Process Optimization and Non-Destructive Evaluation of Micro-Voids in Submarine Composite Structures for Enhanced Mechanical Performance

Abstract

1. Introduction

2. Experimental Methods

2.1. Materials and Specimen Fabrication

2.2. Void Quantification Techniques

2.2.1. Ultrasonic Testing

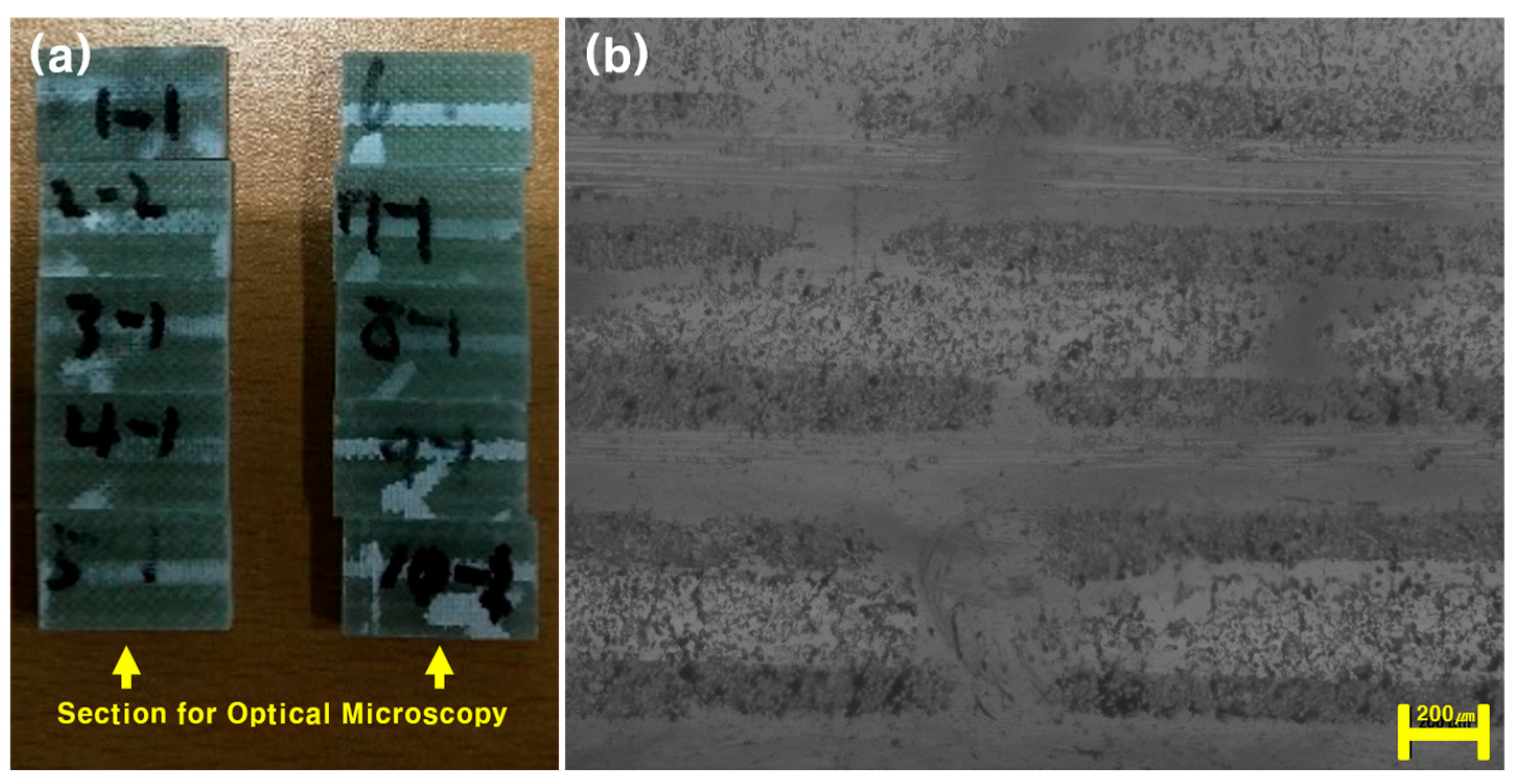

2.2.2. Optical Microscopy and Image Analysis

2.2.3. Micro-Computed Tomography (Micro-CT)

2.3. Design of Experiments

2.4. Mechanical Property Evaluation

3. Results and Discussion

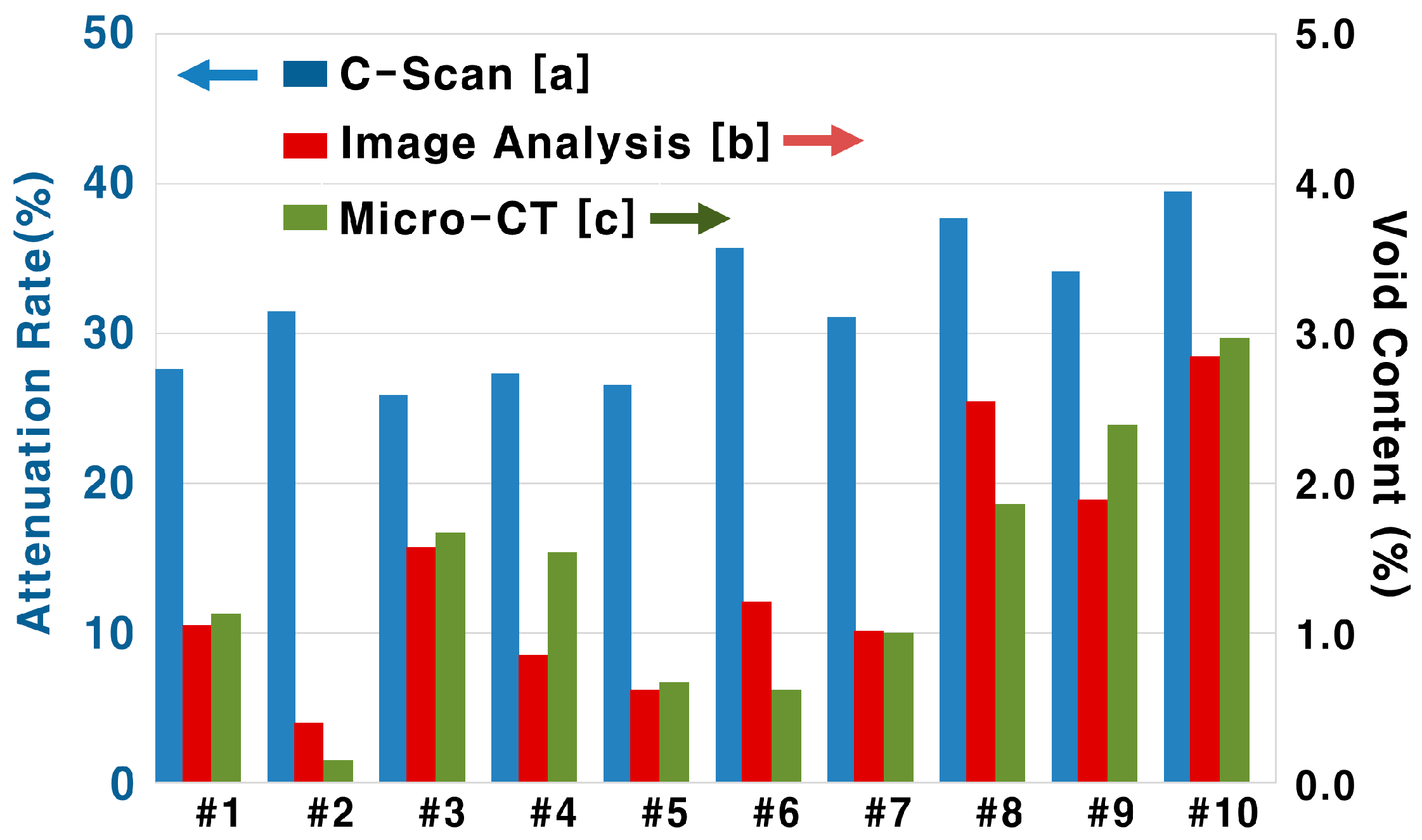

3.1. Comparison of Void Measurement Techniques

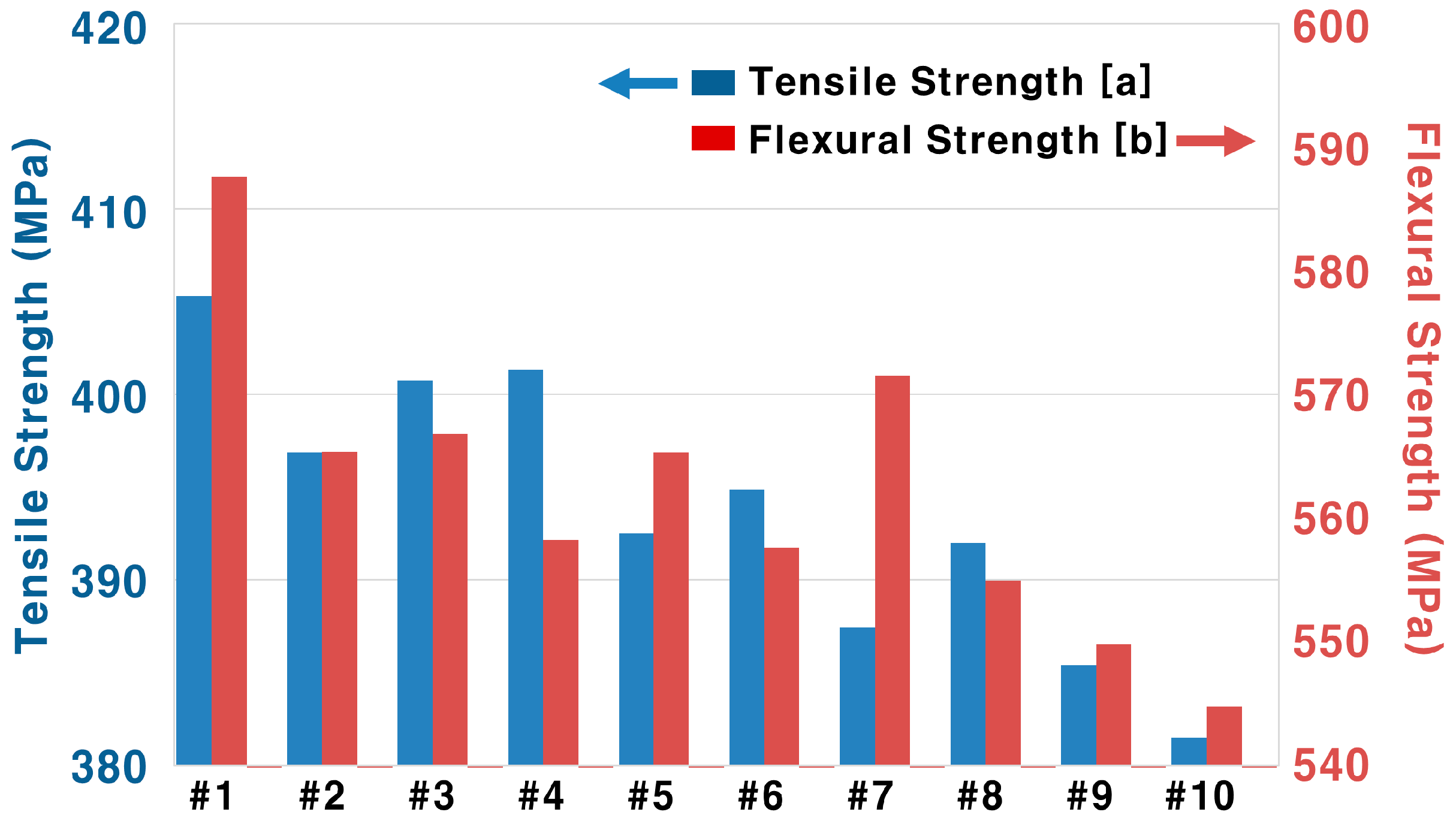

3.2. Comparison of Mechanical Properties Among Specimens with Random Void Distribution

3.3. Optimization of Process Parameters for Micro-Void Control

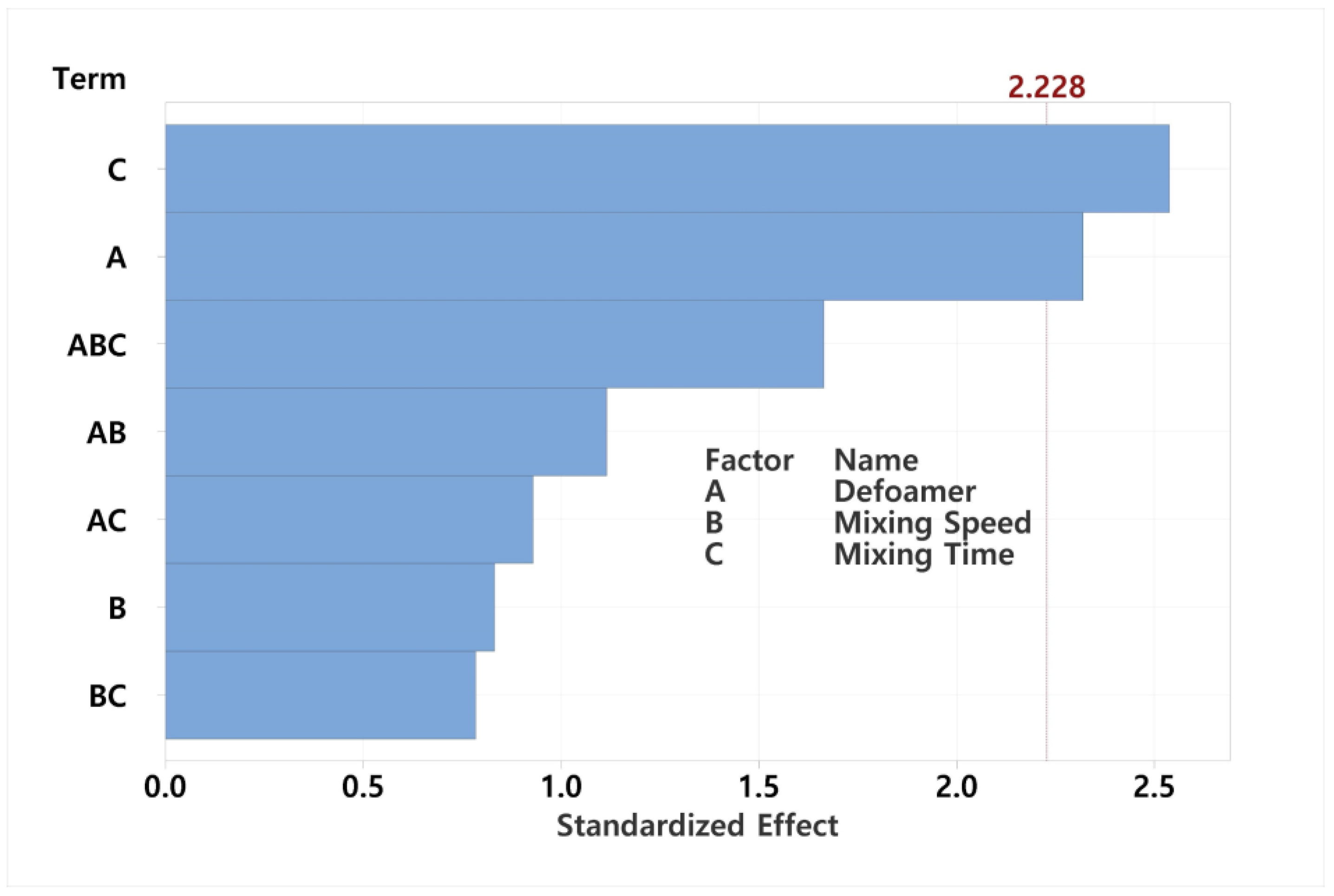

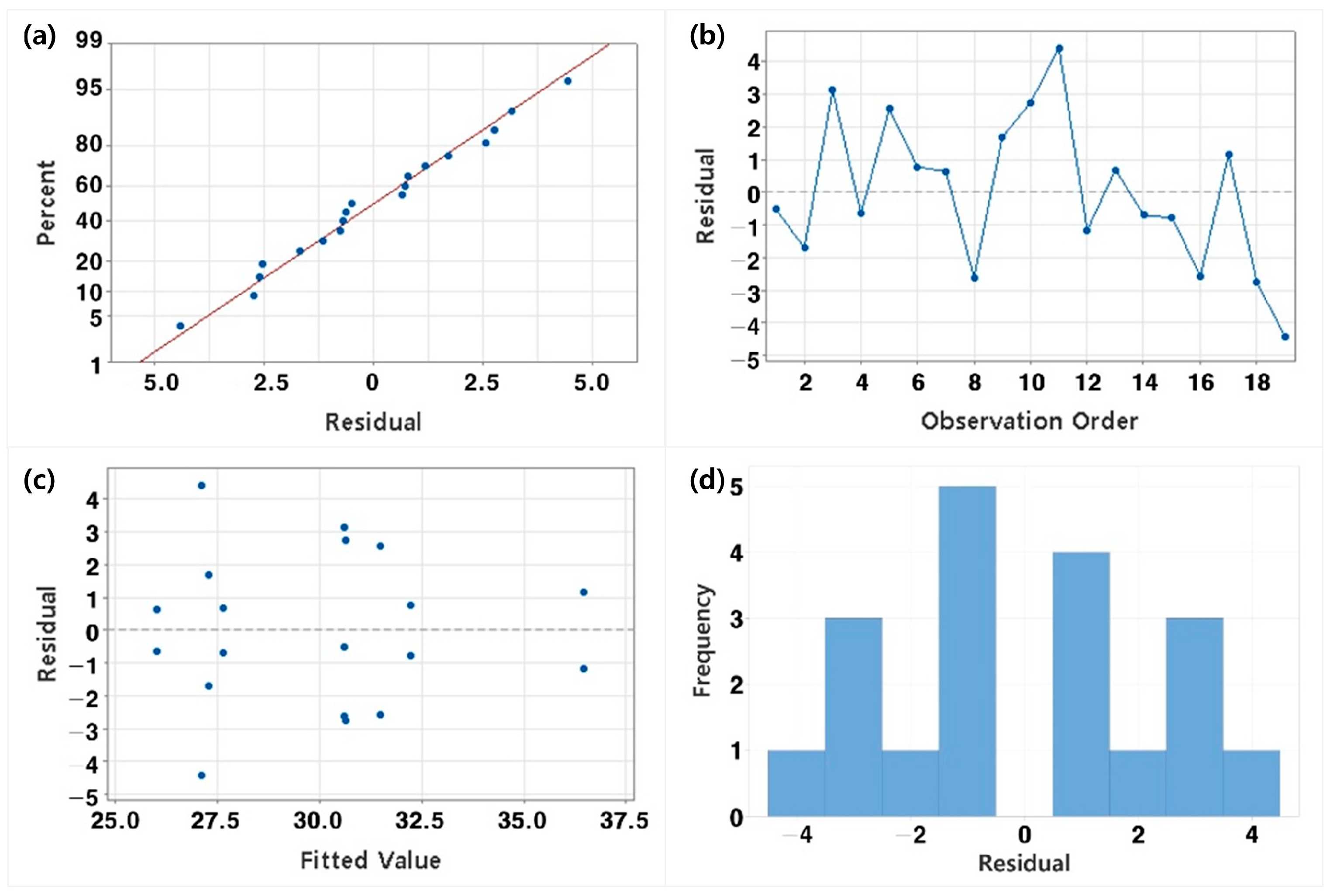

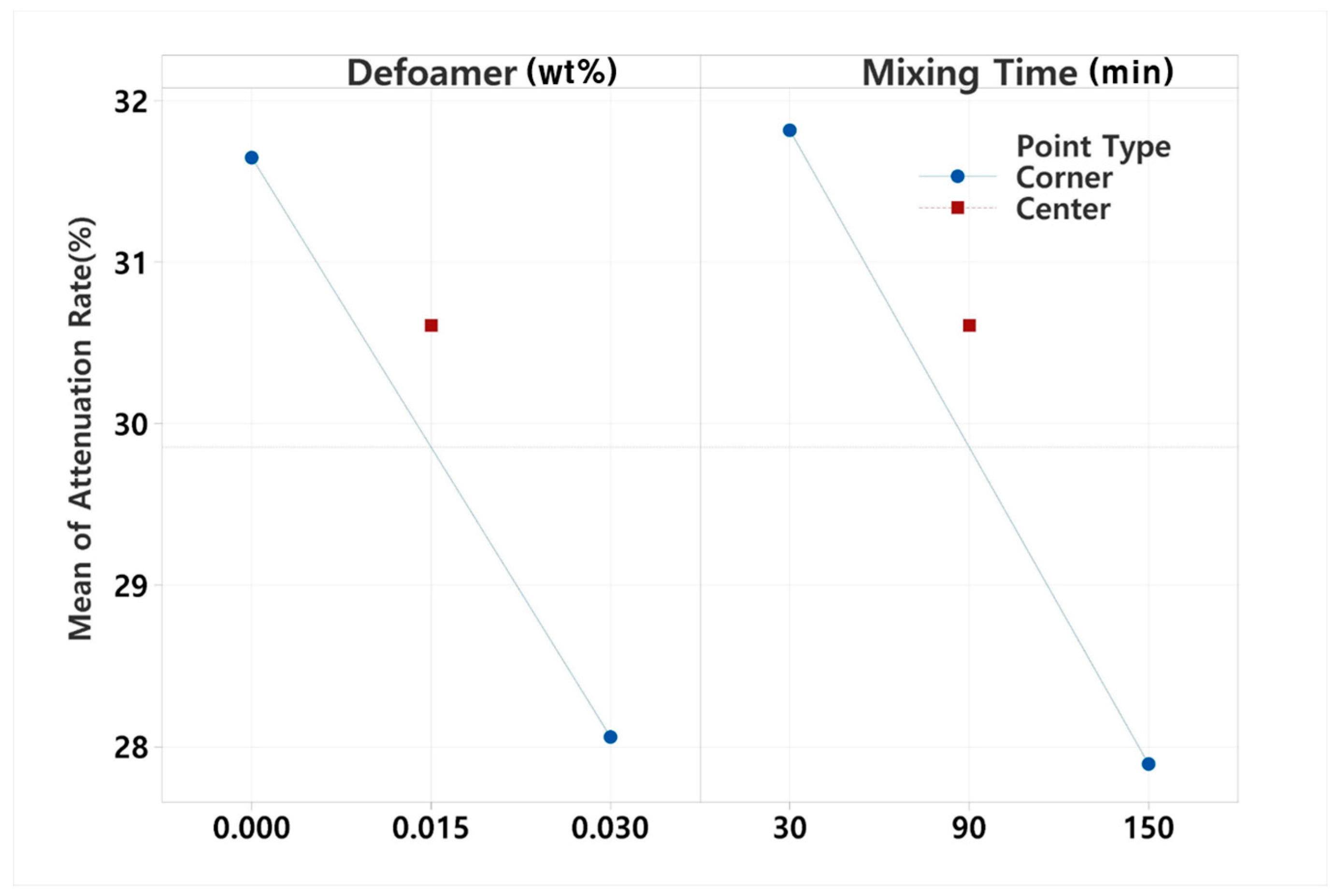

3.3.1. Factorial Design

3.3.2. Steepest Ascent Method

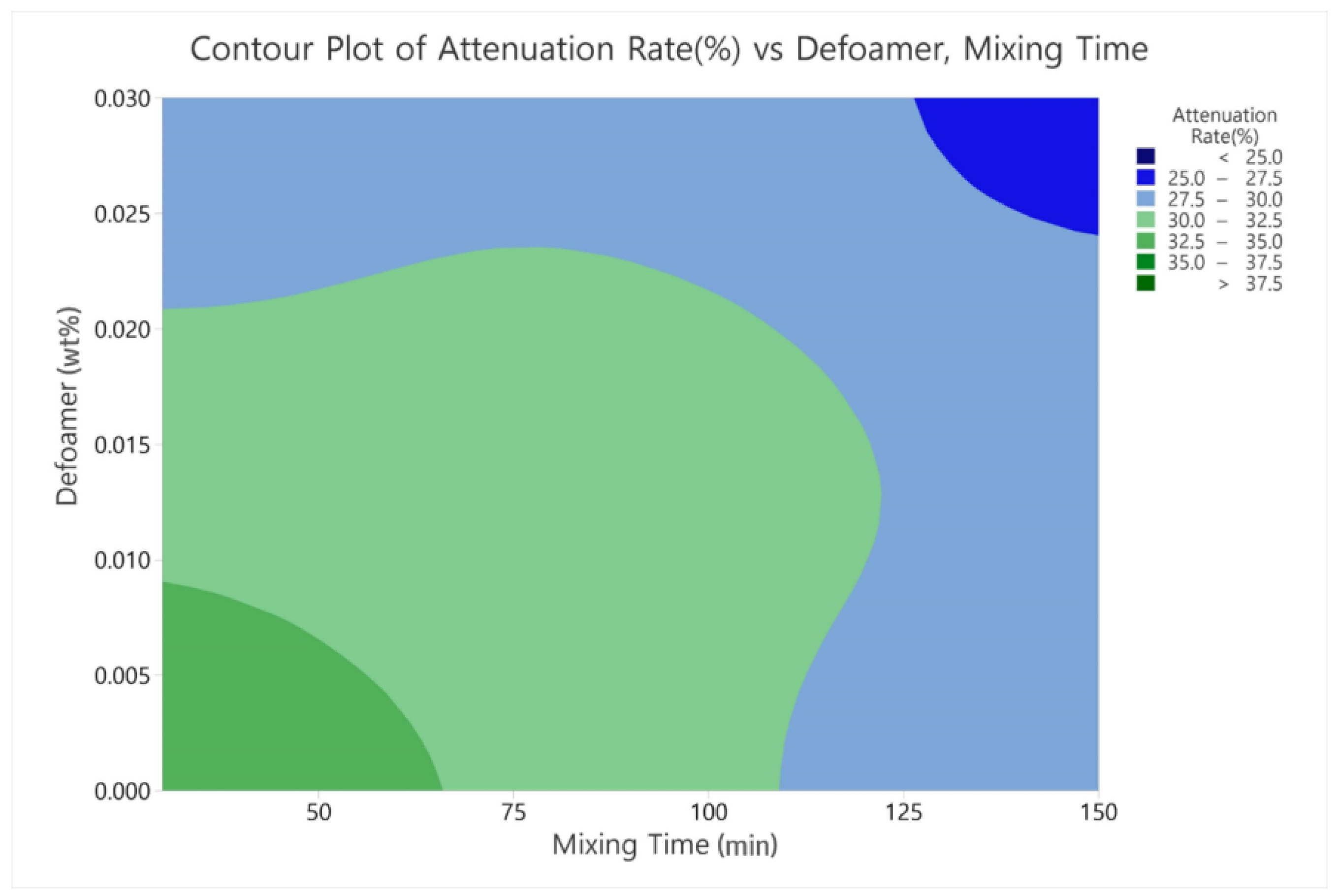

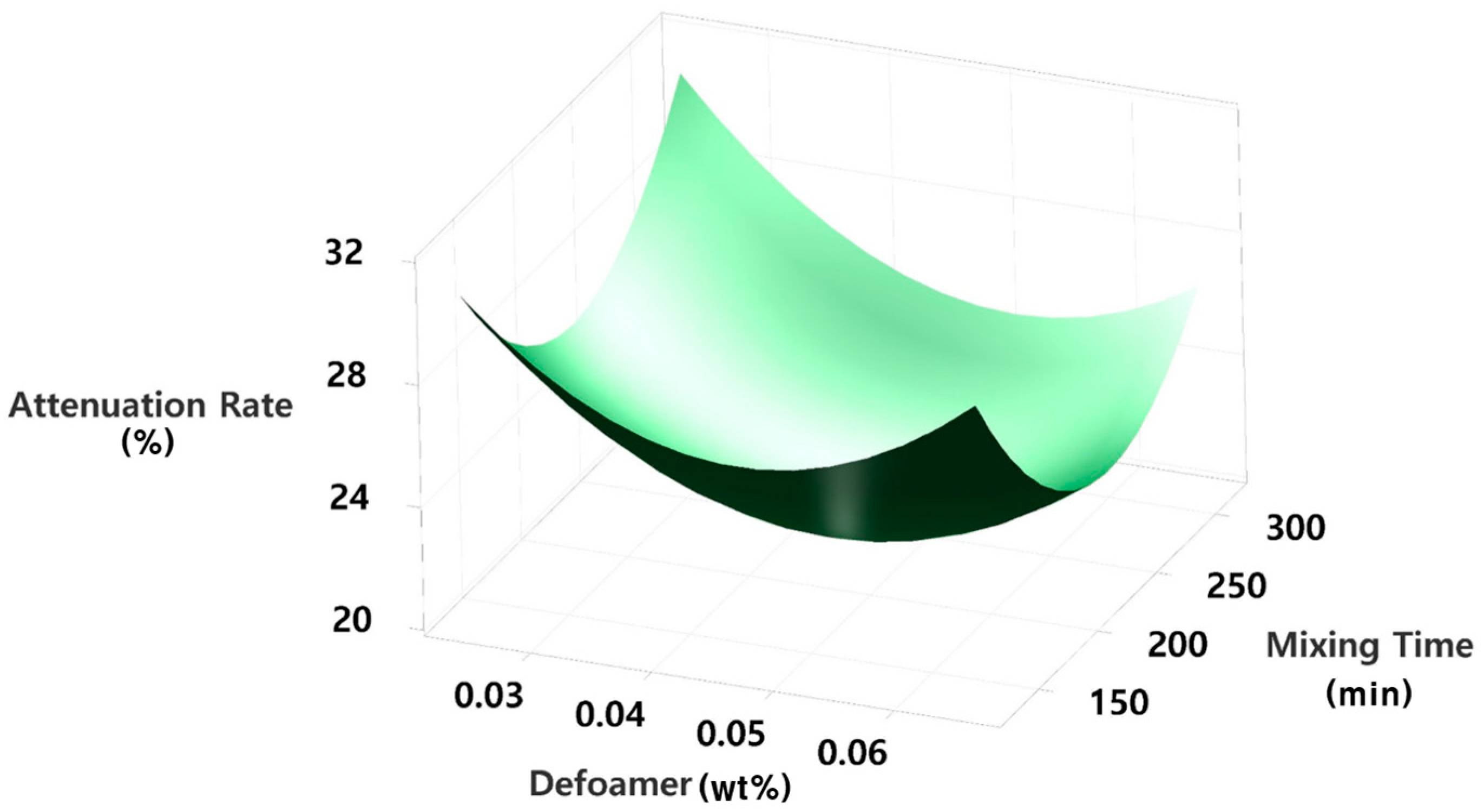

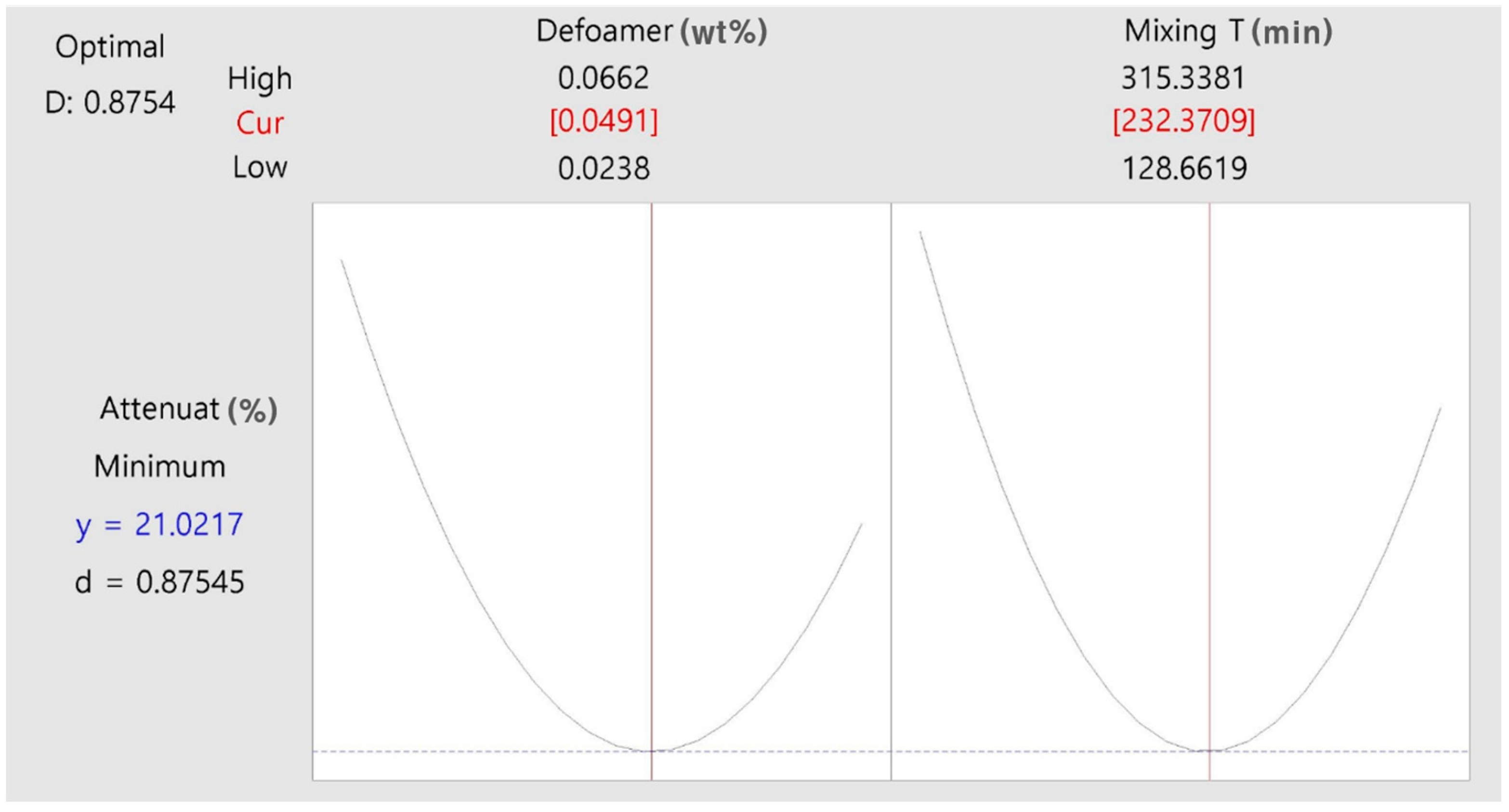

3.3.3. Response Surface Methodology

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Y.; Yu, C.; Wang, W.; Li, H.; Jiang, X. A review on structural failure of composite pressure hulls in deep sea. J. Mar. Sci. Eng. 2022, 10, 1456. [Google Scholar] [CrossRef]

- Eyiler, B.; Bayraktarkatal, E. Investigation of optimum structures at submarine pressure hulls under hydrostatic pressure with finite element method. J. Nav. Archit. Mar. Technol. 2024, 226, 25–35. [Google Scholar] [CrossRef]

- Babu, S.; Bandyopadhyay, S.; Debnath, A.; Kumar, S. Marine application of fiber reinforced composites: A review. J. Mar. Sci. Eng. 2020, 8, 26. [Google Scholar] [CrossRef]

- Ertuğ, B. Advanced fiber-reinforced composite materials for marine applications. Adv. Mater. Res. 2024, 1195, 112–120. [Google Scholar] [CrossRef]

- Mehdikhani, M.; Gorbatikh, L.; Verpoest, I.; Lomov, S.V. Voids in fiber reinforced polymer composites: Formation, characteristics, and effects on mechanical performance. J. Compos. Mater. 2019, 53, 1573–1590. [Google Scholar] [CrossRef]

- Saad, A.; Echchelh, A.; Hattabi, M.; El Ganaoui, M. Review of modeling and simulation of void formation in liquid composite molding. Compos. Mech. Comput. Appl. Int. J. 2018, 9, 50–68. [Google Scholar] [CrossRef]

- Teixidó, H.; Staal, J.; Caglar, B.; Michaud, V. Capillary effects in fiber reinforced polymer composite processing: A review. Front. Mater. 2022, 9, 809226. [Google Scholar] [CrossRef]

- Park, C.H.; Lee, W.I. Modeling void formation and unsaturated flow in liquid composite molding processes: A survey and review. J. Compos. Mater. 2011, 45, 957–977. [Google Scholar]

- Elkolali, M.; Nogueira, L.P.; Rønning, P.O.; Alcocer, A. Void Content Determination of Carbon Fiber Reinforced Polymers: A Comparison between Destructive and Non-Destructive Methods. Polymers 2022, 14, 1212. [Google Scholar] [CrossRef] [PubMed]

- Shukla, A.; Matos, J. Review of implosion design considerations for underwater composite structures. J. Mar. Sci. Eng. 2024, 12, 1468. [Google Scholar]

- Bourmaud, A.; Lejeune, I.; Ferrié, E.; Boisse, P. Impact of process parameters (vacuum, injection pressure, resin viscosity, curing conditions) on void content in Liquid Composite Moulding. Compos. Sci. Technol. 2020, 194, 108126. [Google Scholar]

- Juan, J.; Silva, A.; Tornero, J.A.; Gamez-Perez, J.; Salán, N. Void content minimization in vacuum infusion (VI) via effective degassing. Polymers 2021, 13, 2876. [Google Scholar] [CrossRef] [PubMed]

- Sritharan, R.; Askari, D. A design of experiment study to investigate the effects of hardener concentration, stirring time, and air bubbles on the tensile strength of epoxy resin. J. Elastomers Plast. 2022, 54, 1129–1147. [Google Scholar] [CrossRef]

- Abdelal, N.; Donaldson, S.L. Comparison of methods for the characterization of voids in glass fiber composites: Ultrasonic scanning, epoxy burn off, serial sectioning, and X-ray computed tomography. J. Compos. Mater. 2019, 53, 463–478. [Google Scholar]

- Wang, T.; Steensels, E.; Standaert, A.; Vallons, K.; Gorbatikh, L. Void content characterization and its impact on tensile and flexural performance of fiber reinforced composites. Compos. Sci. Technol. 2022, 217, 109132. [Google Scholar]

- Ono, K. Ultrasonic attenuation of carbon-fiber reinforced composites. J. Compos. Sci. 2023, 7, 479. [Google Scholar] [CrossRef]

- Veiga, R.; Bouville, F.; Gauvin, R.; Scazonatto, J.; Ferri, A. A review of micro-computed tomography (micro-CT) for non-destructive quantitative analysis of voids in fiber-reinforced composites. Compos. Struct. 2021, 256, 113163. [Google Scholar]

- ASTM D3039/D3039M-17; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- Osborne, J.W.; Waters, E. Four assumptions of regression that research practitioners need to know. Pract. Assess. Res. Eval. 2002, 8, 2. [Google Scholar]

- Montgomery, D.C.; Myers, R.H.; Anderson-Cook, C.M. Response Surface Methodology: Process and Product Optimization Using Designed Experiments; Wiley: Hoboken, NJ, USA, 2016. [Google Scholar]

- Bezerra, M.A.; Santelli, R.E.; Oliveira, E.P.; Villar, L.S.; Escaleira, L.A. Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta 2008, 76, 965–977. [Google Scholar] [CrossRef] [PubMed]

- Bayuo, J.; Abukari, M.A. Optimization using central composite design of response surface methodology for biosorption of hexavalent chromium from aqueous media. Appl. Water Sci. 2020, 10, 135. [Google Scholar] [CrossRef]

| RunOrder | Defoamer Concentration (wt%) | Mixing Speed (rpm) | Mixing Time (min) |

|---|---|---|---|

| 1 | 0 | 400 | 150 |

| 2 | 0.015 | 250 | 90 |

| 3 | 0.03 | 400 | 30 |

| 4 | 0 | 100 | 30 |

| 5 | 0.03 | 400 | 30 |

| 6 | 0.03 | 400 | 150 |

| 7 | 0.015 | 250 | 90 |

| 8 | 0.03 | 100 | 30 |

| 9 | 0 | 400 | 30 |

| 10 | 0 | 100 | 30 |

| 11 | 0.03 | 400 | 150 |

| 12 | 0 | 400 | 30 |

| 13 | 0 | 400 | 150 |

| 14 | 0.03 | 100 | 30 |

| 15 | 0 | 100 | 150 |

| 16 | 0.015 | 250 | 90 |

| 17 | 0.03 | 100 | 150 |

| 18 | 0 | 100 | 150 |

| 19 | 0.03 | 100 | 150 |

| Correlation | Significance Level | |

|---|---|---|

| C-Scan | −0.703 | 0.023 |

| Image Analysis | −0.557 | 0.094 |

| Micro-CT | −0.508 | 0.134 |

| Correlation | Significance Level | |

|---|---|---|

| C-Scan | −0.608 | 0.030 |

| Image Analysis | −0.610 | 0.061 |

| Micro-CT | −0.591 | 0.072 |

| Source | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|

| Model | 114.54 | 38.18 | 3.70 | 0.036 |

| Linear | 113.10 | 56.55 | 5.48 | 0.016 |

| Defoamer | 51.48 | 51.48 | 4.99 | 0.041 |

| Mixing Time | 61.62 | 61.62 | 5.97 | 0.027 |

| Curvature | 1.44 | 1.14 | 0.14 | 0.714 |

| Error | 154.87 | 10.32 | ||

| Lack-of-fit | 59.20 | 11.84 | 1.24 | 0.361 |

| Pure Error | 95.67 | 9.56 | ||

| Total | 269.41 |

| Term | Effect | Coef | T-Value | p-Value |

|---|---|---|---|---|

| Constant | 29.855 | 36.90 | 0.000 | |

| Defoamer | −3.588 | −1.794 | −2.22 | 0.044 |

| Mixing Time | −3.925 | −1.962 | −2.43 | 0.029 |

| Defoamer * Mixing time | 1.437 | 0.719 | 0.89 | 0.389 |

| Ct Pt | 0.75 | 0.37 | 0.717 |

| StdOrder | Defoamer (wt%) | Mixing Time (min) | Attenuation Rate (%) |

|---|---|---|---|

| 1 | 0.015 | 90 | 30.8 |

| 2 | 0.030 | 156 | 25.8 |

| 3 | 0.045 | 222 | 21.4 |

| 4 | 0.060 | 288 | 21.0 |

| 5 | 0.075 | 354 | 21.6 |

| 6 | 0.090 | 420 | 20.7 |

| StdOrder | Defoamer (wt%) | Mixing Time (min) | Attenuation Rate (%) |

|---|---|---|---|

| 1 | 0.06 | 156 | 23.6 |

| 2 | 0.045 | 222 | 21.5 |

| 3 | 0.06 | 288 | 21.0 |

| 4 | 0.045 | 222 | 20.8 |

| 5 | 0.03 | 288 | 24.9 |

| 6 | 0.045 | 156 | 25.8 |

| 7 | 0.024 | 222 | 20.1 |

| 8 | 0.066 | 222 | 26.8 |

| 9 | 0.045 | 222 | 25.9 |

| 10 | 0.045 | 128 | 27.5 |

| 11 | 0.045 | 315 | 26.9 |

| 12 | 0.045 | 222 | 22.3 |

| 13 | 0.045 | 222 | 20.8 |

| 14 | 0.045 | 222 | 21.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, W.-S.; Park, J.-Y. Process Optimization and Non-Destructive Evaluation of Micro-Voids in Submarine Composite Structures for Enhanced Mechanical Performance. J. Compos. Sci. 2025, 9, 631. https://doi.org/10.3390/jcs9110631

Choi W-S, Park J-Y. Process Optimization and Non-Destructive Evaluation of Micro-Voids in Submarine Composite Structures for Enhanced Mechanical Performance. Journal of Composites Science. 2025; 9(11):631. https://doi.org/10.3390/jcs9110631

Chicago/Turabian StyleChoi, Woo-Suk, and Jong-Yong Park. 2025. "Process Optimization and Non-Destructive Evaluation of Micro-Voids in Submarine Composite Structures for Enhanced Mechanical Performance" Journal of Composites Science 9, no. 11: 631. https://doi.org/10.3390/jcs9110631

APA StyleChoi, W.-S., & Park, J.-Y. (2025). Process Optimization and Non-Destructive Evaluation of Micro-Voids in Submarine Composite Structures for Enhanced Mechanical Performance. Journal of Composites Science, 9(11), 631. https://doi.org/10.3390/jcs9110631