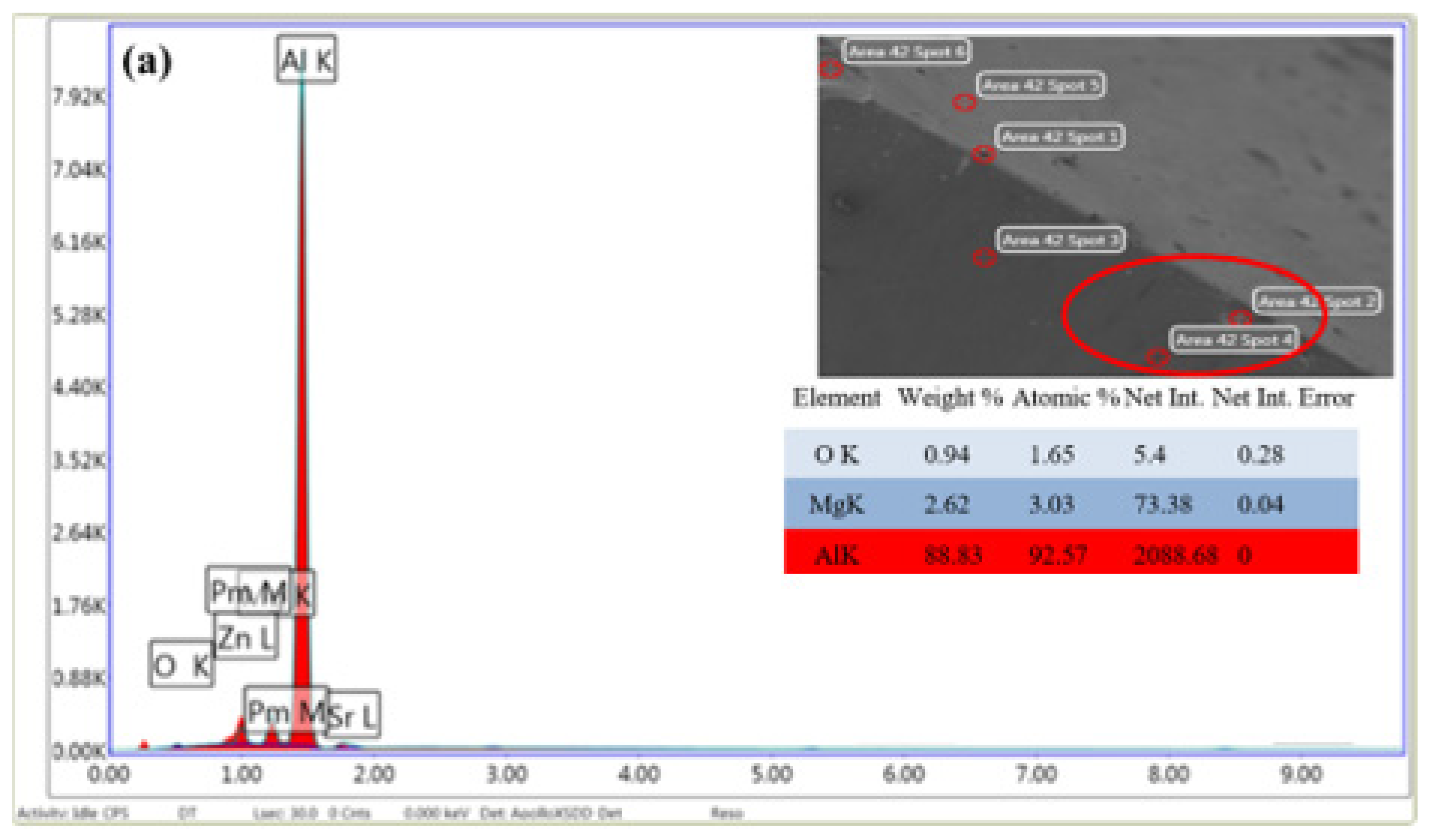

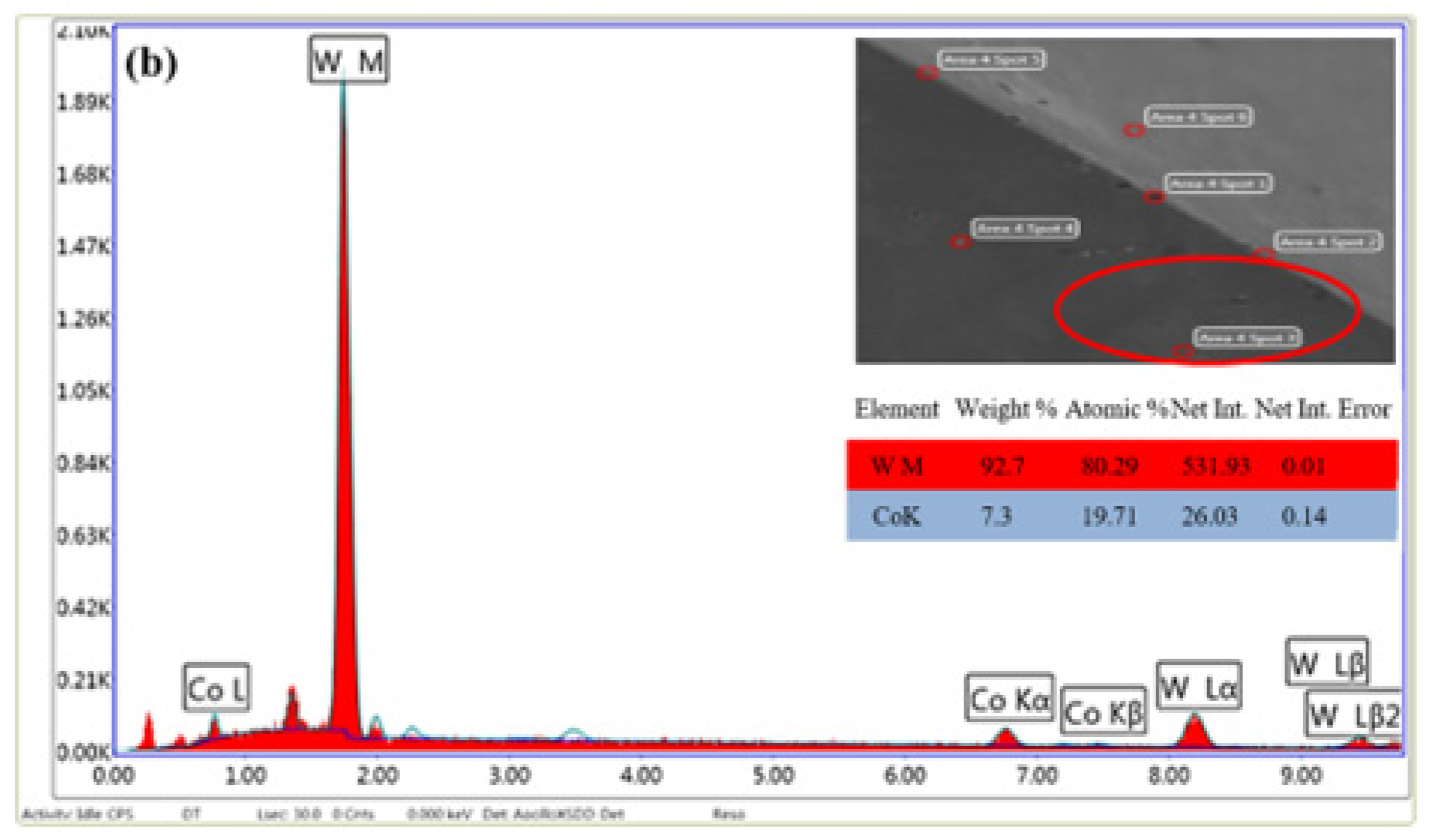

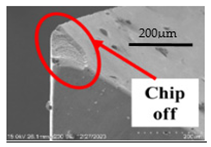

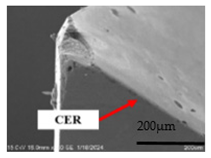

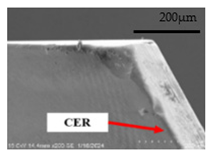

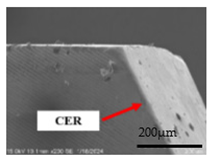

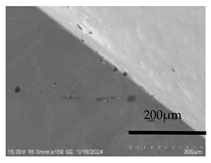

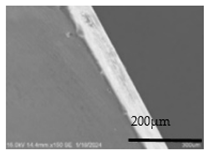

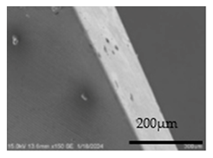

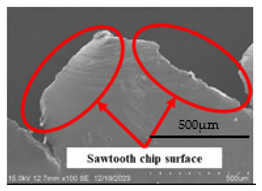

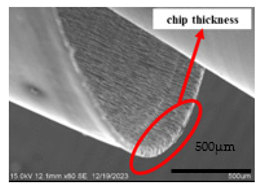

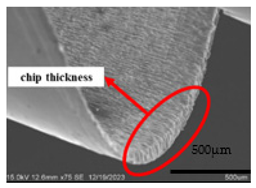

SEM analysis confirmed that all customized drill bits exhibited aluminum adhesion on the cutting lips after drilling operations. Subsequent cleaning removed the adhered layer and revealed the original tungsten and cobalt elements. The abrasive nature of AFRP fibers caused noticeable chipping and the formation of cutting-edge radius (CER), particularly evident in the w-point drill, indicating progressive tool wear.

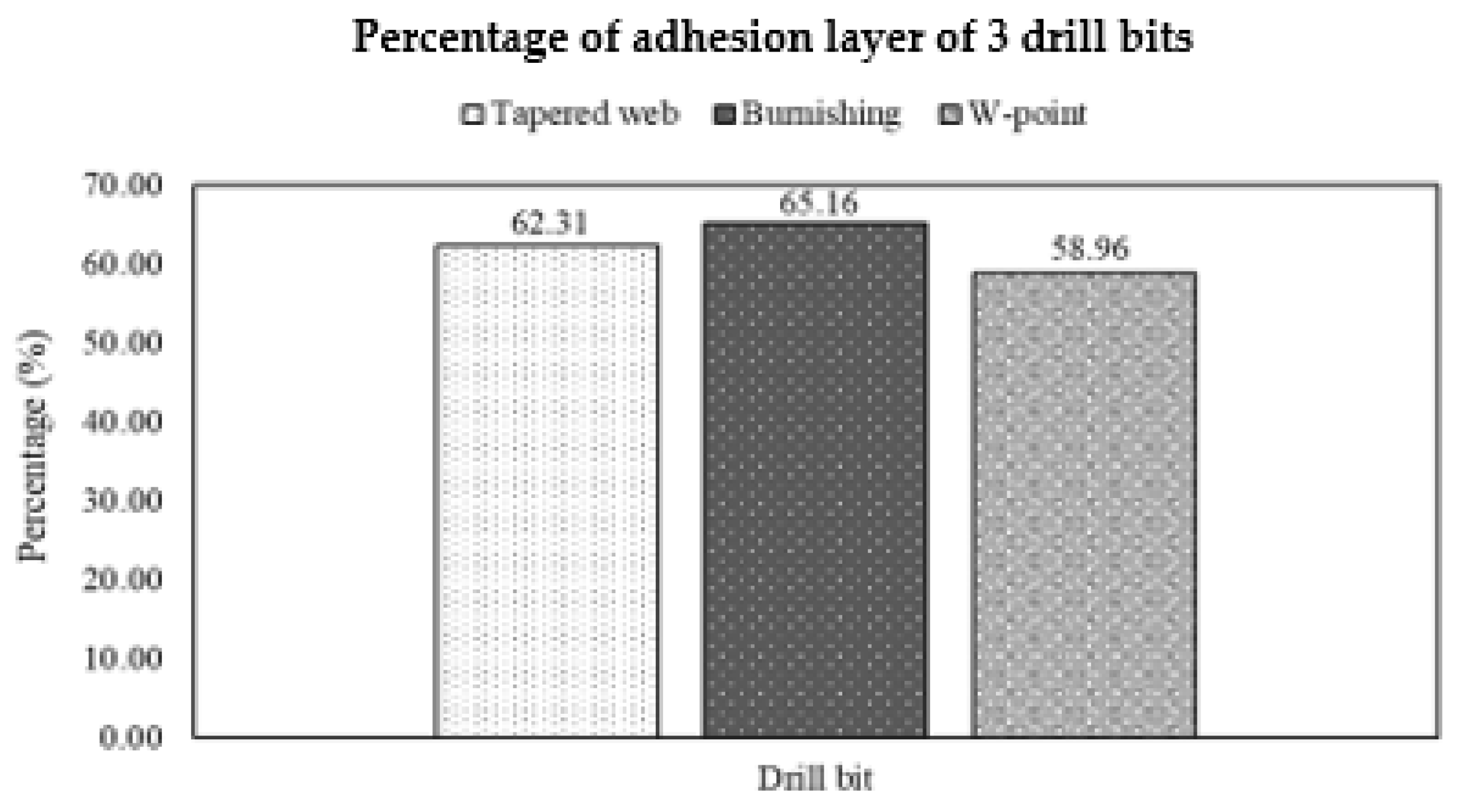

The w-point drill recorded the lowest percentage of adhesion layer (PAL) at 58.96%, followed by the tapered web and burnishing drills. This result indicates that the w-point geometry offers the highest wear resistance and durability among the three designs, making it more suitable for extended drilling of hybrid composite–metal stacks.

The surface roughness results demonstrated that the w-point drill produced the best surface finish in AFRP, whereas the tapered web drill achieved superior results for Al7075-T6. All measured roughness values remained within the aerospace industry’s allowable limits, confirming the capability of the customized drill bits to maintain acceptable hole quality standards.

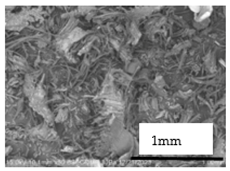

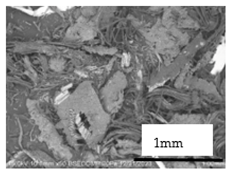

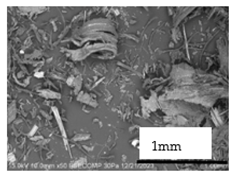

The chip and dust morphology observations revealed that the w-point drill generated finer dust particles and smaller, irregular chips, contributing to improved surface finish and efficient chip evacuation. The smaller point angle of the w-point drill enhanced its cutting performance and minimized heat accumulation, establishing it as the most effective geometry for drilling AFRP/Al7075-T6 stacked materials.

Future work should focus on a comprehensive evaluation of hole quality parameters, including dimensional accuracy, circularity, cylindricity, and delamination factors at both entry and exit interfaces. These parameters may be statistically correlated with tool wear and adhesion data using process capability studies (Cp, Cpk) and Six-Pack analysis to quantitatively assess consistency, reproducibility, and overall process stability. In addition, advanced 3D surface characterization and cross-sectional microscopy could be employed to examine subsurface damage, fiber pull-out, and matrix smearing at microstructural levels. Investigating cutting temperature and thrust force evolution using real-time sensors would also help establish predictive wear models for different drill geometries. Further optimization can be achieved by applying multi-objective statistical tools such as Design of Experiments (DOE) or Response Surface Methodology (RSM) to balance tool life, surface integrity, and drilling efficiency. Additionally, applying coatings will also help to improve the surface quality of the workpiece and wear reduction in the tool. Introduction of lubricants can also be tested to decide its influence in this regard.